Precise automatic gear grinding machine with saw

A gear grinding machine and band saw technology, which is applied to metal sawing equipment, tool dressing of sawing machine devices, and duplication process control systems, etc., can solve the problems of low work efficiency, poor tooth grinding effect, and high manufacturing cost. Simple structure, high grinding precision and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

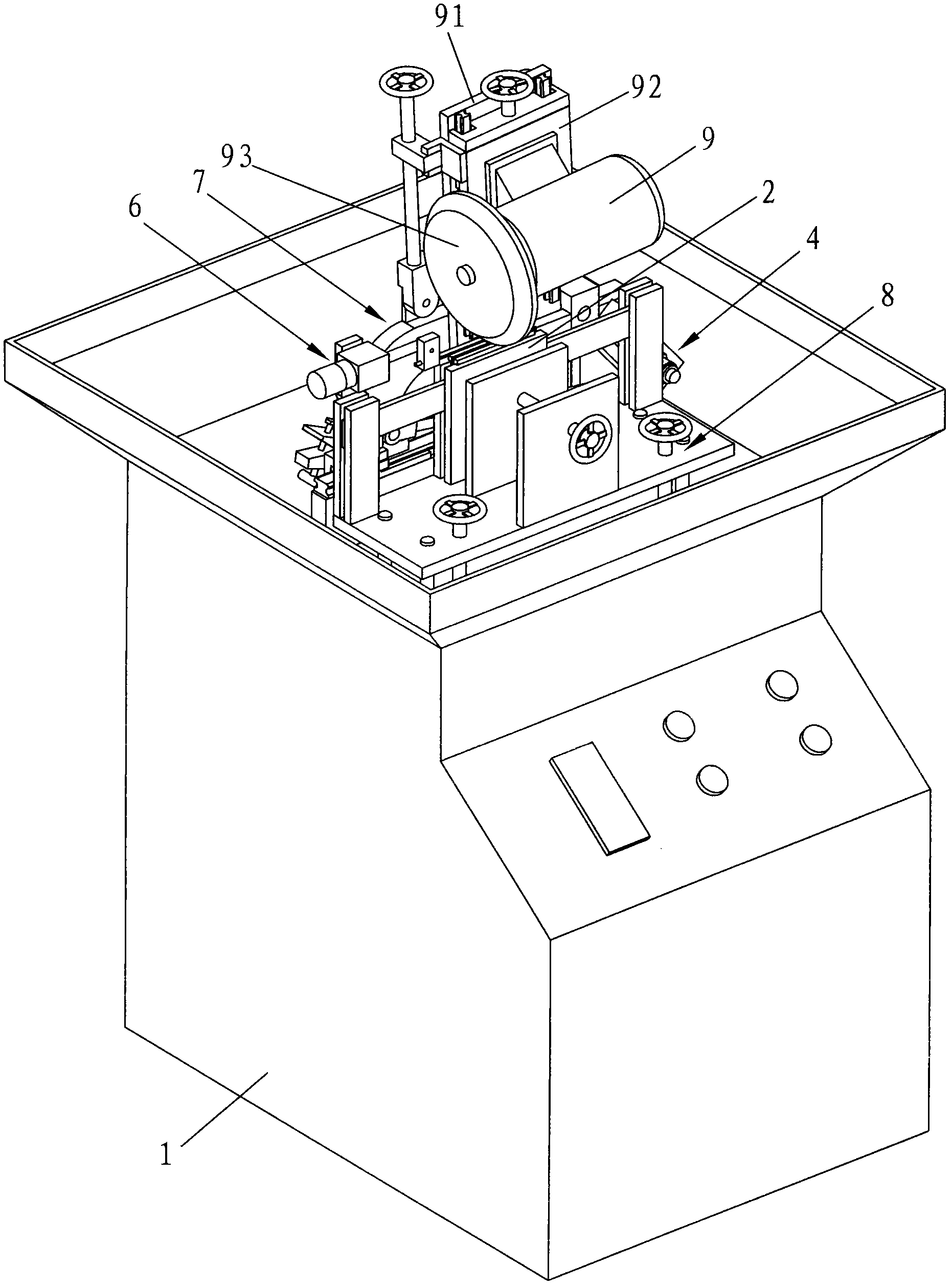

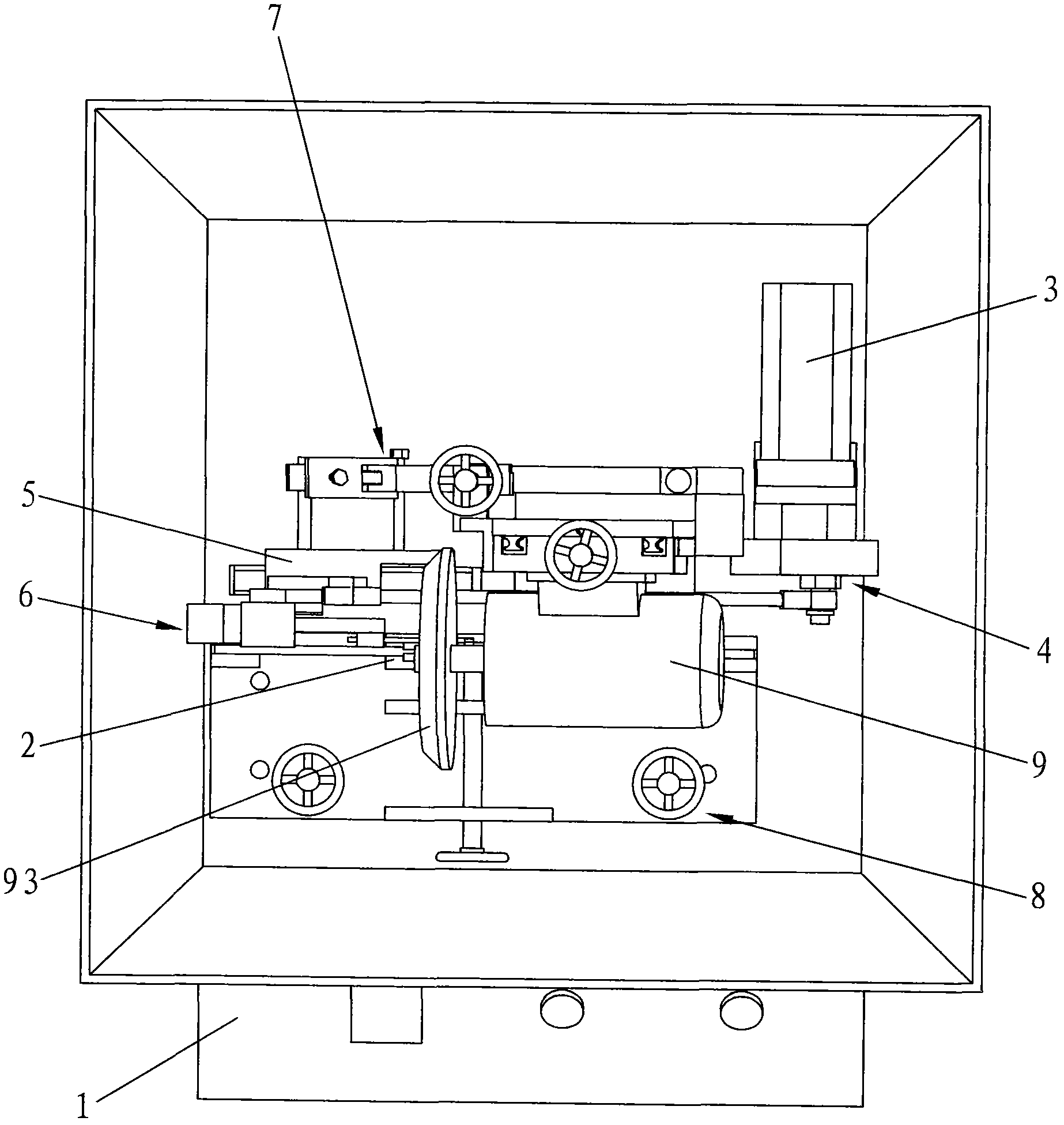

