Patents

Literature

77results about How to "No high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

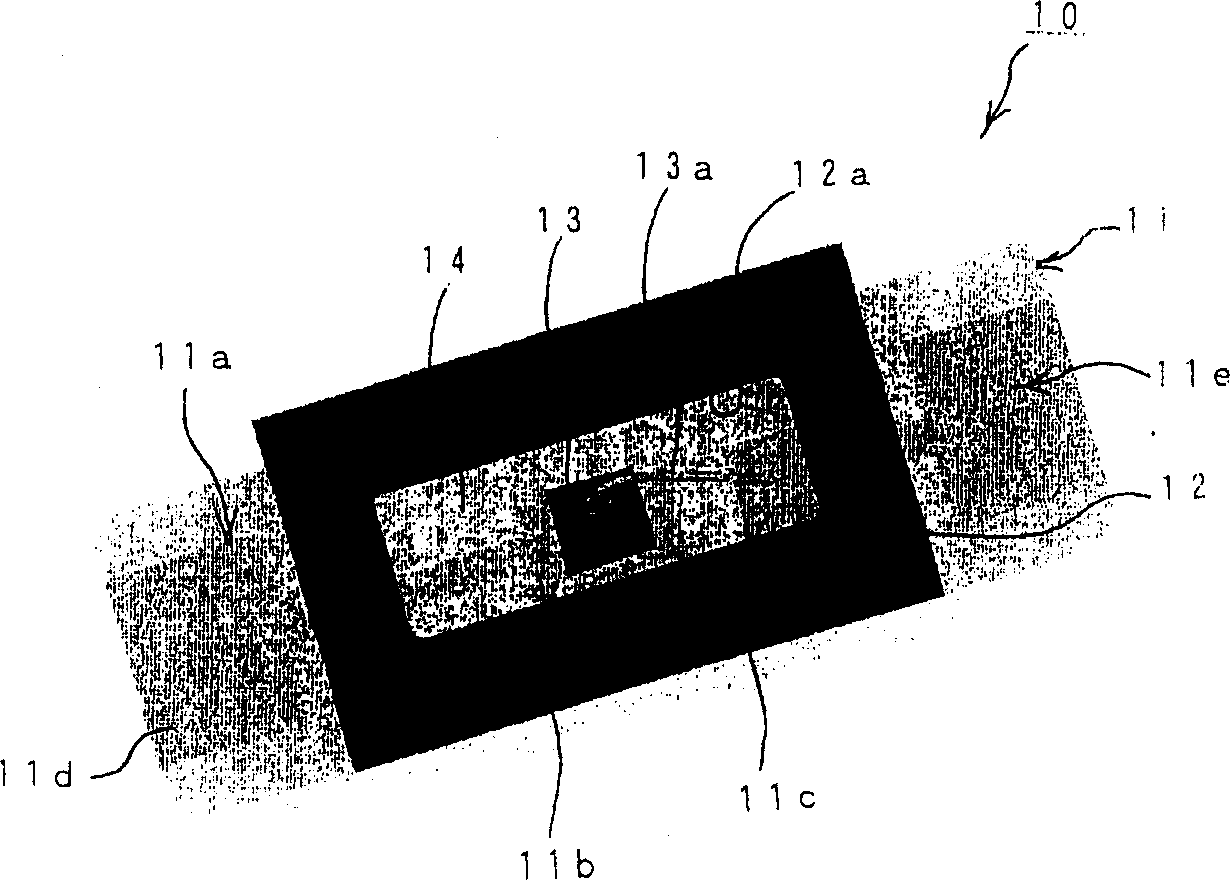

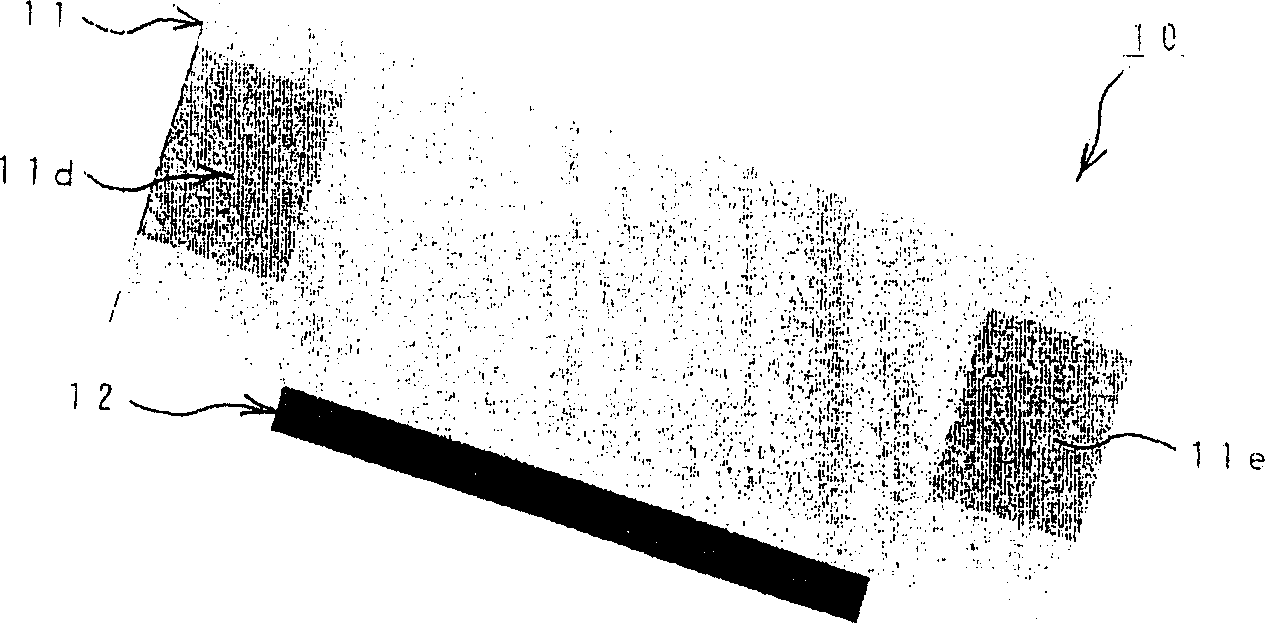

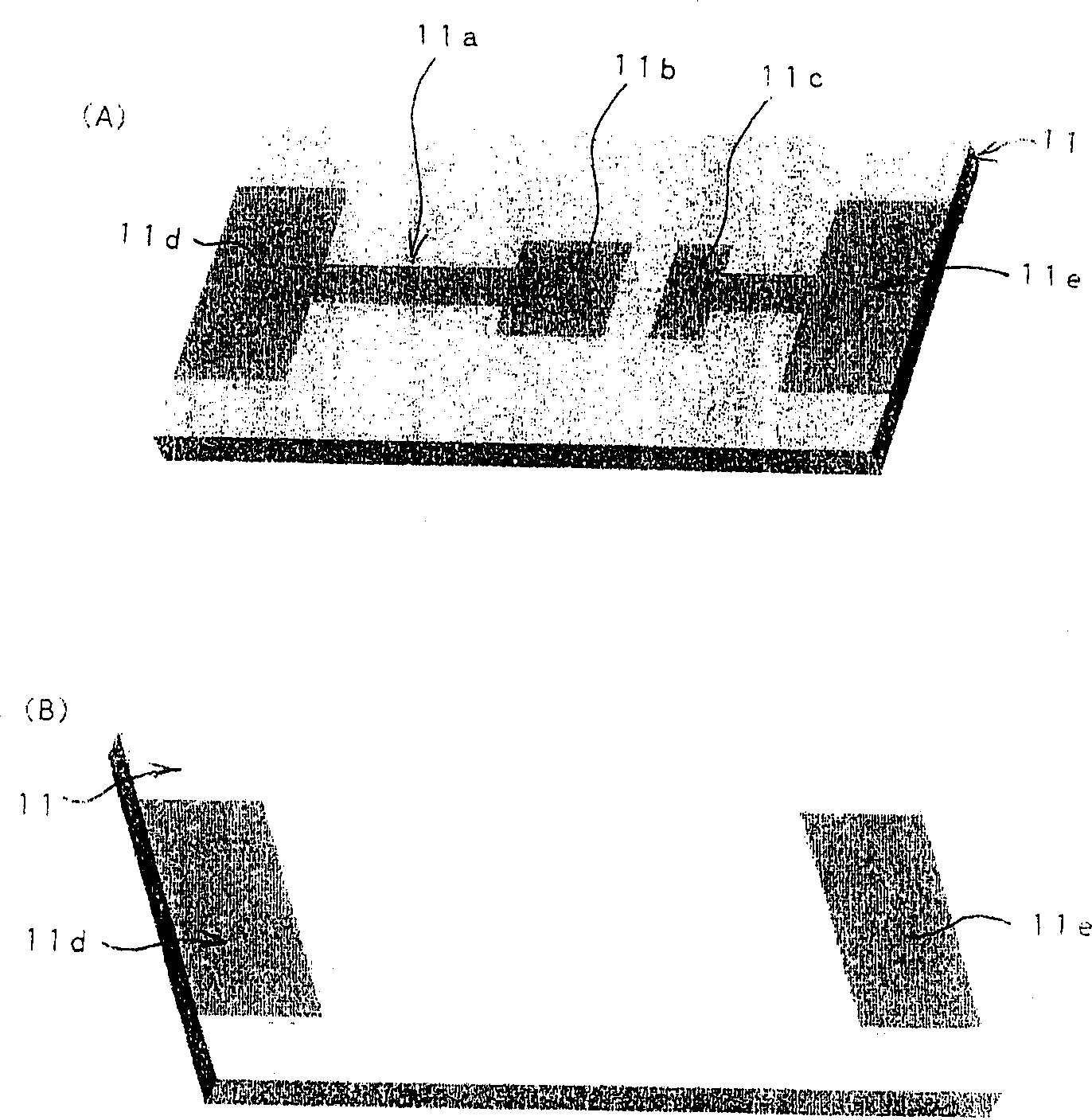

Surface mount LED

InactiveCN1744335ANo high temperatureImprove luminous efficiencySolid-state devicesSemiconductor devicesSurface mountingEngineering

An LED can include a silicon substrate that has a conductive pattern including an LED chip equipped portion, a connection portion, and external electrodes. A glass frame can be anodic-bonded onto the silicon substrate, and can include a through-hole forming a lamp house. An LED chip can be mounted onto the silicon substrate in the through-hole of the glass frame, and a mold portion made of silicone resin can be filled into the through-hole of the glass frame.

Owner:STANLEY ELECTRIC CO LTD

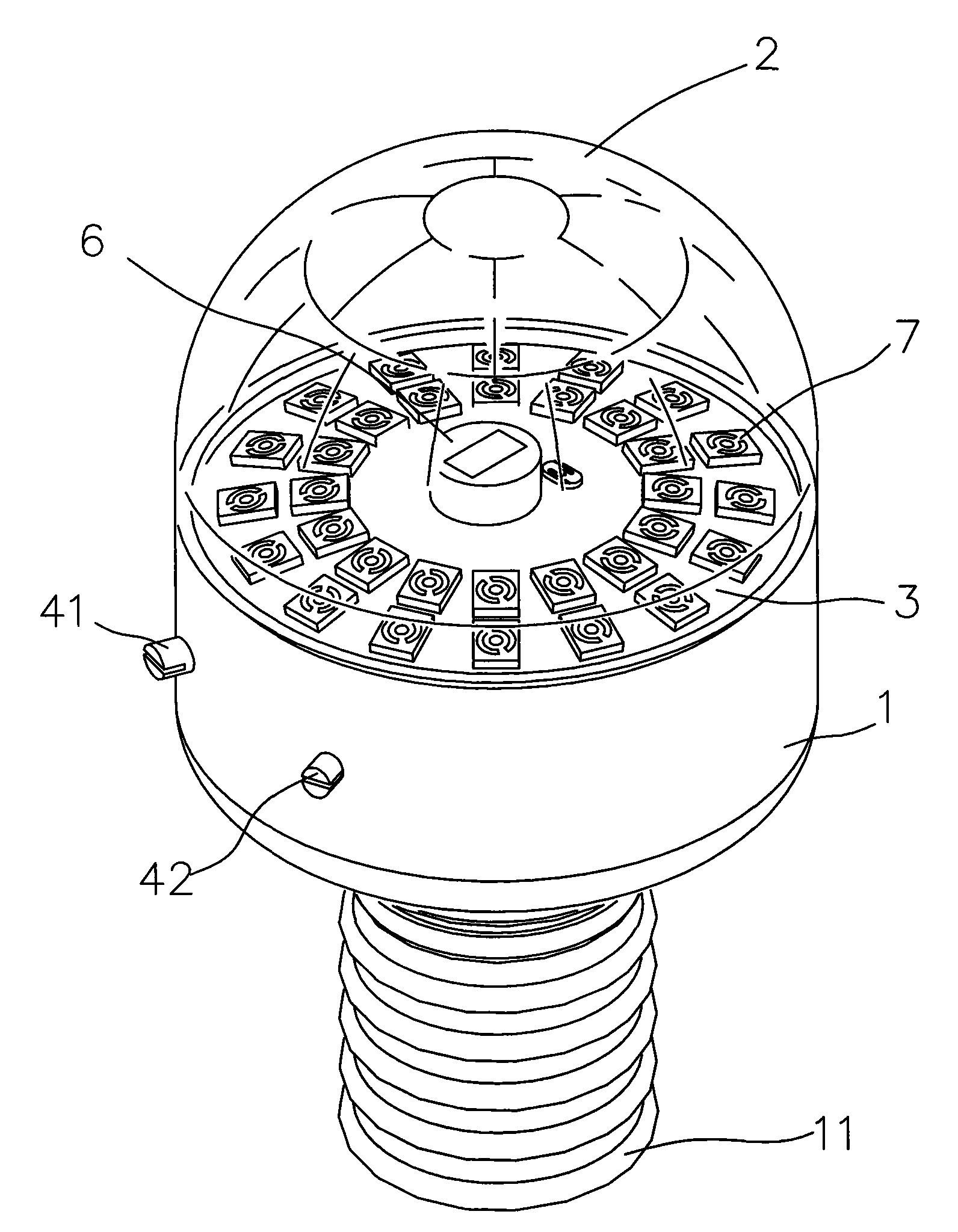

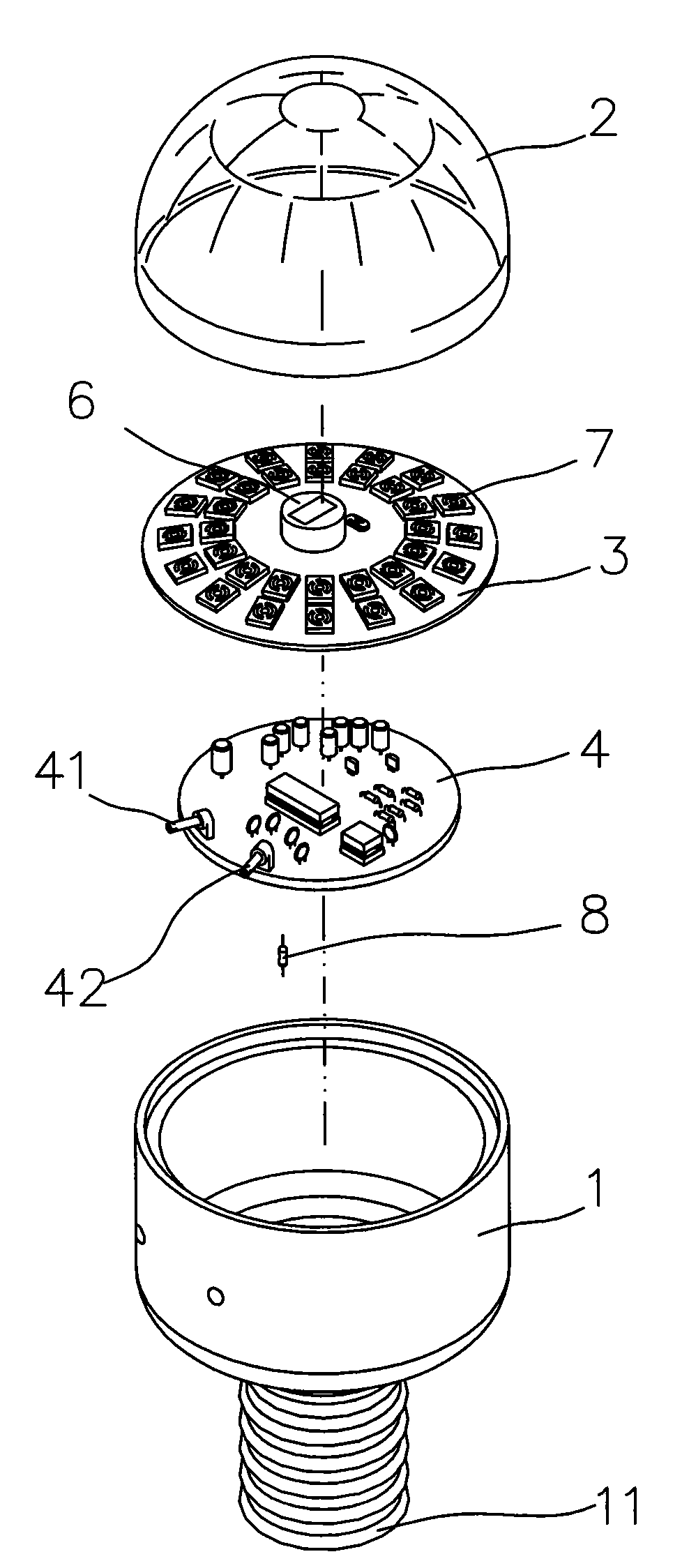

Light-emitting device with sensing function

InactiveCN101586741AWith sensing functionGood light directivityPlanar light sourcesElectric circuit arrangementsEngineeringThermal radiation

The invention discloses a light-emitting device with a sensing function, which comprises a circuit board, a control board and a lower shell, wherein the circuit board is provided with the infrared sensor and a plurality of light-emitting assemblies; the control board is provided with a time adjusting device and a luminance adjusting device and connected with the infrared sensor and the light-emitting assemblies by conducting wires; the control board is arranged in the lower shell, and the lower end of the lower shell is provided a power supply input end; the upper shell of the infrared sensor is arranged above the infrared sensor and the light-emitting assemblies and used for stabling the sensing signals; and the lower end of the upper shell is embedded with the lower shell. The light-emitting device can emit a uniform and soft light source or a bright light source by the transparency of a cover of the sensor, and the infrared sensor has the function of sensing thermal radiation and takes the thermal radiation emitted by a human body as the signal supplying power to the light-emitting assemblies; when the infrared sensor can not sense the thermal radiation emitted by the human body, the infrared sensor stops supplying the power to the light-emitting assemblies by the control board so as to achieve the aim of effectively saving energy resources.

Owner:陈凯柏

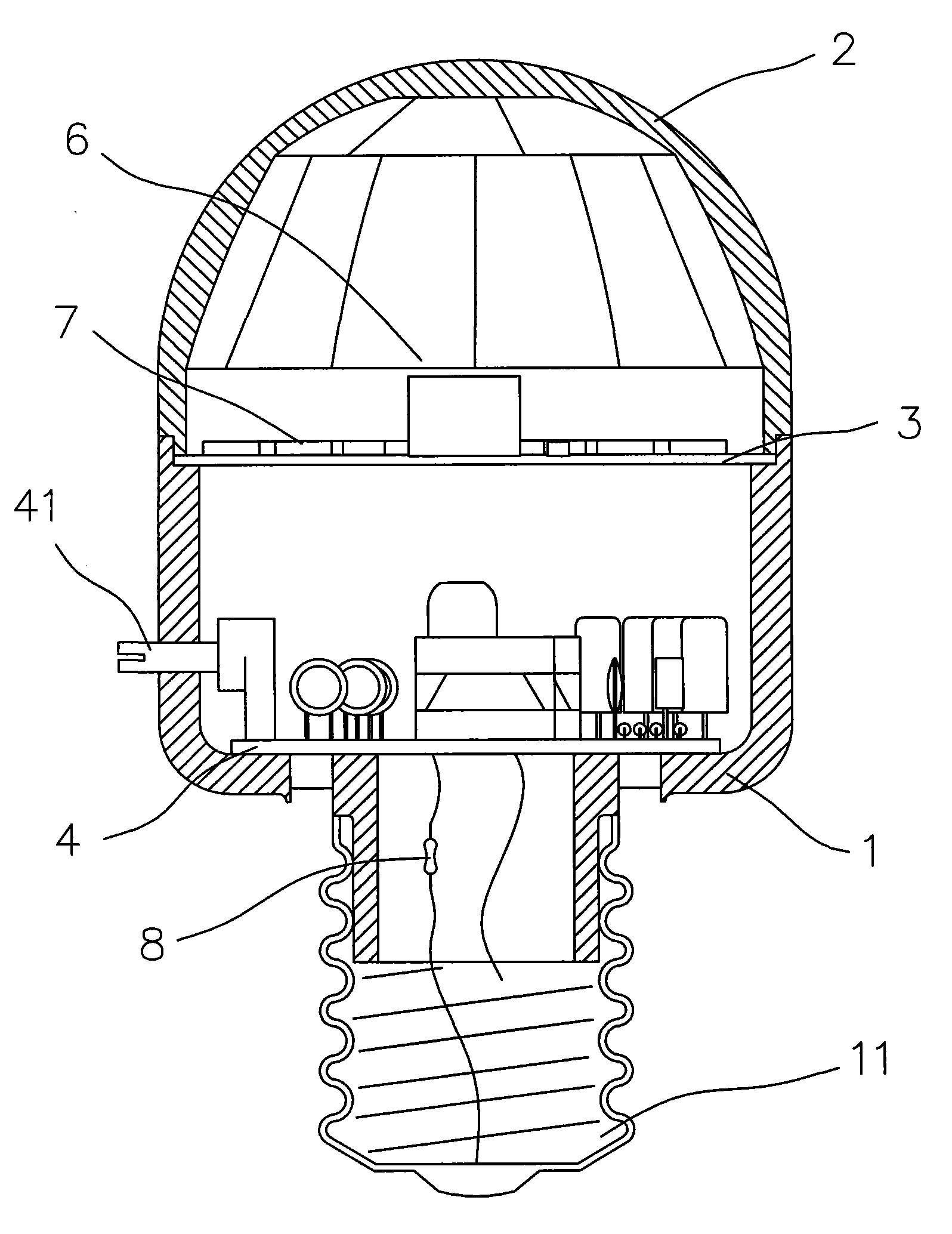

Process for preparing yelk antibody with high bioactivity

ActiveCN1844144AHigh biological potencyImprove biological activityEgg immunoglobulinsImmunoglobulins against bacteriaYolkDrug biological activity

This invention is preparation procedure of the yolk antibody of high biological activity, belonging to the field of bioproduct and industrialized isolation technique. In this invention, we adopt the natural macromolecule gel high -extractive technique and hyperfiltration to extract the yolk-antibody of high biological activity from yolk at an industrialized level, annual output is upto 10 ton. the yolk-antibody content is about 30%-50%, meanwhile we could obtain some by-products like albumen powder, yolk powder, egg oil, vitellin and so on. In the invention high technology like bioimmunology and membrane separation is adopted. The invention is high-tech, high-usage, highly-automated and typical of green food and environmental-friendly.

Owner:NANTONG KANGDE BIOLOGICAL PROD

Method for processing black benne oil

InactiveCN101317610ARetain nutrientsRetain propertiesEdible oils/fatsFood preparationEngineeringBottle

The invention discloses a processing method for preparing purely natural health-caring black sesame oil by using black sesame as the raw material. The method of the invention comprises the steps as follows: colour selecting of the black sesame, washing by clean water, centrifugal dewatering, drying, smoking and dedusting, grinding, stirring with water, separating, depositing, sterilizing and bottle filling; as the stone grinding process is adopted, no high temperature is generated during the grinding process of the invention, thus completely preserving the nutrition composition of the black sesame, generating no glutin or little glutin and generating more oil correspondingly; during the deposition process, diatomite is not added, the black sesame is statically put hermetically under normal temperature; the temperature preservation disposal is not required and the energy resource is not wasted; in the whole processing, no matters are added, thus preserving the unique fragrance and the nutrition composition of the black sesame oil. Compared with the prior art, the processing method of the invention has high yield, the produced black sesame oil can preserve the nutrition composition and the unique fragrance of the black sesame to the utmost extent and has no poor impurities and wastes no energy resource.

