Patents

Literature

67results about How to "Solve welding difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

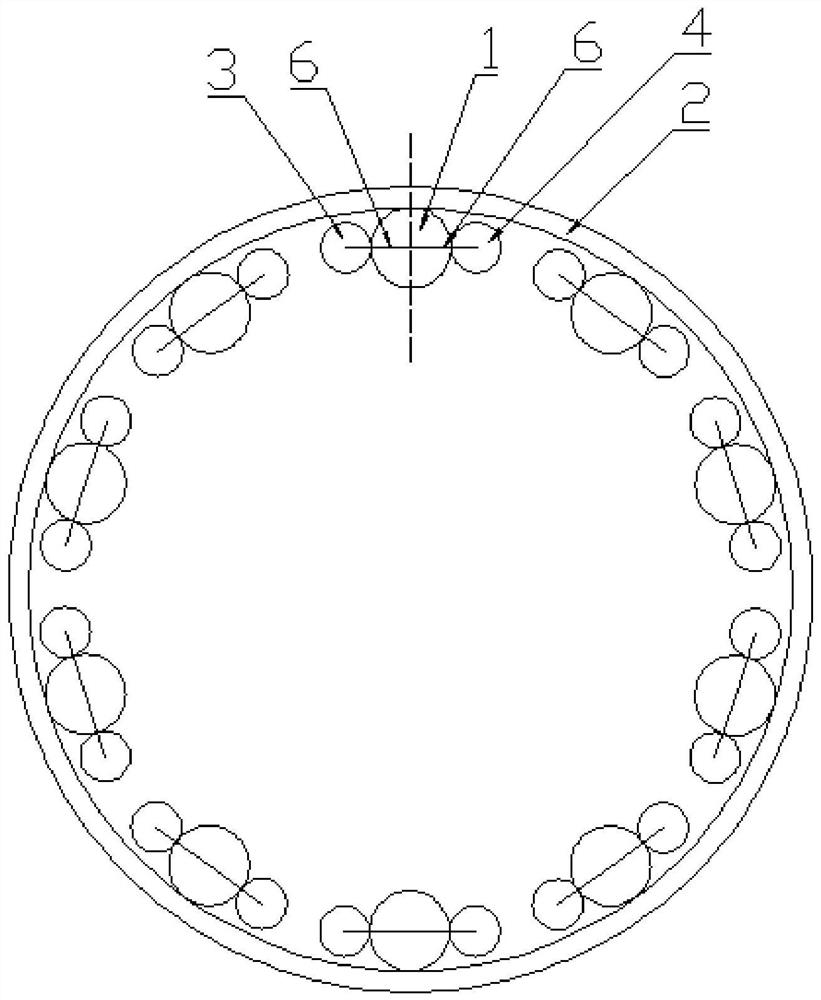

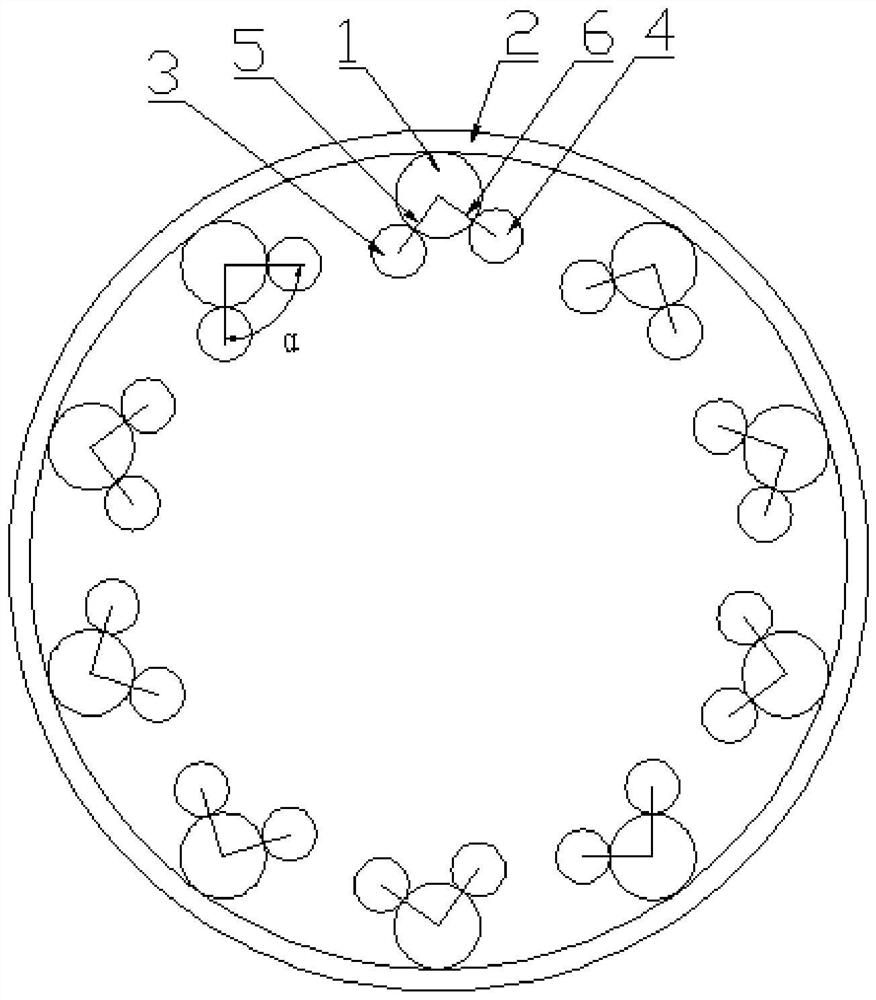

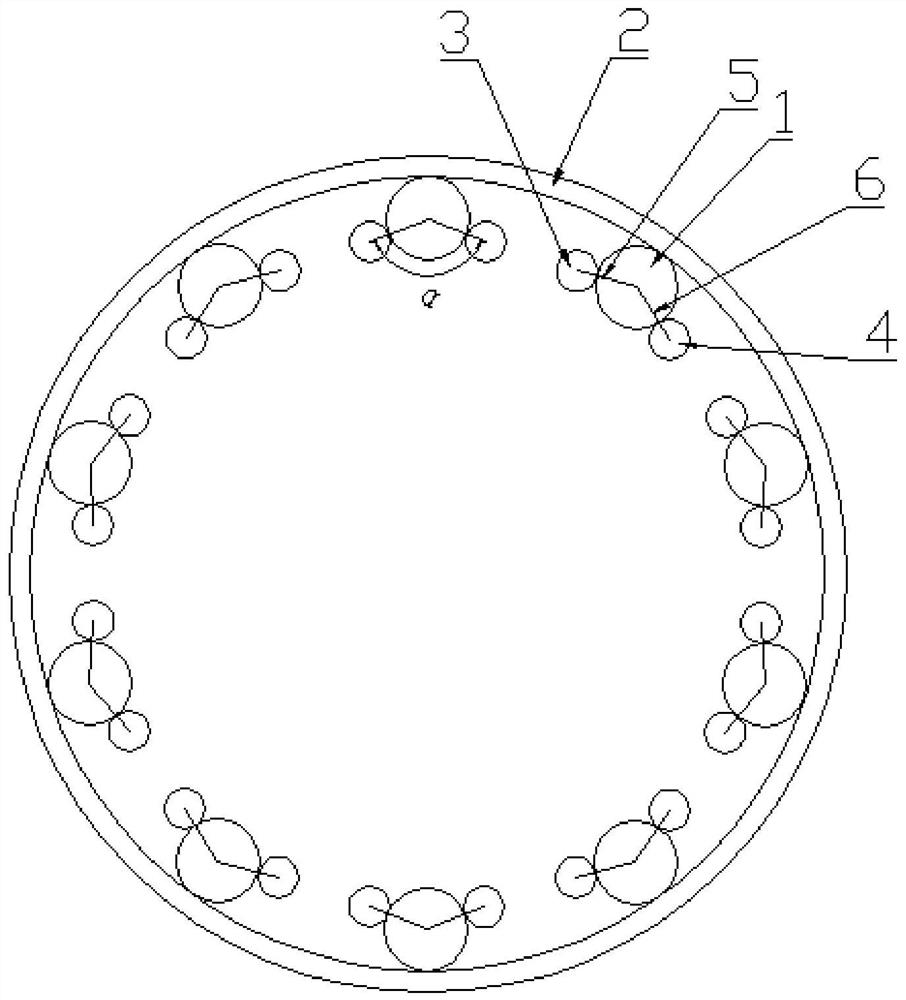

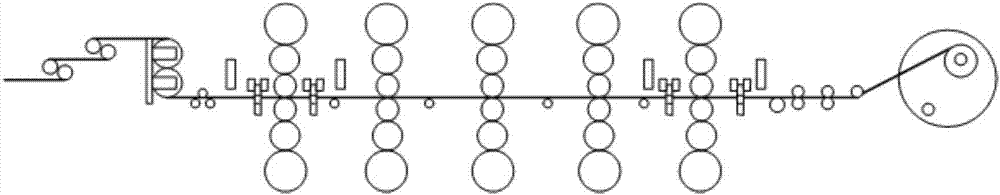

Method for cold rolling high silicon electric steel

InactiveCN101209459ASolve the problem of welding broken stripsGuaranteed surface qualityRoll force/gap control deviceOther manufacturing equipments/toolsMechanical energyAcid washing

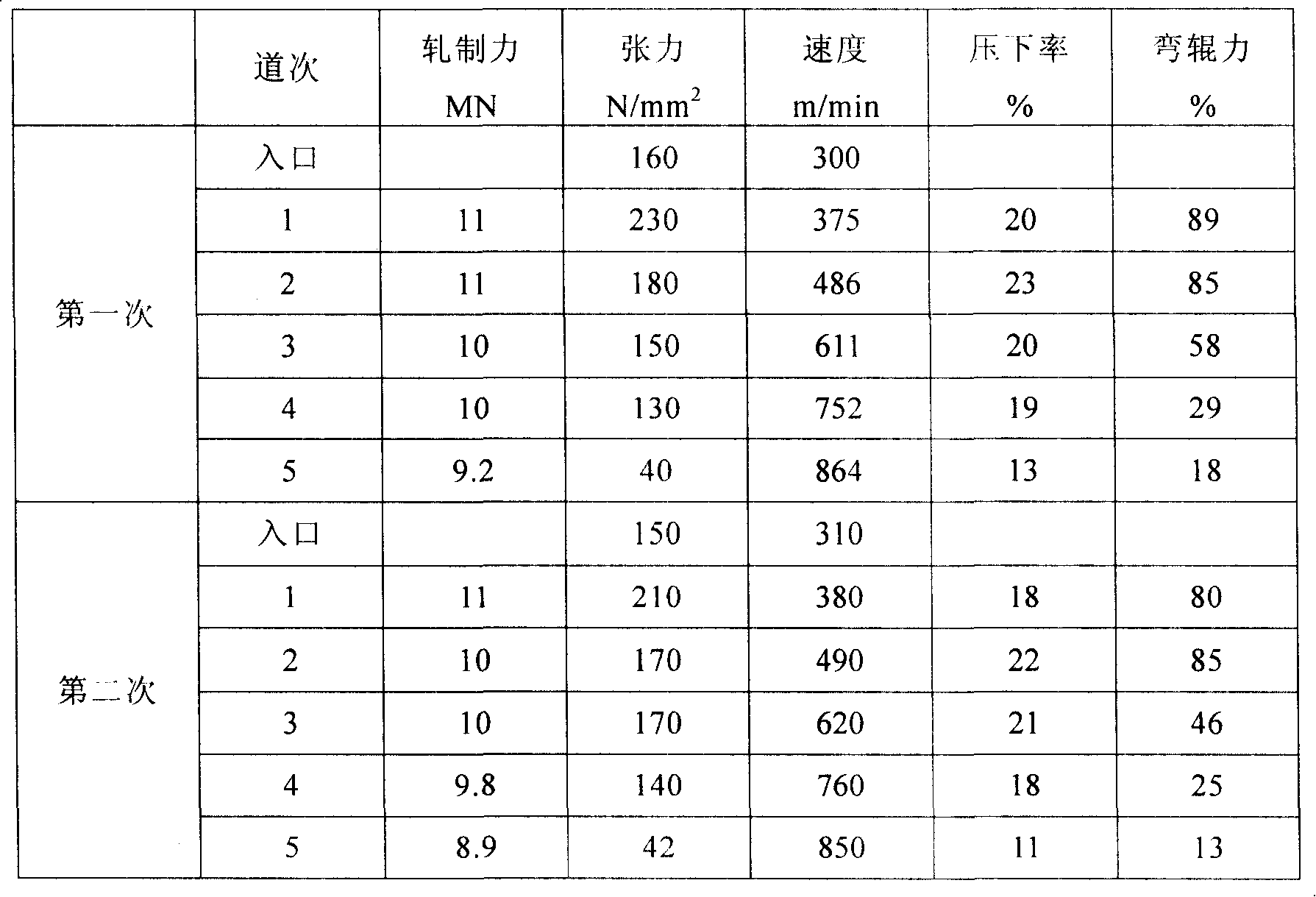

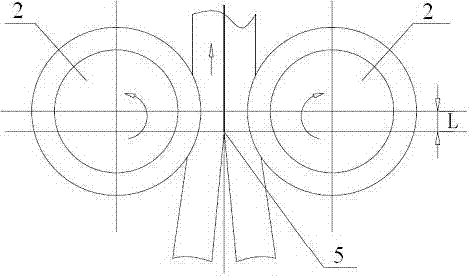

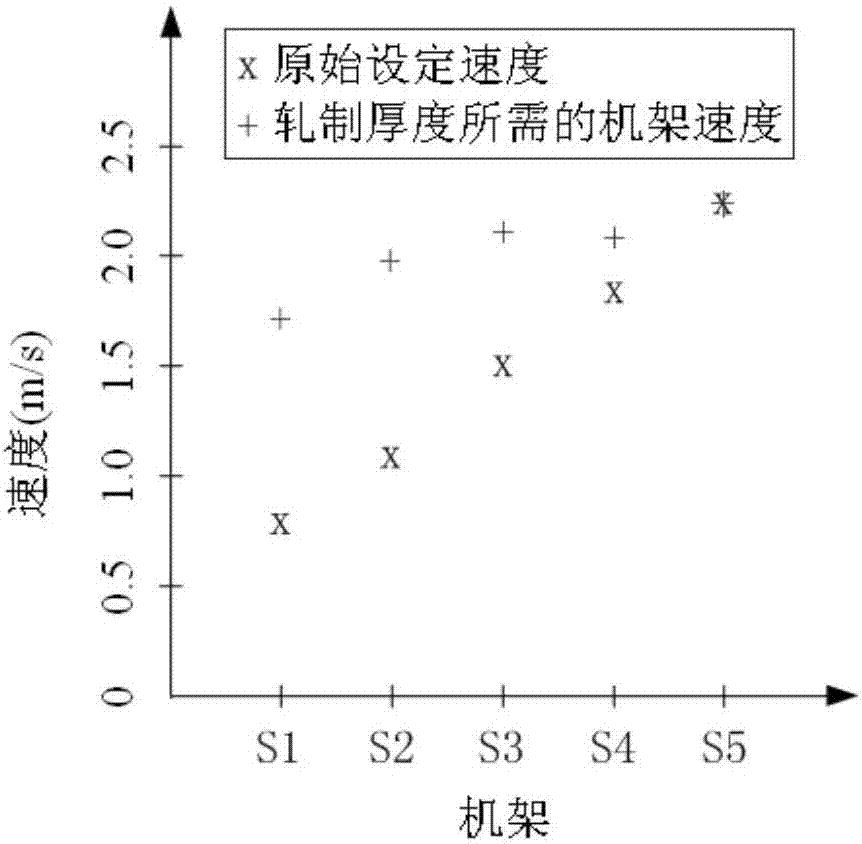

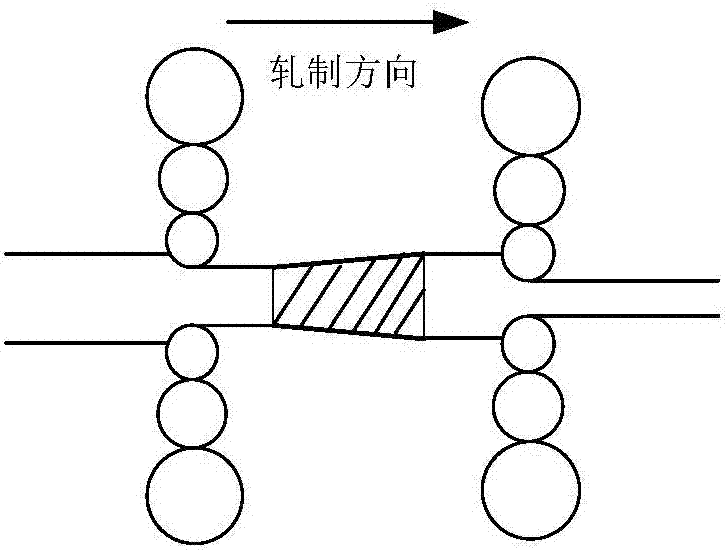

The invention provides a cold rolling method for high-silicon electrical steel. The method comprises conventional processes of a first cold rolling for a hot rolled plate after being treated with acid washing or a second cold rolling with annealing during operation, decarbonization annealing and recrystallization annealing, etc., and is characterized in that the hot rolled plate before being treated with acid washing is done with welding end to end and then continuous endless rolling is done by a mill with multi-stands; a warm rolling is realized by that mechanical energy is transformed into heat energy during the rolling and the temperature of the steel plate raises; the tension among each mill stand is 100-300 N / mm <2> and 30-80 N / mm<2> for the last mill stand; the draft is 15-30 percent and 5-15 percent for the last mill stand and the outlet speed of the rolling mill is no less than 500m / min and the thickness of the finished product is 0.2-0.8mm. By adopting a plurality of mill stands to realize the warm rolling, the invention effectively solves the breakage occurred in edges; the last mill stand is served as the pass mill stand of finished products so as to guarantee the quality of the surface of the steel strip; large tension is adopted during the rolling so as to ensure that a forward slipping area can be reduced and deformation bands are increased. Compared with the method by a single mill stand, the method of the invention prolongs the cycle of roll changing, reduces the labor intensity, shortens the production cycle and improves productivity and quality of steel plates. In addition, the method of welding from head to tail for transition with low-silicon steel can effectively solve the problem of breakage during the welding of the high-silicon electrical steel.

