Method for welding capillary tube heat exchanger tube sheet and capillary tubes

A welding method and capillary tube technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of complex process flow, low connection strength, poor pressure resistance, etc., to reduce costs and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0020] A method for welding capillary tube sheets and capillary tubes of a capillary heat exchanger, comprising the following steps:

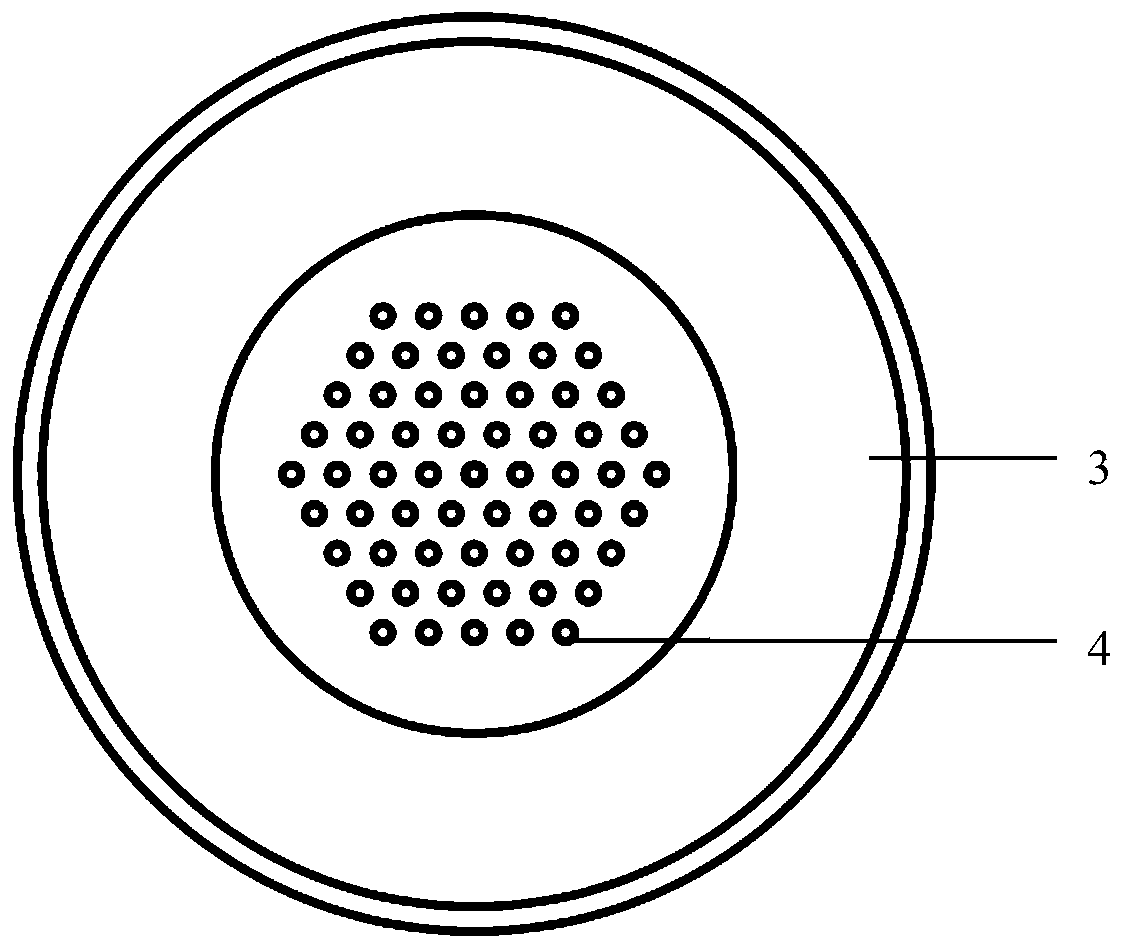

[0021] Step 1, processing tooling 3 (such as image 3 , 4 Shown), the frock 3 is a bowl-shaped structure as a whole, and some small holes 4 are punched at the bottom, and the frock 3 is made of a high-temperature refractory material as a whole.

