Patents

Literature

116results about How to "Optimum Process Parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

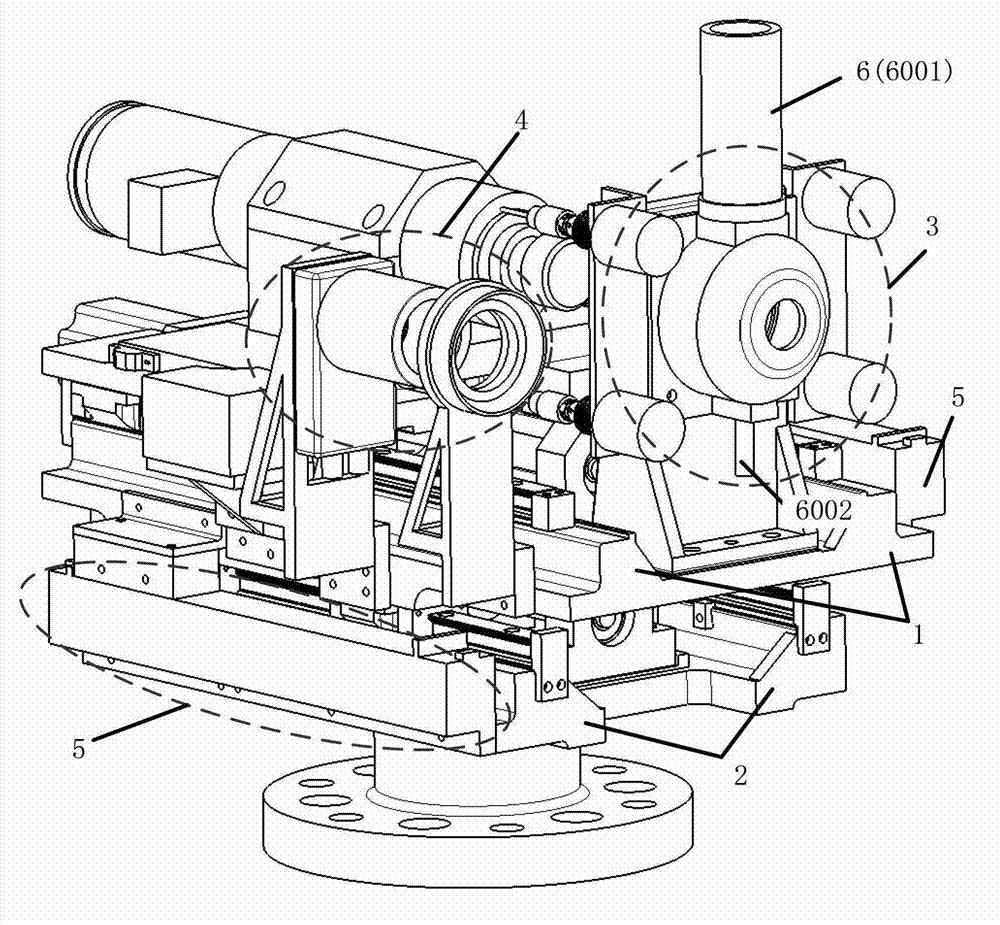

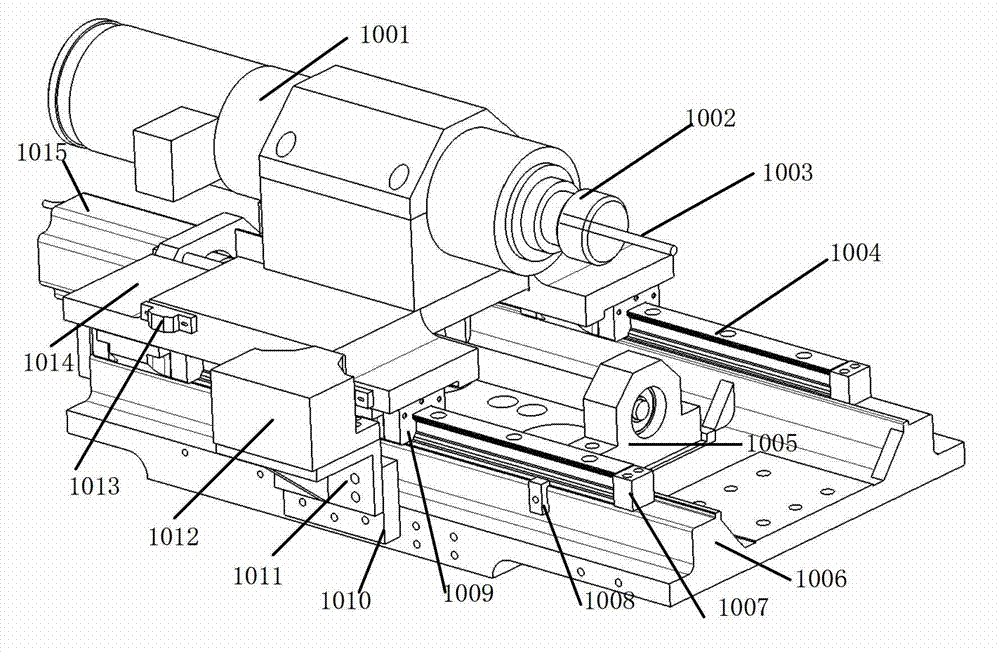

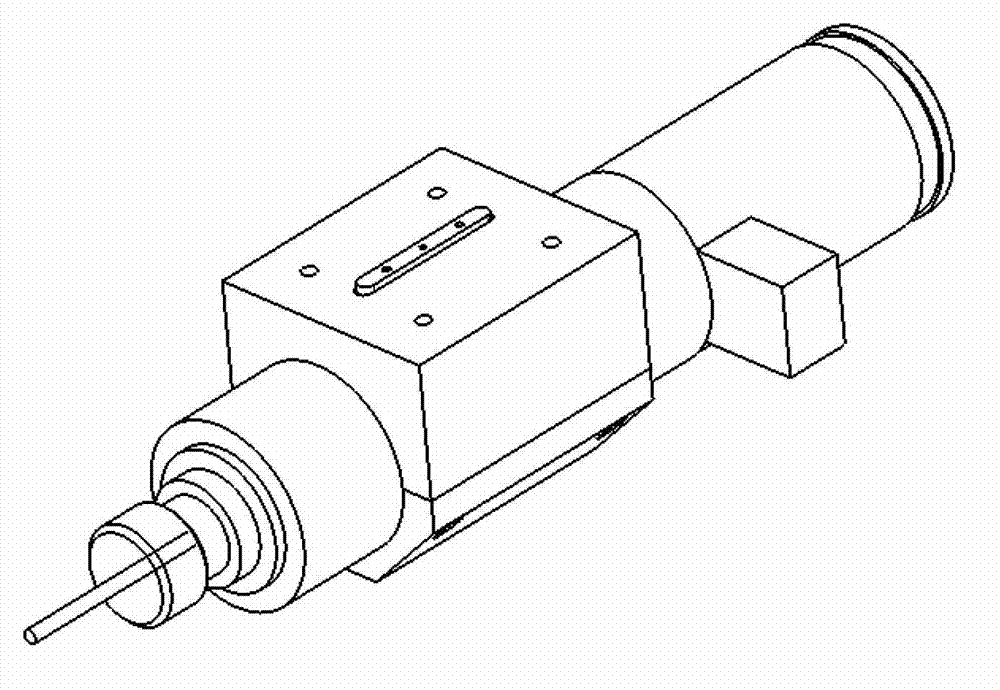

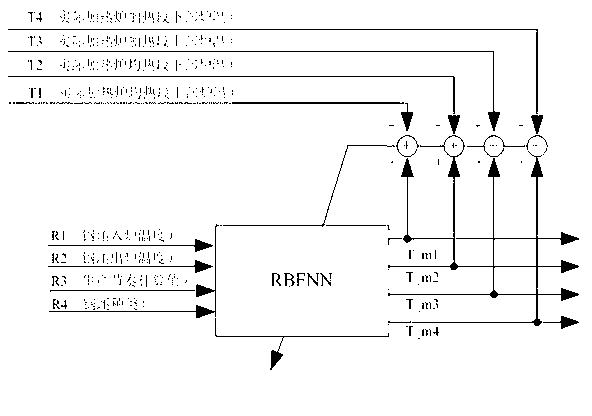

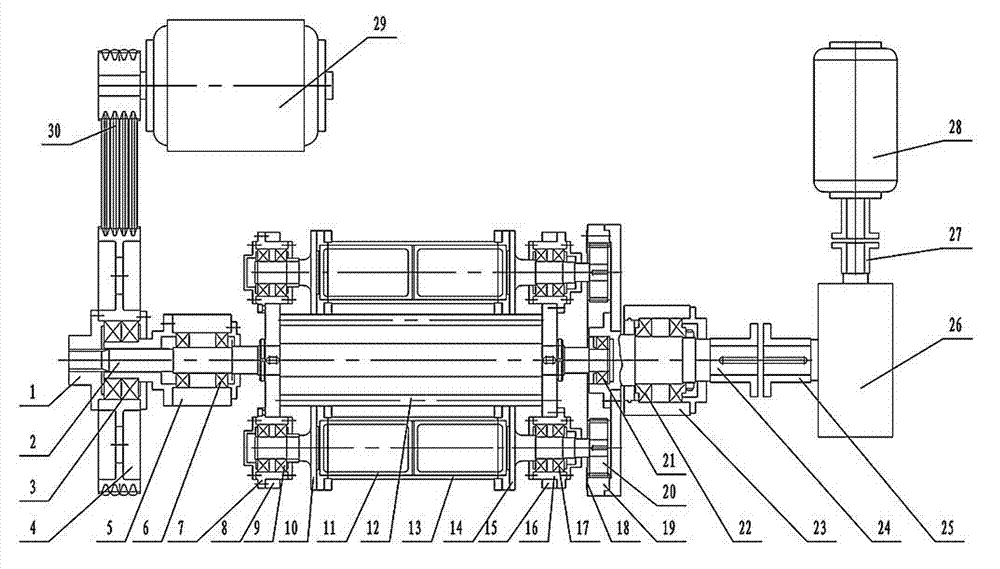

High-accuracy hole forming device for aircraft wall panel and a method of high-accuracy hole forming device

ActiveCN102756138AGuaranteed surface qualityOptimum working parametersAutomatic control devicesMeasurement/indication equipmentsControl systemClosed loop feedback

The invention provides a high-accuracy hole forming device for an aircraft wall panel and a method of the high-accuracy hole forming device. A main shaft module is used for feeding an electric main shaft along a hole forming axis; a feeding module is used for guaranteeing movement of the main shaft module and a pressure pin normal leveling module in the hole forming axis and providing pressure for a pressure pin to be abutted against the wall panel; the pressure pin normal leveling module is used for guaranteeing the stability of the wall panel in the hole forming process; the feeding module is matched with a grating scale module for work to realize accurate control over the hole forming feeding displacement; a visual alignment module and a control system form a closed loop feedback loop; positional deviation error of a projection point of a hole forming main shaft on the wall panel surface and an actual hole forming point can be measured and fed back in real time; and correction is performed through the closed loop system to guarantee that the positional accuracy of a formed hole is within a tolerance requirement range. According to the high-accuracy hole forming device, the positional accuracy, the surface roughness and the dimensional accuracy of the hole can meet the design requirements well; and meanwhile, slanting holes and oblique holes are not formed in the hole forming process, the temperature of a hole forming region is kept at a normal working temperature and the chip removal is normal.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

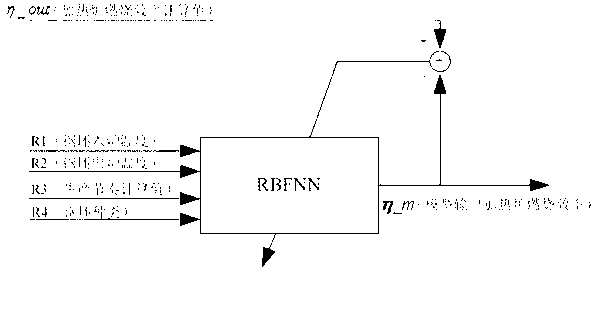

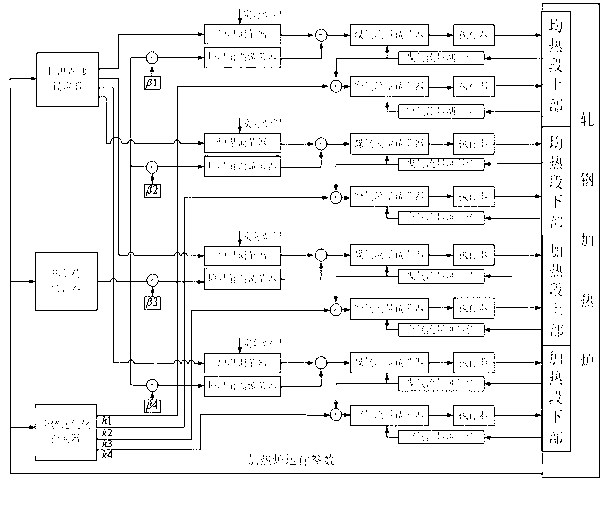

Optimal control system for steel rolling heating furnace

ActiveCN103019097AGuaranteed control accuracyGuaranteed stabilityAdaptive controlFurnace temperatureOptimal control system

The invention discloses an optimal control system for a steel rolling heating furnace, relating to the technical field of steel rolling of a heating furnace. Firstly, an on-line furnace temperature setting device is established according to different billet types, production rhythm, billet initial temperature and billet tapping temperature; the billet tapping temperature is controlled by controlling the temperature of the furnace; based on heat efficiency models under various working conditions, the loading variation of the heating furnace is calculated and taken as a feedforward value of the furnace temperature, and the high-accuracy control on the temperature of the heating furnace under loading fluctuation is realized; and on the basis, an optimal air-fuel ratio is found by establishment of an air-fuel ratio optimal control model, so that the heating furnace achieves an optimal burning condition and the aims of saving fuel and lowering steel loss are achieved.

