Patents

Literature

181results about How to "Enough operating space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

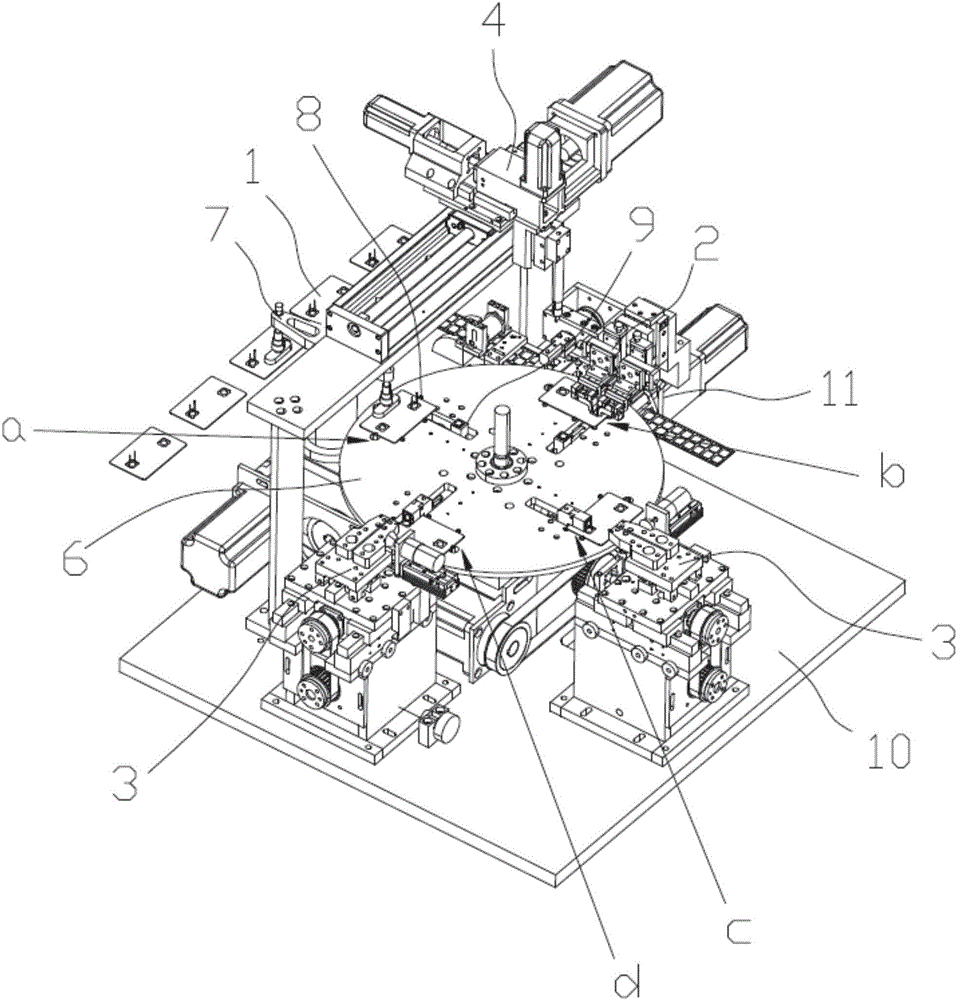

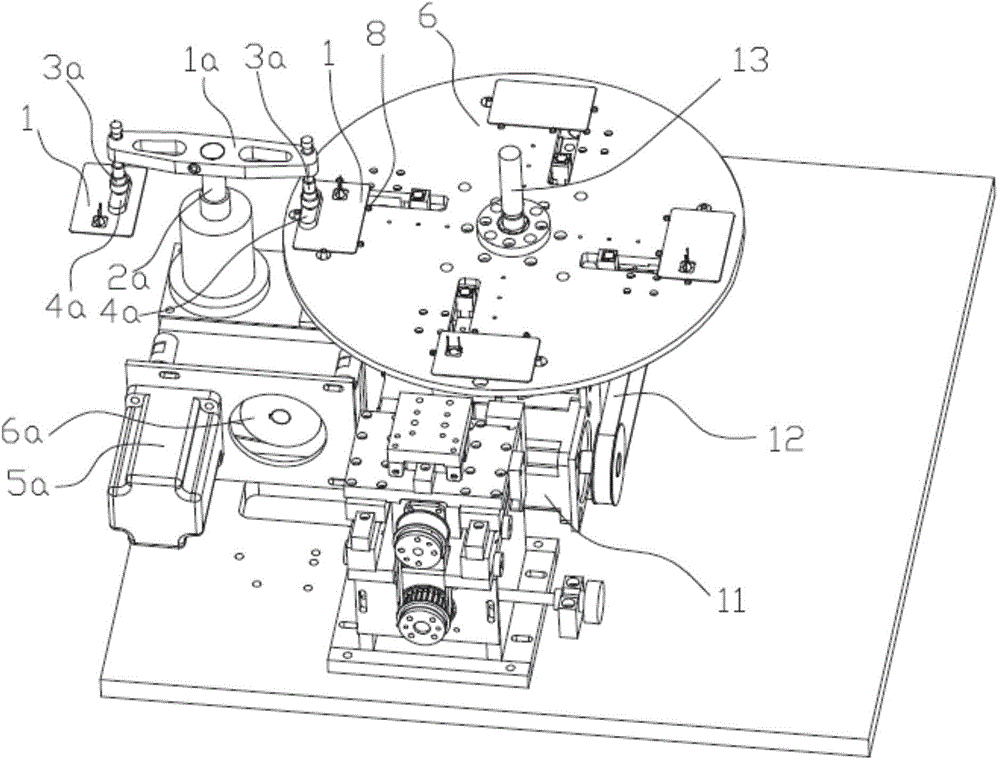

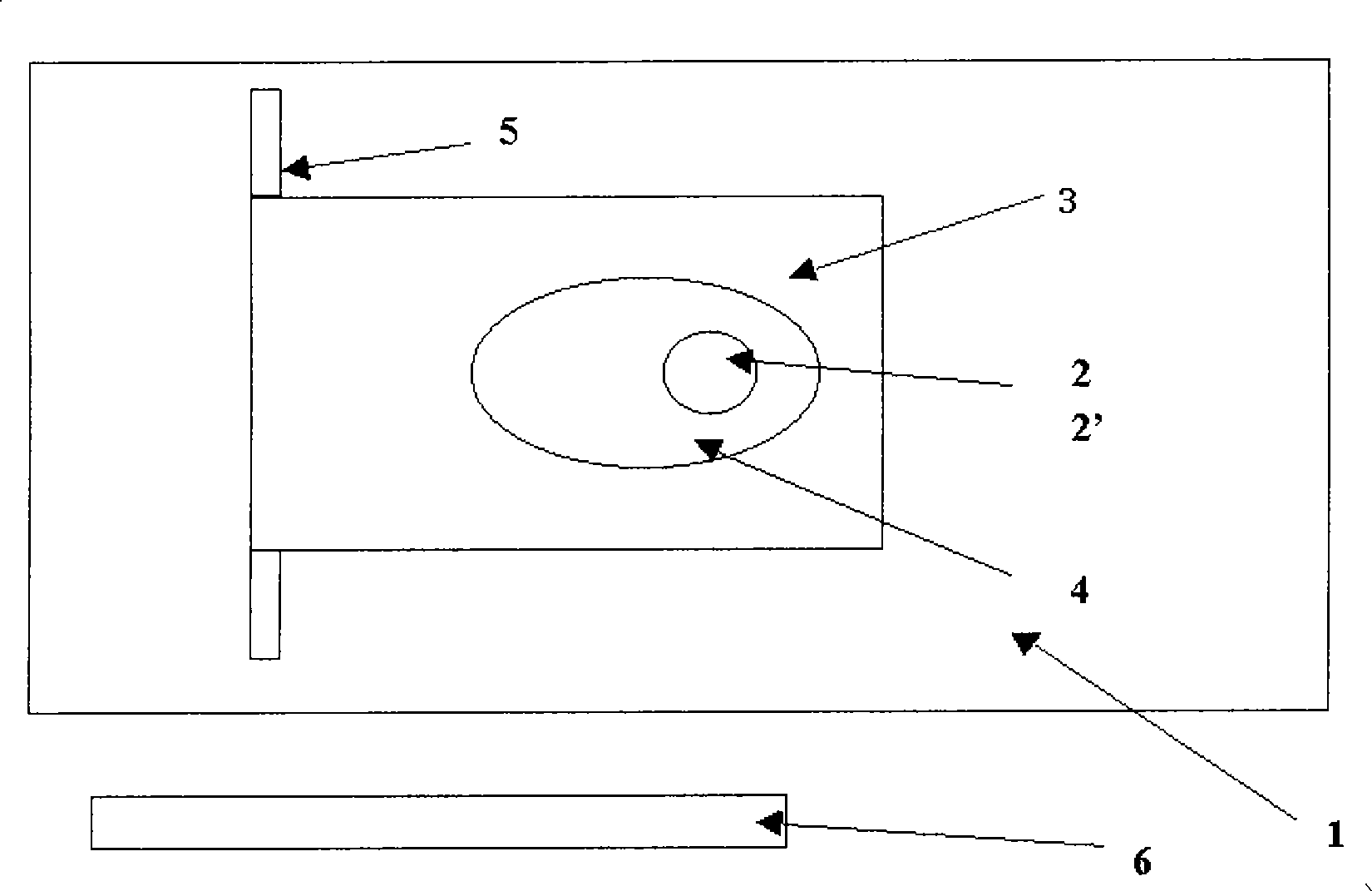

Equipment and method for efficiently welding chips of double-interface intelligent cards

ActiveCN104148834AImprove efficiencyIncrease productivityPrinted circuit assemblingWelding/cutting auxillary devicesSmart cardWork unit

The invention discloses equipment and a method for efficiently welding chips of double-interface intelligent cards. The equipment for efficiently welding the chips comprises a card transfer mechanism, a chip transportation mechanism, chip turnover mechanisms, an antenna correcting device, welding devices and a turntable. The card transfer mechanism is used for transferring each to-be-welded card to a card access station and fetching each welded card from the card access station, the chip transportation mechanism is used for transporting each chip to the card access station, the chip turnover mechanisms are used for turning the chips in horizontal states so that the chips can be in vertical states, the antenna correcting device is used for correcting the perpendicularity of the ends of each antenna, the welding devices are used for welding the ends of the antennas at corresponding welding spots of the chips, the turntable has an intermittent precision stopping function, a plurality of working units which are circumferentially and uniformly distributed are arranged on the turntable, and a card positioning mechanism and the corresponding chip turnover mechanism which can intermittently rotate along with the turntable are arranged in each working unit; working stations which are circumferentially and uniformly distributed are fixedly arranged at the outer periphery of the turntable, and the quantity of the working stations is identical to that of the working units. The equipment and the method have the advantages of high welding efficiency, good welding quality, convenience in use and maintenance and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

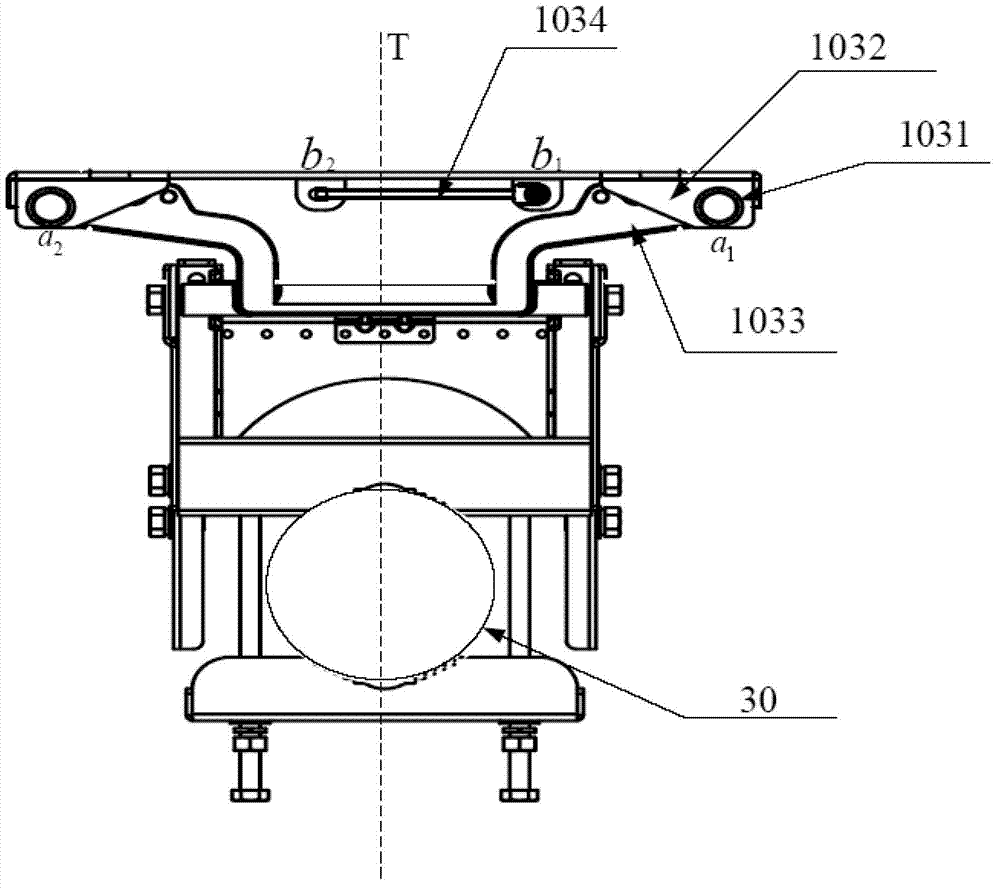

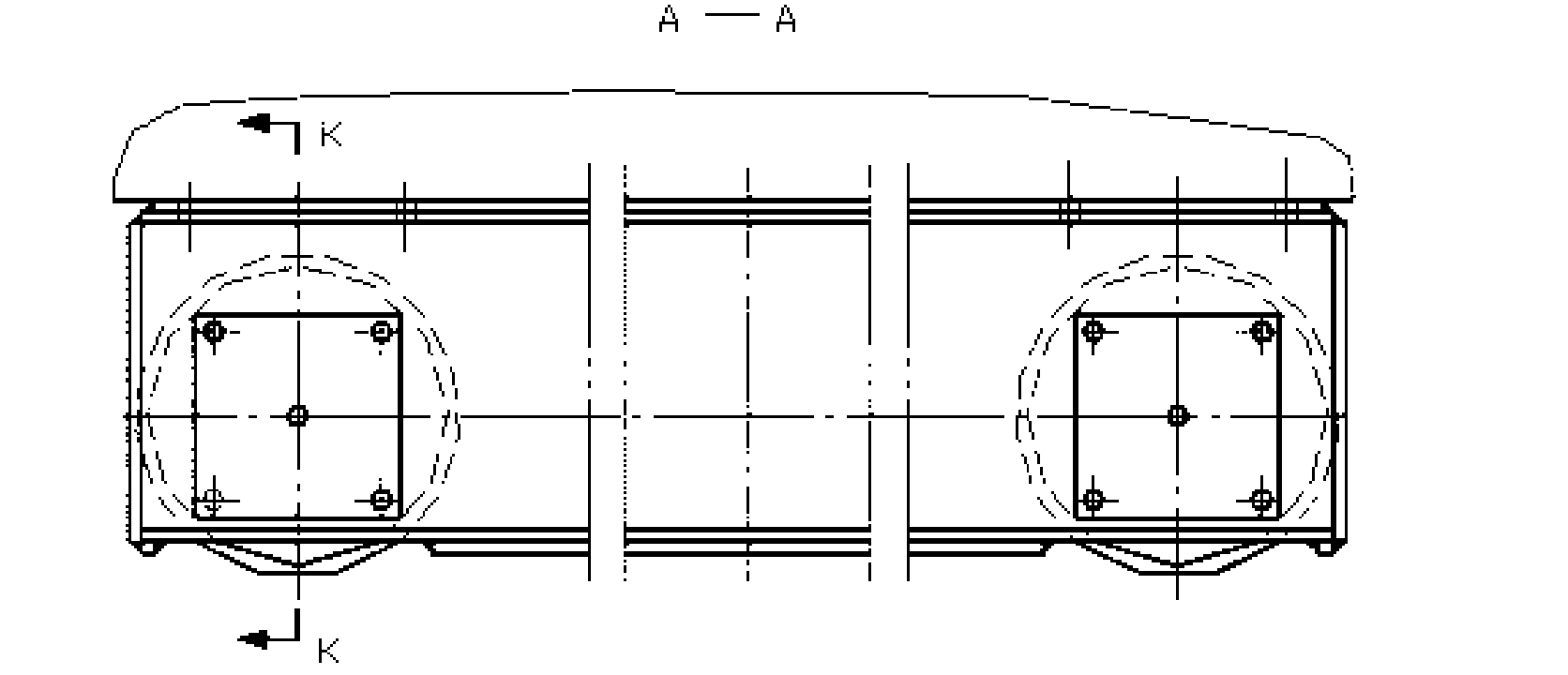

Suspension type monorail traffic system

The invention provides a suspension type monorail traffic system, which comprises a rail beam, an upright post for supporting the rail beam, a truck frame arranged on the rail beam, a carriage suspended below the truck frame, and a driving wheel and a guide wheel which are arranged on the truck frame, wherein the rail beam is a transverse H-shaped beam; the transverse H-shaped beam comprises an upper wing plate and a lower wing plate which are arranged at an interval; the upper wing plate is parallel to the lower wing plate or is at an included angle to but not intersected with the lower wing plate, and a webplate is connected between the upper wing plate and the lower wing plate; and the lower wing plate provides a rolling rail for the driving wheel, and the webplate provides the rolling rail for the guide wheel. The suspension type monorail traffic system has the advantages of compact structure, low cost, simple installation and convenient maintenance.

