Patents

Literature

92results about How to "Effective softening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laundry Product

ActiveUS20080242579A1Effective softeningEffective conditioningSoap detergents with organic compounding agentsSurface-active non-soap compounds and soap mixture detergentsWater solubleLaundry

A unit dose fabric treatment system comprises a water soluble container in which a liquid fabric treatment composition is disposed, the composition comprising one or more fatty acid esters wherein, in at least one of the fatty acid esters, the average proportion of C18 chains is less than 60%, preferably less than 50%, more preferably less than 40%, e.g. less than 30% by weight of the total weight of fatty acid chains in the fatty acid ester.

Owner:HENKEL KGAA

Peel off pack containing activated carbon and preparation method of peel off pack

ActiveCN104606116AStrong degreasing abilityWell-developed pore structureCosmetic preparationsToilet preparationsActivated carbonPolyvinyl alcohol

The invention provides a peel off pack containing activated carbon and a preparation method of the peel off pack. The peel off pack and the preparation method have the beneficial effects that as containing kaolin, sodium carboxymethylcellulose, olive oil and an emulsifier, the peel off pack containing activated carbon, prepared by the preparation method, is wet and elastic after film formation and is capable of lowering damage to skin during peeling; polyvinyl alcohol is a film forming agent; the kaolin is excellent in degreasing ability, so that the skin is smooth and transparent; the activated carbon is developed in pore structure and larger in specific surface area and is capable of effectively adsorbing deep fouling of the skin; the olive oil has the efficacies of refreshing and nourishing skin; honey is capable of effectively softening cuticle and promoting the skin to absorb nutrition and has the actions of a penetrating agent; silk peptide amino acid is rich in content, contains eight kinds of amino acid which are necessary in a human body and is also capable of inhibiting the formation of melanin.

Owner:FUJIAN XINSEN CARBON

Jelly-like nourishing canned sea cucumbers and preparation method thereof

ActiveCN103815439AEasy to eatPromote digestion and absorptionFood freezingFood thermal treatmentIce waterSucrose

The invention relates to jelly-like nourishing canned sea cucumbers and a preparation method thereof. The jelly-like nourishing canned sea cucumbers are obtained by selecting secondary boiling and secondary soaking in ice water to prepare sea cucumbers or sea cucumber pieces, filling washed Chinese dates and / or tremella after soaking and soaked and washed medlar into a sterilized can, then filling the soup base prepared from sucrose, honey and gelidium amansii jelly into the can, and then exhausting, sealing, sterilizing, cooling and standing for condensation, wherein the canned sea cucumbers comprise the following components by weight percent: 30-45% of sea cucumbers or sea cucumber pieces, 5-10% of Chinese dates or / and tremella, 2-8% of medlar, 5-15% of sucrose, 1-5% of honey and 30-45% of gelidium amansii jelly. The jelly-like nourishing canned sea cucumbers have the beneficial effects that the jelly-like nourishing canned sea cucumbers have moist, glutinous, fragrant and sweet taste, are rich and comprehensive in nutrients and have the functions of nourishing and beautifying, tonifying the kidneys and strengthening bodies, replenishing blood and expelling toxins and clearing internal heat; wrapped with the gelidium amansii jelly, the sea cucumbers are free from scaling and residue dropping and have complete appearances and long shelf lives; the preparation method is reasonable in process and is simple to operate.

Owner:张伟

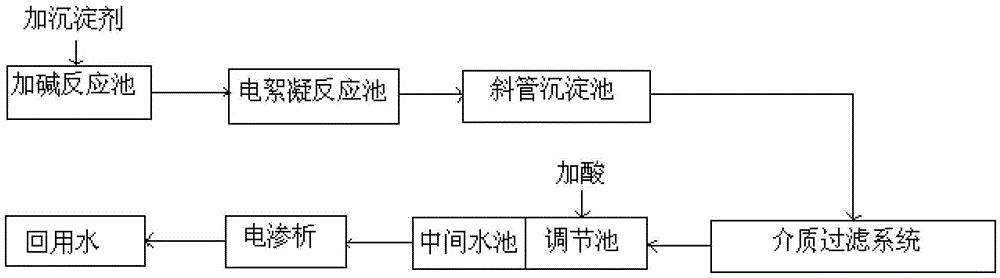

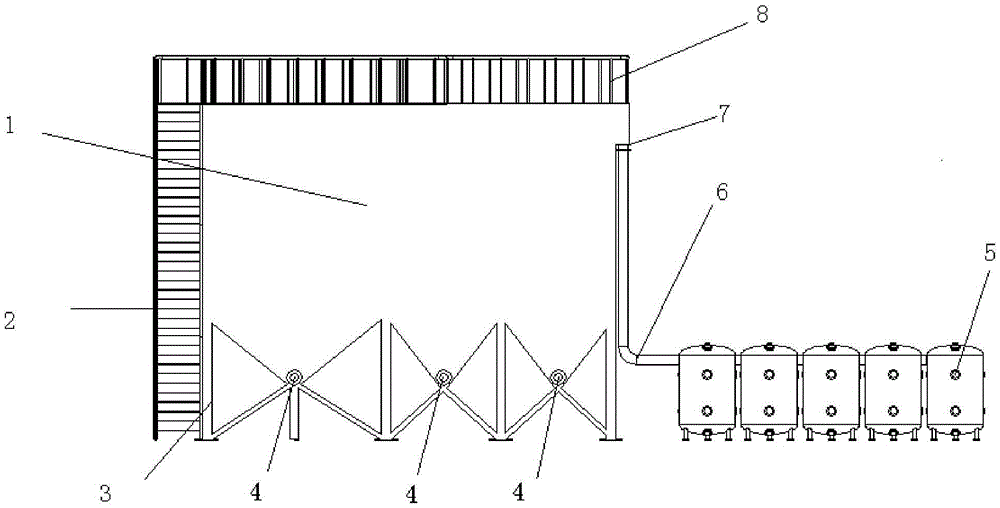

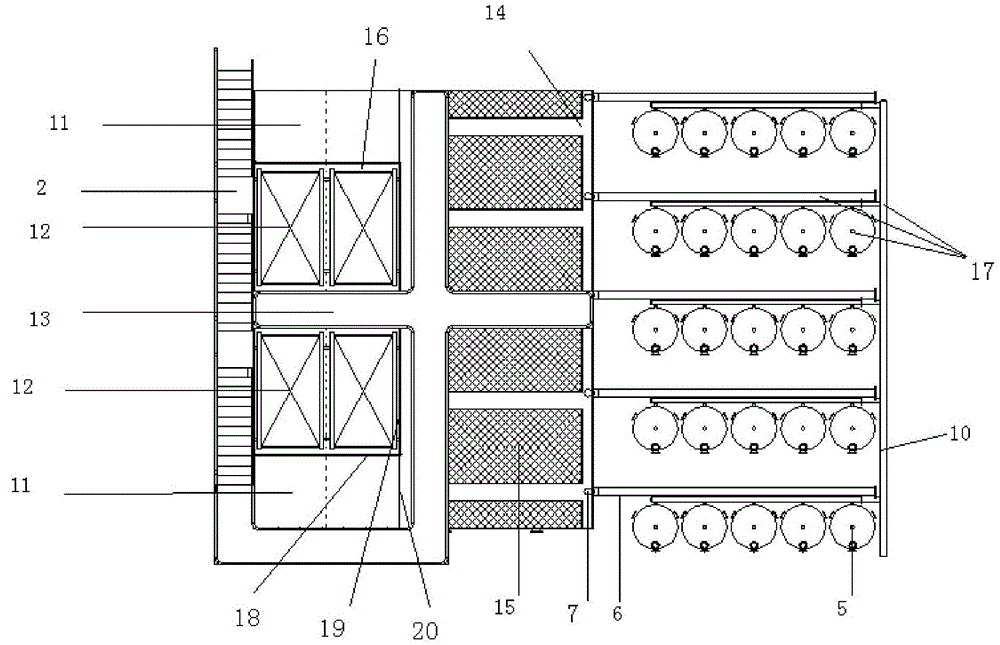

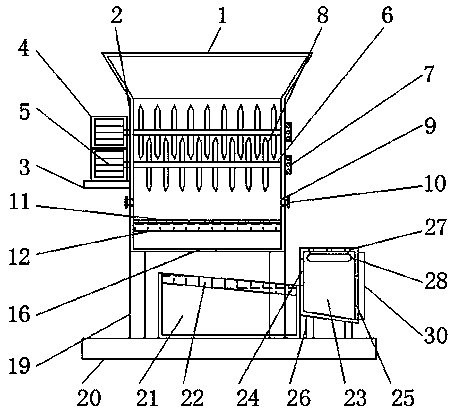

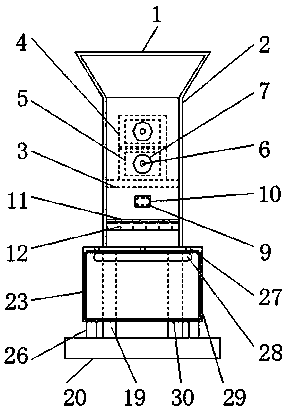

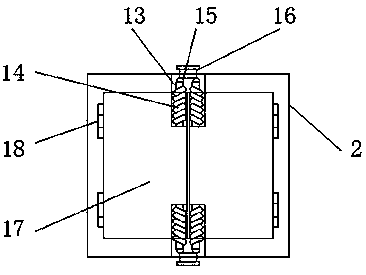

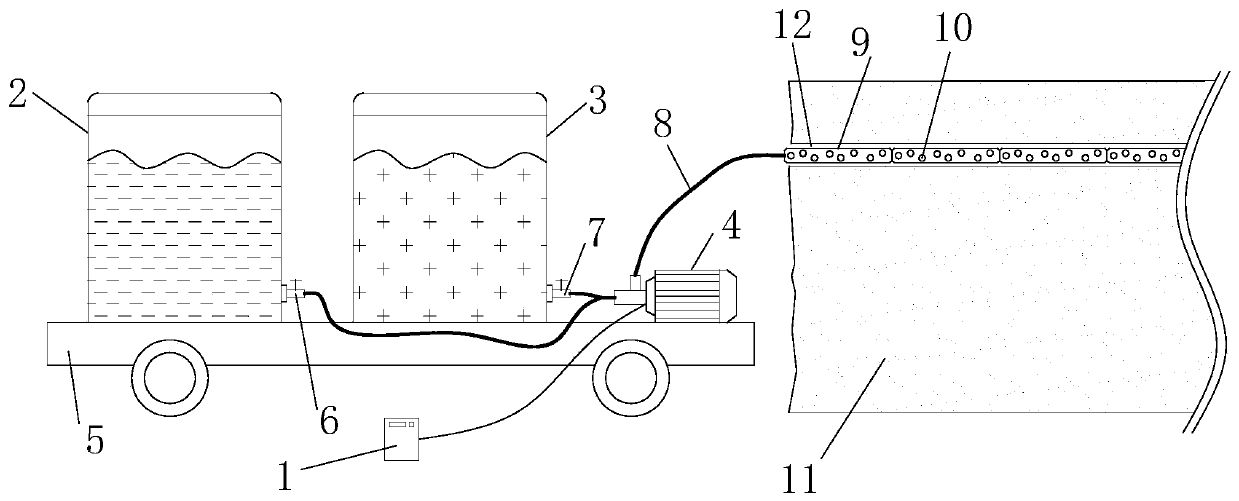

Processing method and equipment for softening hard water through electric flocculation

InactiveCN105417798AOvercome limitationsImprove removal effectSpecific water treatment objectivesTreatment involving filtrationHard waterProcess engineering

The invention relates to the technical field of hard water softening treatment, and discloses a processing method and equipment for softening hard water through flocculation. The method orderly integrates a chemical precipitation method, an inclined tube precipitation method, and an electrodialysis technology, thus has a prominent effect on processing hard water, and has the advantages of low cost, simple process, large hardness reduction, and wide application range. In the equipment, an alkali feeding reaction tank, an electric flocculation reaction tank, an inclined tube precipitation tank, and a medium filtering system cooperate with each other to process hard water; the hard water is processed in the units mentioned above in sequence and is delivered among the units through overflowing; the hard water is effectively softened, the effect is good, the application range is wide, moreover, the water pump is not used, and the energy consumption is saved.