Owner:北京和隆优化科技股份有限公司

Hazard-free treatment and utilization method for aluminium electrolysis waste slot liner

ActiveCN106565120AEfficient and reasonable useAvoid wasting timeSolid waste managementAluminium electrolysisBrick

The invention relates to a hazard-free treatment and utilization method for an aluminium electrolysis waste slot liner. The hazard-free treatment and utilization method is characterized by comprising the steps of (1) performing sorting and separating on the aluminium electrolysis waste slot liner based on an aluminium electrolysis waste negative electrode carbon material and a waste fireproof material; (2) performing smashing separately; (3) performing powder grinding separately; (4) measuring content values of cyanogen and fluorine;(5) adding a solid cyanogen removal agent and a solid fluorine removal agent, and performing material mixing; (6) performing a cyanogen removal and fluorine removal and neutral reaction on the waste fireproof material; (7) performing a cyanogen removal and fluorine removal reaction on the waste negative electrode carbon material; (8) pressing and filtering material slurry obtained in the step (6), recycling the filtering liquid, and taking filtering slag for road pavement; and (9) pressing and filtering material slurry obtained in the step (7), recycling the filtering liquid, and taking filtering slag as carbon brick for manufacturing a blast furnace. By adoption of the hazard-free treatment and utilization method, different kinds of waste materials in the waste slot liner are processed, respective optimal technological parameters specific to different kinds of waste materials are selected, and the hazard-free slag can be sorted and reasonably recycled.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

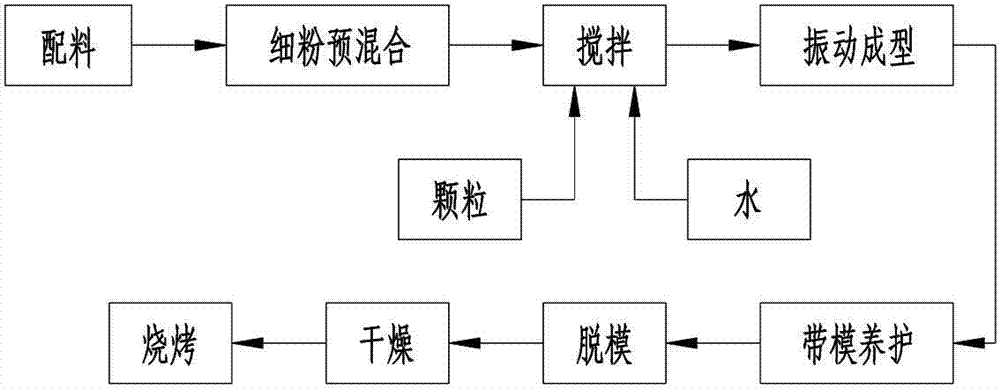

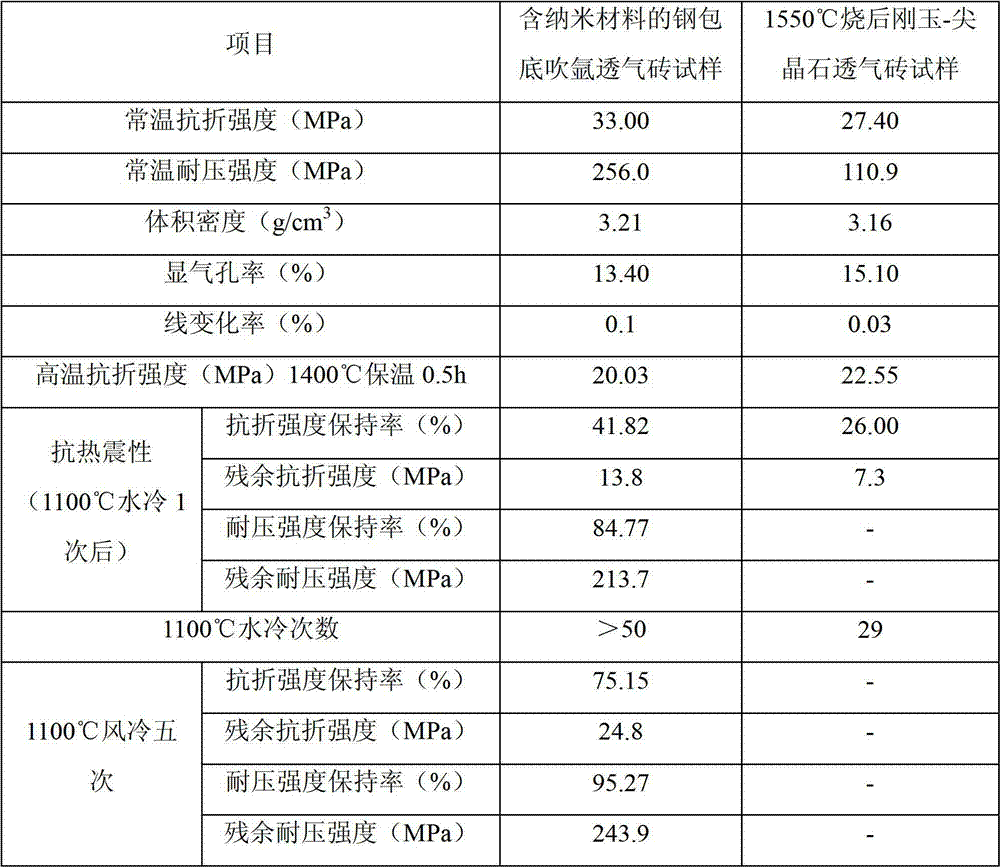

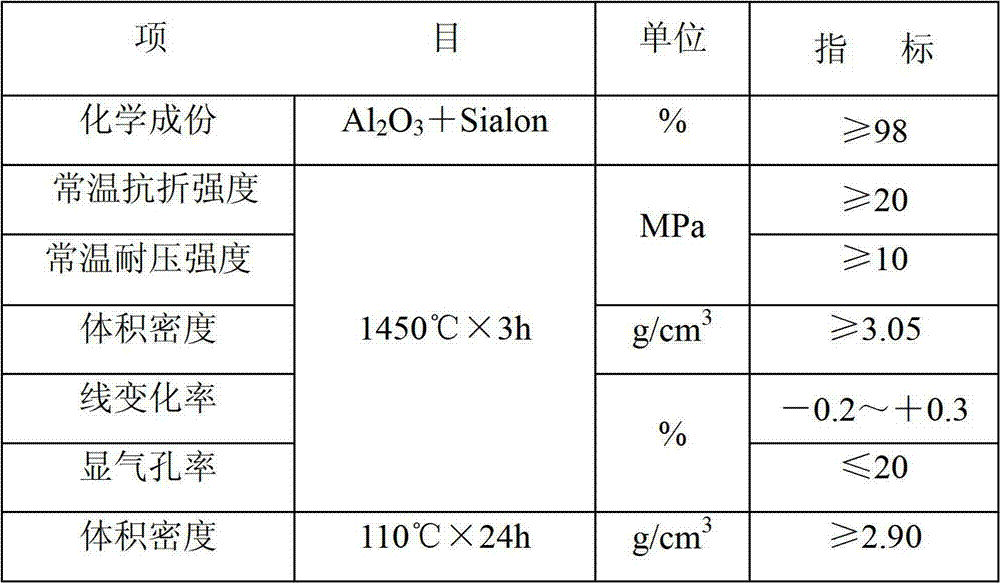

Nanometer material contained ladle bottom argon blowing permeable brick and preparation process thereof

The invention discloses a nanometer material contained ladle bottom argon blowing permeable brick and a preparation process thereof. The permeable brick comprises components of high-purity corundum, spinel, alpha-Al2O3 micro powders, nano calcium carbonate, Si powders, binding agents and antiknock agents. The preparation process of the nanometer material contained ladle bottom argon blowing permeable brick includes the following steps of dosing, fine powder premixing, stirring, vibration forming, curing with molds, demolding, drying and baking. According to the nanometer material contained ladle bottom argon blowing permeable brick and the preparation process thereof, Cr2O3 is not used, and during usage, new pollutants are not generated, so that pollution treatment costs are reduced, and high environmental benefits are achieved; micropores are evenly distributed in the brick, so that cracks are effectively prevented from continuing spreading during usage, the toughness of the permeable brick is improved, the spalling is reduced, the service life of the permeable brick is prolonged, the permeable brick is basically free from bonding slag after usage, cleaning during usage is reduced, and production costs of iron and steel enterprises are reduced.

Owner:成都府天新材料科技有限公司

Steam explosion technique testing desk

InactiveCN101361588ADecompose fullyIncrease energy densityPressurized chemical processFood shapingFiberThermodynamics

The invention relates to a test device for determining parameters of steam explosion technology, belonging to physics test equipment. In the current technology mode, which realizes steam explosion through fast valve opening, long pressure release time reduces the energy density, so the material decomposition degree is low, little facilitating later enzymatic hydrolysis. The technological test bench based on the principle of cylinder explosion piston provided by the invention can finish the steam explosion within milliseconds, improving the energy density and fully decomposing the material. The technical principle of the test bench is also reflected in the design of industrial steam explosion devices, which accurately simulates the production environment for future industrialization of steam explosion and, thereby, accurately determining parameters of the steam explosion technology and providing fiber pretreatment materials for metaphase experiments of biochemical treatment such as enzymatic hydrolysis and the like. Experiments of the invention are relatively independent, creating conditions for contrast tests and final parameter determination.

Owner:于政道

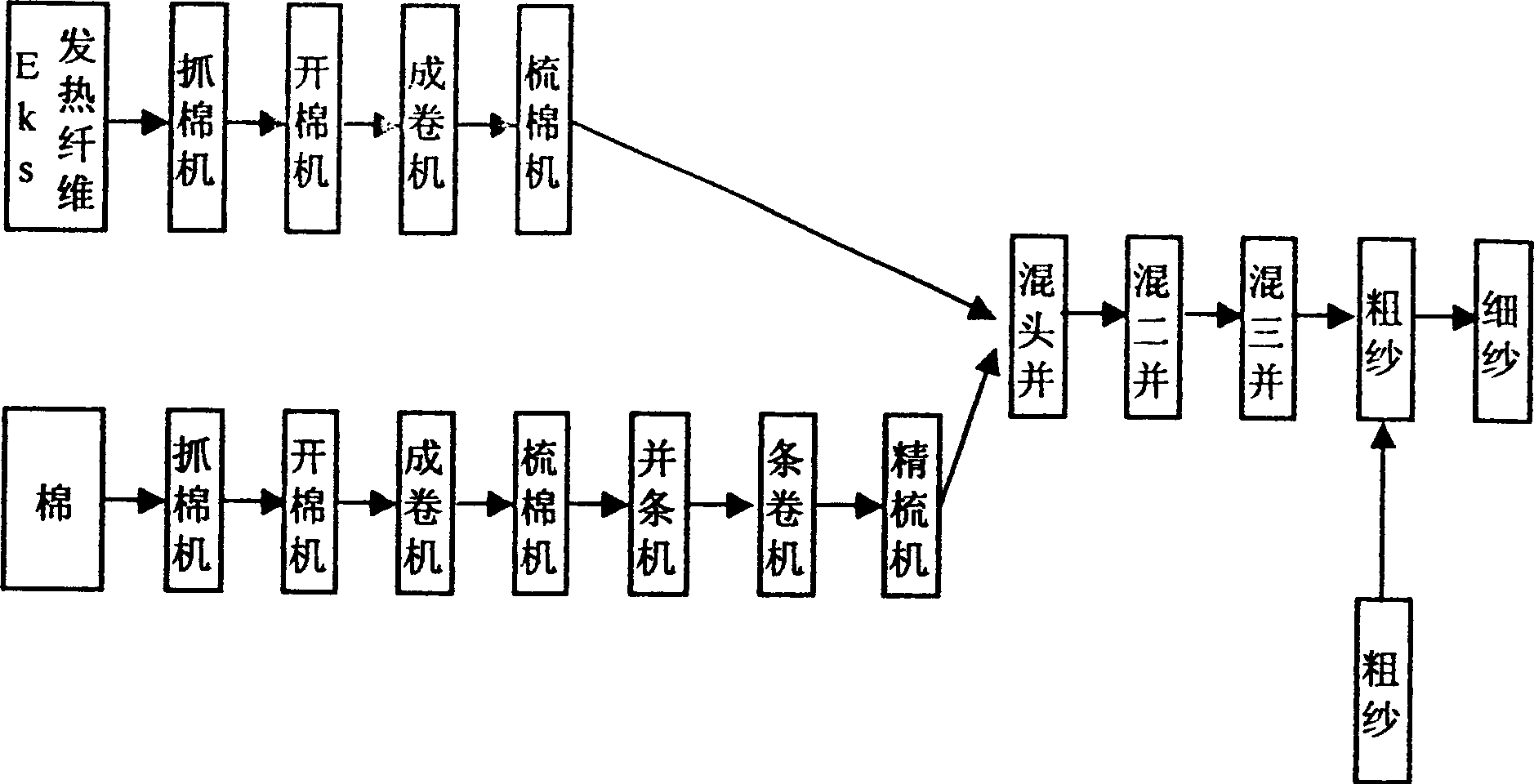

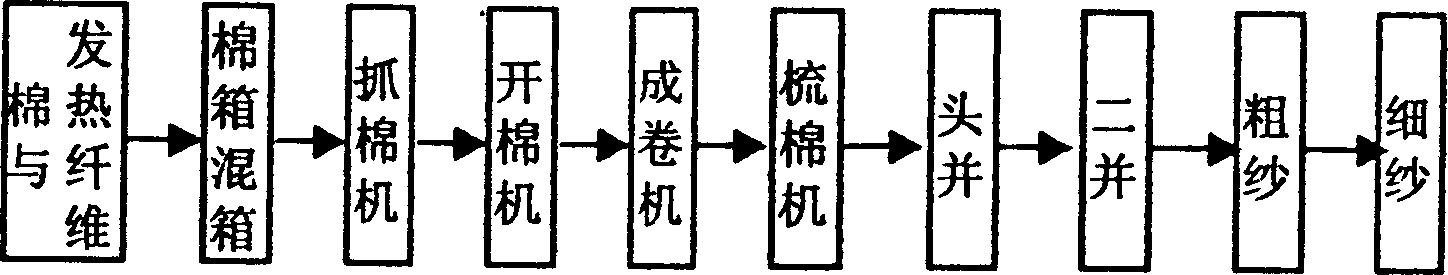

Blended yarn spun by heat generating fiber, cotton and acrylic staple fiber and its production process

InactiveCN1702211AStable and good qualityQuality improvementMonocomponent synthetic polymer artificial filamentYarnYarnManufacturing technology

This invention relates to a blended spun yarn and a technology to produce it. The blended spun yarn is formed from heating fabric and cotton fibre or acrylic fibre. The manufacturing technology uses the common device of the cotton mill, characterized in that it uses the drawing mixing method to blend the heating fabric and combed cotton, while uses the hopper mixing method to blend the heating fabric EKS and the acrylic fibre. The beating speed of the beater in the making process will decrease to 650-750r / min, licker-in speed is 450-500r / min, cylinder speed is 180-210r / min, shuttering speed is 80-100mm / min, and the mixing radical is best to be eight, the stator of rove is 3.8-4.2g / 10m. The technical project can allocate the best processing parameter and get the stable and good textile.