Owner:ZHUZHOU CSR SPECIAL EQUIP TECH

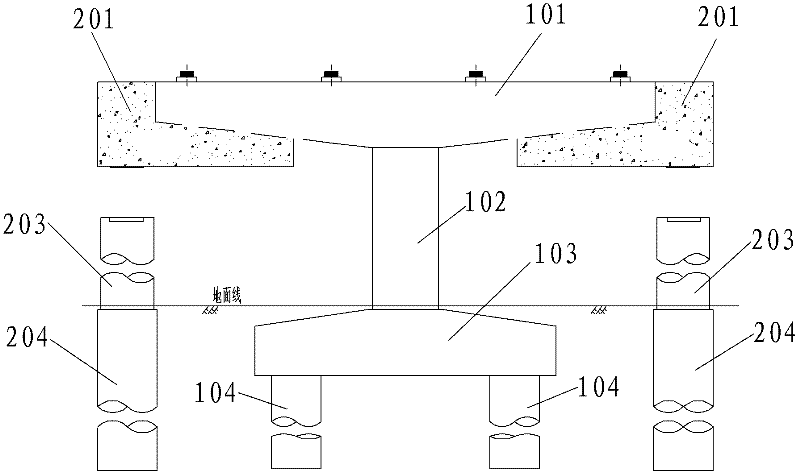

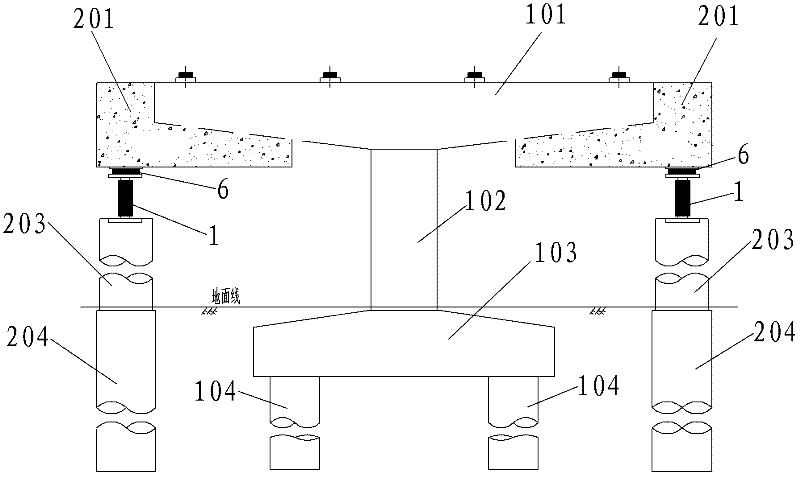

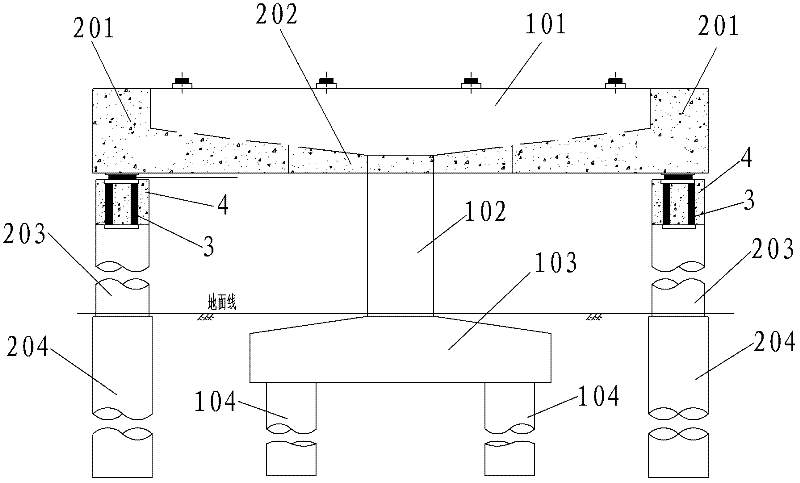

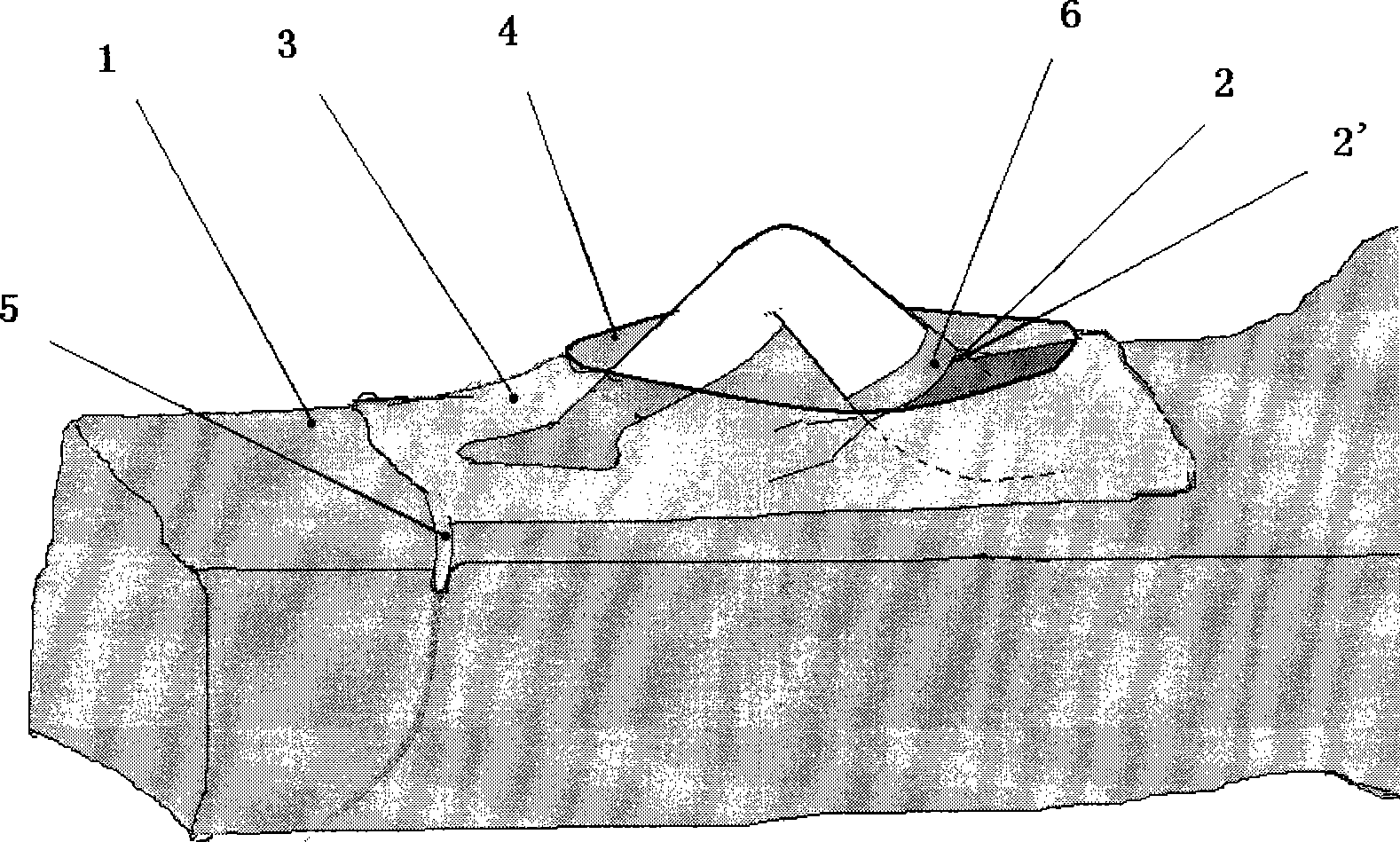

Process for reinforcing adjustable and controllable capping beam of piers

ActiveCN102383379AReduce negative bending momentReduce compressive stressBridge erection/assemblyBridge strengtheningFiberPre stress

The invention discloses a process for reinforcing adjustable and controllable capping beam of piers, comprising the following steps: (1) engraving shearing force grooves on the surface of the original capping beam concrete according to the design, embedding reinforcing steel bars and chiseling; (2) mixing plant fiber and steel fiber with the newly poured capping beam concrete, wherein the plant fiber is mixed in order to prevent the early shrinkage and crack of the concrete, and the steel fiber is mixed in order to prevent the later-stage stressed crack of the concrete; (3) leaving a certain area for secondary pouring in the middle in advance, wherein the area is 1 / 3 the length of the capping beam; (4) jacking capping beams by using two ends of a jack, and adjusting the reasonable load born by the new capping beam and the old capping beam according to a certain proportion by controlling the force and the jacking height of the jack to adjust the internal force of structures according to the design; (5) transferring the internal force of the basic part of the old structure to the basic part of the newly added structure by jacking; and (6) transferring partial or whole load born by the capping beam of the old biers to the new piers and the combined new and old capping beam structure by controlling the number and the position of prestressed steel strands to adjust the proportion of the whole load born by the combined new and old capping beam structure.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