Owner:任艳丽

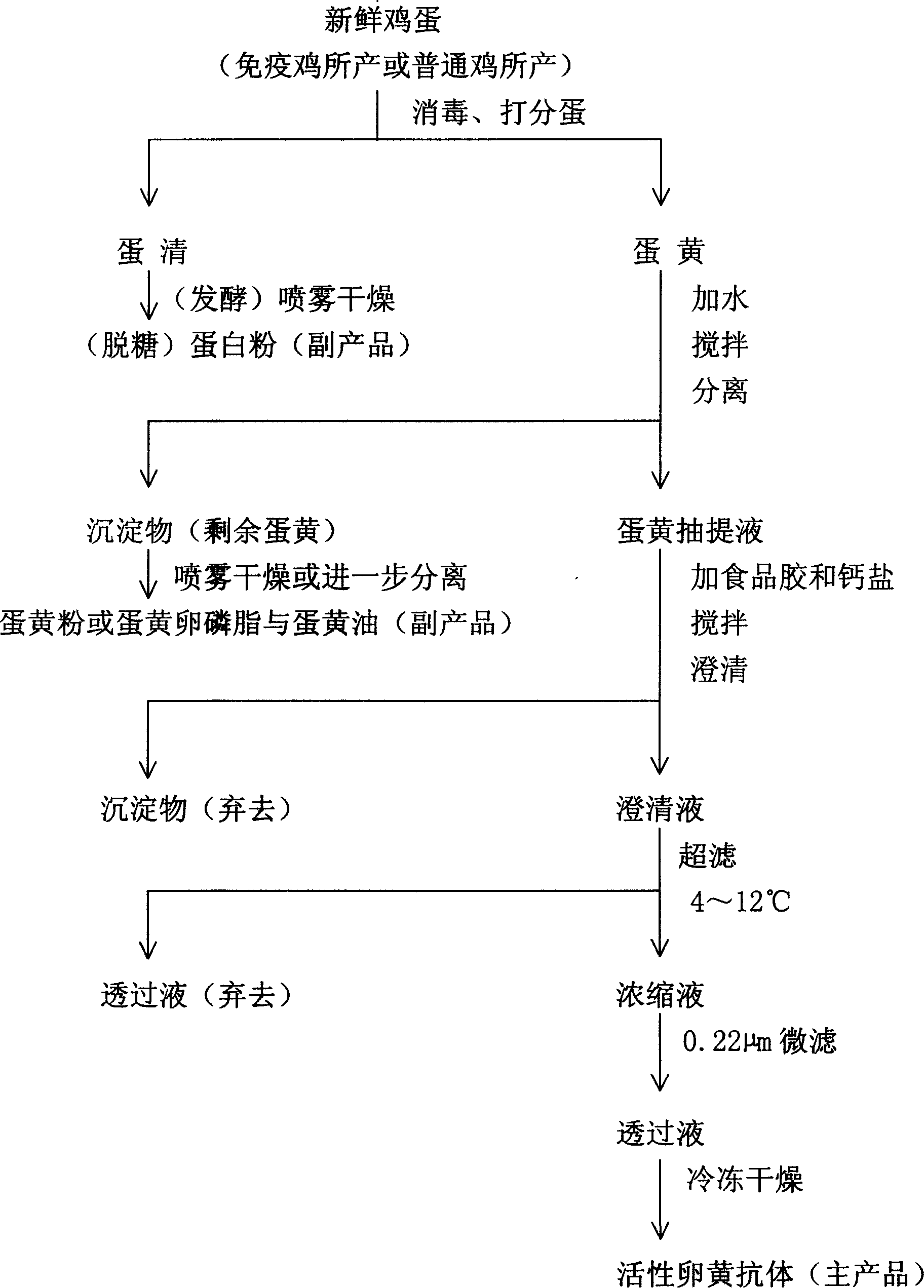

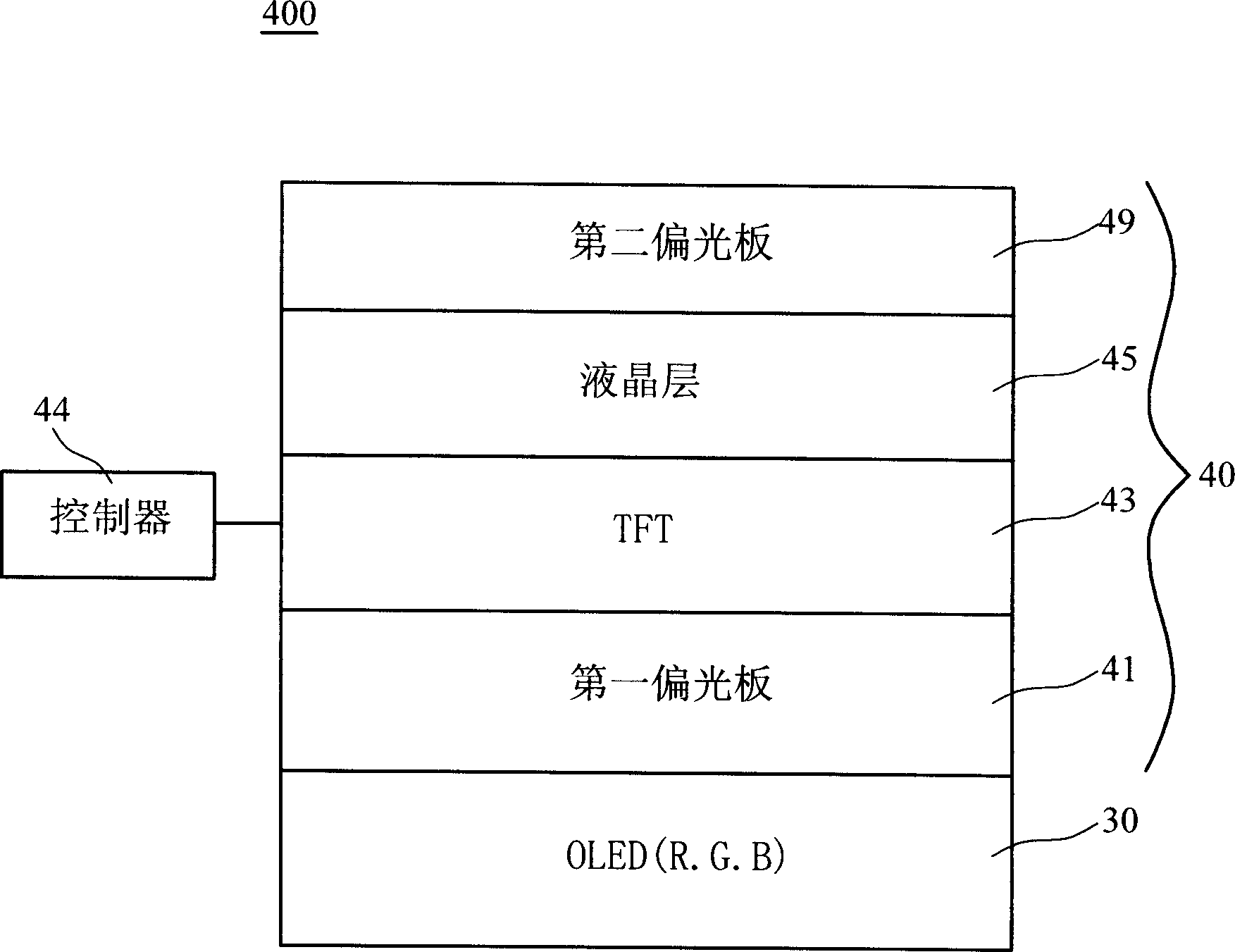

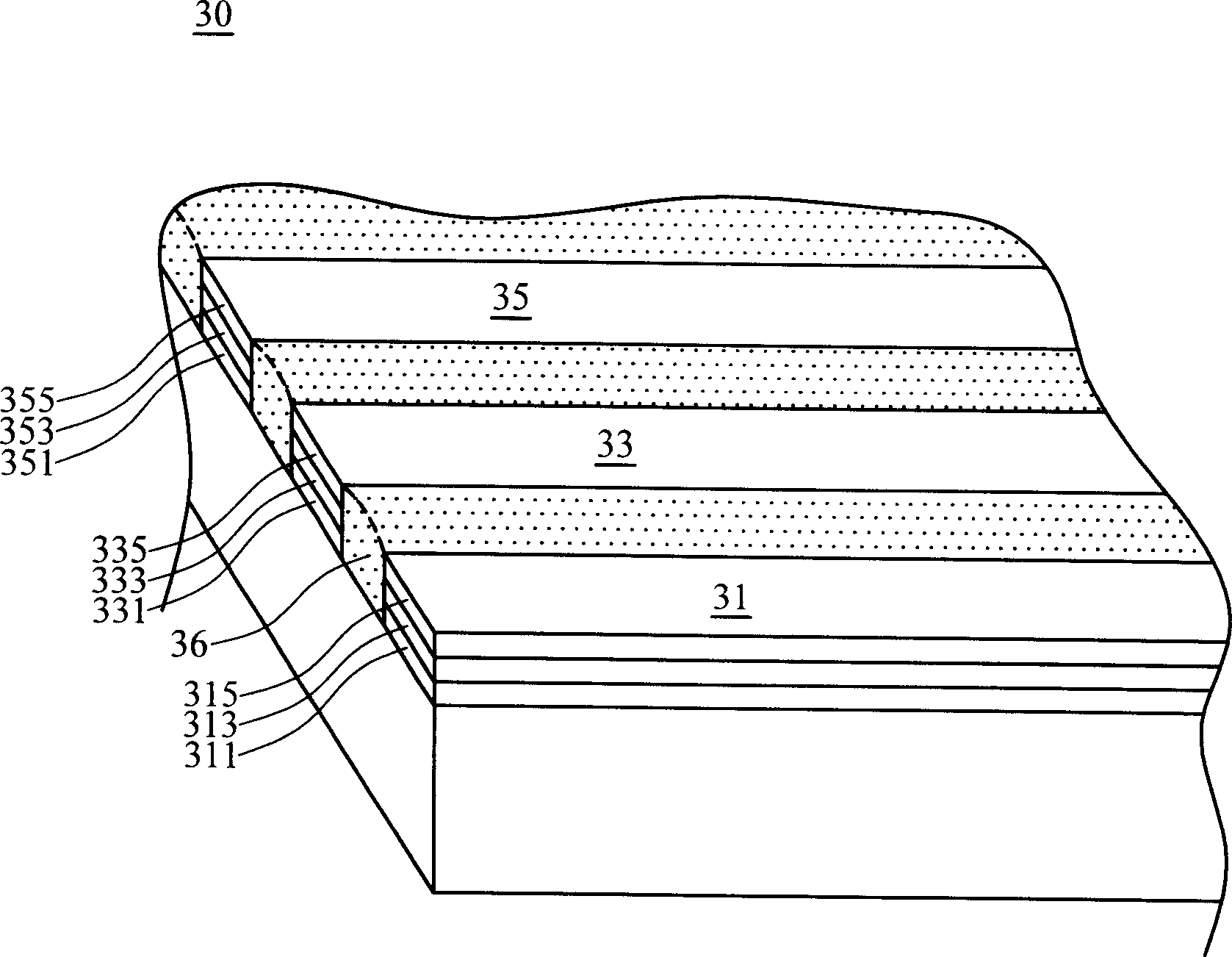

Liquid crystal display device and backlight source thereof

InactiveCN1808242ATo achieve the purpose of full-color displayIncrease display brightnessStatic indicating devicesSolid-state devicesColor gelGreen-light

The invention discloses a liquid crystal display device, especially relates to a liquid crystal display device with organic power excitation light emitting components as back light source. The liquid crystal panel is provided with at least a first organic power excitation light emitting component for generating red light source, at least a second organic power excitation light emitting component for generating green light source, and at lease a third organic power excitation light emitting component for generating blue light source, realizing pixel definition according to liquid crystal panel settings, and realizing liquid crystal display device full colorful display without color filters.

Owner:彭冠璋

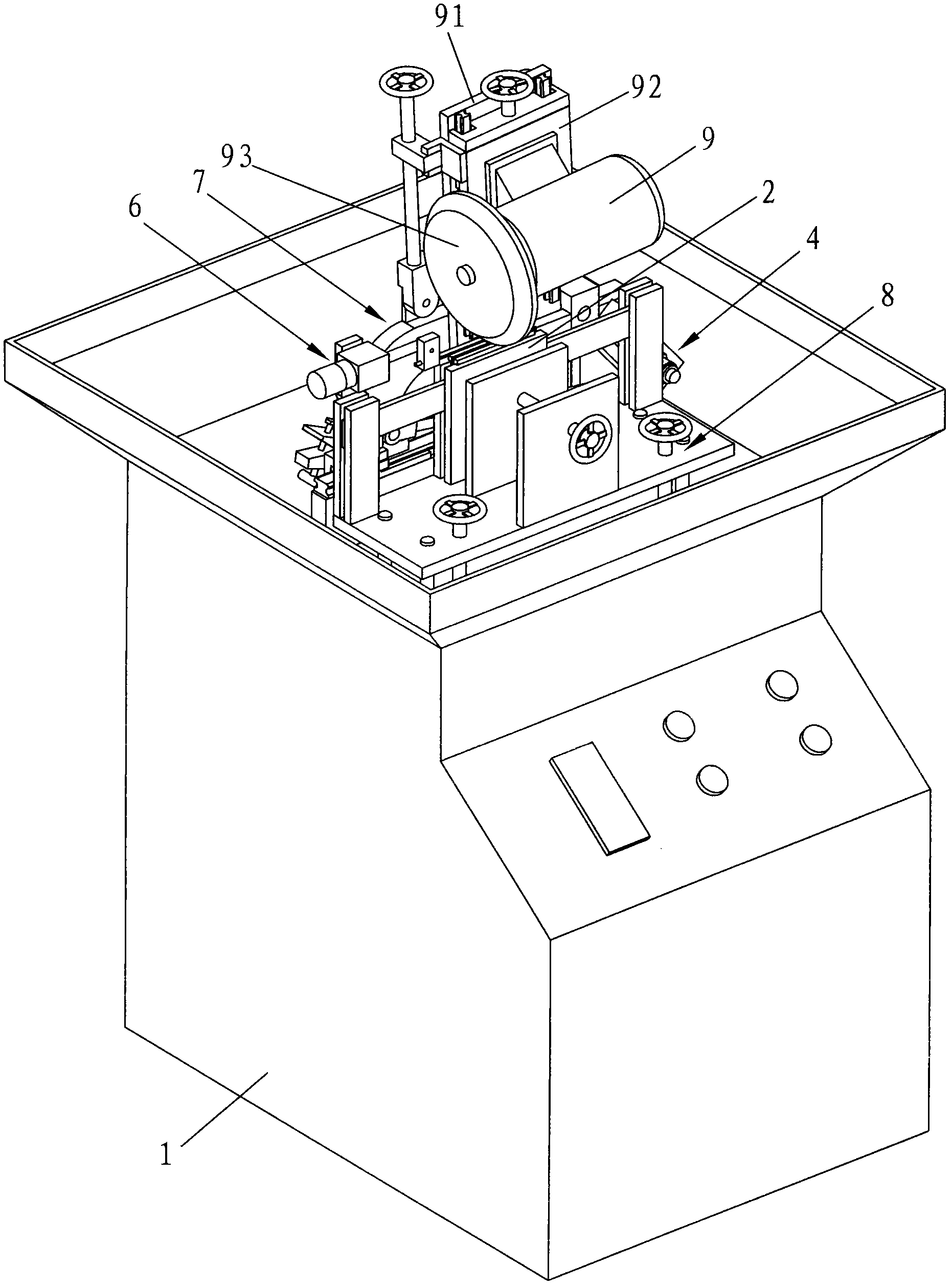

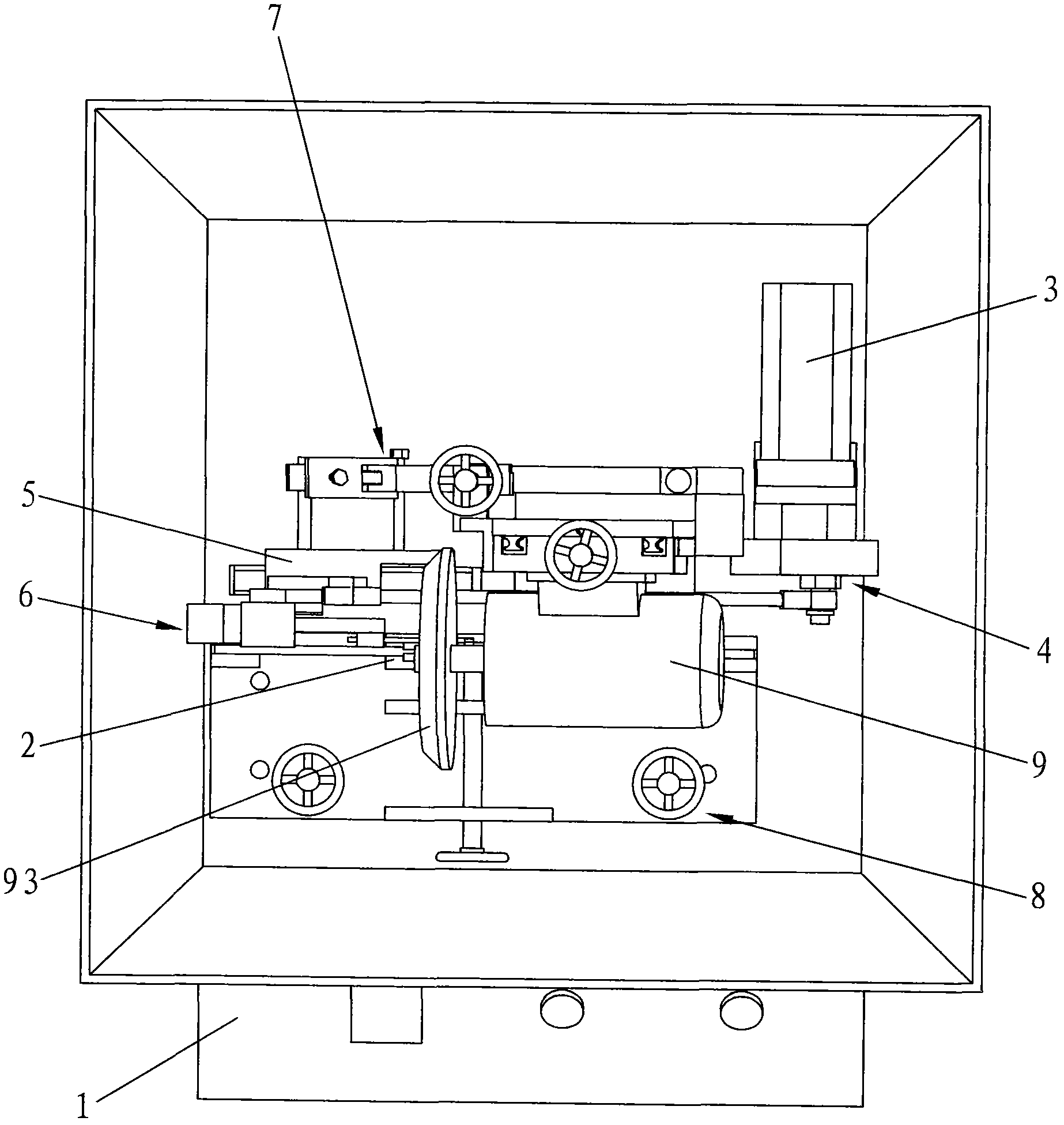

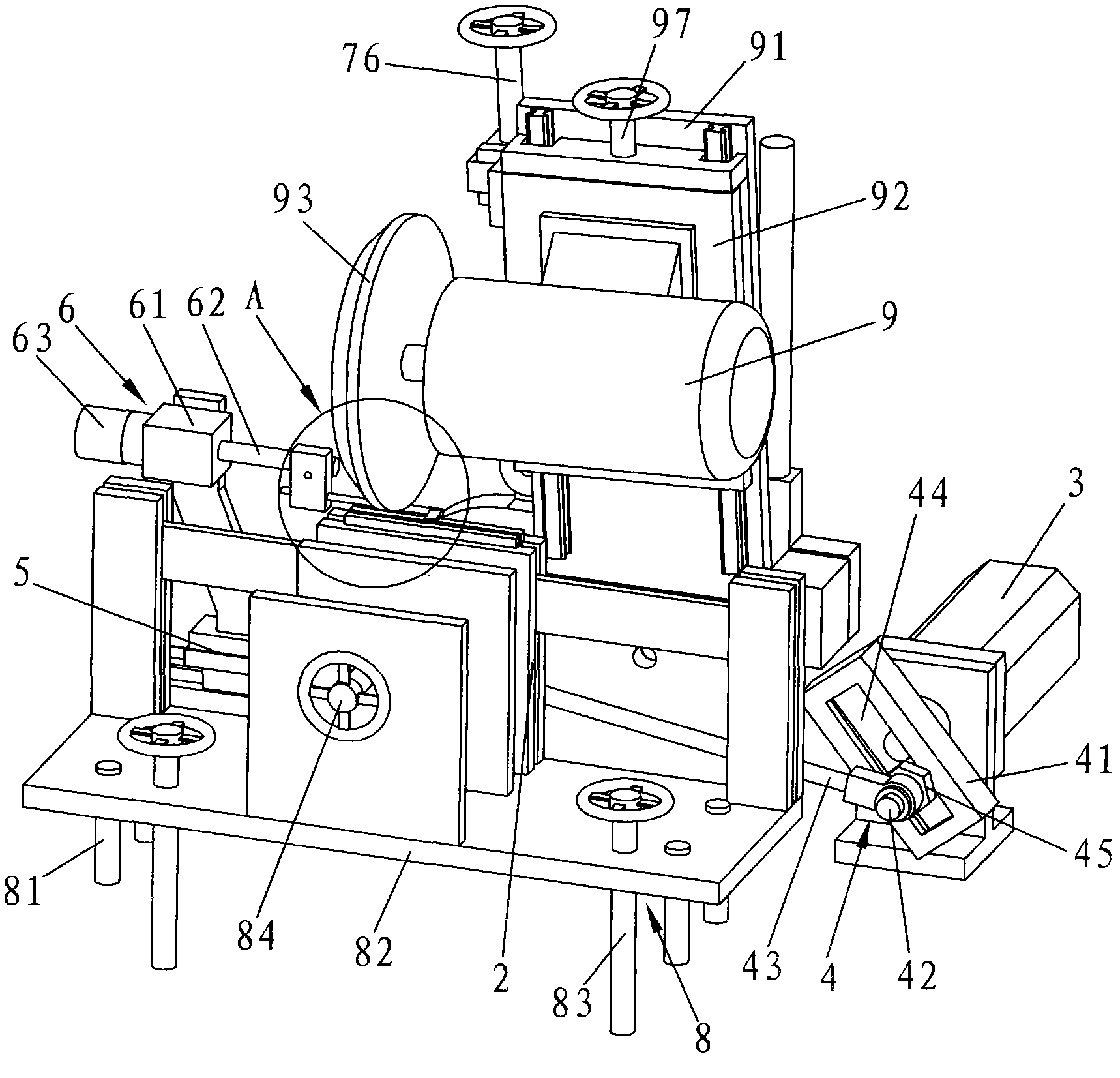

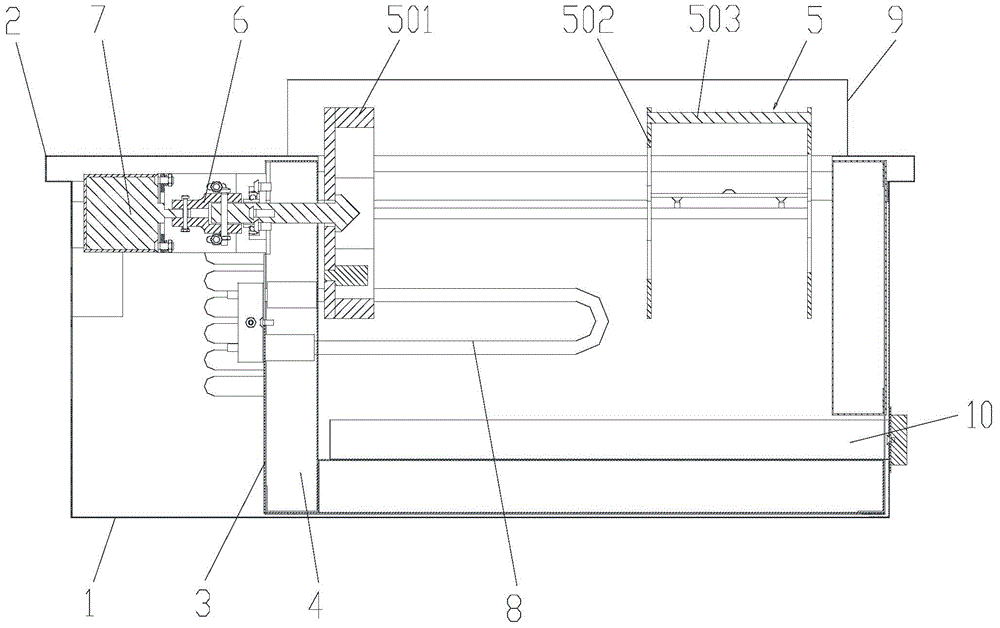

Precise automatic gear grinding machine with saw

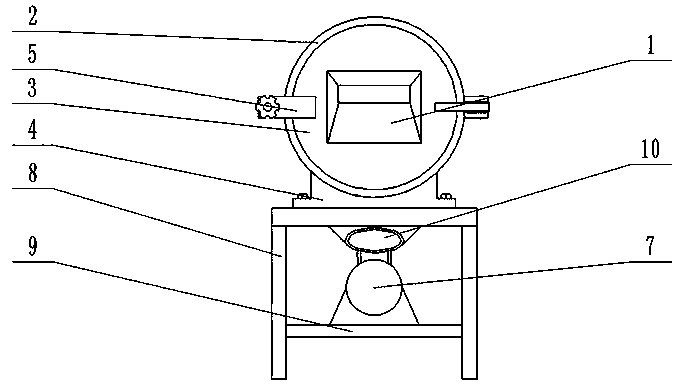

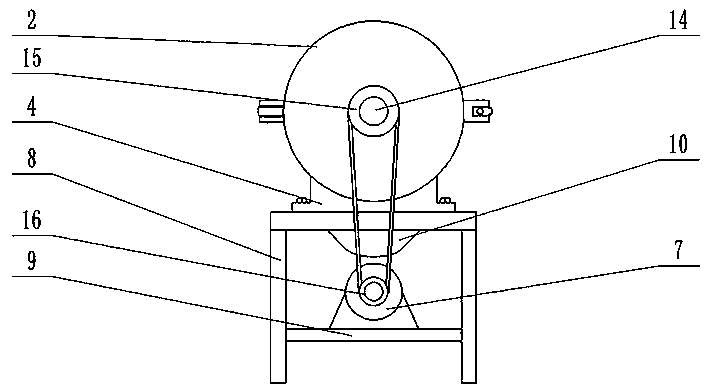

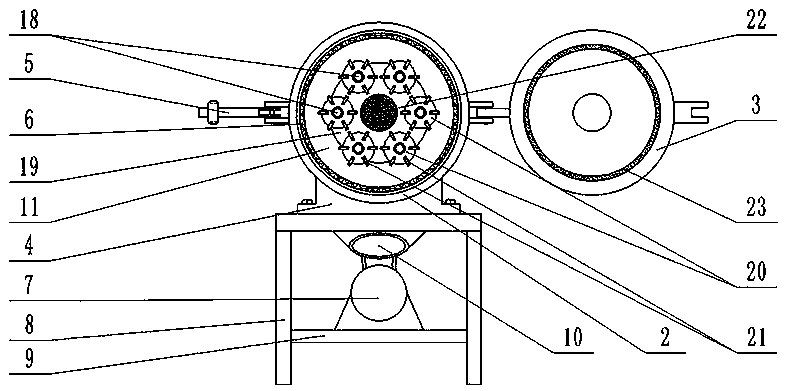

InactiveCN103128370ANo high temperatureImprove grinding precisionCopying process control systemsSawing tools dressing arrangementsGear grindingEngineering

The invention relates to the technical field of machining equipment with band saw blades, in particular to a precise automatic gear grinding machine with a saw. The precise automatic gear grinding machine comprises a machine frame, a material-clamping seat with a material clamping groove, a stepless speed regulating driving motor, an eccentric mechanism, a sliding seat, a motor sliding seat, a motor installation plate, a gear grinding machine, a gear grinding sand wheel and a material pushing device. The gear grinding sand wheel is located above the material clamping groove, an output shaft of the driving motor is connected with the sliding seat through the eccentric mechanism, the material pushing device is connected with the sliding seat, and the motor installation plate is connected with the sliding seat through a tooth-assembling-shaped device. By means of combination movements of the tooth-assembling-shaped device and the material pushing device, the precise automatic gear grinding machine with the saw enables the gear grinding sand wheel to perform automatic grinding according to tooth shapes of the ban saw blade. A circulating water system is adopted for cooling, high temperature cannot be caused at the ground positions, and the precise automatic gear grinding machine with the saw is high in gear grinding precision and working efficiency and simple in structure.

