Multistage composite exhaust-gas processing system

A waste gas treatment and waste gas technology applied in the field of environmental engineering to achieve the effects of low maintenance cost, high degree of modularization, and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

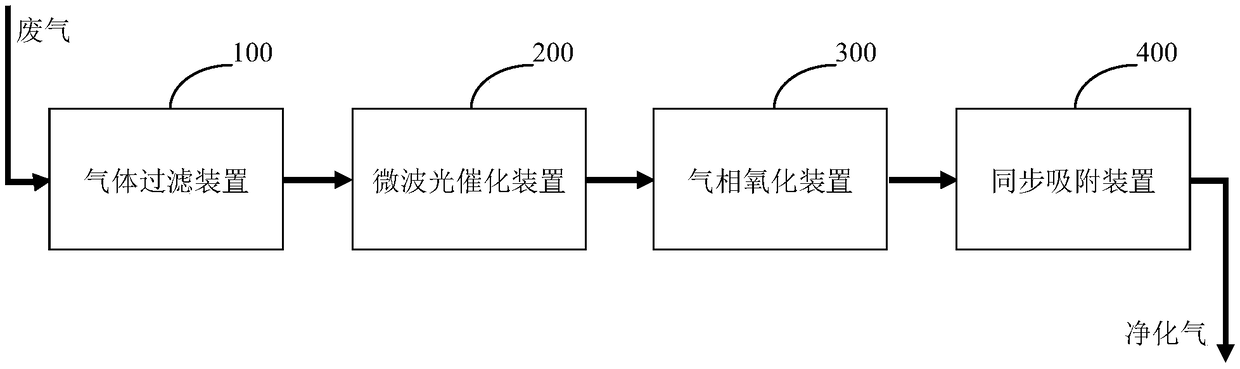

[0052] The structure of the multi-stage composite waste gas treatment system in this example is as follows: figure 1 As shown, it includes a gas filter device 100 , a microwave photocatalytic device 200 , a gas phase oxidation device 300 and a synchronous adsorption device 400 .

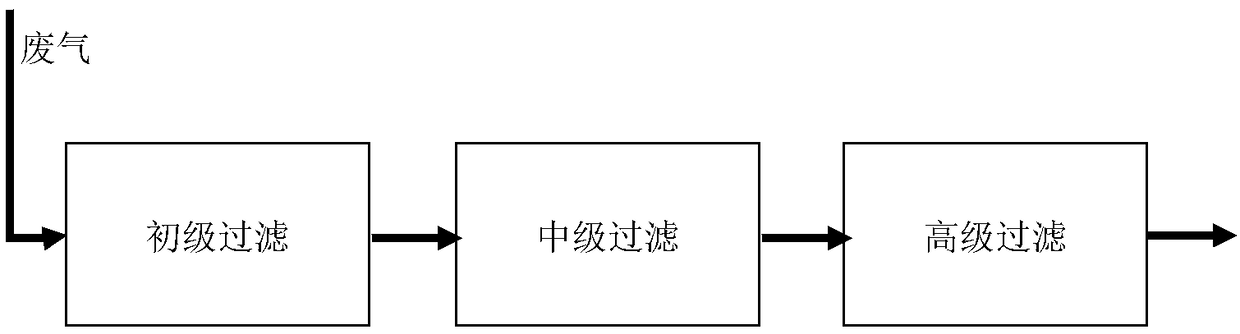

[0053] Exhaust gas enters the gas filter device 100, and after 3 and 3 filters, 70% of solid particles and 98% of paint mist can be removed.

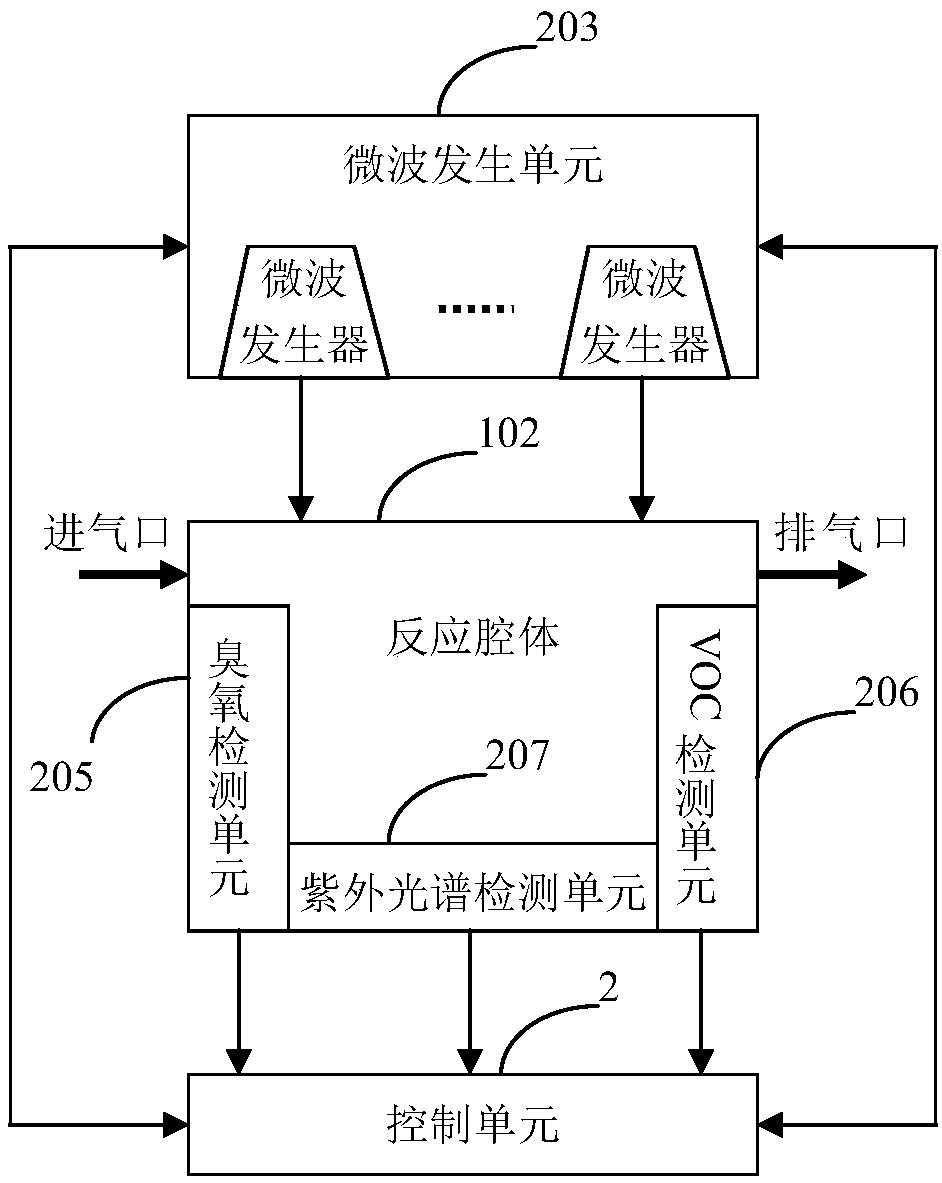

[0054] The filtered exhaust gas enters the microwave photocatalytic device 200 through the connected pipeline, and uses microwave energy to generate ultraviolet light combined with photocatalyst to treat harmful substances in the exhaust gas and remove most of them, such as benzene, toluene and VOC.

[0055] The exhaust gas from the microwave photocatalytic device 200 is sent to the gas phase oxidation device 300 for further treatment, and the harmful substances remaining in the exhaust gas are further oxidized under gas phase conditions.

[0056] The gas pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com