Owner:ANGANG STEEL CO LTD

Method for welding metal under strong magnetic field circumstance

InactiveCN101148009ASolve welding difficultiesReduce welding defectsMagnetic bodiesWelding/cutting auxillary devicesElectricityWeld seam

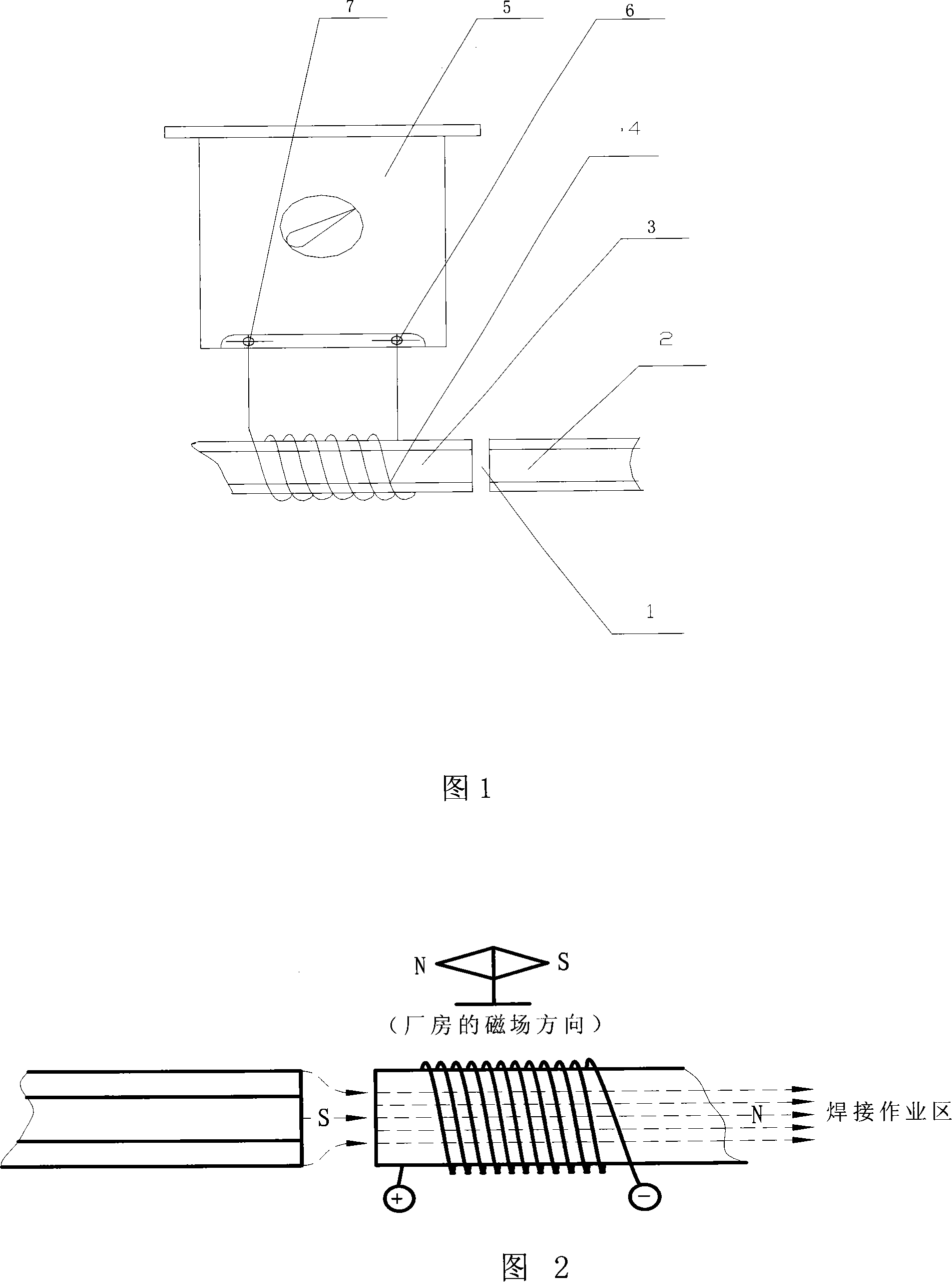

The present invention relates to welding technology, and is especially metal welding method in strong magnetic field environment. The metal welding method in strong magnetic field environment includes measuring the strength and direction of the environmental magnetic field with special instrument, forming one coil of certain turn number and winding direction and connecting the coil to one metal workpiece to be welded, connecting the coil to one DC welder to generate one magnetic field in the same strength as and reverse direction to the environmental magnetic field, and welding with one other welder in no or weak magnetic field condition. The method of the present invention can result in high welding quality, weld seam strength reaching 80 % of mother material strength and tensile strength of the weld seam up to 700 MPa.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

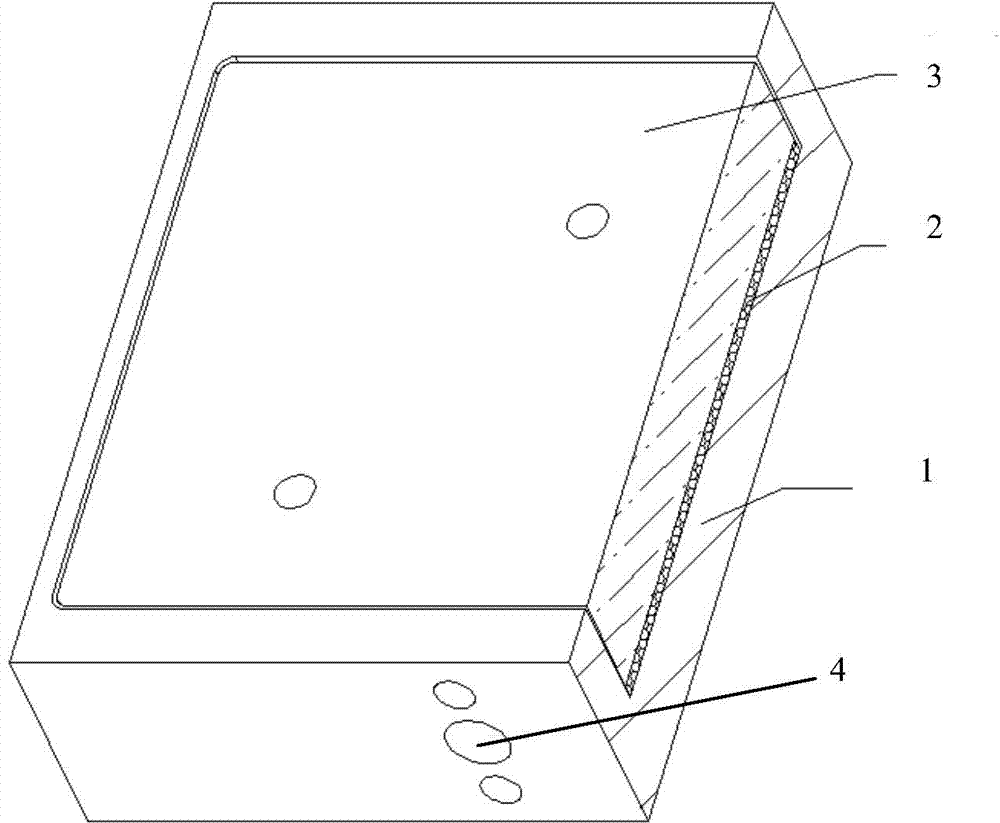

Ultralight lithium ion battery current collector and preparation method thereof

InactiveCN108336357AImprove securityReduce weightElectrode carriers/collectorsEngineeringLithium-ion battery

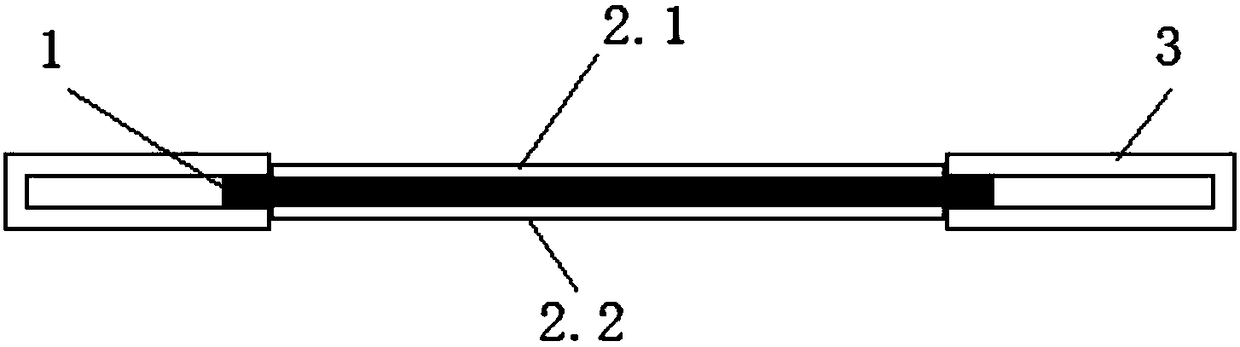

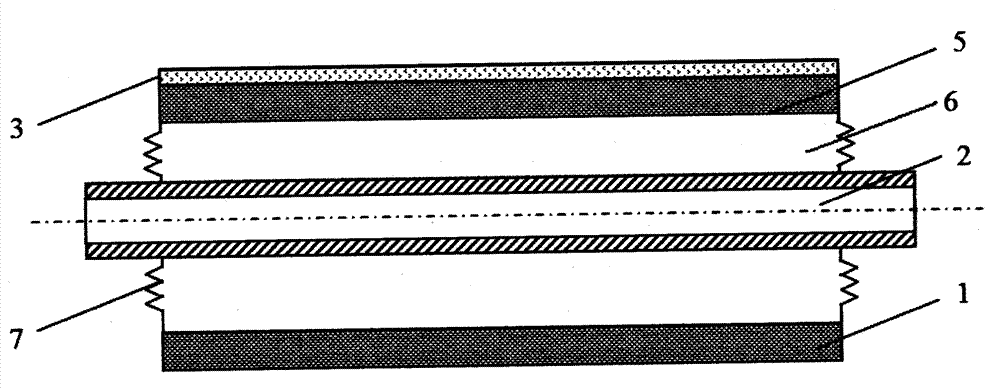

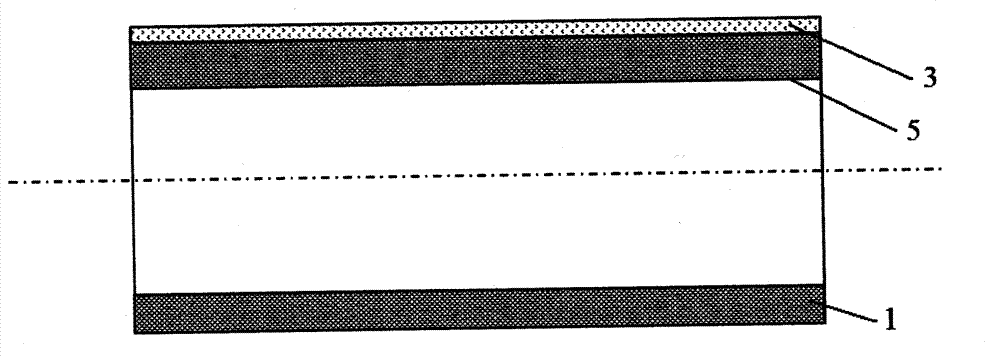

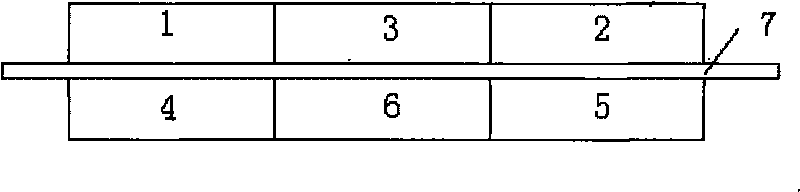

The invention discloses an ultralight lithium ion battery current collector, comprising a PET layer, wherein two ends of the PET layer are respectively connected with a U-shaped sheet metal, and the side surfaces of two sides, located between the sheet metals at the both ends, of the PET layer are plated with an upper metal layer and a lower metal layer. The lithium ion battery current collector of the invention adopts the PET layer as a matrix layer, and the sheet metals at the both ends are of U-shaped structure, the weight and occupied space of the current collector are greatly reduced, soenergy density in increased; moreover, since two side surface of the polymer matrix layer are plated with the metal layers, so burrs are not generated during processing and cutting, and the safety performance of a battery is improved; meanwhile, the current collector of the invention has more excellent processability compared with conventionally industrialized current collectors.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

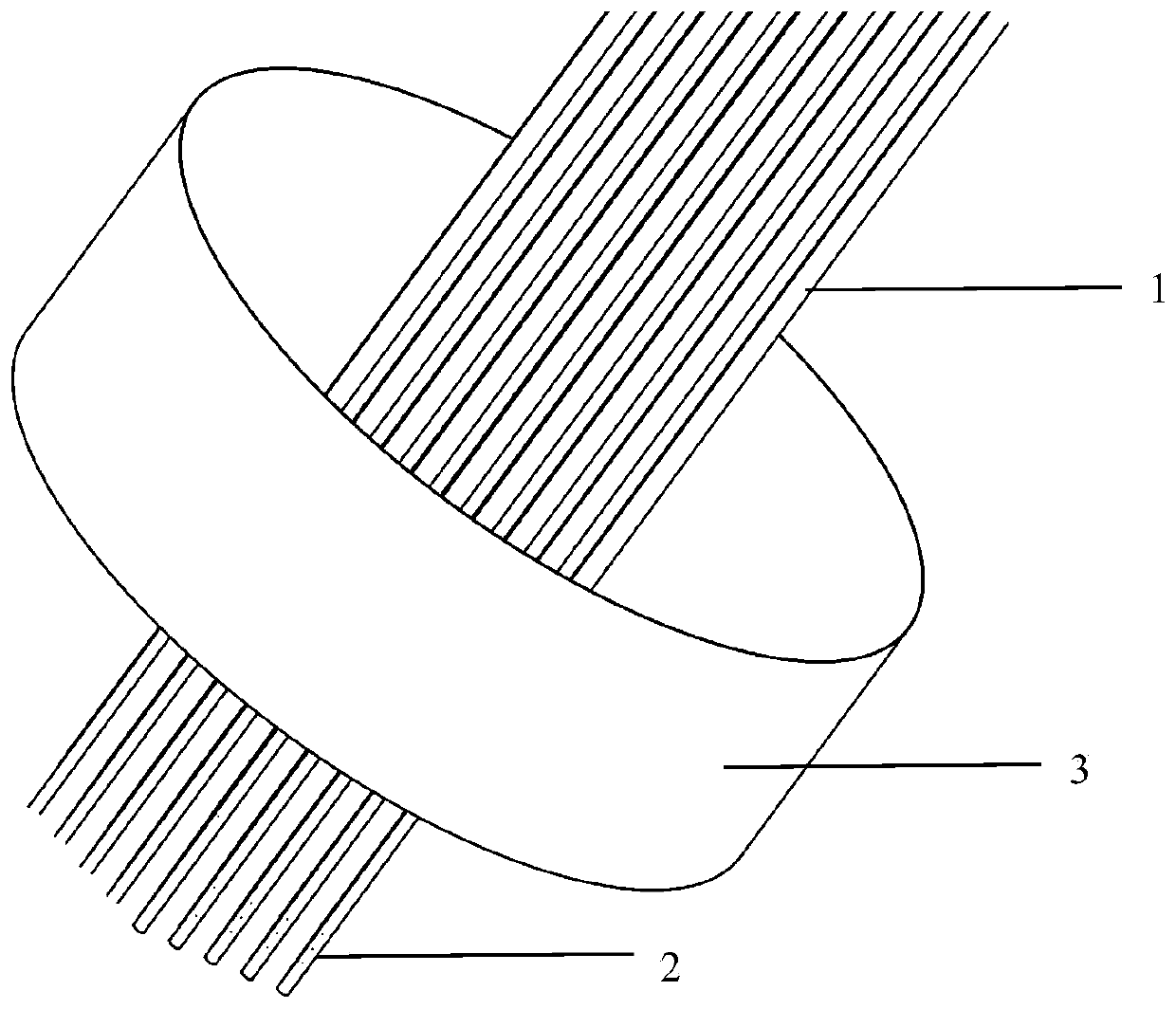

Welding method of titanium welded tube for petrochemical engineering

InactiveCN102962560ASolve welding difficultiesReduce processWelding/soldering/cutting articlesTubular articlesEngineeringThick wall

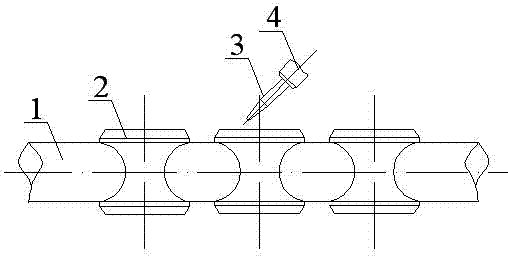

The invention introduces a welding method of a titanium welded tube for petrochemical engineering. A titanium belt is subjected to on-line continuous cold roll forming to form closed bore diameter and then fed into a welding case body, a single gun is adopted for argon tungsten-arc welding, argon tungsten-arc welding is carried out by adopting appropriate welding parameters such as welding inclination angle, welding current and voltage, so as to weld the molded titanium belt into a straight-seam titanium welded tube; and during the welding process, argon gas is used for carrying out internal and external protection on the welded tube, protecting the single gun and protecting a welding support cover, so that the titanium welded tube for petrochemical engineering is prepared. The welding quality, surface quality and the like of the straight-seam titanium welded tube produced by the method can meet the requirements of titanium welded tubes for petrochemical engineering such as PTA (Pure Terephthalic Acid) engineering, the titanium welded tube can be used for replacing seamless titanium tubes for the petrochemical engineering industry, and the welding difficulty of the titanium welded tube with small tube diameter and super thick wall can be solved; and compared with a seamless titanium welded tube preparation method, the method provided by the invention has the advantages of less working procedures, simplicity in operation and easiness for realization of large-batch production.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

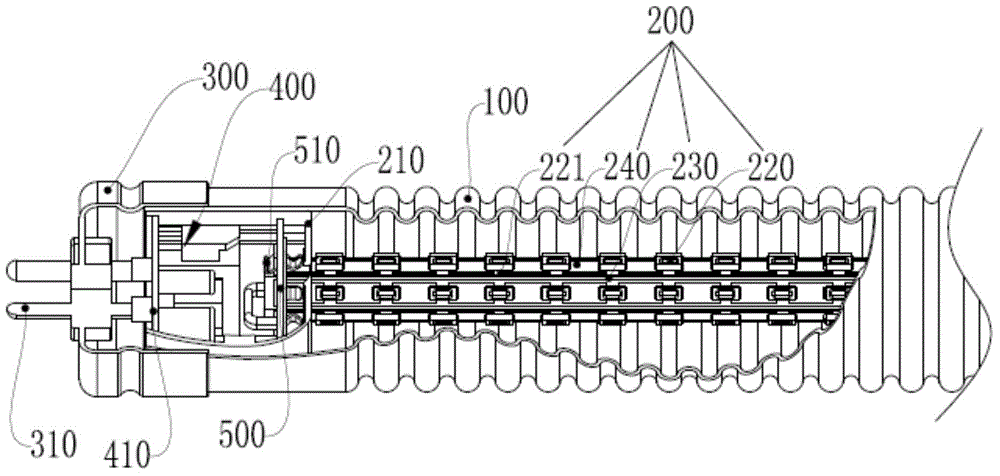

Glass-cover-free tubular solar thermal collector

InactiveCN103196242AReduce heat lossSolve the fragileSolar heating energySolar heat devicesGlass coverMetallic materials

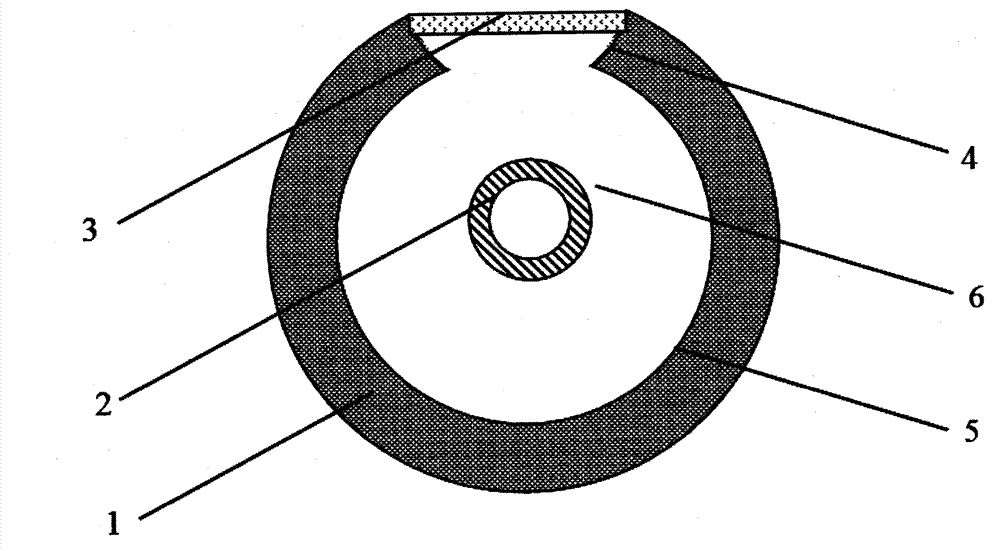

A glass-cover-free tubular solar thermal collector relates to a solar thermal collector, and a problem that a glass cover of the solar thermal collector cracks due to the fact that thermal expansion degrees of a metal material and the glass cover of a tubular thermal absorber are different is solved. A light enclosing cavity is made of a metal material, a heat preservation layer is wrapped on an outer wall of the light enclosing cavity, and the tubular thermal absorber is arranged in the light enclosing cavity and made of the metal material. A light-transmitting port is arranged on the top portion of the light enclosing cavity, an optical window is arranged at the light-transmitting port, and two ends of the light enclosing cavity are connected with the tubular thermal absorber in mechanical mode through metal sealing connecting joints with a function of reducing thermal strain respectively. The axial thermal expansion difference of the light enclosing cavity and the tubular thermal absorber is offset through wave pitch changes of a corrugated metal connecting sealing joint, and the problem that the glass cover is prone to crack, and the glass cover, the tubular thermal absorber and the metal connecting sealing joint of the traditional tubular thermal absorber are hard to weld is solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