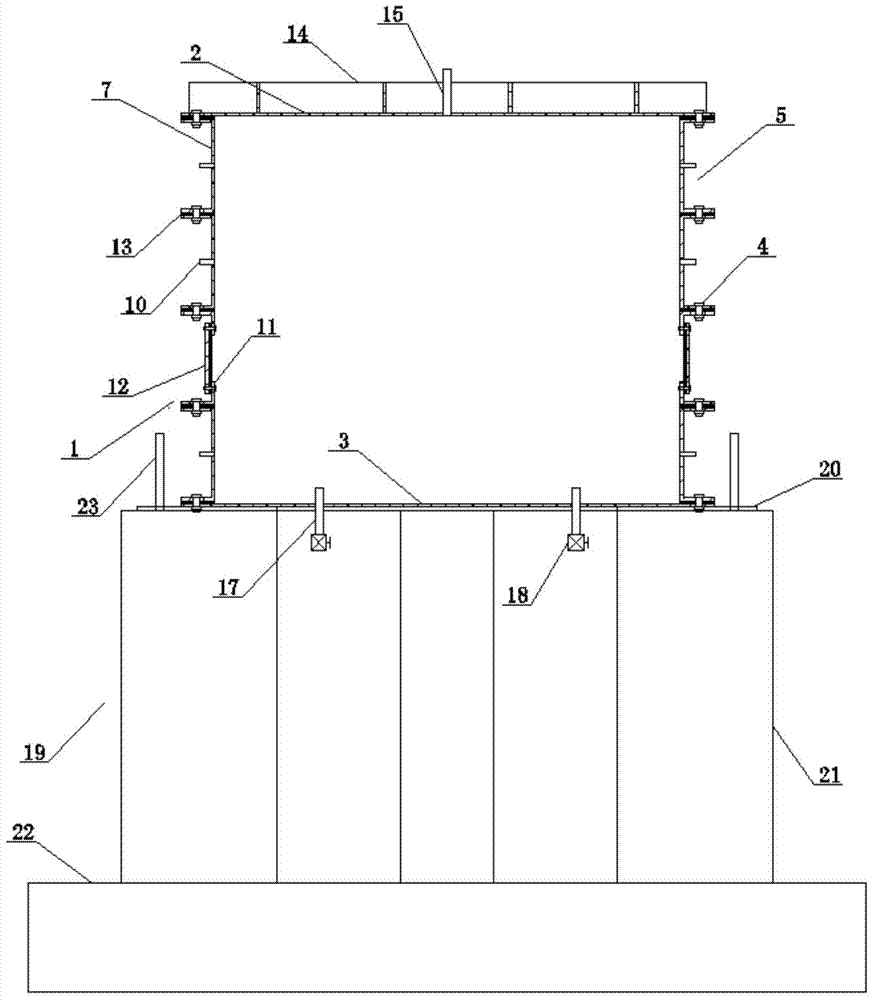

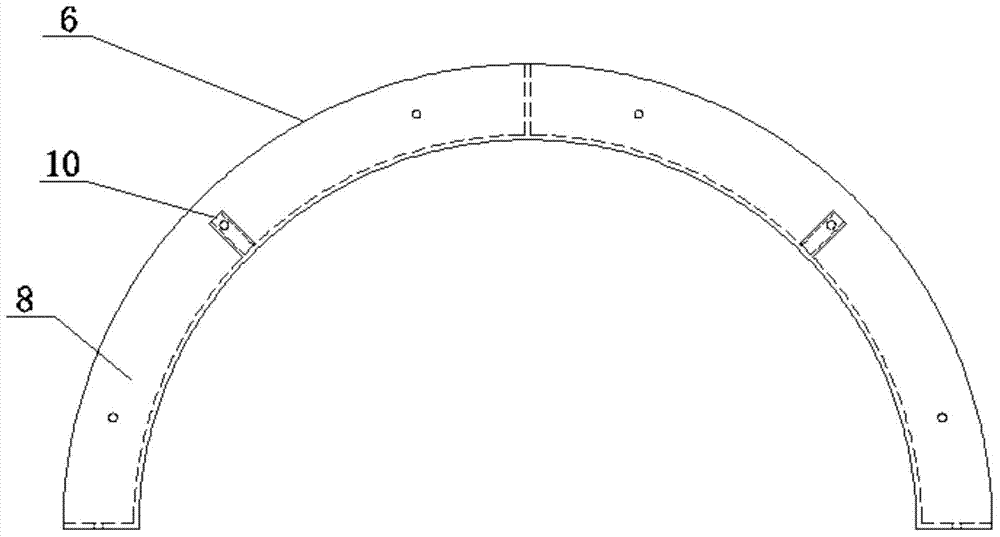

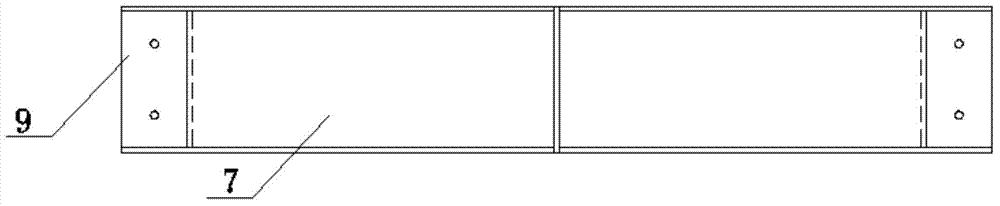

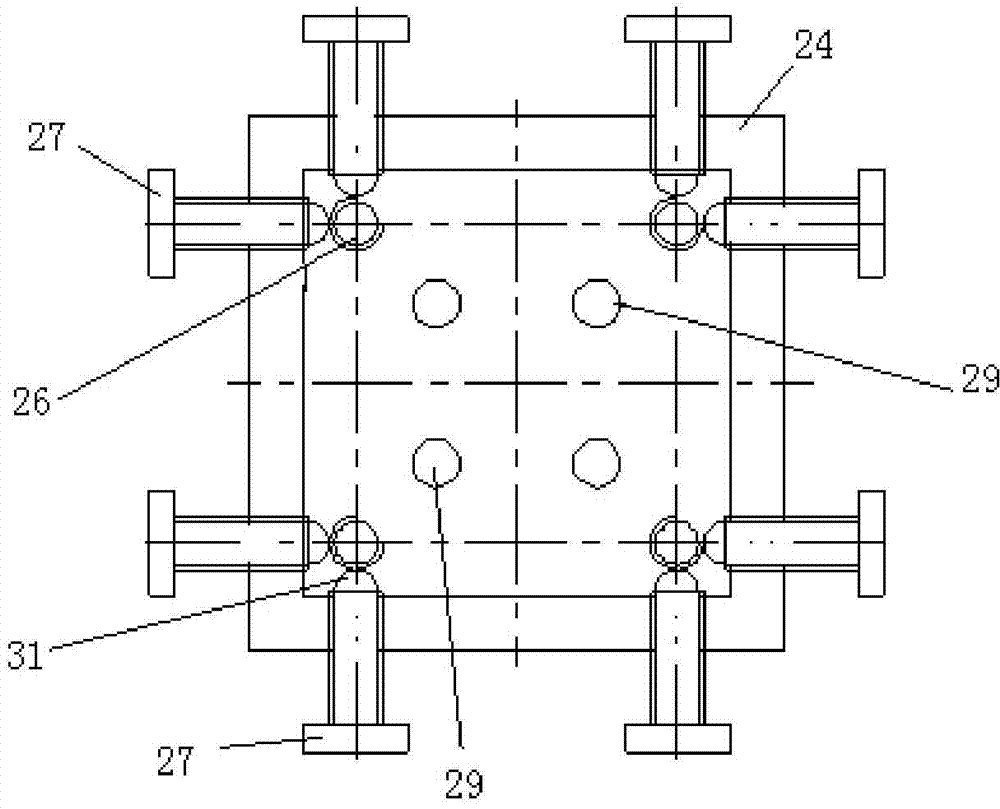

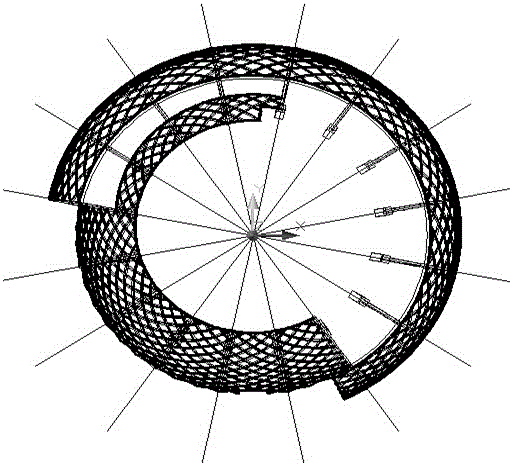

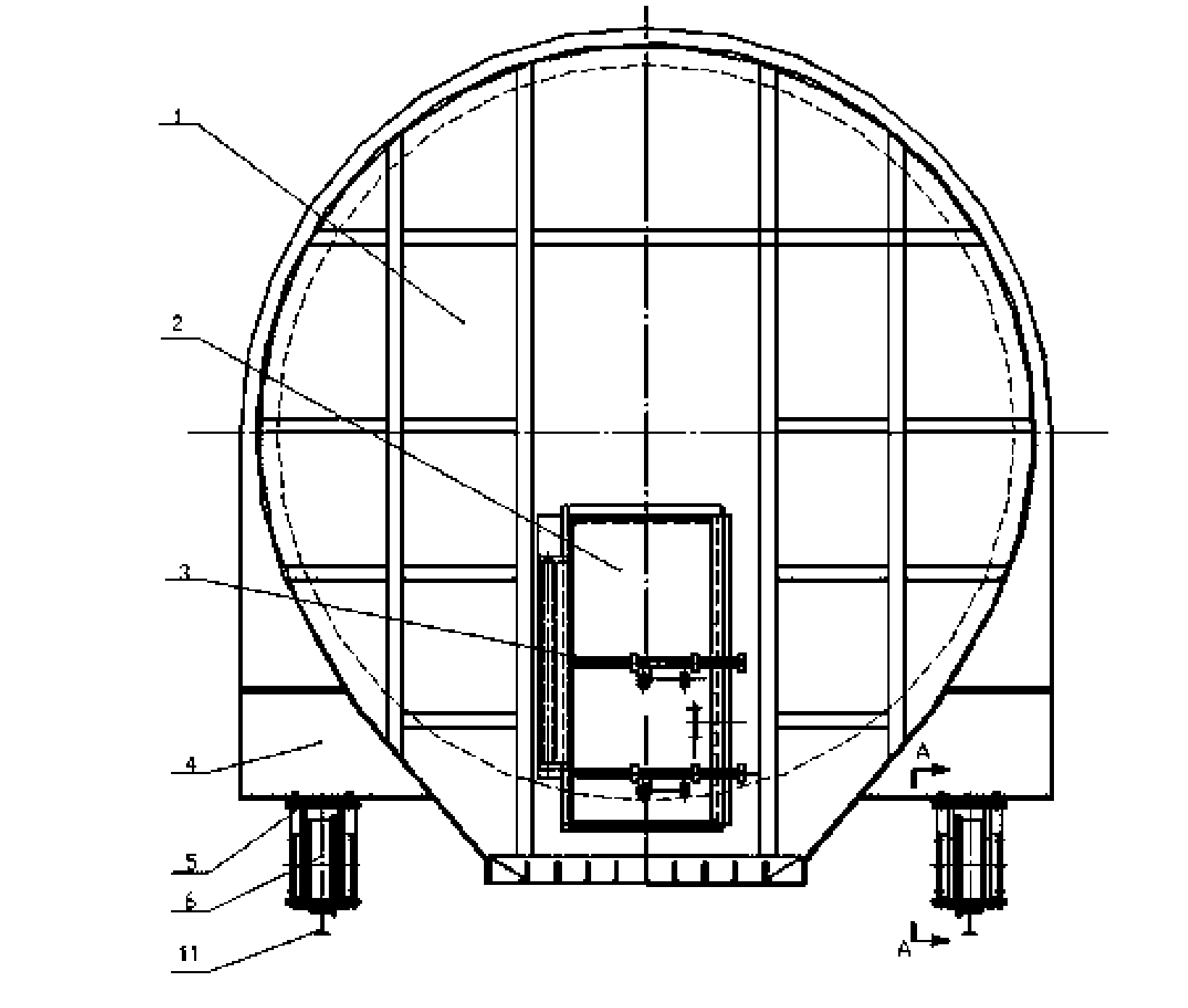

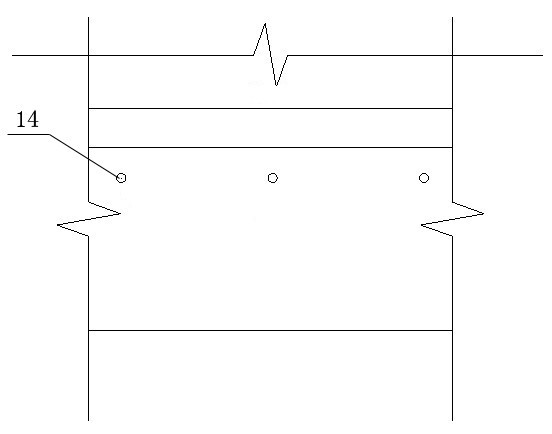

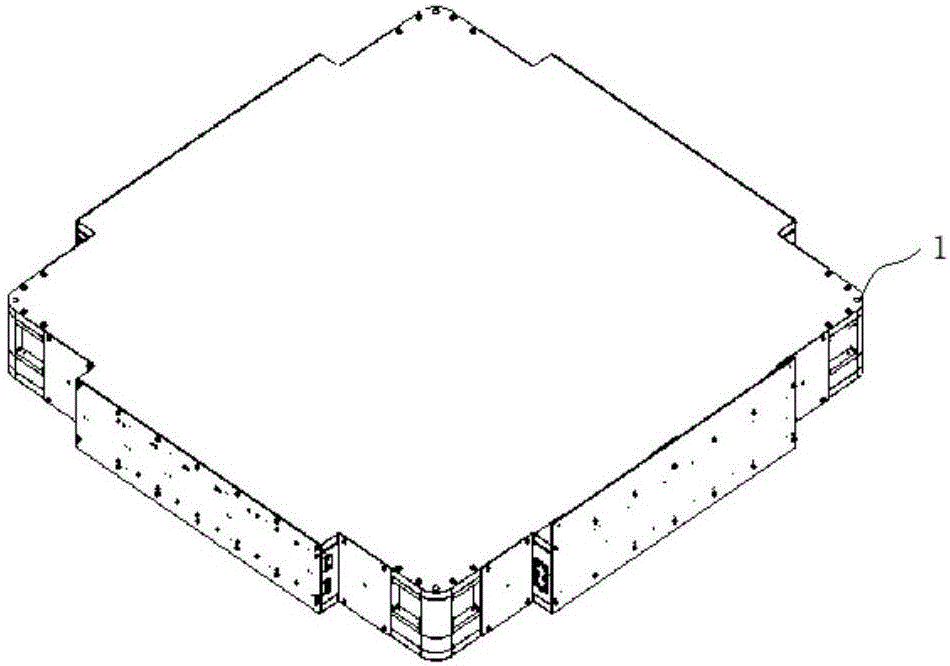

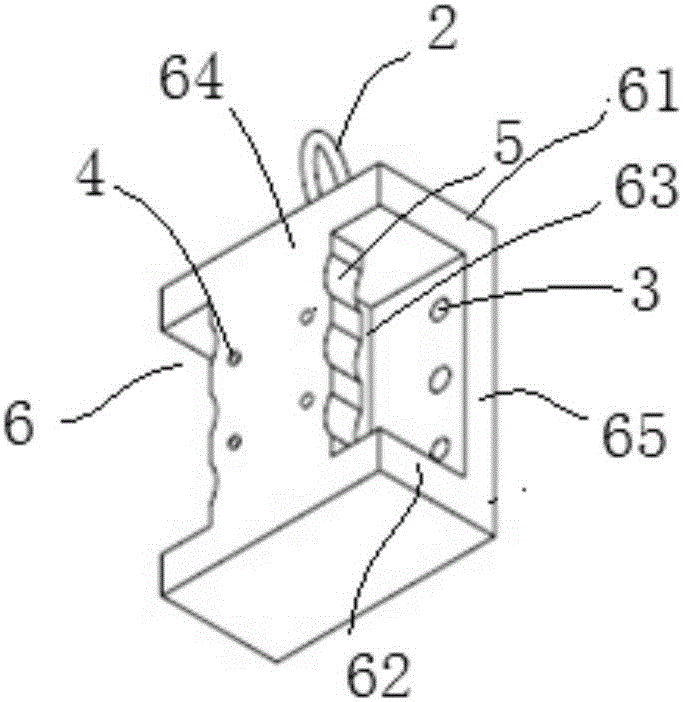

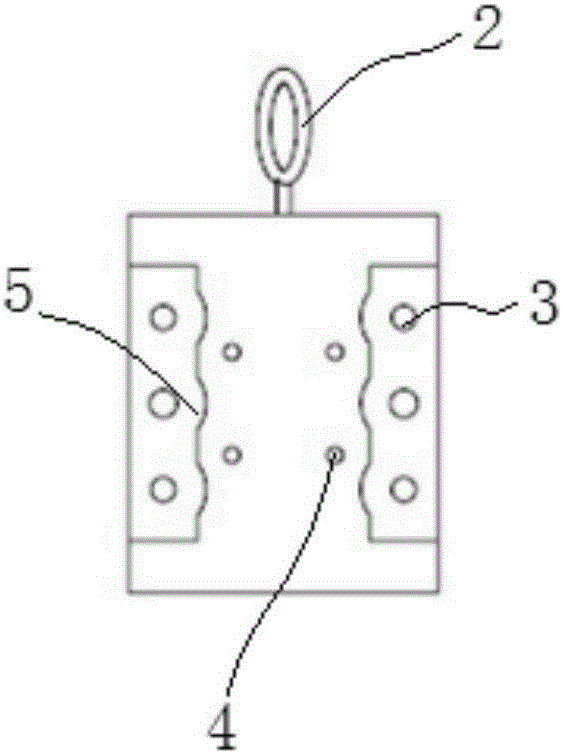

Test bed device for tunnel excavating and grouting model and application method of device

InactiveCN103940968AGuaranteed StrengthGuaranteed stiffnessMaterial analysisReinforced concreteRebar

The invention discloses a test bed device for a tunnel excavating and grouting model and an application method of the device. The test bed device comprises a lateral wall, a head cover for providing and loading a crustal stress platform, and a bottom plate arranged at the top of a reinforced concrete support rack, wherein the lateral wall vertically stands on the bottom plate and is connected with the bottom plate; the head cover is arranged at the top of the lateral wall and connected with the lateral wall; the lateral wall is formed by a plurality of model ring units which are stacked together in the vertical direction and sequentially connected; two round holes are formed in tunnel design positions in the diameter directions corresponding to the model ring units; the round holes are plugged by using arc sealing steel plates which are the same as the lateral wall in radian before tunnel excavation; holes are formed in the positions at four corners of the arc sealing steel plates; the arc sealing steel plates are connected with the lateral wall. By adopting the device, the geological disaster generation process and the later grouting reinforcing process in the tunnel excavation process can be continuously and systematically simulated, and the device has the advantages of being high in strength, and convenient to assemble and dismantle by adopting a modular assembling mode.

Owner:SHANDONG UNIV

Electronic product packaging box

ActiveCN107985760AAvoid shakingReduce extrusion areaPackaging vehiclesContainers for machinesCheck valveEngineering

The invention relates to the technical field of electronic product storage or packaging, in particular to an electronic product packaging box. The electronic product packaging box comprises a box bodyand a box cover and further comprises a support gasbag, a support, a fixed gasbag and at least one lifting mechanism. The support gasbag is provided with a gas inlet and a telescopic pipe which is used for communication of the support gasbag and the fixed gasbag. The telescopic pipe is provided with an exhaust check valve. The support comprises a support bottom plate and two fixed side plates, and a reset part is connected between the support bottom plate and the box body. The two fixed side plates are arranged on a pair of side edges of the support bottom plate symmetrically, and at least one fixed side plate is provided with a first rack. The fixed gasbag is provided with an exhaust opening and comprises two side gasbag bodies and two top gasbag bodies, and the two ends of each top gasbag body communicate with the two side gasbag bodies correspondingly. The lifting mechanism comprises a gear and a second rack. According to the scheme, electronic products can be taken out conveniently, and deformation of cartons is prevented.

Owner:南通昆保达包装科技有限公司

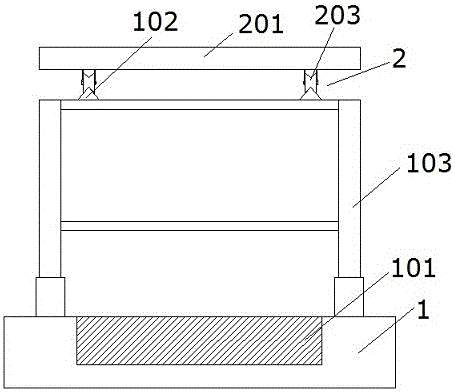

Adjusting device for equipment installing alignment

InactiveCN104723094AReduce labor intensitySimple structureMetal working apparatusStructural engineering

Owner:SHANDONG IRON & STEEL CO LTD

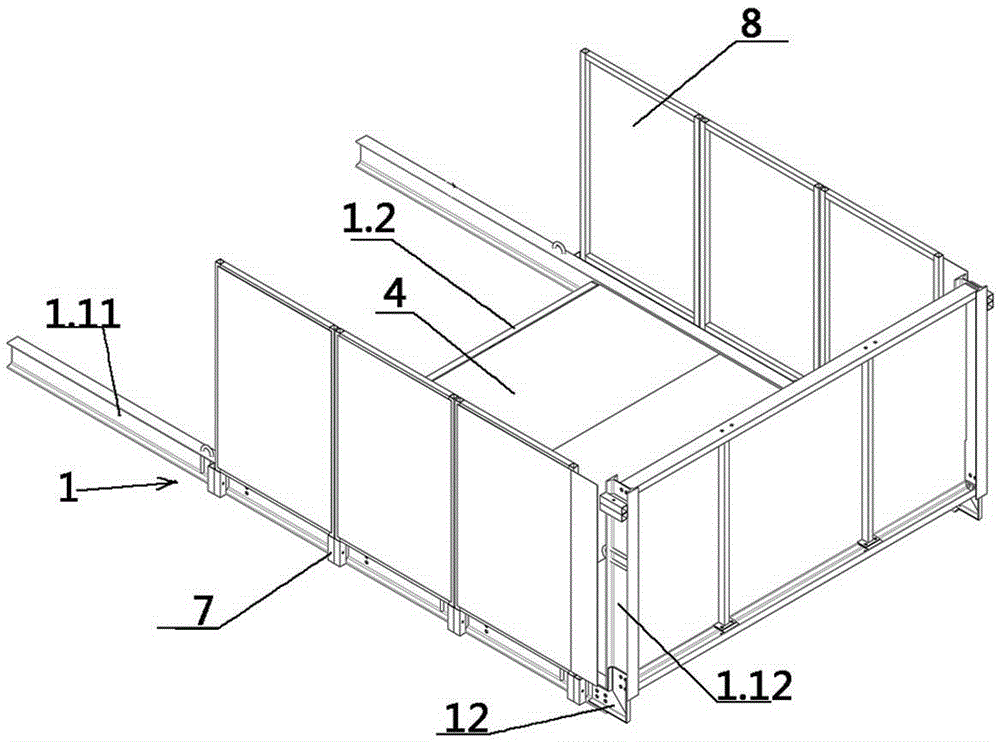

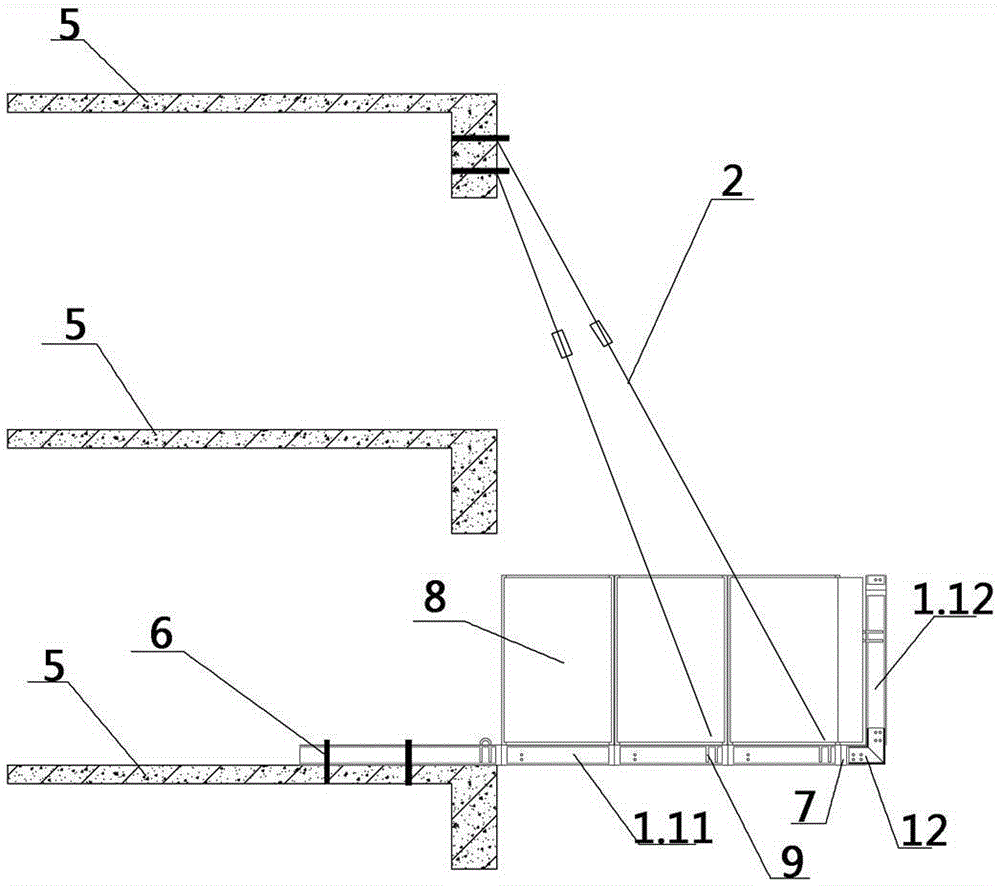

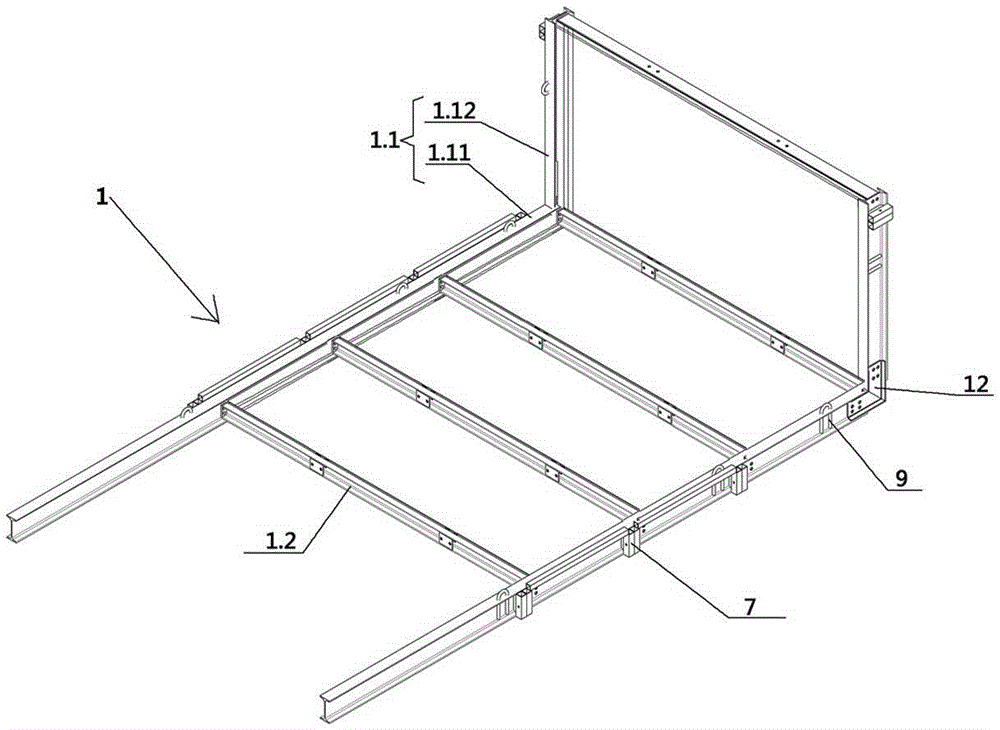

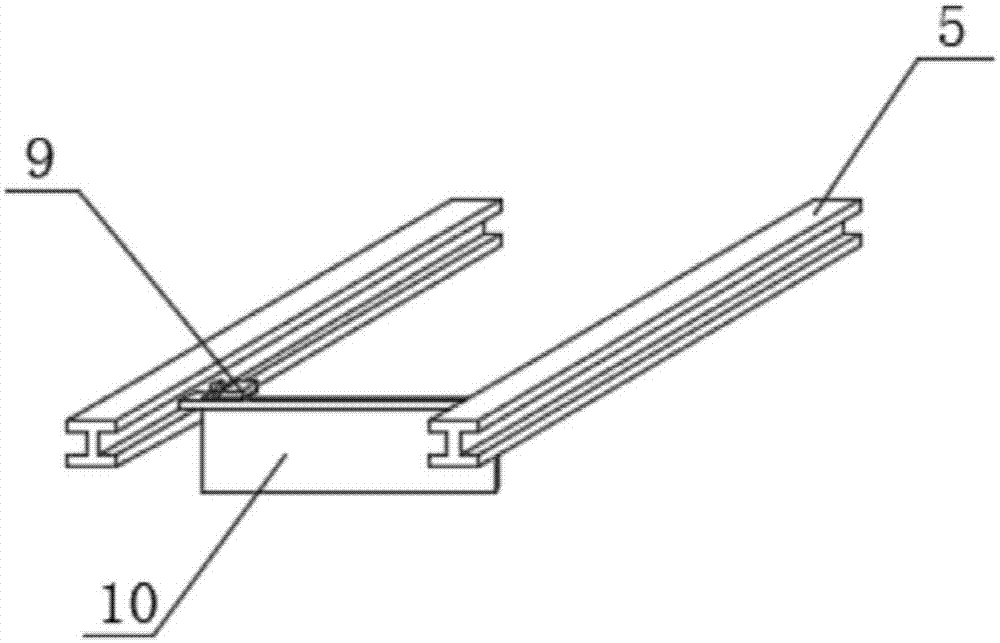

Foldable multifunctional overhanging unloading platform

InactiveCN105239765AReduce weightWill not be affected by constructionScaffold accessoriesBuilding support scaffoldsConstruction engineeringMechanical engineering

The invention provides a foldable multifunctional overhanging unloading platform, a manufacturing method of the foldable multifunctional overhanging unloading platform and a use method of the foldable multifunctional overhanging unloading platform. The foldable multifunctional overhanging unloading platform comprises main beams, sub beams, steel pedals, lateral side guardrails and a front side guardrail, wherein each main beam comprises a fixed part and a foldable part; and the fixed part and the foldable part are connected by a hinge, are fixed through a direct connecting plate in an unfolding state or are fixed by a right-angle connecting plate in a folding state. The foldable multifunctional overhanging unloading platform adopts the modular design; the assembly and the disassembly are convenient; the goal of controlling the length of the platform can be achieved through flexibly regulating the number of the steel pedals and the lateral side guardrails according to requirements; and a sufficient operation space is ensured. When no scaffold is built on the periphery of a building, the foldable part can be folded to be used as the front side guardrail. The foldable multifunctional overhanging unloading platform has the advantages that the fast regulation and switching can be realized under the scaffold-existence condition or under the scaffold-free condition; the external extending range is fast switched according to different requirements; the influence cannot be caused on the building of the unloading platform and the building construction; the universality is high; the foldable multifunctional overhanging unloading platform can be cyclically used for many times; and the cost is low.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

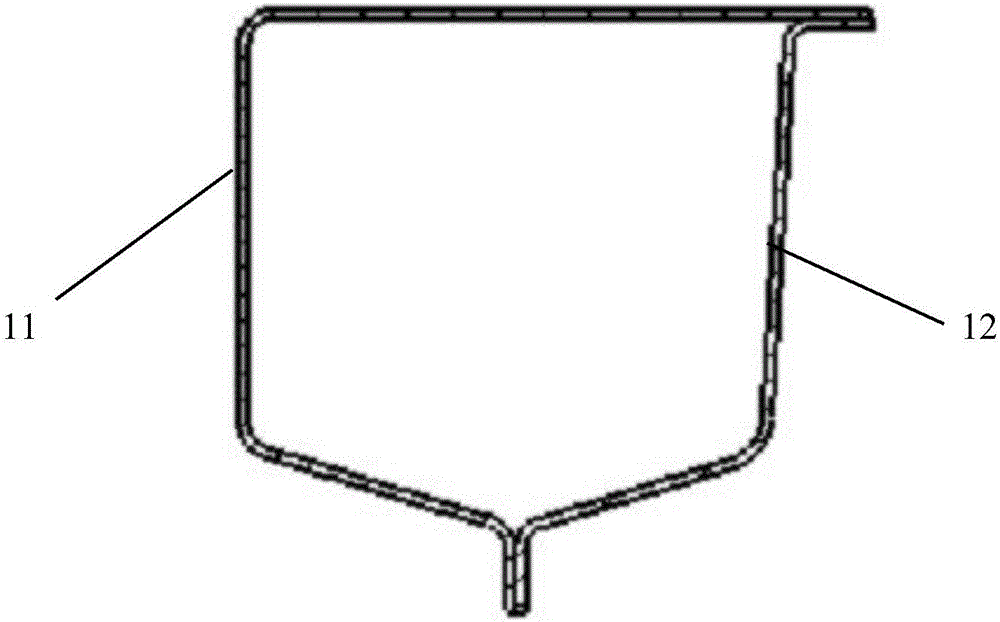

Drain type surgical drape

InactiveCN101496742ARealize the function of surgical drapesIsolate the rest of the bodyDiagnosticsSurgical drapesSurgical ManipulationSurgical site

The invention relates to a medical product, in particular to a drainage type surgical drape which consists of two parts, namely 1, the surgical drape, and 2, a liquid collection flow guide bag. The surgical drape can be connected with the liquid collection flow guide bag into a whole, and the liquid collection flow guide bag also can be combined with the surgical drape in other combined modes for use. The surgical drape is provided with a prepared hole for the surgical part to pass through; a bottom opening of the liquid collection flow guide bag is coincided with the prepared hole on the surgical drape to make the surgical part conveniently pass through the surgical drape to enter the liquid collection guide-flow bag. The top of the liquid collection flow guide bag is provided with macropore for providing open area for doctor to undergo surgery.