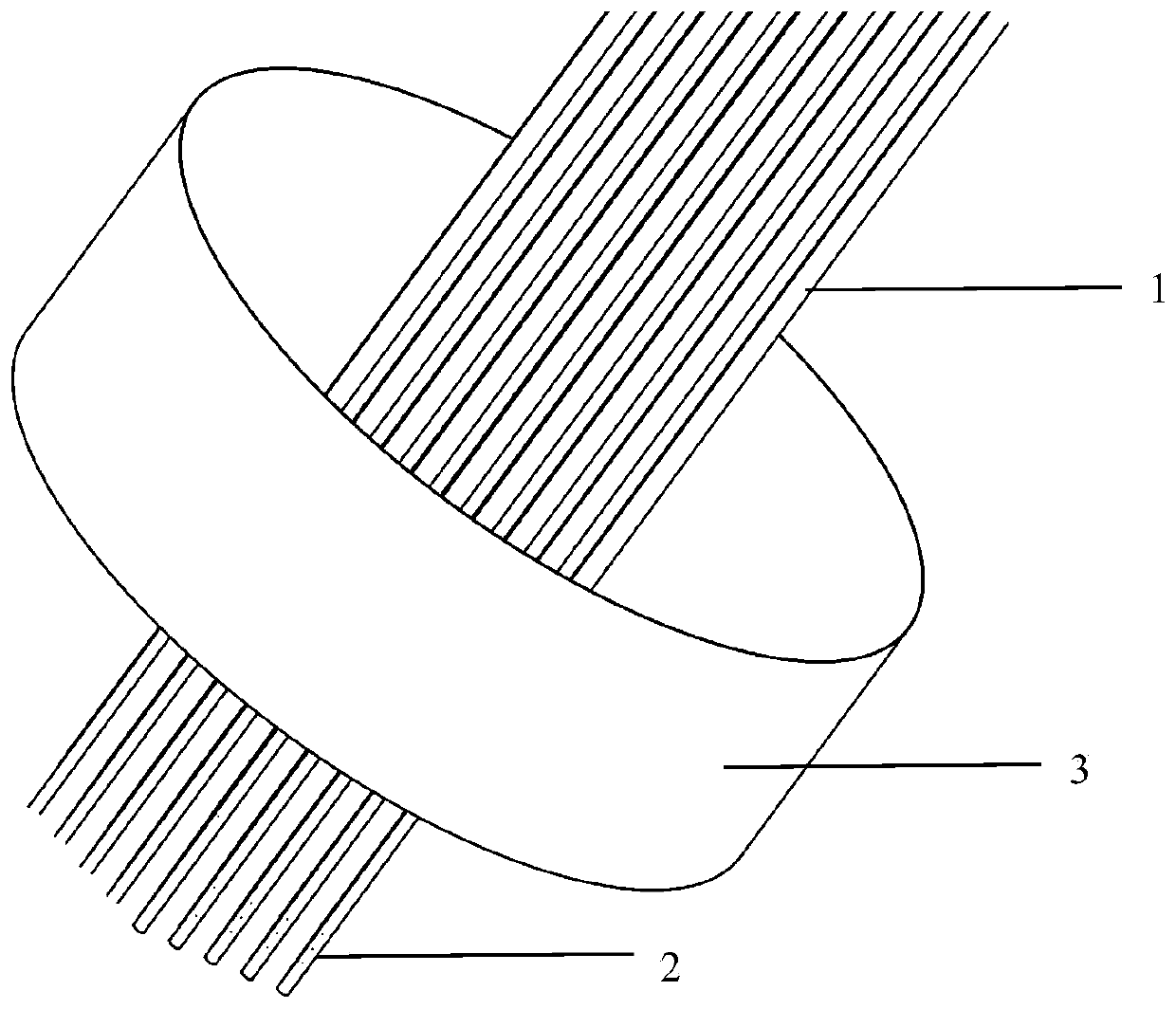

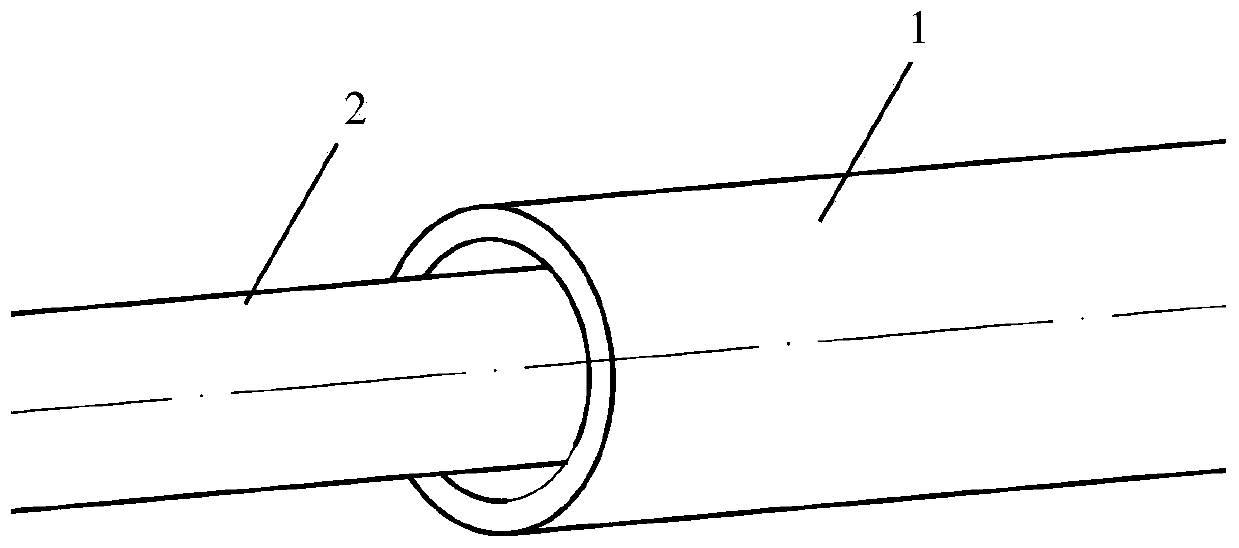

[0022] Step 2, the stainless steel capillary 1 (such as figure 2 shown) are arranged according to the requirements of the capillary tube 1 heat exchanger, so that the metal wires 2 pass through the small holes 4 at the bottom of the tooling 3 in sequence (such as figure 1 As shown), the metal wire 2 should be left with an appropriate length so that the metal wire 2 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com