Owner:东莞市长盛刀锯有限公司

Heat dispersion connector

ActiveCN101055946ALarge current carrying capacityReduce temperature riseElectric connection structural associationsClamped/spring connectionsElectrical resistance and conductanceCarrying capacity

The pipe bus end of the inventive heat radiating type joint and the heat radiating type joint an integrated one. The pipe bus end has a plurality of conducting surfaces, and there is a certain distance between the conducting surface and the conducting surface, so that: 1. It is easy to connect with other equipments; 2. it increases the heat-radiating space; 3. It is helpful to reduce the temperature rise of the end joint; 4. since it is an integrated one withou link bit and contacting resistance, thus reducing the heat, has a large carrying capacity, and ensures the end of the bus will not have a high temperature, and will have safe operation; 5. Since the heat radiating type joint is an integrated one which has canceled original conversion gold, so that it is low cost, light weight, and energy savings.

Owner:广东日昭新技术应用有限公司

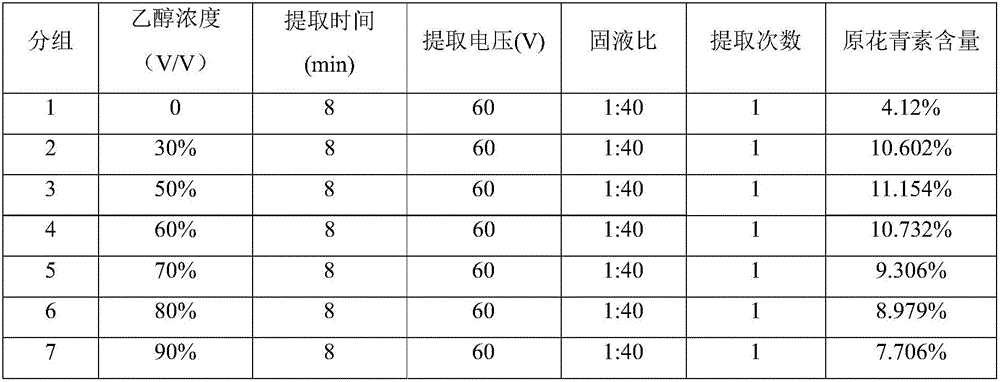

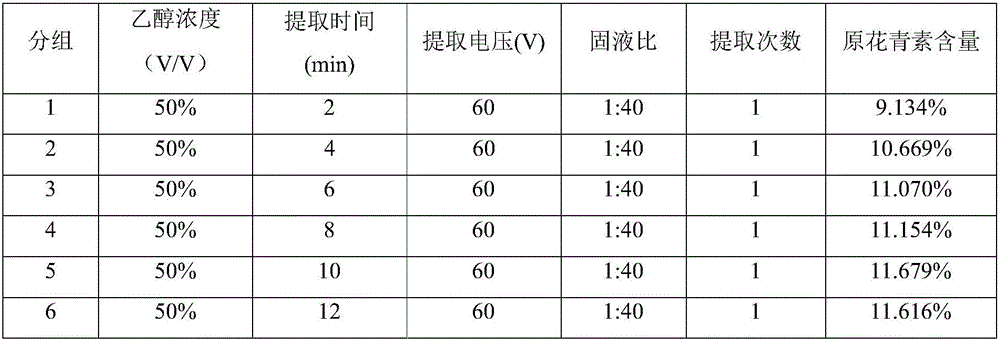

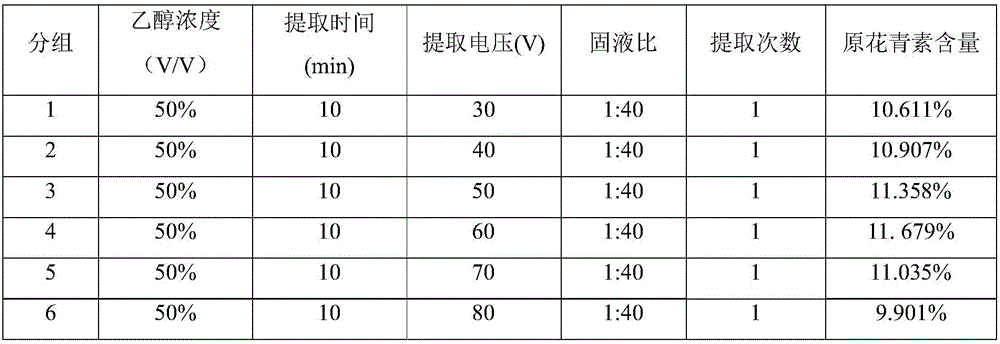

Method for extracting procyanidine from fruit or pomace of aronia melanocarpa elliot

ActiveCN106674185AAvoid decompositionAvoid lostOrganic chemistryUltra Low Temperature FreezerFiltration

The invention relates to a method for extracting procyanidine from fruit or pomace of aronia melanocarpa elliot. The method comprises the steps of dipping the fruit or pomace of the aronia melanocarpa elliot into an organic solvent, conducting Flash extraction for 0.5-30 minutes by using a Flash extractor, carrying out suction filtration and centrifugation to obtain a procyanidine extract solution of the aronia melanocarpa elliot; concentrating the procyanidine extract solution of the aronia melanocarpa elliot by using a negative pressure rotary evaporation device to obtain procyanidine extract concrete of the aronia melanocarpa elliot; and after pre-freezing the procyanidine extract concrete of the aronia melanocarpa elliot by using an ultra-low temperature refrigerator, carrying out freeze drying on the procyanidine extract concrete by using a freeze drying device to obtain the freeze-dried powder of a procyanidine extract of the aronia melanocarpa elliot. According to the method disclosed by the invention, low temperature in the whole course can be realized, procyanidine disintegration caused by high temperature can be avoided, the loss of anthocyanin in the extracting process effectively can be effectively avoided, the operation is simple and the cost is low, and promotion in enterprises can be achieved by forming an automatic production line, so that the method has a relatively high commercial value.

Owner:LIAONING UNIVERSITY

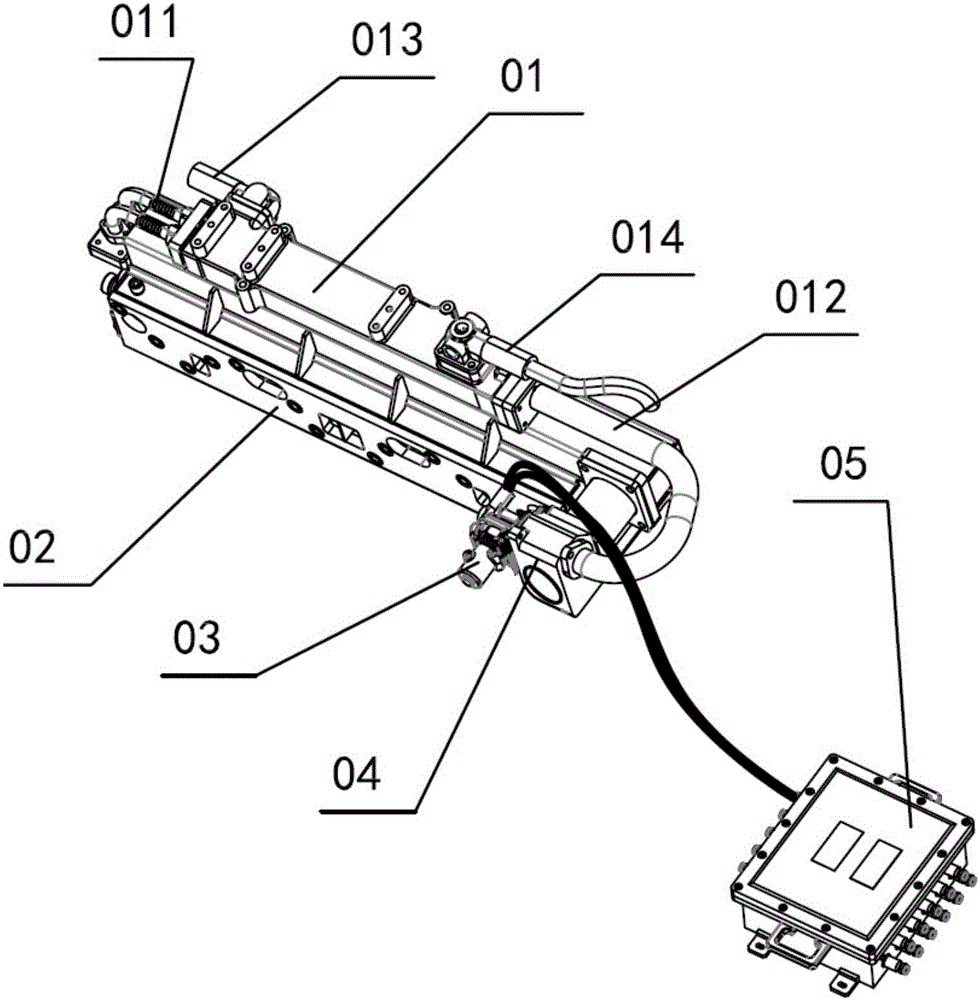

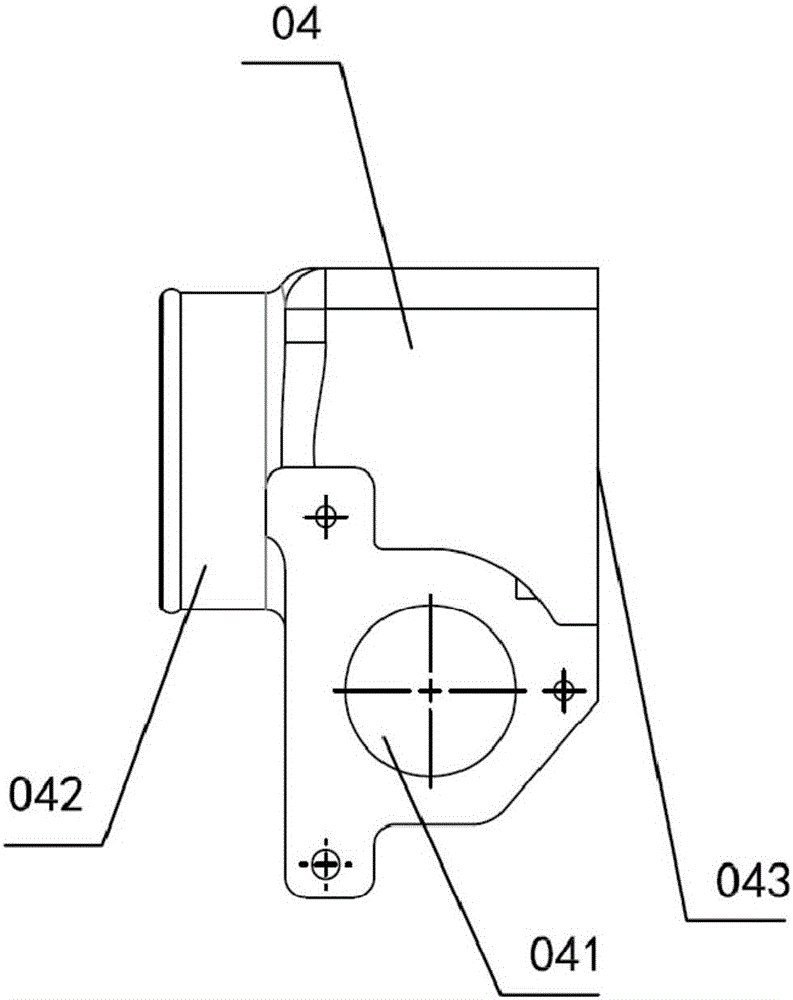

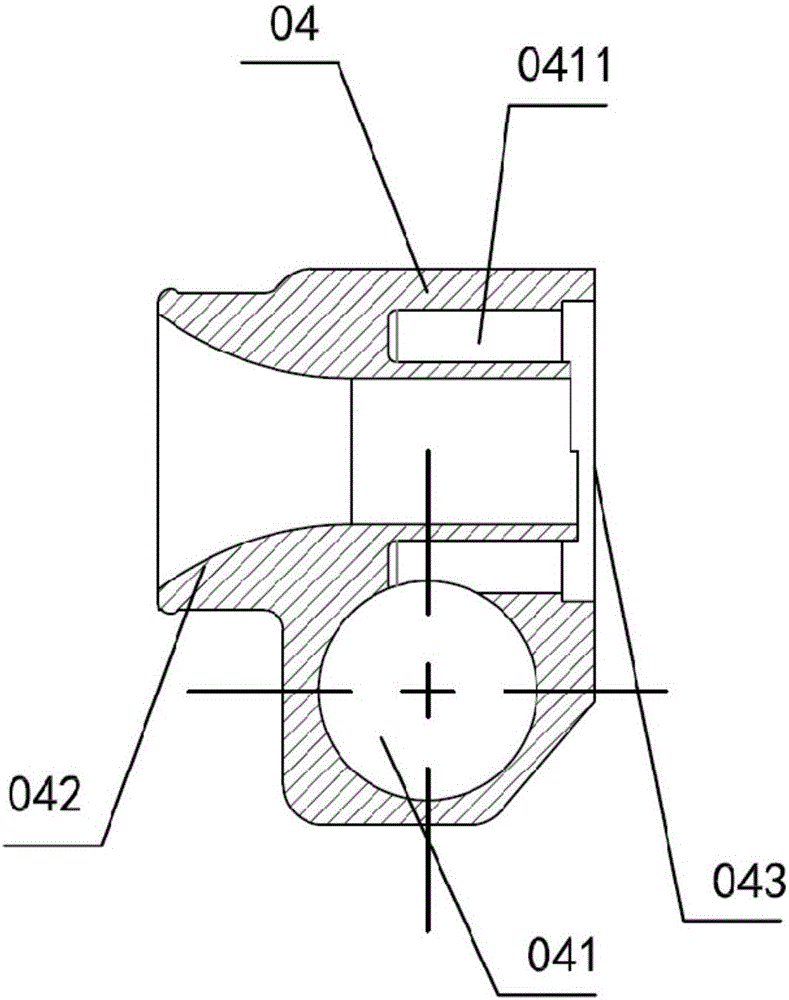

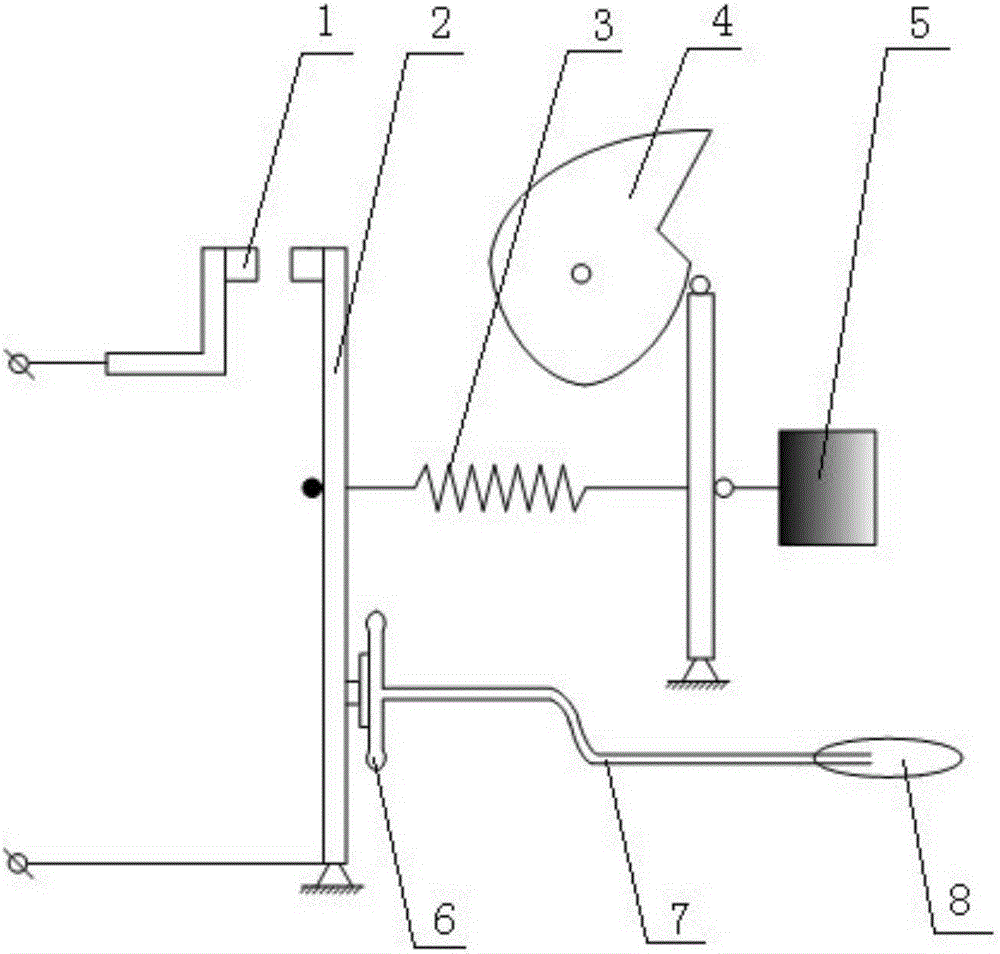

Explosion-proof electrically controlled EGR system for mine

ActiveCN105156235AEmission reductionGood explosion-proofNon-fuel substance addition to fuelInternal combustion piston enginesElectrical controlEngineering

The invention relates to an explosion-proof electrically controlled EGR system for a mine. The EGR system comprises an EGR cooler, an intake and exhaust manifold, an EGR mixing device and an explosion-proof EGR valve, wherein an EGR intake pipe and an EGR exhaust pipe are arranged at the two ends of the EGR cooler respectively; the EGR intake pipe is connected with an exhaust port of the intake and exhaust manifold; the EGR cooler is provided with a water inlet and a water outlet; a waste gas intake port of the EGR mixing device is connected with the EGR exhaust pipe; a mixing gas outlet port of the EGR mixing device is connected with a gas intake port of the intake and exhaust manifold; an explosion-proof EGR valve is connected with the EGR mixing device; the EGR valve is connected with an EGR control unit by a harness; the opening and closing of the explosion-proof EGR valve is controlled by an ECU to control the flow amount of the EGR waste gas; and the EGR control unit is arranged in an explosion-proof electrical control device. The EGR system has good explosion-proof effects, so that the EGR system can be used under the mine, and the exhaust of NOx of an explosion-proof diesel engine can be effectively reduced.

Owner:成都天地直方发动机有限公司 +2

Energy-saving environment-friendly outdoor electrical device

InactiveCN106848893AEfficient use ofIncrease temperatureSubstation/switching arrangement cooling/ventilationCold airWater storage

The invention discloses an energy-saving and environment-friendly outdoor power device, which comprises a cabinet body. A water storage tank is connected above the cabinet body. The bottom area of the water storage tank is larger than the top area of the cabinet body. At least two heating sheets are installed inside the tank wall of the water storage tank. , the tank walls of the water storage tank are heat conduction tank walls, the top of the water storage tank is inserted with an air intake pipe with the air inlet facing downward, and the air outlet of the air intake pipe communicates with the serpentine pipe located inside the cabinet, and the snake One end of the shaped pipe is communicated with the air inlet pipe, and the other end of the serpentine pipe is connected with an air outlet pipe, and the air outlet pipe is connected to the inside of the water storage tank, and the outside of the air inlet pipe and the air outlet pipe are both coated with an insulating layer. The invention obtains hot steam by heating rain and snow, and utilizes the principle of cooling and exothermic heat of the hot steam to perform heat exchange on the cold air inside the cabinet so as to increase the temperature inside the cabinet.

Owner:四川亚润科技有限公司

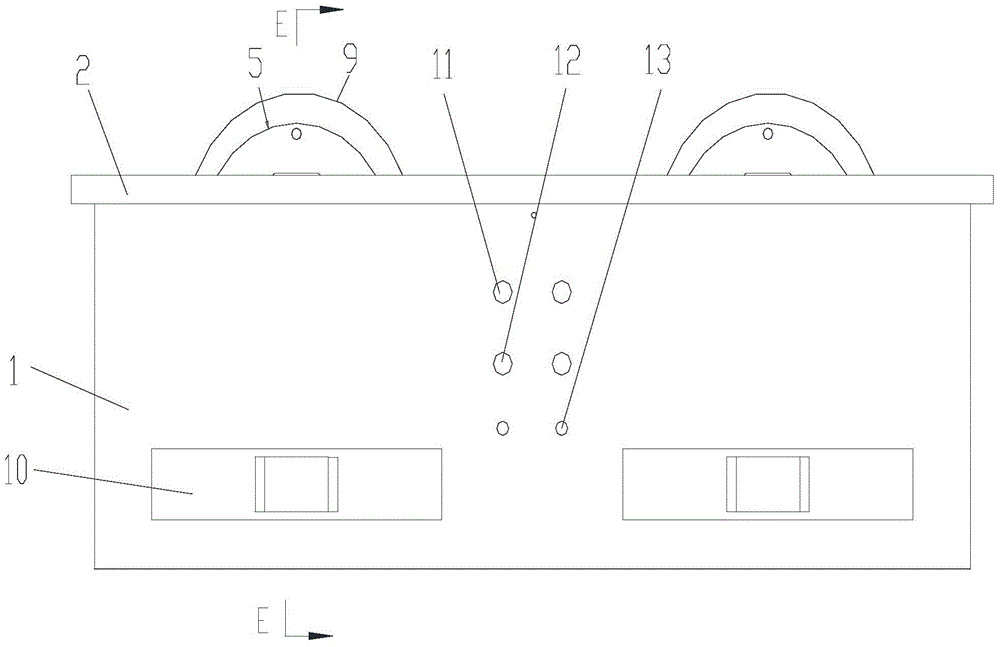

Horizontal automatic skewer baking machine

InactiveCN104921615AClean energyImprove thermal efficiencyBaking surface cleaning/greasingRoasters/grillsCooking & bakingGlass cover

The invention provides a horizontal automatic skewer baking machine which is provided with a housing and a housing cover. Multiple supports are arranged inside the housing in parallel, multiple rectangular holes rightly facing the supports are formed in the housing cover, rollers for skewer arrangement are arranged inside the supports, the upper portions of the rollers are arranged outside the rectangular holes, the rollers are of cylinder cage-shaped structures, a motor for driving the corresponding roller to turn over is arranged outside one end of each support, heating tubes for skewer baking are arranged inside the supports and on two sides of each roller, oil drip plates are arranged under the rollers, tempered glass covers are arranged above the upper end face of the housing cover and the rollers, and the motors drive the rollers to turn over so as to enable skewers to be evenly baked. The horizontal automatic skewer baking machine avoids the problem that oil-water drips drop onto the heating tubes to produce lampblack in baking, is suitable for various skewers, facilitates oil brushing and seasoning scattering in baking, ensures that the skewers are not polluted in the baking process and has the advantages of being high in skewer baking efficiency and safe in operation, reducing the labor intensity of an operator and the like.

Owner:宝鸡市建鑫机械设备有限责任公司

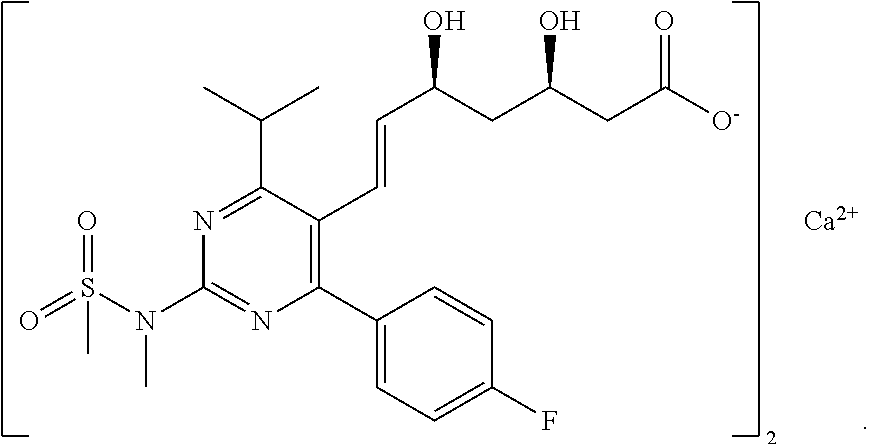

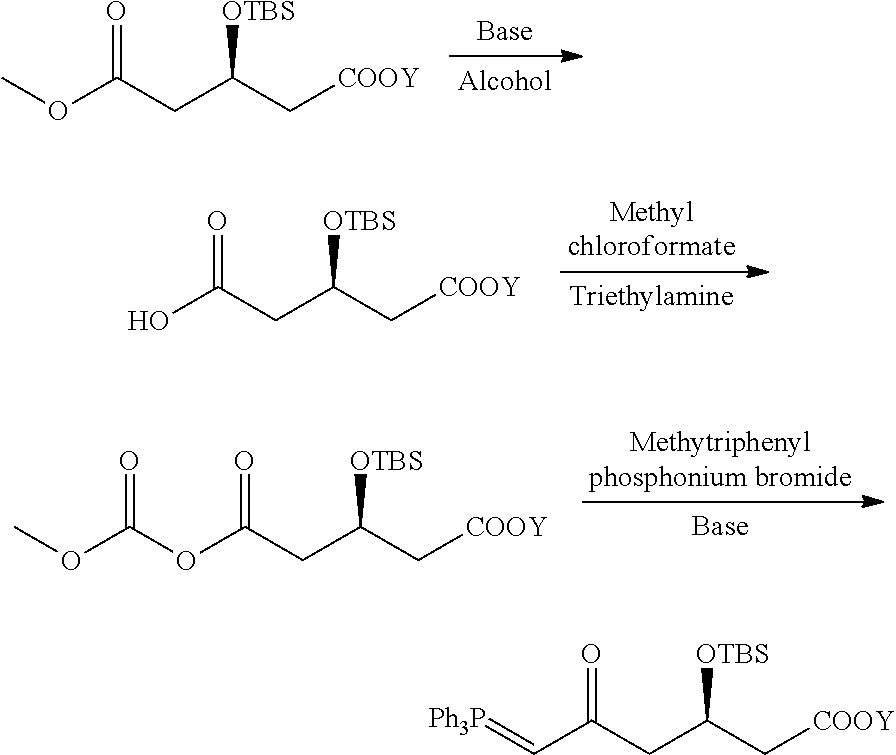

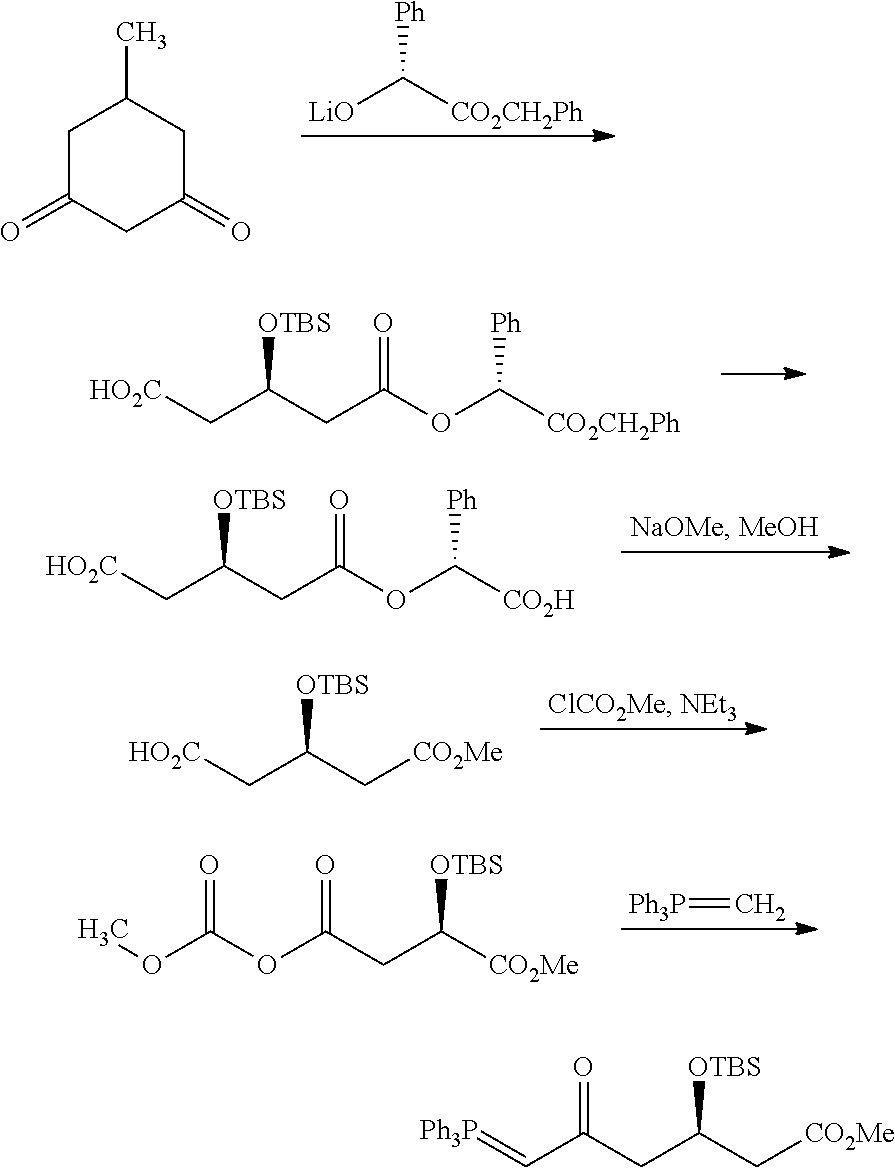

Rosuvastatin calcium intermediate and method for preparing the same

ActiveUS20120310000A1Simple and easy to controlHigh yieldSilicon organic compoundsOrganic compound preparationGrignard reactionWittig reaction

A method for preparing a rosuvastatin calcium intermediate, including a) contacting a halogenated ethene with magnesium metal to obtain a halogenated ethene Grignard reagent, and carrying out a Grignard reaction between the halogenated ethene Grignard reagent and R-epichlorohydrin; b) adding sodium cyanide for carrying out a nucleophilic substitution reaction; c) adding alcohol for carrying out an alcoholysis reaction; d) adding a basic solvent for carrying out protection of a first hydroxyl group; e) selectively oxidizing a second hydroxyl group; and f) adding triphenylphosphine in alkaline condition for carrying out a Wittig reaction.