Owner:CHENGDU FILTRASCALE TECH

Sturgeon leather production method and sturgeon leather produced using same

InactiveCN102154529AImprove wrinkle resistanceFeel goodSpecial leather manufactureEngineeringSturgeon

The invention provides a sturgeon leather production method and a sturgeon leather produced using same. The sturgeon leather production method comprises the following steps of: 1) pretreating a sturgeon leather raw material with a bone deck by means of cleaning, soaking and degreasing; 2) sequentially performing primary softening, pickle softening and tanning to the bone deck of the pretreated sturgeon leather by means of cleaning, soaking and degreasing, so that the bone deck is softened; and 3) treating the sturgeon leather with the softened bone deck by means of neutral retanning, dyeing, greasing and drying to obtain the sturgeon leather with the softened bone deck after the bone deck is treated by means of the primary softening, the pickle softening and the tanning. The sturgeon leather produced by the method is soft and ventilate, and has good tear-resistant performance and buckling-resistant performance, so that the special bone deck of the sturgeon is firmly adhered to the surface of the leather without falling off, the bone deck can be bended at 45-90 degrees without breaking off, and each bone deck is distinct in gradation, natural in decorative pattern, beautiful and fashionable.

Owner:李宏强

Processing method of nutrient rice

The invention discloses a processing method of nutrient rice. The processing method comprises the following steps that 1, rice screening is conducted through adopting a drum primary cleaning sieve anda vibrating screen; 2, impurities are removed; 3, solutions are mixed. The water, edible alkali, carrageenan, protease k and sodium citrate are uniformly mixed, and the mixture is heated to 60-70 DEGC for later usage; 4, soaking is conducted, the rice with the impurities removed in 2 is put into the 60-70 DEG C solution obtained in 3 and the soaking lasts for 20-40 minutes; 5, drying is conducted; 6, the rice is shelled; 7, the husked rice separation machine is adopted for separating the husked rice from the unhulled rice; 8, rice milling is conducted, the husked rice with the water contentof 18% is subjected to roughening and whitening by adopting a rice milling machine; 9, the rice cooling is conducted, the rice obtained in 8 after roughening and whitening is placed in a cooling ricebin to stand for 24 hours; 10, polishing is conducted; and 11, packaging into bags is conducted. According to the method, the flavor and the nutritive value of the nutrient rice can be improved.

Owner:湖南侗都米业股份有限公司

Natural zeolite water treatment agent

InactiveCN104973655AExcellent exchange abilityEliminate radioactivityOther chemical processesWater/sewage treatment by ion-exchangeSodium BentoniteAdhesive

The invention discloses a natural zeolite water treatment agent, belonging to the technical field of multifunctional water treatment agents. The natural zeolite water treatment agent is not-toxic and harmless, does not cause secondary pollution and has remarkable removal effects on ammonia nitrogen, fluorine, phosphorus, radioactive cesium (137Cs) and strontium (90Sr), organic pollutants and heavy metals in water so as to be an ideal product for purifying domestic water, industrial wastewater, domestic wastewater, aquaculture water and water in rivers, lakes and wells. According to the technical scheme, the preparation method of the natural zeolite water treatment agent comprises the following steps: taking 70-85% of zeolite (NH4 and clinoptilolite with substitution amount of greater than 140ml / 100g), crushing, grinding into powder, baking for activating, and modifying; taking 10-25% of activated carbon, crushing, grinding into powder, baking and modifying; fully mixing zeolite and activated carbon; then, adding 5% of a natural adhesive (calcium bentonite); and making spherical or cylindrical granules with the diameter of 1-10mm by adopting a conventional double-roller extruding granulation method or aggregating granulation method.

Owner:北京国投盛世科技股份有限公司

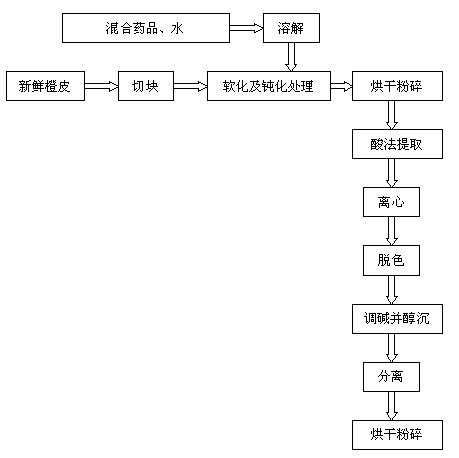

Method for extracting orange peel pectin by softening orange peel and inactivating pectinesterase

The invention discloses a method for extracting orange peel pectin by softening orange peels and inactivating pectinesterase. The method comprises the following step of: soaking fresh orange peels in a mixed solution which is obtained by proportionally mixing sodium hexametaphosphate, citric acid and sodium dihydrogen phosphate, to perform tissue softening treatment and pectinesterase inactivation treatment. The mixed solution contains, per 100 g, 41 g of sodium hexametaphosphate, 40 g of citric acid and 20 g of sodium dihydrogen phosphate. By the above treatments, the molecular weight of the pectin extracted from orange peels is increased and the quality is improved. The orange peel pectin is decolorized by macroporous absorption resin AB-8 to greatly improve the color of the pectin. Besides, during alcohol precipitation, the pH value of the solution is adjusted to 3.5, so as to optimize the sedimentation coefficient of the orange peel pectin and thus to increase the pectin yield.

Owner:NANCHANG UNIV

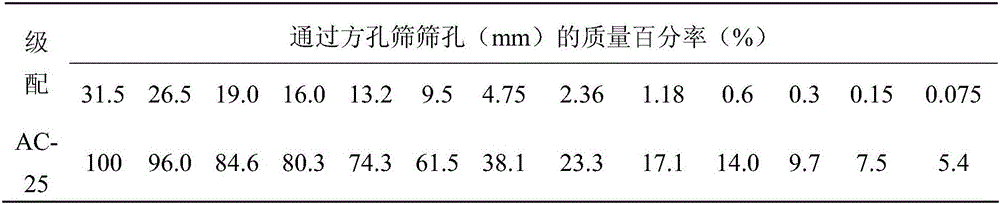

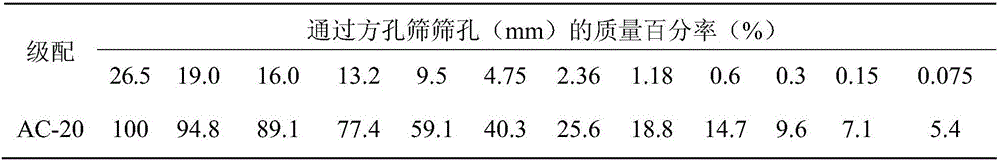

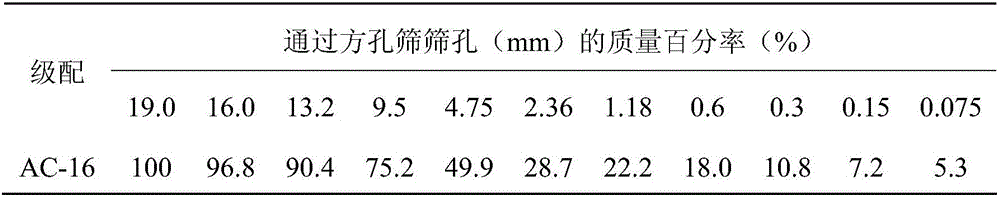

Hot-recycling asphalt mixture containing non-traditional oil and preparation method of hot-recycling asphalt mixture

The invention belongs to the field of utilization of non-traditional resources in the field of environmental protection and discloses a hot-recycling asphalt mixture containing non-traditional oil. The hot-recycling asphalt mixture is characterized by being prepared from a waste asphalt mixture, new aggregate, new asphalt and a non-traditional oil regeneration agent, wherein the waste asphalt mixture accounts for 30%-60% of the total mass of the waste asphalt mixture, the new aggregate, the new asphalt and the non-traditional oil regeneration agent, the new aggregate accounts for 38%-68% of the total mass of the waste asphalt mixture, the new aggregate, the new asphalt and the non-traditional oil regeneration agent, and the new asphalt accounts for 1%-2% of the total mass of the waste asphalt mixture, the new aggregate, the new asphalt and the non-traditional oil regeneration agent; the non-traditional oil regeneration agent accounts for 1%-3.5% of the mass of waste asphalt in the waste asphalt mixture. The implementing process of the mixture is simple, the regeneration effect is good, and the hot-recycling asphalt mixture is economical and environment-friendly.

Owner:WUHAN UNIV OF TECH

Carbon deposit cleaning agent for motor vehicle combustion system

InactiveCN104327964AEffective softeningEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsExhaust valveCombustion chamber

The invention discloses a carbon deposit cleaning agent for a motor vehicle combustion system. The carbon deposit cleaning agent is characterized by comprising three components, wherein the component 1 is prepared from the following raw materials in percentage by weight: 5% of sodium silicate, 2.3% of sodium tripolyphosphate, 1.2% of sodium carbonate, 5% of sodium gluconate and 10% of deionized water, the component 2 is prepared from the following raw materials in percentage by weight: 10% of butyl cellosolve, 5% of butanol, 2.8% of triethanolamine and 10% of deionized water, and the component 3 is prepared from the following raw materials in percentage by weight: 1.5% of EDTA-2Na, 2% of AEO-9 and 45.2% of deionized water. High-temperature carbon deposit, high-temperature greasy filth and the like on a combustion chamber, an air inlet branch, an exhaust branch, an oil spray nozzle, a sparking plug and an air inlet / exhaust valve of a combustion system of an existing motor vehicle can be effectively softened and dissolved by the carbon deposit cleaning agent and cleaned by engine carbon deposit cleaning equipment, so that the engine operating condition of the motor vehicle in use can be effectively recovered and the effects of saving fuel oil and reducing exhaust gas emission are achieved.