Owner:SHANGHAI NO 17 COTTON TEXTILE MILL

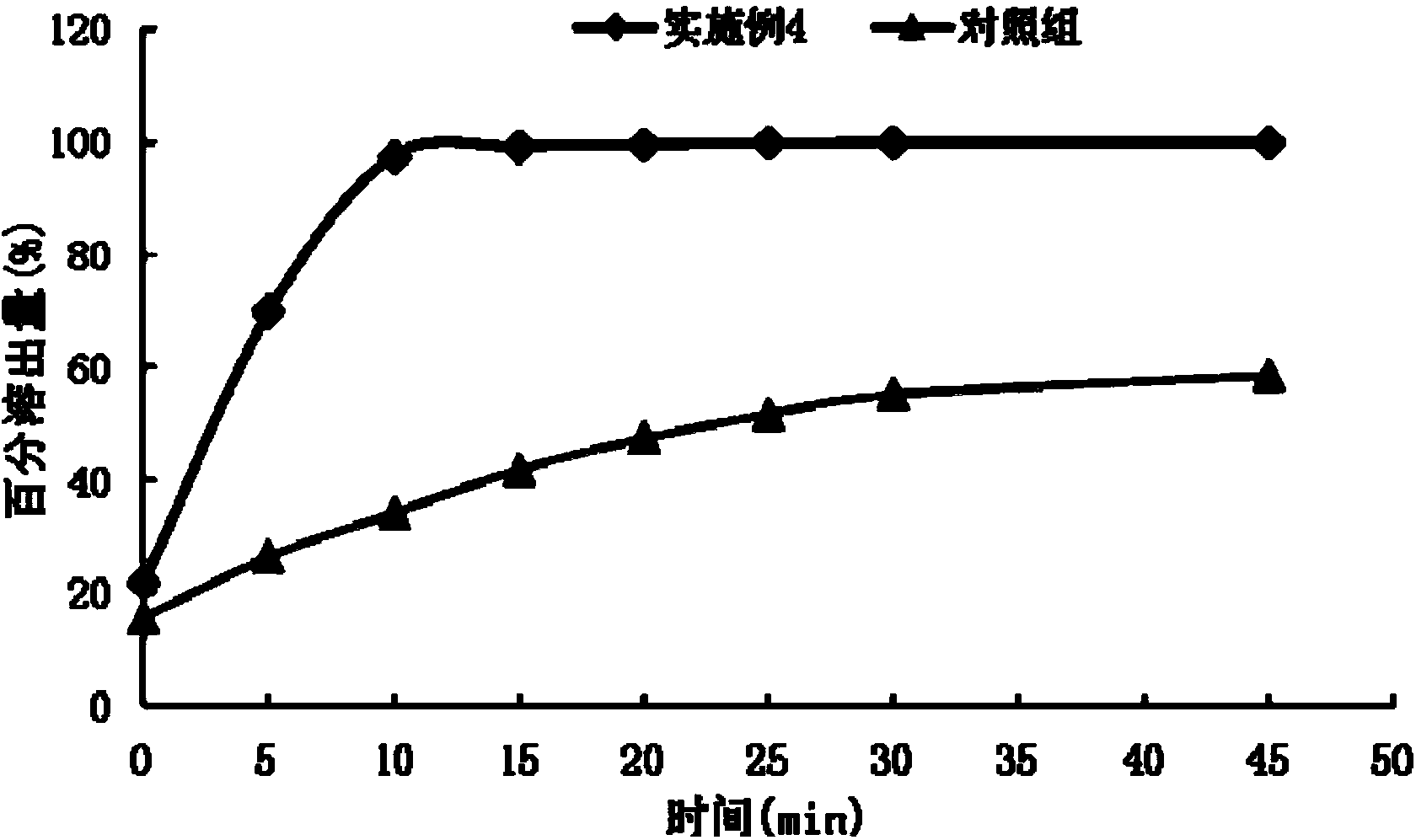

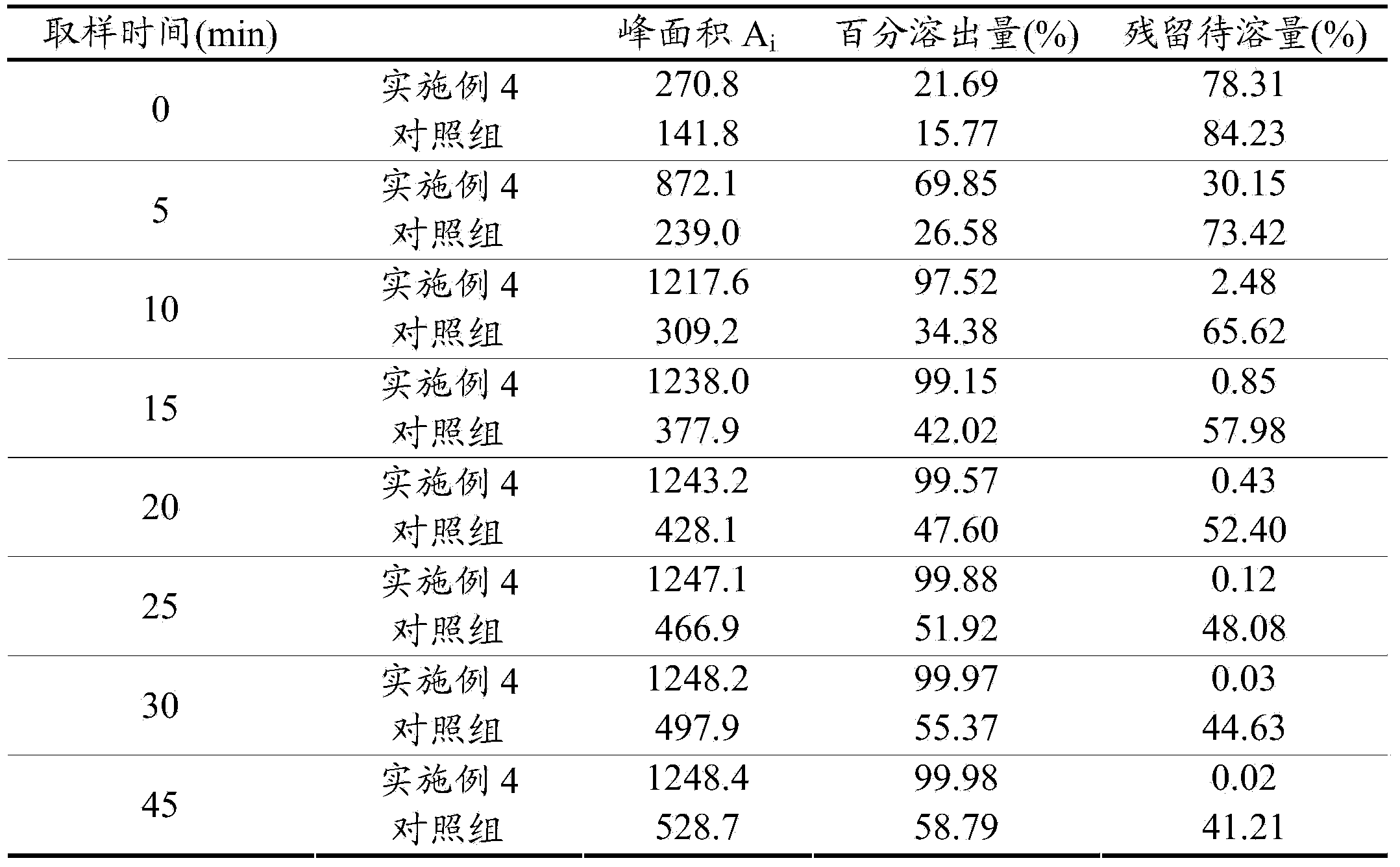

Immunopeptide freeze-dried powder and preparation method thereof

ActiveCN103555799AOptimum Process ParametersThe advantage of the experimental results is significantly improvedPeptide preparation methodsDepsipeptidesFreeze-dryingHigh pressure

The invention discloses immunopeptide freeze-dried powder and a preparation method thereof, belongs to the technical fields of deep-processing of agricultural products and comprehensive utilization of by-products thereof, and relates to immunopeptide freeze-dried powder and a preparation method thereof. With any one of corn gluten meal, wheat protein powder, rice protein powder, soyabean protein powder, mung bean protein powder and poultry and egg white powder as a raw material, a process route comprising superfine grinding of designed raw material, blending and homogenizing of a protein solution, controlled enzymatic hydrolysis under an environment of a high-voltage pulsed electric field, low-temperature enzyme deactivation, low-temperature centrifugation, low-temperature membrane separation and vacuum freeze drying is realized, wherein the moisture content of the raw material is 1.0-5.0% and the protein content of the raw material is 40-70%; the immunopeptide freeze-dried powder of which the moisture content is 1.2-1.8%, the protein content is 72-86% and the molecular weight is 10-30 kDa is obtained. Compared with a control group, an immune activity evaluation experiment proves that the multiplication capacity of splenic lymphocyte of mice of an experimented group is significantly improved.

Owner:JILIN UNIV

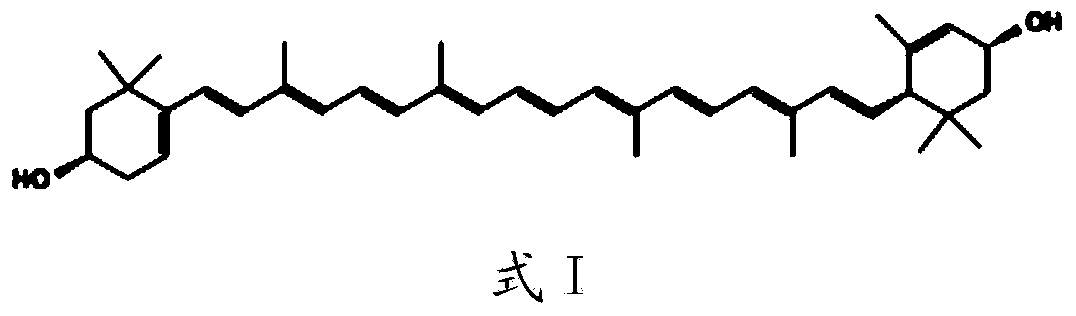

Lutein water soluble powder and preparation method thereof

ActiveCN103860476AOptimum Process ParametersSimple methodPowder deliverySenses disorderSolubilityLutein

The invention discloses lutein water soluble powder and a preparation method thereof. The preparation method comprises the following steps: dissolving lutein, a water soluble carrier, a surfactant and an additive into an organic solvent at a weight ratio of 1:(5-20):(1-5):(0-3) under the condition of 20-60 DEG C; spray-drying so as to remove the organic solvent after the components are totally dissolved. Based on a lot of experiments and research made by the inventor, the optimal technological parameters of the lutein water soluble powder are obtained by using the spray drying method for preparation, and the optimal raw materials for preparing the water soluble powder and the ratio of the raw materials are determined; the method is simple, economical and practical, is easily operated, and is suitable for large-scale production; the lutein water soluble powder prepared according to the method has high water solubility, high stability, homogeneous color and good fluidity, has the solubility of 95 percent above in water, and can be widely used in the fields of food, medicines and the like, so that the application range of lutein is greatly enlarged.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

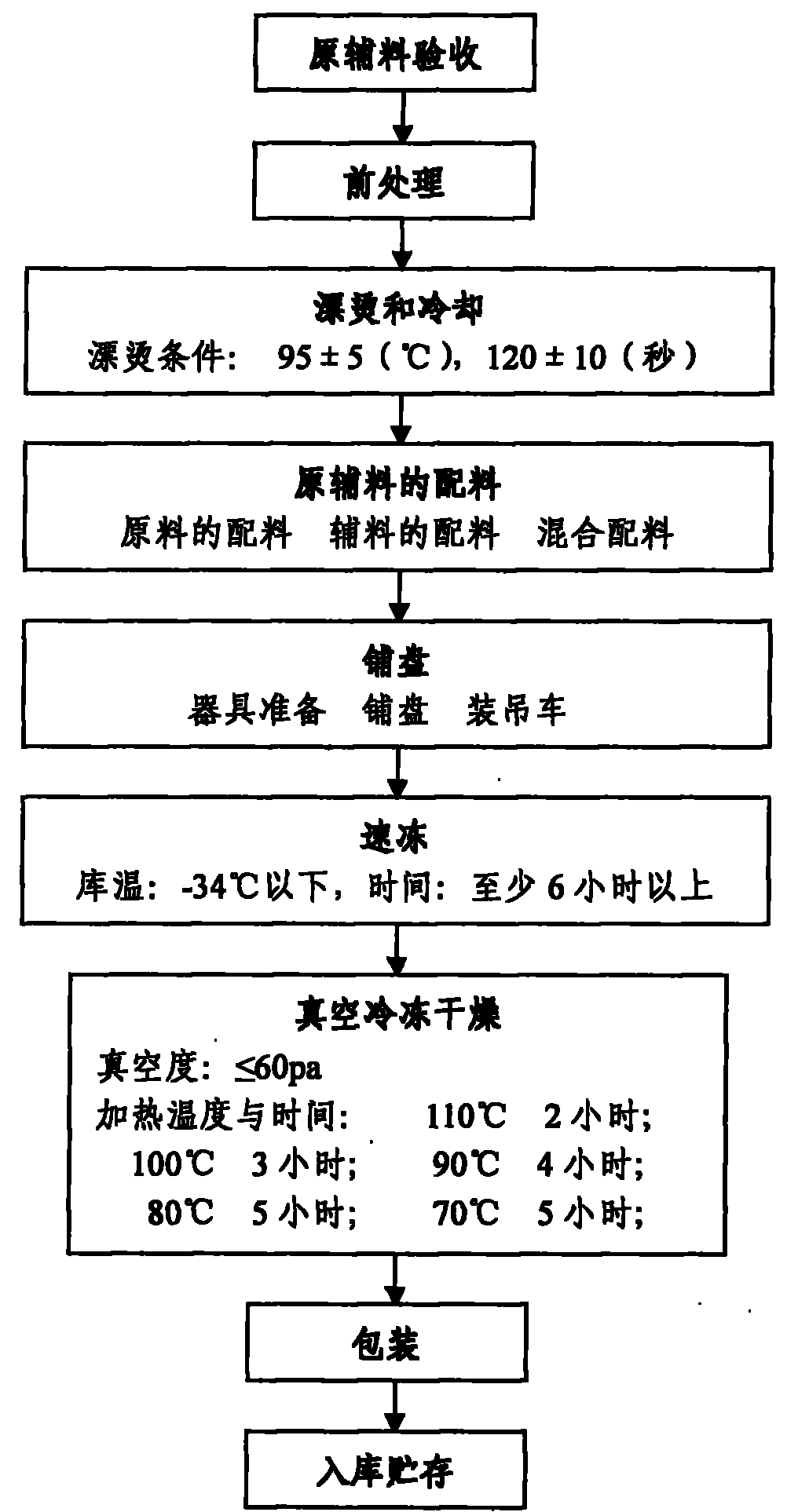

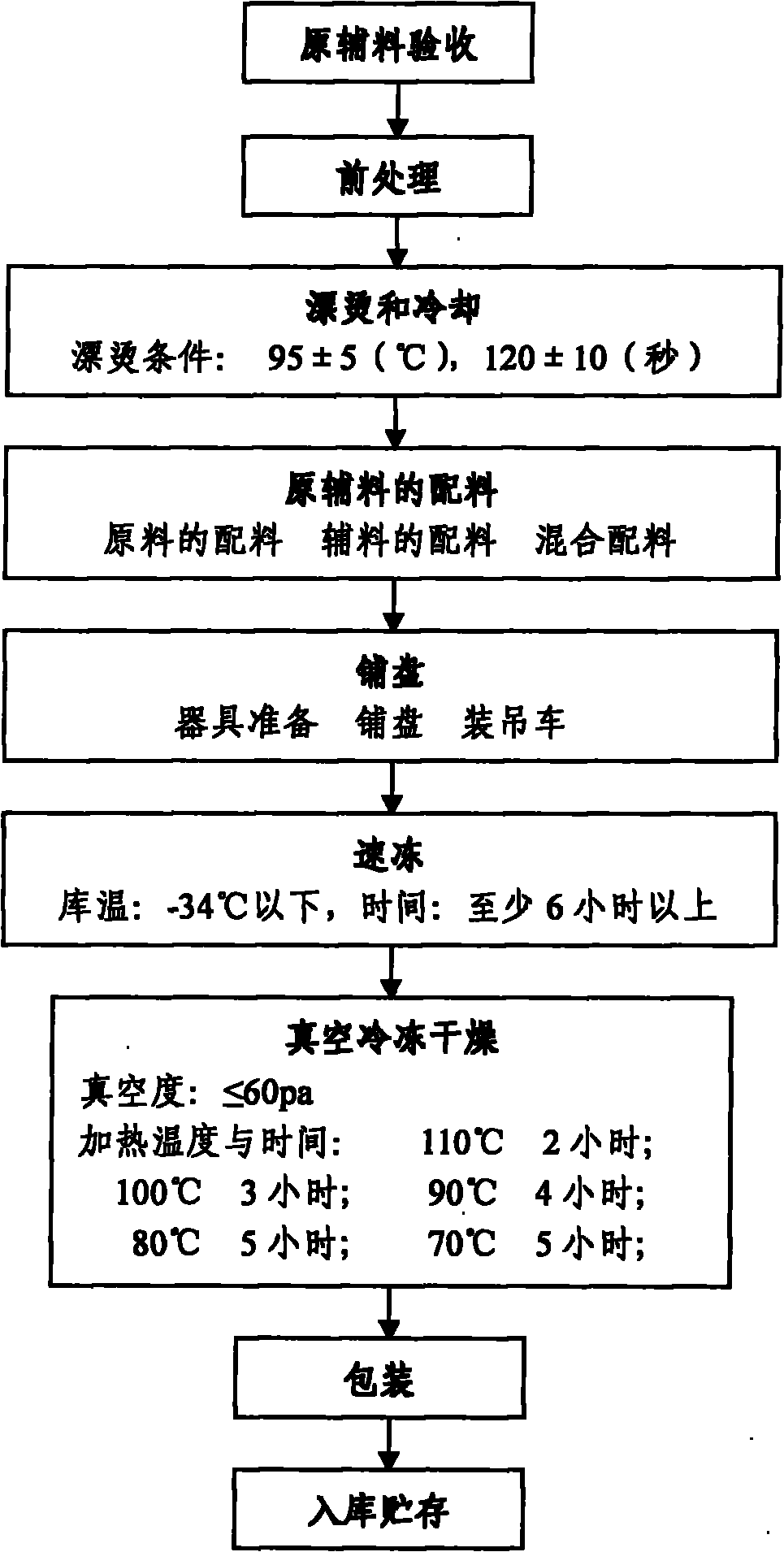

Industrialized production method for convenient soup of edible fungi

The invention provides an industrialized production method for convenient soup of edible fungi. The method comprises the processes of pretreatment, blanching and cooling, proportioning, quick freezing, and vacuum freezing and drying. The optimal industrialized production method for a freeze-dried fungi soup product is determined by controlling process parameters and process flows; the technical problems of non-uniform fungi slice suspension and difficult control of freeze-drying moisture of the edible fungi product are solved; a new industrialized production method is provided for the field of edible fungi processing; and the economic benefit of the culture industry of the edible fungi is improved. By the method, the high-nutrition convenient soup which has fresh flavor, is convenient to eat and does not contain excessive oil in large scale can be effectively produced on a large scale.