Owner:PORTON FINE CHEM

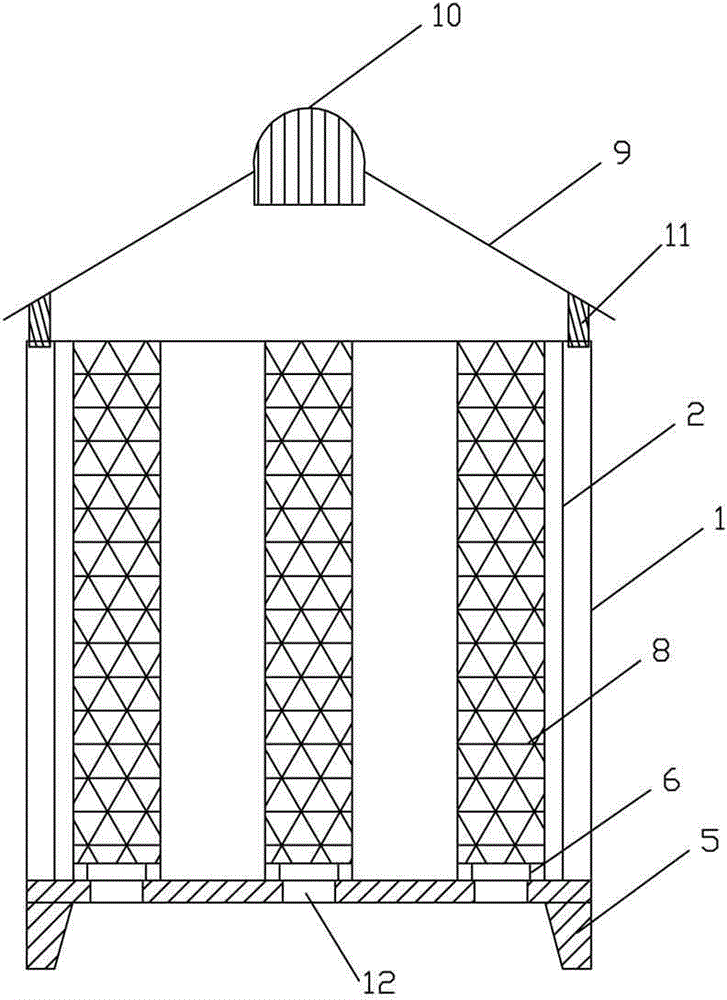

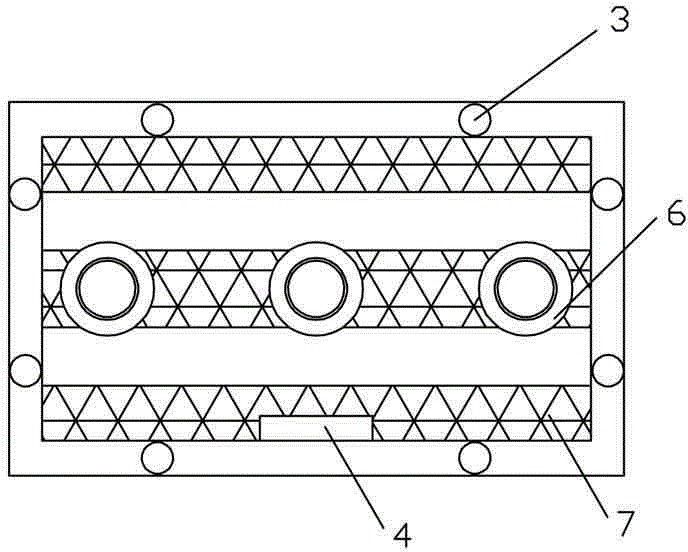

Mouldproof granary

InactiveCN104620785ANo high temperatureImprove breathabilityAgriculture tools and machinesHarvested fruit hanging devicesAgricultural engineeringBreathing

The invention discloses a mouldproof granary. The mouldproof granary comprises a granary body, a granary base and a granary cover. The granary base is connected beneath the granary body, and the granary cover is arranged on the granary body. The granary body is composed of granary stand columns, a granary body iron net and a granary iron sheet. The granary stand columns constitute a granary frame structure, the granary body iron net is arranged on the inner circumference of the granary stand columns, and the granary iron sheet is arranged on the outer circumference of the granary stand columns. Ventilation barrel bases are arranged on the granary base, the lower end of each ventilation barrel is connected with the corresponding ventilation barrel base, and the upper end of each ventilation barrel is flush with the upper end of the granary body. Each ventilation barrel is composed of a ventilation barrel framework and a ventilation barrel iron net. Ventilation holes are formed in the positions, corresponding to the ventilation barrels, of the granary base. The granary base is provided with a grain discharging opening and a granary bottom iron net. The granary cover is provided with granary cover supporting columns, and the granary stand columns are fixedly arranged between the granary body iron net and the granary iron sheet. A granary cover ventilator is arranged at the upper end of the granary cover. The mouldproof granary is good in air permeability and can be prevented from mildewing.

Owner:大石桥市鑫雨稻田养鱼专业合作社

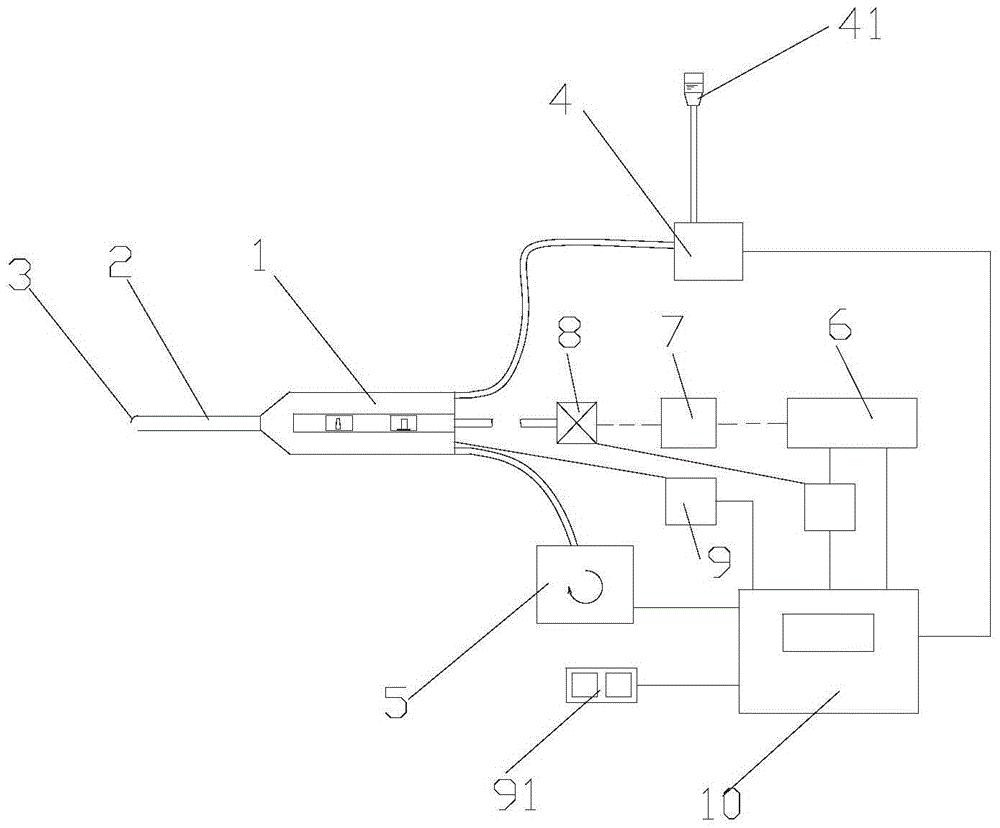

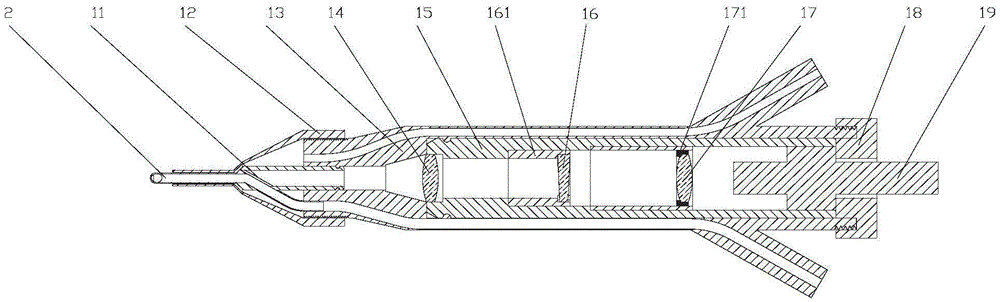

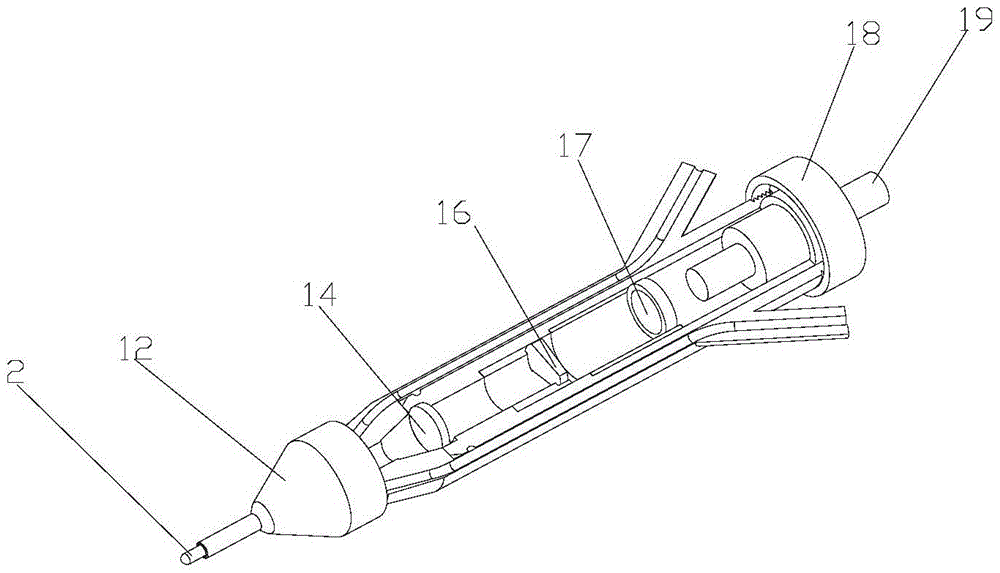

Femtosecond laser cataract emulsifying treatment system

ActiveCN105596143AImprove surgical efficiencySafe surgical approachLaser surgeryFemto second laserPosterior lens nucleus

The invention provides a femtosecond laser cataract emulsifying treatment system which comprises an emulsifier, wherein a needle which can touch the lenticular nucleus of a cataract patient is arranged at the front end of the emulsifier; two channels which can be led to the outside of the emulsifier are arranged in the emulsifier: a negative pressure channel and a lavage suction channel; the end of the negative pressure channel led to the outside of the emulsifier is connected with a negative pressure unit capable of generating a pressure for adsorbing the lenticular nucleus; the end of the lavage suction channel led to the outside of the emulsifier is connected with a lavage suction unit capable of sucking out the emulsified lenticular nucleus; the back end of the emulsifier is connected with a femtosecond laser generator capable of generating femtosecond laser; and the femtosecond laser, the negative pressure unit and the lavage suction unit are all connected with a computer control unit. By adopting full-femtosecond laser capsulorhexis, the system imposes relatively low requirements on the experiences of the operation doctor and can realize accurate positioning of capsulorhexis through computer control.