Owner:毛立江 +1

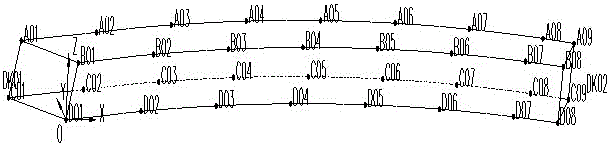

Forming method of bent/torsional component based on BIM technology

The invention discloses a forming method of a bent / torsional component based on a BIM technology. The forming method comprises the following steps: (1) establishing a BIM model of a bent / torsional component, guiding the established BIM model into 3D3S, and establishing a world coordinate system so as to generate absolute coordinates of the bent / torsional component relative to of measurement control points; (2) determining the XOY plane of the component, converting the absolute coordinate system into a relative coordinate system using XOY as the plane; besides, selecting a plurality of control points on the component so as to generate relative coordinates to be used as coordinates for processing control points of the bent / torsional component; and (3) performing push bending and torsion processing on the component to be processed so as to enable each control point to reach the vector height corresponding to the relative coordinates. According to the forming method disclosed by the invention, a parameterized three-dimensional model is established by utilizing related software of BIM, the absolute coordinate value of the bent / torsional component at each mounting key point is read from the parameterized three-dimensional model, and the relative coordinate values for a factory to process key points are calculated by utilizing a coordinate conversion technology, so that a total station is assisted to complete precise control during the manufacturing and the mounting of the bent / torsional component

Owner:CHINA METALLURGICAL CONSTR ENG GRP

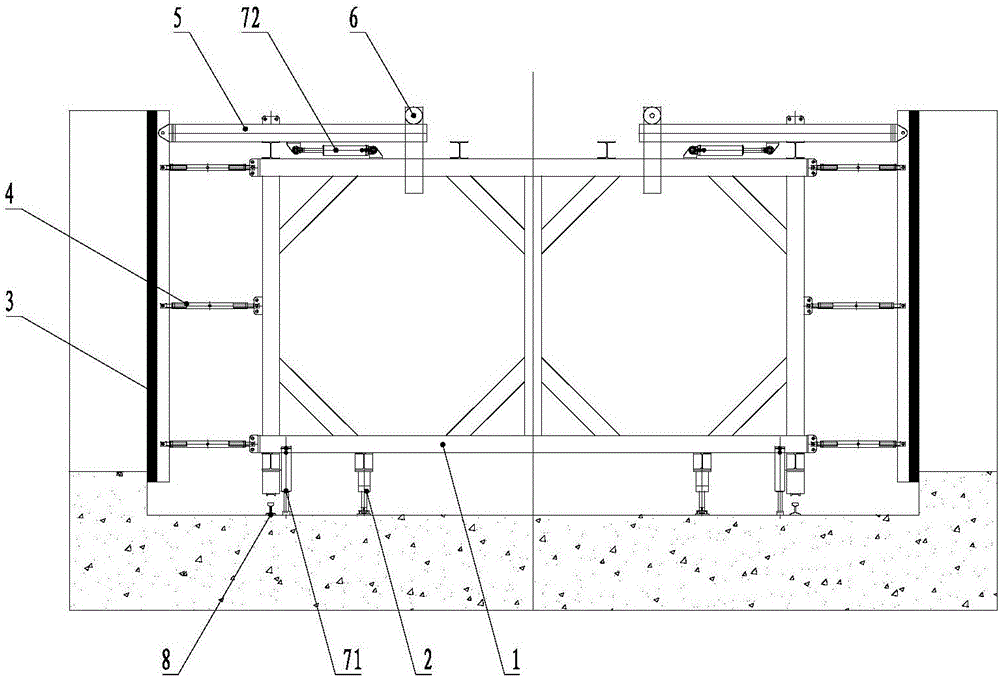

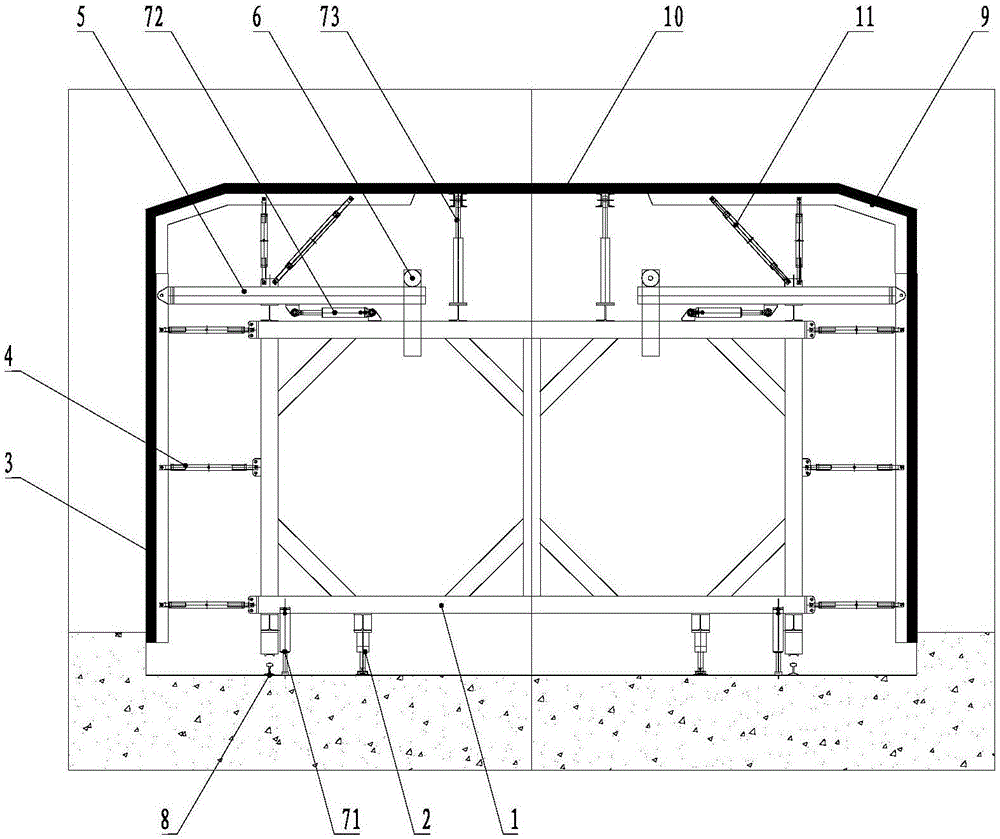

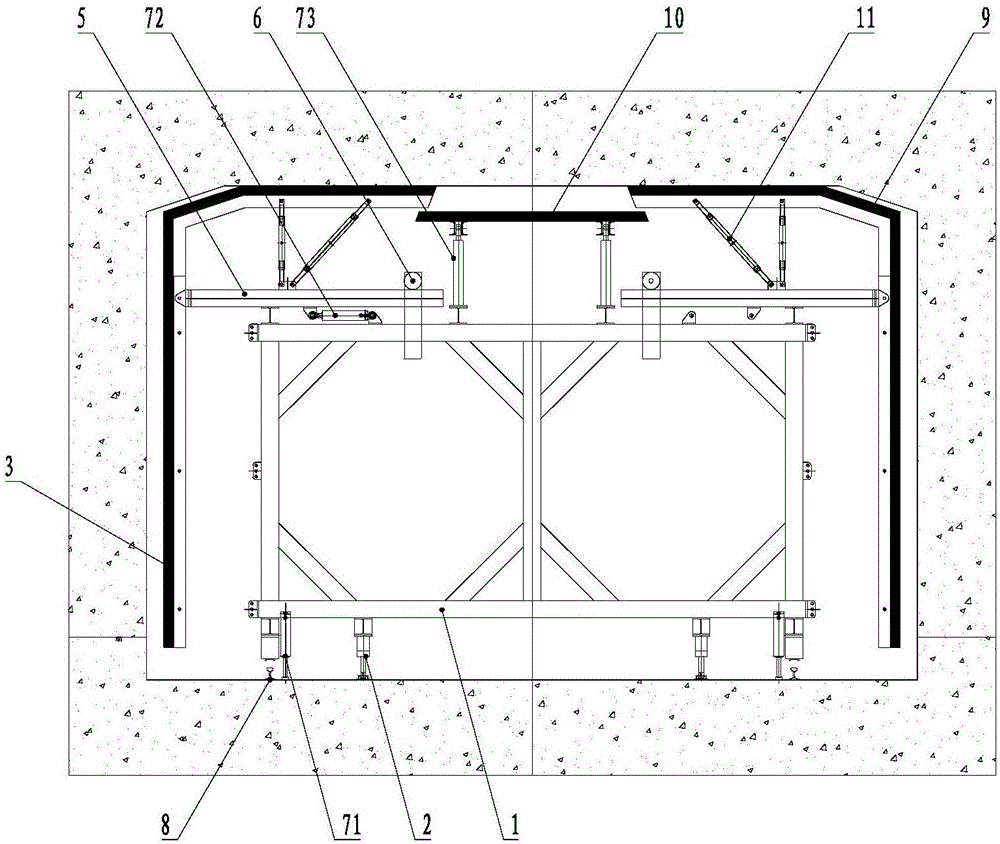

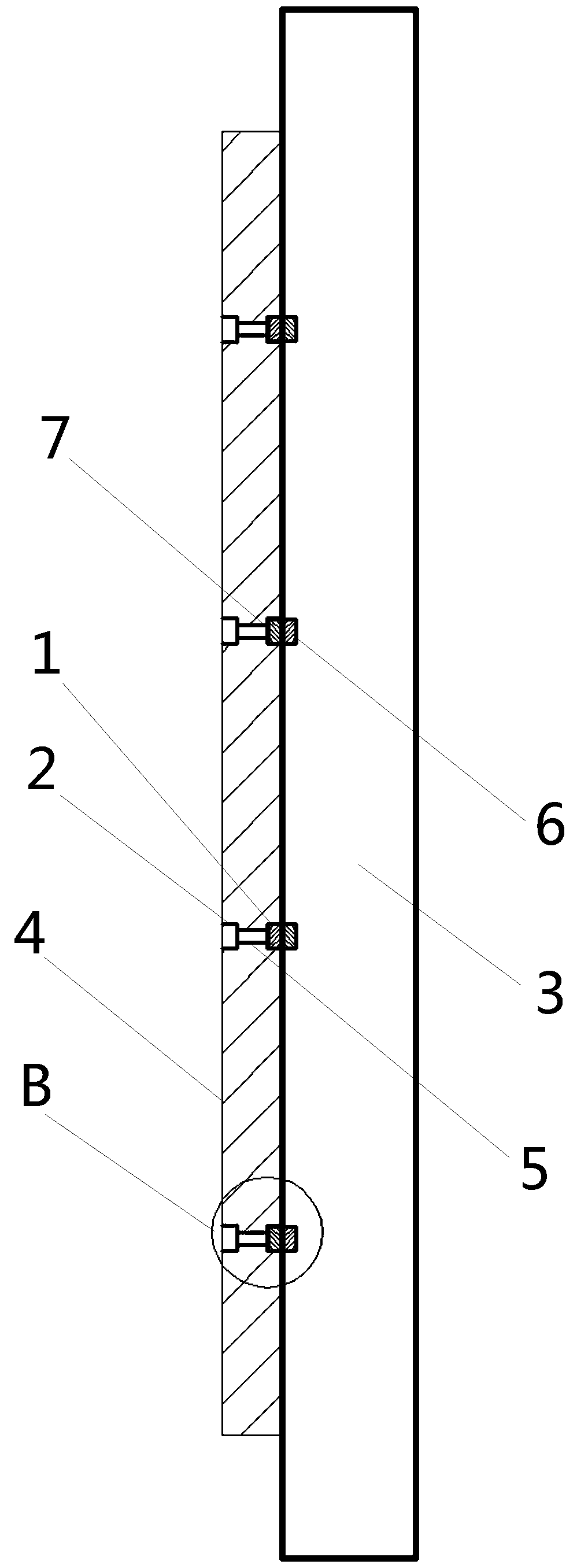

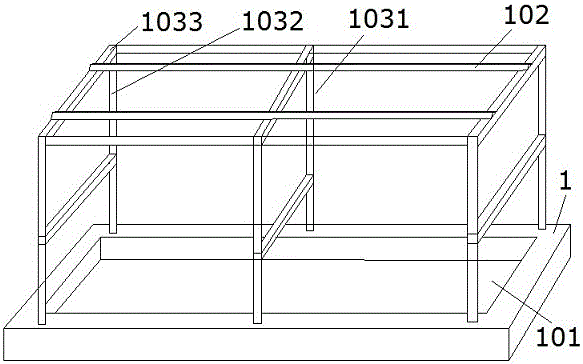

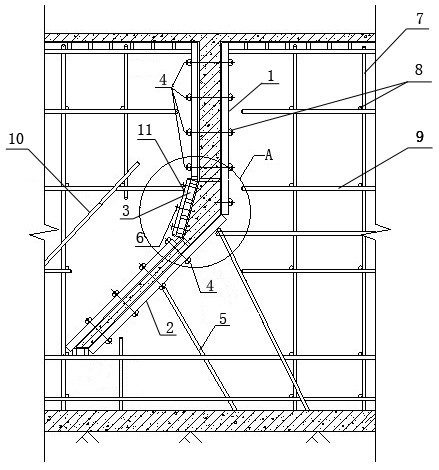

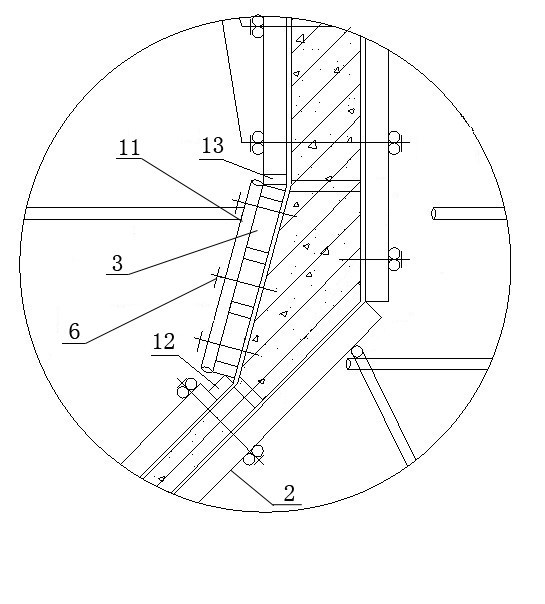

Trolley for construction of rectangular box culvert and tunnel

InactiveCN106194216AImprove molding qualityEasy to operateGround-workUnderground chambersCulvertMetallic Lead