Owner:韦筱兰

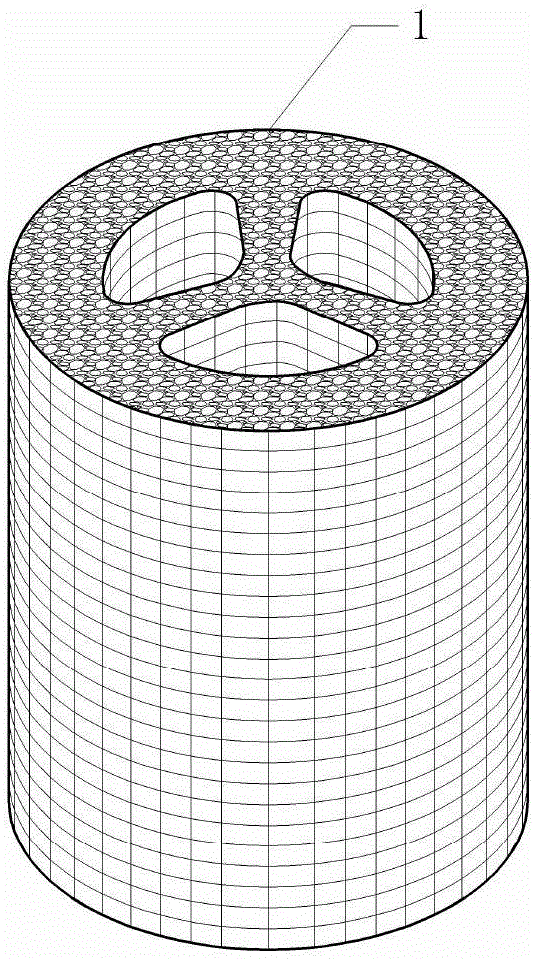

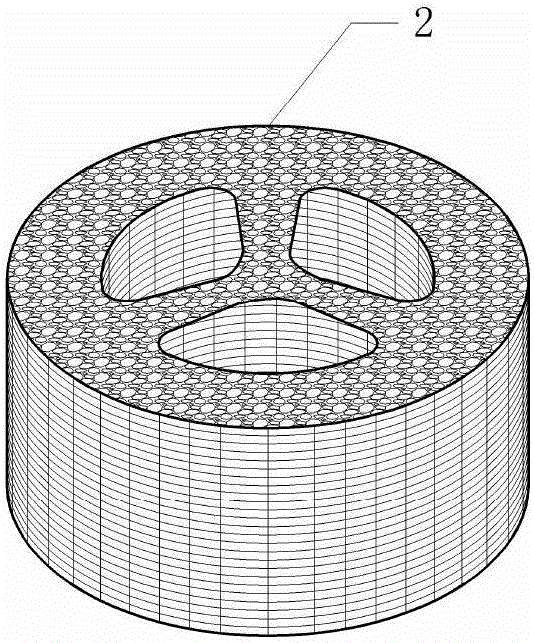

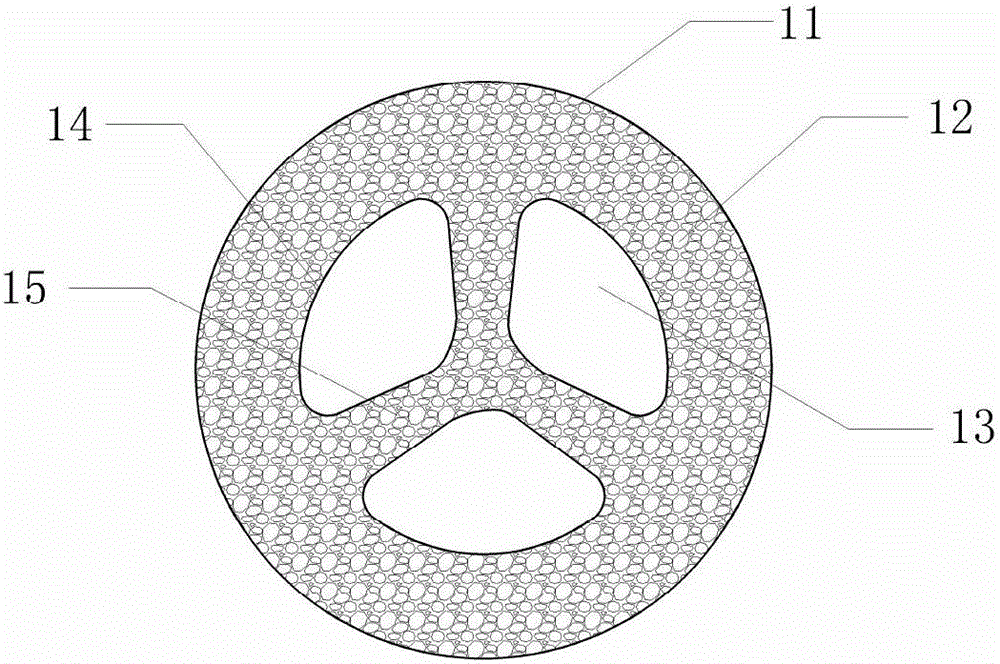

Softening treatment method of columnar loofah sponge

ActiveCN105803759AAvoid yellowingKeep shapeVegetable fibres from other vegetable matterGrip property fibresFiberSurface layer

The invention provides a softening treatment method of a columnar loofah sponge. The method comprises the following steps of: firstly, cutting the columnar loofah sponge with the size of 3cm-5cm and measuring the density; carrying out hot pressing and compression treatment on the cut columnar loofah sponge; then treating the columnar loofah sponge subjected to the hot pressing treatment with an alkali and hydrogen peroxide mixed solution, wherein an alkali is sodium hydroxide and the content of sodium hydroxide is 5%-10%, the content of hydrogen peroxide is 5%-10%, the temperature of the solution is 70-90 DEG C and the immersing time is 40min-1.5h; and finally, carrying out water washing and constant-temperature and constant-humidity treatment to finally obtain the softened columnar loofah sponge. By virtue of the method provided by the invention, the aim that fibers of an outer surface layer, an inner surface layer and a core layer of the columnar loofah sponge can be subjected to the softening treatment very well can be realized; meanwhile, the elasticity in the longitudinal direction of the columnar loofah sponge is relatively good, so that the aim of filling a mattress can be met very well; and meanwhile, the columnar loofah sponge subjected to the softening treatment of the method can meet the requirements of use comfort of the mattress, prevention of yellowing and the like very well.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Treating agent for facilitating dyeing of wicker weaving products

InactiveCN106217564AKeep for a long timeExtension of timeWood treatment detailsReed/straw treatmentPentaerythritolSodium ascorbate

The invention discloses a treating agent for facilitating dyeing of wicker weaving products. The treating agent comprises the following components of furfuryl alcohol, corn stigma boiling liquid, borax, urea, pink soak liquid, sodium ascorbate, pentaerythritol, water and an additive. Compared with a current wicker weaving product treating agent, the treating agent provided by the invention is simple in preparation method; a treatment method after preparation is simple; the dyeing ability of treated wicker weaving products is greatly improved, so that surface permeability and colourability of dye for wicker are greatly improved, and the dye can uniformly and rapidly enter the surface of the wicker; the average time for coloring and color fixing is shortened by 20% compared with that of untreated wicker products; the color fastness is good after dyeing; color is uniform; stability is high; and color fading cannot occur.

Owner:安徽阜南县万家和工艺品有限公司

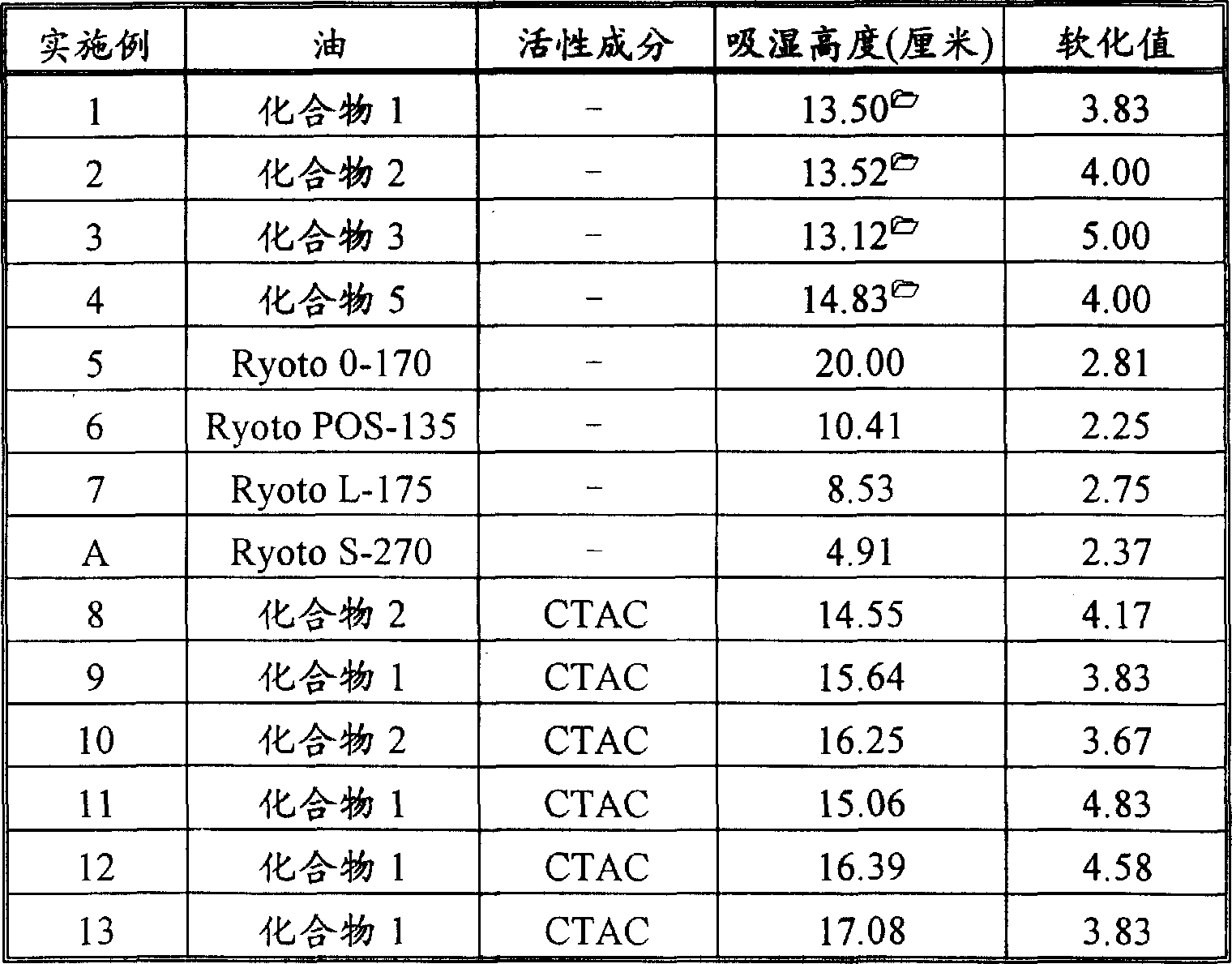

Fabric softening compositio

InactiveCN1240452AEasy to manufactureEffective softeningEsterified saccharide compoundsCationic surface-active compoundsPolyolEther

A fabric softening composition that softens fabrics without affecting the absorbency of the fabric is provided. The conditioner comprises: i) a liquid or soft solid derivative of a cyclic polyol (CPE) or of a reduced saccharide (RSE) resulting from 35 to 100 % of the hydroxyl groups in the cyclic polyol or reduced saccharide being esterified or etherified, the derivate (CPE or RSE) having at least 2 or more of ester or ether groups independently attached to a C8-C22 alkyl or alkenyl chain or mixtures thereof, and containing at least 35 % tri or higher esters; ii) a deposition aid. Also liquid or soft solid fatty acid esters of glucose comprising a mixture of C2-C22 alkyl or alkenyl chains and resulting from a cyclic polyol as above are provided.

