Method for cold rolling high silicon electric steel

A technology of high-silicon electrical steel and low-silicon steel, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of serious edge cracks, frequent welding strip breakage, etc., to extend the roll change cycle, shorten the production cycle, Guaranteed effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The present invention uses a five-stand continuous rolling mill to produce non-oriented high-silicon electrical steel by one-time cold rolling as an example. The chemical composition of the non-oriented high-silicon electrical steel is (weight percent) C: 0.003%, Si: 3.0%, Mn: 0.25%, P≤0.01%, S≤0.005%, Als: 0.24%, Cu: 0.040%, The rest is mainly iron and a small amount of inclusions, the total inclusions ≤ 0.03%.

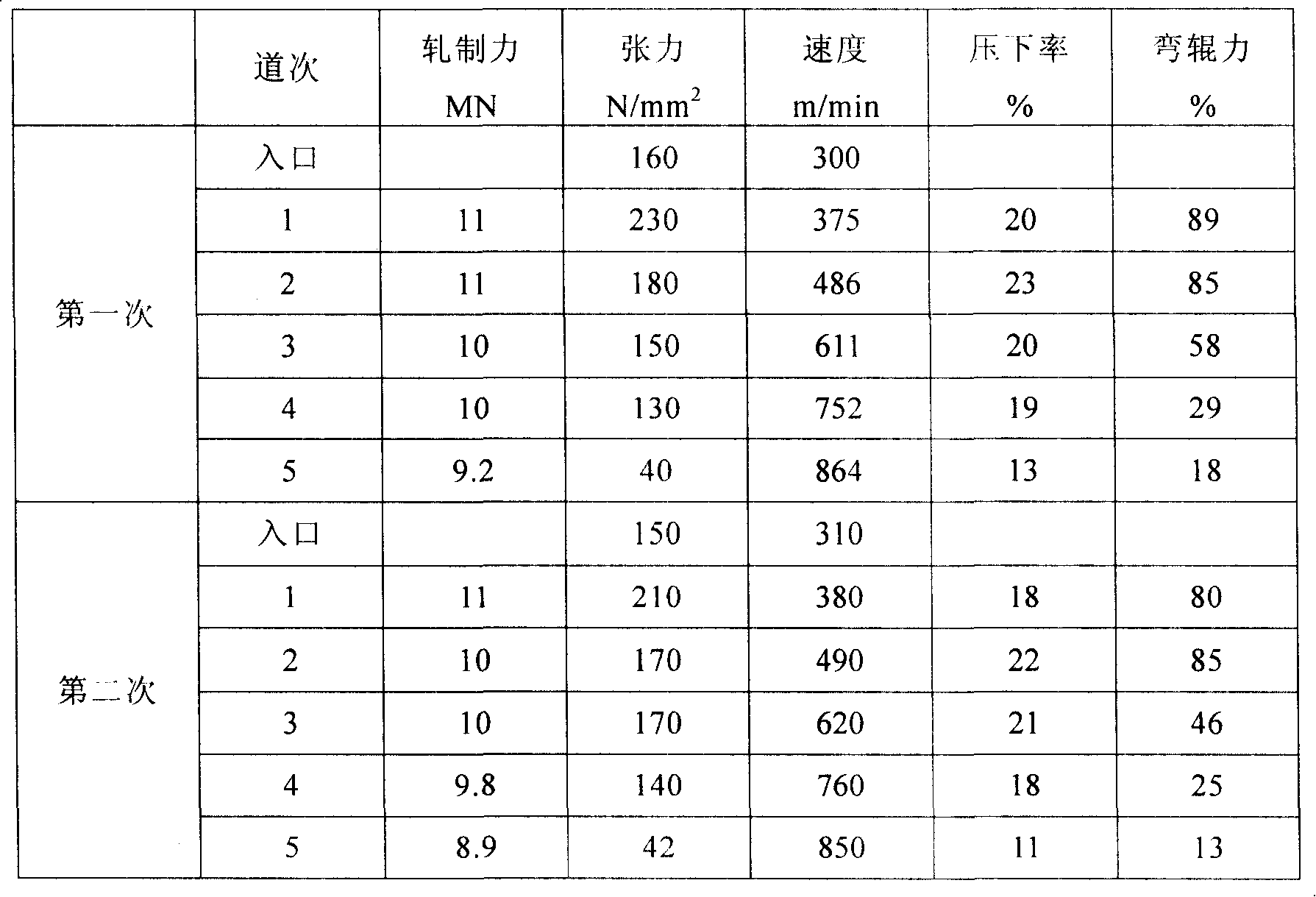

[0010] The steel billet with the above composition is hot-rolled into a 2.3mm hot-rolled plate, and a small section of steel plate of the same specification with a silicon content of 1.2% is added between the head and tail of the high-silicon electrical steel. The head and tail are connected, then pickled, and then continuously rolled by a five-stand cold rolling unit in a single cold rolling method. The temperature of the steel plate is raised to close to 150°C by utilizing the mechanical energy converted into heat energy during the rolling process to realiz...

Embodiment 2

[0016] The present invention uses a five-stand continuous rolling mill to produce oriented high-silicon electrical steel by twice cold rolling as an example. The chemical composition of the oriented high-silicon electrical steel is (weight percent) C: 0.04%, Si: 3.22%, Mn: 0.08%, P≤0.012%, S: 0.03%, Als: 0.34%, Cu: 0.20%, and the rest Mainly iron and a small amount of inclusions, total inclusions ≤ 0.025%.

[0017] The steel billet with the above composition is hot-rolled into a 2.5mm hot-rolled plate, and a small section of steel plate of the same specification with a silicon content of 1.1% is added between the head and the tail of the high-silicon electrical steel. The head and tail are connected, then pickled, and then rolled continuously by two cold rolling units using a five-stand cold rolling unit. The temperature of the steel plate is raised to close to 150°C by utilizing the mechanical energy converted into heat energy during the rolling process to realize warm rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com