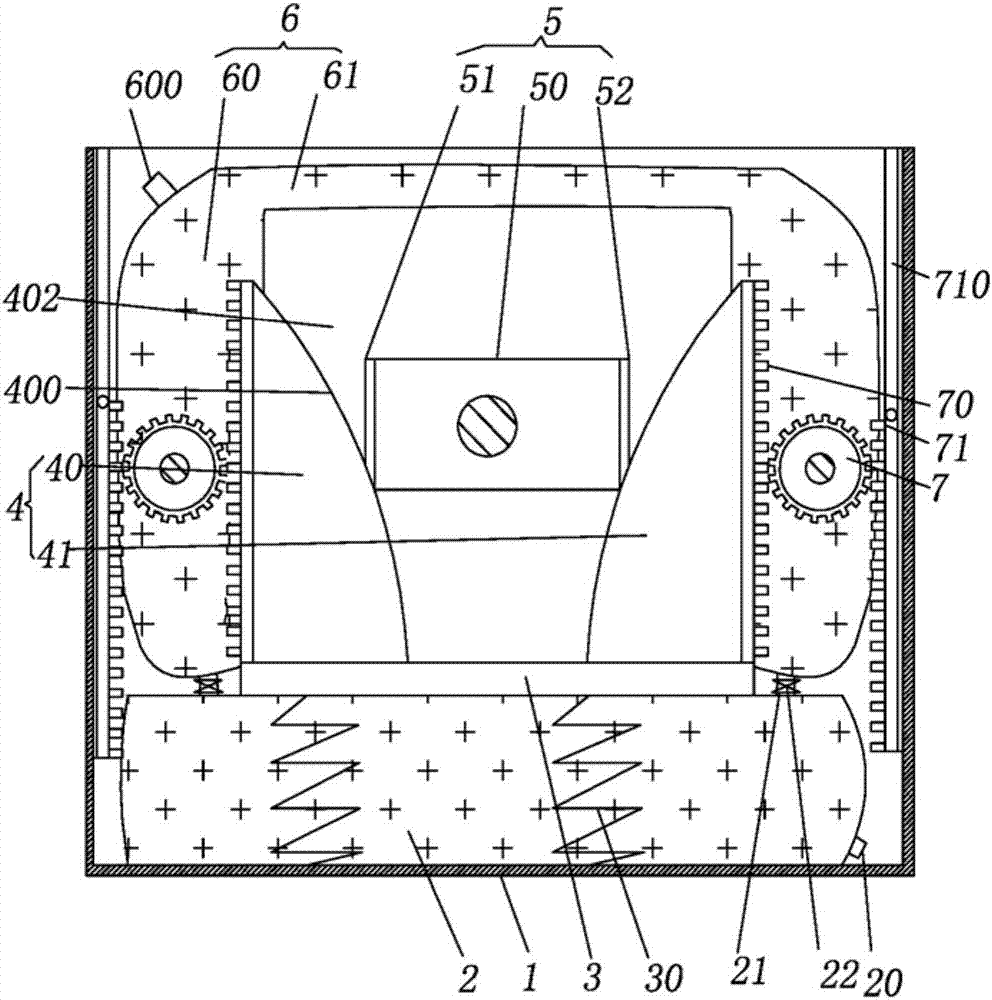

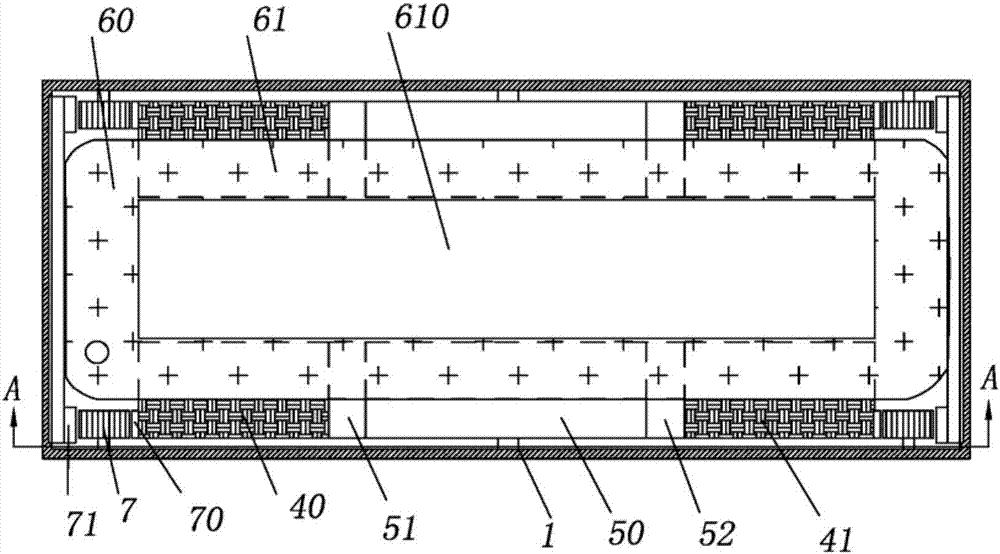

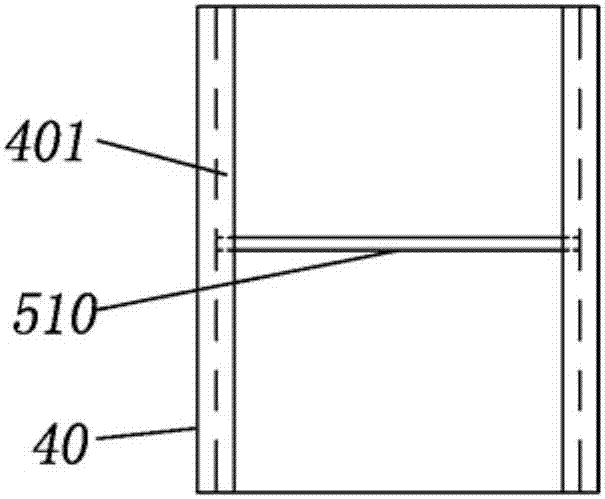

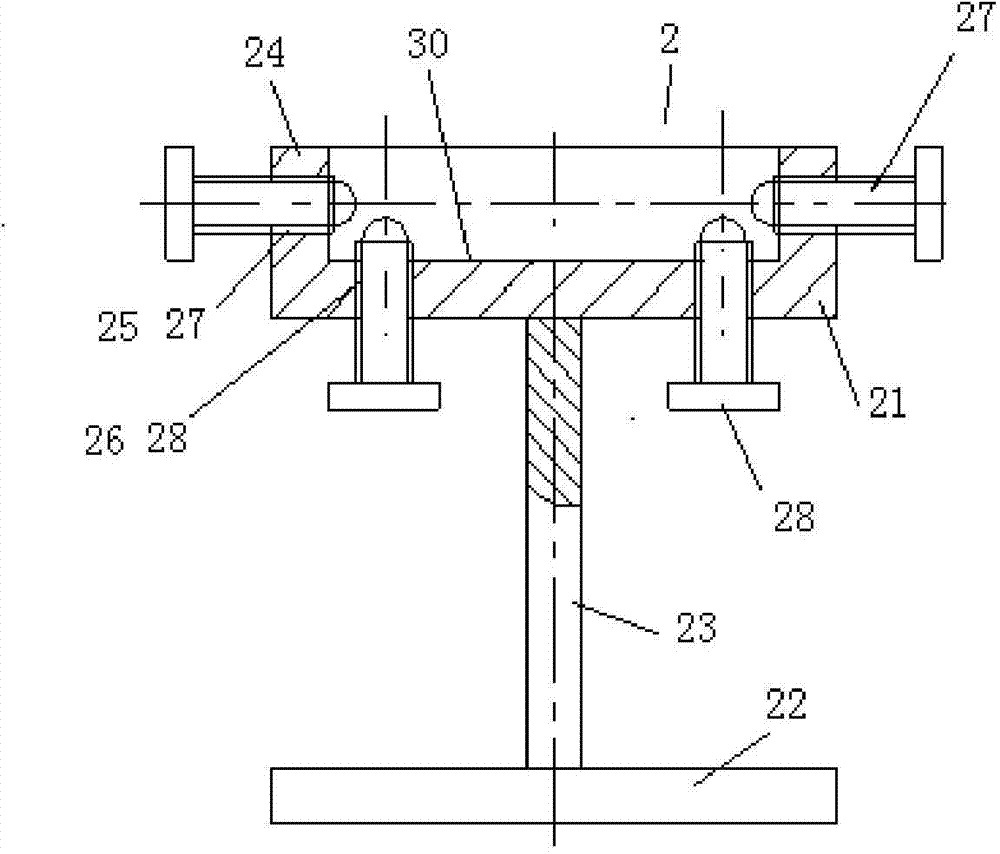

The invention discloses a trolley for construction of a rectangular box culvert and a tunnel. The trolley comprises a steel supporting frame (1) and lateral plate molds (3). The lateral plate molds (3) are connected with the steel supporting frame (1) through lateral supporting rods (4). Counter-force carriages (6) are arranged at the top of the steel supporting frame (1). One ends of transverse moving beams (5) are connected with the corresponding lateral plate molds (3), and the other ends of the transverse moving beams (5) are inserted into the corresponding counter-force carriages (6). Transverse moving power devices are arranged between the transverse moving beams (5) and the top of the steel supporting frame (1). Vertical supporting lead screws (2) are arranged at the bottom of the steel supporting frame (1). The trolley for construction of the rectangular box culvert and the tunnel has the characteristics of being simple in structure, easy to operate, wide in application range, good in concrete pouring forming quality and high in universality, and is particularly suitable for construction of various open-cut box culverts, pipe galleries and tunnels.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

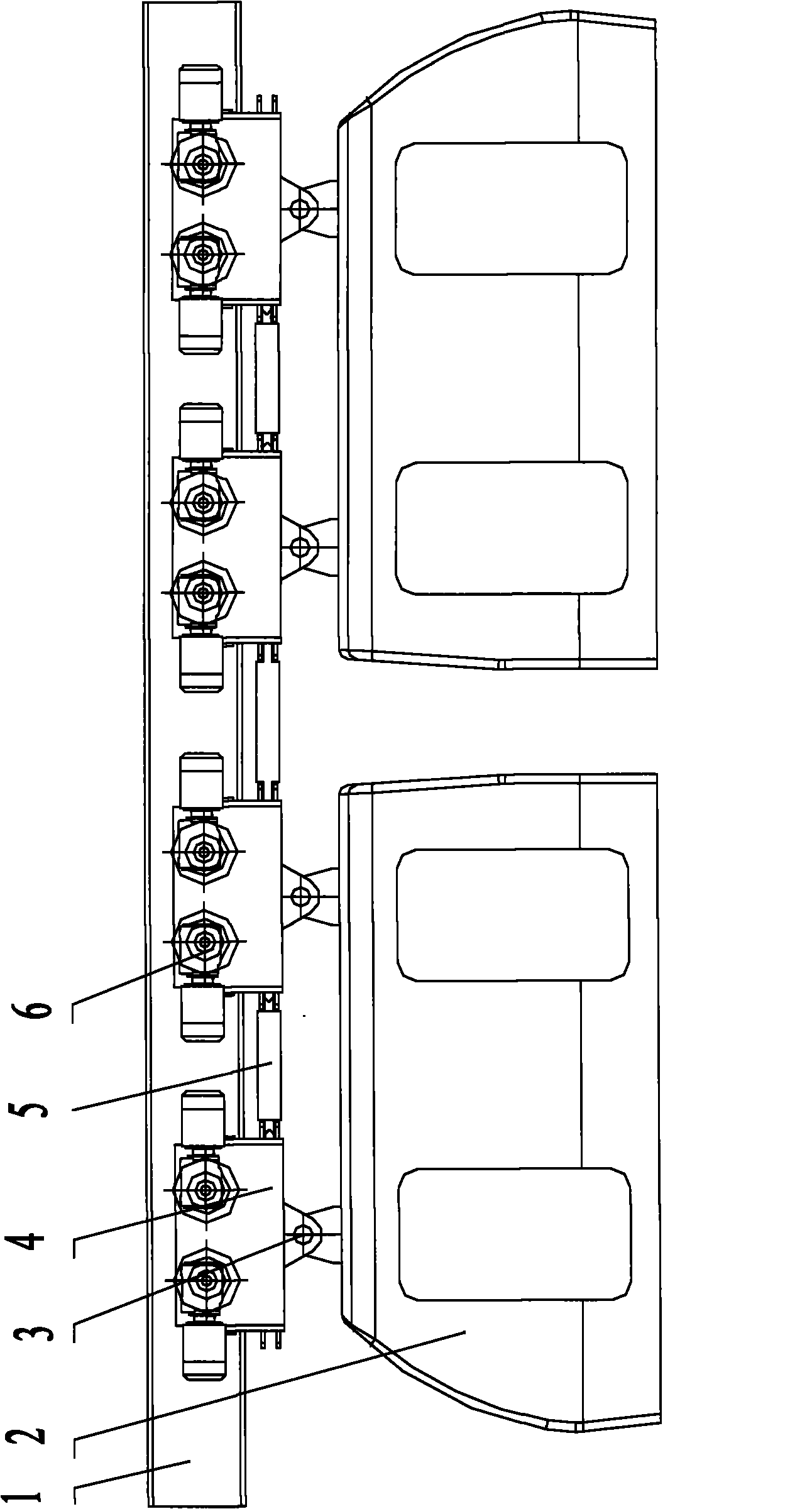

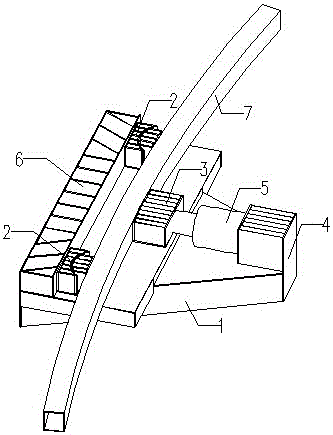

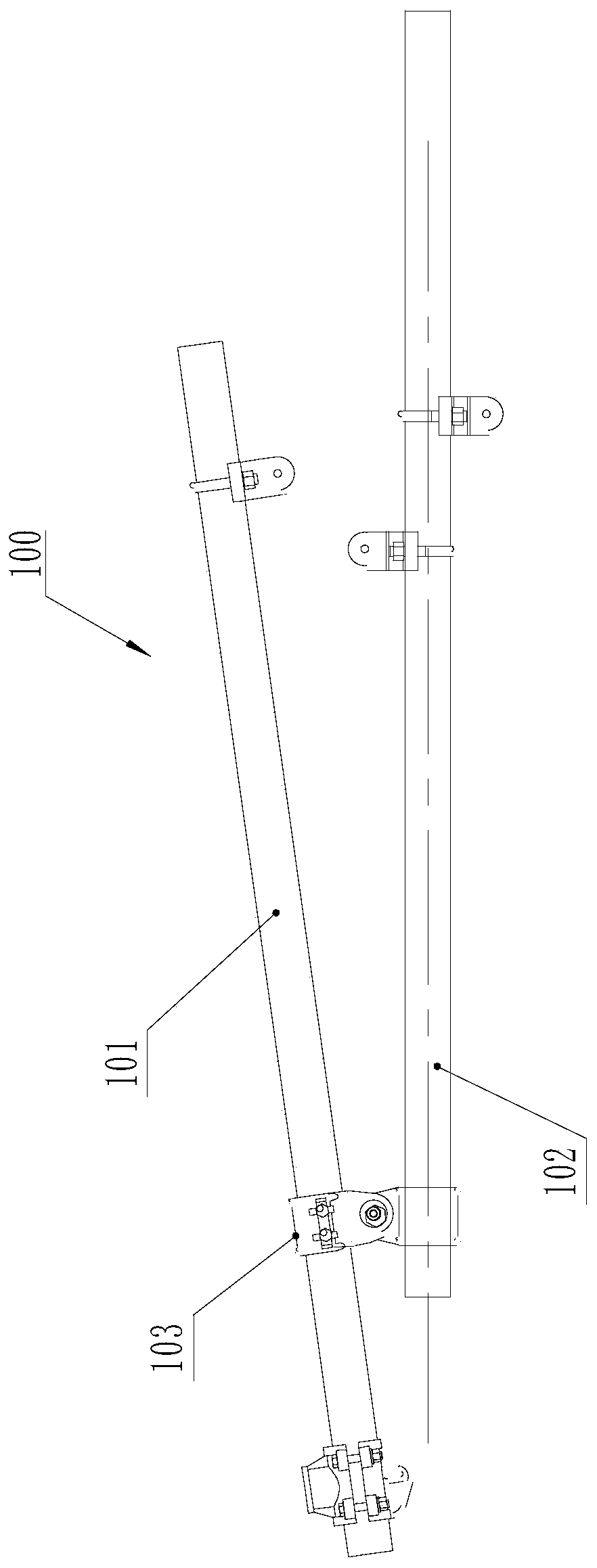

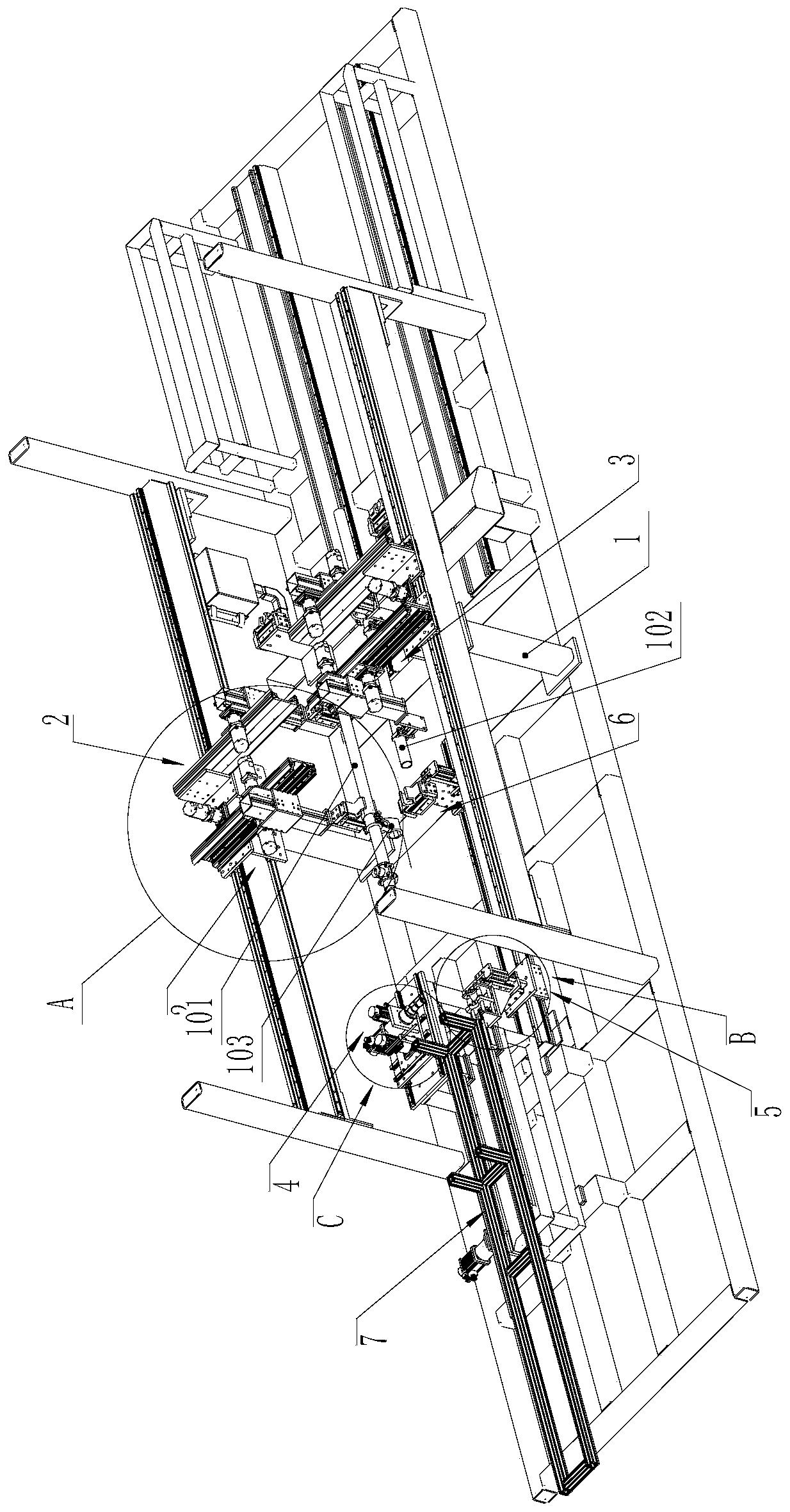

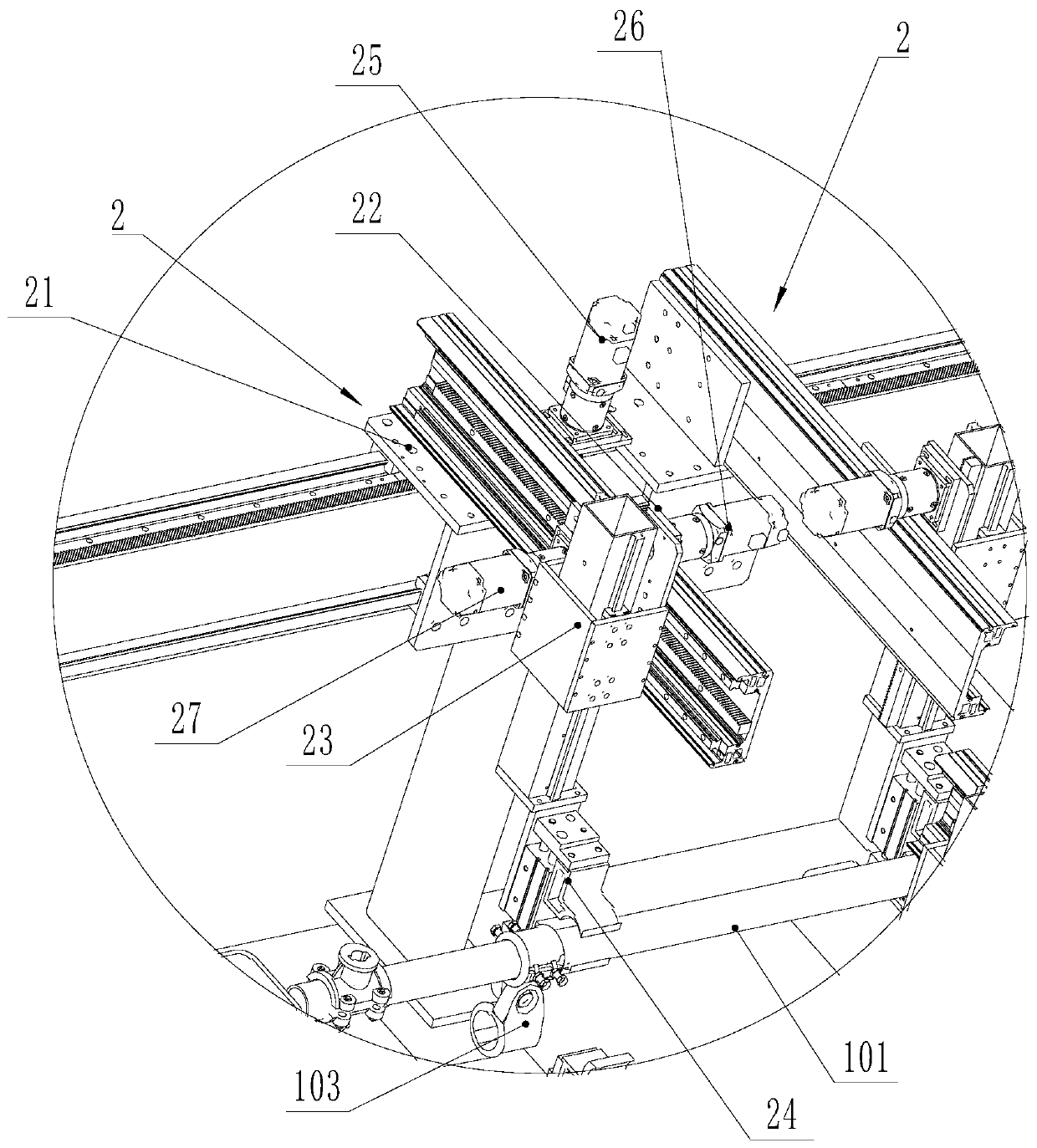

Automatic assembling device and automatic assembling method for railway cantilever assembly

