Rubber and plastic micropore shoe material and preparation method thereof

A microporous and shoe material technology, applied in footwear, applications, clothing, etc., can solve the problems of difficulty in ensuring product dimensions, large shrinkage, and wear resistance, and achieve uniform and fine pore structure, uniform foaming, and improved gloss. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

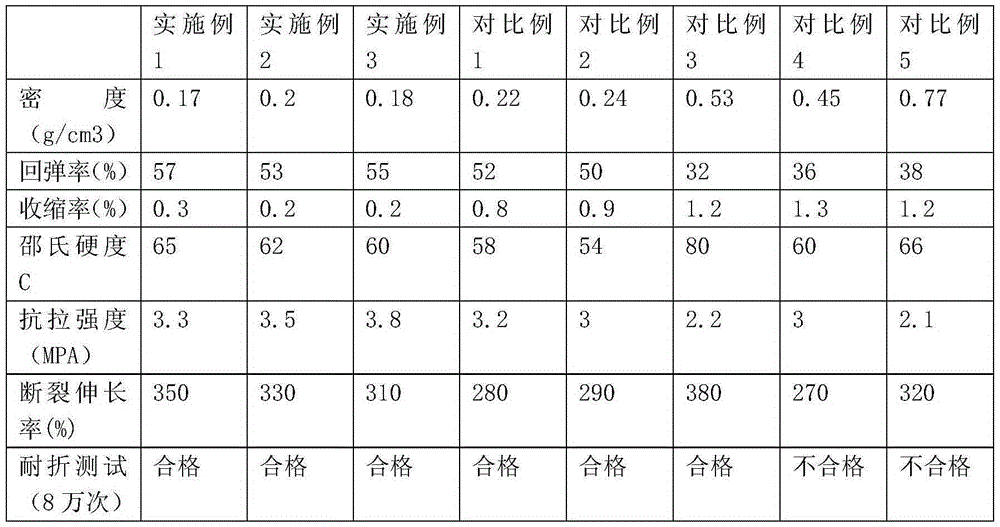

Embodiment 1

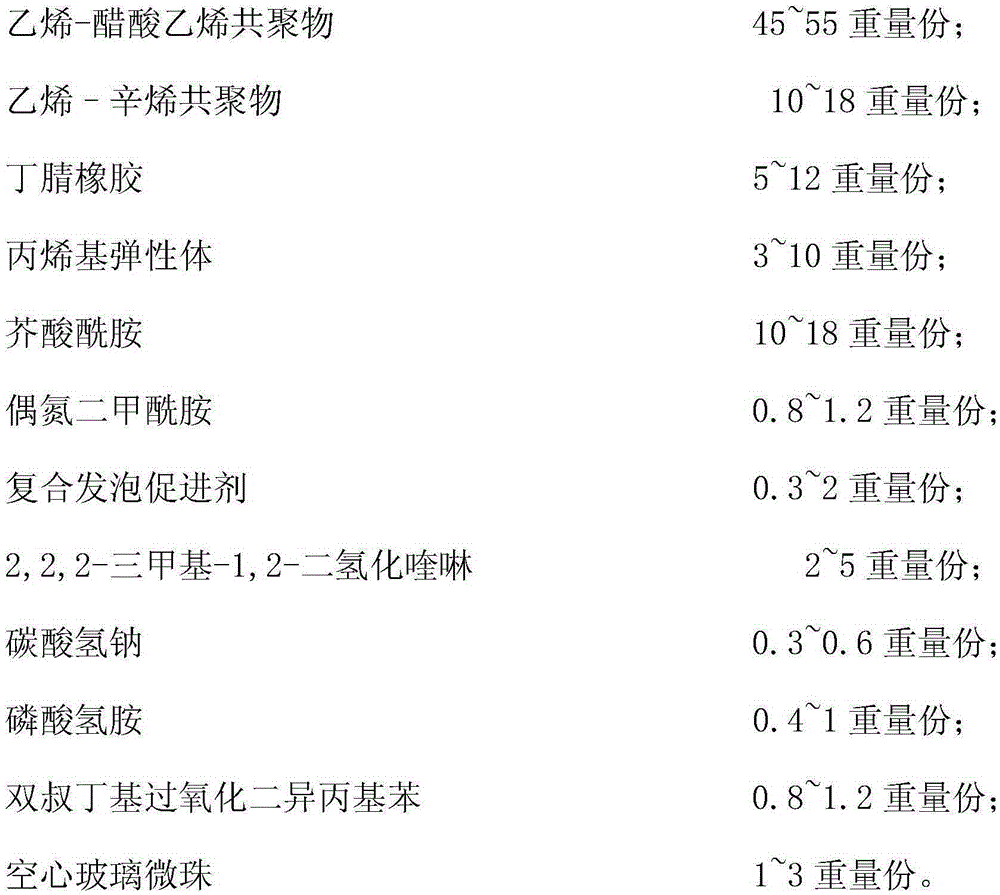

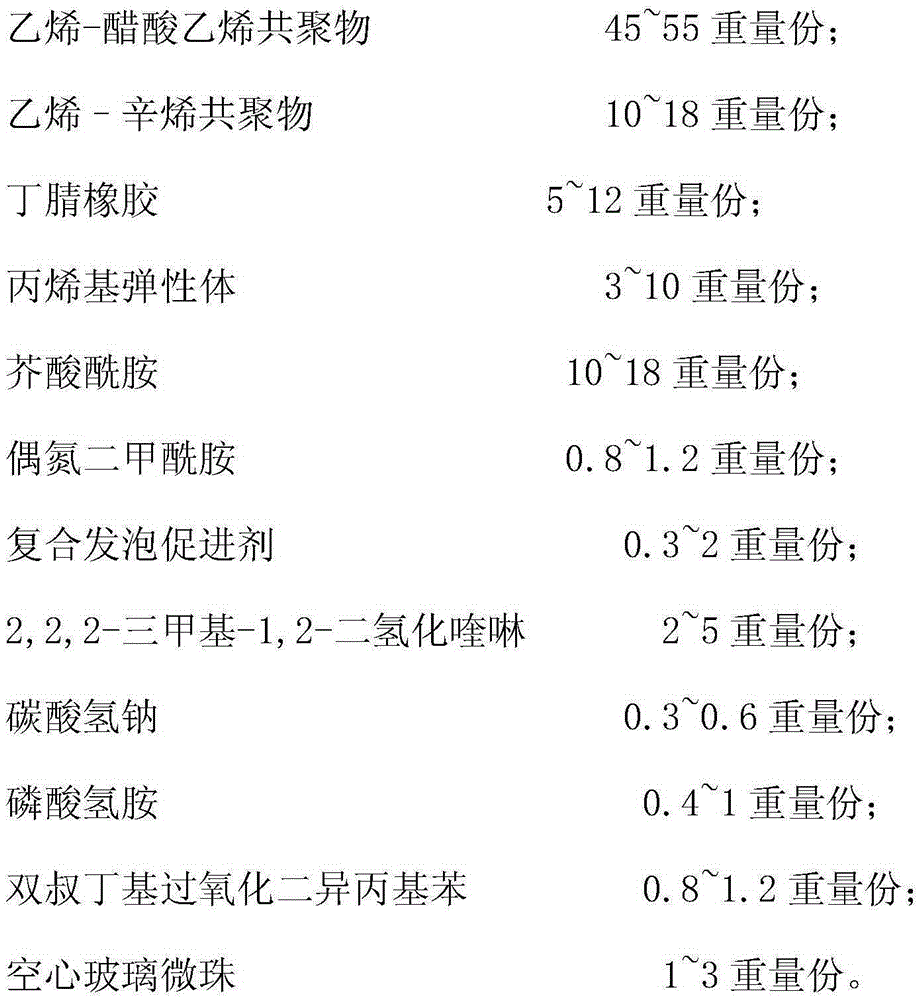

[0022] A rubber-plastic microporous shoe material, consisting of the following components by weight: 45 parts of ethylene-vinyl acetate copolymer; 10 parts of ethylene-octene copolymer; 5 parts of nitrile rubber; 3 parts of propylene-based elastomer; 10 parts of acid amide; 0.8 parts of azodicarbonamide; 0.3 parts of composite foam accelerator; 2 parts of 2,2,2-trimethyl-1,2-dihydroquinoline; 0.3 parts of ammonium hydrogen phosphate; 0.4 parts of sodium; 0.8 parts of dicumyl peroxide; 1 part of hollow glass microspheres.

Embodiment 2