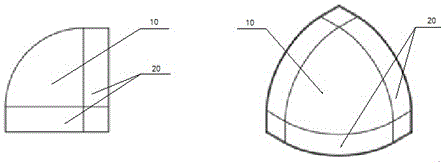

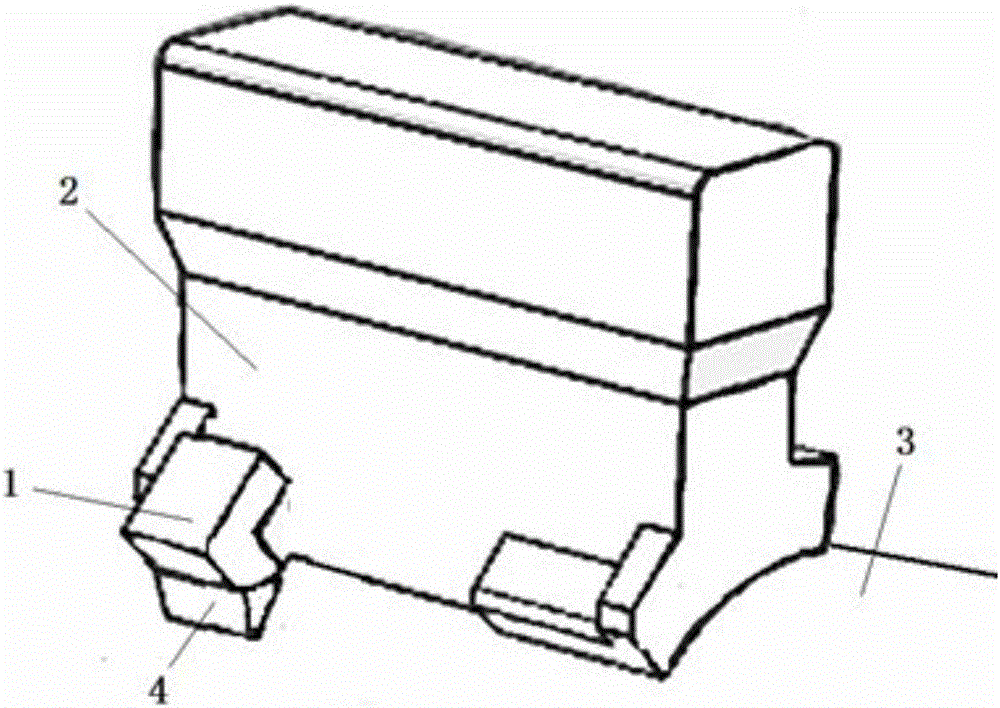

Novel one-eighth sphere corner aluminum alloy end socket and manufacturing method

ActiveCN106838307ASolve corner stress concentrationSolve welding difficultiesPipe elementsPressure vesselsStress concentrationActual use

The invention discloses a novel one-eighth sphere corner aluminum alloy end socket. The one-eighth sphere corner aluminum alloy end socket is used for replacing eight top corners of a vehicle-mounted rectangular box, namely the eight top corners of the vehicle-mounted rectangular box are replaced with eight spherical round corners, straight edge sections are additionally arranged on three edges of the spherical round corners, and the three edges of the spherical round corners and three edges of the vehicle-mounted rectangular box are assembled and spliced in the same plane conveniently; and the spherical round corners are one-eighth spherical round corners. The novel one-eighth ball corner aluminum alloy end socket is mainly used for solving the problems that the eight top corners of the vehicle-mounted rectangular box are concentrated in stress, difficult to weld, low in welding efficiency, prone to breakage by impact, not attractive enough and the like, and actual use requirements are met.

Owner:ANHUI XINLIANXIN HEAVY HEAD

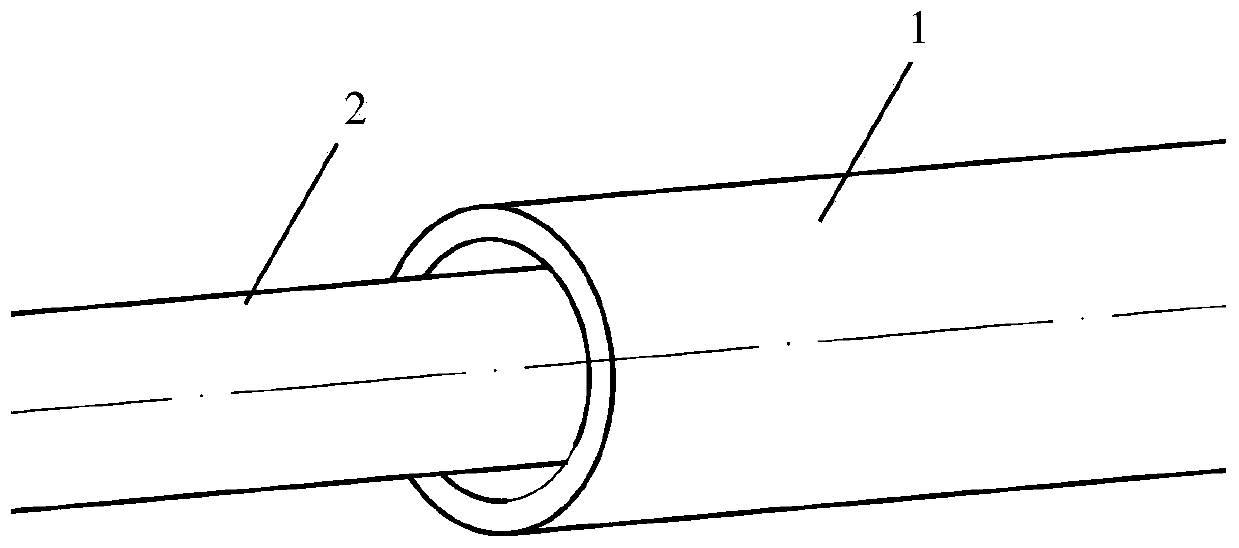

Method for welding capillary tube heat exchanger tube sheet and capillary tubes

ActiveCN109877416ALow costIncrease productivityHeat exchanger casingsStationary tubular conduit assembliesEngineeringSmall hole

The invention provides a method for welding a capillary tube heat exchanger tube sheet and capillary tubes. The method for welding the capillary tube heat exchanger tube sheet and the capillary tubescomprises the following steps that 1, a tool is machined; 2, the stainless steel capillary tubes with high temperature resistant metal wires penetrating through the insidesarearranged according to requirements of a capillary tube heat exchanger and penetrate through small holes at the bottom of the tool; 3, metal is added into the tool; 4, the metal is melted; and5, the tool is removed, the metalwires are extracted, machining and assembling are further conducted, and overall manufacturing of the capillary tube heat exchanger is completed. The method for welding the capillary tube heat exchanger tube sheet and the capillary tubes has the advantages that it is ensured that the problem that the welding of the capillary tubes and the tube sheet of the capillary tube heat exchanger is difficult can be solved while an integrated tube sheet and capillary tube channel structure is obtained by melting solidification, and a microchannel required by the capillary tube heat exchanger is formed; and the cost can be effectively reduced, and the production efficiency is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

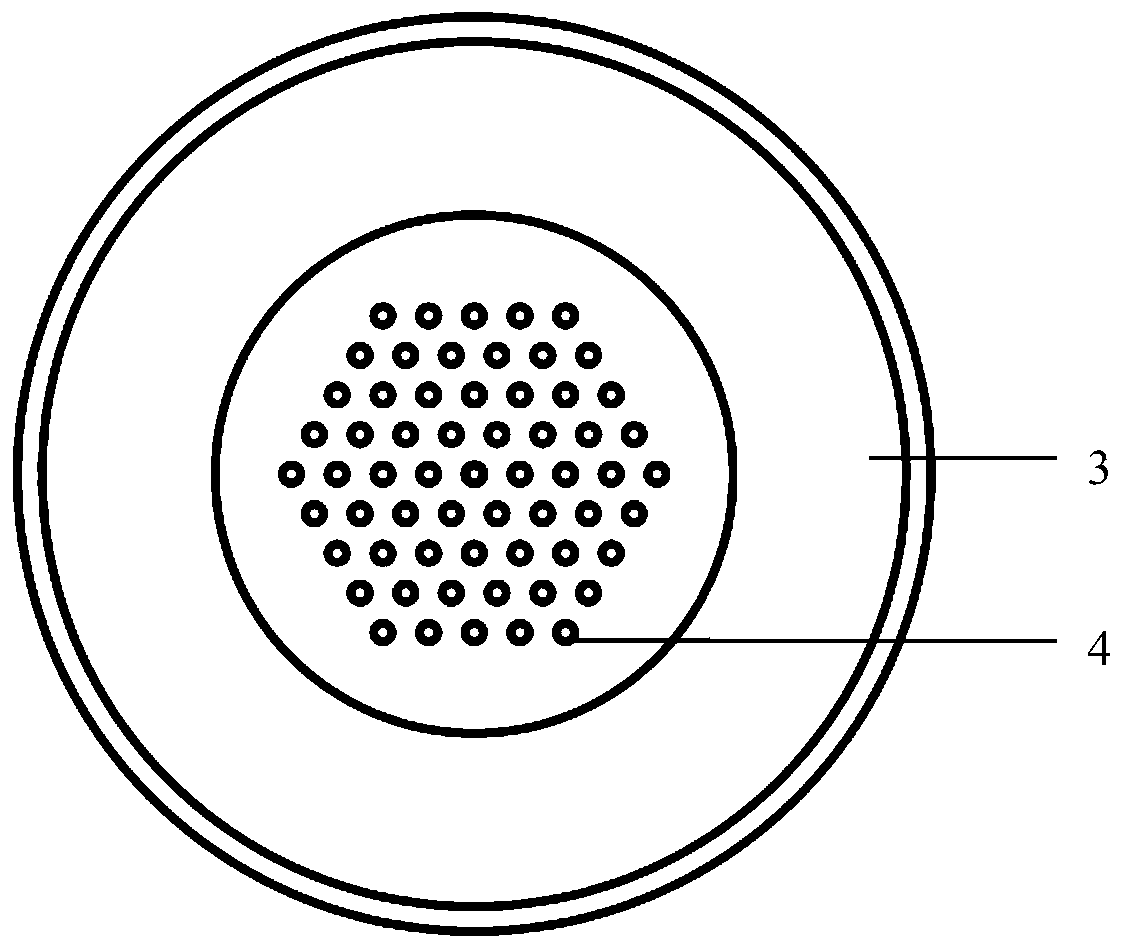

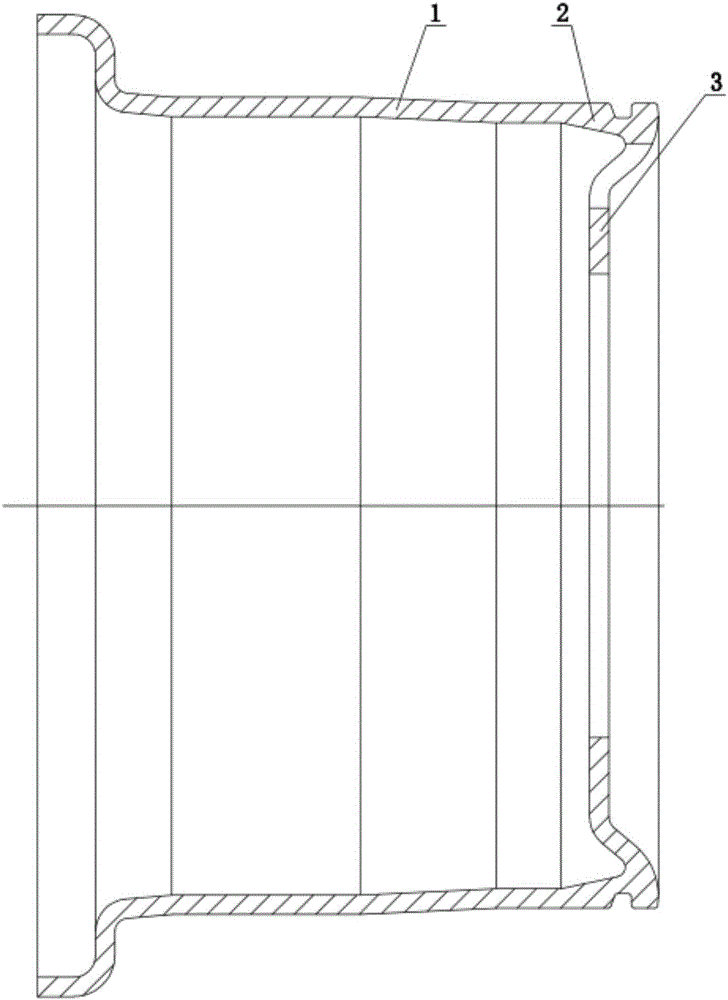

Preparation method of ultra-large polytetrafluoroethylene seal ring

InactiveCN103072275ABreak through the limitation that the outer diameter is only below 2000mmSolve welding difficultiesPolishing machinesDomestic articlesEngineeringPolytetrafluoroethylene sheet

The invention provide a preparation method of an ultra-large polytetrafluoroethylene seal ring, which comprises the steps of (a) cutting the two ends of a polytetrafluoroethylene plate to form inclined planes with the same angle, and (b) welding the two ends of the polytetrafluoroethylene plate together to form the ultra-large polytetrafluoroethylene seal ring, wherein the external diameter of the ultra-large polytetrafluoroethylene seal ring is 2-10m. The ultra-large polytetrafluoroethylene seal ring can be obtained with the adoption of the preparation method.