Owner:山西山宝食用菌生物有限公司

Method for producing functional grease containing rich phytosterin ester from high-acid-value vegetable oil

ActiveCN104178531ARealize the processing effectRealize high-value utilizationFermentationOil and greaseVegetable oil

The invention relates to a method for producing functional grease containing rich phytosterin ester from high-acid-value vegetable oil. The method is characterized by comprising the following steps: (1) addition of reaction raw materials: adding phytosterin, high-acid-value grease and molecular sieve into a reaction kettle, adding 100-200ppm of antioxidant, heating to 45-60 DEG C, stirring and carrying out ultrasonic treatment to obtain a premixture, wherein the mole ratio of the phytosterin to free fatty acids in the high-acid-value grease is 1:1-5:1; (2) enzymatic ester exchange reaction: adding 5-40 g / L lipase into the premixture, and stirring to react at 45-60 DEG C under normal pressure for 6-12 hours; and (3) carrying out after-treatment on the product to obtain the functional grease containing rich phytosterin ester. The method can obviously lower the acid value of the high-acid-value vegetable oil and generate the new functional active component phytosterin ester, and the product is simple for separation and purification; and thus, the method can easily implement large-scale amplification.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

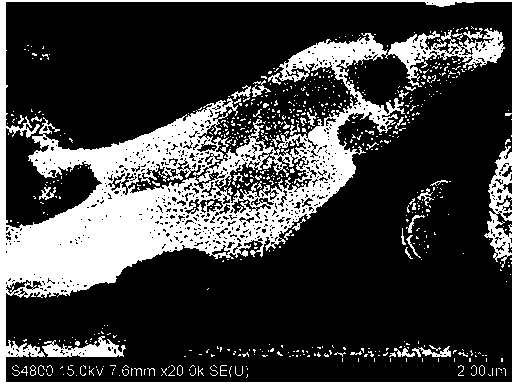

Method for preparing nano porous silicon by utilizing doped silicon particles

ActiveCN103985848AIncrease concentrationHigh hole densityCell electrodesSecondary cellsHydrofluoric acidReaction temperature

The invention discloses a method for preparing nano porous silicon by utilizing doped silicon particles. The method comprises the following steps: selecting silicon particles with a certain doping concentration, washing with hydrofluoric acid, then enabling the silicon particles to react in a solution which is prepared by selecting nitrate, hydrofluoric acid and oxidant with assistance of ultrasonic process centrifugally washing the silicon particles, and finally washing the silicon particles by using dilute nitric acid to obtain the three-dimensional nano porous silicon. The optimal process parameters such as best constitution of chemical etching corrosive agent, volume ratio and specific concentration of a reaction reagent, reaction time, reaction temperature, ultrasonic frequency, processing time and the like are screened out through a great number of experiments, and the prepared high-purity three-dimensional doped porous silicon is regular in pore shape, uniform in distribution and applicable to the fields such as lithium batteries, solar batteries, semiconductors and sensors. The method is strong in process maneuverability, low in cost, high in yield and applicable to industrialized mass production.

Owner:南京卓胜自动化设备有限公司

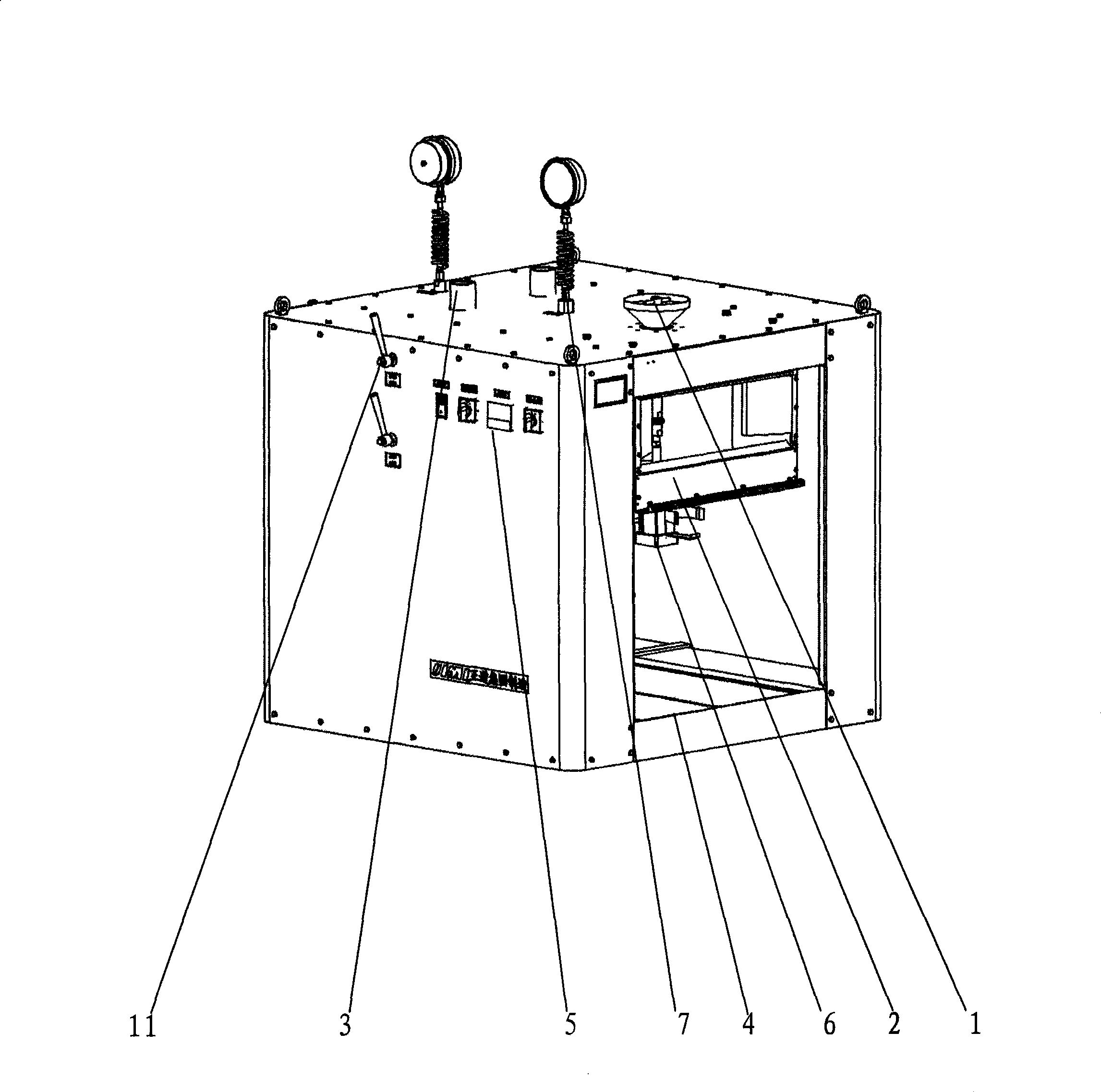

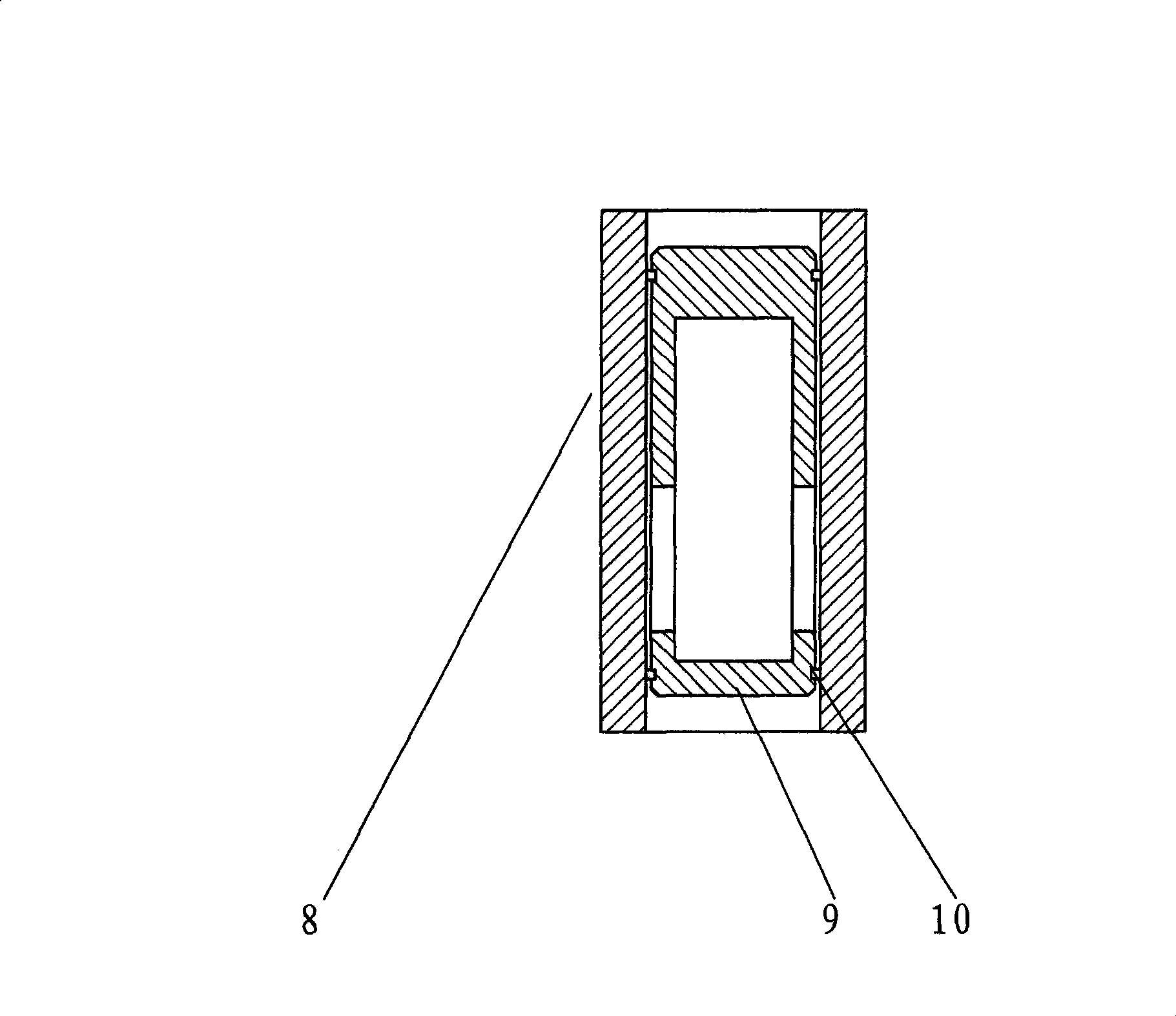

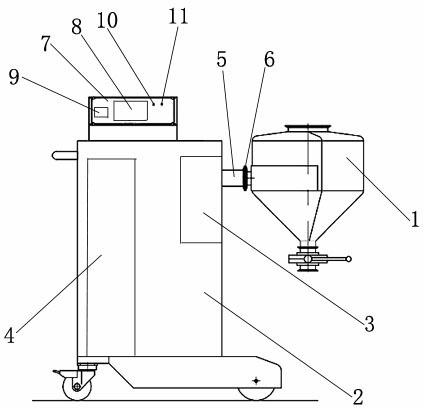

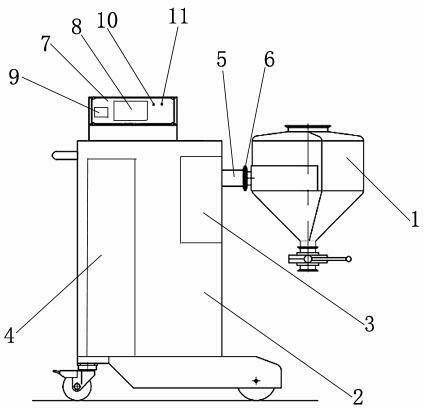

Laboratory hopper mixing machine

InactiveCN102688718AWell mixedOptimum Process ParametersRotating receptacle mixersMixing methodsControl systemPower switching

The invention discloses a laboratory hopper mixing machine, comprising a hopper, a base, and a rotation system and a control system disposed in the base. A rotation shaft is arranged at one side of the base, and is connected with the rotation system. The hopper is mounted on the rotation shaft and is fixed in a way as a cantilever is fixed, an included angle is formed between the hopper and the rotation shaft, and a sensing element is disposed in the rotation shaft assembly. An operation panel is disposed above the base, and the operation panel is provided with a touch screen that displays running time, rotation speed and accumulated turns of rotation, a printer, a power switch and an emergency stop switch. The laboratory hopper mixing machine can rotate 360 degrees to realize more thorough mixing, and rotation speed, accumulated turns of rotation and running time are displayed on the touch screen, so that optimal process parameters can be explored based on mixing results.

