High-accuracy hole forming device for aircraft wall panel and a method of high-accuracy hole forming device

A technology for aircraft wall panels and hole-making devices, which is applied in the direction of automatic control devices, feeding devices, manufacturing tools, etc., can solve the problems of further improvement, affect the quality of hole-making, and need to be improved, so as to achieve convenient use and ensure the surface of hole-making quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

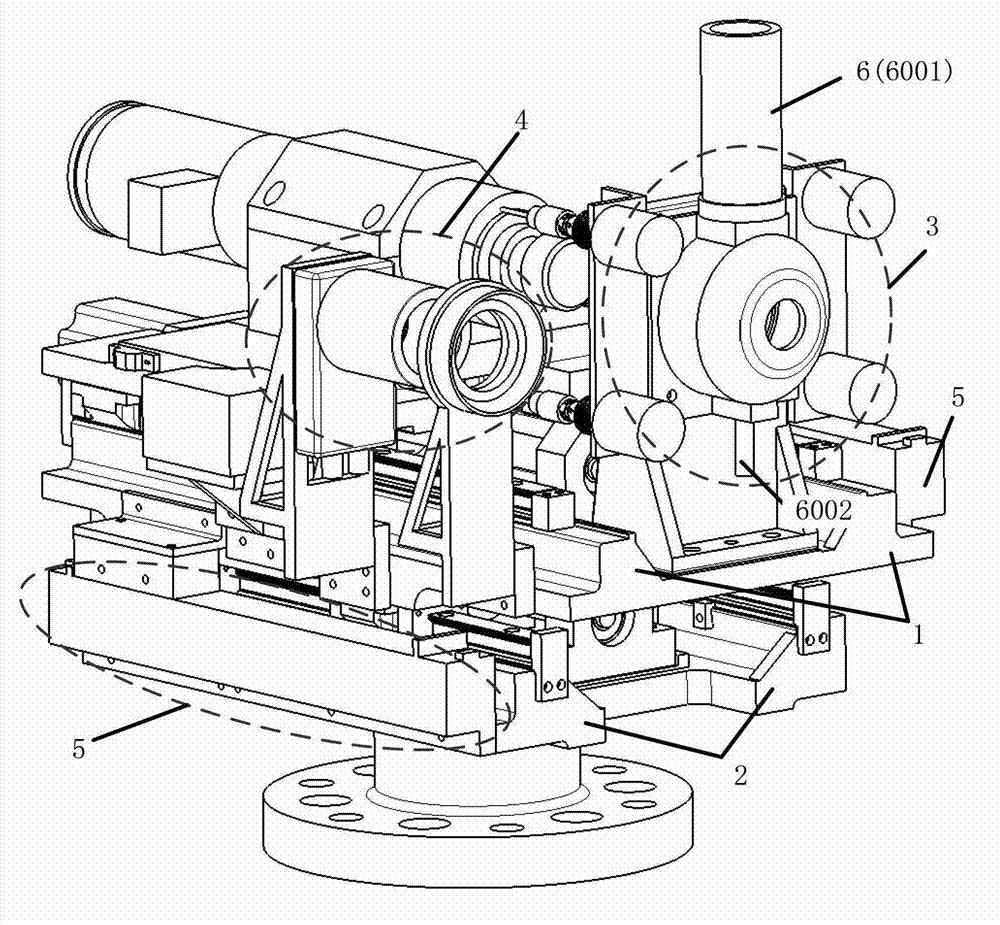

[0046] The technical solution adopted by the present invention to solve the technical problem is: including a spindle module, a feeding module, a pressure foot normal leveling module, a visual alignment module, a grating ruler module, and a dust suction and cooling module. The structure and installation position of each part are as follows figure 1 shown.