Owner:UNILEVER NV

Recovery device facilitating crushing on plastic woven bags

InactiveCN108943509AEasy to crushFully cut and crushedPlastic recyclingMechanical material recoveryEngineeringWater collection

The invention discloses a recovery device facilitating crushing on plastic woven bags. The recovery device comprises a first feed port, rubber plugs, first support pillars and a storage box. One sideof the first feed port is provided with a box. One side of the box is provided with a carrying plate. The rubber plugs are clamped in water inlets. A magnetic plate is mounted in the box. The first support pillars are mounted on the side, close to a first box door, of the box. The storage box is mounted on one side of a water collection tank. A heating plate is mounted on the side, close to air vents, of the storage box. The side, far away from second hinges of the storage box, of the storage box is provided with a second box door. The recovery device facilitating crushing on the plastic wovenbags is provided with the heating plate, and the heating plate is mounted in the storage box. Through the arrangement, the crushed plastic woven bags in the storage box can be effectively dried through the heating plate, so that the crushed plastic woven bags are in a dry state, and subsequent collection and sorting are facilitated.

Owner:安徽中能包装制品有限公司

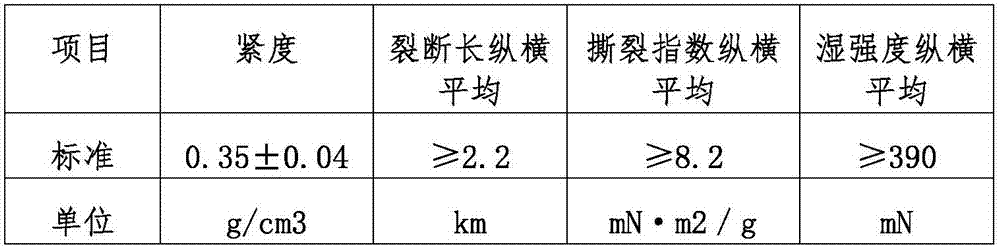

Treatment method of paper mulberry bark for papermaking

ActiveCN106988139AFully softenedHigh whitenessMechanical/thermomechanical pulpRaw material divisionPapermakingChemical agent

The invention belongs to the technical field of papermaking, and particularly relates to a treatment method of paper mulberry bark for papermaking. The treatment method of the paper mulberry bark for the papermaking includes the following steps of bark airing, first-time bark soaking, first-time bark steaming, second-time bark soaking, bark washing, bark kneading, bark and plant ash mortar stirring, and mortar mashing; according to the treatment method of the paper mulberry bark for papermaking, through a mode in which second-time bark soaking in water, second-time bark soaking in lime, second-time bark steaming, bark and plant ash mortar stirring, mechanical rolling and manual rolling are combined, the paper mulberry bark can be fermented to the maximum degree, and therefore paper mulberry base fibers can be softened more sufficiently; in the treatment process, no chemical agent is added, the integrity of the fibers is maintained to the maximum degree, so that prepared paper mulberry base fibers are relatively high in whiteness and yield, and fundamental guarantee is provided for the requirements of current markets for high-quality paper.

Owner:贞丰县民族民间工艺厂

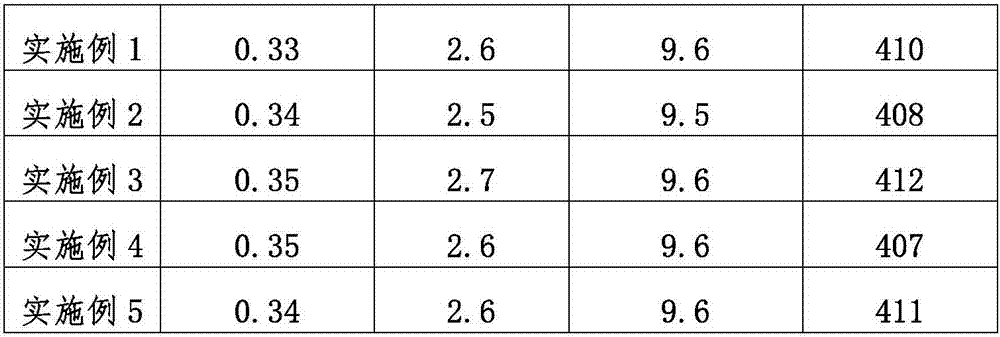

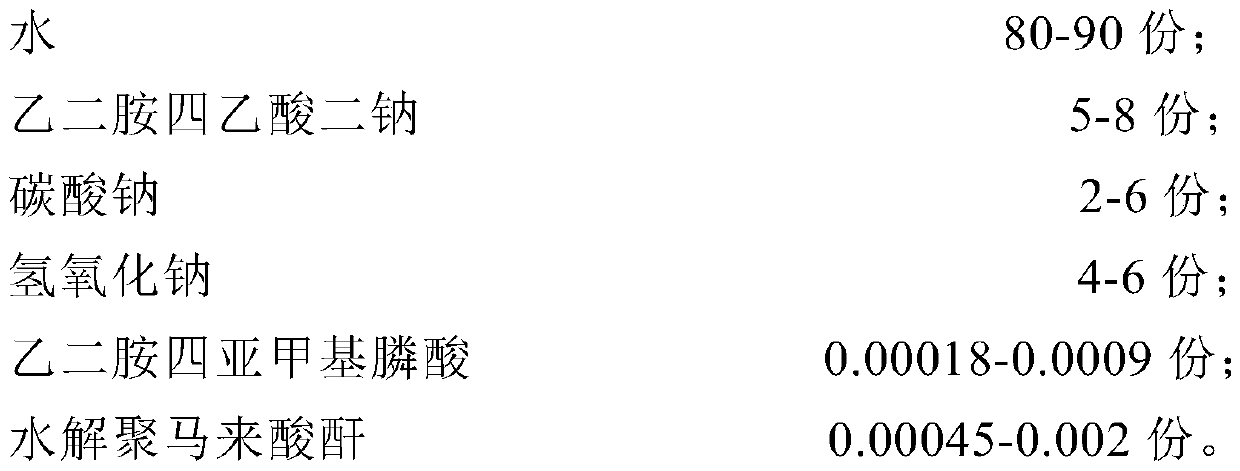

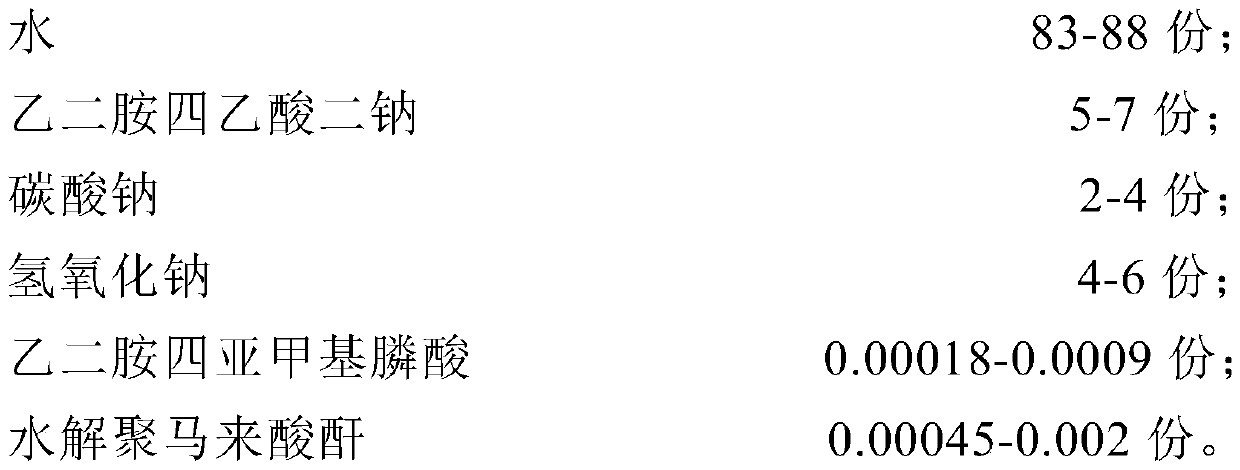

Cleaning agent applicable to descaling of landfill leachate evaporator and preparation method and application thereof

InactiveCN111205934ADirt hardImprove solubilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansing AgentsEthylenediaminetetra(methylenephosphonic)acid

The invention provides a cleaning agent applicable to descaling of a landfill leachate evaporator and a preparation method and application thereof, and the cleaning agent applicable to descaling of the landfill leachate evaporator is characterized by comprising the following components by weight: 80-90 parts of water; 5-8 parts of ethylenediamine tetraacetic acid disodium salt; 2-6 parts of sodiumcarbonate; 4-6 parts of sodium hydroxide; 0.00018-0.0009 parts of ethylenediamine tetramethylenephosphonic acid; 0.0003-0.0004 parts of sodium hydroxide; and 0.00045-0.002 parts of hydrolytic polymaleic anhydride. The invention further discloses a preparation method and application of the cleaning agent applicable to descaling of the landfill leachate evaporator. The cleaning agent can effectively soften and remove dirt generated by the landfill leachate evaporator in the landfill leachate treatment process, basically has no corrosion loss and side reaction to evaporation equipment, is simplein formula and good in descaling effect, and solves the problem of scaling of the landfill leachate treatment evaporator.

Owner:大连广泰源环保科技有限公司

Method for preparing bamboo mat used for external cable packaging

InactiveCN107443529APrevent bacterial regenerationNot easy to mothWood treatment detailsCane mechanical workingUreaChemistry

The invention discloses a method for preparing a bamboo mat used for external cable packaging. The method includes the following steps that branches and leaves of bamboo are removed, the bamboo is split to form bamboo chips, and the bamboo chips are dried to obtain pretreated bamboo; the pretreated bamboo is placed into a hydrochloric acid solution and subjected to standing, then filtering and natural air drying are conducted, and a product is placed into a sodium hydroxide solution and subjected to standing, so that a material A is obtained; the material A is carbonized, and then a product is delivered to a hot press to be flattened to form a material B; and the material B is delivered into an ethanol solution, cocamidopropyl betaine and butyl titanate are added into the ethanol solution and stirred, hydrochloric acid, urea, citric acid complexing silver nitrate and microcrystalline wax are added, and then heated stirring, filtering, washing, drying and knitting are conducted, so that the bamboo mat used for external cable packaging is obtained. The method can completely kill bacteria and eggs in bamboo and effectively soften a bamboo fiber bundle, so that the stability of the formed bamboo mat in use is guaranteed; meanwhile, the sterilization and antibacterial effects of bamboo fibers are effectively improved, the bamboo fibers are prevented from absorbing moisture and gas in air, and the effects of corrosion prevention and deformation prevention are achieved.