Owner:WUXI XIANGJIAN PTFE PROD

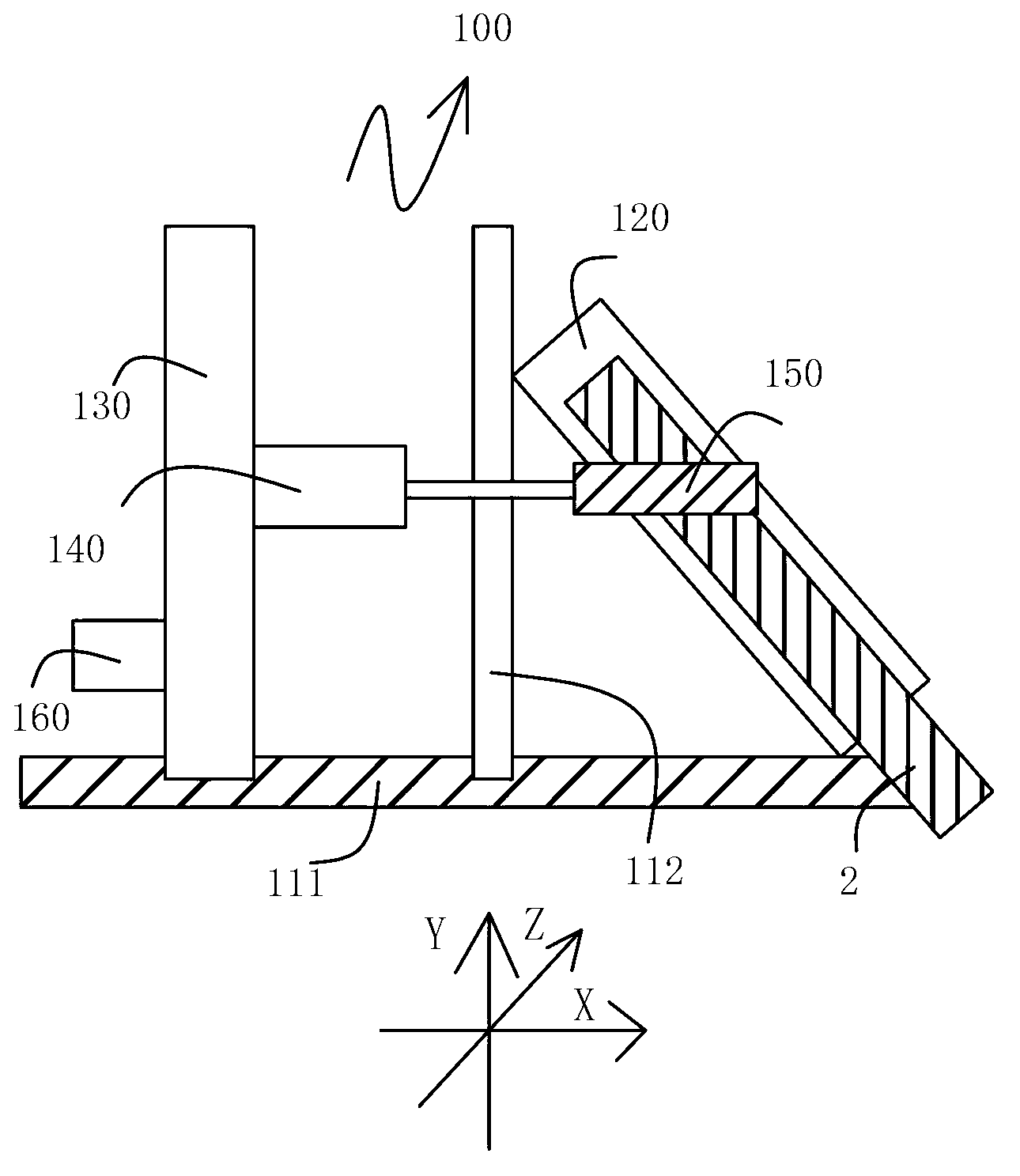

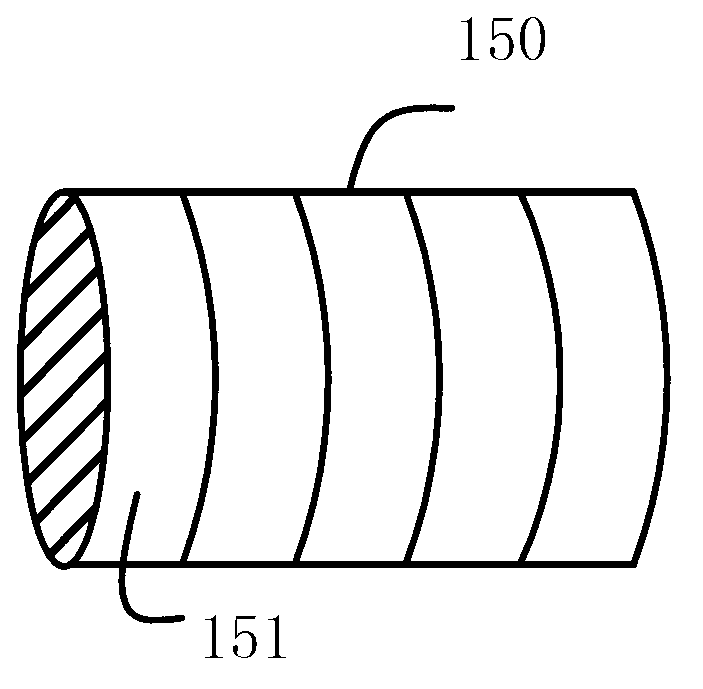

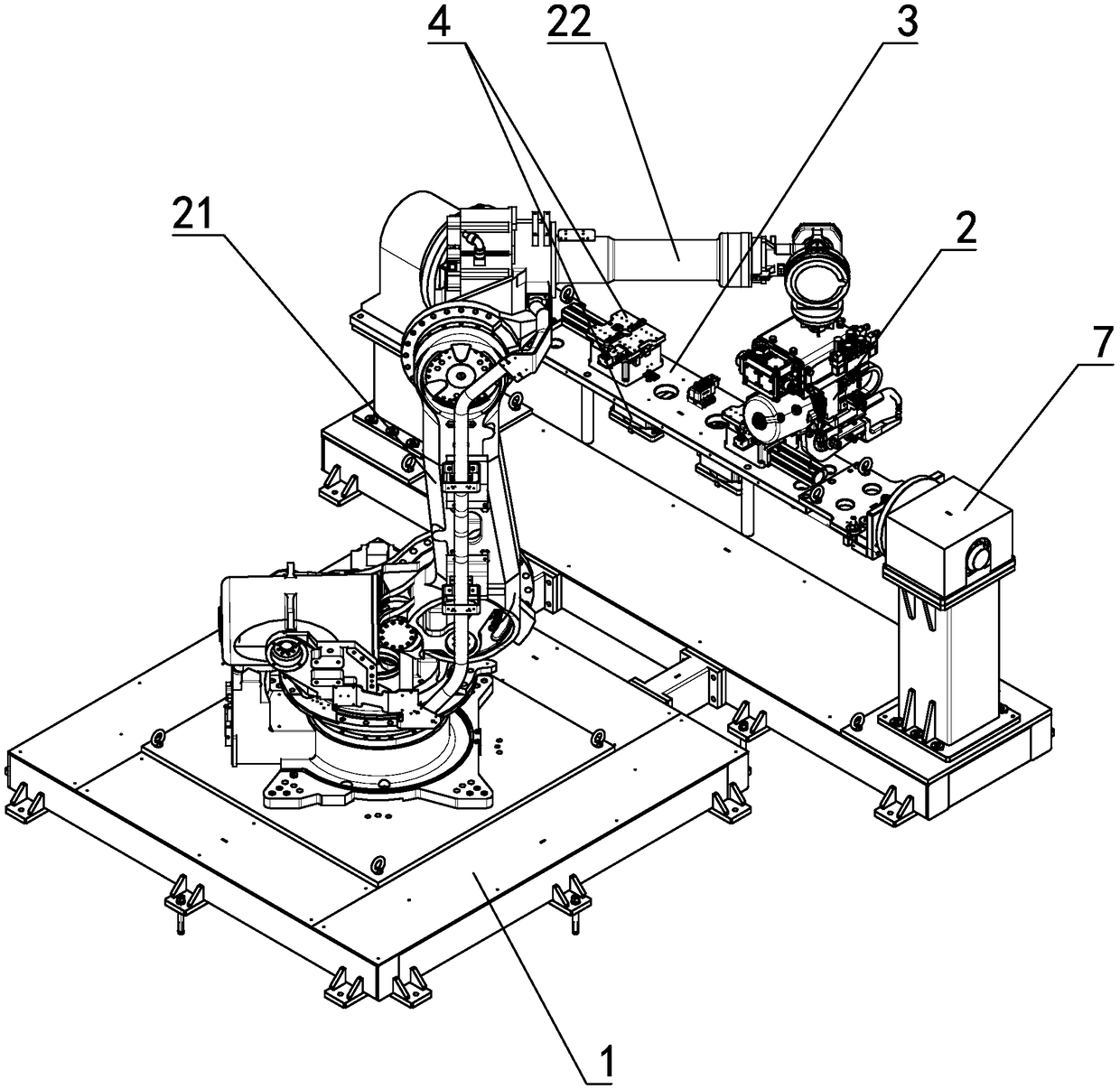

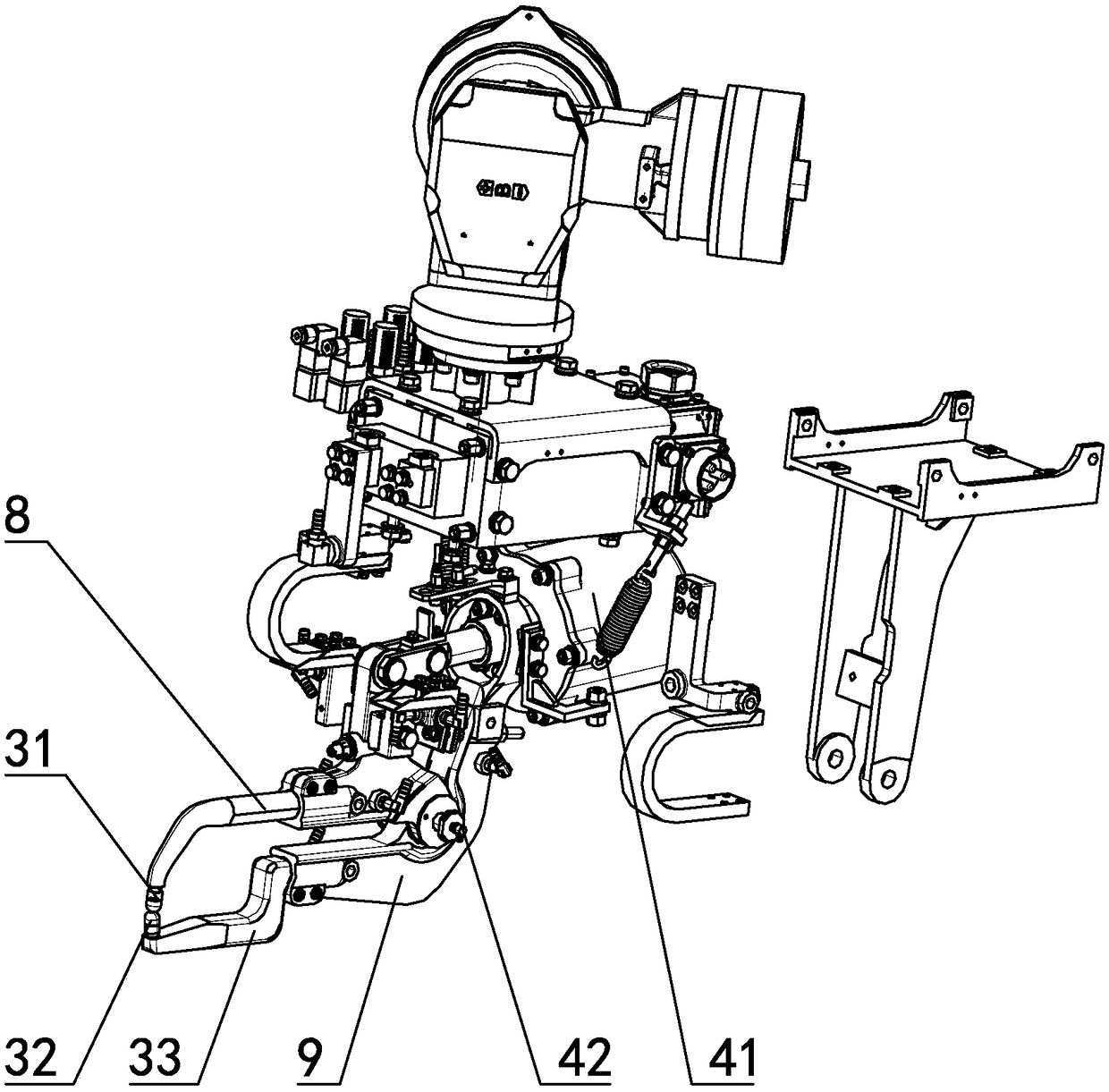

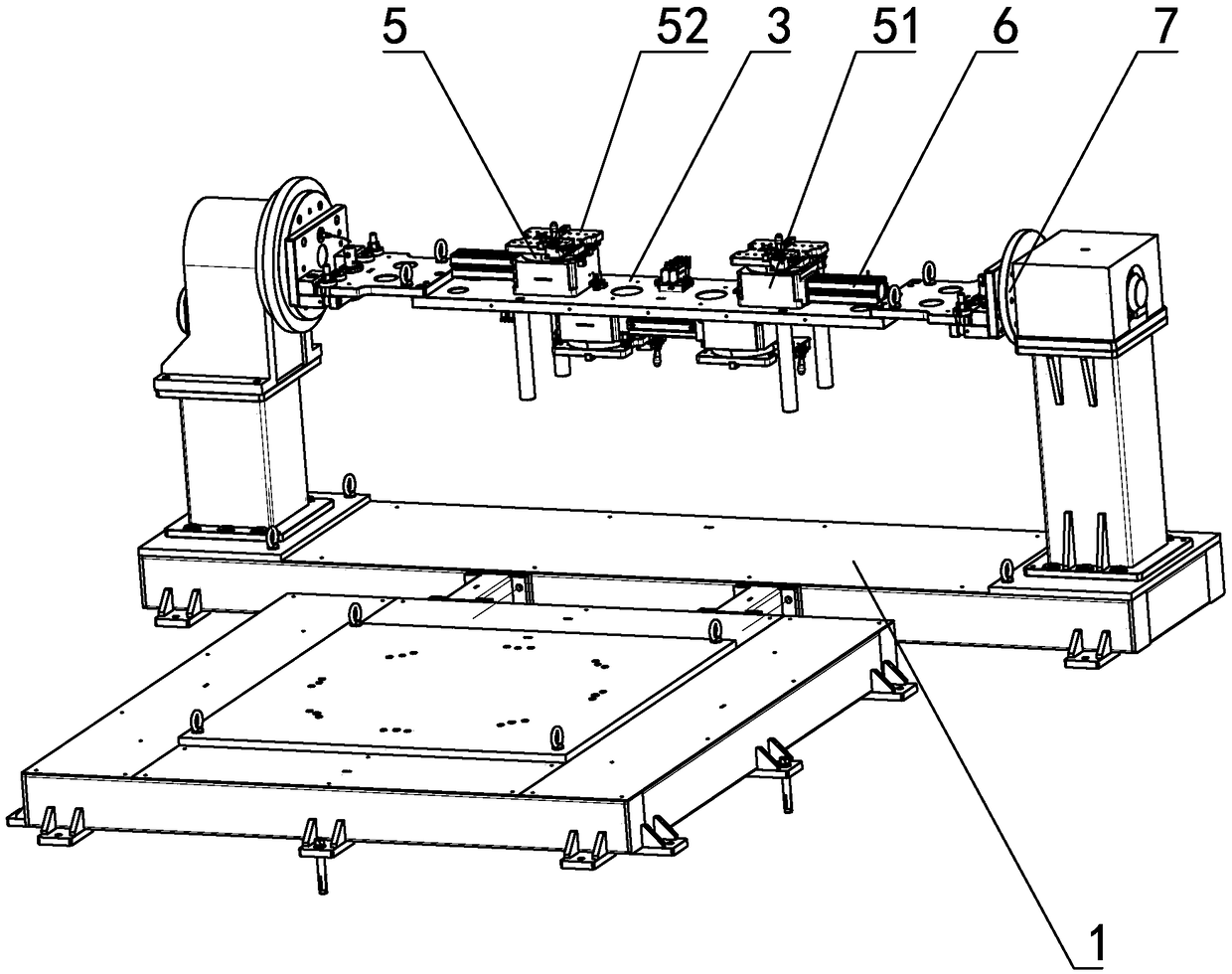

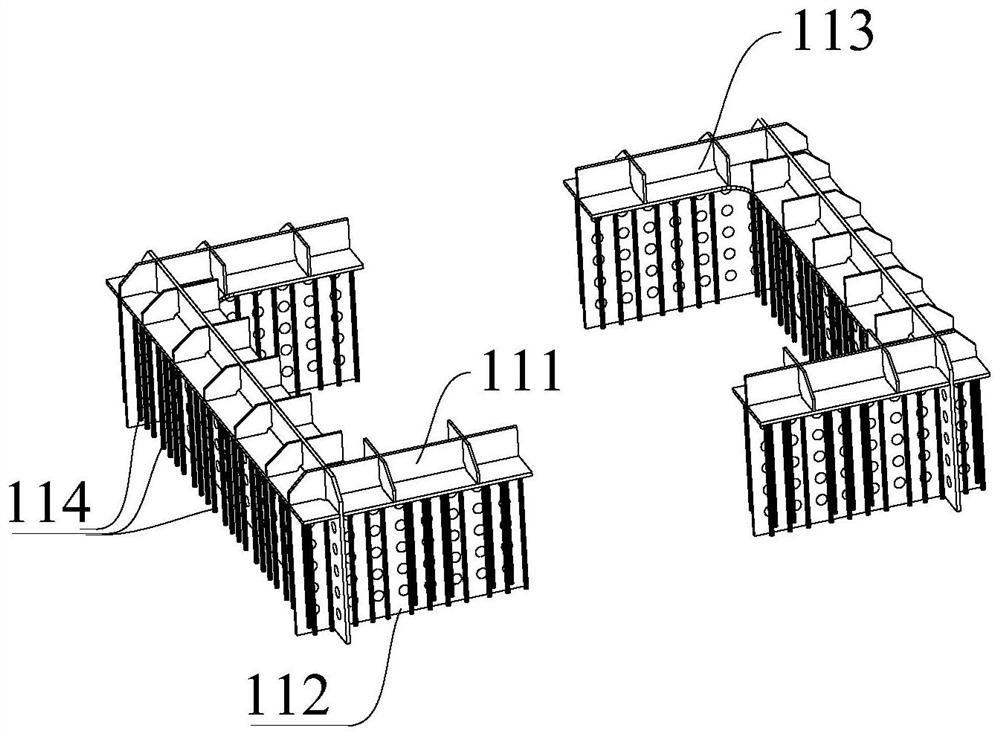

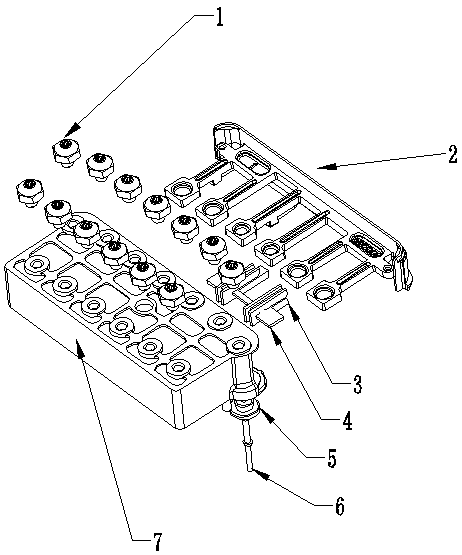

Automatic robot point welding equipment

PendingCN108746972AEasy to weldImprove welding efficiencyResistance welding apparatusEngineeringSpot welding

The invention discloses automatic robot point welding equipment. The equipment comprises a base, a fixing tool, a mechanical support arranged on the base, and a welding gun connected with the mechanical support. The fixing tool comprises a base plate, and workpiece installing positions arranged on the front face and the back face of the base plate. The workpiece installing positions are connectedwith a first rotating motor and a straight air cylinder which can drive the workpiece installing positions to move. The base plate is installed on the base through a position changing machine. The mechanical support comprises multiple mechanical arms connected through power assemblies. The welding gun comprises an upper welding gun body and a lower welding gun body which can be opened or clamped.According to the equipment, by means of the mechanical structure, the problem of welding difficulty is solved, welding of all angles and all positions of products is achieved, and the welding qualityis ensured; the multiple welding stations are arranged, while welding is achieved, workers can take and load workpieces synchronously, non-stop welding can be carried out, and the welding efficiency is improved substantially; and a point welding gun head is arranged, welding is carried out by means of the clamping manner, and the welding efficiency is improved.

Owner:宁波格罗勃自动化有限公司

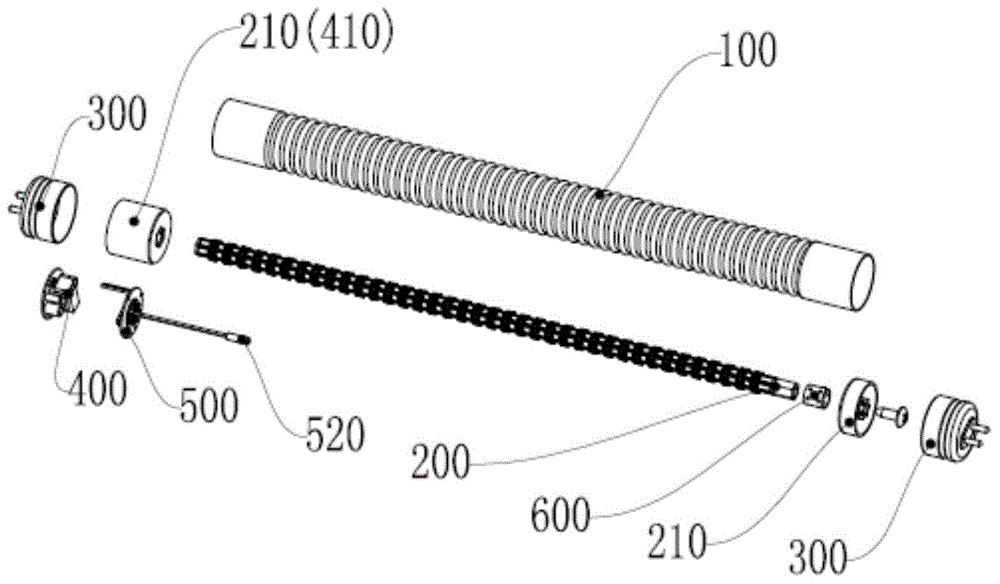

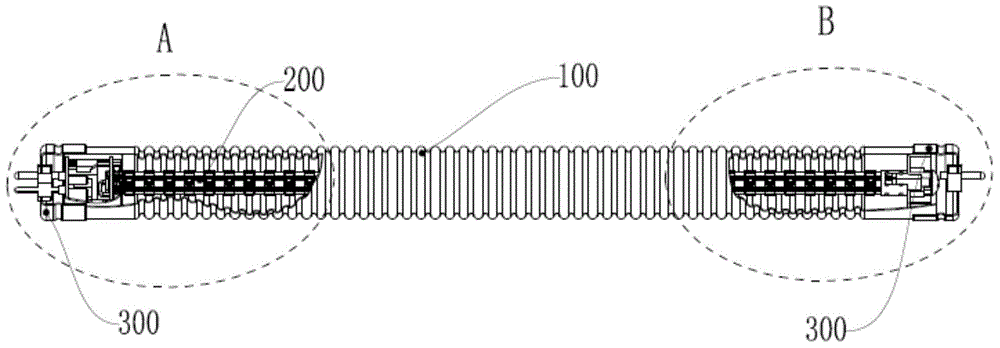

Novel all-around light LED (Light Emitting Diode) lamp

ActiveCN105987295AAvoid overly complex wiringEasy to installPoint-like light sourceElectric circuit arrangementsCopper foilEngineering

The invention relates to the field of lighting fixtures, in particular to a new type of full-circumference LED lamp, which is composed of a lamp tube shell, a wick installed inside the lamp tube shell, and end caps connected to both ends of the lamp tube shell; the wick is composed of a polygonal column The wick bracket is composed of the LED chip installed on the wick bracket and the copper foil wire connected to the LED chip. The drive circuit assembly is arranged on the end cover, and an insulating layer is provided between the surface of the wick bracket and the copper foil wire. , the wick is connected to the drive circuit assembly through an elastic contact and a temperature sensor arranged on a conducting member; according to the above structure, the present invention solves the problem of difficult welding of the wick base material and the LED chip and copper wire, and also avoids The circuit in the LED lamp is too complicated, and it is more convenient to install, which makes the internal structure of the LED lamp simpler and more compact, and the safety and illumination range are also greatly improved.