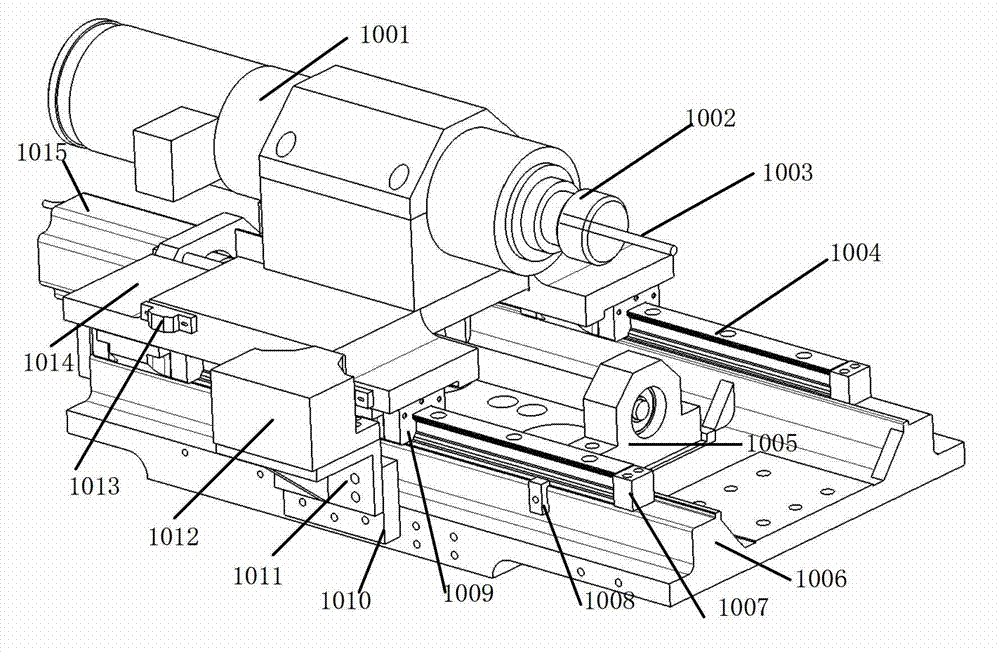

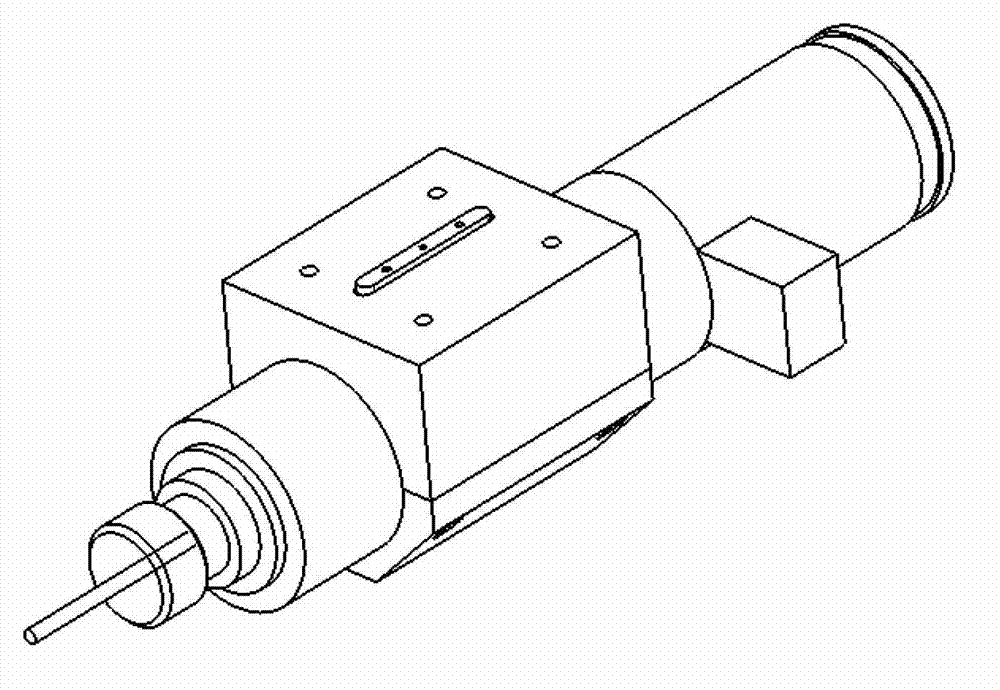

[0047] Among them, the spindle module 1 is mainly used for the feeding of the electric spindle along the axis of the hole making. The rational design and finishing of the electric spindle connecting plate and the spindle support plate ensure the coaxiality and radial runout of the electric spindle, tool holder and tool. At the same time, ensure that the hole diameter tolerance of the hole is within the range of design requirements; the feed module 2 is used to ensure that the spindle module 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com