Owner:上海婷伊美科技有限公司

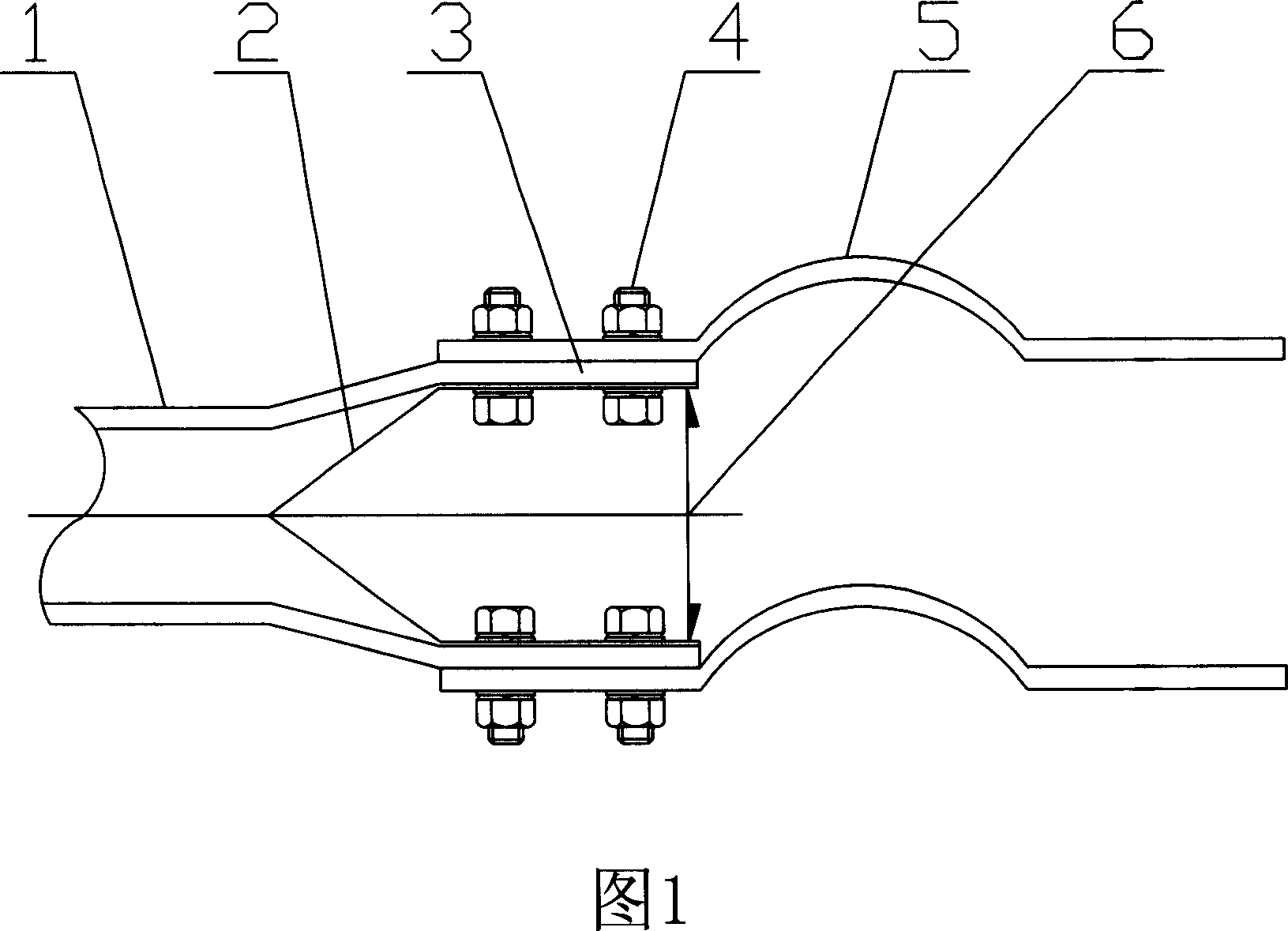

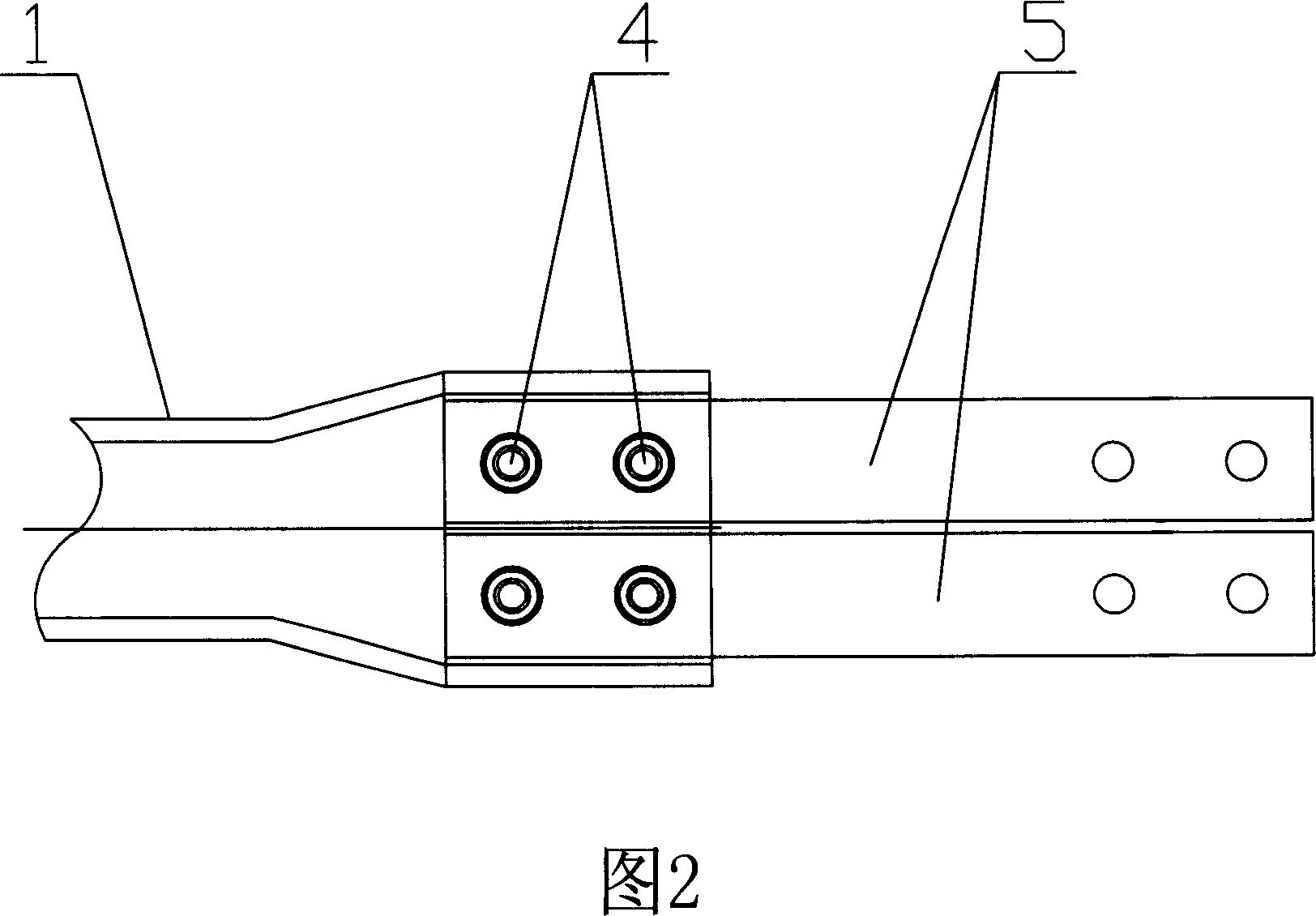

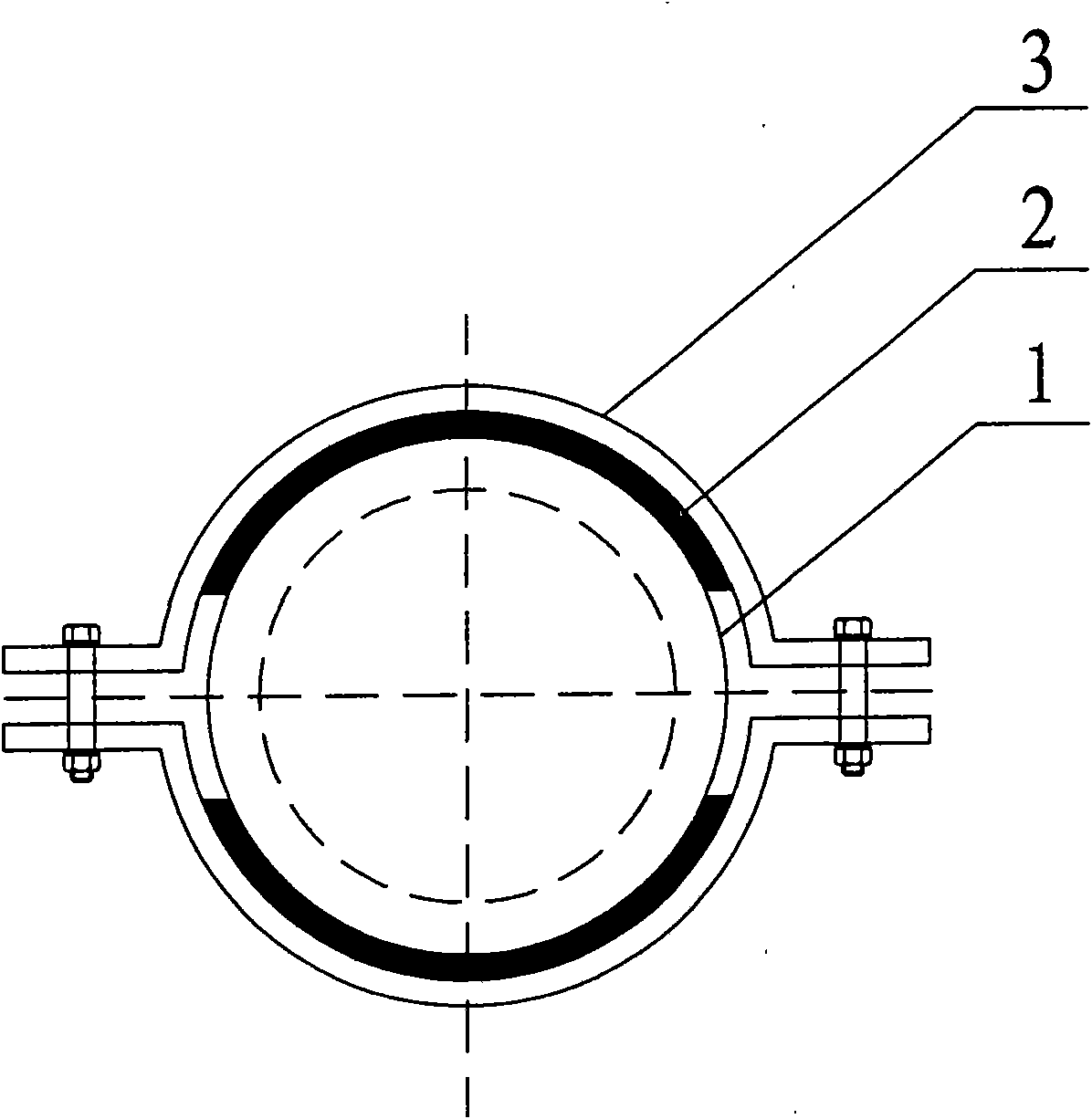

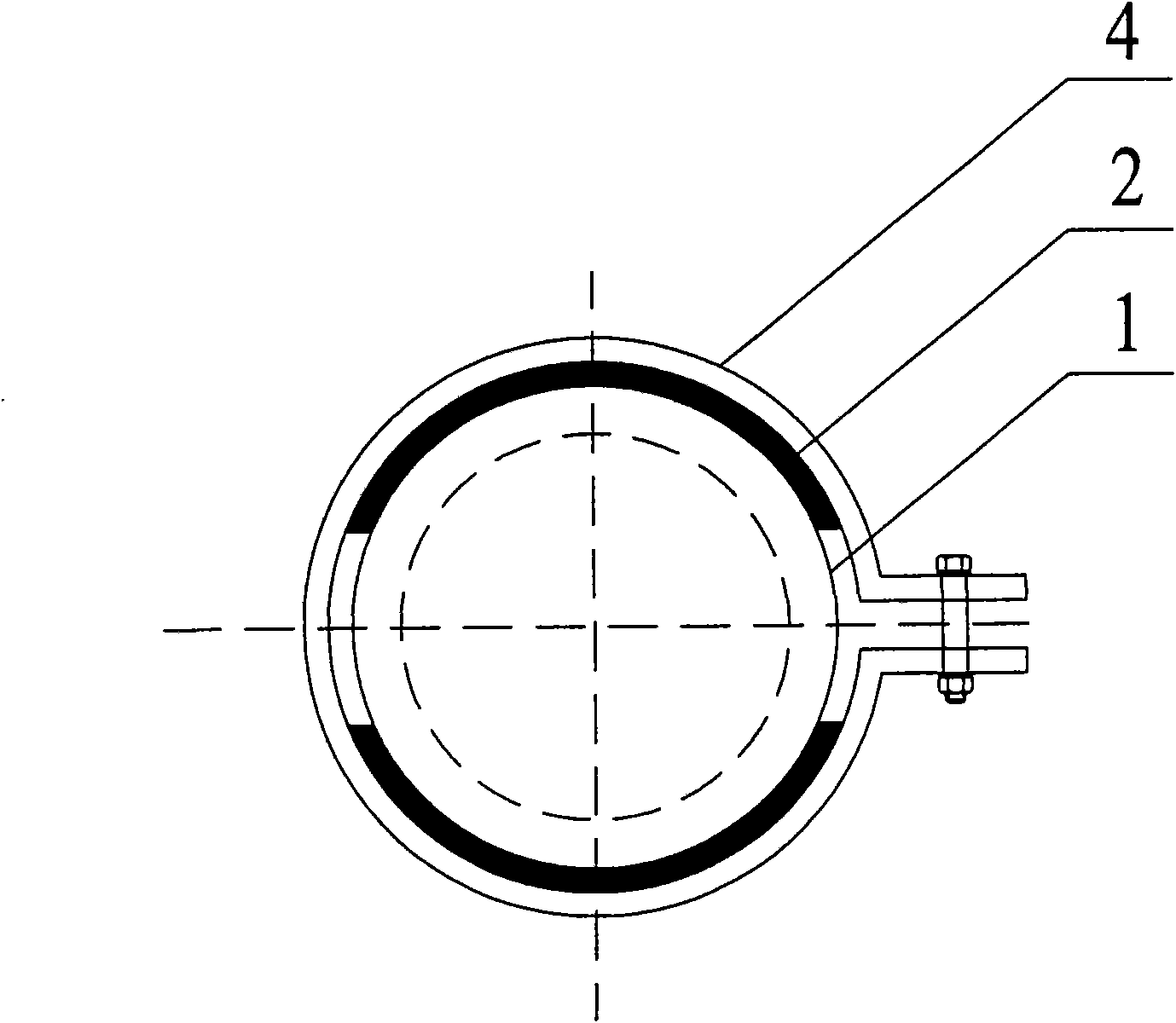

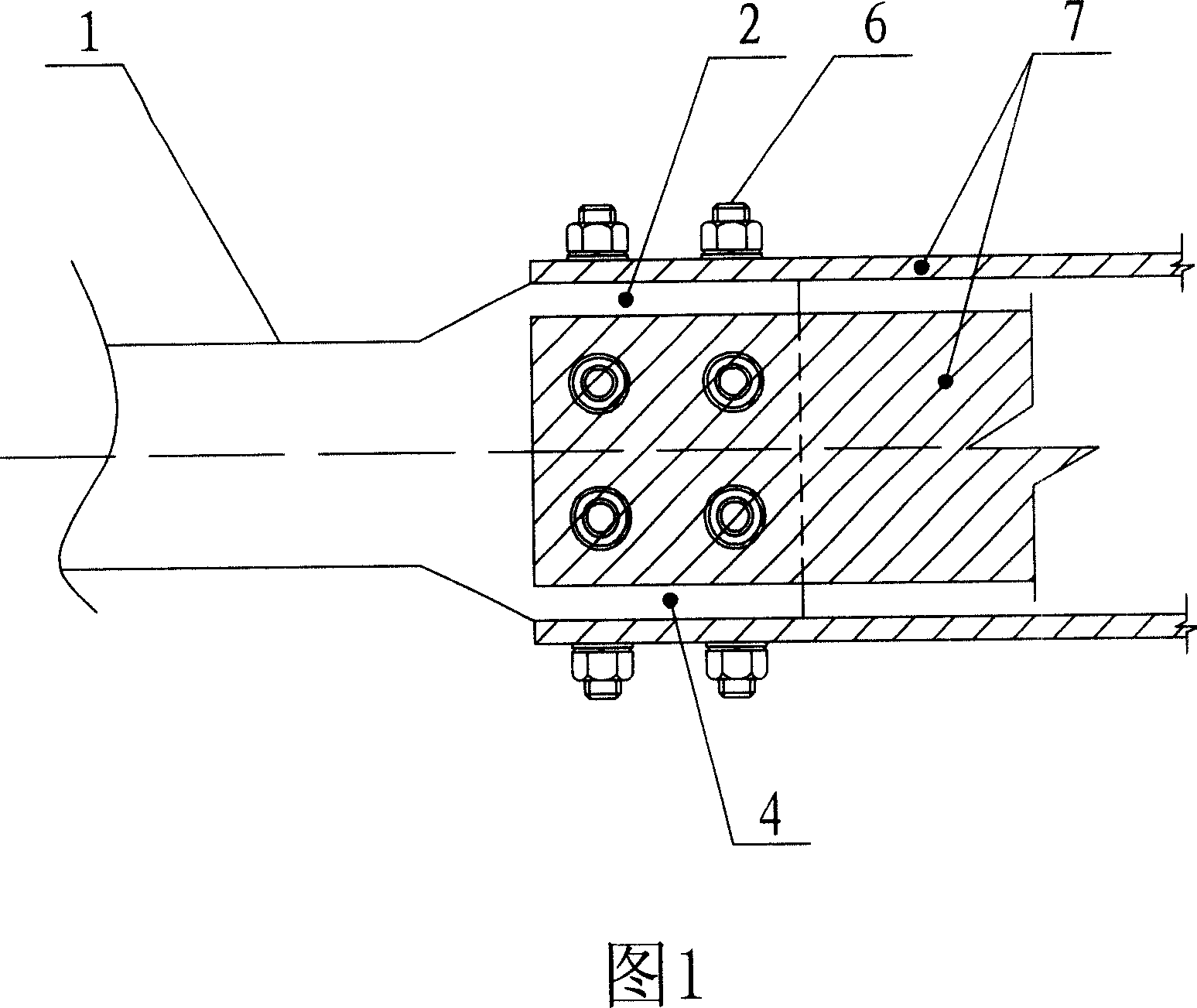

Tube busbar joint

ActiveCN101540437ALarge current carrying capacityReduce temperature riseClamped/spring connectionsConnection contact member materialElectrical resistance and conductanceBusbar

The invention discloses a tube busbar joint which is formed by adopting an anchor ear and a metallic sheath at the ends of copper and aluminium tube busbars and a copper composite tube busbar, or using an arc-shaped metallic pressing board to tightly fix soft copper and aluminium tapes on the end of the busbar by a screw bolt directly. The soft copper and aluminium tapes of the tube busbar joint is connected with terminals of other equipment, and the tube busbar joint tightly fixes the soft copper and aluminium tapes on the end of the busbar directly to form an integrated type, thus having no link bit, no contact resistance, reducing heat productivity, having large current carrying capacity, guaranteeing that the end of the busbar does not generate high temperature, and ensuring safe operation; and the busbar joint is the integrated type, thus cancelling original conversion hardware fittings, lowering cost directly, reducing the weight of the busbar and consumptive materials, and saving nonferrous metal and energy.

Owner:广东日昭电工有限公司

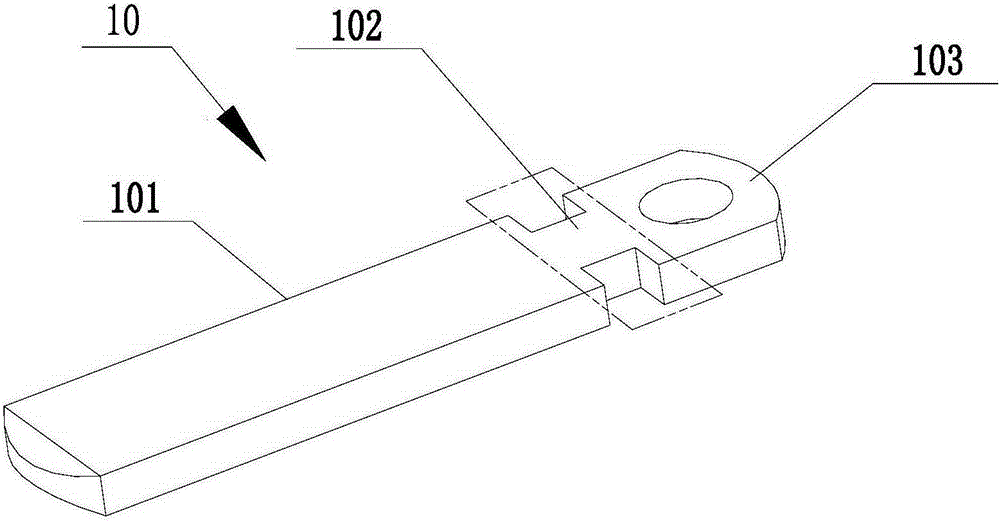

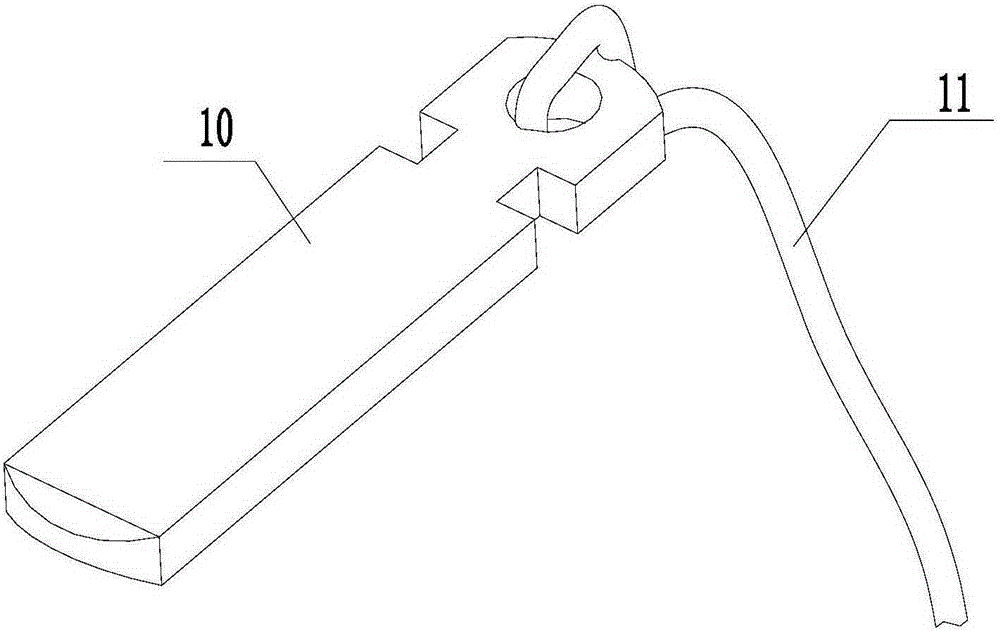

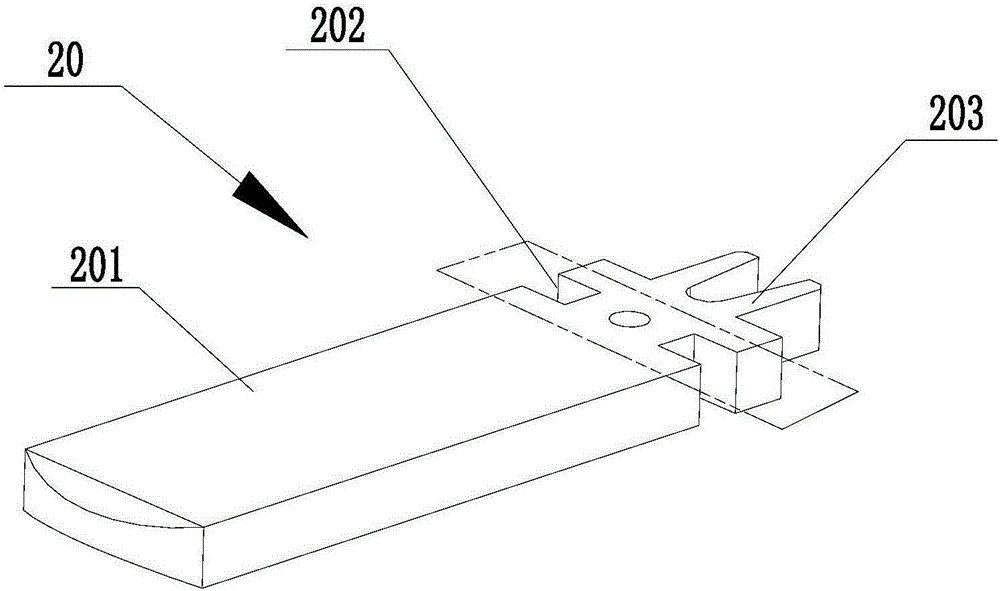

Pins and plug assembly with same

InactiveCN105206965AImprove reliabilityHigh strengthCoupling contact membersRiveted connectionsUltimate tensile strengthElectrical and Electronics engineering

The invention discloses pins and a plug assembly with the same. A round through hole is formed in the middle of each plastic part embedding and ejecting part, and a Y-type prong is arranged on each connecting-out power source. The plug assembly comprises a pair of pins, a plastic part and a pair of adaptor metal elastic pieces, the plastic part embedding and ejecting parts of the pins make tight contact with the plastic part, through holes are formed in the adaptor metal elastic pieces and are suitable for the Y-type prongs to penetrate through, and the pair of adaptor metal elastic pieces and the pair of pins are tightly connected into one through riveting. The round through hole is additionally formed in the plastic part embedding and ejecting part of each pin, so that the reliability and strength of connection of the pins and the plastic part are higher; in addition, a round through hole of each connecting-out power source is changed into the Y-type prong with a C-type chamfer and a round chamfer, the Y-type prongs will not fracture when extending to the two sides, and secondary damage to the pins of the plug assembly is avoided.

Owner:PHICOMM (SHANGHAI) CO LTD

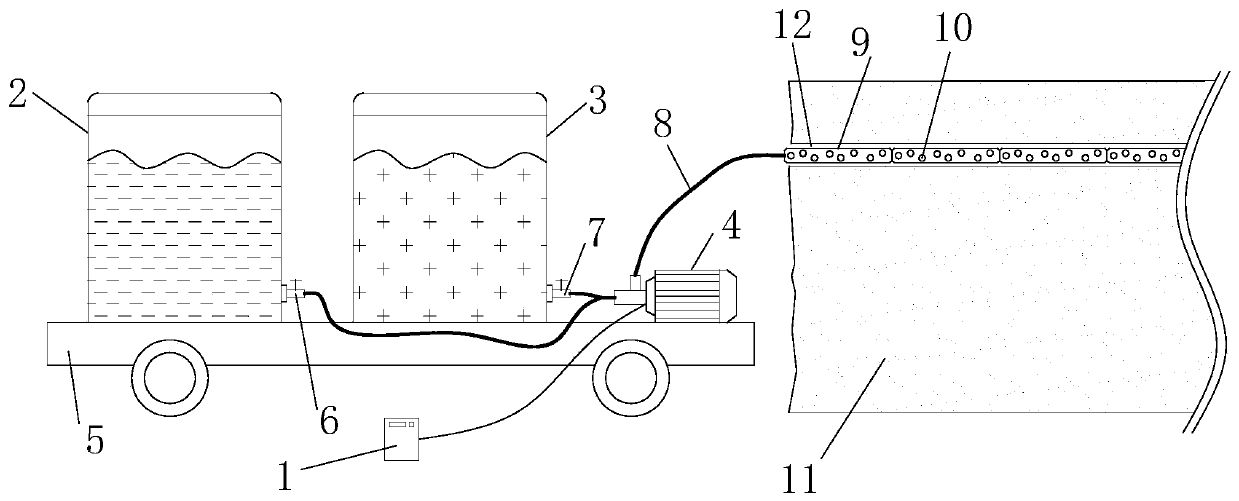

Coal seam static expansion, cracking and antireflection equipment and method

ActiveCN111535790ANo high temperatureImprove securityFluid removalDrilling compositionStructural engineeringTruck

The invention discloses coal seam static expansion, cracking and antireflection equipment and method. The coal seam static expansion, cracking and antireflection equipment comprises a grouting truck and a grouting pipeline. A grouting pump, an expansion agent tank, an acidolysis agent tank are arranged on the upper part of the grouting truck, an expansion agent discharging outlet is formed in thebottom of the expansion agent tank, an acidolysis agent discharging outlet is formed in the bottom of the acidolysis agent tank, and the expansion agent discharging outlet and the acidolysis agent discharging outlet are separately connected with a liquid inlet of the grouting pump; and the grouting pipeline is connected with a liquid outlet of the grouting pump through a pipeline, and the groutingpipeline comprises a plurality of sections of rotating pipes connected to one another and arranged in a coal seam borehole. The coal seam static expansion, cracking and antireflection equipment has the beneficial effect that through mechanized operation, a drag reducing expansion agent is injected into the coal seam borehole to produce static expansion, the coal seam is promoted to rupture and generate cracks, then chemical decomposition is carried out through a decomposer to clean drag reduction expansion agent defective materials in the coal seam borehole, the connectivity between the borehole and the surrounding coal seam crack channels is ensured, and the coal seam static expansion, cracking and antireflection equipment has the advantages of low economic cost and high safety factor.

Owner:SHANDONG UNIV OF SCI & TECH

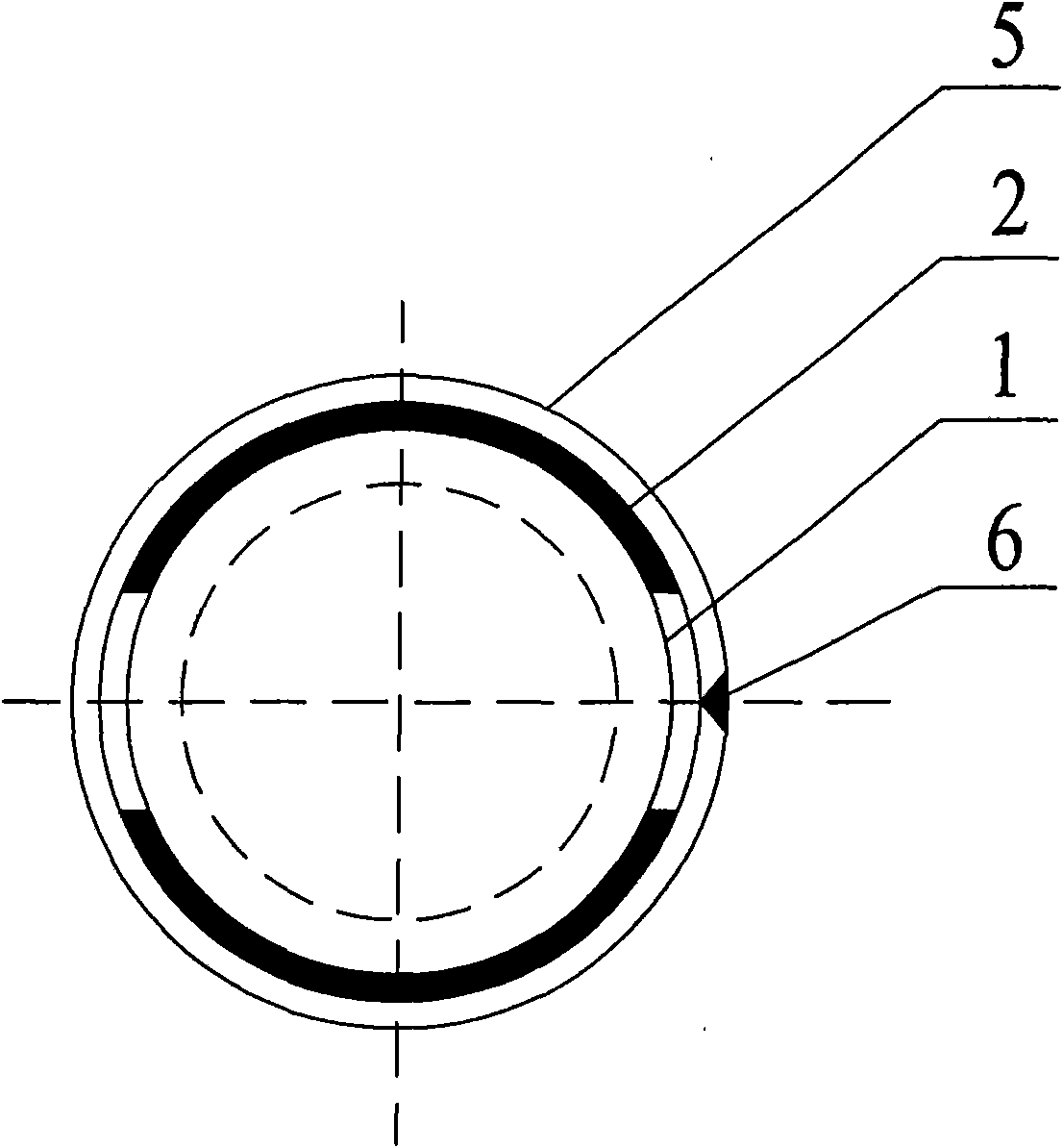

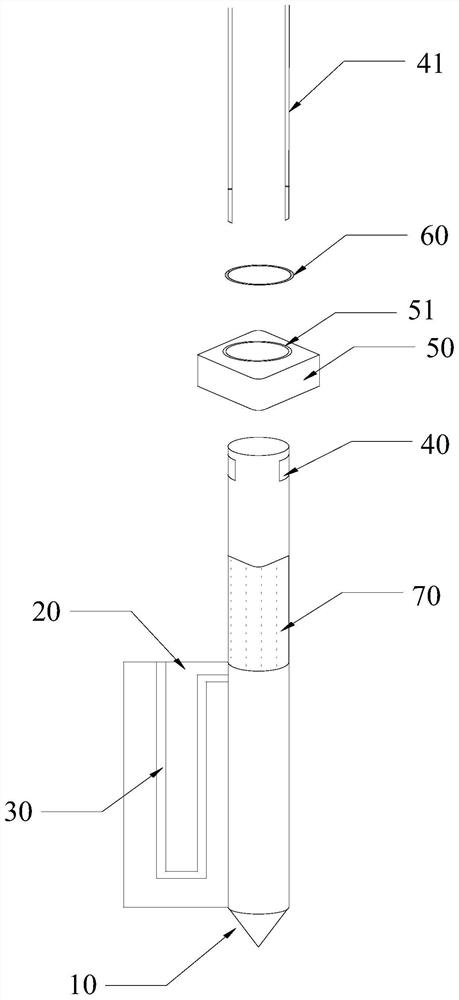

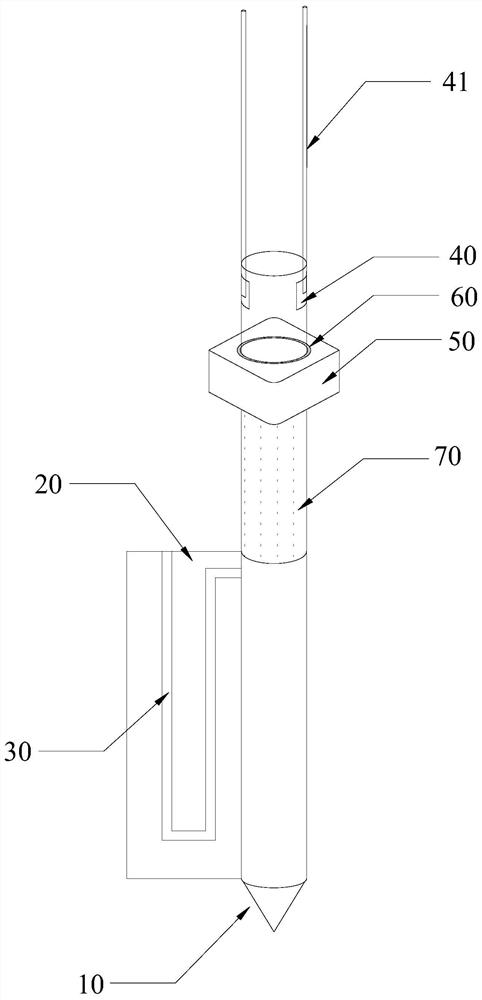

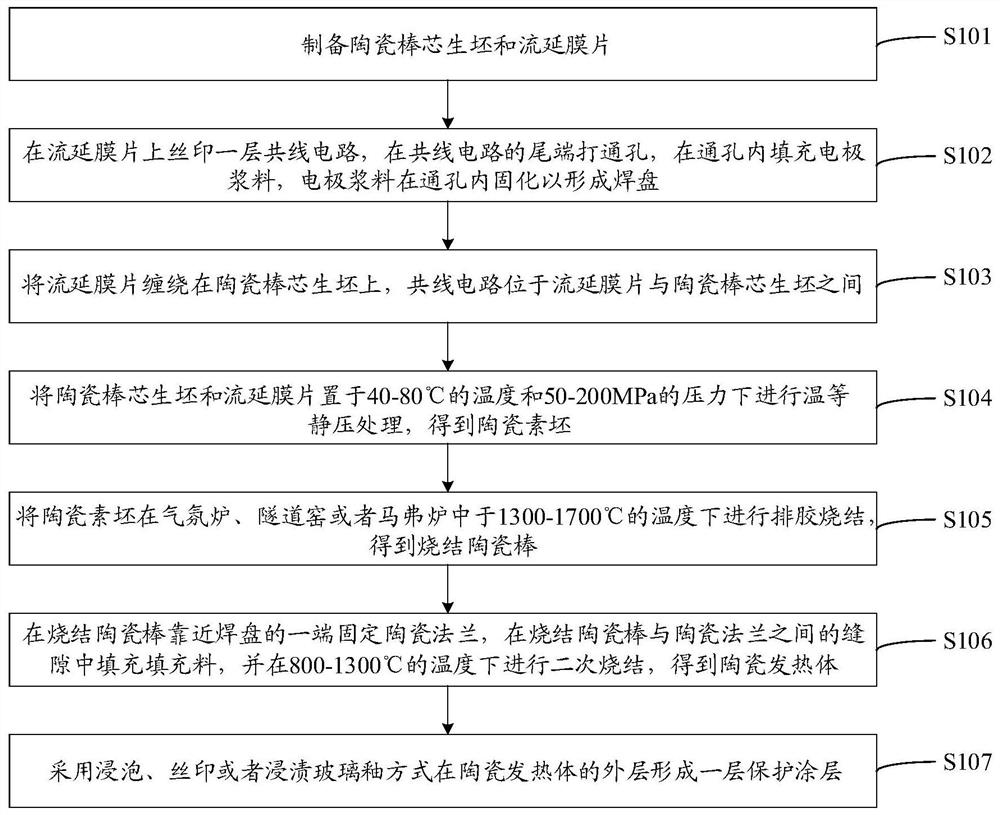

Ceramic heating element for heat-not-burn electronic cigarette and preparation method of ceramic heating element

PendingCN113545528APrevent temperature hysteresisHarm reductionTobaccoTemperature controlElectronic cigarette

The invention discloses a ceramic heating element for a heat-not-burn electronic cigarette and a preparation method of the ceramic heating element. The ceramic heating element comprises a ceramic rod core; a ceramic casting diaphragm arranged on the outer side of the ceramic rod core; a collinear circuit arranged on the ceramic casting diaphragm and used for controlling heating of the ceramic heating body and measuring the temperature of the ceramic heating body; a bonding pad which is arranged at the tail end of the collinear circuit and is used for connecting the outer electrode and the collinear circuit; a ceramic flange sleeving the ceramic rod core, wherein the ceramic flange is arranged close to one end of the bonding pad; and a protective coating arranged on the outer circumferential surface of the ceramic rod core. By means of the mode, heating and temperature control can be collinear, the difficulty of the printing technology is simplified, the hysteresis phenomenon of temperature control of the ceramic heating body is prevented, the temperature control precision is high, high temperature cannot be generated in the using process, and harm of toxic and harmful substances generated by the high temperature to the human body is reduced.