Owner:FOSHAN HECAI TECH SERVICE

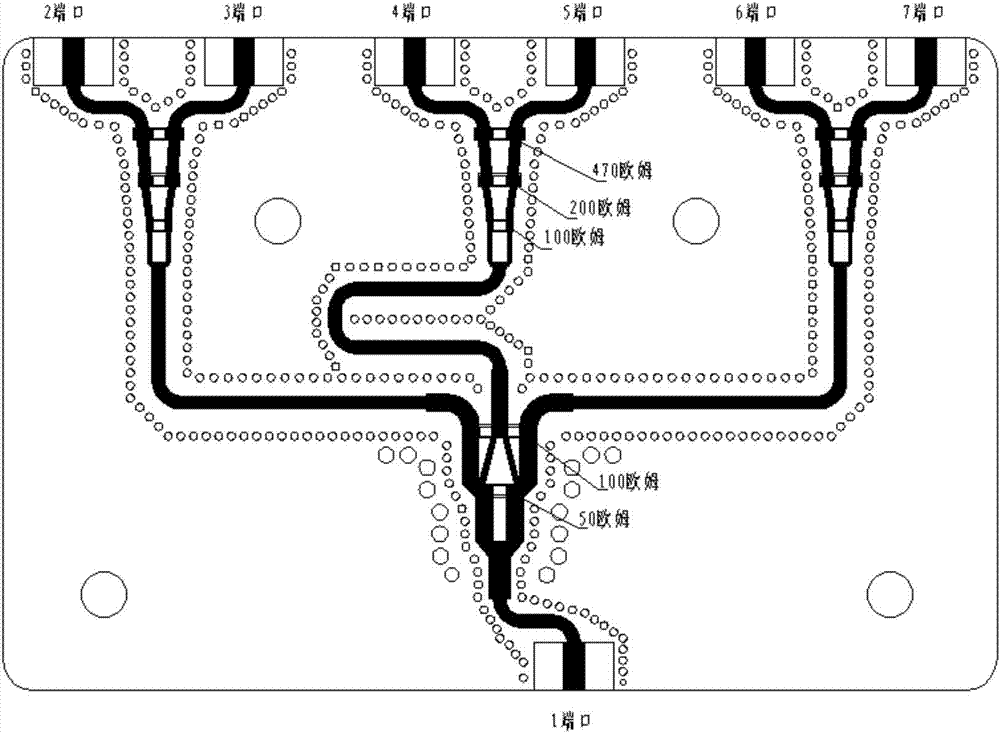

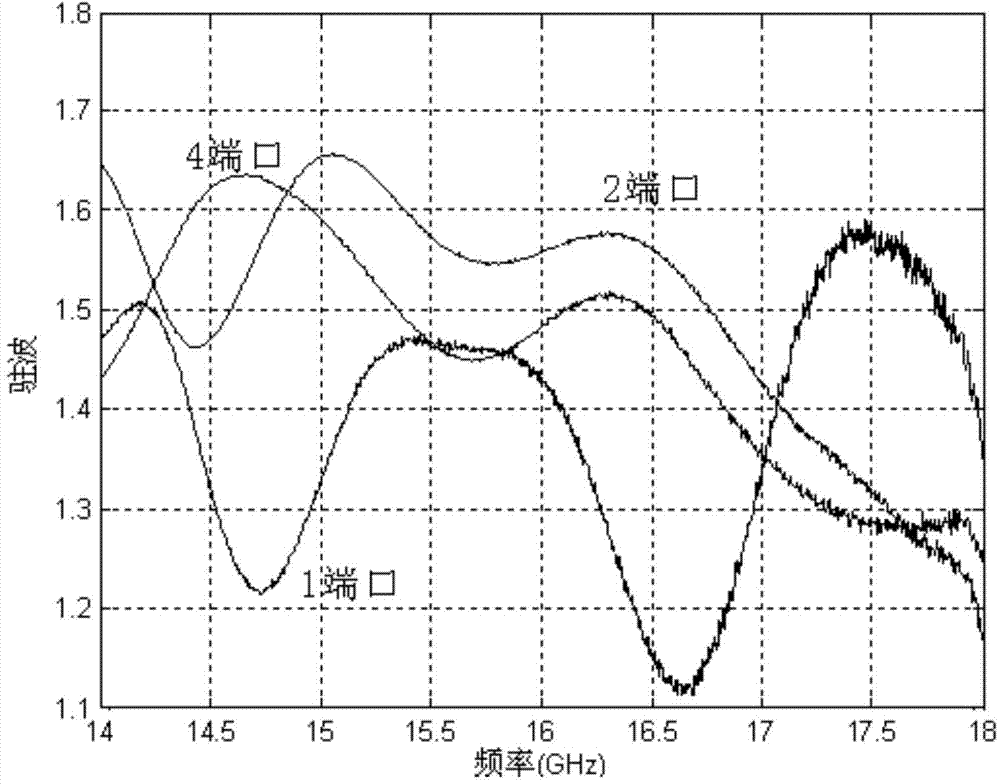

One-into-six equipower distributor

InactiveCN103700918ASmall transmission lossSolve welding difficultiesCoupling devicesHigh isolationCopper

The invention provides a one-into-six equipower distributor. The power distributor comprises a box body, a PCB (Printed Circuit Board), a box cover and an SMA connector joint; a metal copper-clad bottom layer, a lower medium layer, a middle transmission line layer, an upper medium layer and a metal copper-clad top layer are sequentially arranged on the PCB from bottom to top, an input end is arranged on one side of the middle transmission line layer, the input end is connected with a one-into-three equipower distribution circuit after being led out, the tail ends of the one-into-three equipower distribution circuit are connected with a one-into-two equipower distribution circuit, the tail ends of the one-into-two equipower distribution circuit are output ends and extend to the other side of the middle transmission line; the PCB and the box cover are fixedly arranged in the cavity of the box body, the metal copper-clad bottom layer of the PCB and the bottom of the cavity of the box body are fit, the box cover and the metal copper-clad bottom layer of the PCB are fit, the input end and the output end of the PCB respectively correspond to the position of the SMA connector joint on the box body, and an SMA connector is arranged on the SMA connector joint. The one-into-six equipower distributor has the characteristics of being capable of realizing wideband, low loss and high isolating degree, low in cost and the like.

Owner:北京理工雷科电子信息技术有限公司

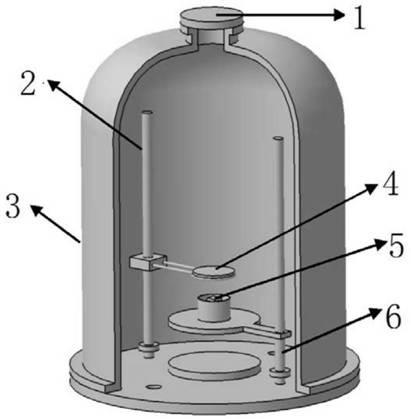

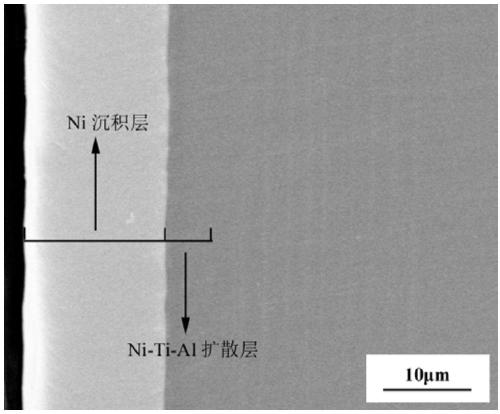

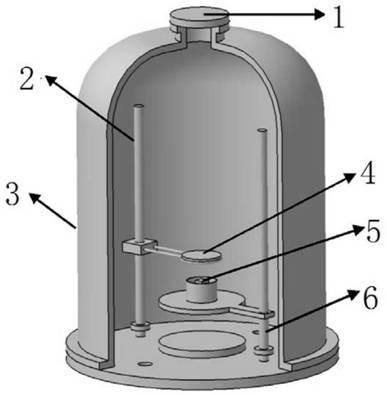

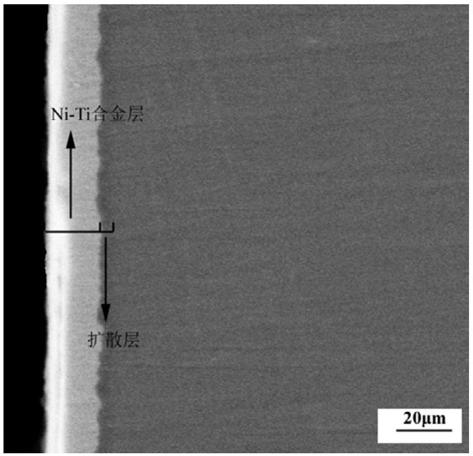

Surface treatment method for improving welding properties of Si3N4 ceramic and gamma-TiAl alloy

ActiveCN109161865AImprove welding effectSolve welding difficultiesVacuum evaporation coatingSputtering coatingGlow plasmaNickel alloy

The invention discloses a surface treatment method for improving the welding properties of Si3N4 ceramic and gamma-TiAl alloy. The method comprises the following steps: (1), preparing nickel alloy layer on the surface of the gamma-TiAl alloy from a Ni-Ti alloy target material by adopting a double glow plasma surface metallurgy method, wherein the nickel alloy layer comprises a nickel deposition layer and an inter-diffused layer; (2), injecting Ti ions on the surface of the Si3N4 ceramic through an ion injection method, so as to treat the surface of the Si3N4 ceramic; and (3), welding the gamma-TiAl alloy treated through the double glow plasma surface metallurgy method in the first step and the Si3N4 ceramic subjected to surface treatment in the second step in vacuum diffusion welding equipment. According to the method, the nickel alloy layer is prepared on the surface of the gamma-TiAl alloy, the Ti ions are injected to the surface of the Si3N4 ceramic through the ion injection method,and the vacuum diffusion welding between the Si3N4 ceramic and the gamma-TiAl alloy can be directly realized. The method is high in efficiency, and can greatly improve the application of vacuum diffusion welding to the welding technology of the Si3N4 ceramic and the gamma-TiAl alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

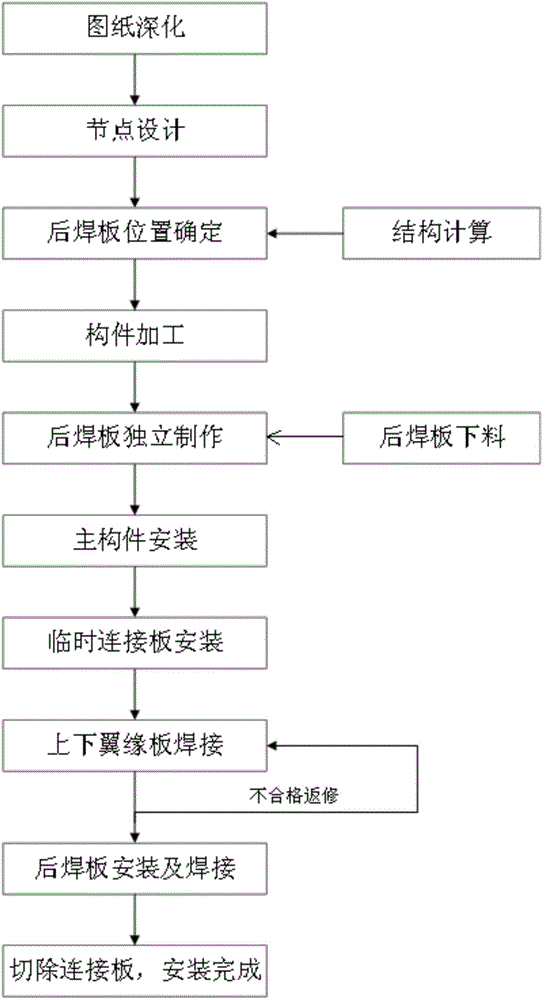

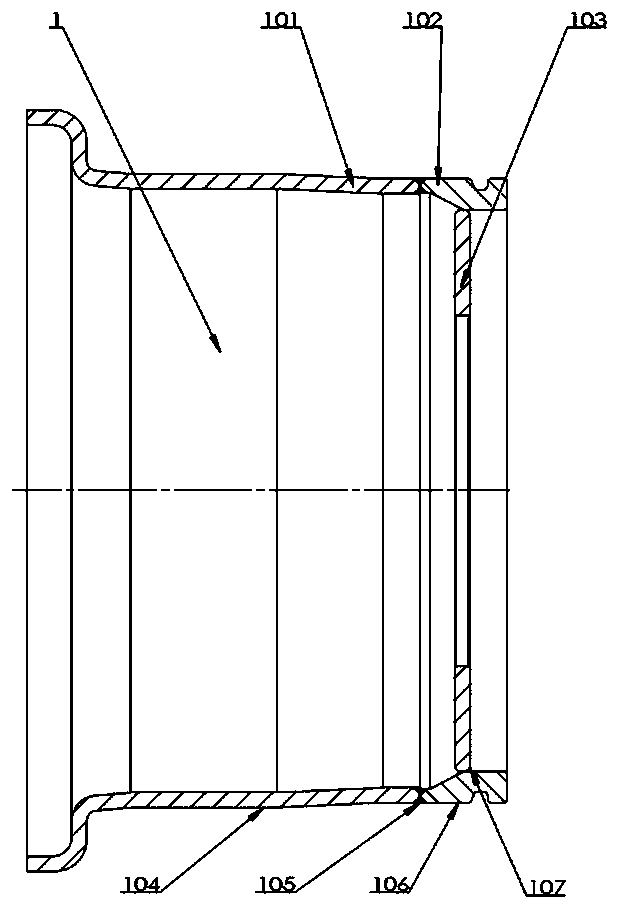

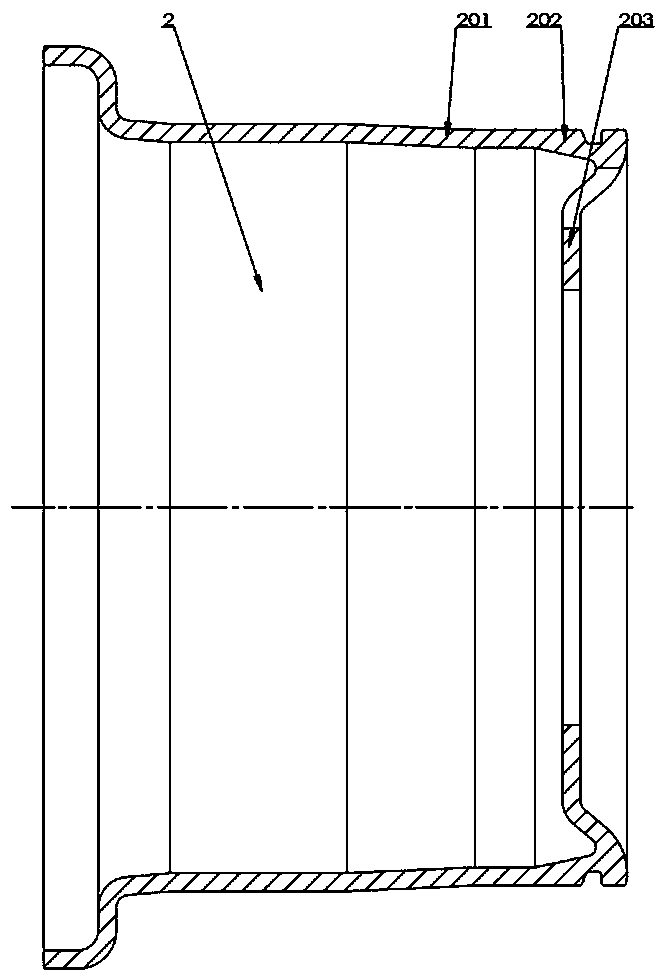

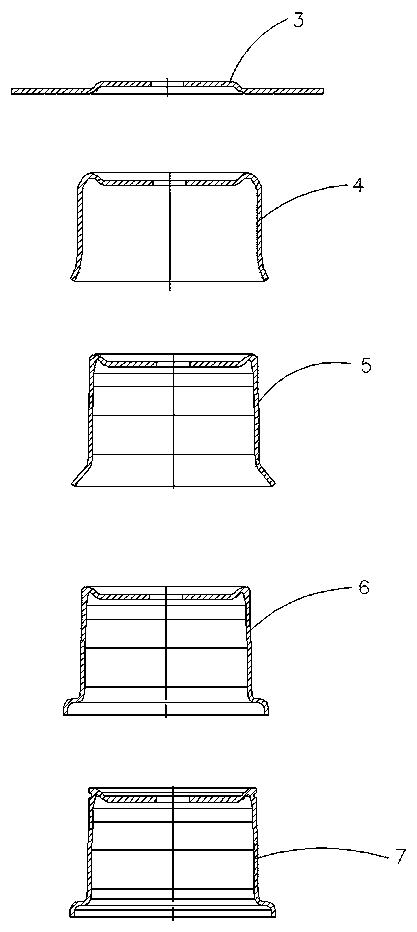

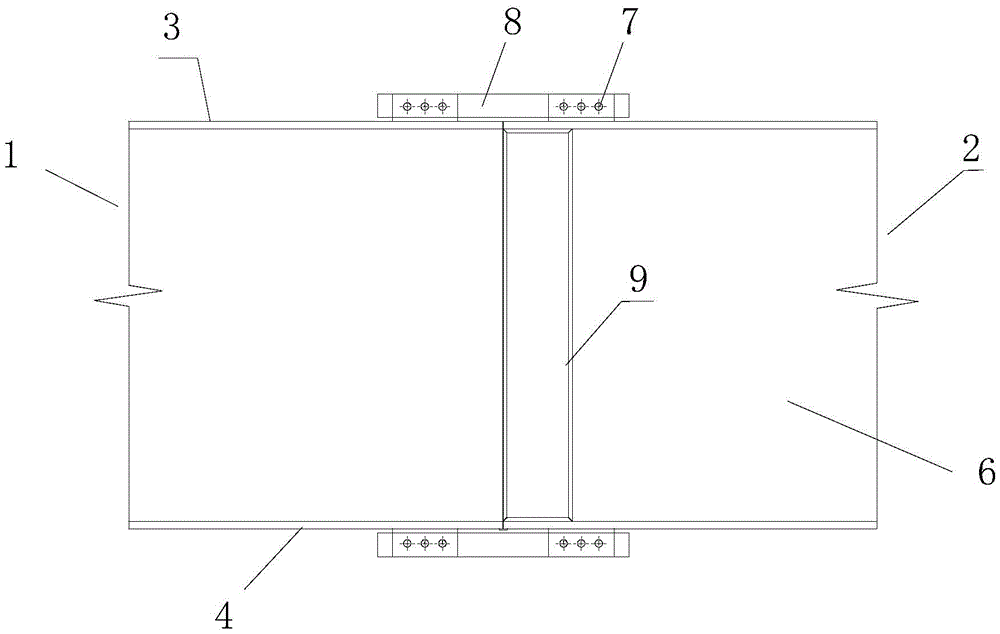

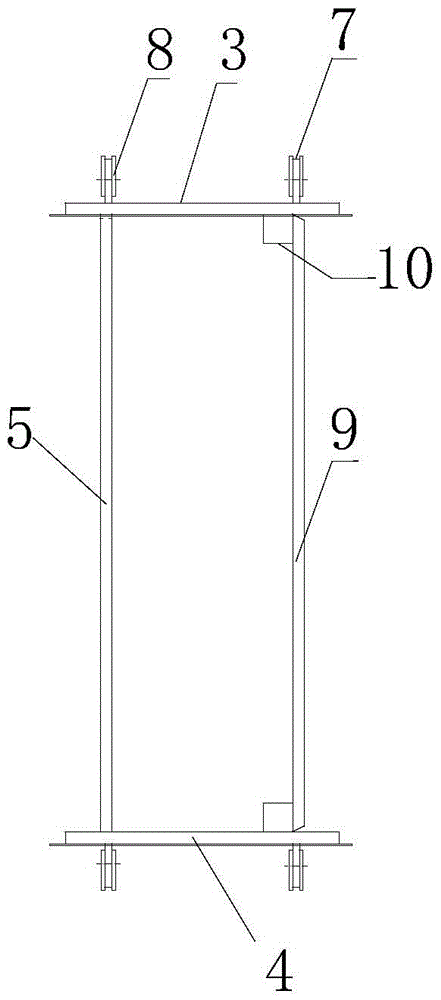

Technique for processing joint where box steel beams with relatively large slenderness ratios of sections are in butt joint

ActiveCN104929051ALow costEasy to installBridge erection/assemblyBuilding material handlingHead positionEngineering

The invention discloses a technique for processing a joint where box steel beams with relatively large slenderness ratios of sections are in butt joint. A rear plate is reserved on the side face for butt joint of the box steel beams, an upper flange plate and a lower flange plate are provided with dual connection lug plates and are fixedly connected by means of a connecting plate, flat welding and vertical position welding are used for positioning, so that the upper flange plate, the lower flange plate and two webs of each box steel beam are obtained, and then vertical position welding and horizontal position welding are used for welding a rear weld plate. By the adoption of the technique, the situation that potential quality hazards or defects are caused by over-head position welding occurring during installation of the box steel beams can be reasonably avoided; in addition, installation is convenient, a bolt connecting plate with holes does not need to be additionally arranged on the side face, and thus good economical benefits and good construction period benefits are obtained.