Owner:NANJING HUAITENG MACHINERY TECH

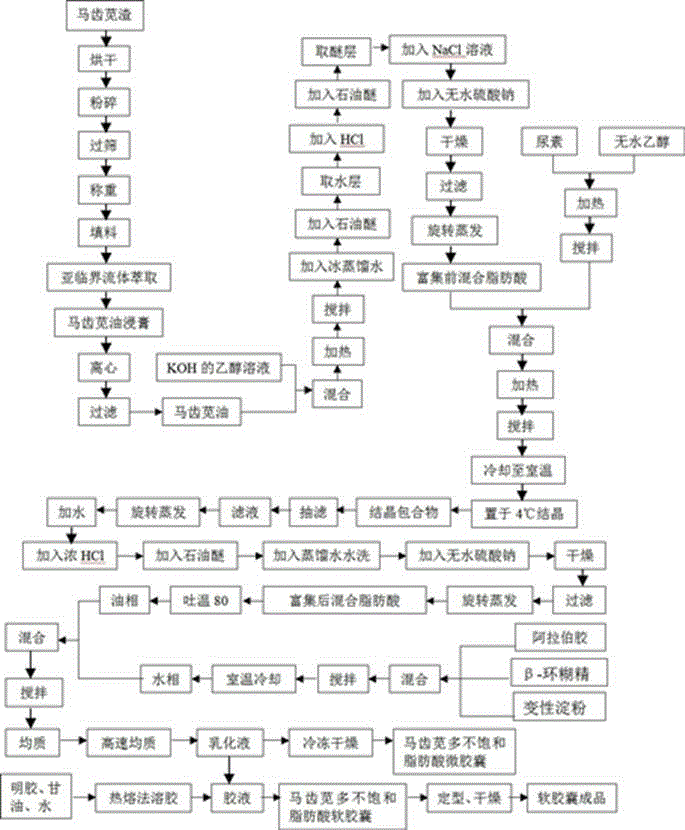

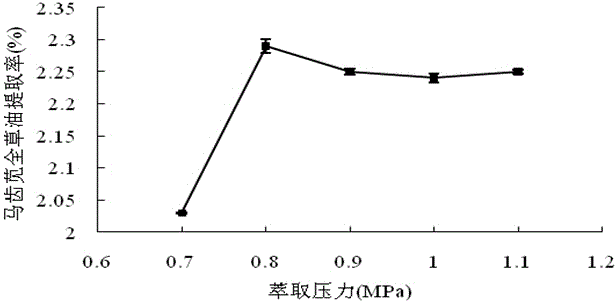

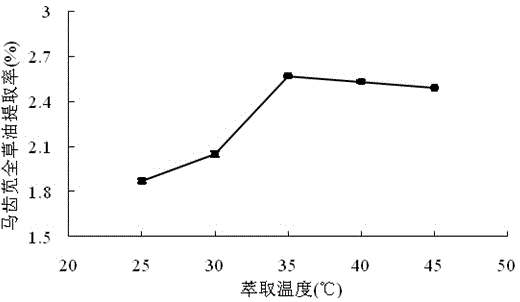

Method of preparing purslane polyunsaturated fatty acids from purslane residues

ActiveCN104059774AOvercoming technical bottlenecksGreat application valueFatty acid chemical modificationFatty acids production/refiningUnsaturated fatty acidSoft gel capsule

The invention discloses a method of preparing purslane polyunsaturated fatty acids from purslane residues. The method comprises the following steps: selecting the purslane residues; raising the extraction pressure of subcritical fluid extraction by 0.8MPa and raising the extraction temperature by 40 DEG C, and extracting for 150 minutes; saponifying and hydrolyzing to prepare a fatty acid mixed before enrichment; heating and stirring urea and anhydrous ethanol for reflux at 60 DEG C in a ratio m / m of urea and fatty acid mixed before enrichment of 1 to 1 and in a ratio m / v of fatty acid mixed before enrichment and ethanol of 1 to 16; after dissolving urea and uniformly mixing with the fatty acid mixed before enrichment, heating and stirring for reflux for 20 minutes; cooling to room temperature; crystallizing for 24 hours at 4 DEG C; filtering to obtain the fatty acid mixed after enrichment. Verified by diabetic rat test, the prepared purslane polyunsaturated fatty acid microcapsule and soft capsule can effectively reduce the levels of blood glucose and insulin and have wide application value and prospect in preparing foods or medicines for preventing and treating diabetes.

Owner:XINJIANG UNIVERSITY +1

Preparation method and application of insoluble and soluble squid melanin

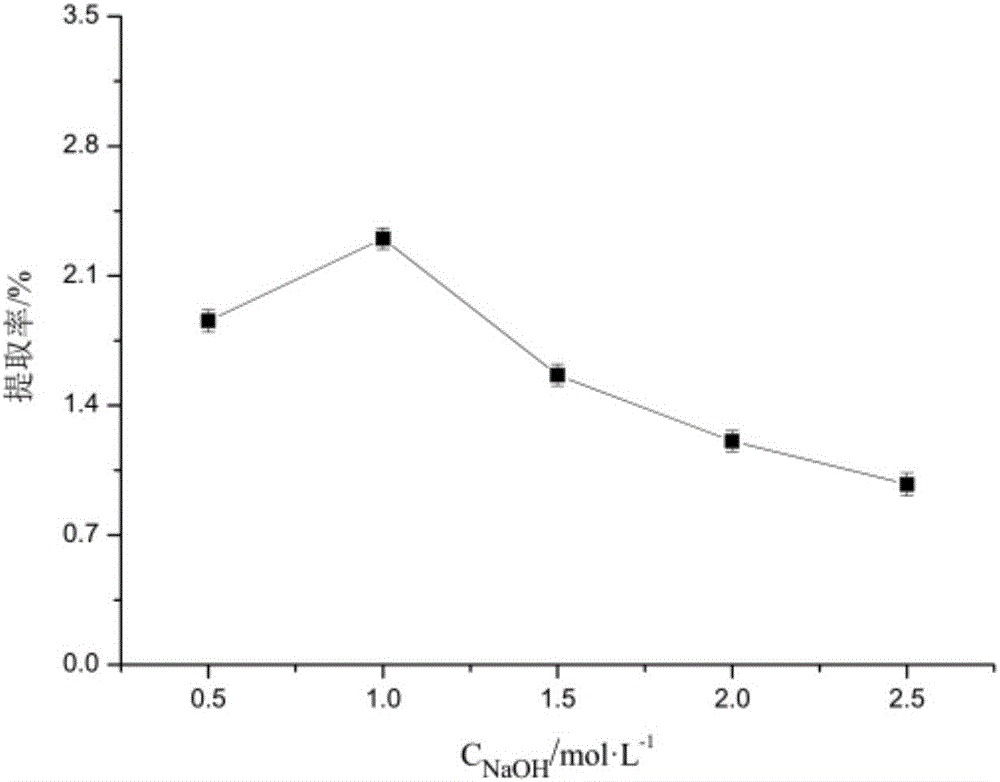

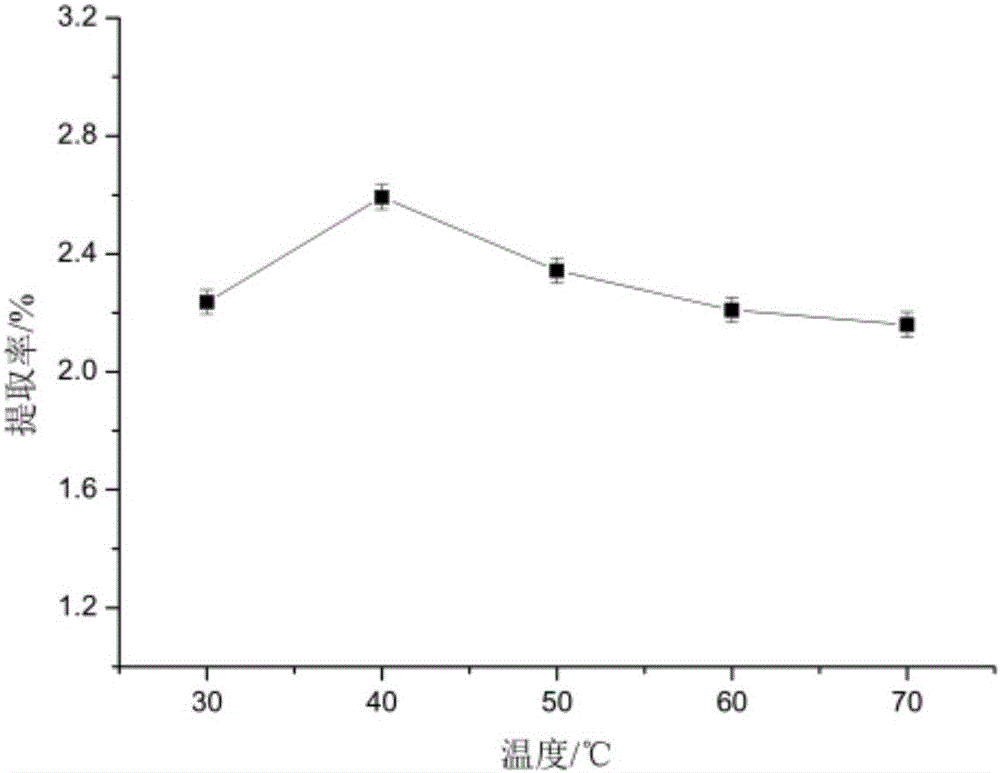

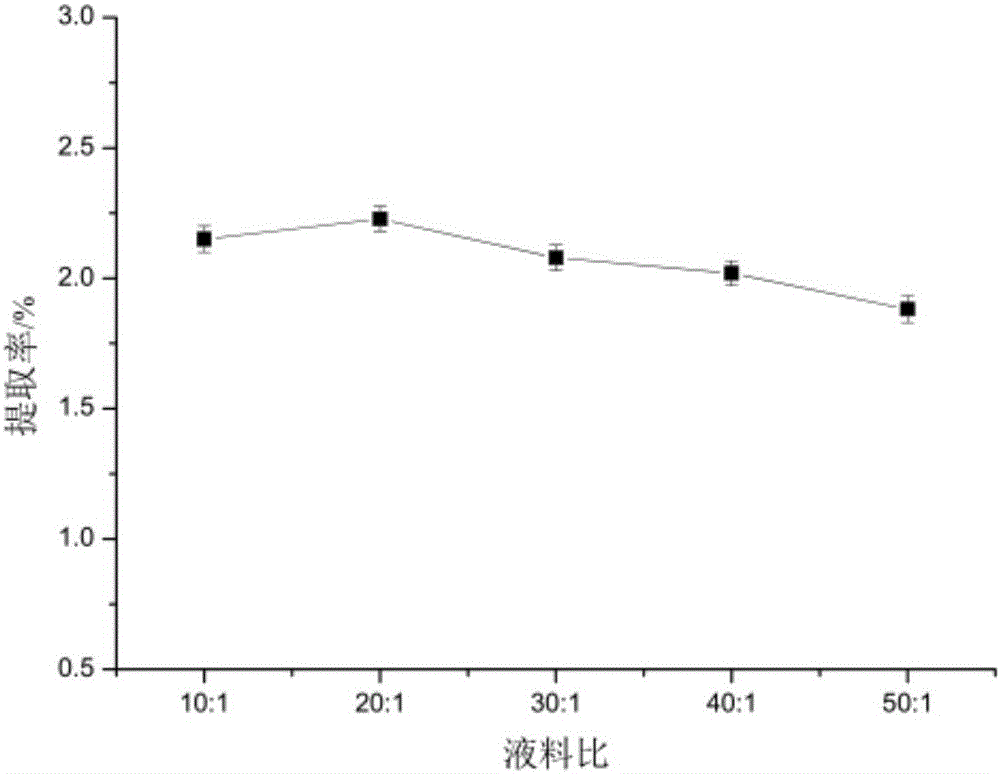

InactiveCN105733299AHigh purityHigh extraction rateCosmetic preparationsToilet preparationsChemistrySquid melanin

The invention discloses a preparation method of insoluble and soluble squid melanin.The method includes the steps of refrigerating and smashing, centrifuging and shelling, secondary centrifuging, alkali dissolving, acid depositing and the like.Prepared squid ink is high in purity, high in extracting rate and suitable for industrial large-scale production and preparation.The invention further discloses application of soluble squid melanin prepared through the method in anti-radiation skincare products.

Owner:FISHERIES RES INST OF FUJIAN

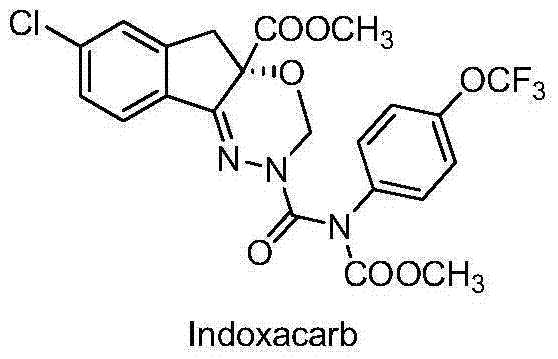

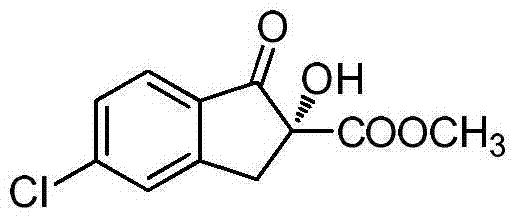

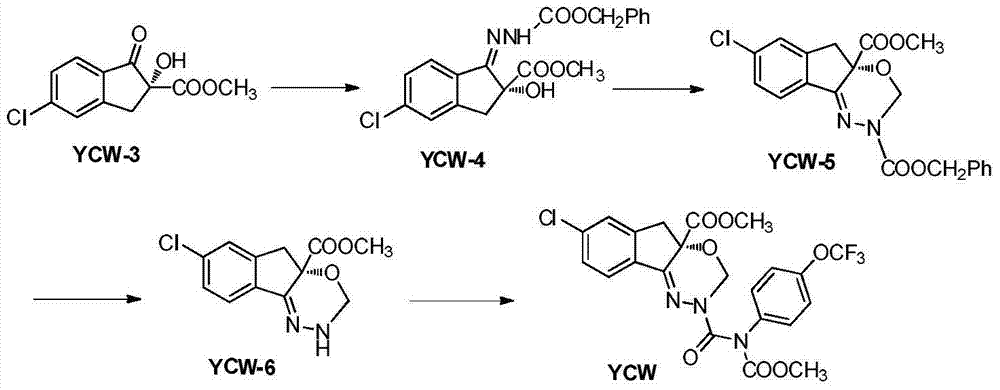

Method for synthesizing intermediate of agricultural insecticide indoxacarb

ActiveCN104262285AHigh yieldReduce decompositionOrganic chemistryRoom temperatureReaction temperature

The invention discloses a method for synthesizing an intermediate of agricultural insecticide indoxacarb. The method comprises the following steps: (1) putting YCW-4, Lewis acid and methylbenzene into a reaction container according to a proportion, stirring, heating to a reacting temperature of 105-110 DEG C, dripping a methylbenzene solution of diethoxymethane, adding benzyl carbazate, and reacting at the reacting temperature until the reaction is carried out completely, wherein azeotrope of ethanol and diethoxymethane serving as a byproduct is constantly vaporized and eliminated in the reacting process; (2) stopping heating after the reaction is finished, cooling to room temperature under a stirring condition, concentrating at reduced pressure to reclaim methylbenzene, cooling and crystallizing the concentrate at low temperature by using a crystallization solvent, suction-filtering, washing, and baking to obtain light yellow crystal which is a target product, namely the intermediate of agricultural insecticide indoxacarb. The synthesizing method has the technical advantage of high yield.