ActiveCN110000530AAccurate insertionControl lengthRailway transportMetal working apparatusEngineeringCantilever

The invention discloses an automatic assembling device for a railway cantilever assembly. The automatic assembling device for the railway cantilever assembly comprises a rack, a first clamping and feeding mechanism, a second clamping and feeding mechanism, an assembling and positioning mechanism and a bolt tightening mechanism, wherein the first clamping and feeding mechanism is used for clampinga flat cantilever pipe and feeding the flat cantilever pipe to the assembling and positioning mechanism, and a connecting sleeve is placed on a positioning and supporting groove so as to be positioned; and then the second clamping and feeding mechanism is used for clamping an inclined cantilever pipe to horizontally insert into the connecting sleeve, and the inclined cantilever pipe is tightened through the bolt tightening mechanism. The automatic assembling device can be used for automatically assembling the flat cantilever pipe and the inclined cantilever pipe, so that the assembling efficiency and the assembling precision are improved. In addition, the invention further discloses an assembling method using the automatic assembling device, so that manpower is replace, the assembling precision is high, and the efficiency is high.

Owner:中铁建电气化局集团南方工程有限公司 +2

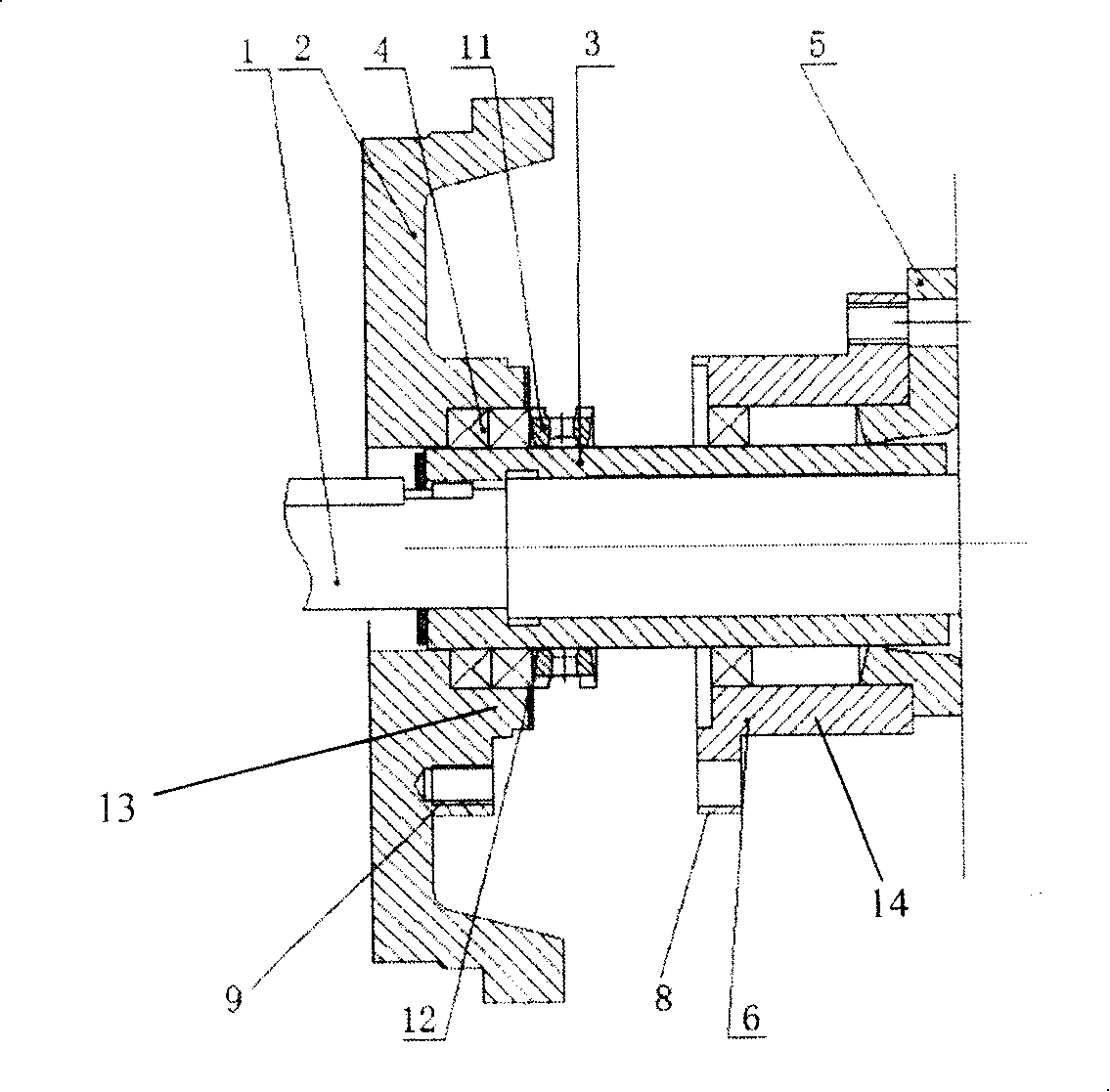

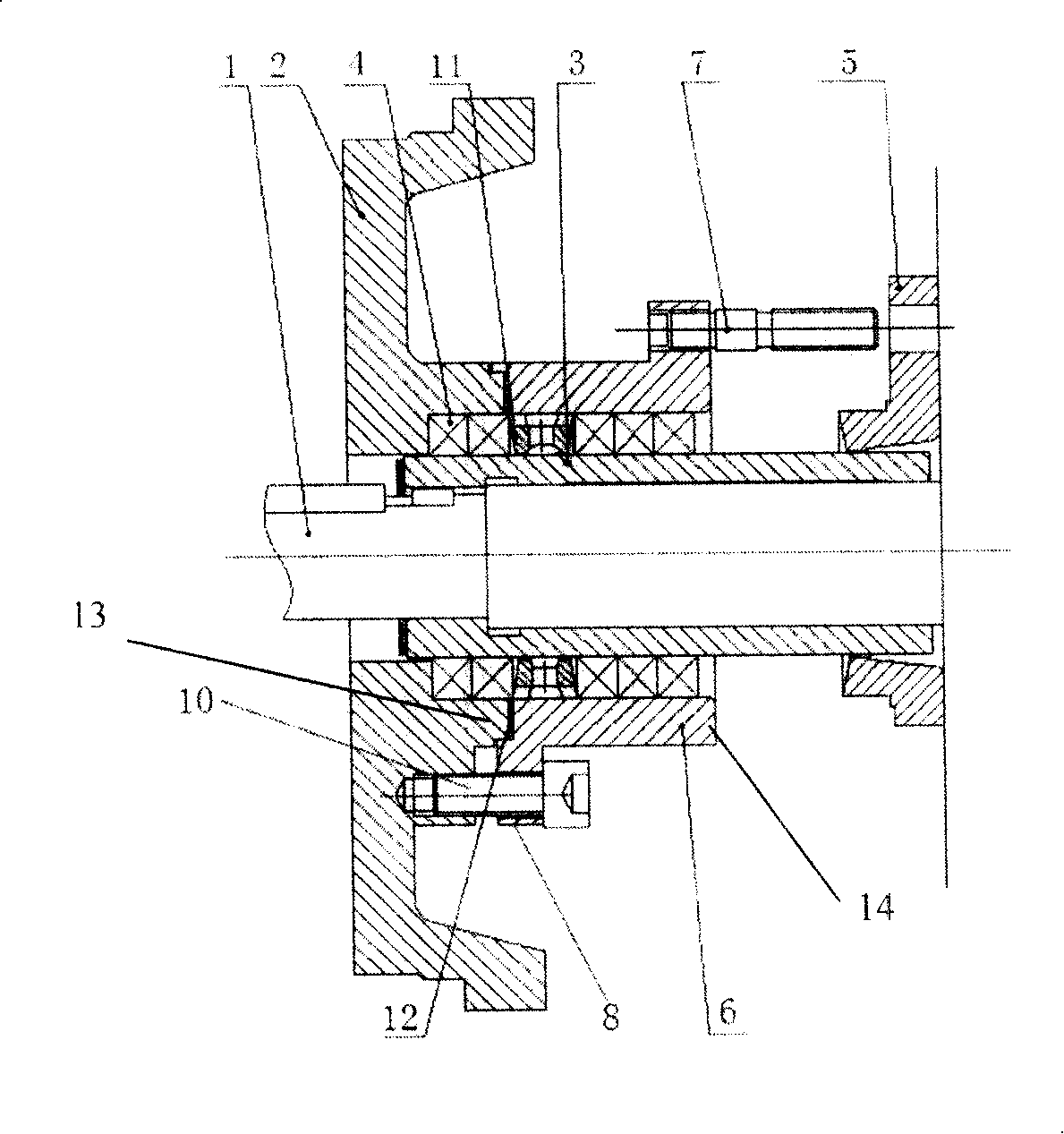

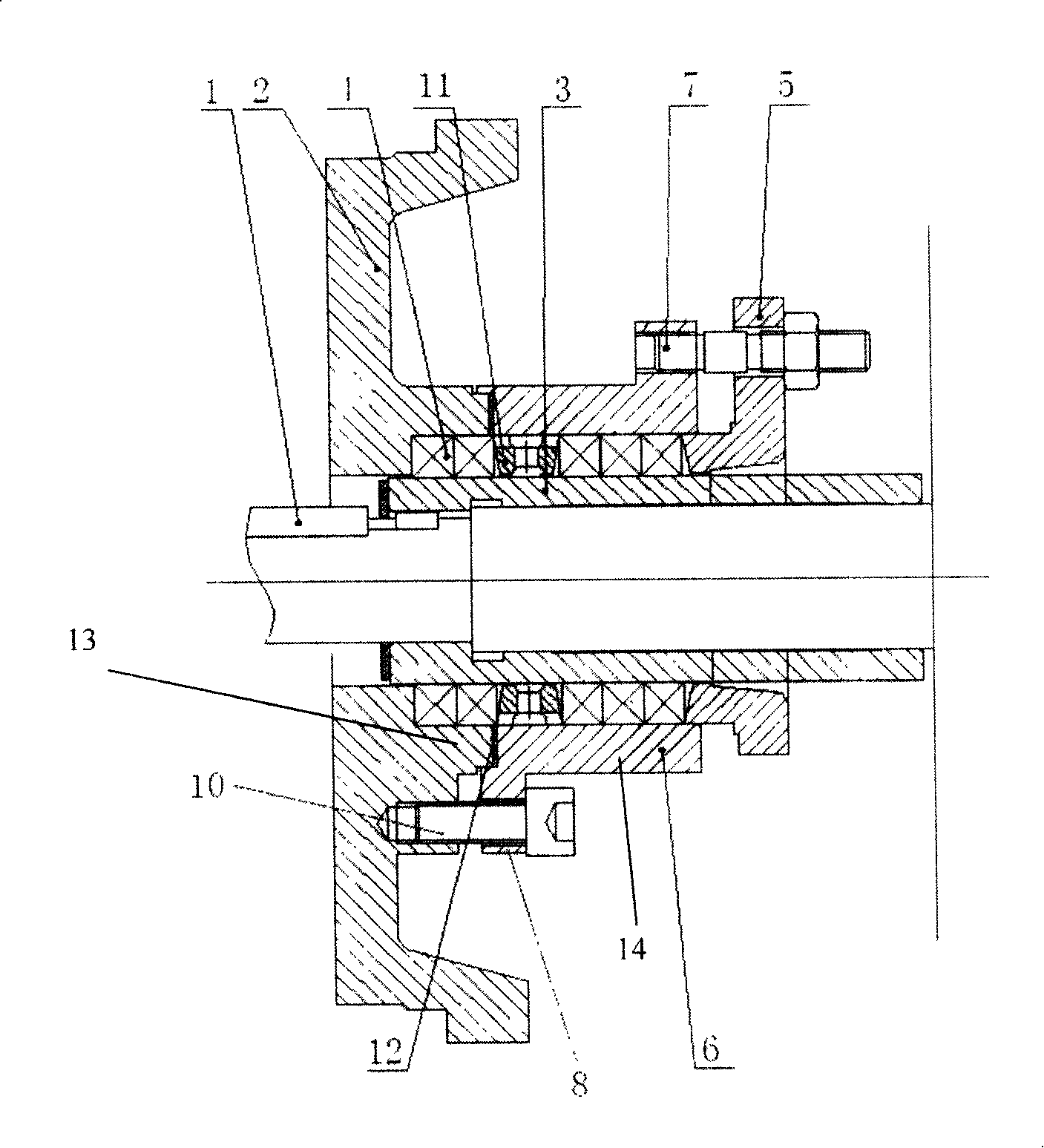

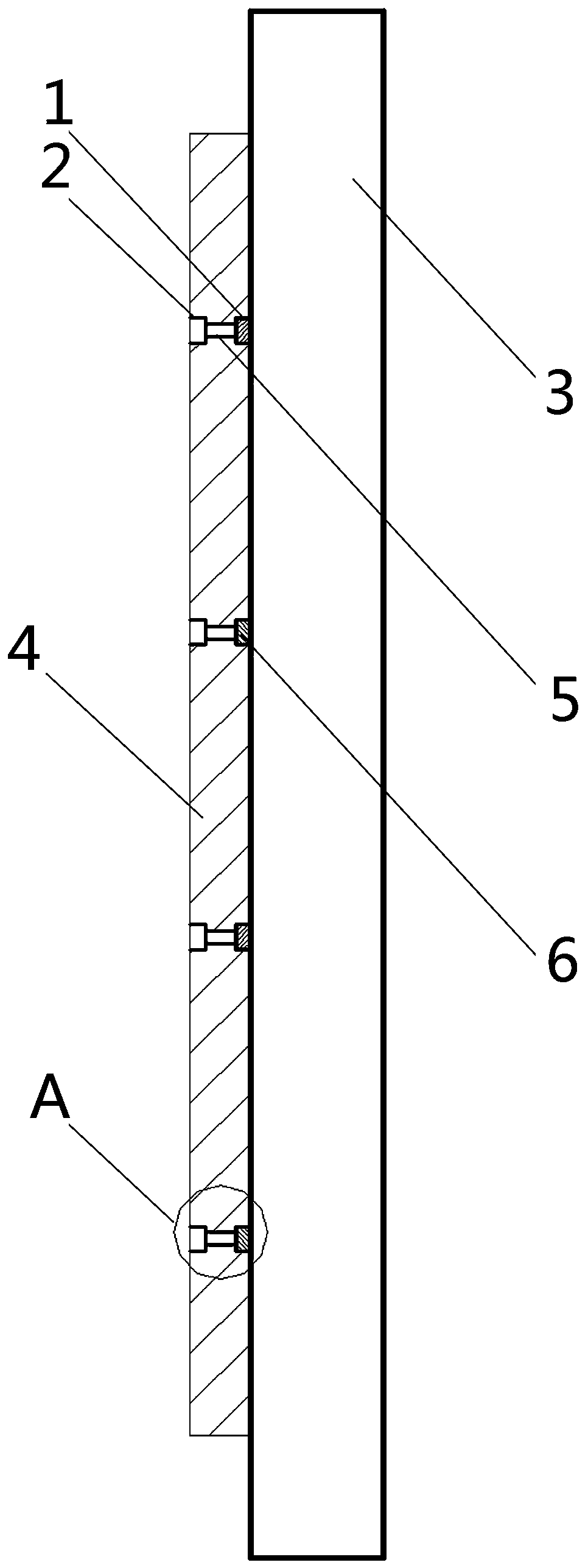

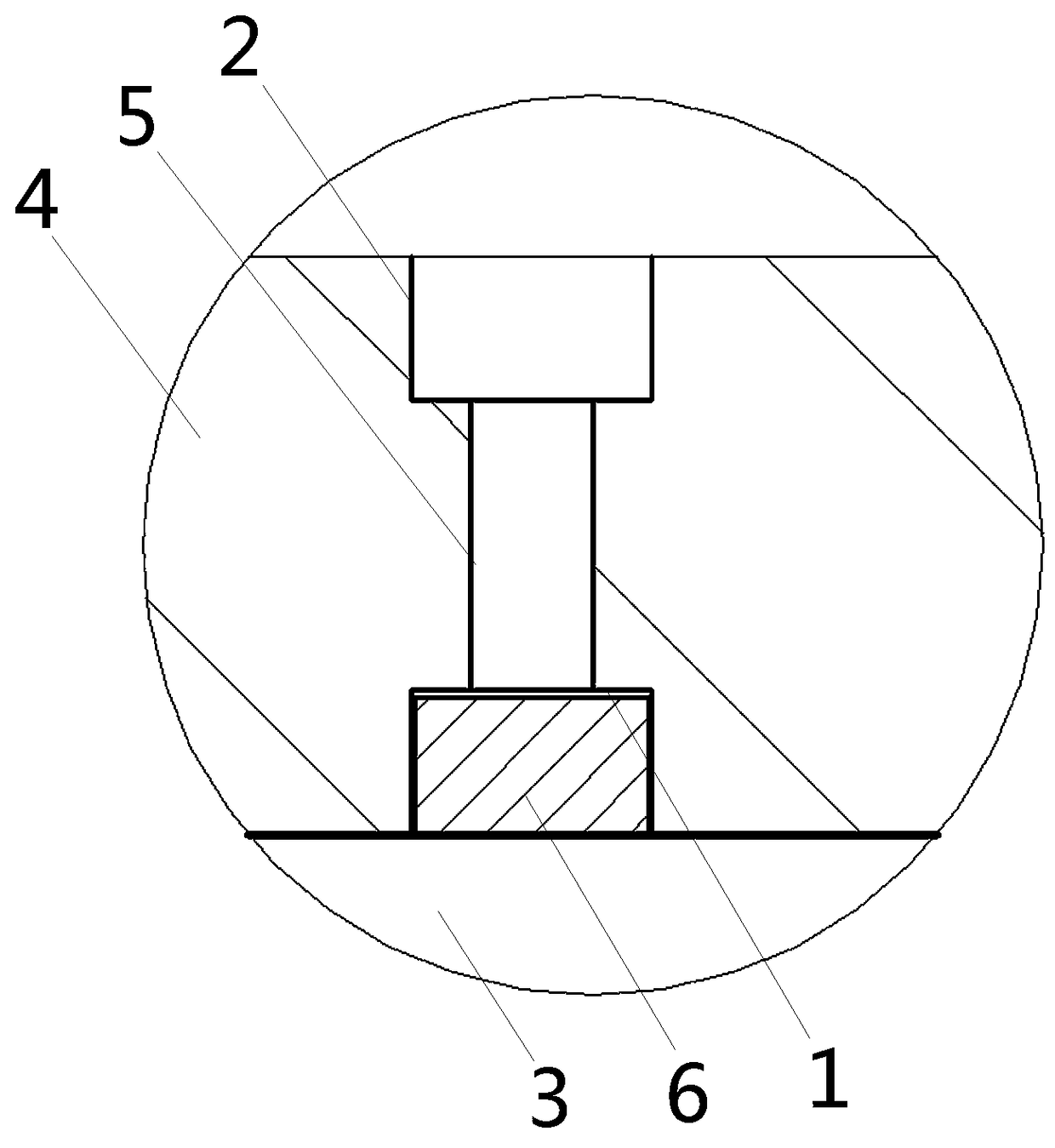

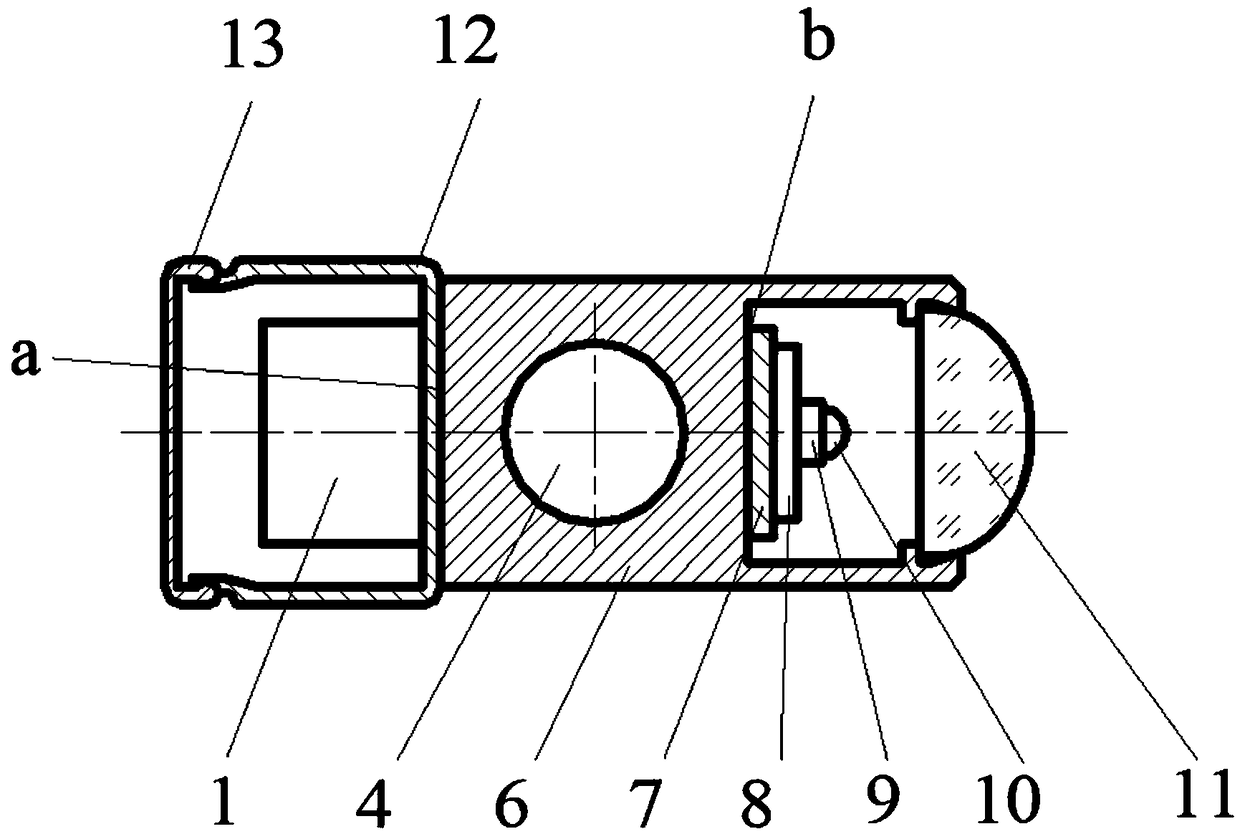

Series connection separable filling sealing device for pump

InactiveCN101210571AReplace enoughEnough operating spaceEngine sealsPump componentsEngineeringStuffing box

The invention relates to a series-connected detachable stuffing sealing device for a pump, which is composed of a pump cover, a shaft housing, stuffing and a stuffing pressure cover. The inner side of the pump cover is connected with a cylindraceous stuffing box which is coaxial with the shaft housing; a stuffing cavity is arranged between the internal circumference of the stuffing box and the external circumference of the shaft housing; the stuffing pressure cover is sheathed with the shaft housing; the stuffing pressure cover is arranged at one end of the stuffing box; the stuffing is arranged in the stuffing cavity; the stuffing box is composed of a first cylinder and a second cylinder, the first cylinder and the second cylinder are both sheathed with the shaft housing, the first cylinder is fixed with the inner side of the pump cover, the second cylinder is fixed with the inner side face of the pump cover via a screw, and the stuffing pressure cover is fixed with the second cylinder via the screw. When replacing the stuffing, the first cylinder is separated from the second cylinder; thereby enough operating room is obtained. By utilizing the detachable stuffing box and a method of replacing stuffing step by step, the invention can solve the problem that the stuffing can not be replaced conveniently when the pump is at maintenance or repair.

