Coal seam static expansion, cracking and antireflection equipment and method

A static expansion, coal seam technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of high economic cost of hydraulic fracturing and permeability enhancement, poor safety of explosive blasting and permeability enhancement, etc., to ensure connectivity, Low cost and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

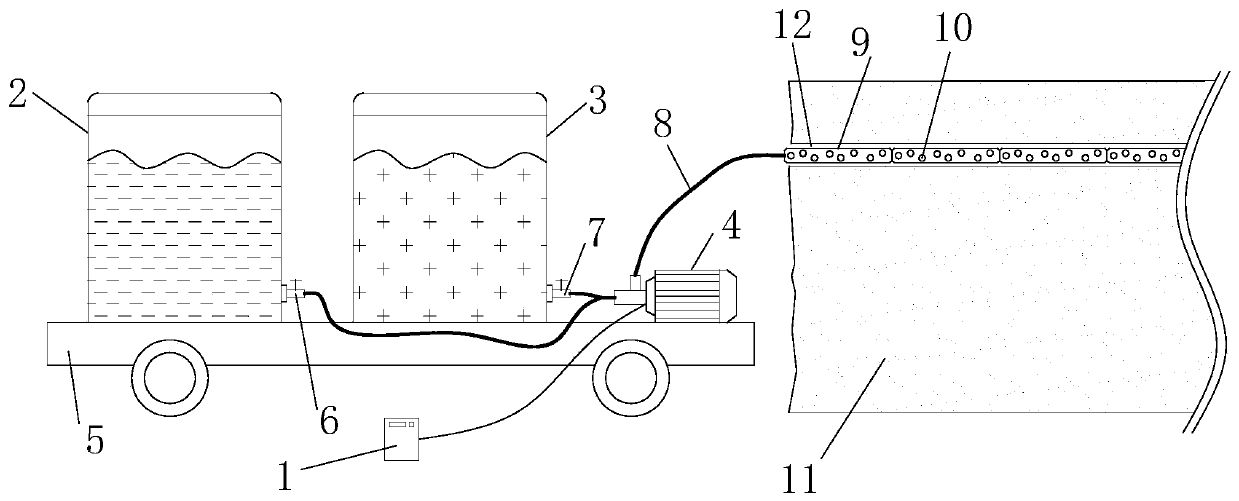

[0035] Such as figure 1 As shown, a coal seam static expansion fracturing anti-permeability equipment includes a grouting vehicle and a grouting pipeline. Above the chassis 5 of the grouting vehicle, a grouting pump 4 and an expansion agent hopper for holding a drag-reducing expansion agent are arranged. 2, the acidolysis agent material box 3 that holds the acidolysis agent, the bottom of the above-mentioned expansion agent material box 2 is provided with an expansion agent discharge port, the bottom of the acidolysis agent material box 3 is provided with an acidolysis agent discharge port, and the expansion agent The outlet of the agent and the outlet of the acidolysis agent are respectively connected to the liquid inlet of the grouting pump 4 through the pipeline 8; The pipeline includes several sections of connected swivel pipes 9 arranged in the boreholes of the coal seam 11 , and a plurality of grouting holes 10 are opened on the pipe wall of each section of the swivel pi...

Embodiment 2

[0043] The invention also discloses a coal seam static expansion cracking and anti-permeability method. The coal seam anti-permeability enhancement method of a certain number of coal seam working face in a certain mine is used as the project Beijing, and the coal seam static expansion and cracking anti-permeability equipment disclosed in the embodiment is adopted, which specifically includes the following steps :

[0044] Step 1. Determining the strength of the coal body and selecting the specifications of the acid hydrolysis capsule

[0045] Several groups of coal samples were collected at the site of a working face, and basic mechanical tensile tests were carried out to measure the tensile strength K of the coal body c Equal to 10MPa, therefore, the selected acid hydrolysis capsule specification is that the compressive strength of the capsule is equal to 10MPa.

[0046] Step 2. Layout drilling and connecting pipelines

[0047] First, a mine drilling rig is used to lay a 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com