Self-positioning vacuum brazing technique for multi-cavity electrical bridge waveguide

A brazing process and self-positioning technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the difficulty of ensuring the dimensional accuracy of the multi-cavity bridge waveguide, uneven heating of the multi-cavity bridge waveguide, and cavity welding deformation Large quantity and other problems, to achieve the effect of improving dimensional accuracy and surface roughness, reducing production and processing procedures, and high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

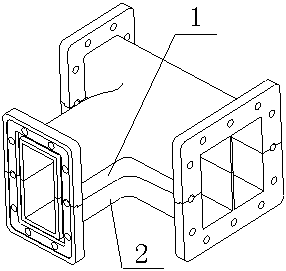

[0035] like figure 1 Shown is the multi-cavity bridge waveguide manufactured according to the process of the present invention, the self-positioning multi-cavity bridge waveguide vacuum brazing process, which includes the following steps:

[0036] (1) Raw materials are prepared, and the machining of the upper part 1 of the waveguide and the lower part 2 of the waveguide is completed according to the design.

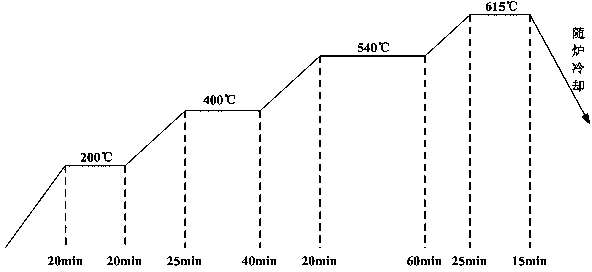

[0037] (2) Pickling the processed waveguide upper part 1 and waveguide lower part 2 respectively; the pickling includes the following steps: Step 1: Use 60℃~80℃, 8%~10% NaOH aqueous solution to treat the waveguide upper part 1 Etch with the lower part 2 of the waveguide, and the etching time is 1 to 2 minutes; the second step: put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com