Owner:SHANGHAI EAST PUMP(GRP) CO LTD

Prefabricated component embedded assembly and installation method thereof

PendingCN109500992AReduce stepsEasy to operateCeramic shaping apparatusEmbedded systemStandardization

The invention discloses a prefabricated component embedded assembly and an installation method thereof. The prefabricated component embedded assembly and the installation method thereof solve the technical problems that prefabricated component embedded parts are difficult to install and construct and lack of standardization. The prefabricated component embedded assembly comprises lower-side embedded parts and upper-side embedded parts, the lower-side embedded parts are arranged between a fixed steel formwork table and the lower side of a prefabricated component, the lower-side embedded parts and the upper-side embedded parts are fixedly connected through rigid rods and communicate with each other up and down, and the lower-side embedded parts are detachably connected with the fixed steel formwork table through magnetic attraction positioning blocks. According to the prefabricated component embedded assembly, the embedded parts arranged into the whole up and down are provided, so that the complicated operation of performing pre-burying up and down correspondingly is omitted, reserved holes do not need to be formed in the fixed steel formwork table, and a lifting arm does not need tobe arranged on a side formwork table for installing and positioning of the upper-side embedded parts; and the embedded parts can be quickly positioned and pre-buried, moreover, disassembly is convenient and fast, repeated use can be achieved, and the pre-burying operation can be performed on the embedded parts at different positions of the prefabricated component.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

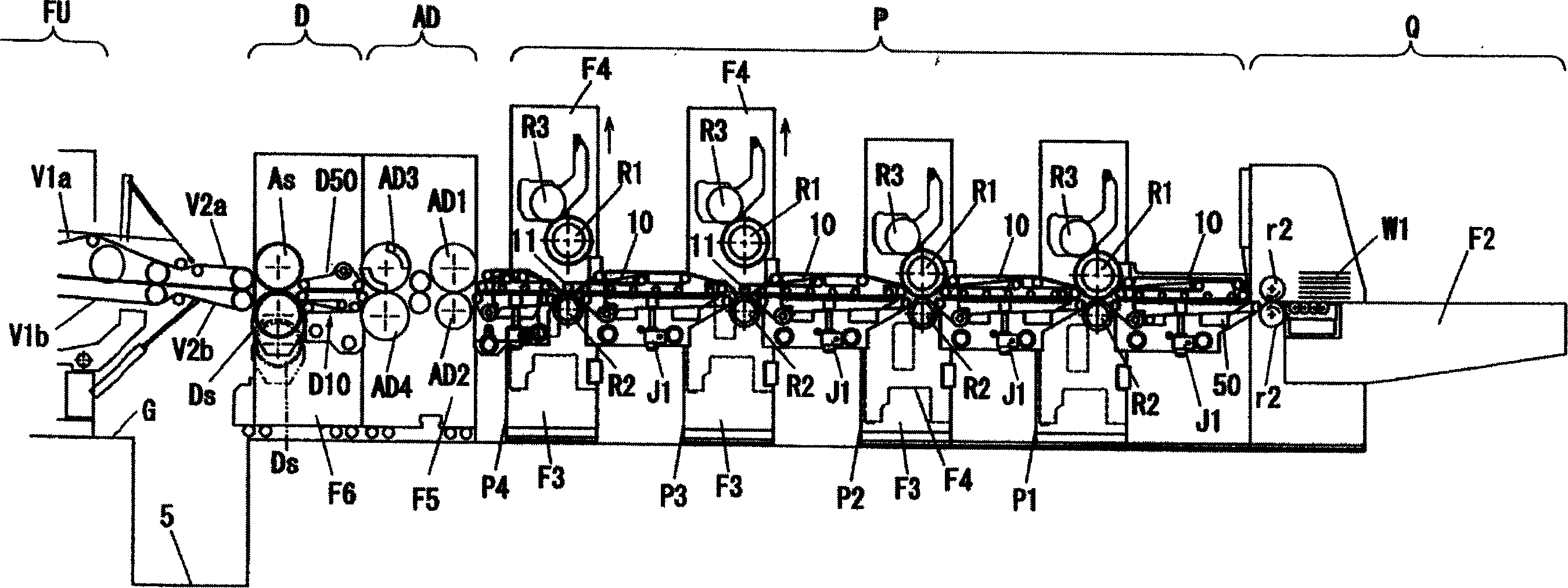

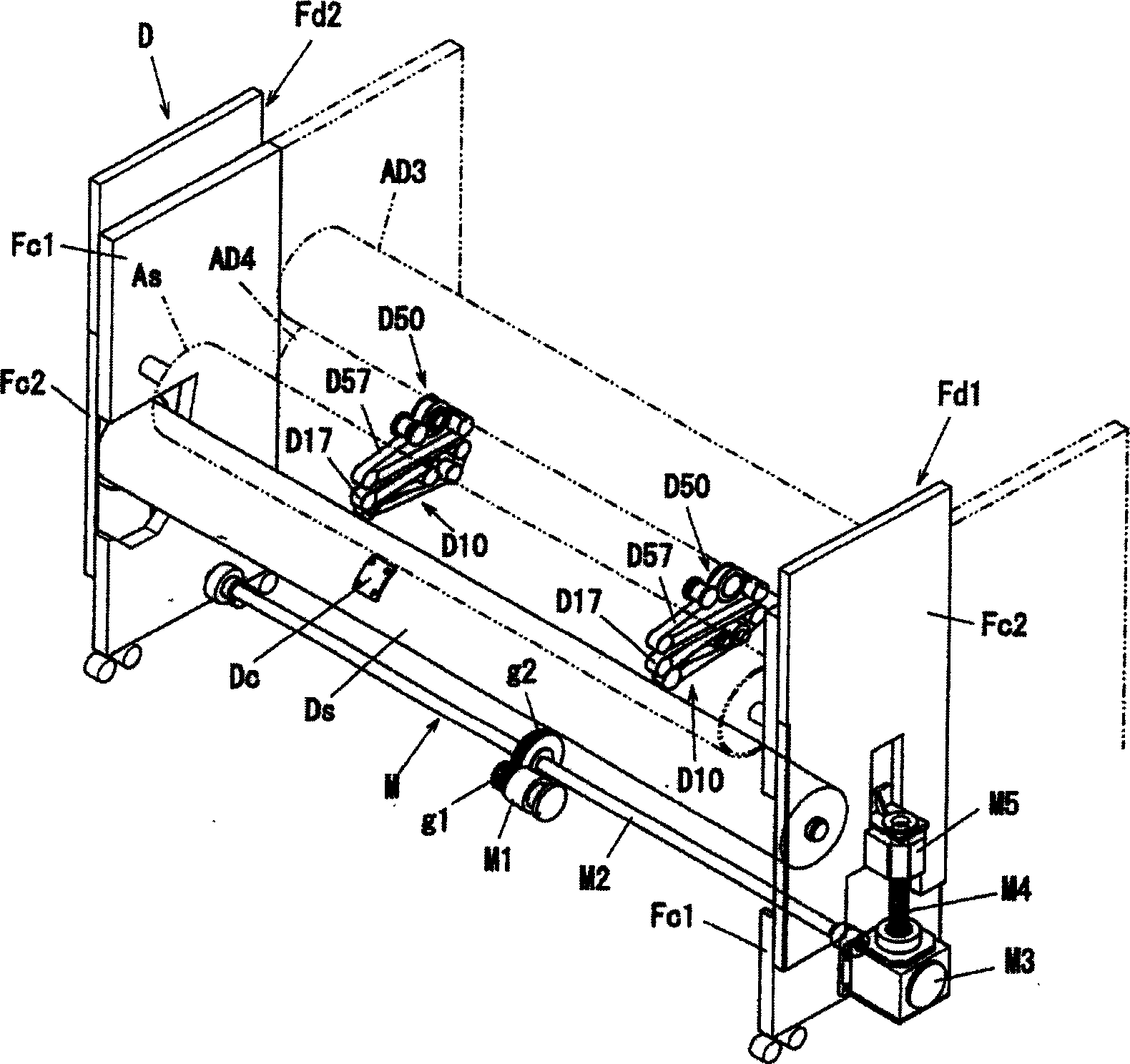

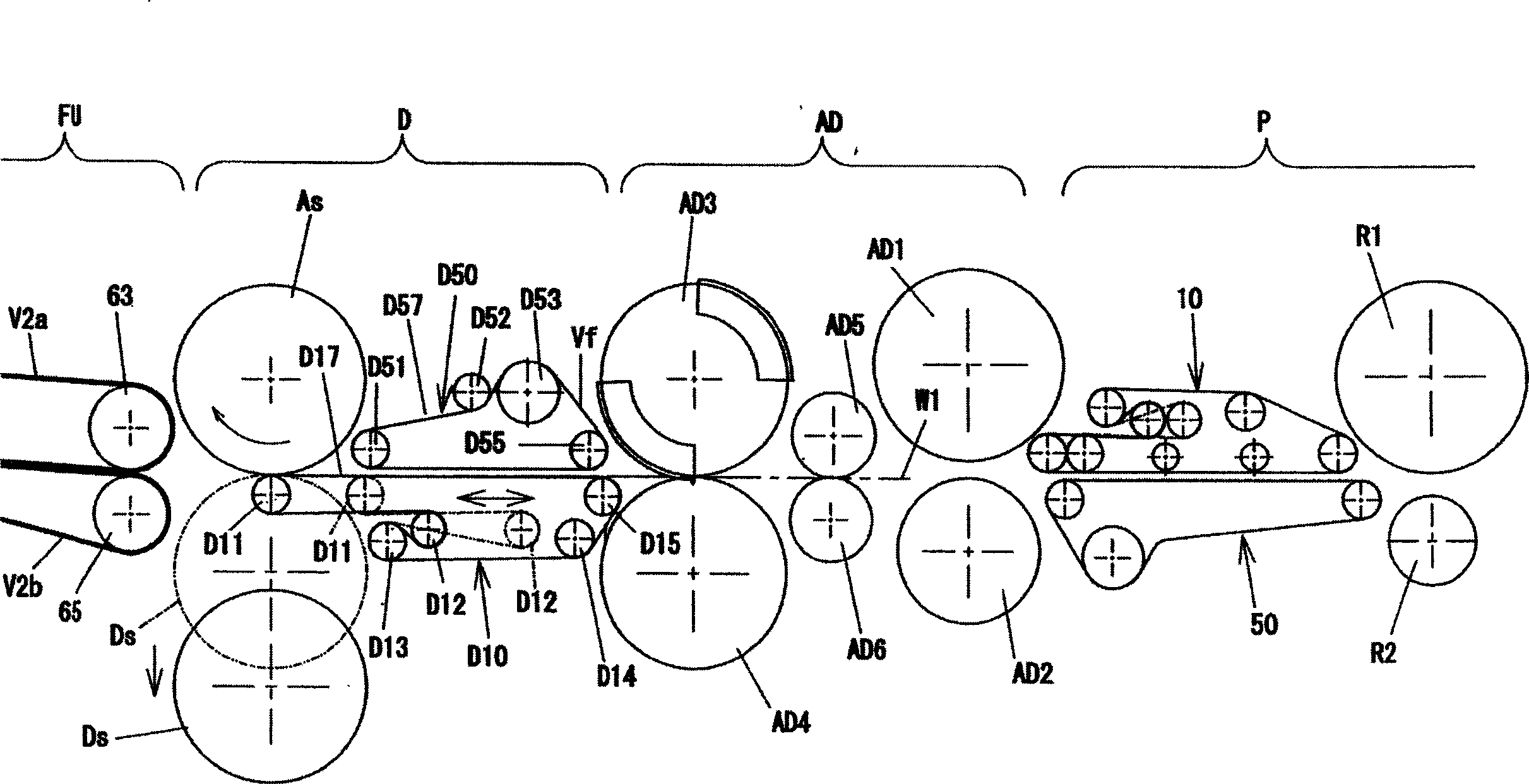

Punching cutting assembly and folding assembly for single workpiece

To achieve the facilitation of the replacement of a die in a die cutter unit constituting a box making machine and the stable feed of a sheetlike work at the time of replacement of the die and to prevent the transfer of cut refuse produced in the die cutter unit to a folding unit. The front end of the feeder belt of a feeder conveyor unit D10 placed in front of a die cylinder Ds is formed into a movable structure and the front end of the feeder belt is allowed to approach an anvil cylinder As in place of the die cylinder Ds retracted in the direction separated from the anvil cylinder As at the time of replacement of a cutting die. The sheetlike work W1 is forcibly fed by the anvil cylinder As and a feeder belt, and the folding belts V2a and V2b of the folding unit FU placed behind the die cutter unit D are made susceptible to on-off operation centering around a pulley on the downstream side to be retracted from the die cylinder Ds at the time of replacement of the cutting die. (C)2005,JPO&NCIPI.