Owner:广德县泉村竹制品有限公司

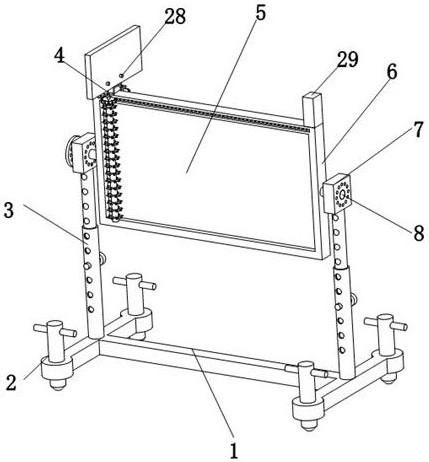

Warning board device for river dredging

ActiveCN112554086ALiberate manpowerGuaranteed stabilityCleaning using toolsTraffic signalsSludgeBrush

The invention belongs to the technical field of riverway treatment, and discloses a warning board device for riverway dredging, which comprises a base, reinforcing mechanisms are arranged at four corners of the base, two groups of height adjusting mechanisms are arranged on the outer wall of the top of the base, and adjusting blocks are fixed on the outer walls of the tops of the height adjustingmechanisms through bolts. The adjusting block is rotationally connected with a fixing frame through an adjusting shaft, a warning plate is clamped to the inner wall of the fixing frame, a cleaning mechanism is arranged on the outer wall of the fixing frame, the cleaning mechanism comprises two cleaning rollers and a rolling gear, cleaning brushes making contact with the warning plate are arrangedon the outer side walls of the cleaning rollers, and the cleaning rollers are fixedly connected with the rolling gear through cleaning shafts; the outer walls of the tops of the two cleaning shafts are jointly and rotationally connected with the same support, the inner wall of the support is rotationally connected with a driving device, the cleaning mechanism of the device can effectively and automatically clean floating dust and sludge blocks on the warning board, and the labor intensity of workers is reduced.

Owner:吴春海

Hand-washing solution with nourishing effect

InactiveCN102397180AAdd cleaning functionPromotes nutrient absorptionCosmetic preparationsToilet preparationsAdditive ingredientBamboo salt

The invention discloses a hand-washing solution with a nourishing effect. Major ingredients of the hand-washing solution include 40-65 percent of deionized water, 2-15 percent of anionic surfactant, 4-15 percent of non-ionic surfactant, 3-10 percent of amino acid, 1-3 percent of lanoline, 4-20 percent of bamboo vinegar and 2-15 percent of bamboo salt. The hand-washing solution has the effects of effectively softening and removing horny layer on the surface of skin, promoting skin metabolism, helping skin effectively absorb nutrients, tightening, smoothening and softening the hand skin, resisting bacteria and disinfecting.

Owner:崔士强

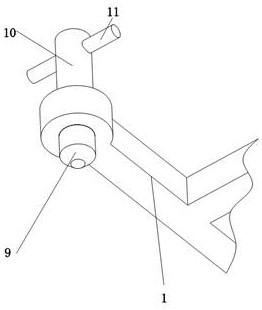

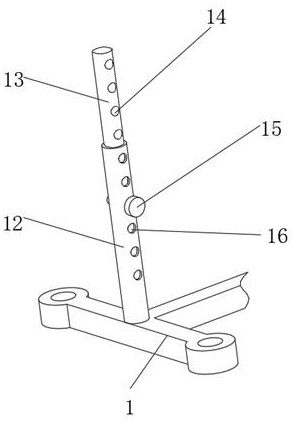

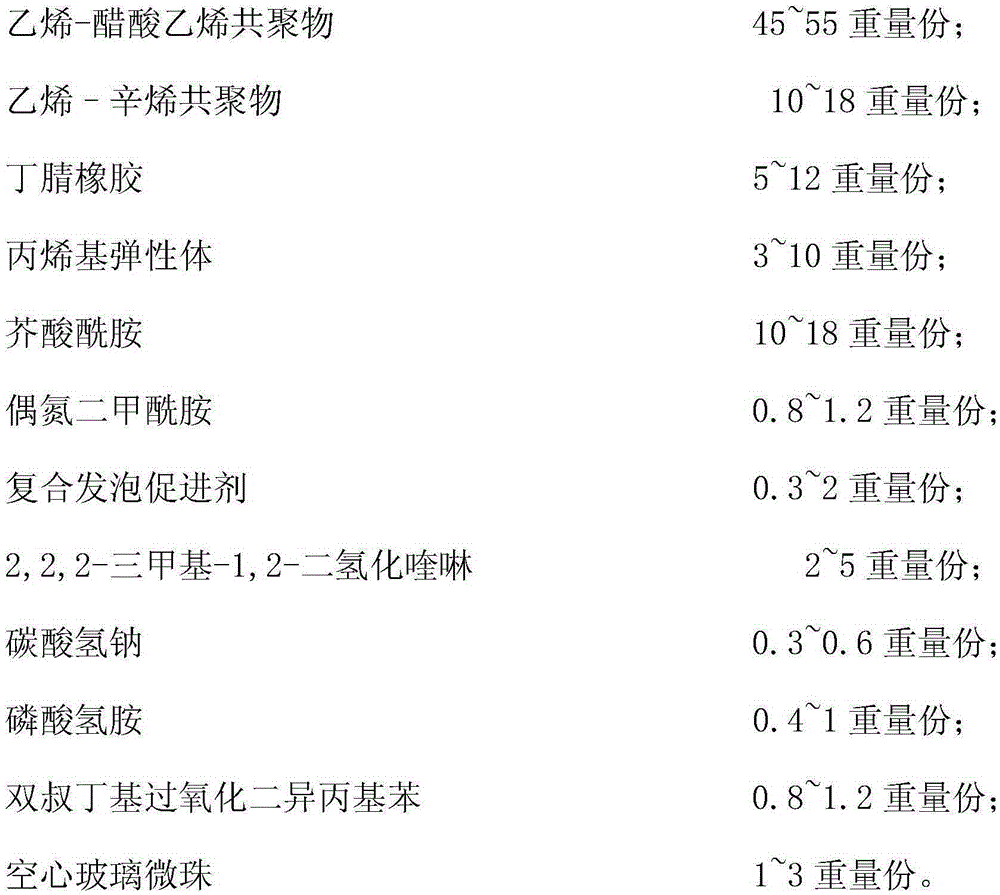

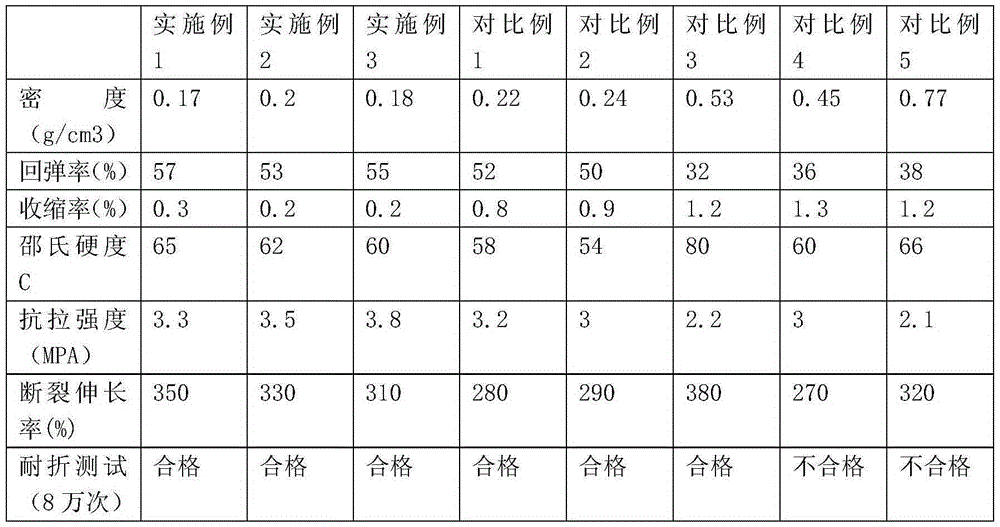

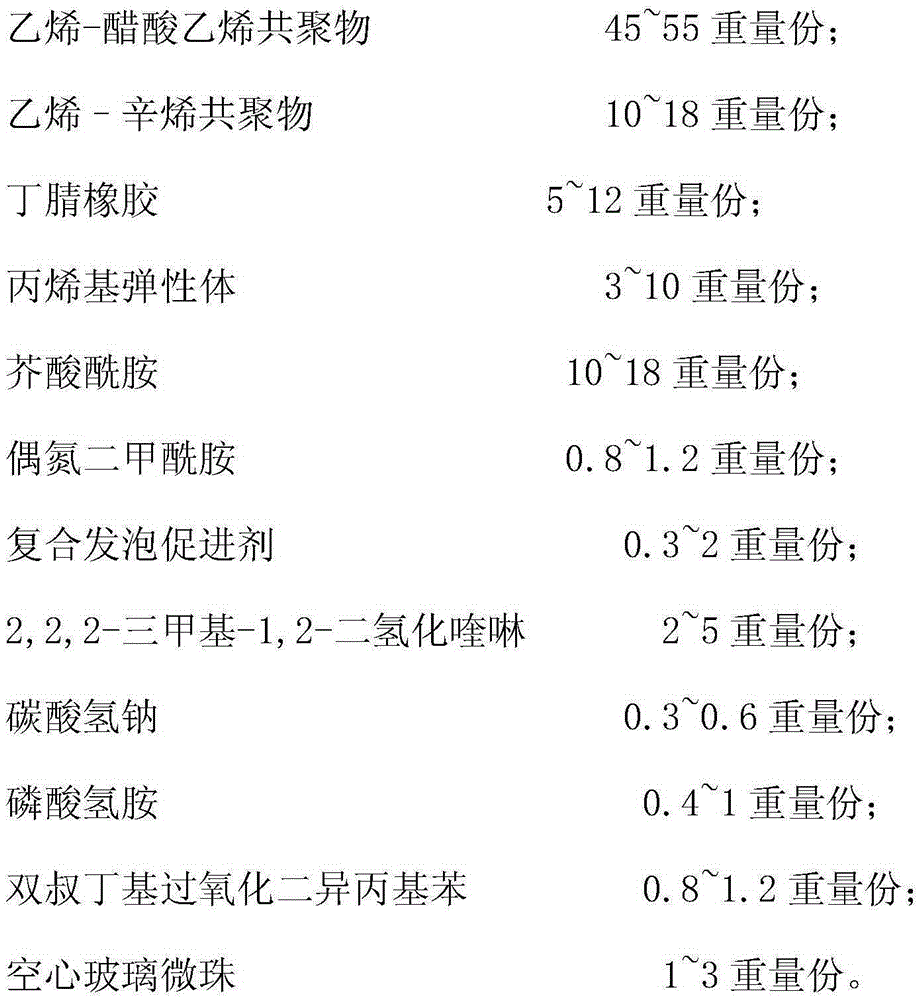

Rubber and plastic micropore shoe material and preparation method thereof

The invention discloses a rubber and plastic micropore shoe material which comprises the following components: ethylene-vinyl acetate copolymer, ethylene-octene copolymer, nitrile rubber, propenyl elastomer, erucicamide, 0.8 part of azodicarbonamide, 0.3 part of a compound foaming accelerator, 2,2,2-trimethyl-1,2-dihydroquinoline, stearic acid, zinc stearate, ditert-butyl peroxide diisopropyl benzene and hollow glass beads, wherein the compound foaming accelerator is a mixture consisting of chlorinated paraffin, ethylene acrylic acid copolymerized zinc salt and calcium oxide. According to the provided rubber and plastic micropore shoe material, the proper formula and auxiliaries are adopted to obtain a sizing material through secondary granulation, and the sizing material is foamed so as to prepare the shoe material; the shoe material is portable, aesthetic, rich in elasticity, good in compression resistance and small in shrinkage rate.