Owner:中建五局第三建设有限公司

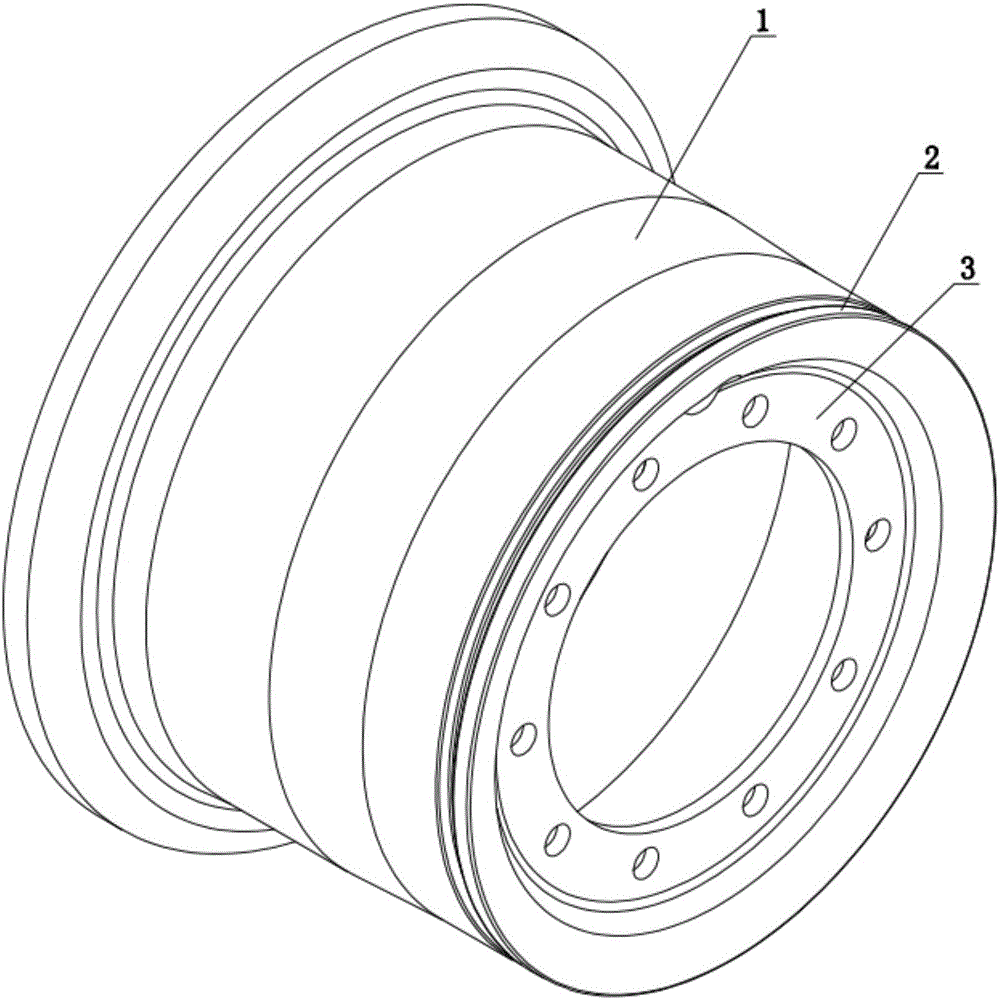

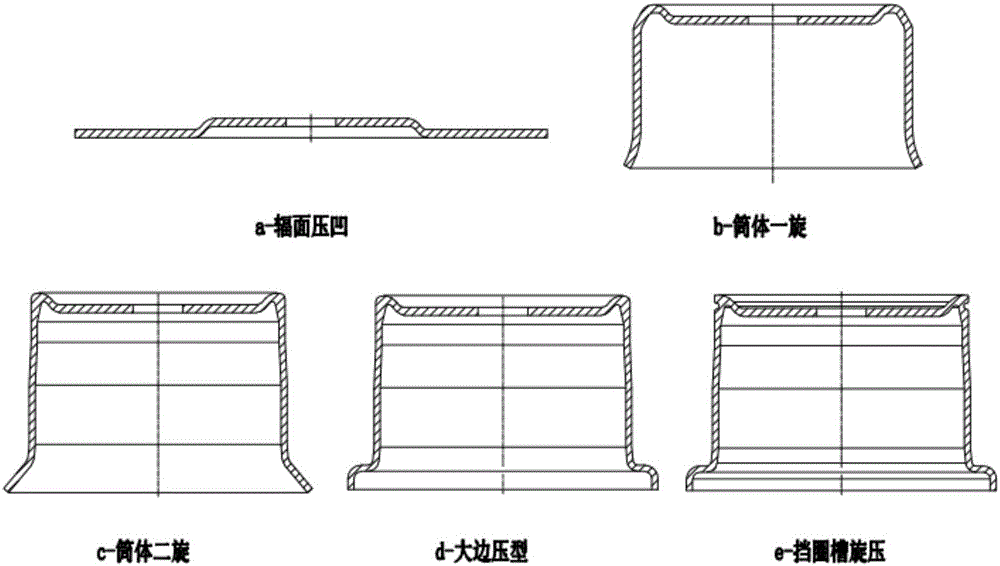

Welding-free unequal-thickness wheel type engineering machinery wheel and manufacturing technology for same

A welding-free unequal-thickness wheel type engineering machinery wheel and a manufacturing technology for the same are provided. A round steel plate with a certain size is molded through a series offorming technologies; welding is not required during all the forming and processing procedures; a wheel type engineering machinery wheel with a traditional way of wheel spokes, wheel rim cylinders andbead seat combined welded together can be replaced; in the welding-free unequal-thickness wheel type engineering machinery wheel and the manufacturing technology for the same, the wheel spokes, the wheel rims and the bead seat are integrated, so great overall surface quality can be achieved; deficiencies of welding difficulties and overall strength deficiencies during the welding and assembling can be overcome; wheel manufacturing technology processes and production management can be greatly simplified; wheel product strength and precision can be greatly improved; and pollution caused by welding can be eliminated.

Owner:QUANZHOU TAIDA WHEEL EQUIP

Self-healing parallel capacitor structure

ActiveCN106449088AIncrease in sizeRealize pull-off protectionFixed capacitor housing/encapsulationSelf-healingInterference fit

The invention discloses a self-healing parallel capacitor structure. The self-healing parallel capacitor structure comprises a top cover, an aluminum tank, an element, a pressure relief pipe, a bottom cover, an insulating copper belt and resin, wherein the top cover is arranged at the top of the aluminum tank; the bottom cover is arranged at the bottom of the aluminum tank; the aluminum tank is internally equipped with the insulating copper belt and the element; a hollow thin-wall circular ring is arranged in the middle of the upper part of the bottom cover; one end of the pressure relief pipe is connected with the hollow thin-wall circular ring and the other end of the pressure relief pipe is connected with the top cover; a connection part of the pressure relief pipe and the bottom cover is in interference fit and has no gap, and a pressure relief channel is formed; a ladder-shaped round structure is arranged at a connection part of the hollow thin-wall circular ring and the bottom cover; the element is supported by the ladder-shaped round structure; the insulating copper belt is connected with the top cover through welding; the insulating copper belt is distributed at the outer side of the element; gaps among the aluminum tank, the top cover, the bottom cover and the element are filled with resin. According to the self-healing parallel capacitor structure disclosed by the invention, problems that pressure relief and welding are difficult are solved; the self-healing parallel capacitor structure is simple in structure and convenient in assembling; the product has a good heat dissipation property and stable performances, is safe to operate and is long in service life.

Owner:KBR POWER QUALITY MANAGEMENT SHANGHAI

Method for installing Co40 cushion block on water beam in walking beam type heating furnace

ActiveCN106078019AImprove bending resistanceGuaranteed installation stabilityWelding/cutting auxillary devicesArc welding apparatusEngineeringHeating furnace

The invention discloses a method for installing a Co40 cushion block on a water beam in a walking beam type heating furnace. An extending part is additionally arranged on the lateral part of a clamping block; a first welding part is arranged between the extending part and the Co40 cushion block; the Co40 cushion block and the clamping block are fixedly connected through the first welding part; the clamping block and the water beam are connected through a second welding part; the first welding part and the second welding part can form an integral welding part; and two ends of the Co40 cushion block and the water beam are integrally welded. The method has the following advantages: the extending part is arranged on the side of a force bearing point of the clamping block, and the cushion block is welded with the same side of the force bearing point of the clamping block, so that the fracture resistance and the bending resistance of the clamping block can be greatly improved; and in addition, the difficulty in welding between the Co40 cushion block and the water beam is overcome, and the installing stability of the Co40 cushion block is further ensured.

Owner:BENGANG STEEL PLATES

Welding process of three-way valve seat and valve body

ActiveCN102990200AReduce toughnessReduced crack resistanceArc welding apparatusHeat-affected zonePower flow

The invention relates to a welding process of a valve seat and a valve body, in particular to a welding process of a three-way valve seat and a valve body of a supercritical thermal power unit; the welding process comprises the following steps that the beneficial impact of multi-layer welding is fully utilized, multi-layer welding is adopted, and a latter layer plays the roles of dehydrogenating and improving the tissue of a heat affected zone to a former layer; heat input is controlled through a method in which low welding current welds more quickly, and the heat input of welding is strictly controlled; and high-strength steel is more sensitive to the heat input of welding, and over heat input can reduce the toughness of a welding connector and thus reduce the anti-cracking performance. Post heat treatment is carried out soon after welding, so that cold cracks are prevented from generating in a period of time after welding, and the welding requirements are met. According to the welding process, the problem that WB36 and F6a special steel welding is difficult is fully solved, cracking and other phenomena after welding are avoided, and the weld seam quality can be fully ensured.

Owner:DALIAN DAGAO VALVE

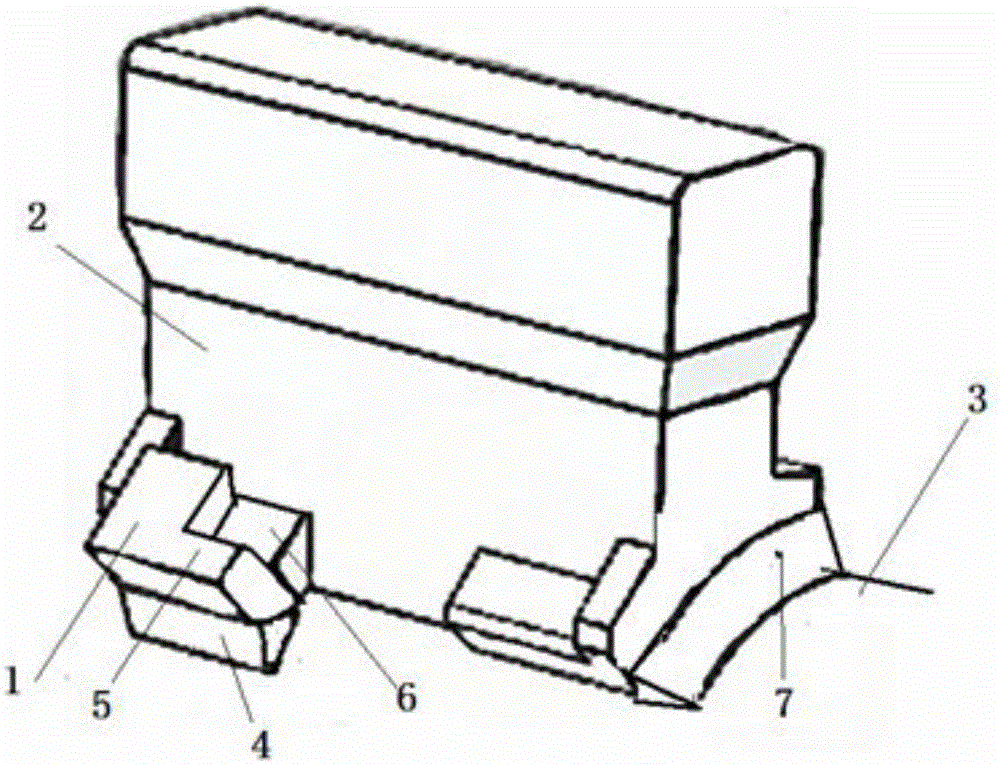

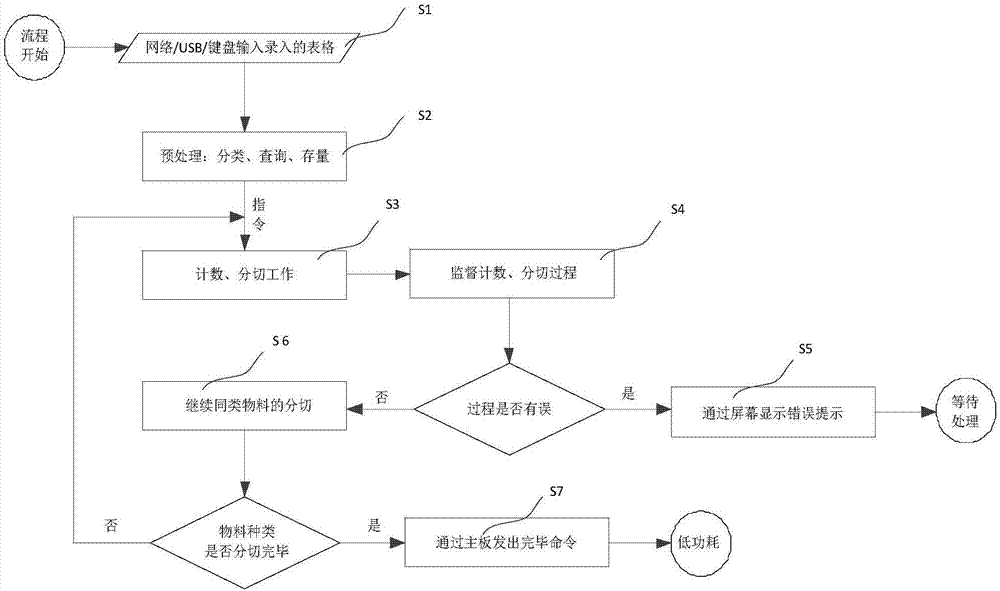

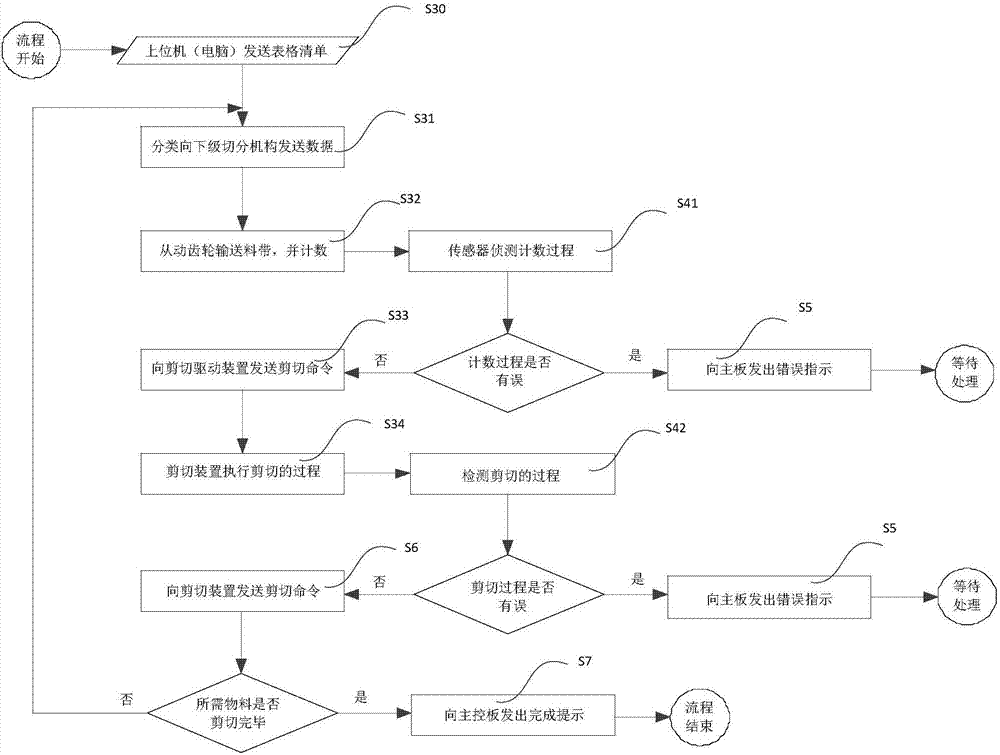

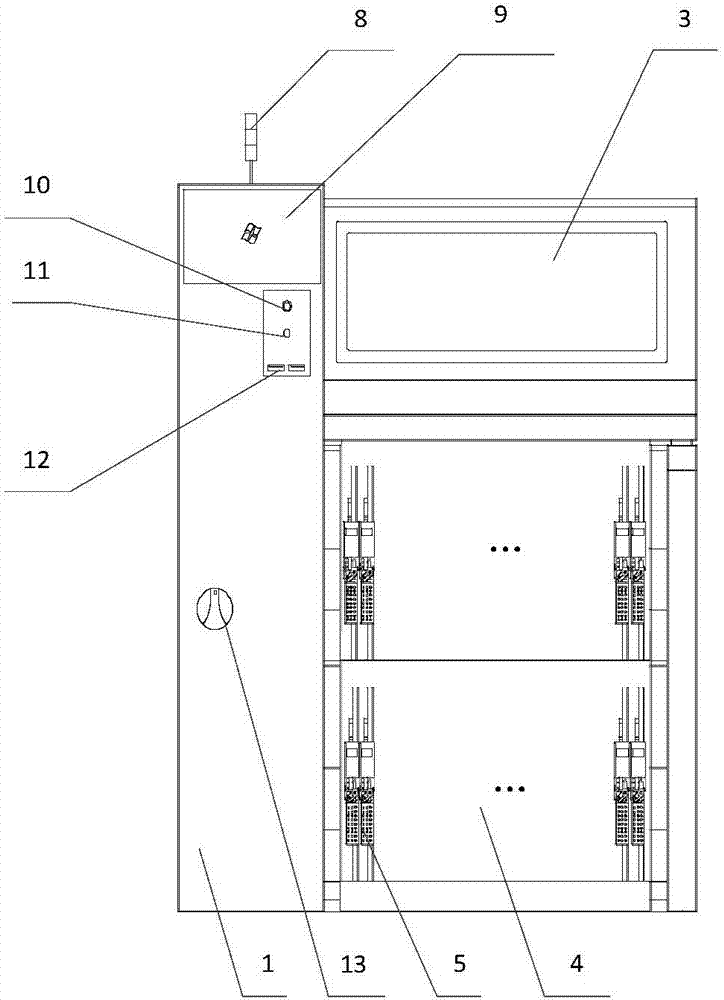

Distributing device for electronic components and control method of distributing device

ActiveCN107253226AEasy to manageImprove distributionConveyorsMetal working apparatusEngineeringTouchscreen

The invention discloses a distributing device for electronic components and a control method of the distributing device. The problems that in the prior art, the manual segmentation efficiency is low, mistakes are prone to occurring, the shearing technology is limited by skills, the sizes are all different, and storage and welding are not facilitated are mainly solved. The device comprises a device cabinet, material gun shelves, an electrical device compartment, a touch screen, a three-color indicator lamp and distributing guns, wherein the material gun shelves are arranged on the right side of the device cabinet in parallel, the electrical device compartment is pressed at the tops of the material gun shelves, the left side edge of the electrical device compartment is fixed to the side edge of the device cabinet, the touch screen is inserted into the upper edge of the front portion of the device cabinet, the three-color indicator lamp is installed at the top of the device cabinet, and the two rows of distributing guns are inserted into the material gun shelves and are evenly distributed. Two rows of square holes used for allowing the distributing guns to be inserted into are formed in the front portions of the material gun shelves. By adoption of the scheme, the distributing device has the advantages that segmentation is efficient, operation is convenient and rapid, counting is accurate, segmentation is even, and the production cost is reduced, and the distributing device has pretty high practical value and popularization value in the field of distributing of the electronic components.