Owner:ZHEJIANG UNIV

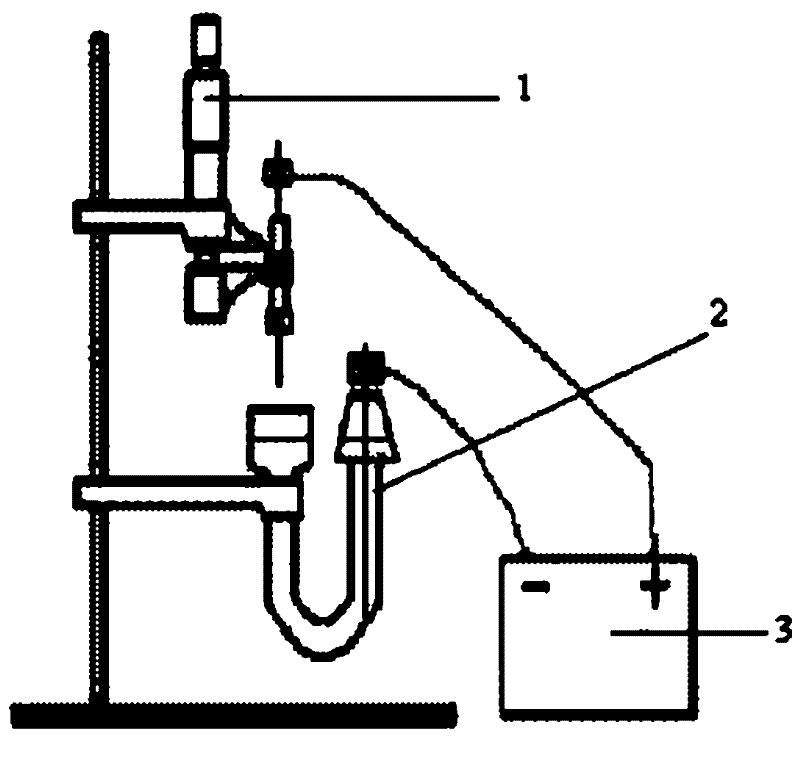

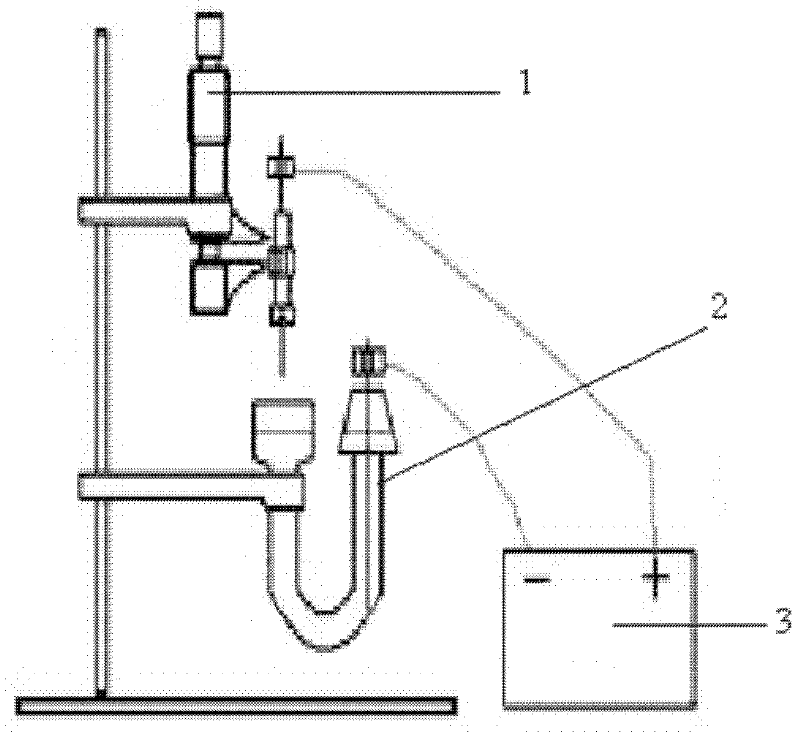

Alternating-current electrochemical corrosion method of field emission electron source

ActiveCN102339704AEasy to operateWide range of availableCold cathode manufactureElectron sourceSingle crystal

The invention discloses an alternating-current electrochemical corrosion method of a field emission electron source. According to the electrochemical corrosion method, an alternating-current signal source and a certain proportion of alkaline solution are adopted to form a novel electrochemical de-corrosion method. According to the alternating-current electrochemical corrosion method, corrosion conditions are optimized by controlling parameters of the depth of a single crystal tungsten wire, which is dipped into the liquid level of corrosive liquid, the concentration of the corrosive liquid, the amplitude of voltage, frequency of signals, and the like to obtain the optimal process parameters of corrosion, and therefore an ideal pinpoint shape is obtained. The corrosion method has the advantages of simpleness in operation and control, control accuracy, good stability, and success rate reaching more than 95 percent once the optimal conditions are obtained.

Owner:PEKING UNIV

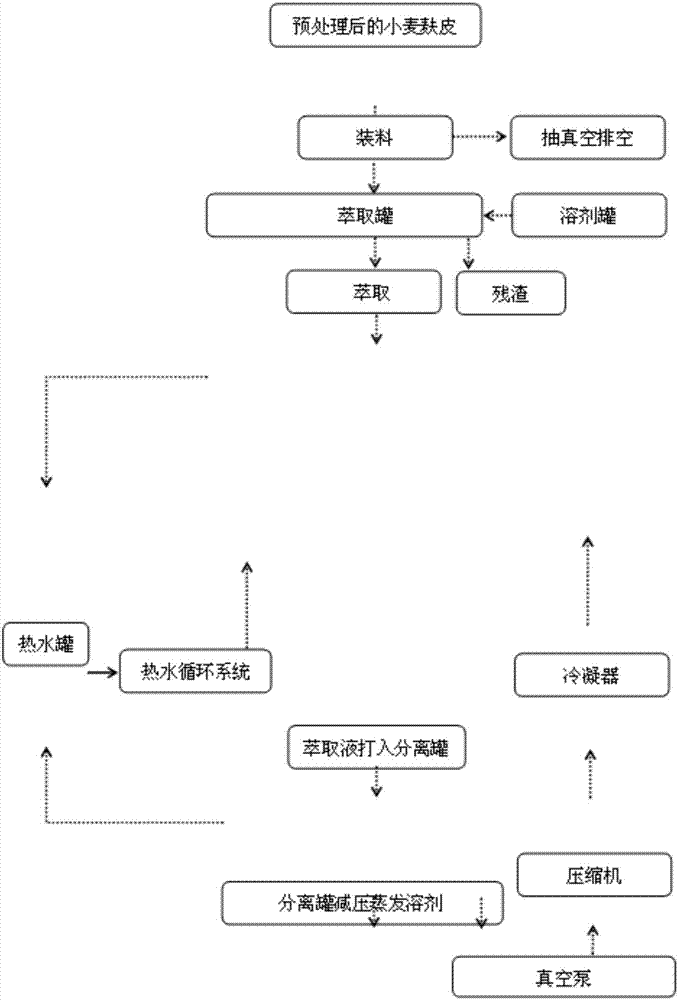

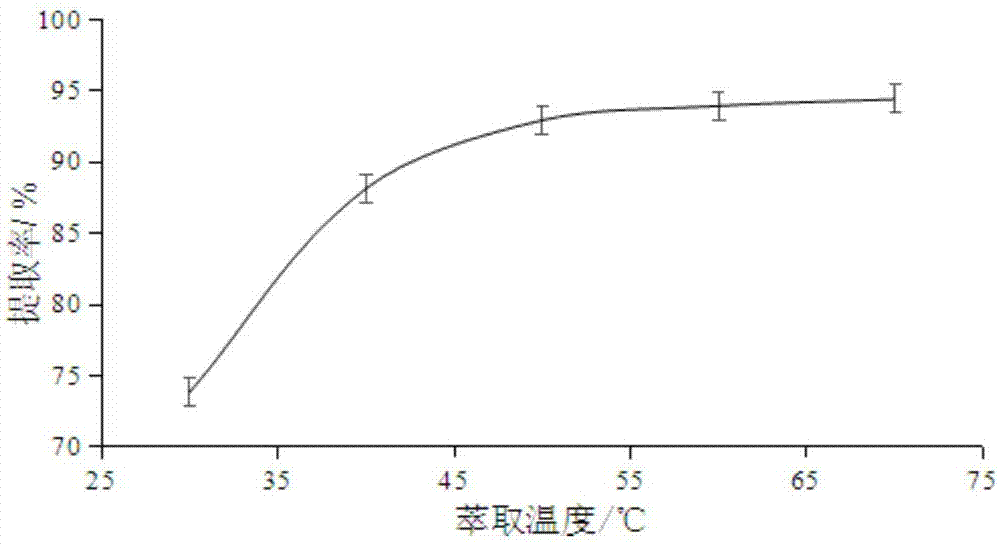

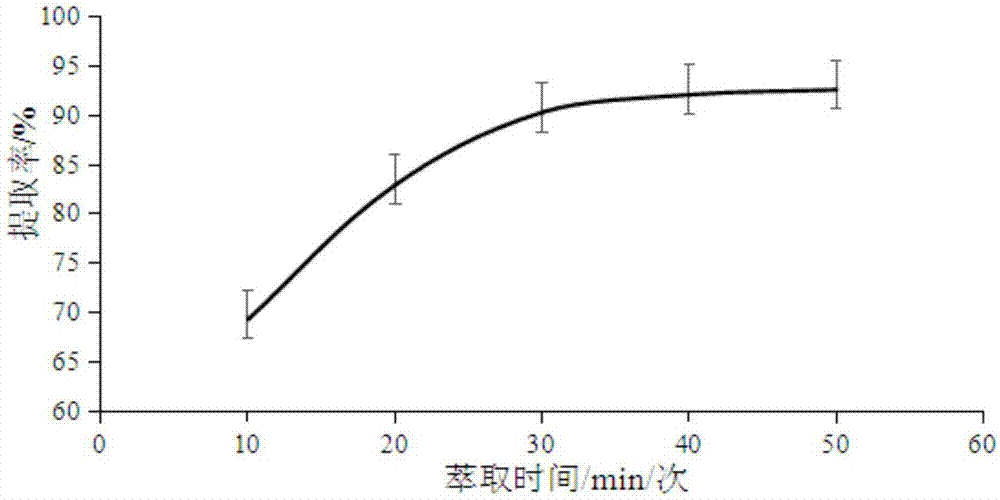

Wheat bran oil production technology using subcritical butane extraction

InactiveCN107338106ASimple processHigh extraction rateFatty-oils/fats productionMethyl linoleateDistillation

The invention discloses a wheat bran oil production technology using subcritical butane extraction, and belongs to the field of food engineering. Wheat bran undergoes subcritical butane extraction multiple times, and the obtained extract liquid undergoes reduced pressure distillation to remove an extractant to obtain the wheat bran oil containing methyl palmitate, methyl linoleate and methyl oleate. The wheat bran is cyclically extracted by adopting a subcritical butane technology, and technologic optimization researches of factors affecting the yield of the wheat bran oil are carried out by adopting Box-Benhnken center combination response surface test design in order to obtain optimum technologic parameters; and a gas chromatograph-mass spectrometer (GC-MS) is used to analyze the fatty acid components of the wheat bran oil obtained through the subcritical extraction in order to provide reference for the development and the utilization of wheat bran resources. The wheat bran oil production technology is simple, allows the extraction rate to reach up to 86.92%, is suitable for industrial application, and provides a new way for the further utilization of the wheat bran.

Owner:QILU UNIV OF TECH

High energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder

InactiveCN102773134AImprove work efficiencyReduce manufacturing costGrain treatmentsGear transmissionHigh energy

The invention relates to a high energy horizontal planetary ball milling equipment for production of nanometer traditional Chinese medicine powder. The equipment comprises a main motor, a driving belt, belt wheels, a main shaft, a left wheel disc, a left half axle, a right half axle, ball milling jar sleeves, a right wheel disc, a planetary gear, an internal gear, an internal gear transmission shaft, a first shaft coupling, a worm and gear speed reducer, a second shaft coupling and a vice-motor, wherein the main shaft is horizontally disposed, a plurality of the ball milling jar sleeves are horizontally disposed and are circumferentially and uniformly arranged around the main shaft and between the left wheel disc and the right wheel disc, the main motor is driven by the driving belt and drives the main shaft to rotate, circular rotation of the ball milling jar sleeves around the axis of the main shaft is realized through the rotation of the main shaft, the left wheel disc and the right wheel disc, the ball milling jar sleeves are connected with the right half axle, the planetary gear on the right half axle is engaged with the internal gear, the internal gear is arranged on the internal gear transmission shaft, and the vice-motor drives the internal gear to rotate through the worm and gear speed reducer.

Owner:CHANGCHUN CHAOWEI PHARMA TECH DEV

Flame-retardant anticorrosion knitted polyester fabric

InactiveCN104047091AFeel comfortableImprove flame retardant performanceFibre typesWoven fabricsFiberPolyester

The invention discloses a flame-retardant anticorrosion knitted polyester fabric. The warp of the fabric is formed by combining three strands of fifteen flame-retardant polyester fibers, and the weft of the fabric is formed by combining two strands of thirty flame-retardant polyester fibers; the fabric is soaked in steeping liquid containing 45%-50% composite finishing agents at the temperature ranging from 50 DEG C to 55 DEG C for seven hours to eight hours and then is placed at the constant temperature ranging from 125 DEG C to 130 DEG C for six hours to eight hours after being taken out. The flame-retardant anticorrosion knitted polyester fabric is comfortable in hand feel, and the flame-retardant anticorrosion knitted polyester fabric further has excellent flame-retardant and anticorrosion properties.

Owner:JIANGSU JINHONG KNITTING

Method for producing polystyrene extruded sheet profiled bar through carbon dioxide foaming agent

InactiveCN105199252AImprove the mixing effectImprove appearance performancePolymer scienceFoaming agent

The invention discloses a method for producing a polystyrene extruded sheet profiled bar through a carbon dioxide foaming agent. The method includes the following steps: taking a polystyrene melt as the main component, and taking carbon dioxide as a polymer melt of the foaming agent, and simultaneously adding the two objects into an extruder according to a certain proportion to form a polymer melt; injecting carbon dioxide from the middle section of the extruder to the melt through a foaming agent injection system to form foamable gelatin; along with the forward conveying of the melt, and under the shearing action of a screw, fully mixing the foaming agent with the polystyrene melt; performing mixing and temperature reduction and cooling to the polymer melt through a heat exchanger, so as to reduce the temperature of the gelatin to the optimal foaming temperature; extruding the cooled gelatin through a die with required shapes to form the polystyrene extruded sheet profiled bar. The method for producing the polystyrene extruded sheet profiled bar through the carbon dioxide foaming agent, provided by the invention, is economic and environment-friendly, is simple in technology, and has excellent market prospect.

Owner:南京法宁格节能科技股份有限公司

Flame-retardant knitted fabric

InactiveCN104047092AFeel comfortableImprove flame retardant performanceFibre treatmentWoven fabricsCarboxymethyl celluloseTetrakis(hydroxymethyl)phosphonium chloride

The invention discloses a flame-retardant knitted fabric. The warp of the fabric is DTY150D / 48F, and the weft of the fabric is ATY320D / 96F; the fabric is soaked in steeping liquid containing 35%-40% composite finishing agent at the temperature ranging from 70 DEG C to 75 DEG C for five hours to six hours and then is placed at the constant temperature ranging from 155 DEG C to 160 DEG C for five hours to seven hours after being taken out. The composite finishing agent is prepared with the following methods that 2 parts to 3 parts of carboxymethyl cellulose, 4 parts to 5 parts of vinyl trimethoxy silane, 8 parts to 9 parts of tetrakis hydroxymethyl phosphonium chloride, 1 part to 2 parts of phosphorous ester and three parts to four parts of triethoxy ethyl silane are mixed, then, 7 parts to 8 parts of cyclic phosphonate ester and 6 parts to 7 parts of molybdenum trioxide are synchronously and slowly added, material feeding is completed within eight minutes to ten minutes, continuous mixing lasts for ten minutes to fifteen minutes, and the composite flame-retardant agent is prepared. The flame-retardant knitted fabric has excellent flame-retardant performance.

