Vacuum oven and heat preservation method thereof

A vacuum oven and vacuum drying technology, applied in drying, dryer, local stirring dryer, etc., to avoid poor thermal balance, reduce maintenance costs, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

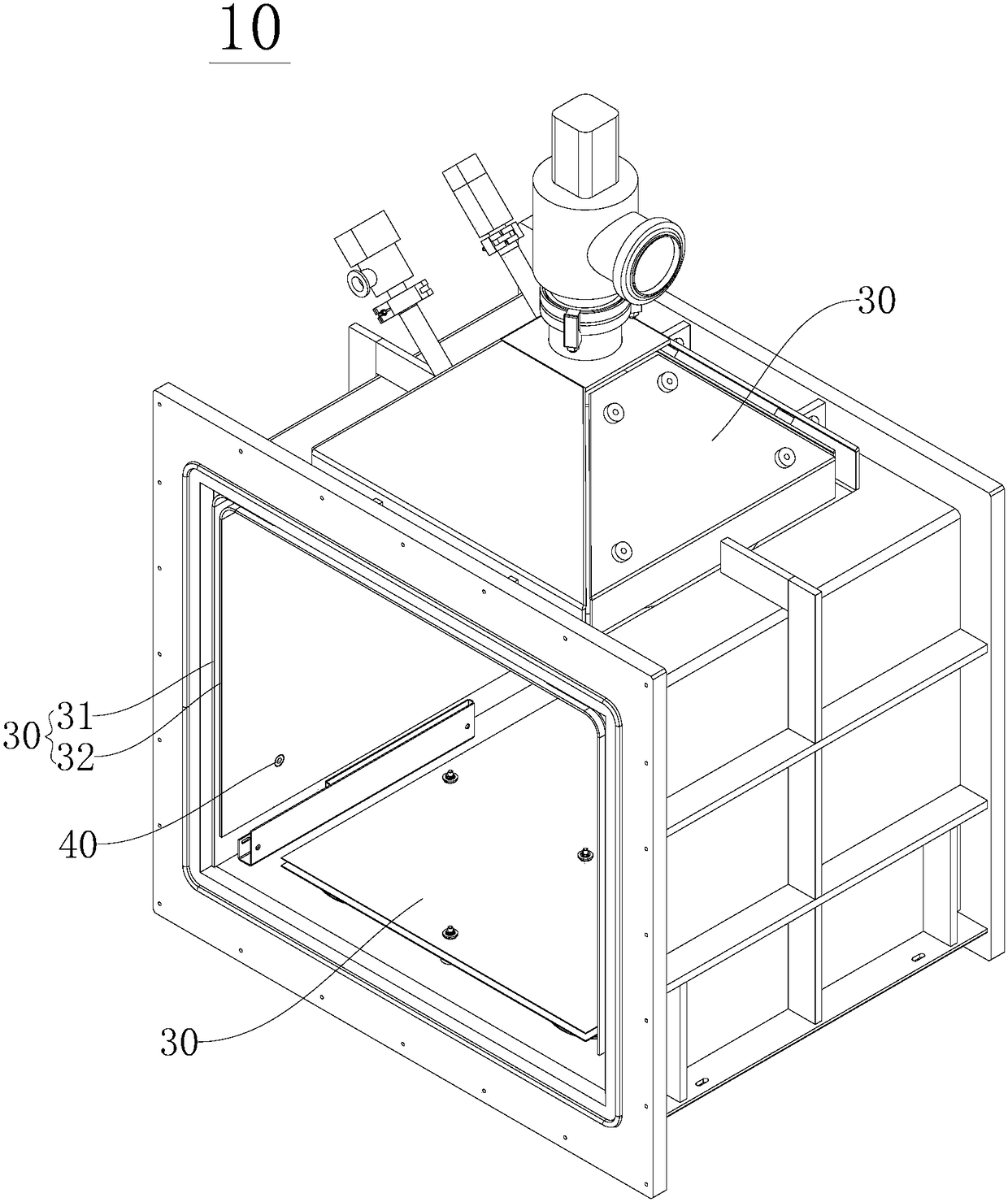

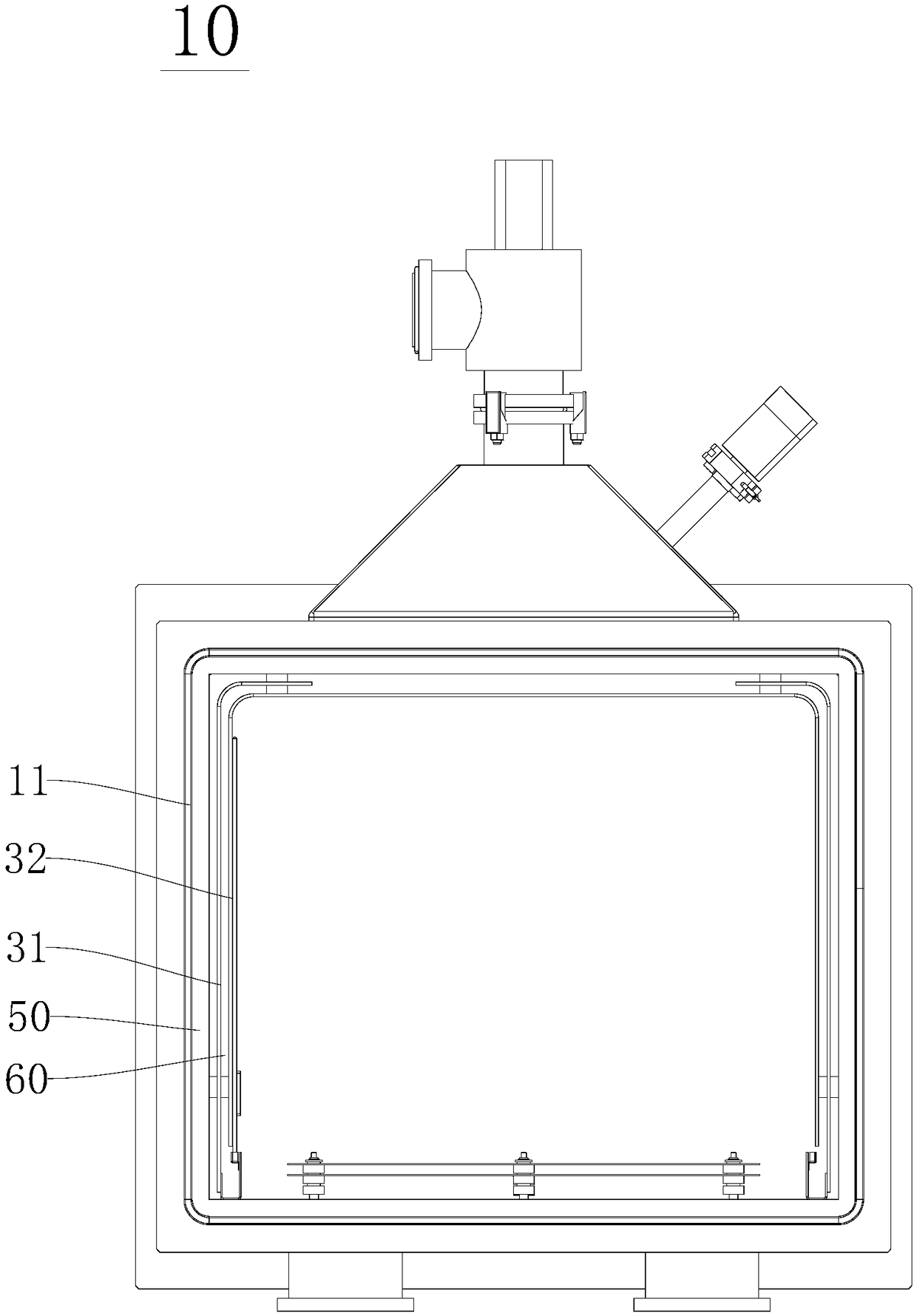

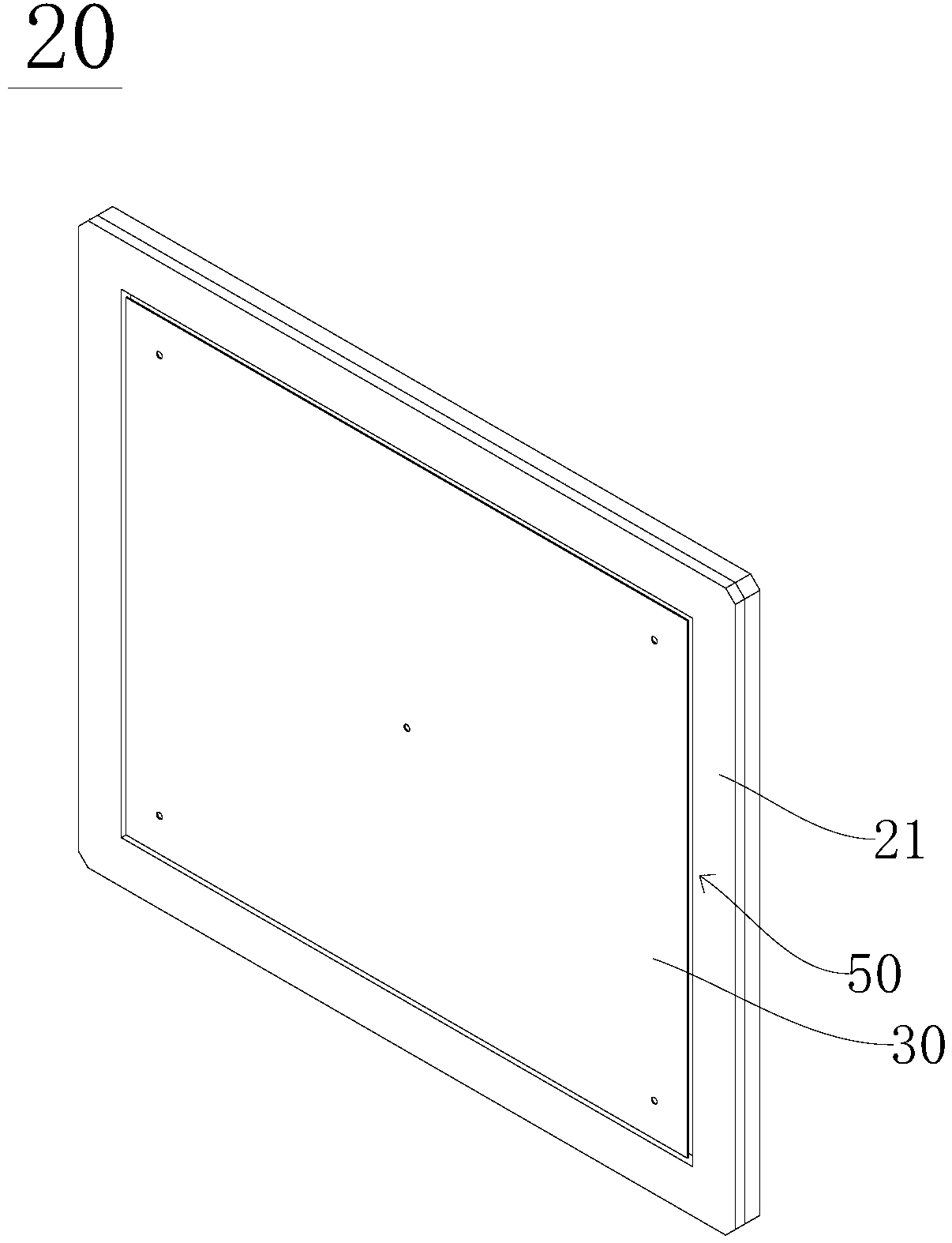

[0020] Figure 1 to Figure 3 Some examples shown are vacuum ovens for vacuum drying of batteries and supercapacitors. refer to Figure 1 to Figure 3 , the vacuum oven includes a box body 10 and a box door 20 . The innovative content is that on the basis of the existing vacuum oven, a heat insulation structure is added to achieve the purpose of reducing heat loss, avoiding the problem of poor thermal balance caused by heat dissipation, and reducing equipment maintenance costs.

[0021] For this reason, described vacuum oven also comprises several plate bodies 31,32, and described several plate bodies are covered on the inner surface of described box body 10 and box door 20 to form the radiation baffle plate 30 that blocks heat from radiating outwards, each The radiation baffle 30 is separated from the inner surfaces 11 and 21 by a certain distance so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com