Owner:SHENZHEN TAOTAO TECH CO LTD

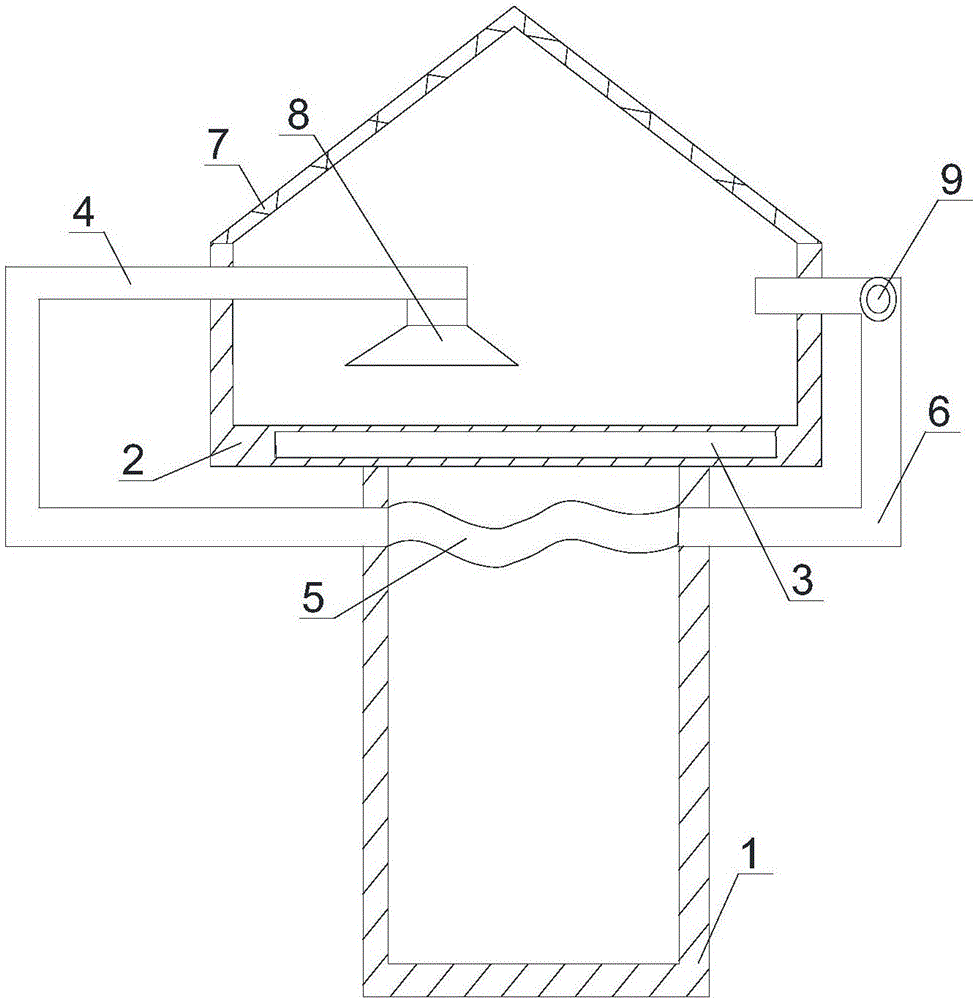

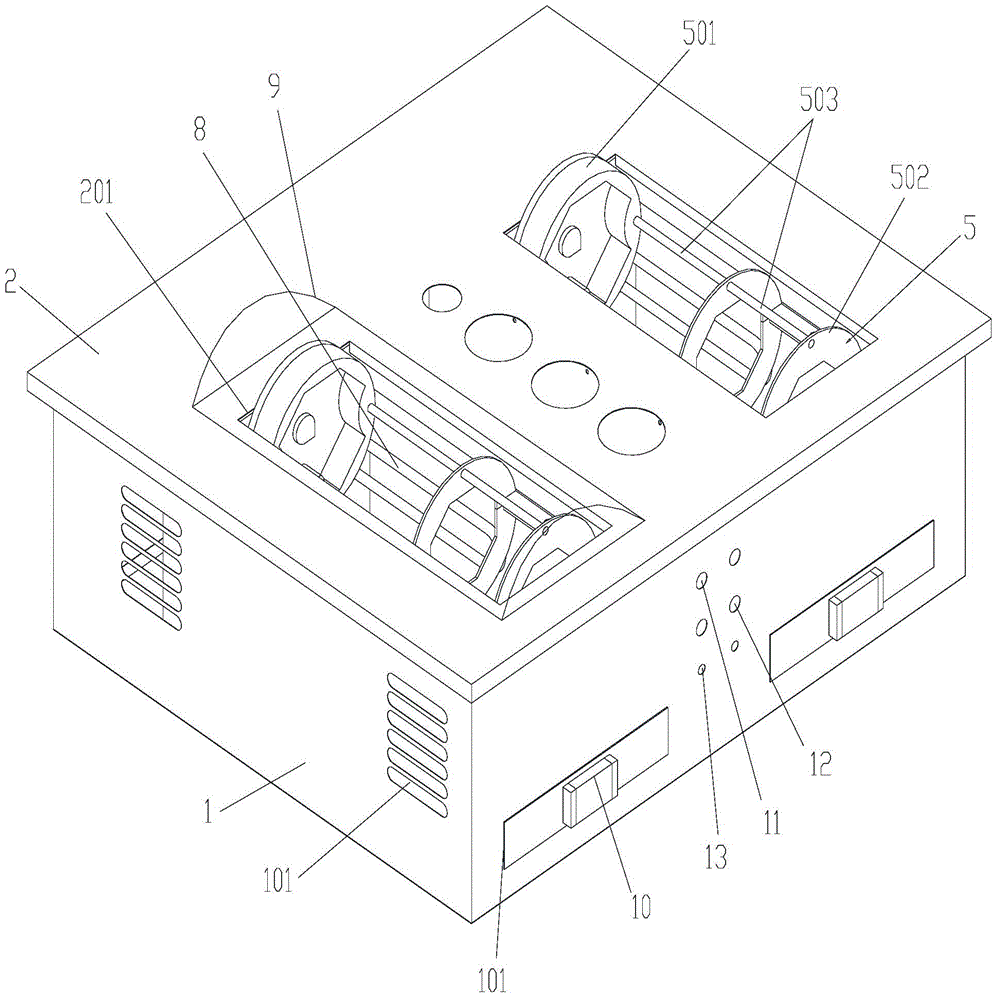

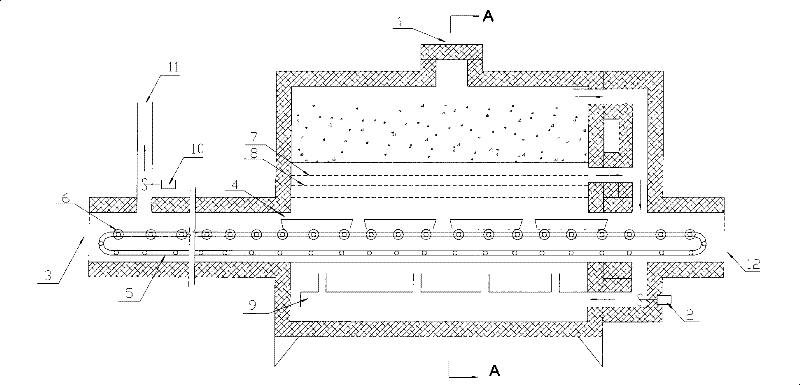

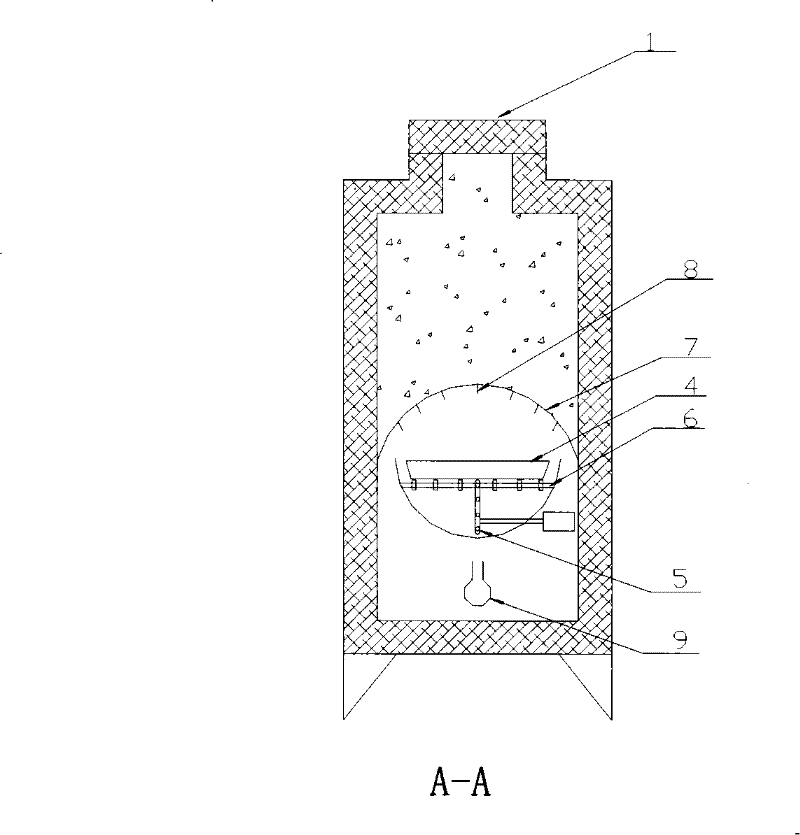

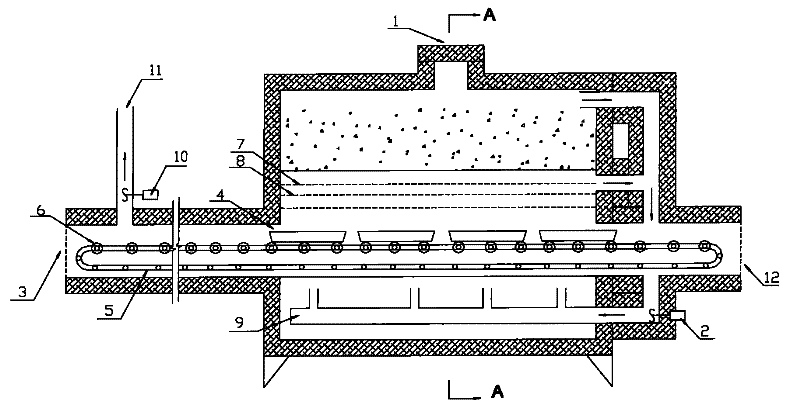

Method and equipment of cultivated silkworm fresh cocoon quick-freezing for cocoon suffocation

ActiveCN101328617BLittle impact on qualityImprove qualitySilk cocoons cleaning/classifyingNatural stateDry ice

The invention provides a quick freezing pupa killing method for fresh silkworm cocoons, particularly comprising the following steps that: solid dry ice is taken as a cold source to absorb heat of the fresh silkworm cocoons, and simultaneously carbon dioxide obtained through sublimation of the dry ice is taken as the cold source to blow over the fresh silkworm cocoons and exchange heat with the fresh silkworm cocoons so as to make the temperature of the fresh silkworm cocoons reduced to below a given temperature and maintain for a period of time. The invention simultaneously provides a device for realizing the method, comprising an insulated cabinet body and an endless apron, wherein, a cold source cabinet body is arranged on the upper part of the insulated cabinet body, and the solid dry ice is arranged inside the cabinet body; the bottom of the cold source cabinet body is provided with a heat exchange plate; a cold blast pipe is arranged on the lower side of the endless apron, and anopening of the cold blast pipe faces to the endless apron; the cold blast pipe is communicated with the cold source cabinet body; and a fan is arranged on an inlet end of the cold blast pipe. By adoption of the method and the device, the pupa killing production cycle can be obviously shortened and the labor efficiency can be obviously improved; moreover, because pupae are killed at a low temperature, fresh cocoon shells and pupal cells maintain natural state, thereby the quality of the fresh cocoon shells and the pupal cells is slightly influenced and good-quality raw materials are provided for the silk reeling technique and deep-processing of fresh pupae.

Owner:广东省蚕业技术推广中心 +3

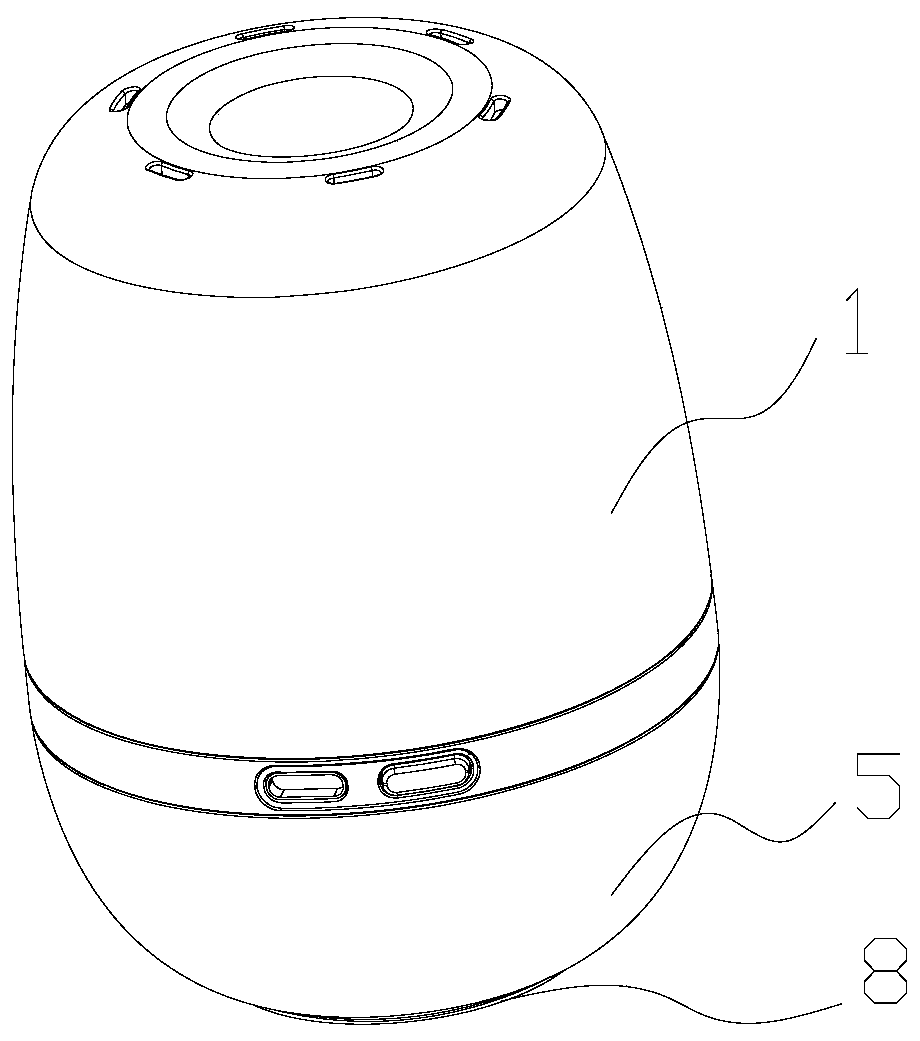

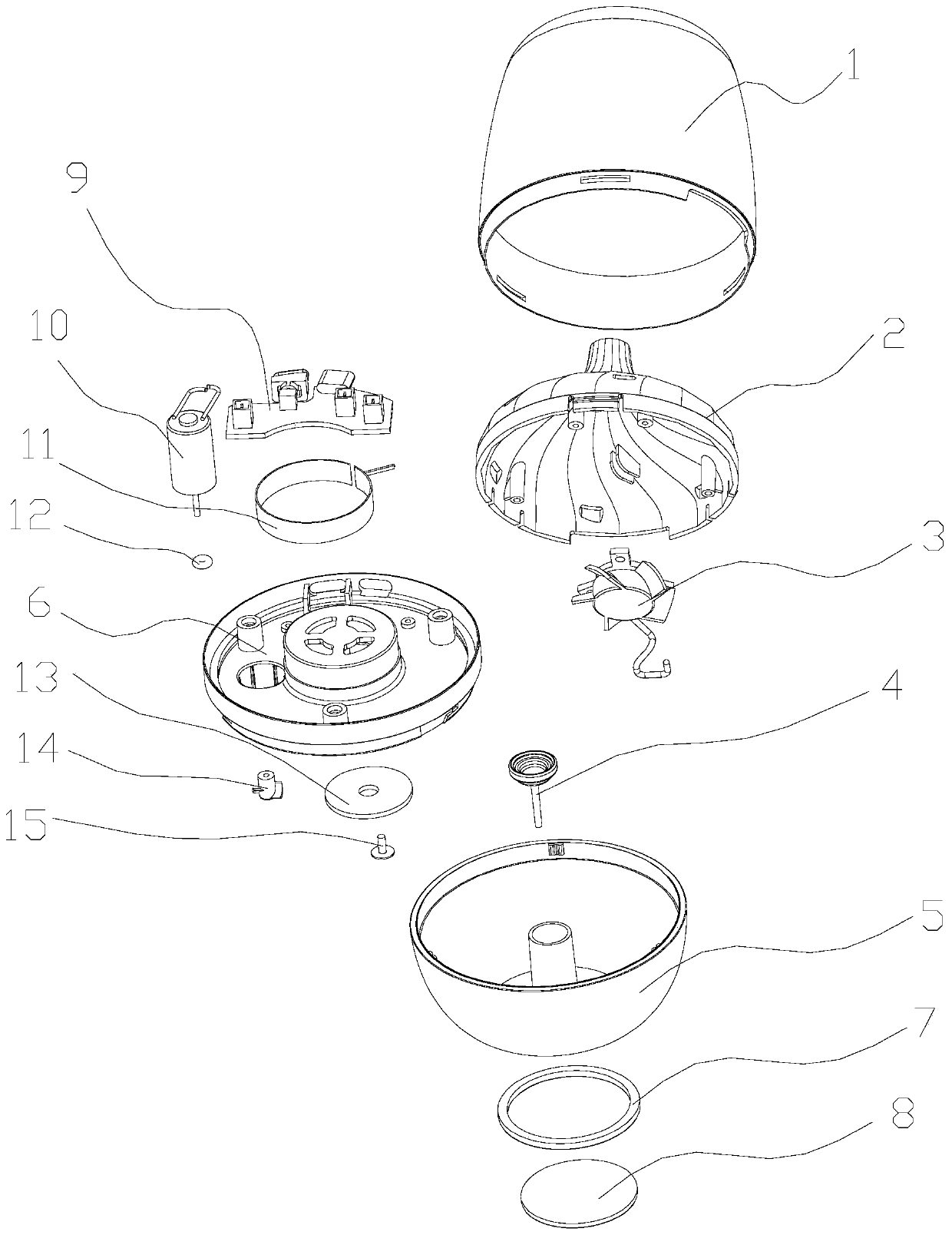

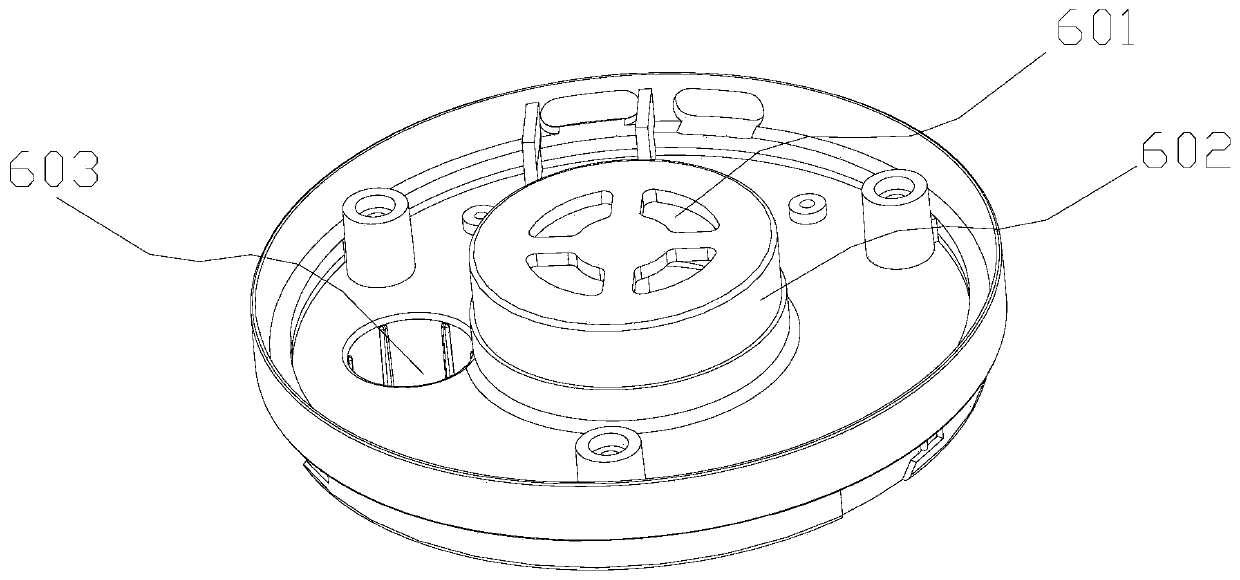

Aroma generating device

PendingCN111514356AReduce volatilityNo high temperatureTransportation and packagingRotary stirring mixersAromaElectric machinery

The invention discloses an aroma generating device which comprises a lower casing, wherein the lower casing is used for storing liquid; a middle casing is movably clamped and buckled in an opening ofthe lower casing in a sealed way; the middle casing is provided with a stirring tube extending to a position below the liquid level in the lower casing in a downwards extending way; a stirring blade is arranged in the stirring tube; the stirring blade is driven to rotate by a motor; hollow parts communicating with the middle casing are also arranged on the middle housing; an upper casing is arranged above the middle casing in a sealed way; a fan is arranged in a position of an upper opening of the upper casing; and when the fan works, the air in the lower casing is exhausted through the air convection formed through the hollow parts via the upper opening of the upper casing. The aroma generating device has the advantages that the liquid volatilization quantity is small; in addition, aromacan be fast output; the aroma volatilization time is long; and the use risk is low.