Owner:JIANGSU JINHONG KNITTING

Method for reducing viscosity of corn flour in gelatinization process by means of irradiation technology

InactiveCN103892186AOptimum Process ParametersLow viscosityFood shapingFood dryingControl electronicsMoisture

The invention belongs to the technical field of deep-processing of corns and discloses a method for reducing viscosity of corn flour in a gelatinization process by means of an irradiation technology. According to the method, the corn flour serves as a raw material, the viscosity serves as a measurement index of a technical effect, and due to the single factor and response surface design, the heating area temperature, main engine rotating speed and feeding speed during double-screw extrusion expanding, the microwave strength, vacuum degree, drying temperature and drying time during microwave vacuum drying and the material moisture content, irradiation dose and irradiation time controlled in electron accelerator irradiation serve as critical control points. A processing technical route of 'double-screw extrusion expanding, microwave drying, superfine grinding and accelerator irradiation' is designed, and the viscosity value is reduced from 1078.57Pa.s to 5.89Pa.s when the size mixing mass concentration of the corn flour subjected to irradiation treatment is 10 percent. The production technical route is simple, and the comprehensive utilization of corn resources to develop a series of high-end starch sugar products and the industrialized demonstration research are promoted.

Owner:JILIN UNIV

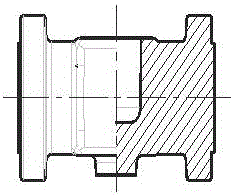

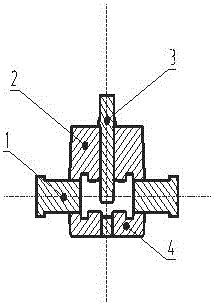

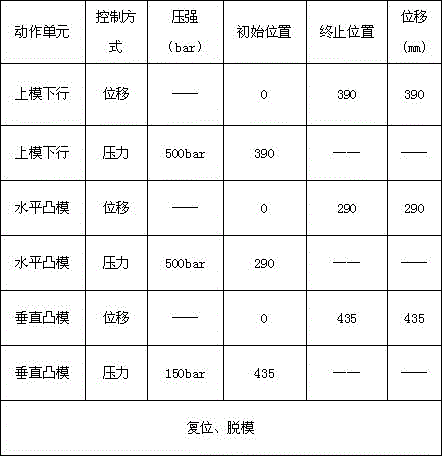

Multidirectional precise die forging process for valve body with flange

InactiveCN106077389AExcellent surface quality of forgingsGood mechanical propertiesMetal-working apparatusNondestructive testingEnergy consumption

The invention belongs to the technical field of machinery manufacturing and particularly discloses a multidirectional precise die forging process for a valve body with a flange. The forging process comprises the following steps of (1) computer numerical simulation, (2) blank preparation, (3) blank heating, (4) die preparation, (5) multidirectional precise die forging forming, (6) forge piece cooling, (7) nondestructive testing, and (8) forge piece shot blasting treatment. According to the multidirectional precise die forging process, one-fire once forging is adopted for forming the valve body forge piece which is complex in shape, with an inner hole, precise in dimension and is close to a fabricated part, continuity of the valve body forging streamline and good overall performance are ensured, thus the production efficiency is improved, materials are saved, and energy consumption is reduced.

Owner:22MCC GRP PRECISION FORGING

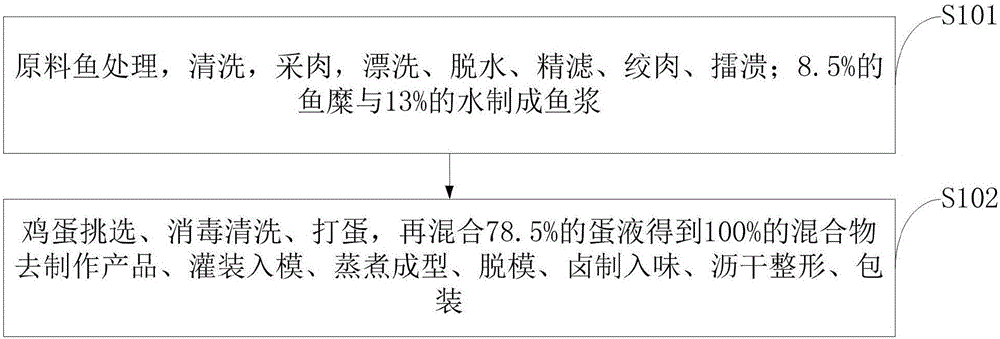

Snack instant surimi-containing dried egg and making method thereof

The invention discloses a snack instant surimi-containing dried egg and a making method thereof. The method comprises the following steps: raw material fish processing, cleaning, meat separation, rinsing, dehydration, fine filtration, meat mincing, and grinding; production of fish cream from 8.5% of surimi and 13% of water; and egg choosing, sterilization cleaning, egg breaking, production of 100% of a mixture through mixing the fish cream with 78.5% of egg liquid, filling of a die with the mixture, boiling molding, demolding, marinating, drainage shaping, and packaging. Marinating brine comprises 1500 g of water, 5 g of anise, 5 g of little pepper powder, 5 g of cinnamon bark, 15 g of cooking wine, 5 g of Chinese prickly ash, 30g of ginger, 40 g of rock sugar, 15 g of dark soy sauce, 15 g of light soy sauce, 2 g of bay leaves, 50 g of salt, 10 g of garlic and 5 g of Fructus Foeniculi. The snack instant surimi-containing dried egg overcomes the disadvantages of non-uniform internal texture and poor integral mouthfeel of dried eggs, reaches product protein complementation, and weakens the disadvantages of dry mouthfeel and easiness in getting of excess internal heat, caused by oil frying making technologies of instant fish tofu products in the market.

Owner:程学勋

Preparation method of annular thin-wall boron carbide-aluminum oxide pellets

The invention belongs to the technical field of application of nuclear fuel pellets, and in particular relates to a method for preparing a thin-walled annular boron carbide alumina pellet. Dry Al2O3 powder and B4C powder, then mix Al2O3 powder and B4C powder according to the mass ratio of 86:14, then mix them with absolute ethanol and zirconia balls on a planetary ball mill, take out the slurry and put it in an oven Drying treatment; binder addition, the binder system is polypropylene-paraffin-stearic acid; put the aged material after banburying into the granulator to ensure the uniformity of the banburying material; The material is put into the injection molding machine to obtain the required thin-walled WABA green body; the degreasing process is divided into two stages; the pressed pellets are placed in the crucible and cooled with the furnace, and the cooled pellets are released from the furnace. The process of the invention is simple, and the domestic production capacity of B4C-Al2O3 pellets is prepared, and the localization of the pellets is realized.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Laser additive repair alloy powder and method of laser welding blast hole of cast aluminum radiator

InactiveCN109877458AMeet performance requirementsOptimum Process ParametersLaser beam welding apparatusThermal conductivityHigh energy

The invention relates to laser additive repair alloy powder and method of a laser welding blast hole of a cast aluminum radiator. The alloy powder mainly comprises AlSiMgMnCuFeNiZnSnNd. The alloy powder is prepared by adopting an air atomization method, and powder particles are in a spherical shape, and the particle size is 15-65[mu]m. Firstly, tensile strength and elongation are increased, and comprehensive mechanical properties are improved; secondly, higher repair speed can be provided, the generation of refractory alumina in repair welding repair process is reduced, and the burning loss ofalloy elements is reduced, so that the repair quality is improved; thirdly, a laser can provide higher energy density, and poor fusion phenomenon caused by good thermal conductivity of aluminum alloyis overcome; fourthly, compared with a traditional repair welding repair method, the laser additive repair method has fewer process parameters affecting repair quality, and the probability of secondary defects such as cracks and pores due to improper operation or improper process parameters can be reduced; and fifthly, compared with the traditional repair welding repair method, the laser additiverepair method has the characteristics of good repair quality, high applicability to the size of the blast hole at the repair place and the like.

Owner:SHENYANG POLYTECHNIC UNIV

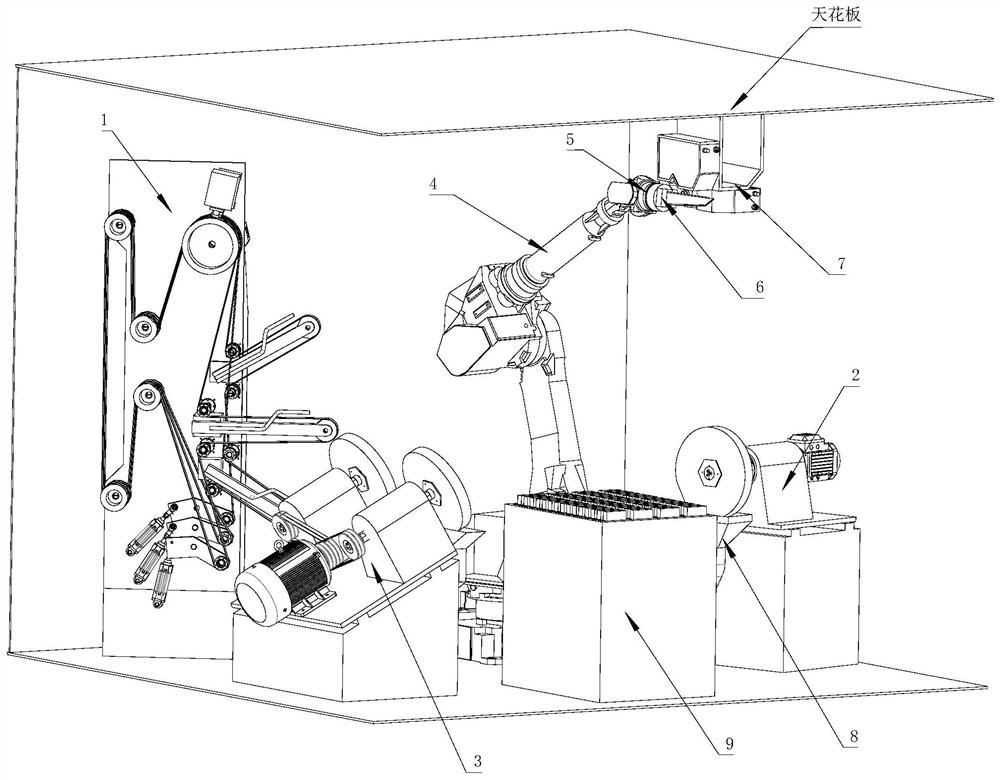

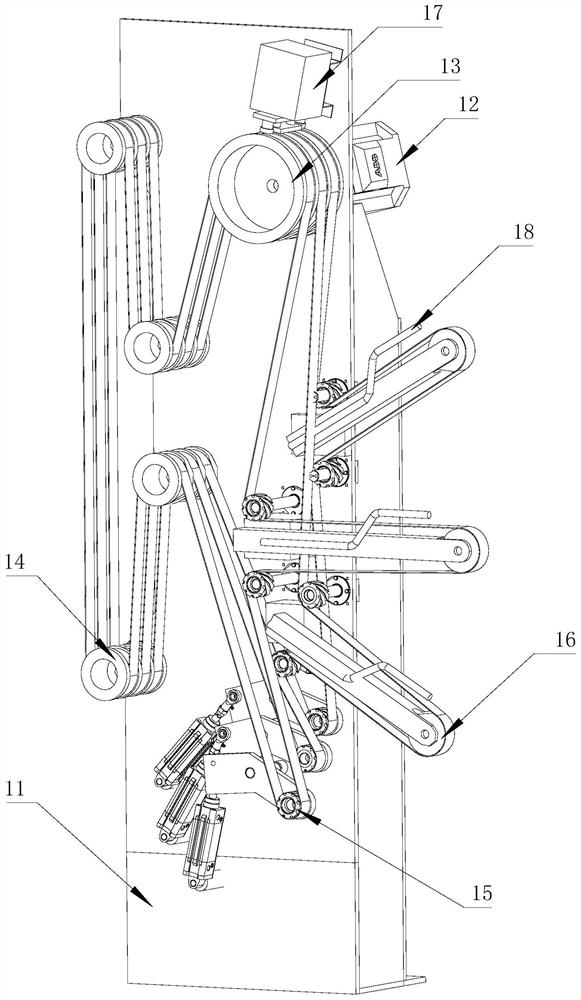

Compressor blade polishing equipment

PendingCN111687726AOptimum Process ParametersNo need for manual rearrangingGrinding carriagesBelt grinding machinesSanderPolishing

The invention discloses compressor blade polishing equipment. The compressor blade polishing equipment comprises a multi-station belt sander, a first grinding wheel power sliding table, a second grinding wheel power sliding table, a polishing robot, a blade clamp and an intelligent control system; the blade clamp is connected to an end effector of the polishing robot and is used for clamping a blade; and under the driving action, the polishing robot works, so that the different parts of the blade clamped by the blade clamp are in contact polishing with a sanding belt of the multi-station beltsander, a grinding wheel of the first grinding wheel power sliding table and a grinding wheel of the second grinding wheel power sliding table. The compressor blade polishing equipment is large and medium-sized polishing equipment which can adapt to the surface treatment of various specifications of compressor blades. The compressor blade can be automatically polished, and a uniform and smooth polishing surface without manual rearranging is achieved.

