High-performance tin-phosphor bronze strip and production method thereof

A high-performance tin-phosphorus and tin-phosphorus bronze strip technology, applied in the field of high-performance tin-phosphorus bronze strip and its production, can solve the problems of increased absolute reduction in thin strip rolling, affecting tolerance and rolling safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

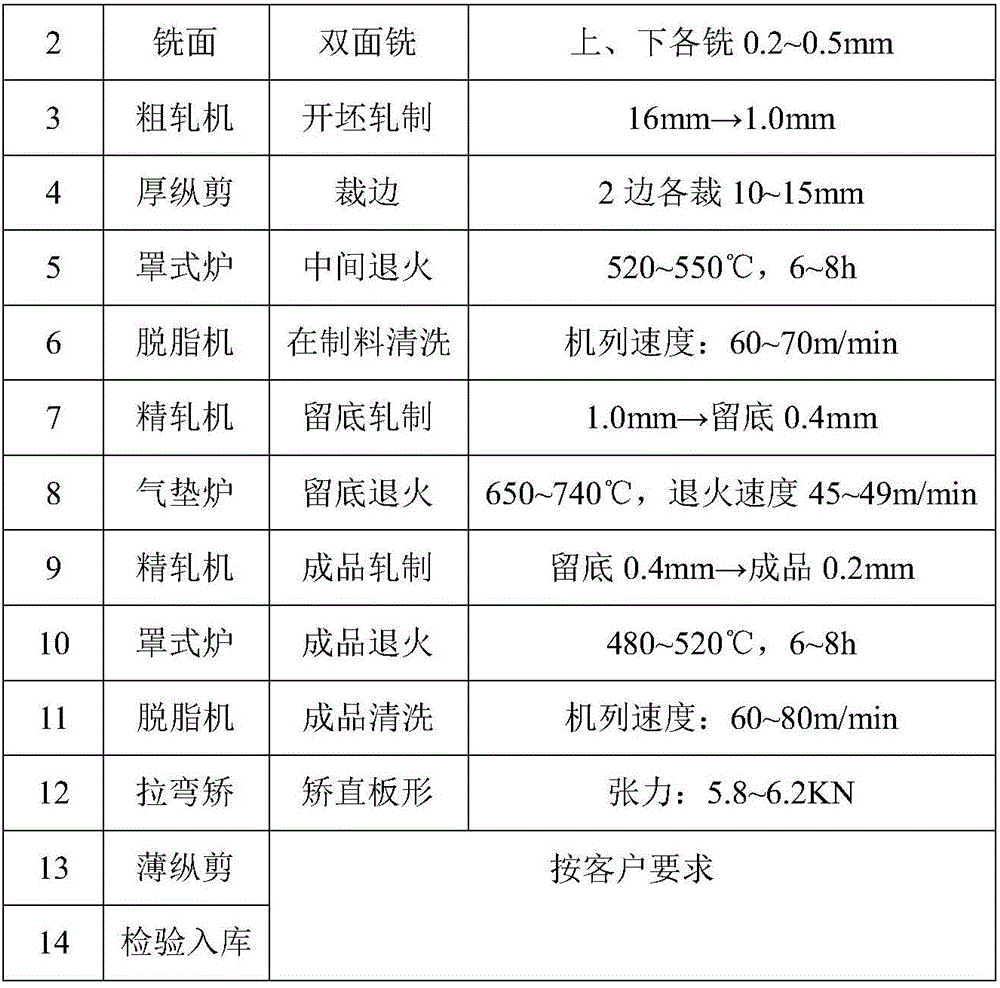

[0026] A high-performance tin phosphor bronze strip contains the substances shown in Example 1 in Table 2 by weight percentage.

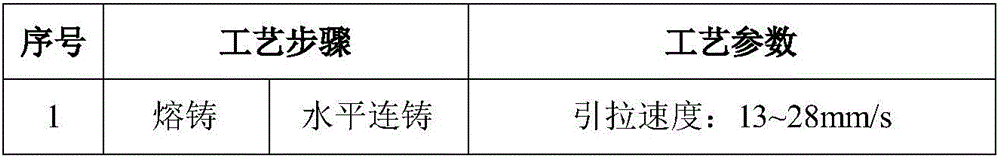

[0027] The production method of the above-mentioned high-performance tin-phosphorus bronze strip includes the following processes: melting and casting—double-side milling—slab rolling in a rough rolling mill—edge trimming—intermediate annealing in a bell furnace—degreasing and cleaning—retaining in a finishing mill Bottom rolling—annealing at the bottom of the air cushion furnace—finished product rolling in the finishing mill—annealing of the finished product in the bell furnace—degreasing and cleaning—straightening the shape—slitting and packaging of the finished product; the parameters of each process are as shown in Table 3 Shown in embodiment 1.

[0028] A kind of production method of high-performance tin phosphor bronze strip, wherein the parameter of each process is as shown in embodiment 1 in table 3;

[0029] Wherein the traction process pa...

Embodiment 2

[0035] A high-performance tin phosphor bronze strip contains the substances shown in Example 2 in Table 2 by weight percentage.

[0036] The production method of the above-mentioned high-performance tin-phosphorus bronze strip includes the following processes: melting and casting—double-side milling—slab rolling in a rough rolling mill—edge trimming—intermediate annealing in a bell furnace—degreasing and cleaning—retaining in a finishing mill Bottom rolling—annealing at the bottom of the air cushion furnace—finished product rolling in the finishing mill—annealing of the finished product in the bell furnace—degreasing and cleaning—straightening the shape—slitting and packaging of the finished product; the parameters of each process are as shown in Table 3 Shown in embodiment 2.

[0037] A kind of production method of high-performance tin phosphor bronze strip, wherein the parameter of each process is as shown in embodiment 2 in table 3;

[0038] Wherein the traction process pa...

Embodiment 3

[0044] A high-performance tin phosphor bronze strip contains the substances shown in Example 3 in Table 2 by weight percentage.

[0045] The production method of the above-mentioned high-performance tin-phosphorus bronze strip includes the following processes: melting and casting—double-side milling—slab rolling in a rough rolling mill—edge trimming—intermediate annealing in a bell furnace—degreasing and cleaning—retaining in a finishing mill Bottom rolling—annealing at the bottom of the air cushion furnace—finished product rolling in the finishing mill—annealing of the finished product in the bell furnace—degreasing and cleaning—straightening the shape—slitting and packaging of the finished product; the parameters of each process are as shown in Table 3 Shown in embodiment 3.

[0046] A kind of production method of high-performance tin phosphor bronze strip, wherein the parameter of each process is as shown in embodiment 3 in table 3;

[0047]Wherein the traction process par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com