Owner:吴江市风尚鞋厂

Traditional Chinese medicine composition for treating clavus

InactiveCN102078463AEffective softeningGood treatment effectDermatological disorderPlant ingredientsSide effectGlycerol

The invention discloses a traditional Chinese medicine for treating clavus, solving the defects that the treating effect of the existing medicine for treating clavus is not ideal, clavus is easy to relapse, the treating process is painful, the cost is high, and the like. The traditional Chinese medicine composition for treating clavus has the advantages of good treating effect, no side effect, low cost and the like, the treating process is not painful or itching, and clavus is not easy to relapse. The formula is composed of the following raw medicines in parts by weight: 10-30 parts of radix adenophorae, 10-30 parts of root of red rooted salvia, 10-20 parts of hemlock parsley, 10-20 parts of safflower, 5-10 parts of wolfberry bark and 5-10 parts of tuber pinellia. The preparation method comprises the following steps: pulverizing the raw medicines, screening with a sieve of 20 meshes, then adding glycerol and mixing evenly.

Owner:杜香琳

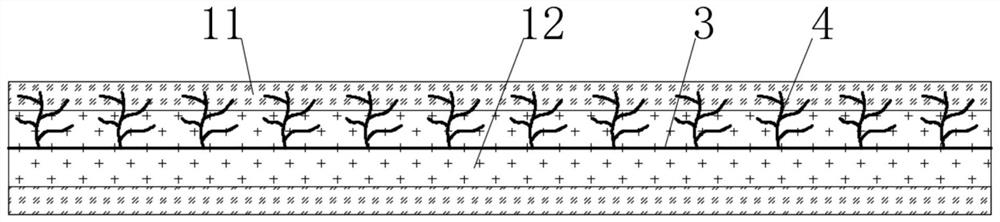

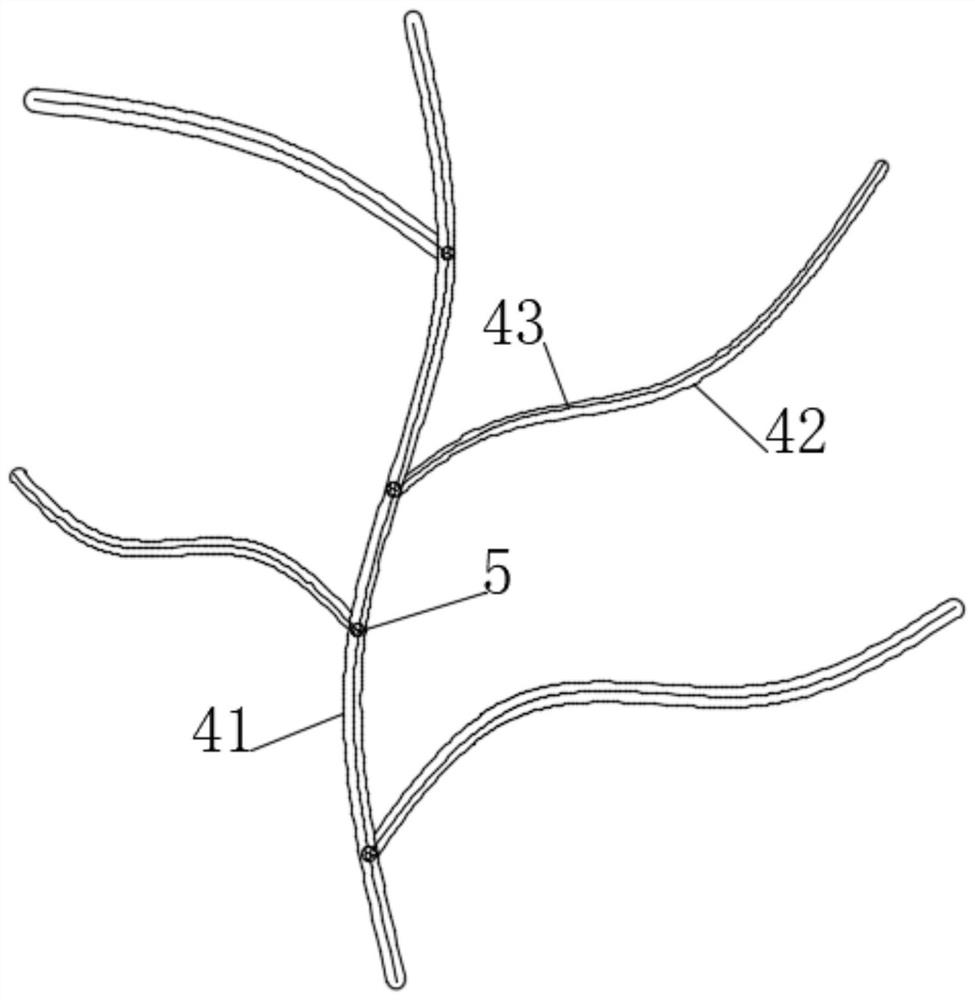

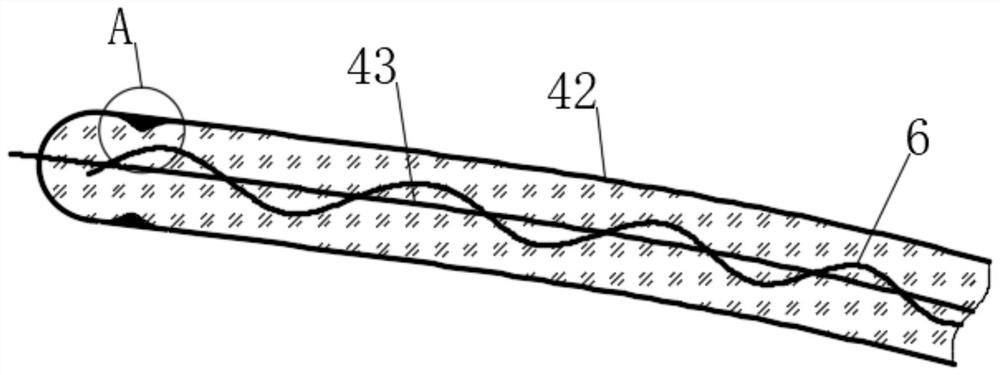

Water-soft anti-falling anti-seepage outer wall

The invention discloses a water-soft anti-falling impervious outer wall, and belongs to the field of building outer walls. The water-soft anti-falling impervious outer wall comprises an inner concretelayer, outer waterproof layers are fixedly connected to two outer ends of the inner concrete layer, and a water-soft tension cluster is arranged, so that the water-soft anti-falling impervious outerwall presents certain hardness when not meeting water and can be integrated with a wall body. When the outer wall has a water seepage condition, the water soft pulling force clusters absorb water andthen soften to a certain extent, so that the water soft pulling force clusters have certain elasticity, and when the concrete blocks fall off due to long-time water seepage, the water soft pulling force clusters are softened to a certain extent, so that the water soft pulling force clusters have certain elasticity; the concrete block can be pulled to a certain extent through the softened pulling force side branches and the inner water guide fibers, the situation that the concrete block falls off and hurts pedestrians is effectively reduced, potential safety hazards are remarkably reduced, meanwhile, the falling concrete block can be obviously hung on the outer wall under the action of the inner water guide fibers, and the concrete block is not prone to falling off. Workers can be remindedof timely maintenance conveniently, and potential safety hazards are further reduced.

Owner:赵先峰

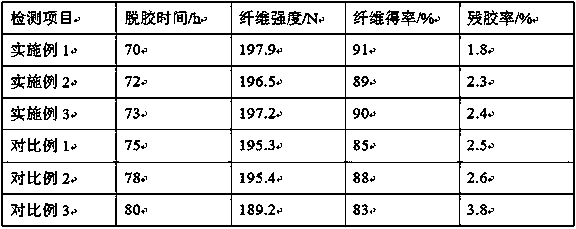

Method for degumming flax

InactiveCN109989114AEffective softeningBreak bondVegetable materialPolyvinyl alcoholNutrient solution

The invention relates to a method for degumming flax, and belongs to the field of flax degumming. The invention solves the problems of long degumming time and poor degumming effect of existing flax degumming. According to the invention, firstly, water in the flax is lost through drying; a part of micropores are formed inside the flax, soaking liquid is added to treat the flax; the soaking liquid takes polyvinyl alcohol as a raw material, is degraded through hydrogen peroxide in an alkaline solution, and then is combined to an additive, the flax can be effectively softened, and meanwhile, the flax can compete with gum substances to damage the degree of combination of the gum substances and the flax; and secondly, a trace additive is added in the invention, metal ions in the trace additivescan be effectively supported on the surface and pores of the flax, and then are mixed with a nutrient solution, and natural fermentation treatment is carried out to complete degumming of the flax.

Owner:常州市雄图纺织有限公司

Preparation method of bamboo mat not prone to deformation

InactiveCN108407015APrevent regenerationAvoid absorptionWood treatment detailsCane mechanical workingPolyvinyl alcoholCarbonization

The invention discloses a preparation method of a bamboo mat not prone to deformation. The method comprises the following steps: S1, carrying out carbonization treatment of a pretreated bamboo, then feeding the bamboo into a hot press and flattening the bamboo to obtain the carbonized bamboo, wherein the carbonization treatment is characterized by feeding the bamboo into a drying and disinfectingcarbon dryer, the heating temperature of the drying and disinfecting carbon dryer is 160-190 DEG C, the heating time is 2-4 hours, and the bamboo is carbonized at a carbonization degree of 5-30%; andS2, feeding the carbonized bamboo into an ethanol solution, adding soyabean lecithin and tetraisopropyl titanate, then stirring, adding hydrochloric acid, tartaric acid complex copper nitrate and polyvinyl alcohol, increasing the temperature and stirring, filtering, washing, drying and knitting to obtain the bamboo mat not prone to deformation.