Owner:广东博科数控机械有限公司

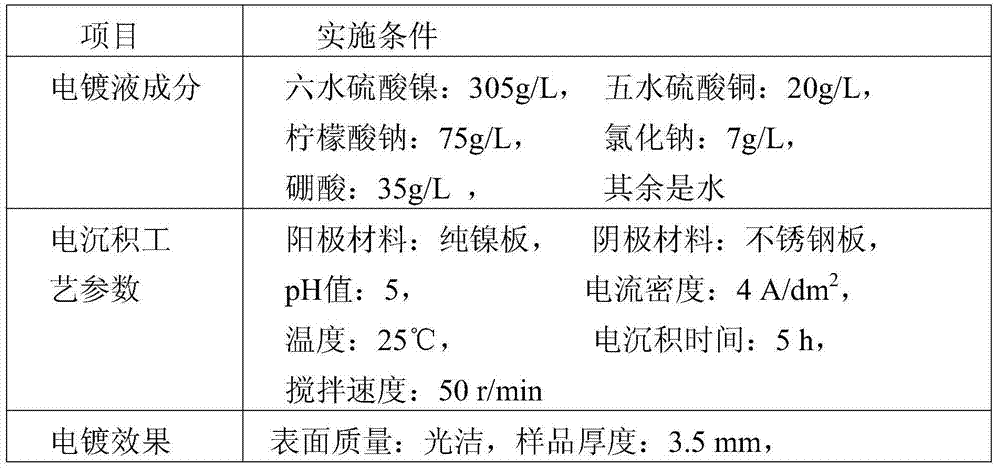

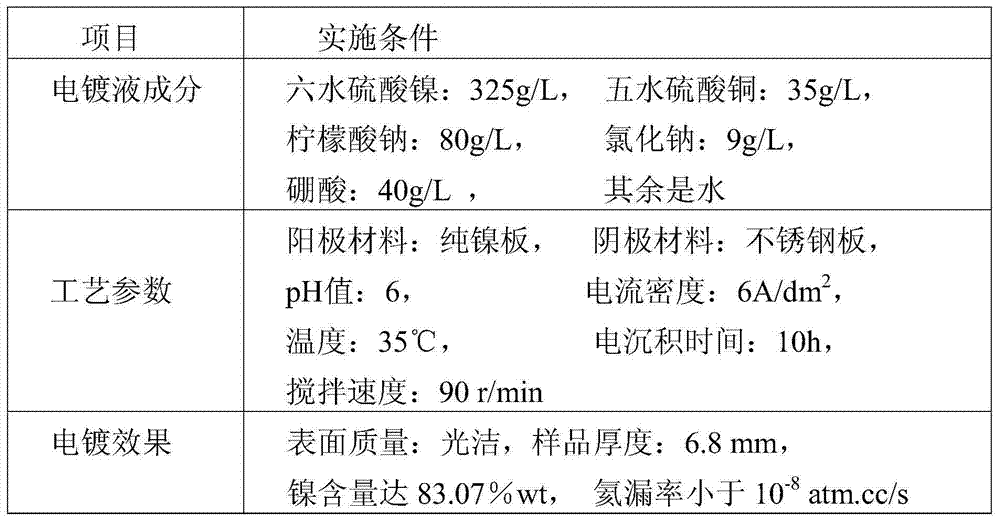

Method for preparing high-gas tightness nickel-copper alloy for travelling wave tube

The invention discloses a method for preparing a high-gas tightness nickel-copper alloy for a travelling wave tube and belongs to the technical field of alloy material preparation. The method solves the problem of high difficulty of high-gas tightness nickel-copper alloy preparation. The method comprises the following steps of before electrodeposition, polishing an anode pure-nickel plate and a cathode stainless steel plate by sand paper to remove surface oxides, carrying out ultrasonic cleaning orderly by acetone, alcohol and distilled water to remove impurities such as oil stain on the anode and cathode surfaces and to obtain the clean surfaces, and carrying out nickel-copper alloy electrodeposition by an electroplate liquid comprising 305-350g / L of nickel sulfate hexahydrate, 20-50g / L of copper sulfate pentahydrate, 75-90g / L of sodium citrate, 7-12g / L of sodium chloride, 35-50g / L of boric acid and the balance water under the conditions of a pH value of 5-7, current density of 4-8A / dm<2>, a temperature of 25-45 DEG C, electrodeposition time of 5-15h and a stirring speed of 50-120r / min. The method can prepare the high-gas tightness nickel-copper alloy and has simple processes and easily controllable technological parameters.

Owner:BEIJING UNIV OF TECH

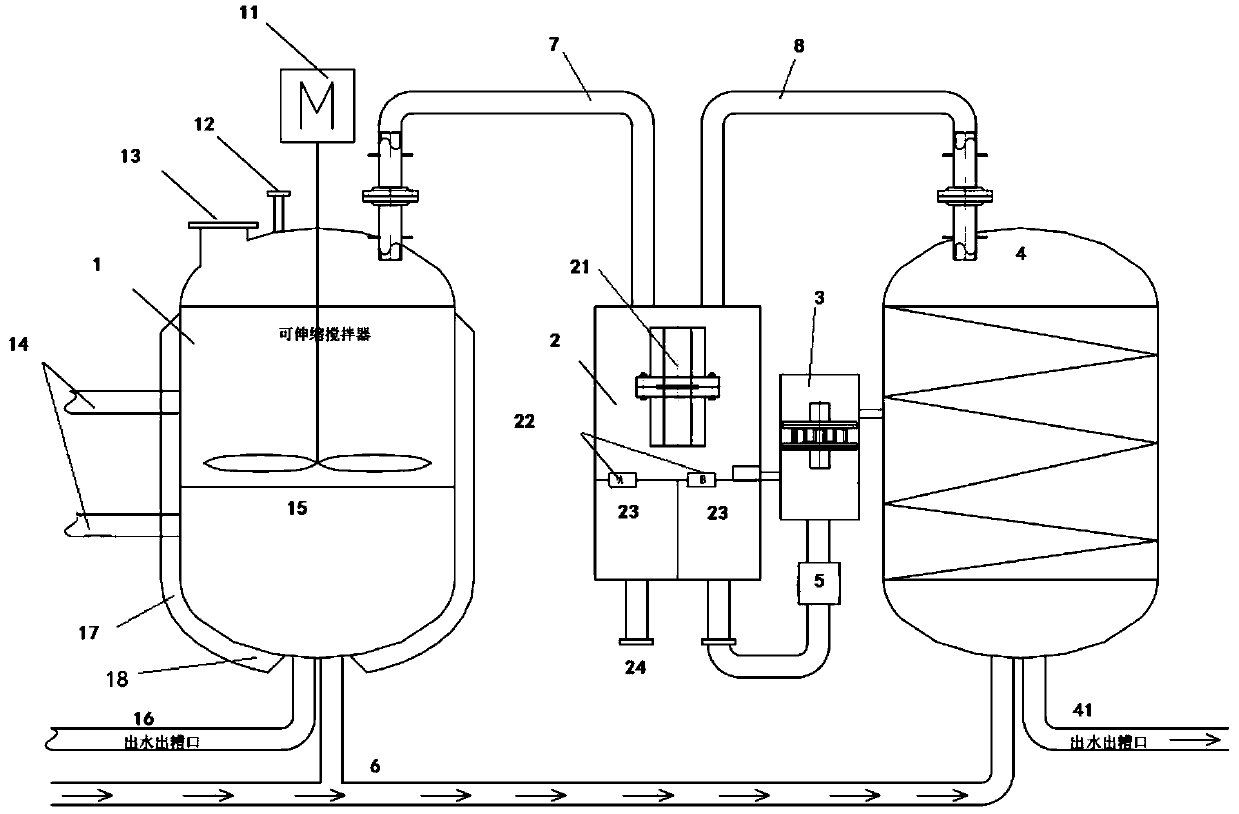

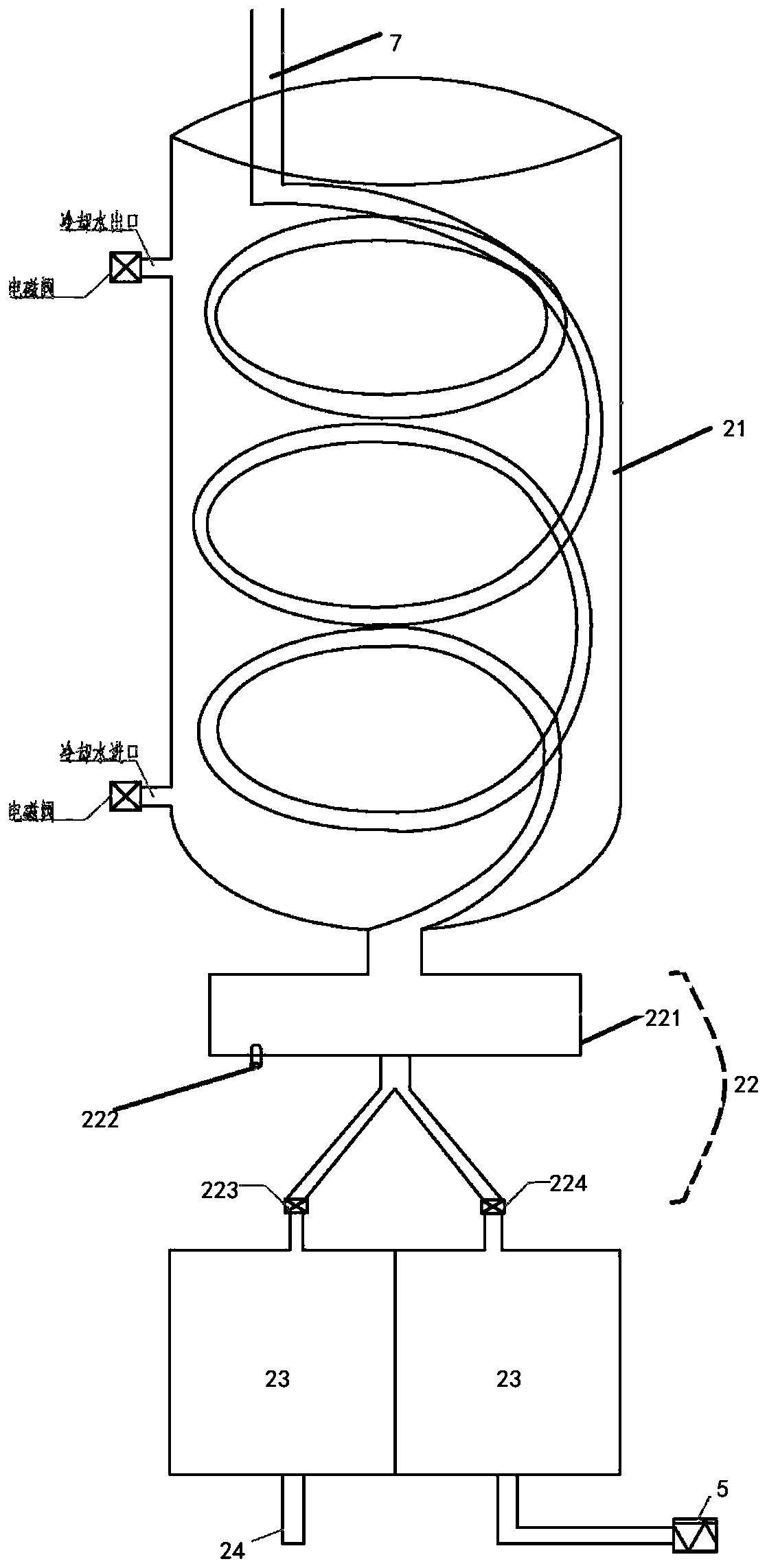

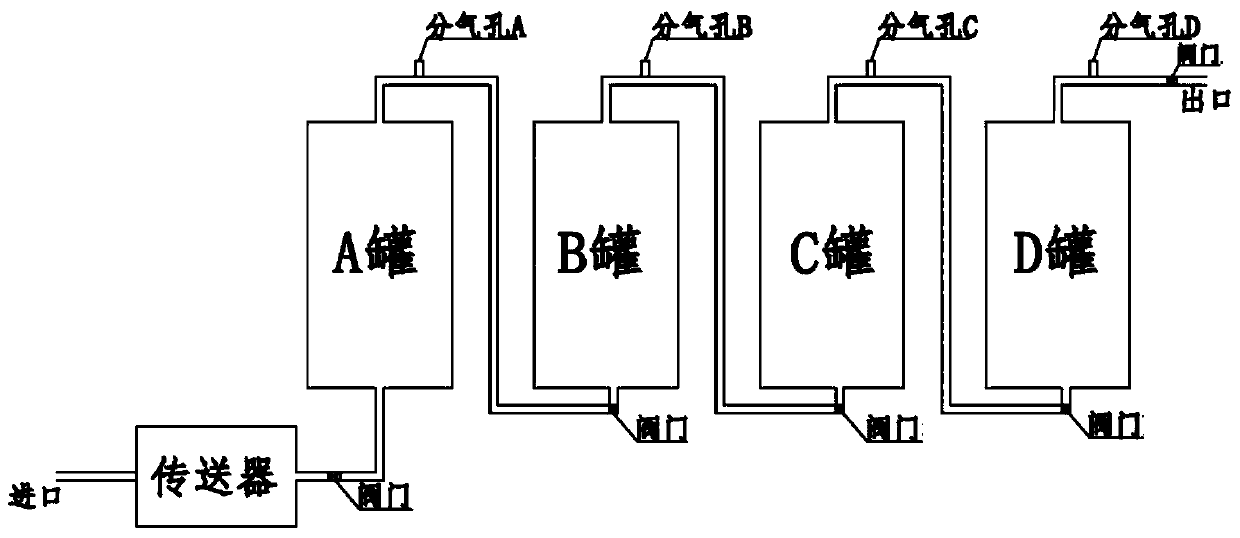

Integrated intelligent fermentation and wine formation equipment

PendingCN111454800AUniform qualityPure qualityAlcoholic beverage preparationAutomatic controlBuffer tank

The invention discloses integrated intelligent fermentation and wine formation equipment. The equipment comprises a control box, an intelligent fermentation system, an intelligent wine separating system, conveyors, a high polymer material extractor and an intelligent distillation system, wherein an electric appliance control box achieves automatic control; the intelligent fermentation system comprises a tank body, a feeding device, a yeast feeding device, a stirrer, cooling devices and a steam device; the intelligent wine separating system comprises a condensation device, wine separating devices, buffer tanks and wine outlets; the condensation device is connected with the fermentation tank body and connected with the wine separating devices; each wine separating device is provided with twoelectromagnetic valves A / B; each electromagnetic valve A communicates with one wine outlet; each electromagnetic valve B communicates with one buffer tank; the lower part of each buffer tank is connected with the high polymer material extractor through one conveyor; and the intelligent distillation system is connected with the high polymer material extractor and communicates with the condensationdevice and the lower part of the intelligent distillation system is connected with steam. According to the integrated intelligent fermentation and wine formation equipment, dozens of processes for making wine are condensed into a whole; the equipment is simplified; and through an automatic control technology, the operation is convenient and the labor force is reduced.

Owner:仲崇涛

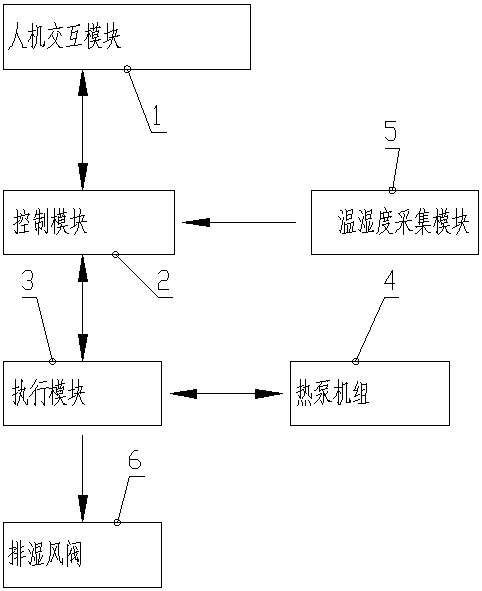

Heat pump drying room dehumidification control system based on time and target, and dehumidification method

ActiveCN109114890AGuaranteed to closeAvoid the defects caused by too long opening time or even unable to closeDrying gas arrangementsDrying solid materialsControl systemProcess engineering

The invention discloses a heat pump drying room dehumidification control system based on time and a target. The system comprises a drying room, a human-computer interaction module used for human-computer interaction, a control module, an execution module, a heat pump unit, a temperature and humidity acquisition module and a dehumidification air valve. The control module is provided with a parameter storage inside. The invention further discloses a dehumidification method. The dehumidification method comprises the steps of firstly, carrying out drying operation according to an existing technology; secondly, carrying out air valve opening and closing cycle operation based on time on the dehumidification air valve; and thirdly, carrying out air valve opening and closing cycle operation basedon the humidity target and time on the dehumidification air valve till drying operation is finished. With the heat pump drying room dehumidification control system based on time and the target, and the dehumidification method, it can be guaranteed that effective dehumidification operation is carried out on the drying room, energy loss caused by the situation that the dehumidification air valve isopened for too long is avoided as well, it is avoided that a drying technology cannot be normally carried out because the temperature in the drying room cannot rise effectively, the purposes of energysaving and benefit increase are achieved, and the purpose of guaranteeing effective operation of the drying technology is achieved.

Owner:HENAN BAIHENG ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com