Owner:CHENGDU SHIYUAN FREQUENCY CONTROL TECH

Leakproof welding method of stainless steel pipe and copper fin

InactiveCN101733524AGuaranteed stabilityGuaranteed deformationArc welding apparatusWelding/soldering/cutting articlesSpace environmentHeat sink

The invention relates to a welding method of a heterogenous metal between a stainless steel pipe and a copper fin, which comprises the following steps of: carrying out necessary tests and leak detection for parts to be welded; finishing the welding of the parts by applying a special argon arc welding process; and inspecting according to a corresponding inspection condition to ensure that a product satisfies the use requirement of a space environment simulation test. The method is particularly beneficial to the splice welding of the stainless steel pipe and the red copper fin in a heat sink, and an obtained weld can still keep vacuum tightness under the condition of long-term cool-heat exchange at high and low temperatures.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

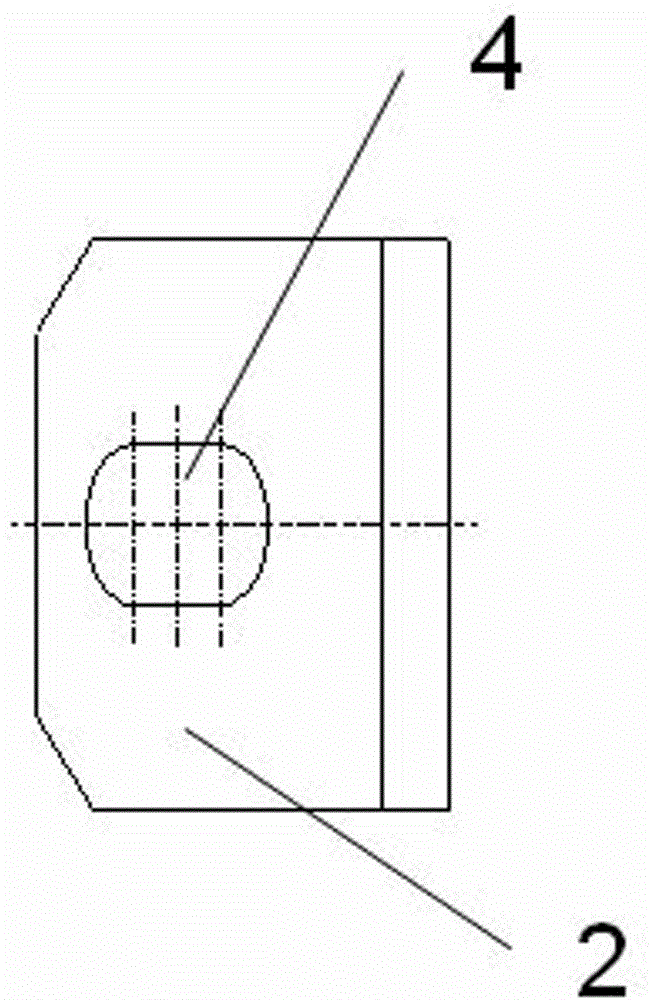

Bearing plate component

The invention relates to a bearing plate component. The bearing plate component comprises a bearing plate I and a bearing plate II; the bearing plate I is fixedly connected with an air chamber bracket assembly; the bearing plate II is fixedly connected with a plate spring base; the bearing plate I and the bearing plate II are connected by a bolt; the bearing plate I is provided with a connecting hole I; the bearing plate II is provided with a connecting hole II; the connecting hole I and the connecting hole II are oblong hole structure; and the axis of the connecting hole I is perpendicular to the axis of the connecting hole II. The bearing plate component has the advantages of simple structure, flexible adjustment, smooth welding, and high production efficiency.

Owner:SINO TRUK JINAN POWER

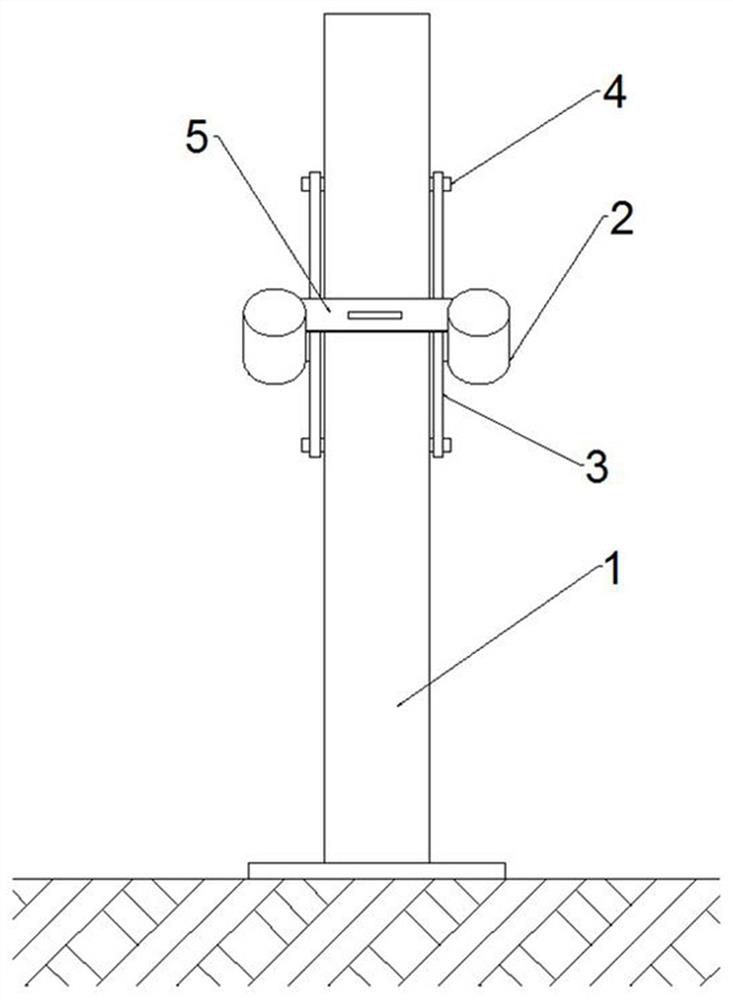

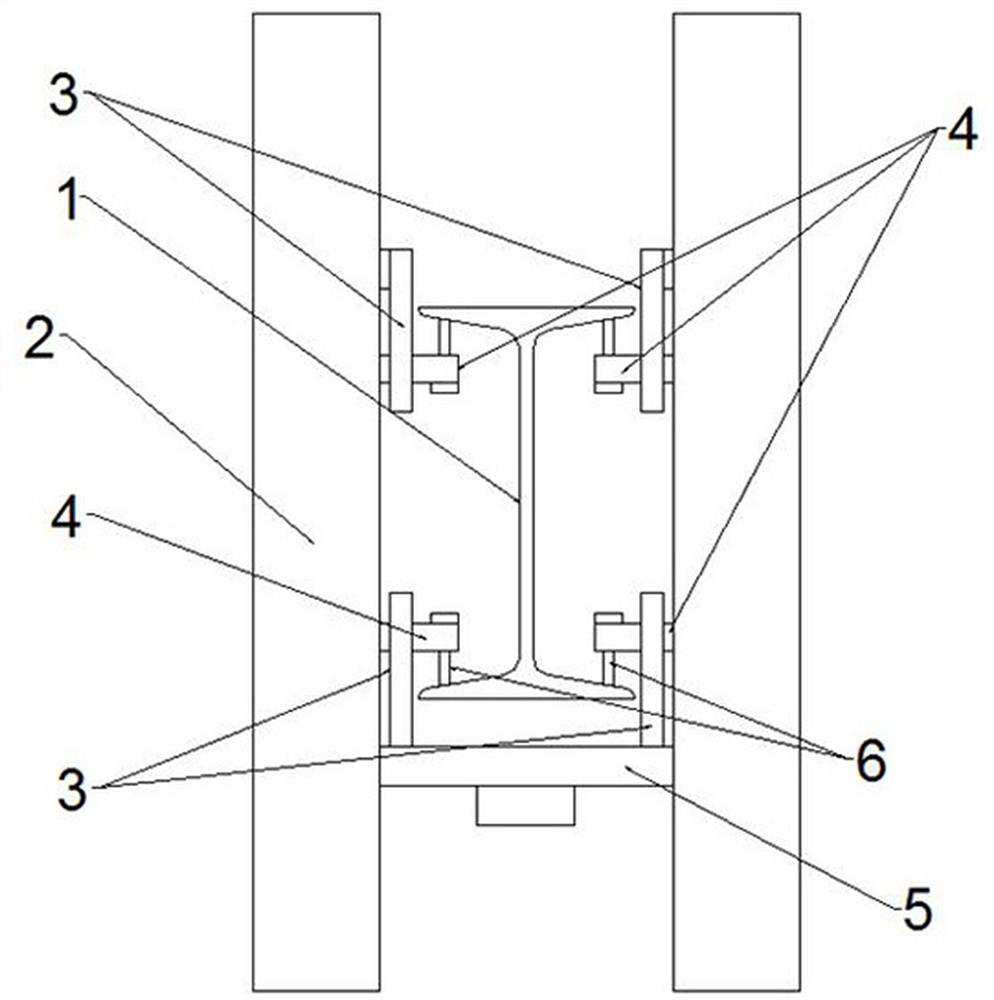

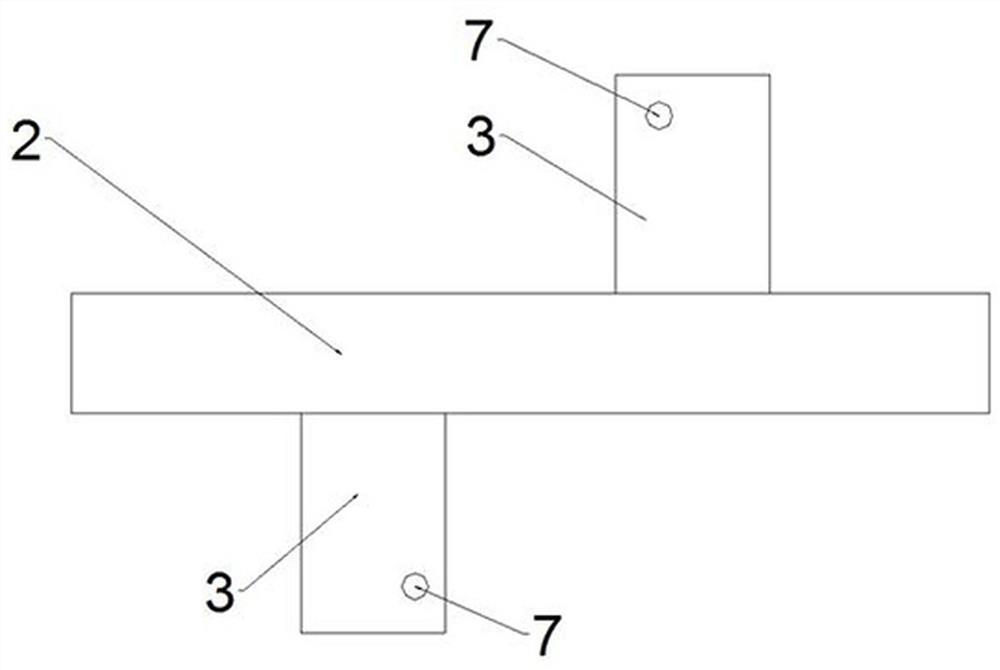

Device and method for dynamically adjusting angle of feet-lock anchor pipe in tunnel

ActiveCN114876538ASimple structureImprove the qualified rate of weld seamDrilling rodsHydro energy generationEngineeringPipe

The invention relates to the technical field of tunnel feet-lock anchor pipe installation, in particular to a dynamic adjusting device and method for the angle of a feet-lock anchor pipe in a tunnel, and the dynamic adjusting device comprises two guide pipes which are used for guiding a drill bit; the two ends of the pushing piece are correspondingly connected to the two guide pipes respectively; the two fixing plate sets are arranged between the two guide pipes; the shaft pin is detachably connected to the fixing plate and correspondingly extends into the abdominal cavity of the arch foot I-shaped steel; and the fixing bolts are arranged at the ends, extending into the abdominal cavity of the arch foot I-shaped steel, of the shaft pins and abut against the inner side of the flange of the arch foot I-shaped steel so as to fix the guide pipes. The adjusting device is simple in structure, all materials are common materials in building construction, it can be guaranteed that the angle error of the tunnel feet-lock anchor pipe is within 5 degrees through the adjusting device, the qualification rate of weld joints of feet-lock connecting ribs is greatly increased, and the production efficiency is improved. And meanwhile, the problems that the angle error is large and the lock foot connecting rib is difficult to weld due to original manual drilling are solved.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD +1

A treatment process for butt joints of box-shaped steel beams with relatively large slenderness ratio

ActiveCN104929051BSolve problems such as the extremely unfavorable welding position of overhead weldingEasy to installBridge erection/assemblyBuilding material handlingButt jointFlange

The invention discloses a technique for processing a joint where box steel beams with relatively large slenderness ratios of sections are in butt joint. A rear plate is reserved on the side face for butt joint of the box steel beams, an upper flange plate and a lower flange plate are provided with dual connection lug plates and are fixedly connected by means of a connecting plate, flat welding and vertical position welding are used for positioning, so that the upper flange plate, the lower flange plate and two webs of each box steel beam are obtained, and then vertical position welding and horizontal position welding are used for welding a rear weld plate. By the adoption of the technique, the situation that potential quality hazards or defects are caused by over-head position welding occurring during installation of the box steel beams can be reasonably avoided; in addition, installation is convenient, a bolt connecting plate with holes does not need to be additionally arranged on the side face, and thus good economical benefits and good construction period benefits are obtained.

Owner:中建五局第三建设有限公司

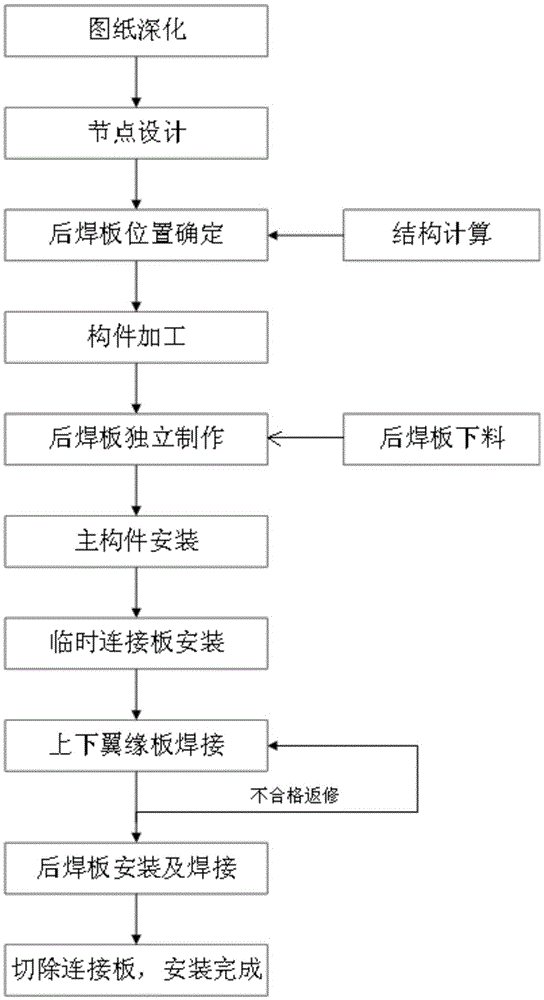

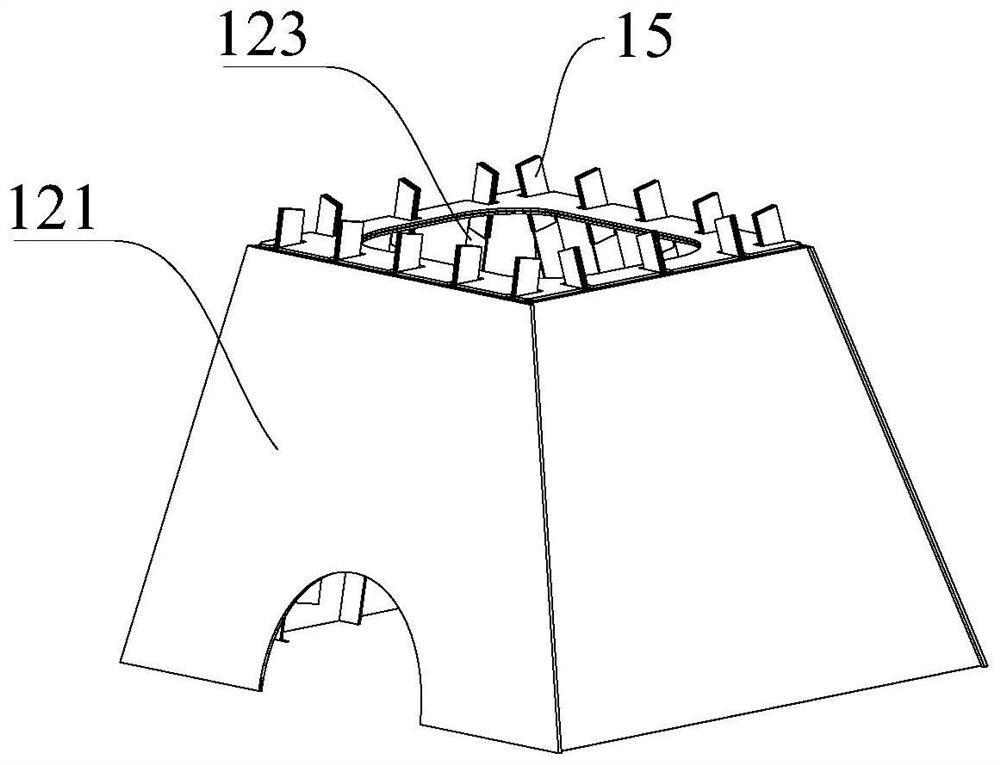

Novel main tower crown structure and sectional installation method thereof

ActiveCN114033234ASmall weight and geometric sizeEasy to moveTowersWind energy generationTransportation safetyArchitectural engineering

The invention provides a novel tower crown structure of a main tower. The novel tower crown structure comprises a tower crown body, the tower crown body is of a three-section segmented structure and is sequentially segmented into a first tower crown section, a second tower crown section and a third tower crown section in the height direction of the tower crown body, wherein the first section of tower crown and the second section of tower crown are sectioned from the starting point of the tower crown slope section, and the first section of tower crown and the second section of tower crown are welded and fixed; the second section of tower crown and the third section of tower crown start to be sectioned on the slope section, reinforcing transverse partition plates are arranged at the sectioning positions, and connecting and fixing plates are arranged at the reinforcing transverse partition plates; and the second section of tower crown is fixedly connected with the third section of tower crown through a connecting and fixing plate. The invention further provides a sectional installation method of the tower crown structure. The method has the advantages that a sectional manufacturing and mounting process is adopted, so that manufacturing of the tower crown is facilitated, welding quality is guaranteed, transportation is facilitated, transportation safety is guaranteed through loading and fixing, hoisting is facilitated, mounting safety and mounting precision are guaranteed through fixing, later stay cable construction hoisting is facilitated, and cost is saved.