Owner:施文杰

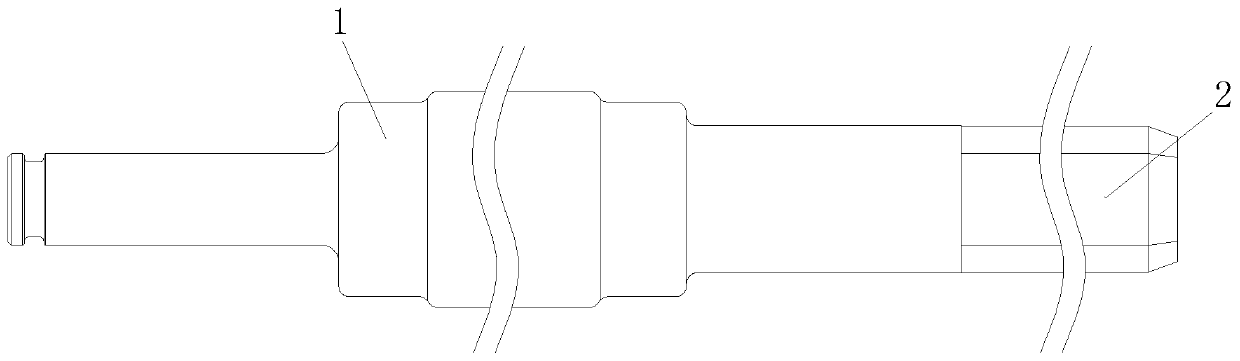

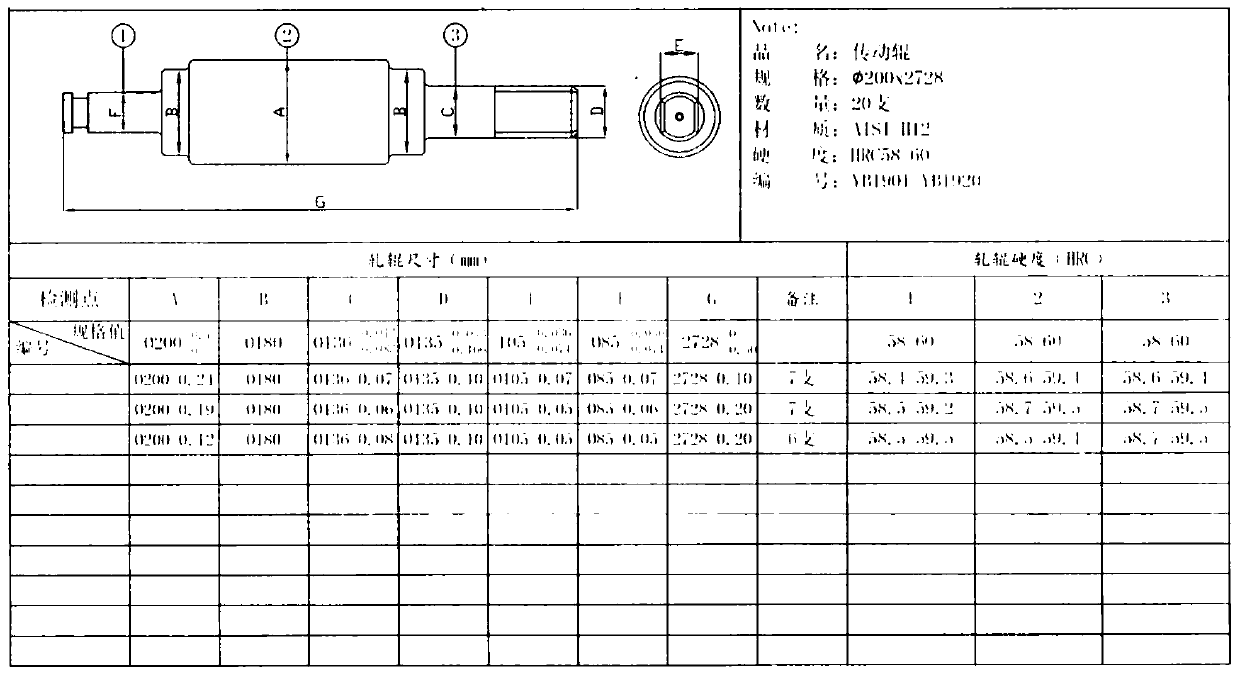

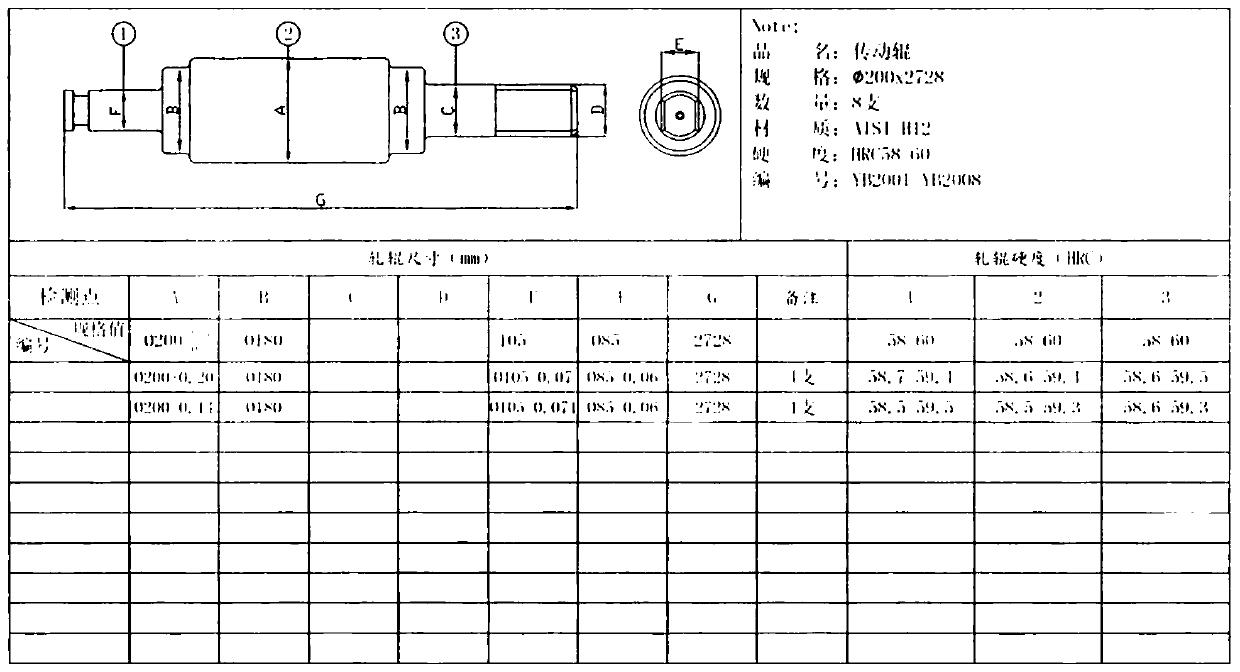

Novel cold rolled driving roller heat treatment process

PendingCN111549205AHigh hardnessReduce deformationFurnace typesHeat treatment furnacesTemperingEngineering

The invention relates to the technical field of cold rolled driving roller heat treatment, and discloses a novel cold rolled driving roller heat treatment process. According to the process, a workpiece and a driving side end are included, wherein the driving side end is located at one end of the workpiece, the workpiece and the driving side end are firstly subjected to preheating treatment, and then is subjected to heating, a heated workpiece is subjected to constant-temperature quenching, the quenched workpiece and the driving side end are cooled, then low-temperature tempering is carried out, after low-temperature tempering is conducted, heating and preheating are carried out, then two-time high-temperature tempering is carried out, and a cold rolled driving roller is preheated after subjected to high-temperature tempering and cooling, high-temperature tempering is performed on the driving side end separately and then cooling is conducted. According to the novel cold rolled driving roller heat treatment process, residual austenite can be converted into martensite, after secondary high-temperature tempering, the residual austenite accounts about 8%-10%, the residual austenite is converted into the martensite, the wear resistance and the service life of the cold rolled driving roller are effectively increased and prolonged, the crack condition is effectively solved during rolling by a customer, and the service life of a roller is prolonged.