[0024] A rubber-plastic microporous shoe material, consisting of the following components by weight: 55 parts of ethylene-vinyl acetate copolymer; 18 parts of ethylene-octene copolymer; 12 parts of nitrile rubber; 10 parts of propylene-based elastomer; 18 parts of acid amide; 1.2 parts of azodicarbonamide; 2 parts of composite foam accelerator; 5 parts of 2,2,2-trimethyl-1,2-dihydroquinoline; 0.6 parts of ammonium hydrogen phosphate; 1 part of sodium; 1.2 parts of dicumyl peroxide; 3 parts of hollow glass microspheres.

Embodiment 3

[0026] A rubber-plastic microporous shoe material, consisting of the following components by weight: 50 parts of ethylene-vinyl acetate copolymer; 14 parts of ethylene-octene copolymer; 8 parts of nitrile rubber; 7 parts of propylene-based elastomer; 14 parts of acid amide; 1 part of azodicarbonamide; 2 parts of composite foam accelerator; 4 parts of 2,2,2-trimethyl-1,2-dihydroquinoline; 0.4 parts of ammonium hydrogen phosphate; 0.6 parts of sodium; 1 part of dicumyl peroxide; 2 parts of hollow glass microspheres.

[0027] The composite foam accelerators in Examples 1-3 are all composed of chlorinated paraffin, ethylene acrylic acid copolymerized zinc salt and calcium oxide in a weight ratio of 5:5:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com