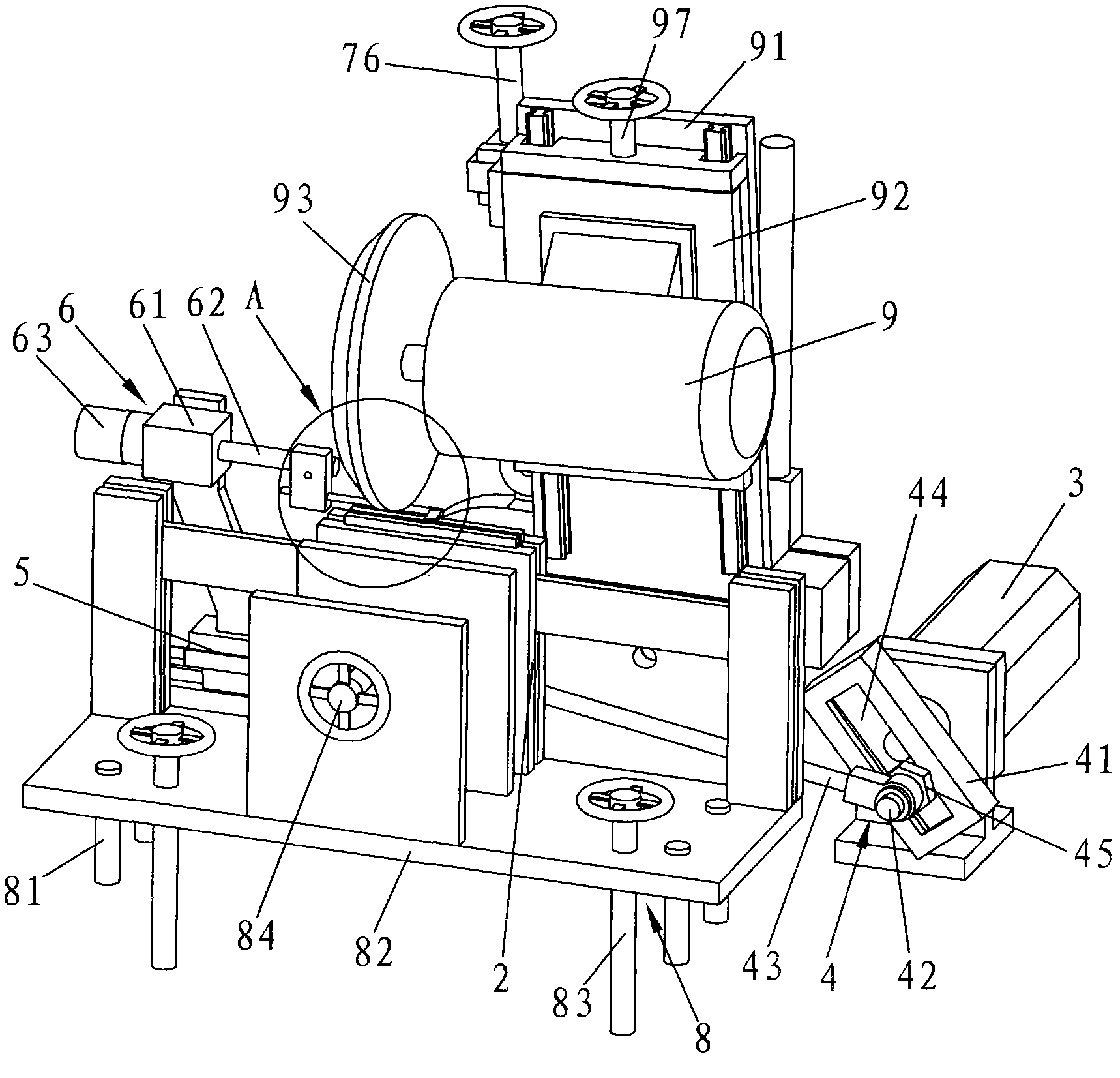

[0021] Below in conjunction with accompanying drawing, the present invention will be further described, see Figure 1~6 As shown, the precision band saw automatic gear grinding machine of the present invention includes a frame 1, and the top of the frame 1 is provided with a material clamping seat 2 with a material clamping groove 21, a stepless speed regulation drive motor 3, an eccentric mechanism 4, a sliding The sliding seat 5 that is arranged on the frame 1, the motor sliding seat 91, the motor mounting plate 92 that is slidably connected on the motor sliding seat 91, the gear grinding motor 9 that is fixed on the motor mounting plate 92, the gear grinding motor 9 that is arranged on the output The tooth grinding wheel 93 at the end, the pusher device 6 positioned at one side of the clamping tank 21, the grinding gear grinding wheel 93 is located above the clamping tank 21, the output shaft of the driving motor 3 is connected to the sliding seat 5 through the eccentric mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com