Owner:WUXI YIBAO MACHINERY EQUIP CO LTD

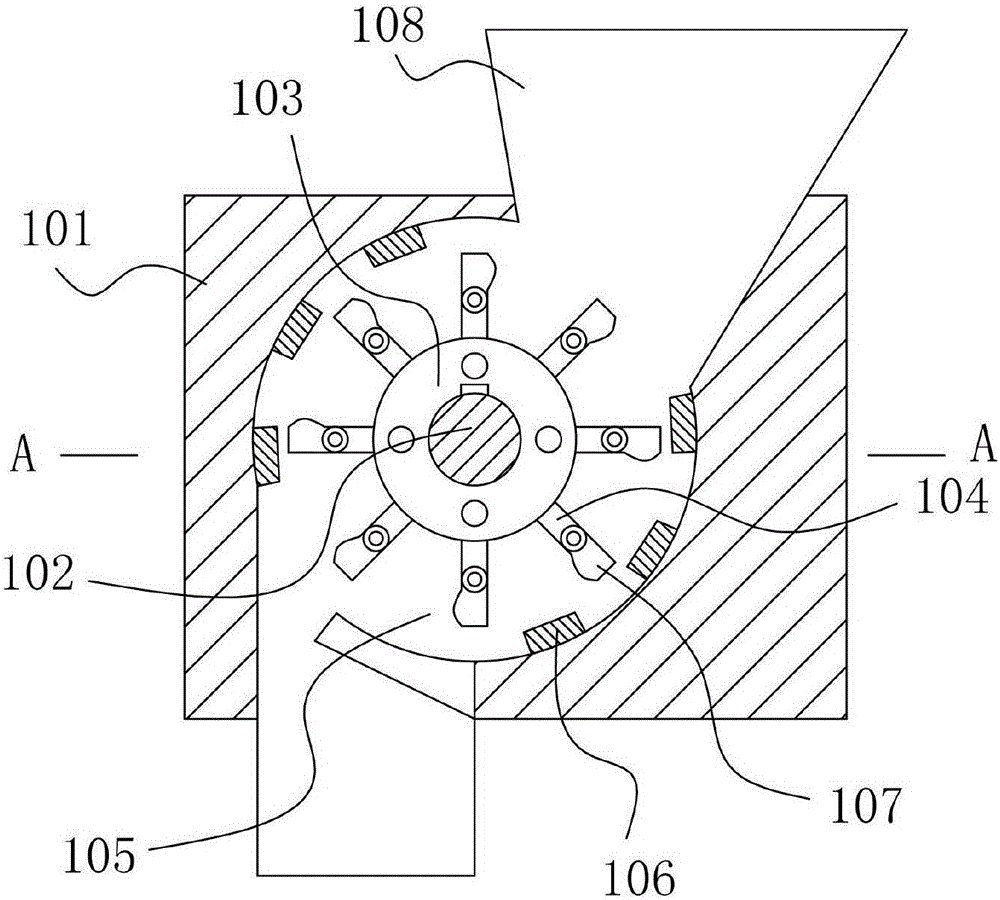

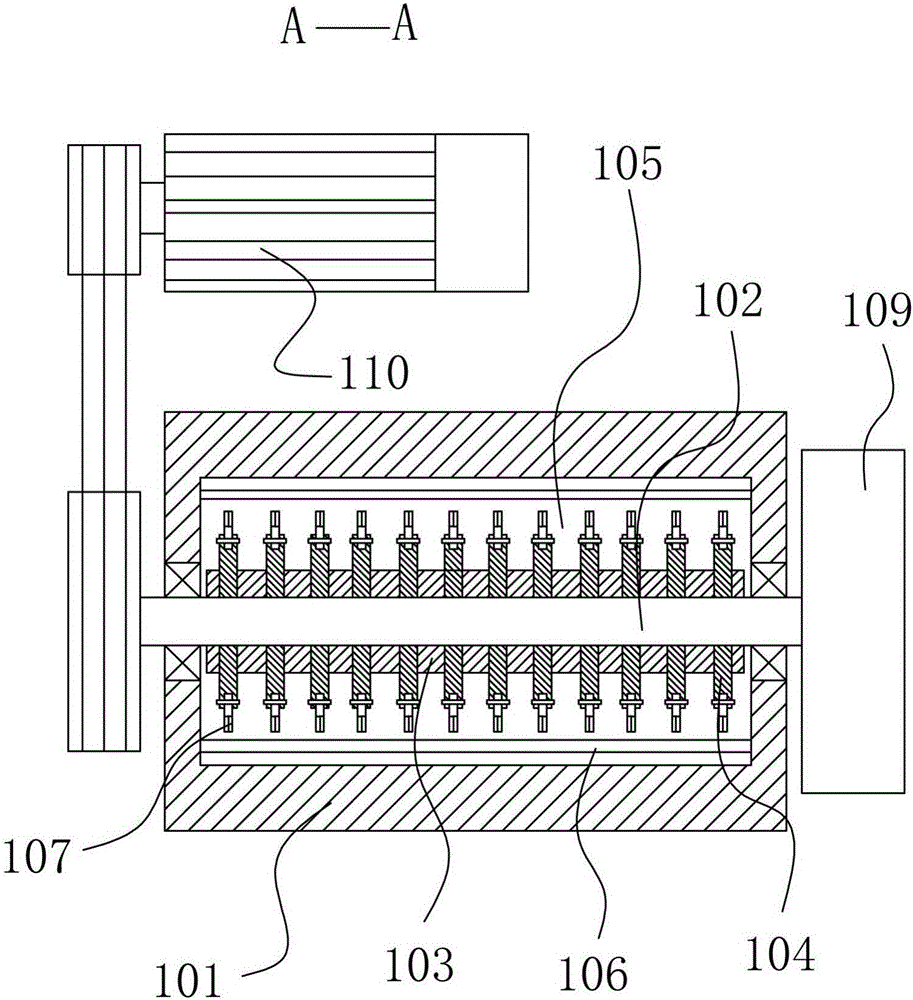

Wood fiber manufacturing method

PendingCN111136748AEffective softeningOptimum Process ParametersWood treatment detailsWood impregnation detailsFiberIndustrial engineering

The invention discloses a wood fiber manufacturing method. The wood fiber manufacturing method comprises the following steps of selecting corn stalk husk and fast-growing poplar as raw materials; cutting the raw materials into strips with the thickness of 2 cm and the width of 2 cm and the appropriate length in the range adaptive to a hydraulic machine; soaking the cut wood strips in a wood soaking solution for 6 to 10 hours; drying flattened and soaked wood by adopting hot air; and crushing the dried raw materials in a fiber crushing machine and screening through bottom screens by rubbing androlling under the actions of high-strength friction force, shear force and impact force of the fiber crushing machine, so that the wood fibers with the length-to-diameter ratio of 3 to 7 can be obtained according to the screens with different specifications. According to the wood fiber manufacturing method, the corn stalk husk and the fast-growing poplar are selected as the raw materials; dryingcharacteristics of the wood fibers and a process control method are provided; wood can be effectively softened by adopting the wood soaking solution provided by the invention, so that the wood fibersare kept intact; high-quality wood fibers are prepared by matching optimal process parameters; and the wood fiber manufacturing method is energy-saving and environment-friendly, and has popularizationand application value.

Owner:TAIZHOU UNIV

Preparation method of pug of stone gold purple sand utensil for softening water quality and accelerating sobering

The invention relates to a preparation method of mud of a stone gold purple sand utensil for softening water quality and accelerating sobering. The method comprises the following steps: manually selecting raw ore materials of the yellow stone scattered in a tender mud paragenic ore layer, airing and drying the weathered raw ore materials by adopting a winter-summer two-season open-air stacking natural weathering method, grinding by using a hard stone mill, crushing into 60-mesh and 80-mesh powder and 120-mesh fine powder, adding water, uniformly mixing and stirring, and sealing for ageing; andcarrying out sealed aging and three times of repeated vacuum pugging to prepare the purple sand pug of the purple sand utensil for softening water quality and accelerating sobering. According to themethod, the design color requirement is met through different firing temperatures and methods, the product quality is good, the utensil metal texture is achieved, the glass phase is extremely good, and the purpose of turning waste purple sand waste mineral aggregate into wealth can be achieved. The finished product can effectively soften the water quality, is sweet and pure to drink, improves thetaste, and has a certain health-care effect. The product can be used for quickly decanting wine drinks, and is mellow and soft in taste.

Owner:宜兴市天恩陶舍紫砂文化有限公司

Coal seam static expansion, cracking and antireflection equipment and method

ActiveCN111535790ANo high temperatureImprove securityFluid removalDrilling compositionStructural engineeringTruck

The invention discloses coal seam static expansion, cracking and antireflection equipment and method. The coal seam static expansion, cracking and antireflection equipment comprises a grouting truck and a grouting pipeline. A grouting pump, an expansion agent tank, an acidolysis agent tank are arranged on the upper part of the grouting truck, an expansion agent discharging outlet is formed in thebottom of the expansion agent tank, an acidolysis agent discharging outlet is formed in the bottom of the acidolysis agent tank, and the expansion agent discharging outlet and the acidolysis agent discharging outlet are separately connected with a liquid inlet of the grouting pump; and the grouting pipeline is connected with a liquid outlet of the grouting pump through a pipeline, and the groutingpipeline comprises a plurality of sections of rotating pipes connected to one another and arranged in a coal seam borehole. The coal seam static expansion, cracking and antireflection equipment has the beneficial effect that through mechanized operation, a drag reducing expansion agent is injected into the coal seam borehole to produce static expansion, the coal seam is promoted to rupture and generate cracks, then chemical decomposition is carried out through a decomposer to clean drag reduction expansion agent defective materials in the coal seam borehole, the connectivity between the borehole and the surrounding coal seam crack channels is ensured, and the coal seam static expansion, cracking and antireflection equipment has the advantages of low economic cost and high safety factor.

Owner:SHANDONG UNIV OF SCI & TECH

Biochemical pretreatment technology of high-hardness and high-salinity papermaking wastewater

InactiveCN106045215AReduce hardnessLow Inorganic Salt ContentSludge treatment by de-watering/drying/thickeningWater treatment parameter controlWater qualityPapermaking

The invention discloses a biochemical pretreatment technology of high-hardness and high-salinity papermaking wastewater. The biochemical pretreatment technology comprises a physicochemical treatment step, a conveying step, a strong aeration step, a precipitating step and a discharging step, wherein strong aeration is performed through a jet aeration system adopting variable frequency control and a staggered perforated aeration pipe which are arranged inside a strong aeration tank, so that the papermaking wastewater is fully mixed in the strong aeration tank. The biochemical pretreatment technology of the high-hardness and high-salinity papermaking wastewater, provided by the invention, is simple and feasible, and stable in treatment effect; by the biochemical pretreatment technology, the high-hardness and high-salinity papermaking wastewater can be effectively softened to improve water quality and reduce water hardness and inorganic salt content, so that a requirement on continuous and stable operation of a subsequent biochemical system is met; a whole process is clean and pollution-free, environment-friendly and energy-saving, and very low in running energy consumption and running cost.

Owner:东莞顺裕纸业有限公司

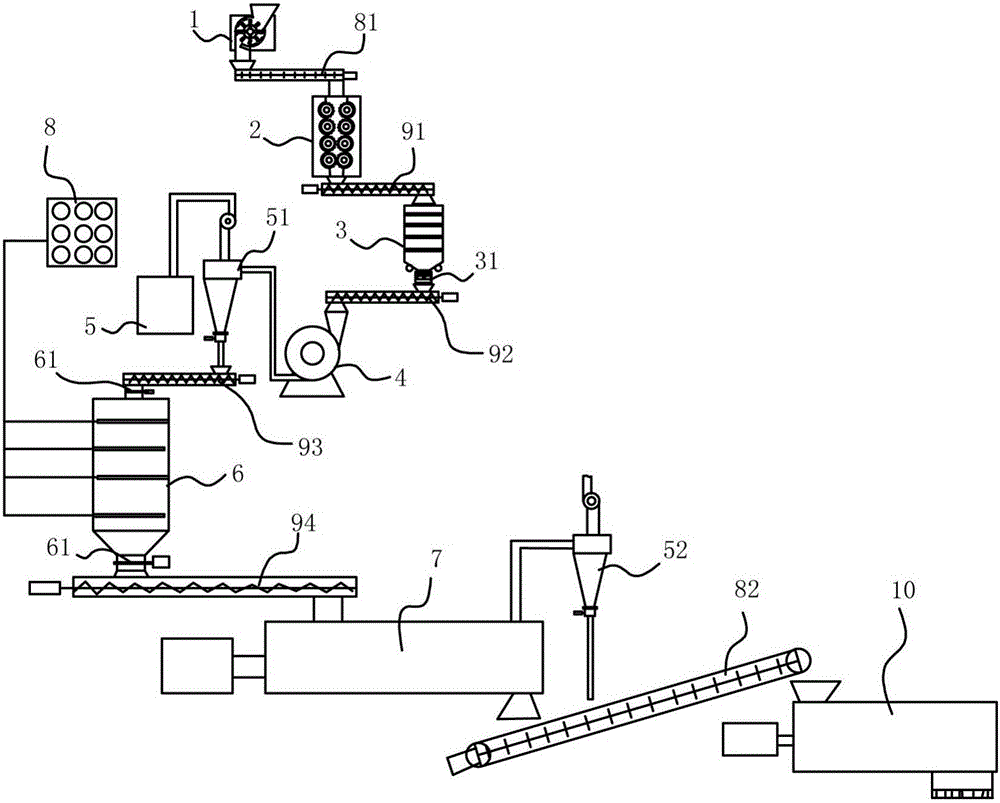

Method for preparing biomass fuel

A method for preparing biomass fuel includes the following steps that firstly, a wood pile is poured into a smashing machine and scattered and broken off by the smashing machine; secondly, the wood pile smashed by the smashing machine is conveyed to a front-stage roller press through a first scraper conveying device, and the wood pile is pressed into wood pile pieces by the front-stage roller press; thirdly, the wood pile pieces are conveyed to an iron removal device through a first spiral conveyer, and iron residues in the wood pile are cleaned out by the iron removal device; fourthly, the wood pile pieces with the iron residues removed are conveyed to a rear-stage smashing device through a second spiral conveyer, and the wood pile is smashed into wood pile powder by the rear-stage smashing device; fifthly, the wood pile powder is conveyed to a softening furnace to be heated and softened by a third spiral conveyer; sixthly, the heated and softened wood pile powder is conveyed to a granulator to be granulated by a fourth spiral conveyer, and biomass fuel particles are prepared.

Owner:YIDU JINGHU BIOLOGICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com