Method for preparing biomass fuel

A biomass fuel, feed port technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of crusher and granulator damage, irregular shape, large size of wood pile, etc. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

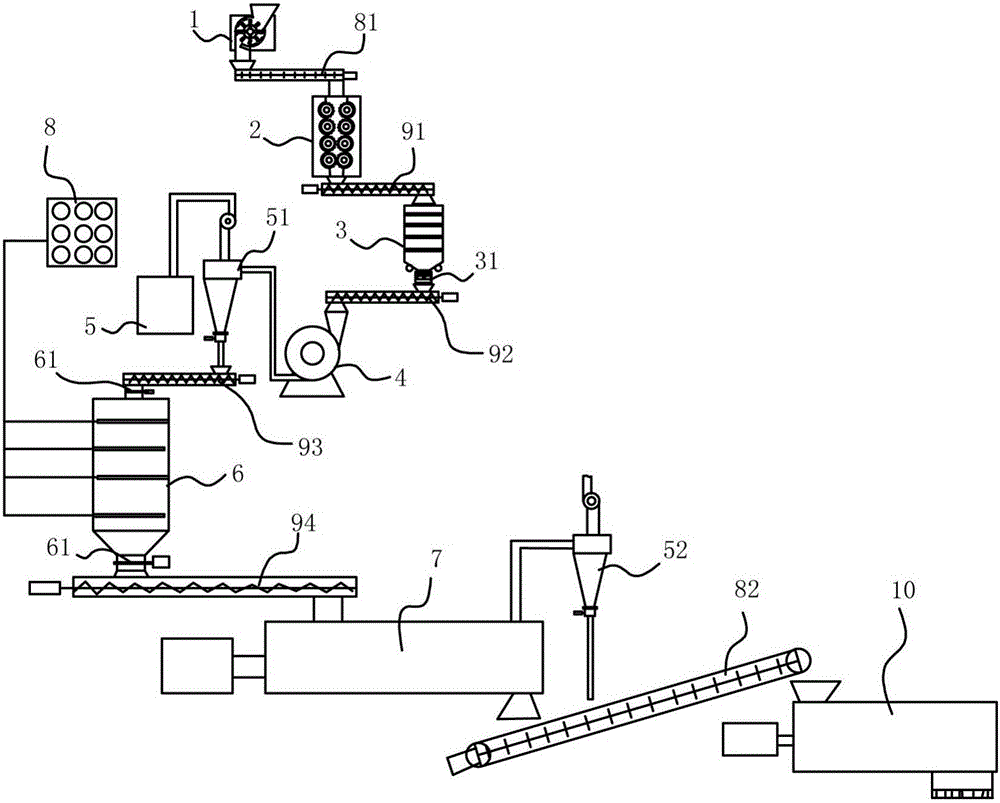

[0033] A method for preparing biomass fuel, comprising the steps of:

[0034] Step 1. Pour the wooden pile into the crusher 1, and break the wooden pile through the crusher 1;

[0035] Step 2, after the wooden piles crushed by the crusher 1 are transported to the front-stage roller press 2 by the first scraper conveyor 81, the front-stage roller press 2 presses the wooden piles into wooden pile sheets;

[0036] Step 3, sending the pile sheet to the iron removal device 3 through the first screw conveyor 91, and the iron removal device 3 cleans out the iron slag in the pile sheet;

[0037] Step 4, the wood pile sheet that has cleaned iron slag is transported to the post-stage crushing device by the second screw conveyor 92, and the post-stage crushing device crushes the wood pile into wood pile powder;

[0038] Step 5, the pile powder is transported to the softening furnace 6 by the third screw conveyor 93 for heating and softening;

[0039] Step 6: Transport the heated and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com