Owner:SHENZHEN QUANJIA MENGFU CREATIVE DESIGN CO LTD

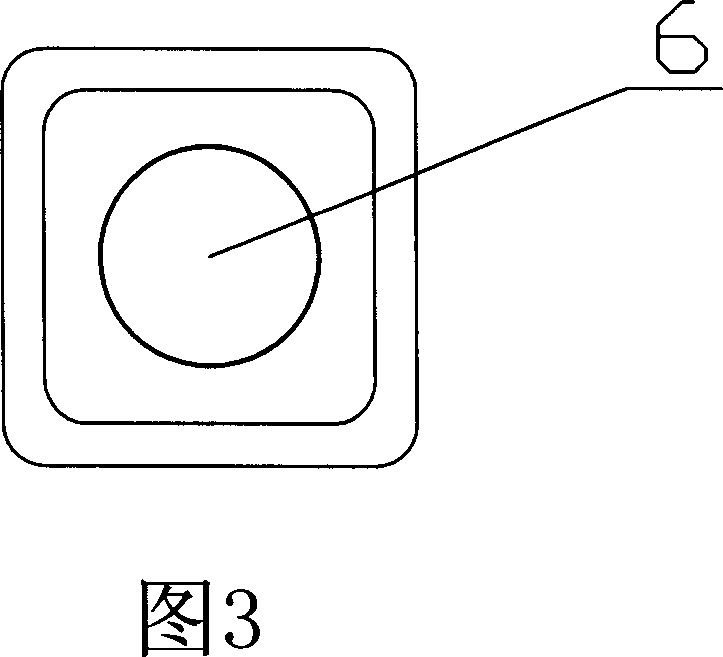

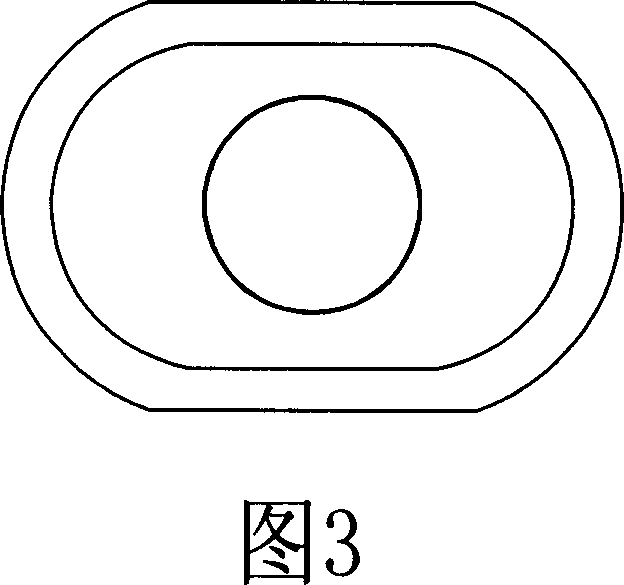

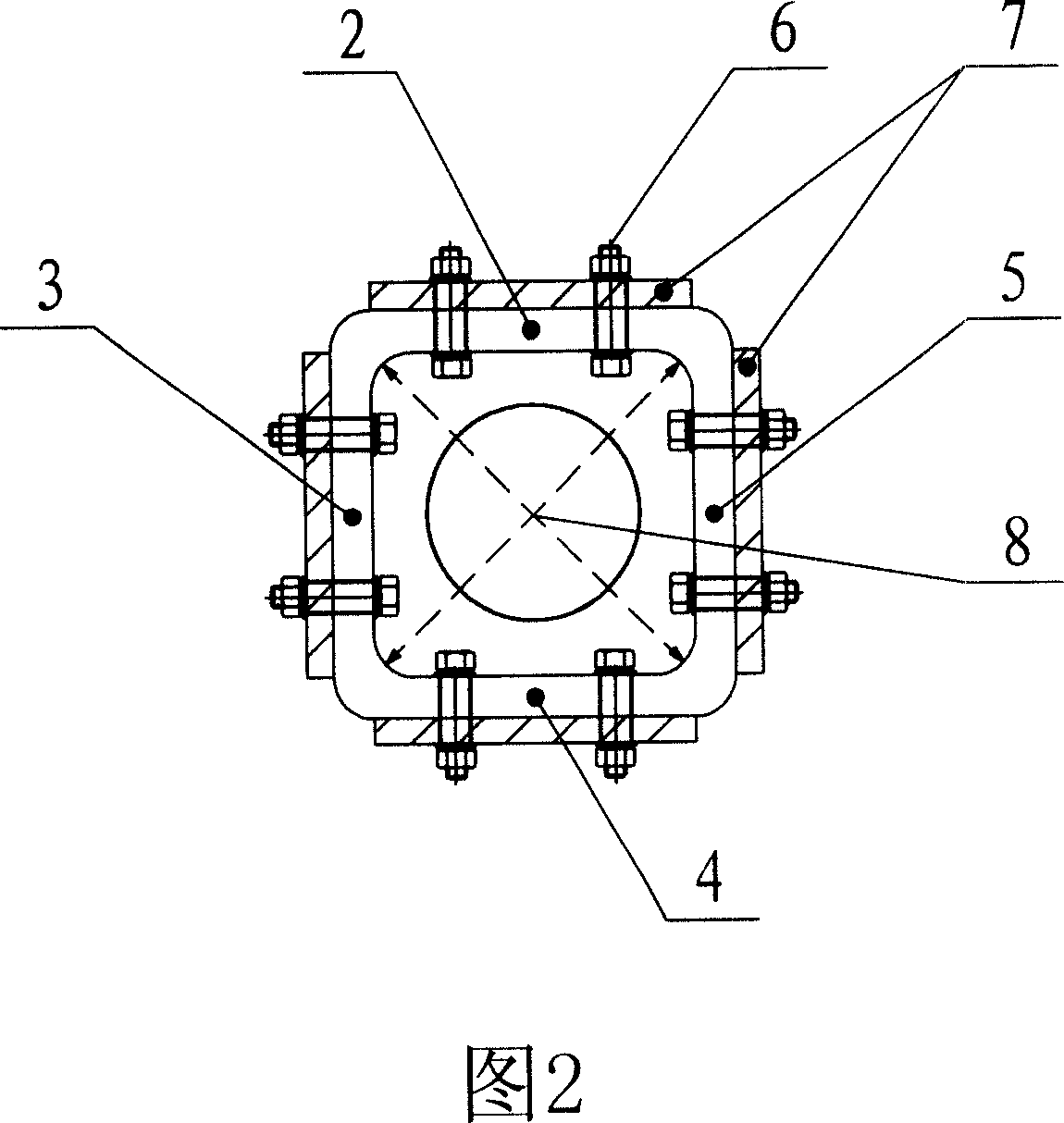

Hollow four-side connector

InactiveCN101055947AReduce temperature riseReduce weightElectric connection structural associationsClamped/spring connectionsElectrical resistance and conductancePunching

The pipe bus end calibre of the inventive hollow four-side joint copper, aluminium pipe bus and copper multiple tube bus (steel pipe or aluminium pipe is claded in the copper pipe) is moulded into four hollow copper and aluminum conducting surfaces by a punching technology. The suitable mould are configured according to actual carrying capacity requirement and the requirement of bus calibre, to process the conducting surfaces (shapes such as a square, a rectangle and two plane ellipse). Since it is an integrated one withou link bit and contacting resistance, thus ensuring the end of the bus will not have a high temperature, and will have safe operation.

Owner:罗志昭

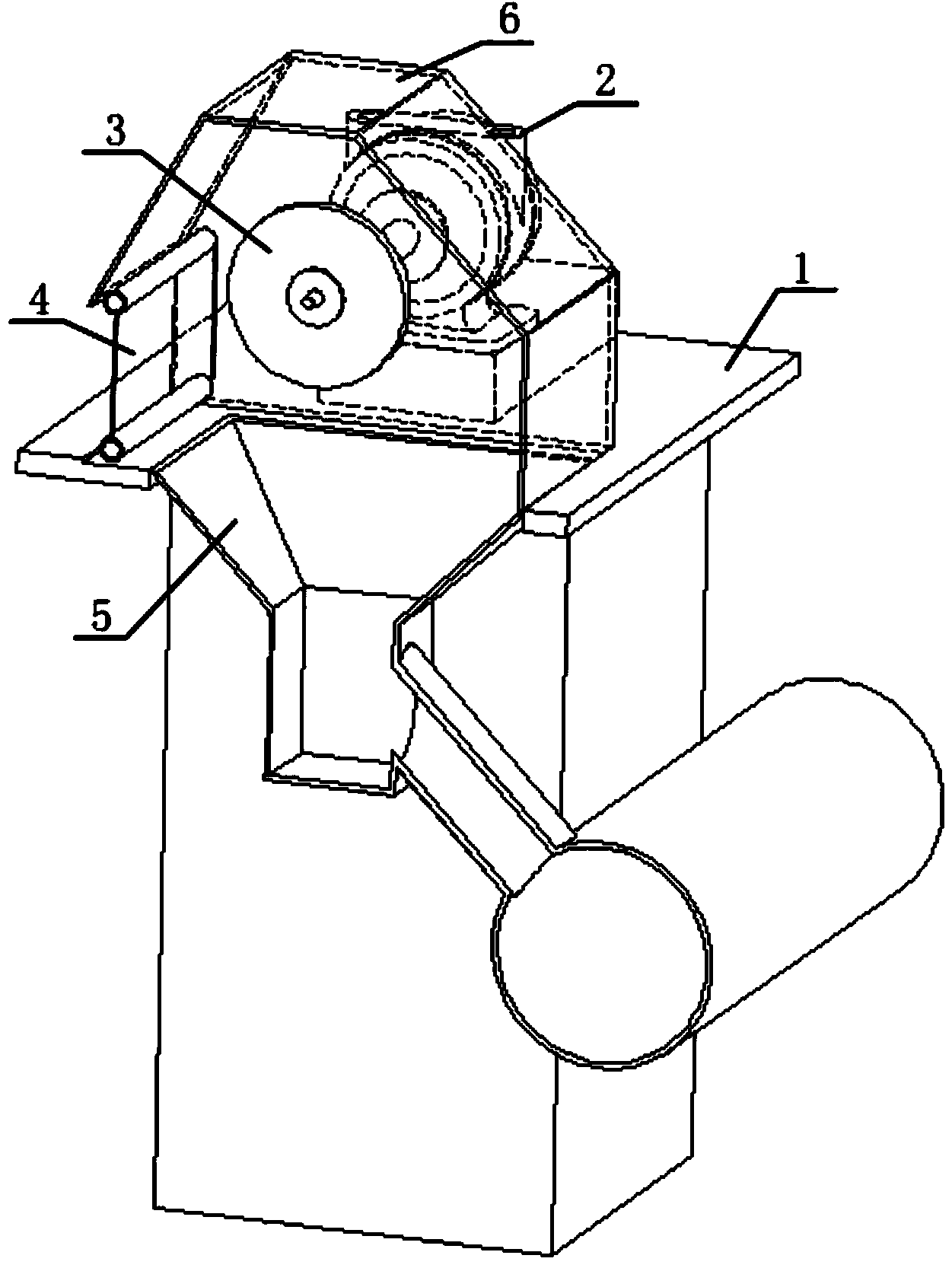

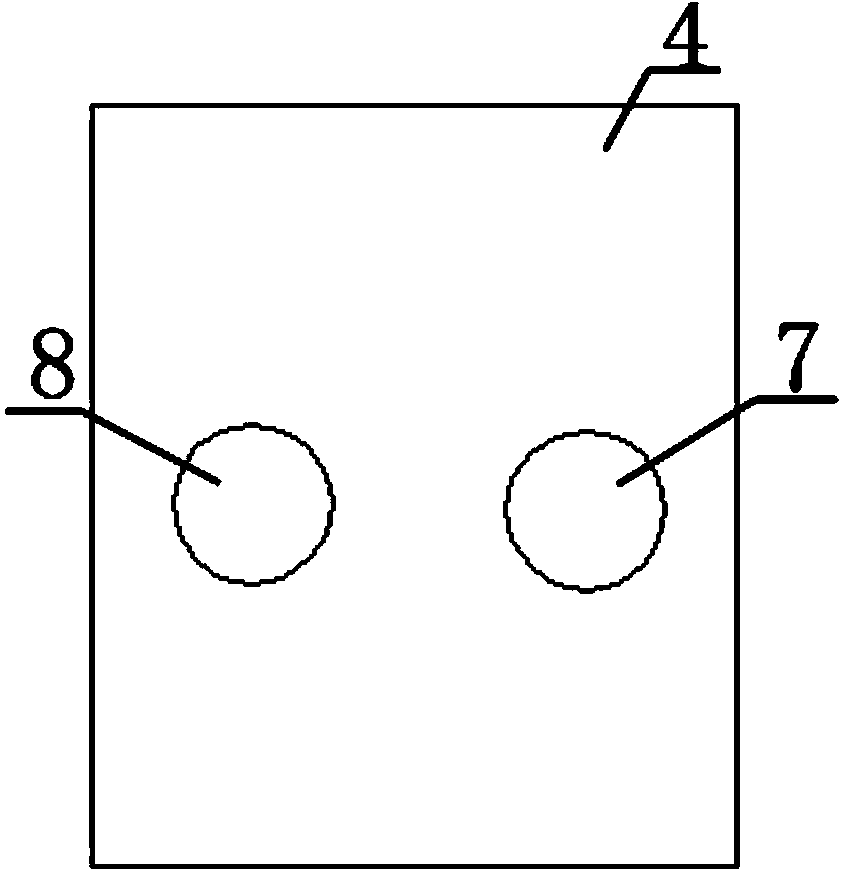

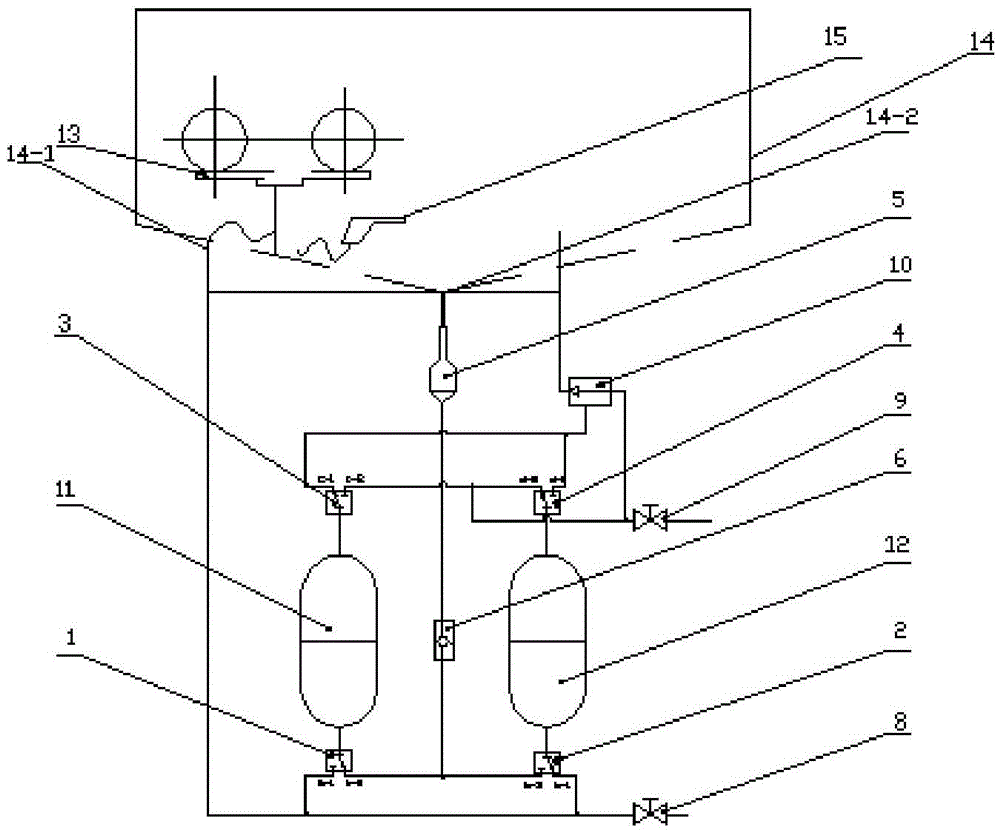

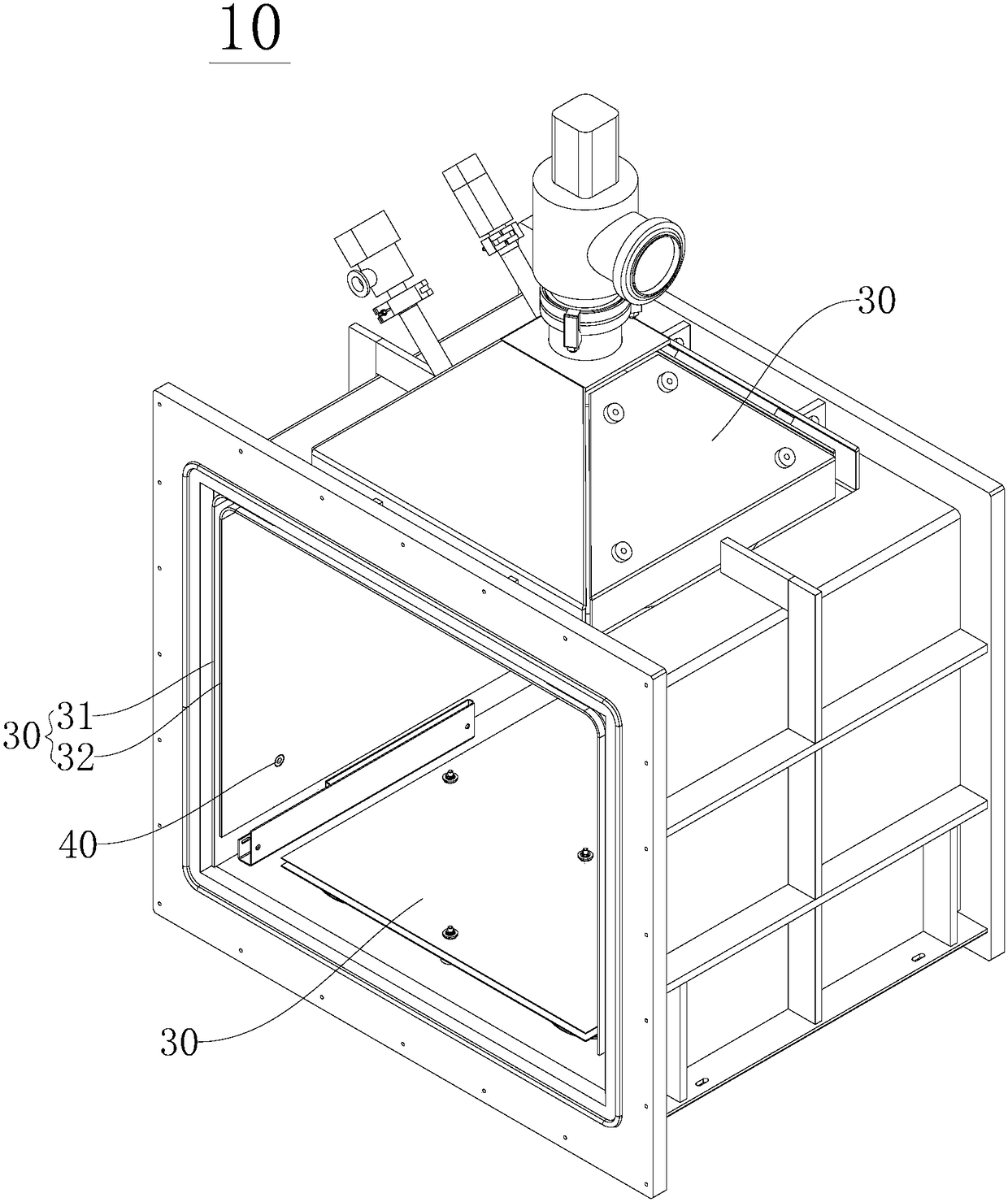

Grinding and recovering system

InactiveCN104249302APrevent leakageAvoid wastingGrinding/polishing safety devicesElectricityEngineering

The invention discloses a grinding and recovering system which comprises an outer frame, a motor, a rotating wheel, an air curtain, an absorbing groove and an outer cover. The motor, the rotating wheel, the air curtain, the absorbing groove and the outer cover are arranged on the outer frame, the rotating wheel is positioned in the outer cover and fixedly connected with a rotating shaft of the motor, the absorbing groove is arranged below the rotating wheel, an inlet is arranged between the outer cover and the outer frame, the air curtain and the outer cover are connected to seal the inlet, and a working inlet is arranged on the air curtain. The air curtain is arranged, so that chippings or precious metal particles during grinding are prevented from leaking to the outside of the absorbing groove, and avoiding of material waste is facilitated; a pneumatic motor is adopted to replace an original electric motor, and the pneumatic motor which works continuously does not generate high temperature, so that an air conditioner of a work room is enabled to normally run, and electricity is saved.

Owner:CHOW SANG SANG JEWELRY

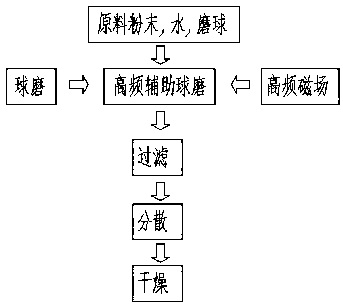

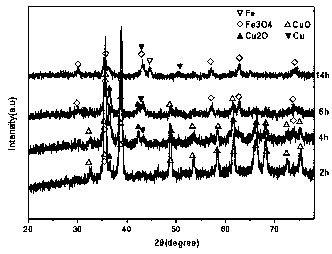

High-frequency magnetic field auxiliary ball-milling preparation method of catalyst for sewage treatment

The invention discloses a high-frequency magnetic field auxiliary ball-milling preparation method of a catalyst for sewage treatment. The catalyst is prepared according to the following steps: a, adding raw material powder into a ball-milling tank, adding water into the ball-milling tank to obtain a product A, and adding grinding balls into the ball-milling tank; b, stirring the grinding balls, ball-milling the product A, applying a high-frequency magnetic field to the product A, performing high-frequency auxiliary ball milling, and taking out the mixed solution after 5 to 20 hours to obtain aproduct B; c, filtering the product B to obtain viscous solid, namely a product C; d, adding the product c into ethanol and putting into ultrasonic wave to wash to obtain a product D; and e, drying the product D to obtain fine powder, namely the finished product. The high-frequency magnetic field auxiliary ball-milling preparation method of the catalyst for sewage treatment has the following characteristics: the preparation cost of the product is low, the preparation time of the product is short, the preparation efficiency of the product is high, the conversion rate of the raw materials is high, the preparation process is green and environment-friendly, and the prepared product has an excellent effect of catalyzing degradation of organic dye, is easy to recover and reuse and avoids secondary pollution when being applied to sewage treatment.

Owner:GUIZHOU INST OF TECH

Compressed air type mechanical part cleaning machine and use method thereof

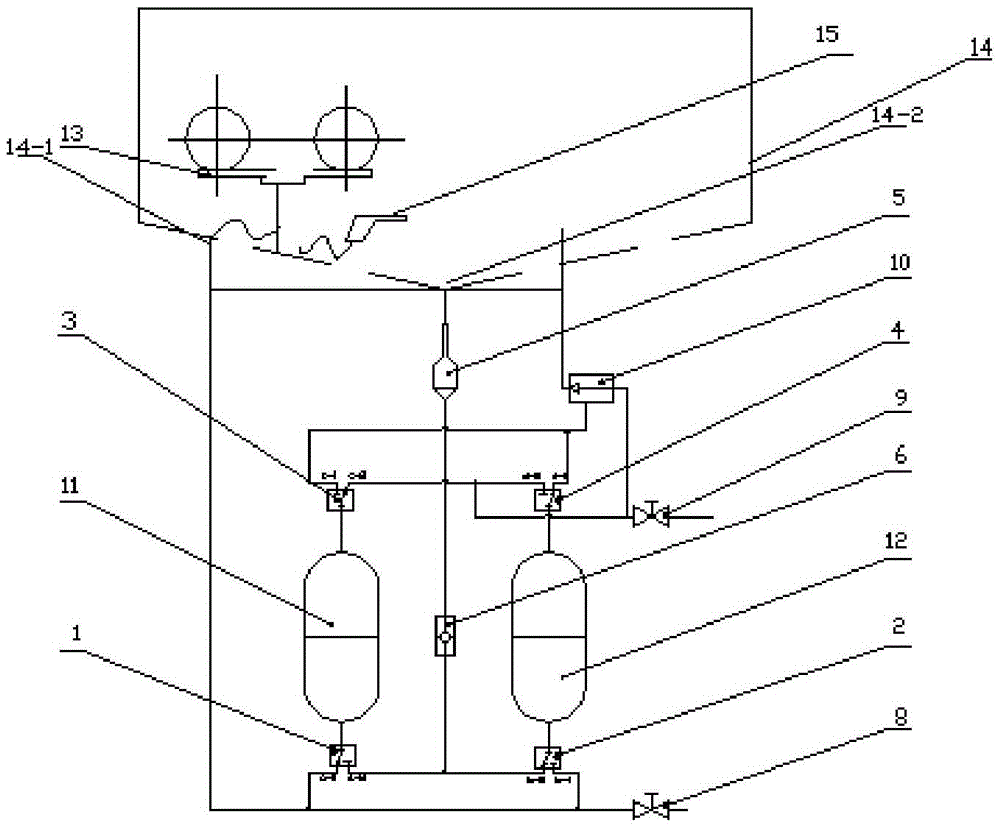

ActiveCN105057263ASpeed up filteringNo high temperatureCleaning using liquidsMechanical componentsMachine parts

The invention relates to the field of production and manufacturing, and particularly relates to a compressed air type mechanical part cleaning machine, and the invention further provides a use method of the compressed air type mechanical part cleaning machine. The compressed air type mechanical part cleaning machine comprises a cleaning chamber and a cleaning liquid circulating system, wherein the cleaning chamber is provided with a workbench, a spray gun, a cleaning chamber inflow opening and a cleaning chamber outflow opening, and the cleaning chamber inflow opening and the cleaning chamber outflow opening are connected with the spray gun; the cleaning liquid circulating system comprises a cleaning liquid filter, a check valve, a pressure vessel and a liquid storage tank; through the conversion of four three-way valves, the pressure vessel and the liquid storage tank alternately realize the functions of a cleaning tank and the liquid storage tank by utilizing a vacuum generator and compressed air. The cleaning machine is not provided with an electric control system, so that the risk of sparks is avoided; a driving component is not arranged in the whole cleaning machine, so that high temperature of the cleaning machine cannot happen, thereby avoiding the risks of burning and explosion of a common small cleaning machine, and the effects of safety and no hidden danger are really achieved.