Owner:安徽省路港工程有限责任公司

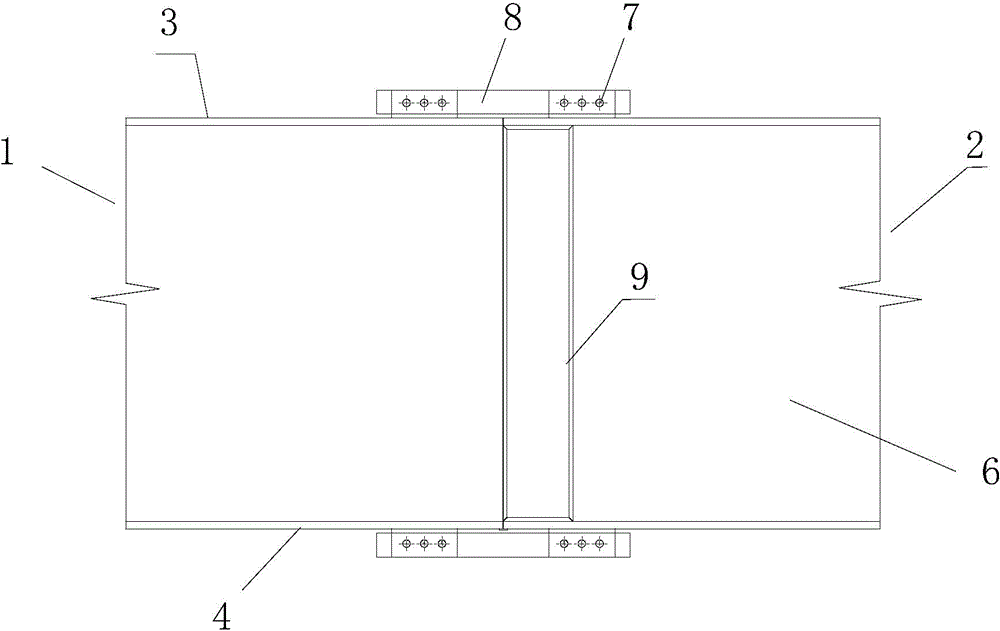

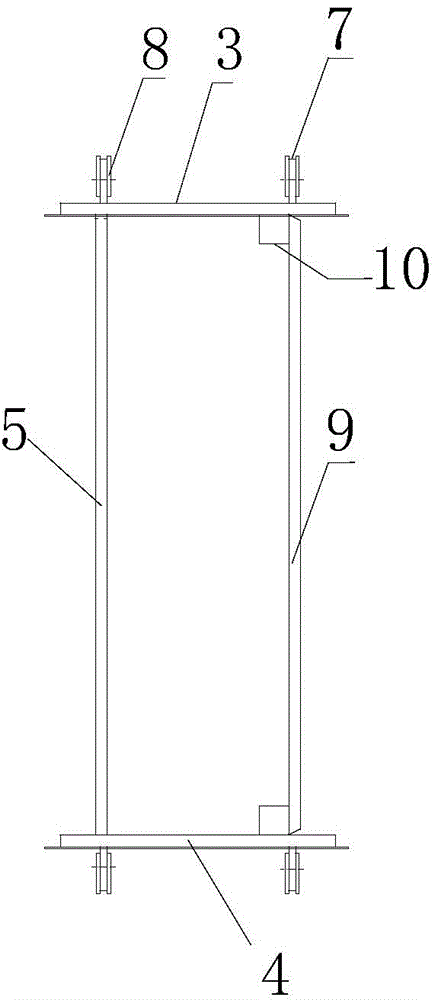

Surface treatment method for improving welding properties of Al2O3 ceramic and Ti6Al4V alloy

ActiveCN109161864AInhibition of sprouting and expansionImprove fracture toughnessVacuum evaporation coatingSputtering coatingTi6al4v alloySurface finishing

The invention discloses a surface treatment method for improving the welding properties of Al2O3 ceramic and Ti6Al4V alloy. The method comprises the following steps: (1), preparing Ni-Ti alloy layer on the surface of the Ti6Al4V alloy from a Ni-Ti alloy target material by adopting a double glow plasma surface metallurgy method, wherein the Ni-Ti alloy layer comprises a Ni-Ti deposition layer and an inter-diffused layer; (2), injecting Ti ions on the surface of the Al2O3 ceramic through an ion injection method; and (3), welding the Ti6Al4V alloy prepared in the first step and the Al2O3 ceramicsubjected to surface treatment in the second step in vacuum diffusion welding equipment. The method can directly realize vacuum diffusion welding between the Al2O3 ceramic and the Ti6Al4V alloy through the treatment of the double glow plasma surface metallurgy method and the ion injection method, is high in efficiency, and can greatly improve the application of vacuum diffusion welding to the welding technology of the Al2O3 ceramic and the Ti6Al4V alloy.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

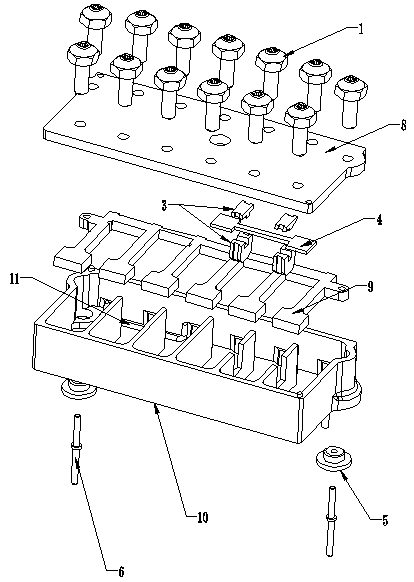

Three-stage filter

PendingCN110289470AAvoid separate installationAvoid WeldingWaveguide type devicesResonant cavityResonance

A three-stage filter includes a cavity, wherein the interior of the cavity is divided into a plurality of resonant cavities by separating plates; each resonant cavity is provided therein with a resonant plate; the resonant plates in every two adjacent resonant cavities are connected to each other; flying rod seats are mounted on two separating plates; flying rod pieces are mounted on the flying rod seats; two flying rod wires are mounted on two resonant plates; the cavity is a structural member with an open upper end and an open lower end; the separating plates and the resonance plates are all implanted into the sidewall of the cavity; the separating plates, the resonator plates and the cavity are integrally formed; the upper end cover of the cavity is provided with an upper cover plate; the lower end cover of the cavity is provided with a lower cover plate; and the upper cover plate and the lower cover plate cooperate to seal the openings of the cavity. The three-stage filter uses a three-stage structure, the resonance plates and the cavity form an integrated structure, the lower cover plate is provided, the number of internal parts is reduced, an assembly mode is optimized, the resonance plates are prevented from being separately mounted and welded, and the resonance plates and the cavity are integrally designed to solve the welding difficulties in the production process.

Owner:TONGYU COMM INC

Non-welding unequal-thickness wheel of wheel type construction mechanical vehicle and machining process thereof

InactiveCN105946442AAchieve lightweightSolve welding difficultiesMetal-working apparatusWheel manufactureTire beadSpoke

A non-welding unequal-thickness wheel of a wheel type construction mechanical vehicle comprises a rim, a bead seat and a spoke. The rim and the bead seat are integrally formed through spinning, and the bead seat and the spoke are integrally formed through forging and pressing. The wheel is finally formed after multiple procedures with spinning as the main procedure, automatic production can be conveniently achieved, and machining precision is high. The spoke and the rim are formed through spinning of one blank material and are free of any assembling joint face, welding line and solder filler, the structure is fine, and the strength is improved. A welding link is omitted in the machining process of the wheel, the difficult welding problem of high-strength steel can be solved, and the defects in hot rolling, welding and grinding are overcome; meanwhile, the welding link is omitted, so that sparks, dust and other pollutions caused by welding are eliminated; and the problem that rim weld positions and spoke weld positions are prone to cracking is solved, and potential traffic safety hazards are greatly reduced.

Owner:泉州市泰智机械发展有限公司

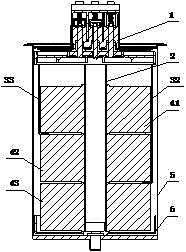

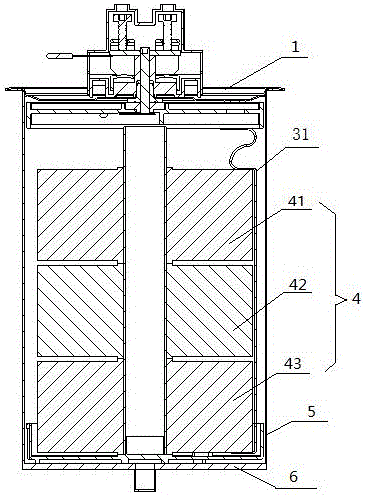

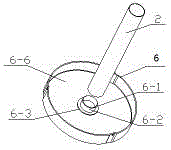

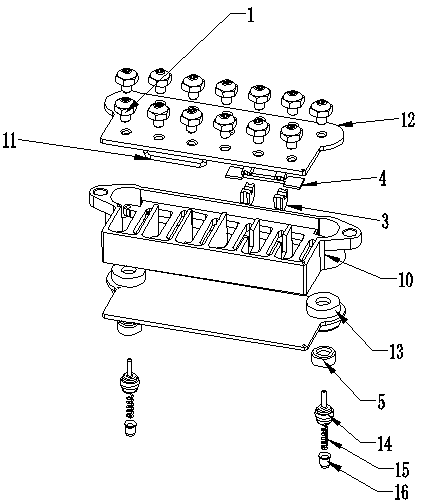

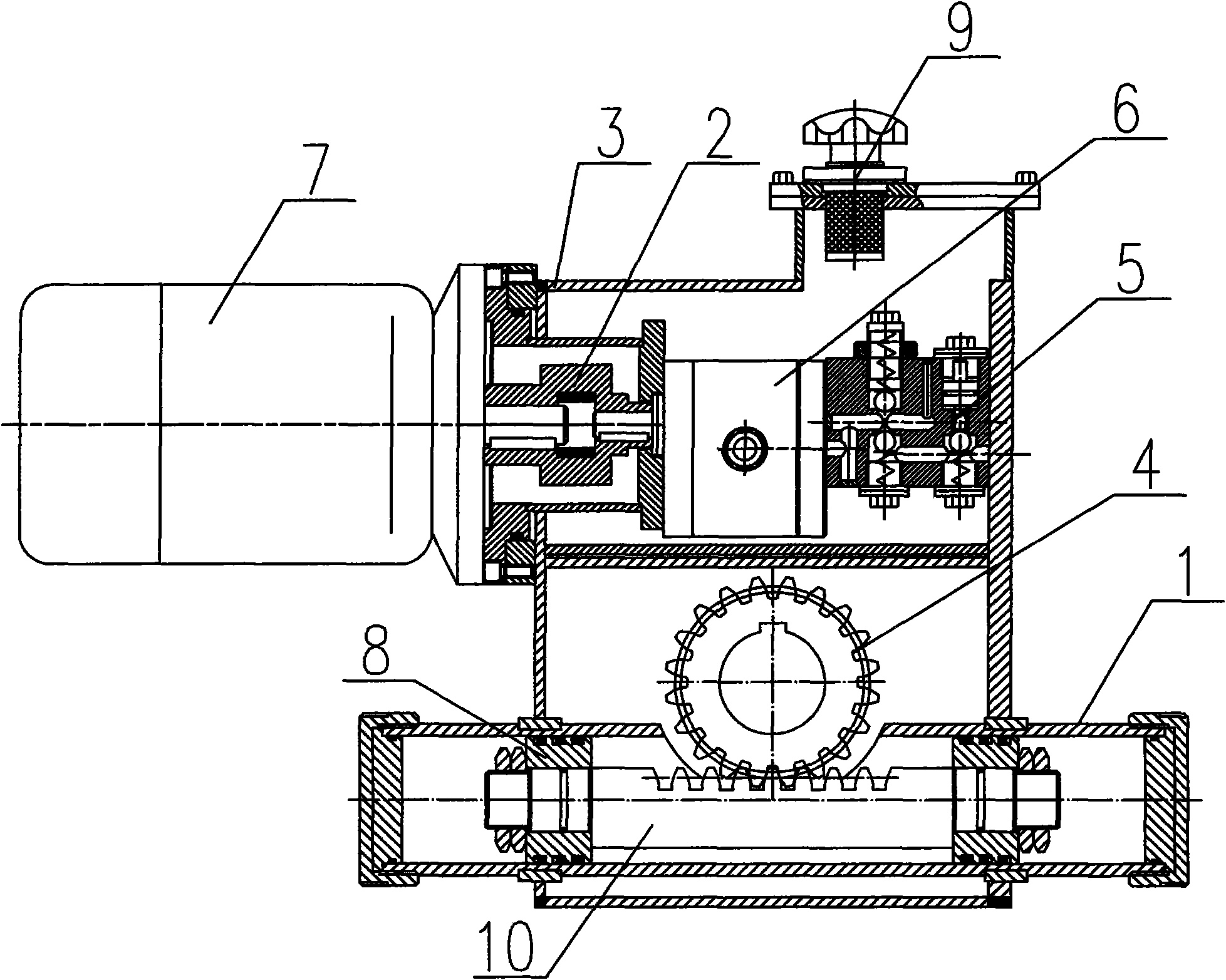

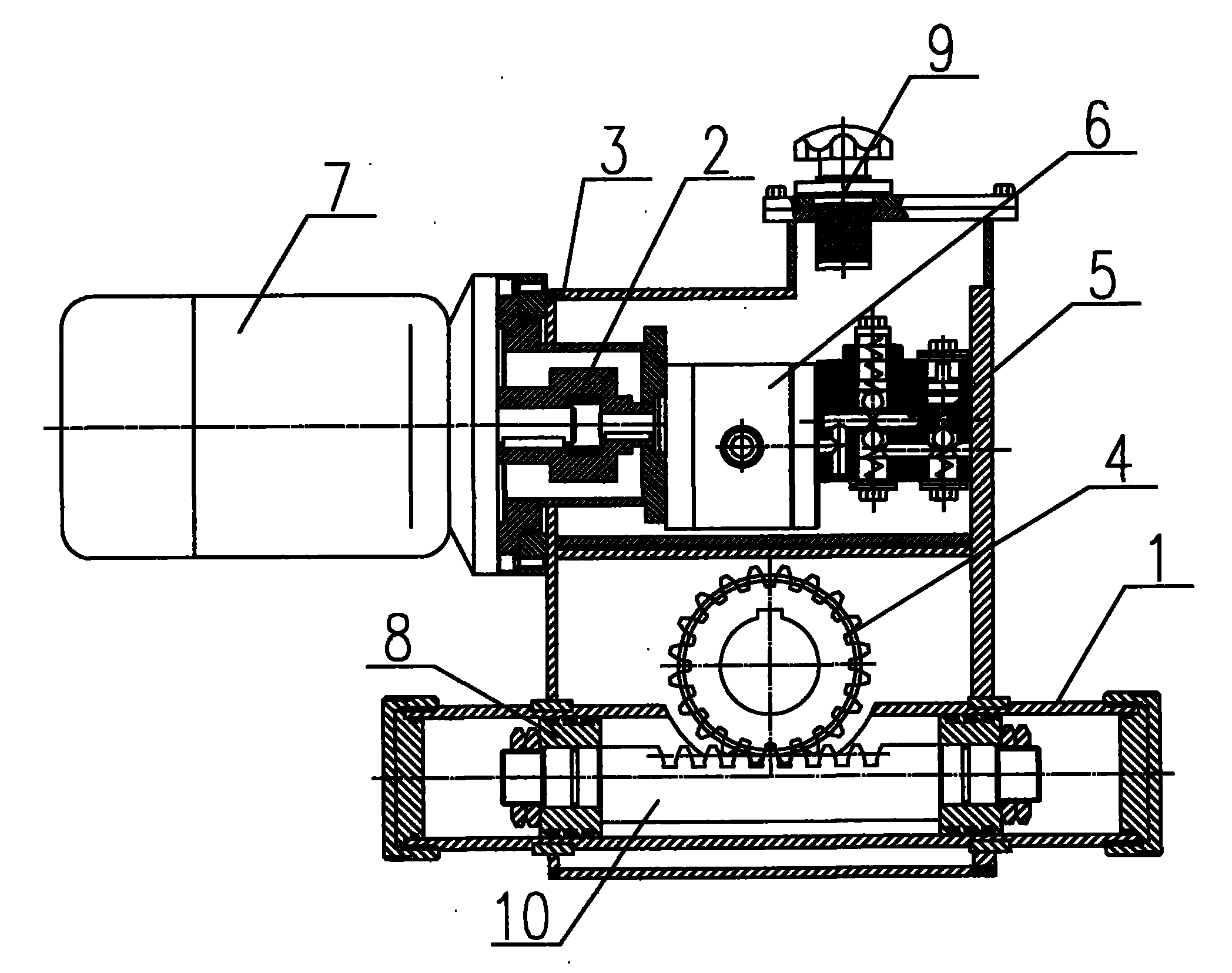

Electrohydraulic gyrator

InactiveCN101846114ASolve welding difficultiesSolve the problem of easy oil leakageFluid-pressure actuatorsGear pumpAir filter

The invention, which belongs to the technical field of hydraulic control, relates to an electrohydraulic gyrator. The electrohydraulic gyrator comprises a motor and an oil storage tank, a gear pump is arranged in the oil storage tank, and is connected with the motor through a coupling, the other end of the gear pump is connected with a hydraulic manifold block, the upper part of the oil storage tank is provided with an air filter, the electrohydraulic gyrator also comprises a rotary gear, an oil cylinder, a piston and a rack, and the oil storage tank is a cylinder. Since the oil storage tank of the electrohydraulic gyrator is modified into the cylinder, the cylinder does not need to be welded, only the joints between the cylinder and the surrounding parts need to be welded, consequently, the welding area is reduced compared with the old product, and thereby the problems of the electrohydraulic gyrator, including difficult welding and easy oil leakage, are effectively solved.

Owner:YANGZHOU ZHONGRUI TECH DEV

Welding process for wall bars of steel bar cage

The invention provides a welding process for wall bars of a steel bar cage. The process particularly comprises the steps of arranging welding of two main reinforcements after a main reinforcement of the entire steel cage is laid. The main reinforcement and two side bars of reinforcement cage are welded at 90 degree or 135 degree. The welding process has the advantages of easy on-site construction,easy operation, high welding qualification rate, and can meet the design requirements of standard specifications.

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

A strip-head rolling method for cold continuous rolling limit thickness strip steel

ActiveCN105772513BImprove rolling control precisionSolve the problem of strip threading in rolling millRare end control deviceMetal rolling arrangementsControl systemStrip steel

Owner:HIGH END EQUIP & RAIL TRANSIT TECH R & D CENT OF HAIAN TAIYUAN UNIV OF SCI

Method for mounting support column of slag notch of incinerator

The invention discloses a method for mounting a support column of a slag notch of an incinerator. The method includes steps of 1), properly positioning so that the angle between an oblique support plate and a horizontal plane is 40 degrees; 2), unscrewing a nut on a bolt connected between an upright column body and an upright column connector so that the upright column connector can freely rotate around the bolt; 3), adjusting the position of the upright column connector so that a support surface of the upright column connector completely contacts with the oblique support plate; 4), adjusting the elevator of the bottom of the upright column body; 5), welding a base of the upright column body with an embedded plate on a foundation; 6), firmly welding the upright column connector with the oblique support plate; and 7), screwing down the nut and firmly welding a hinge position. During installation, the upright column connector can sufficiently contact with the oblique support plate, accordingly, the problem of difficult welding is solved, work efficiency is improved, and installation time is shortened. In addition, a proper oblique angle of the oblique support plate is guaranteed, a support surface of the oblique support plate can be completely fit with the bottom surface of the slag notch, and service lives of the slag notch and the support column are prolonged.

Owner:CHONGQING SANFENG COVANTA ENVIRONMENTAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com