Owner:ZHEJIANG SIEKON PRECISION MACHINERY CO LTD

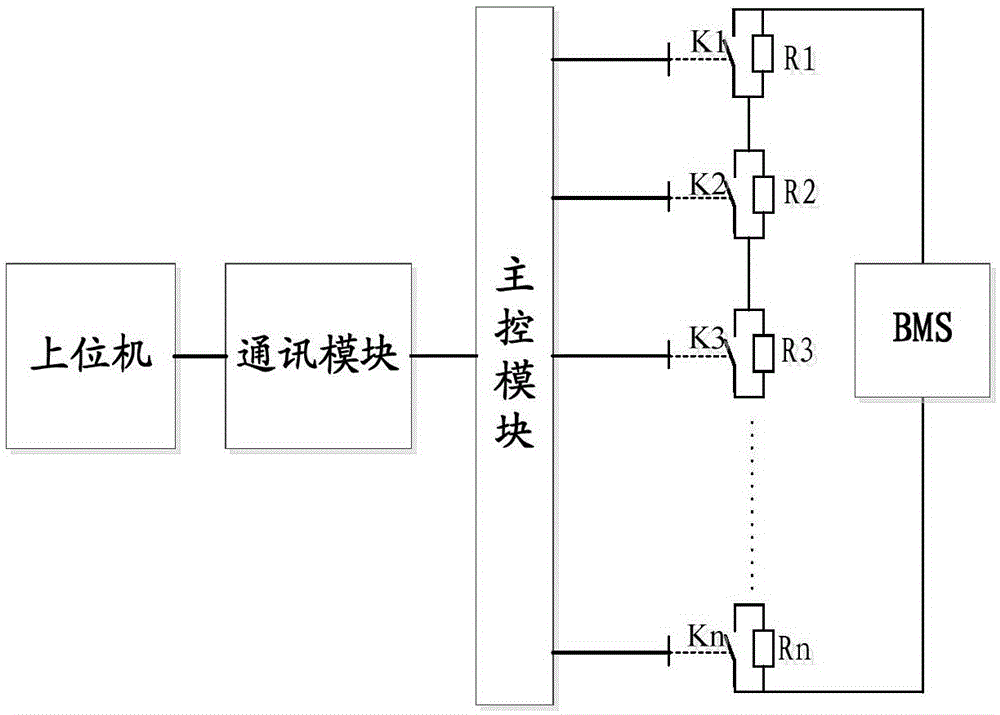

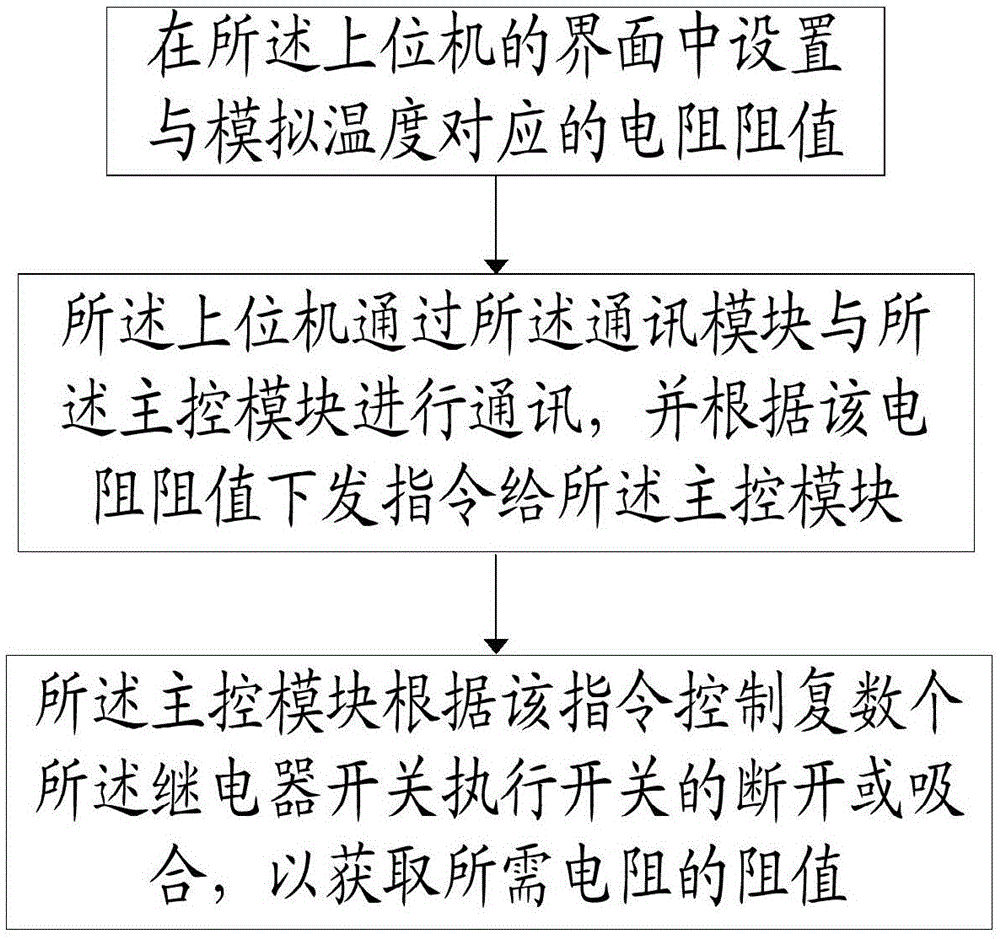

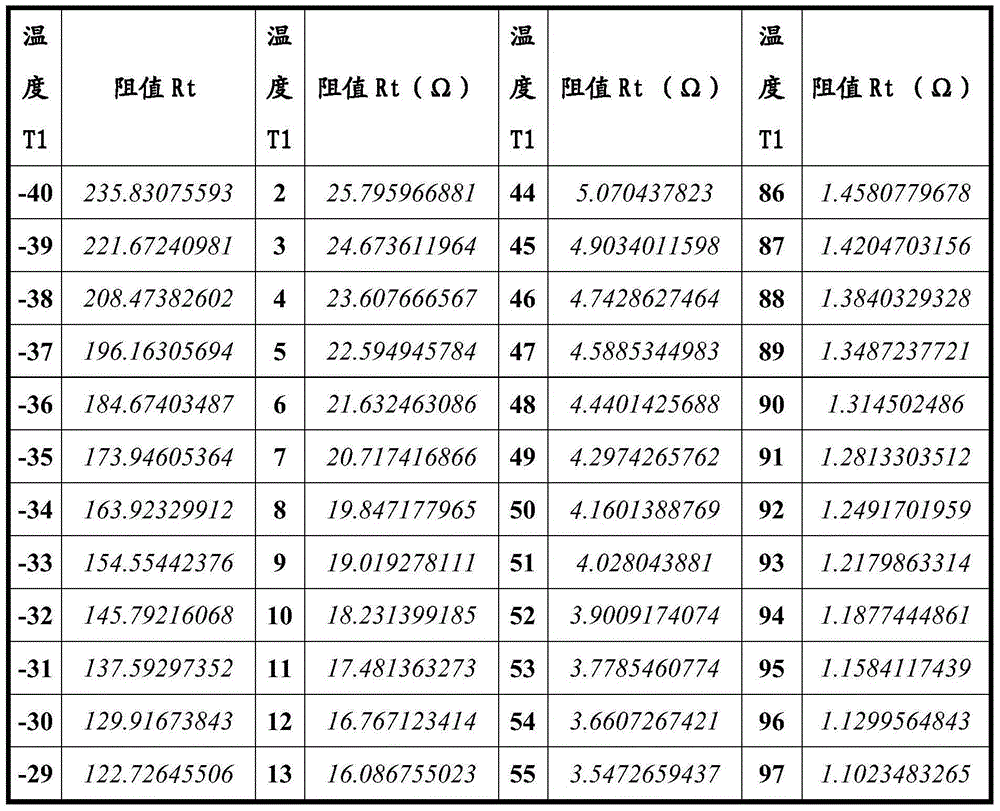

High-low-temperature simulation system and method used for simulating thermistor detection

InactiveCN105158594ASolve the problem of long temperature change timeHigh speedElectrical testingElectrical resistance and conductanceEngineering

The invention provides a high-low-temperature simulation system used for simulating thermistor detection. The system includes an upper computer, a communication module, a main control module, a plurality of relay switches and a plurality of resistors in one-to-one correspondence with the plurality of relay switches, wherein the upper computer is connected with the main control module through the communication module; the main control module is connected with the plurality of relay switches; and the plurality of resistors are connected in sequence, and the relay switches are connected to two ends of the resistors in parallel. The invention also includes a method used for simulating thermistor detection, a resistance value can be preset according to temperature required by testing, and when the switches are switched, a temperature signal changes instantly, thereby solving the problem that temperature change time is long, and improving the speed of a high-low-temperature protection test; neither heating nor refrigeration is needed, thereby solving the problem of large energy consumption; and passive resistors are adopted, so high temperature is not generated actually, thereby solving the problem of high temperature scalding risks.

Owner:FUJIAN NEBULA ELECTRONICS CO LTD

Corn grinder

InactiveCN110665589ADoes not affect the crushing effectImprove work efficiencyCocoaGrain treatmentsDrive shaftGear wheel

The invention discloses a corn grinder which comprises a feeding hopper, a machine body, a machine cover, a base, a fastening handle, a screen, a motor, a support, a supporting plate and a discharginghopper. The screen is arranged in the machine body. The corn grinding is characterized in that a gear ring is installed between a clamping plate and the machine body; a sun gear is installed at the center position of the gear ring; a drive shaft is sleeved with the sun gear; the drive shaft penetrates the machine body, and the end portion of the drive shaft is sleeved with a driven belt wheel; the driven belt wheel is connected with a drive belt wheel through a belt; the drive belt wheel is arranged on the output end of the motor in a sleeving manner; the sun gear is engaged with planetary gears; the six planetary gears are arranged around the sun gear at equal intervals; the planetary gears are engaged with the gear ring; the planetary gears are arranged on transmission shafts in a sleeving manner; the transmission shafts penetrate a rotary disc, breaking teeth are installed on a breaking rotating body, and the rotary disc center, arranged around the rotary disc, of the breaking rotating body is provided with a center smashing boss matched with the breaking rotating body, and a side smashing wall is arranged at the position, corresponding to the breaking rotating body, of the machine shell. The corn grinder has the beneficial effects that the structure is simple, the machining efficiency is high, and maintenance is convenient.

Owner:王刚

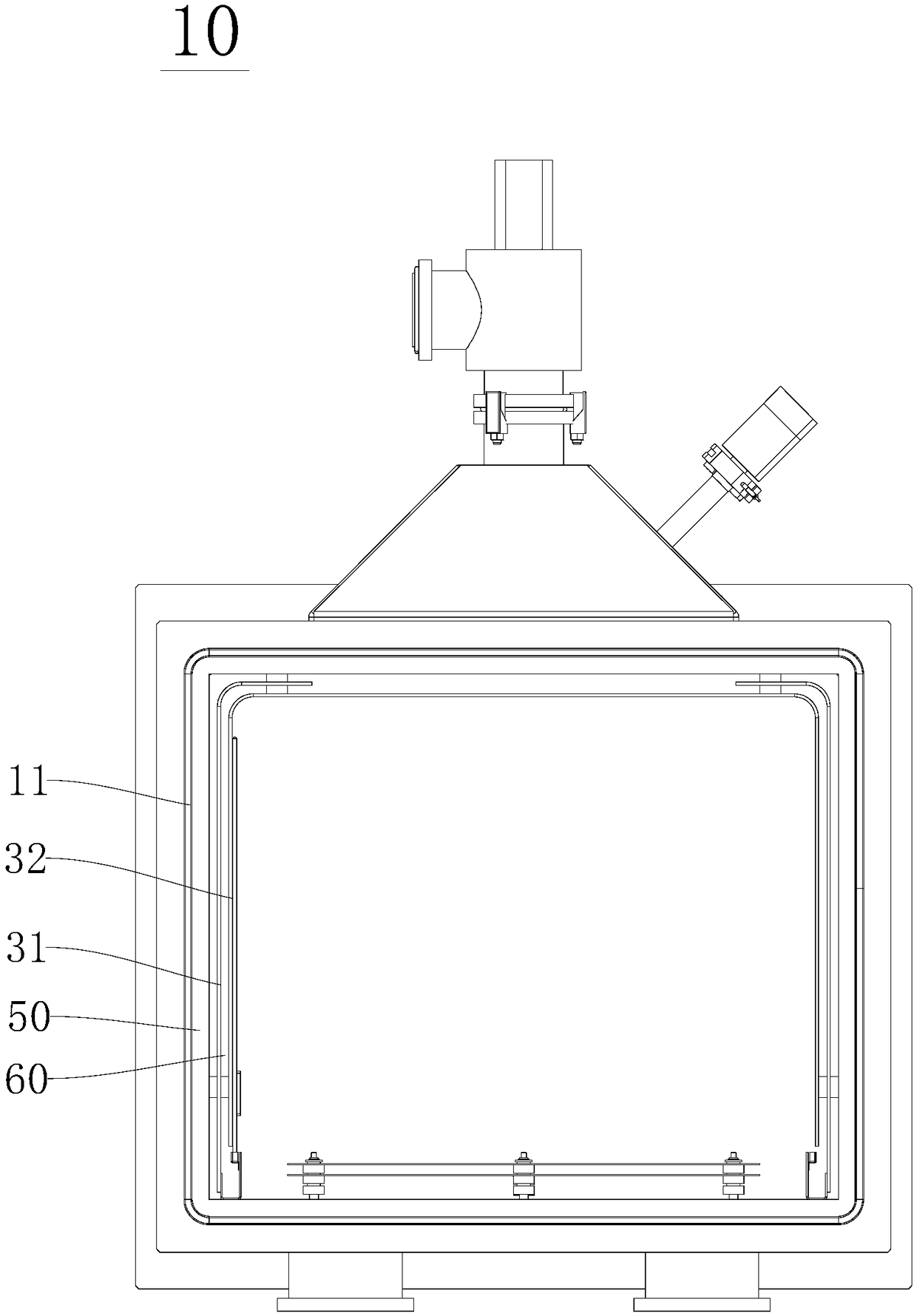

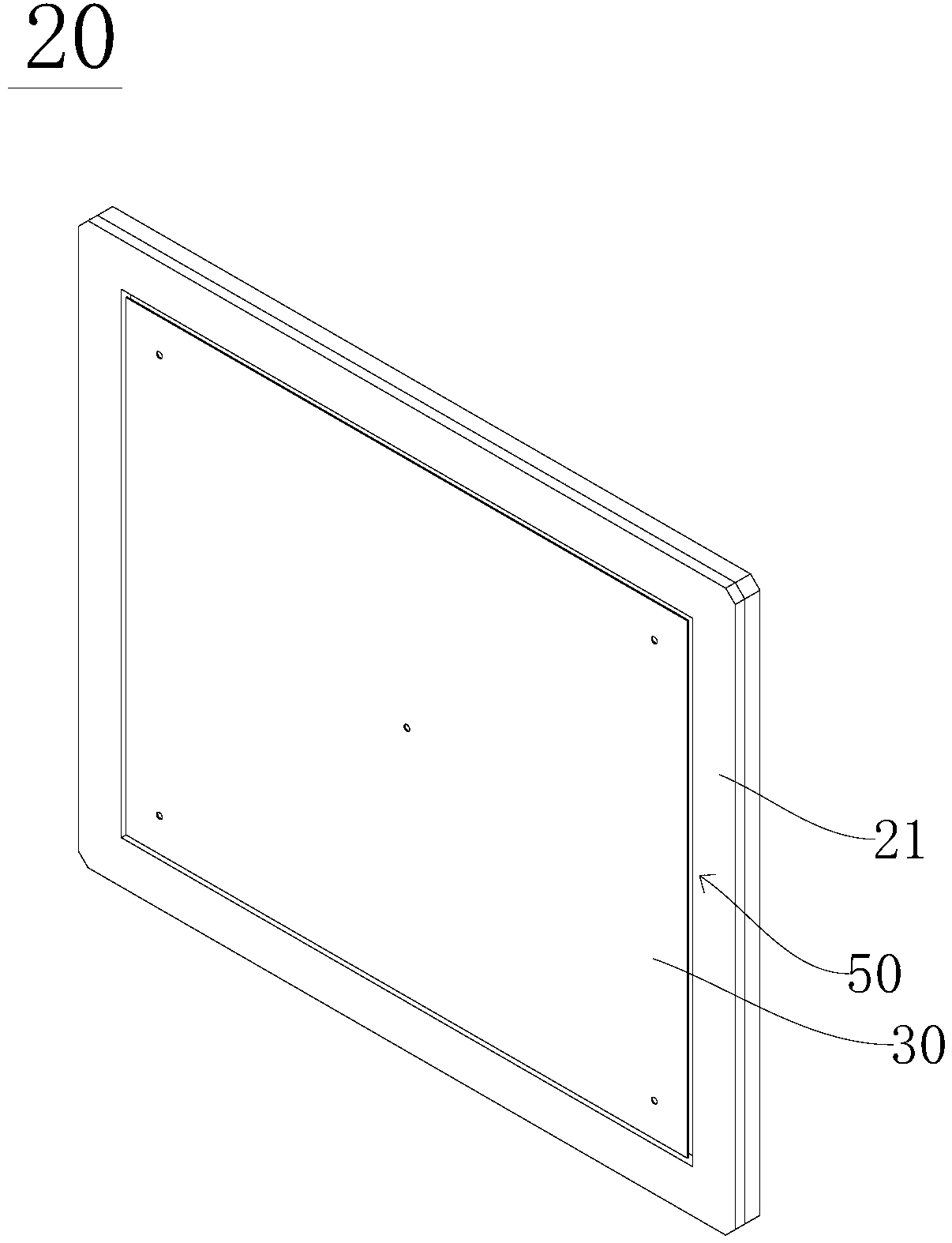

Vacuum oven and heat preservation method thereof

PendingCN108072236AReduce heat lossAvoid poor thermal balanceDrying solid materials without heatDrying machines with local agitationCapacitanceEngineering

The invention provides a vacuum oven and a heat preservation method thereof. The vacuum oven is used for vacuum drying of a battery or a super capacitor; the vacuum oven comprises a box body, a box door and a plurality of plate bodies; the plurality of plate bodies cover the inner surfaces of the box body and the box door to form radiation baffles for prevent outward heat radiation; each radiationbaffle has a certain distance from the inner surface where the corresponding radiation baffle is positioned so that a heat insulating space is formed at the inner walls of the box body and the box door; and after the box body is internally vacuumized, the air in each heat insulating space is exhausted to form vacuum heat insulating layers. The heat preservation method comprises the following steps: the inner surface of the box body is provided with the radiation baffles for preventing outward heat radiation; and each heat insulating space is formed between the corresponding radiation baffle and the inner surface of the corresponding radiation baffle is positioned. The radiation baffles and the vacuum heat insulating layers form one or a plurality of heat insulating layers inside the box body, thus heat loss can be greatly reduced, the problem about poor heat balance caused by heat dissipation is prevented, and the maintenance cost of equipment is lowered.

Owner:深圳力士智造科技有限公司

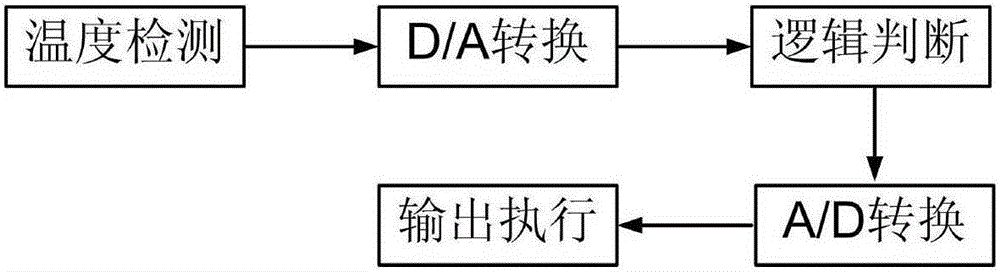

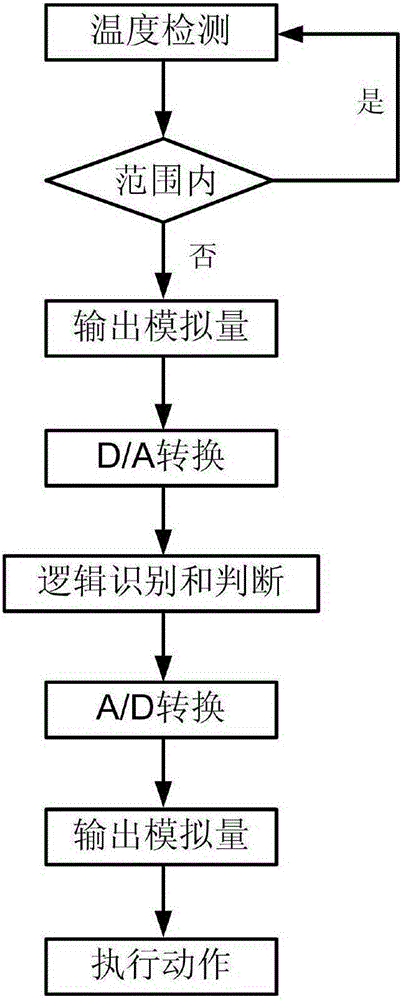

Novel intelligent lock for back screen cabinet of protection screen

InactiveCN105186325ATemperature checkSpeed up circulationBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationProgrammable logic controllerEmbedded system

The invention relates to a novel intelligent lock for a back screen cabinet of a protection screen. The novel intelligent lock comprises a temperature sensing part, an intelligent control part and an execution part, wherein the temperature sensing part is used for detecting and recognizing a temperature and transmitting a recognition result to the intelligent control part; the intelligent control part is used for receiving a signal of the temperature sensing part, making logic judgment and outputting a logic judgment result; and the execution part is used for executing starting or closing operation after receiving the judgment result. On the basis of temperature detection and recognition, intelligent control is achieved by programming of a programmable logic controller (PLC), and the novel intelligent lock which has a temperature detection function and can be used for automatically adjusting an opening-closing angle of the protection screen with temperature change is finally provided.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Hollow four plane tie-in

InactiveCN1967942ALarge current carrying capacityReduce temperature riseClamped/spring connectionsElectrical resistance and conductanceEngineering

The invention relates to a hollow four-face connector, wherein it end diameter of tube main line is punched into hollow four-plane conductive plane; and it is integral without connecting part, it has low contact resistance, to avoid high temperature at end.

Owner:罗志昭

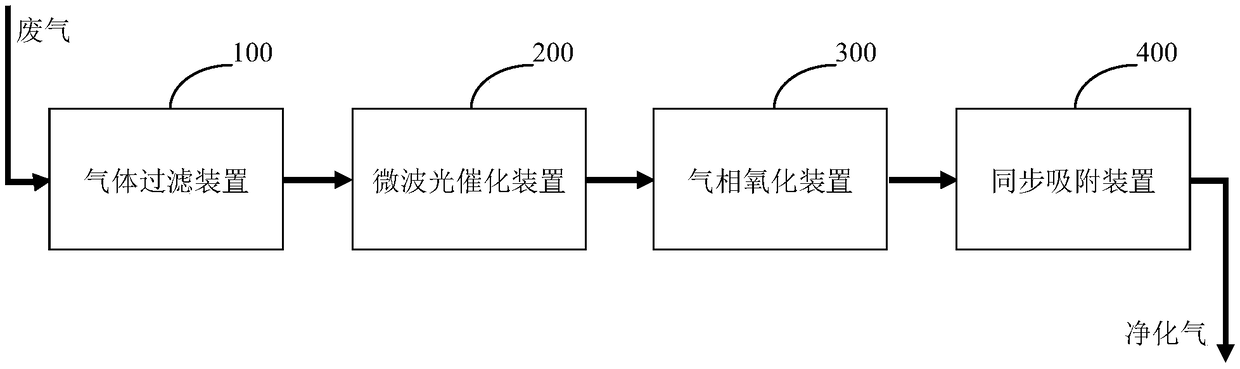

Multistage composite exhaust-gas processing system

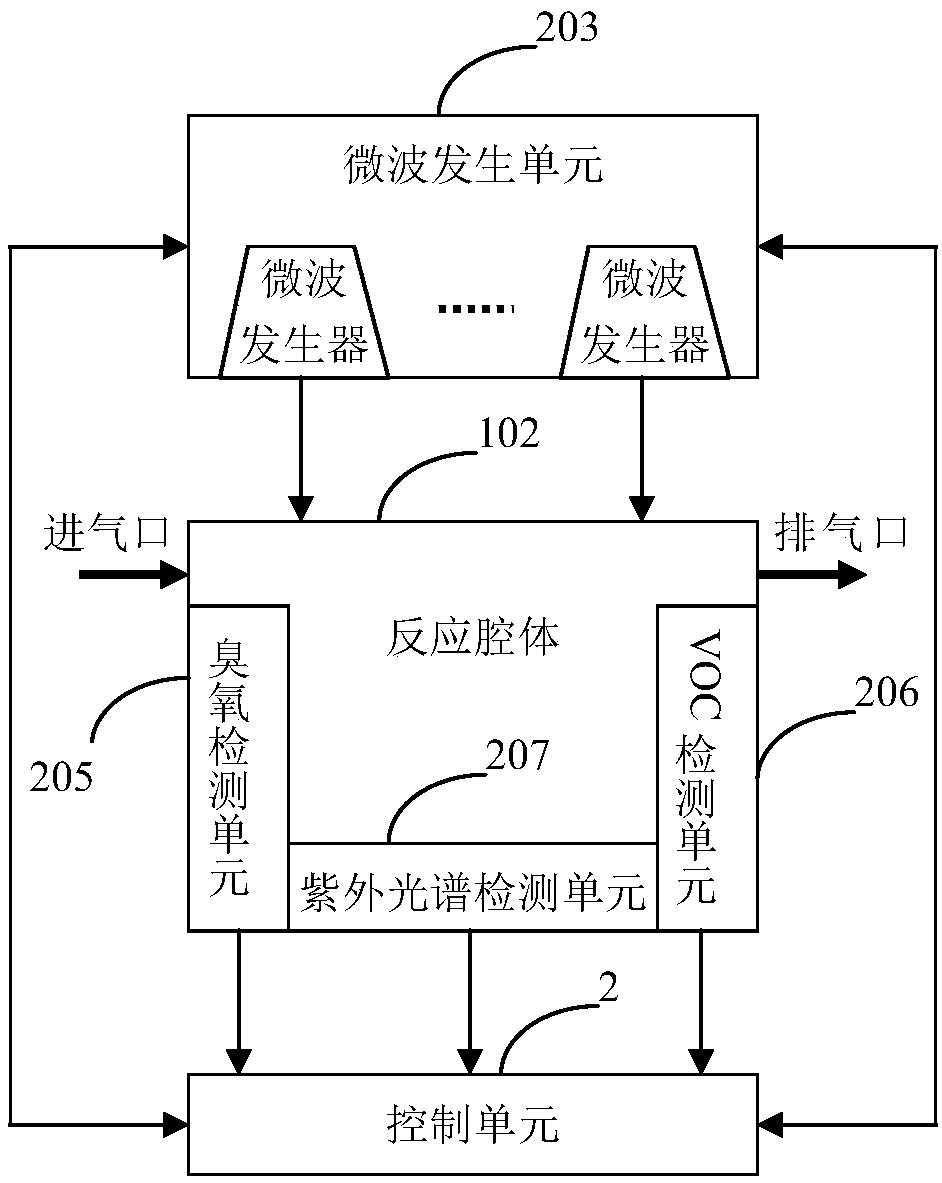

PendingCN109289467AImprove processing efficiencySuitable for handlingGas treatmentDispersed particle filtrationGas phaseUltraviolet lights

The invention belongs to the technical field of gas pollutant processing, and discloses a multistage composite exhaust-gas processing system. The multistage composite exhaust-gas processing system comprises a gas filtering device, a microwave photocatalysis device, a gas phase oxidation device, and a simultaneous adsorption device; the microwave photocatalysis device comprises a reaction chamber,a control unit, a microwave generation unit, an ozone monitoring unit, a VOC monitoring unit, and an ultraviolet light spectrum monitoring unit; an electrodeless lamp tube is arranged in the reactionchamber; the reaction chamber is connected with a waste water collecting discharging unit through a pipeline; the ozone monitoring unit, the VOC monitoring unit, and the ultraviolet light spectrum monitoring unit are connected with the control unit; the microwave generation unit comprises at least two microwave generators which are used for generating strong electromagnetic wave, and stimulating the electrodeless lamp tube to generate short wave ultraviolet light; the microwave generators are connected with the control unit. The multistage composite exhaust-gas processing system is high in exhaust gas processing efficiency, no second pollution is generated in processing process, safety hidden troubles such as high temperature and blasting are avoided, and the multistage composite exhaust-gas processing system is especially suitable to be used for processing of exhaust gas from auto repair factory baking varnish houses.

Owner:成都美人鱼环保工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com