Owner:ISHIKAWA SEISAKUSHO

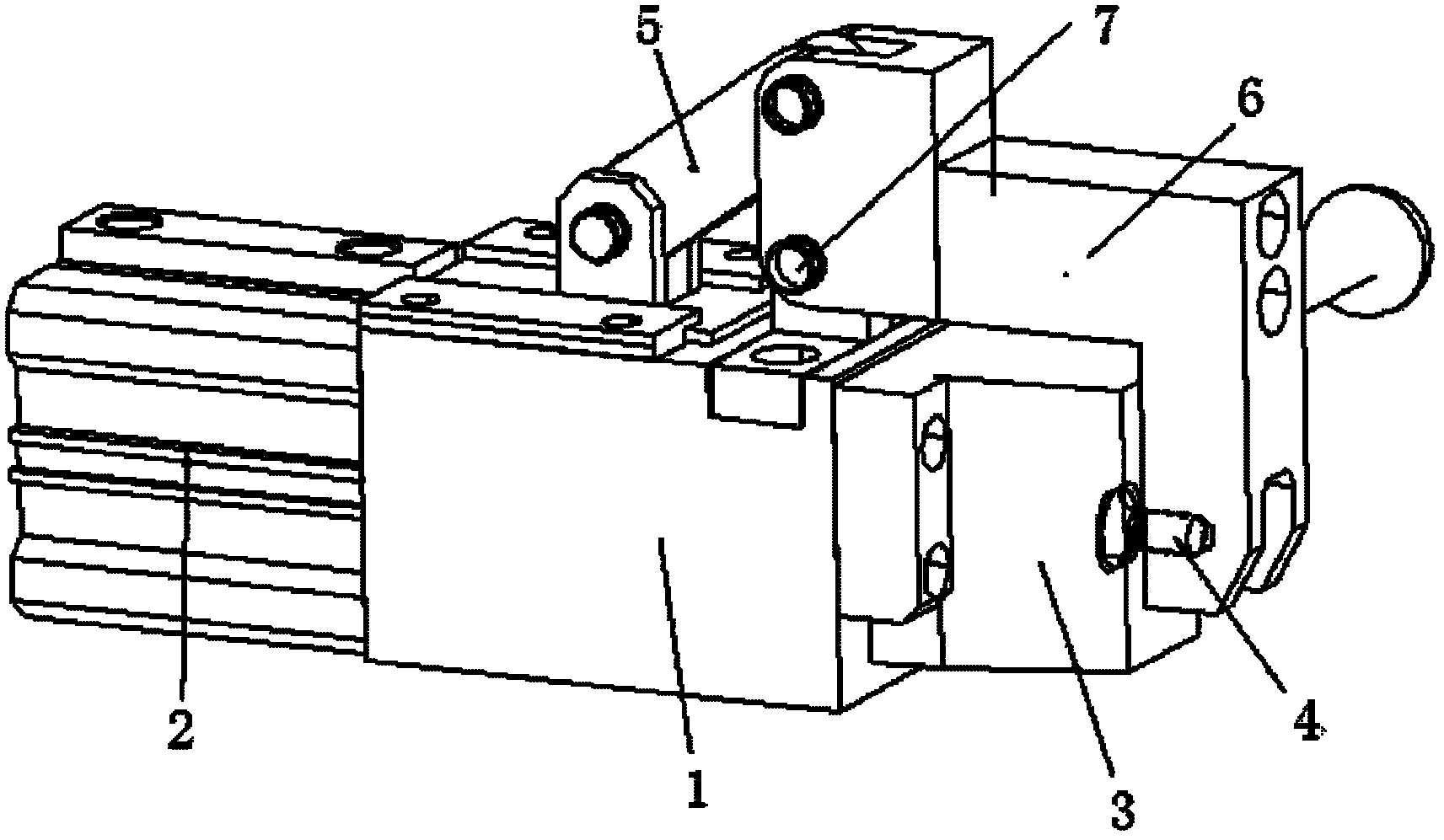

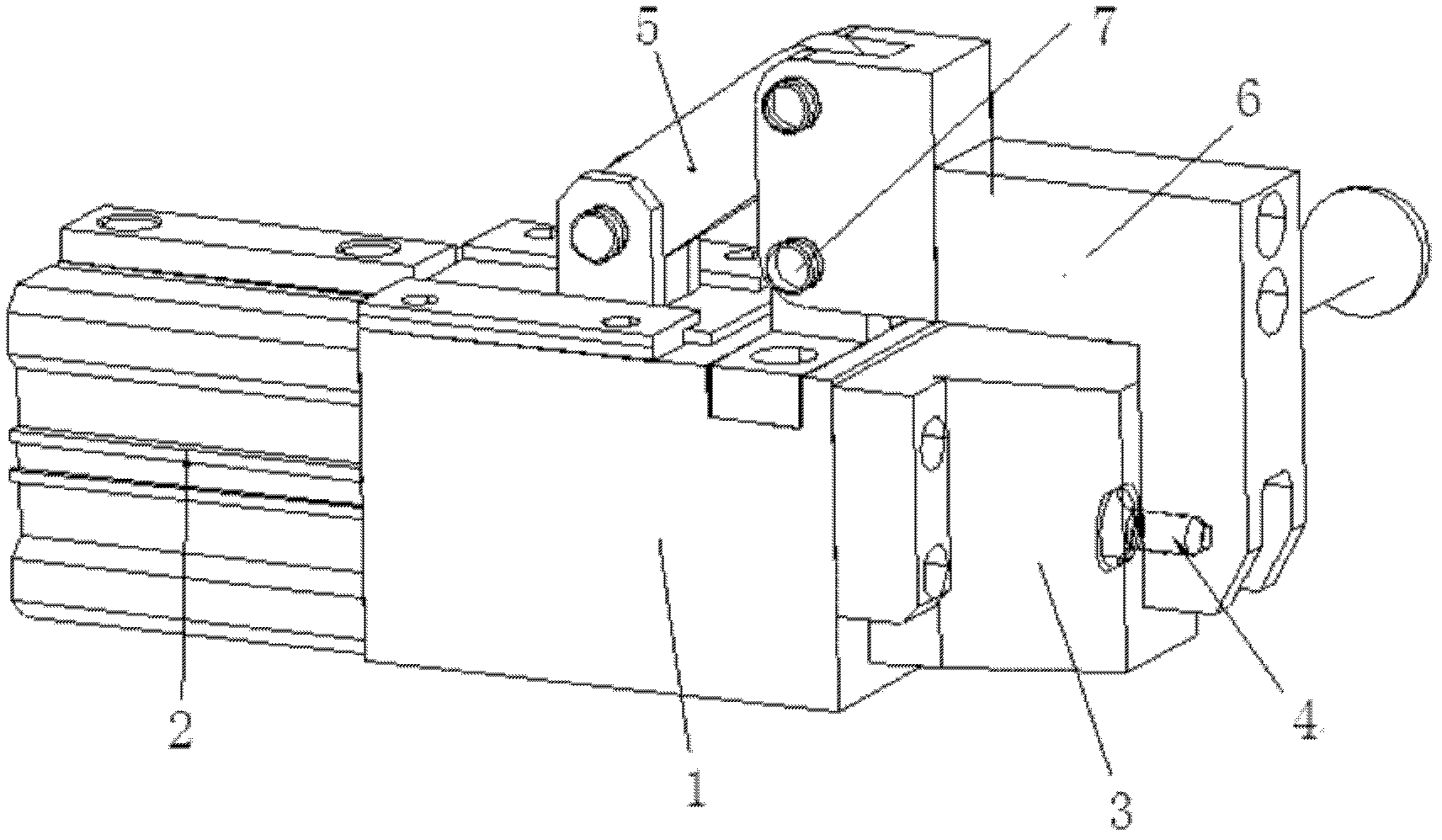

Positioning and clamping mechanism of welding fixture of automobile stamping piece

ActiveCN102554537AReduce manufacturing costEnough operating spaceWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention discloses a positioning and clamping mechanism of a welding fixture of an automobile stamping piece, which comprises an installing seat which is installed on a bottom board of the welding fixture; one end of the installing seat is provided with a locking cylinder, and the other end of the installing seat is fixed with a supporting block; a piston rod of the locking cylinder penetrates through the installing seat and the supporting block; a positioning pin which is positioned towards a positioning hole of the stamping piece is fixed on the extending end of the piston rod of the locking cylinder; the upper end of the installing seat is hinged with a bent pressing block; the lower end of the pressing block is buckled outside the supporting block; and a hinge mechanism is also fixed on the piston rod of the locking cylinder and is hinged with the upper end of the bent pressing block through a connecting rod. According to the invention, one locking cylinder is adopted for simultaneously realizing positioning and clamping functions; the manufacturing cost of the fixture is reduced; and an enough space for operation is reserved for a welding gun, so as to be convenient for operation of workers and favorable for enhancing production efficiency.

Owner:河南平原众创知识产权运营管理有限公司

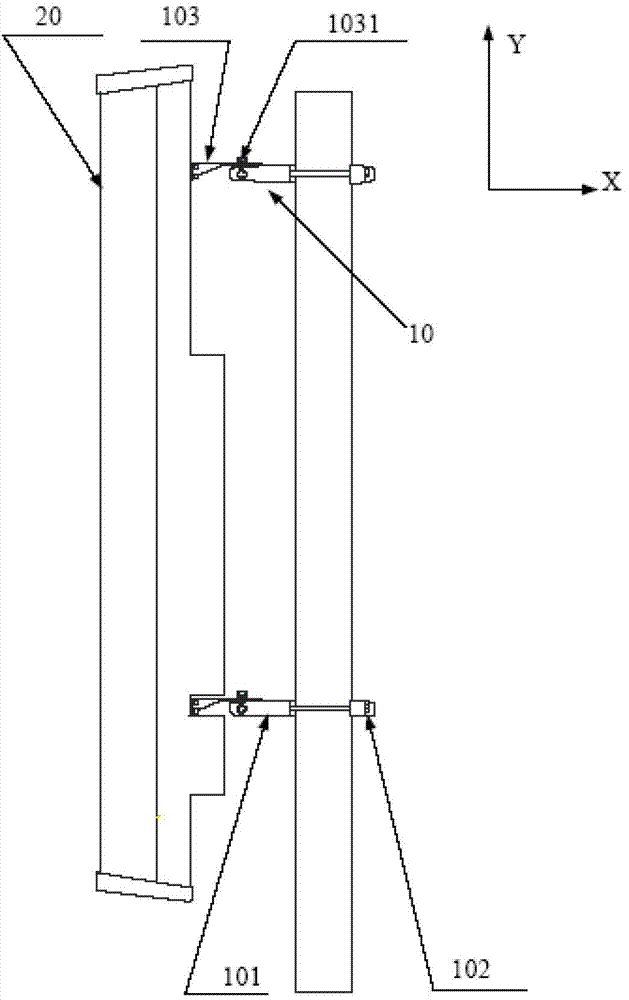

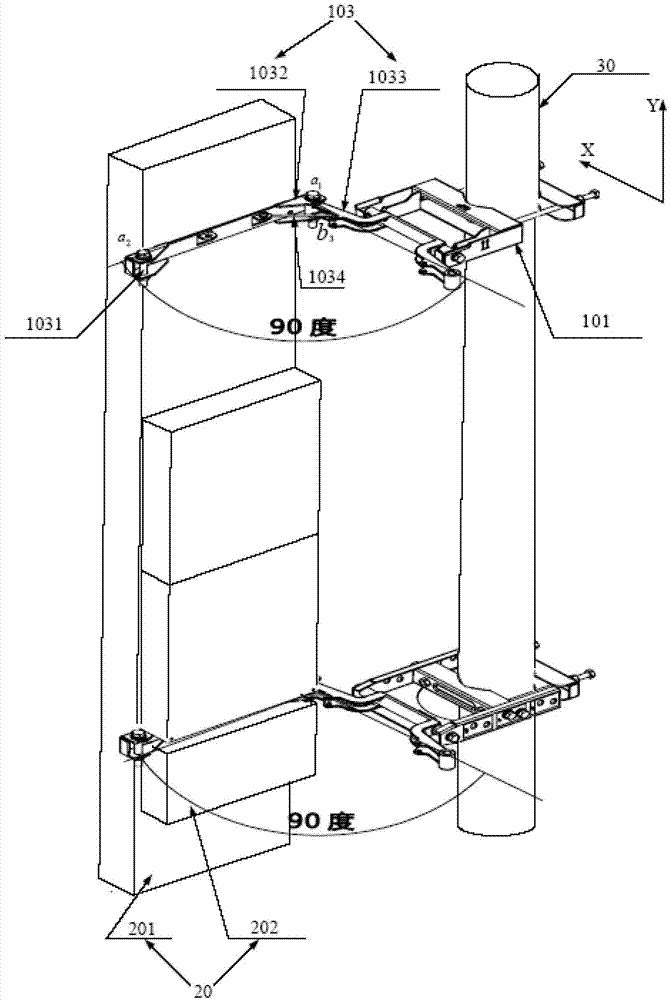

Mounting component

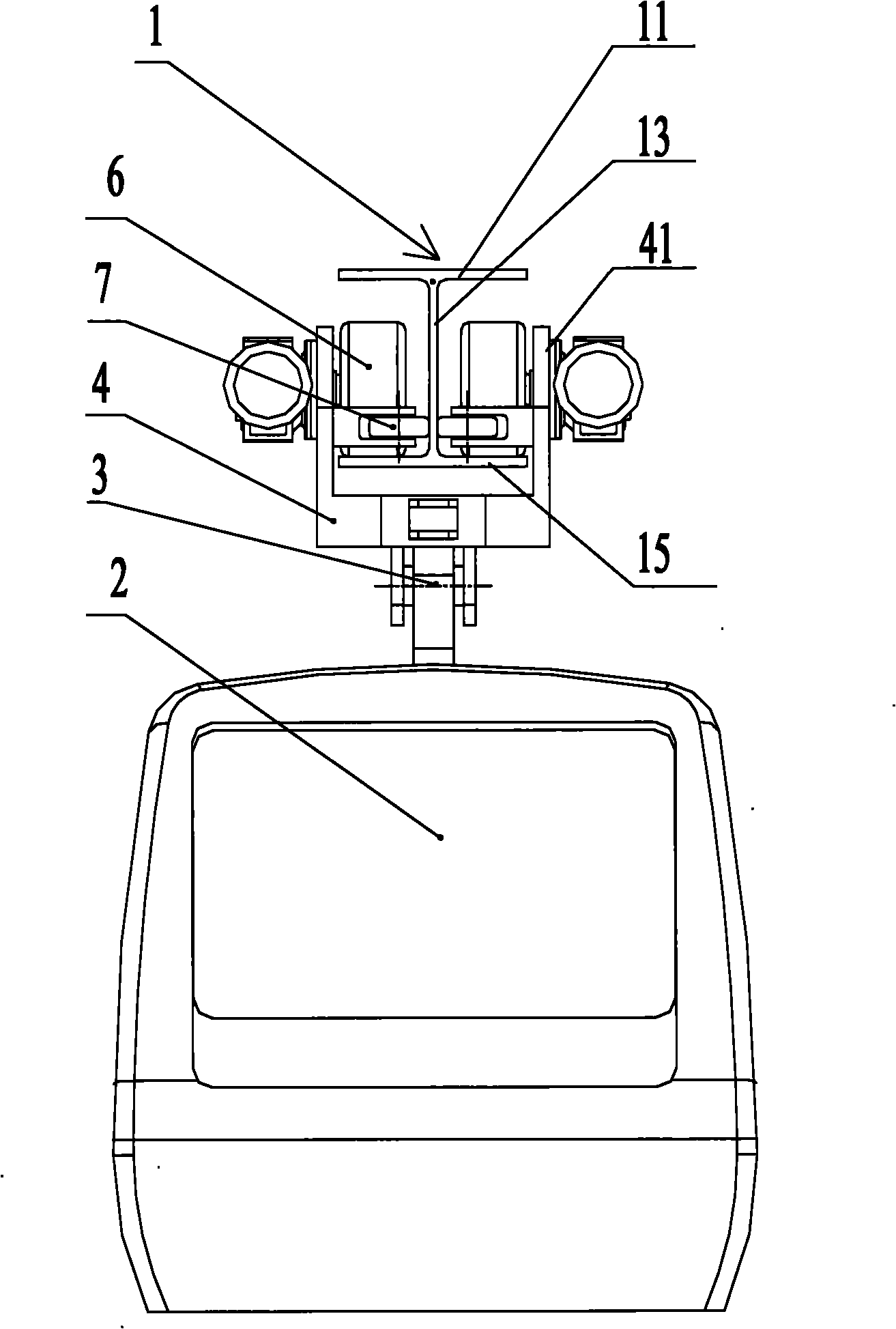

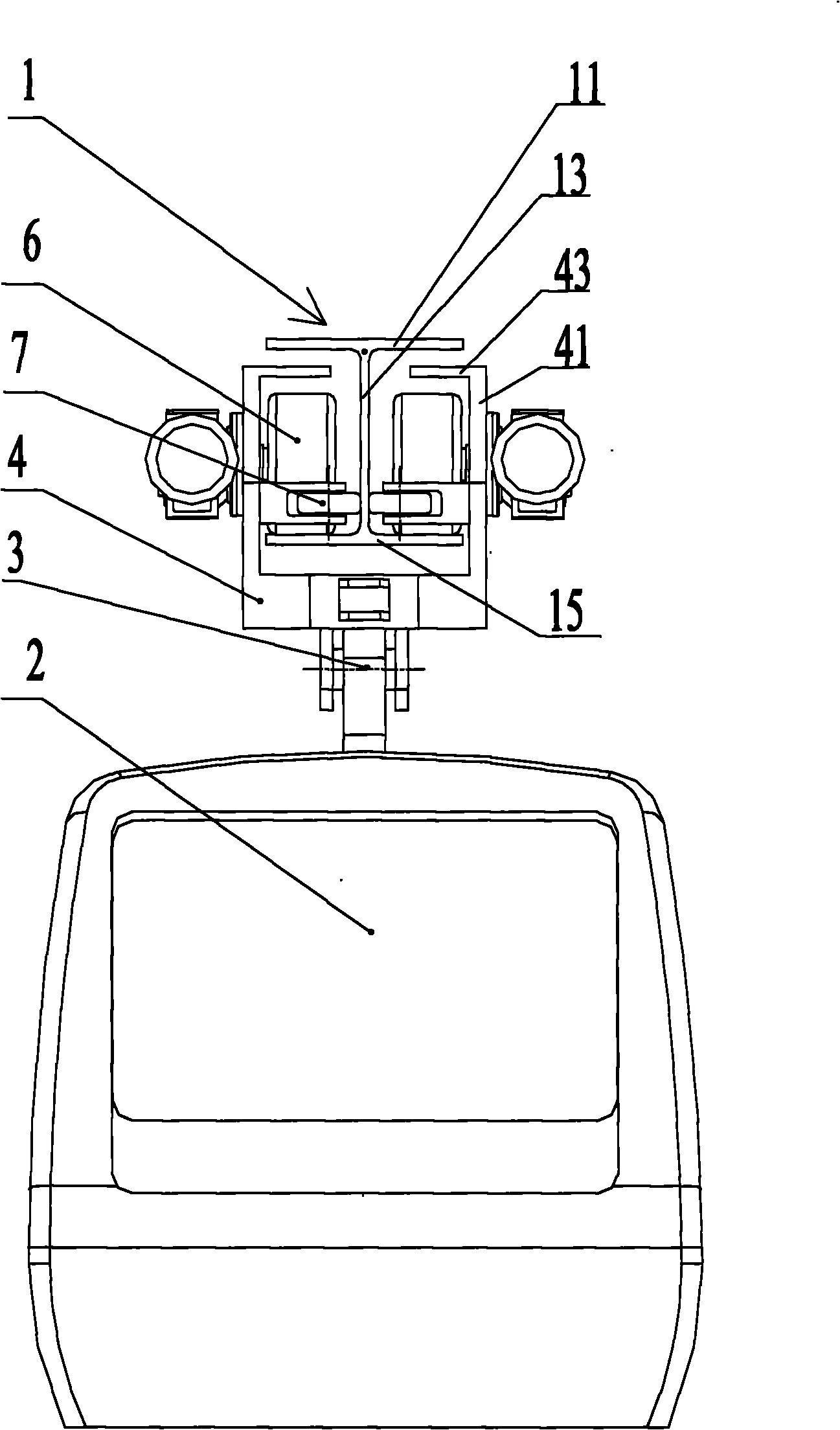

InactiveCN102856624AAvoid Positioning EffectsAvoid reinstallationAntenna supports/mountingsEngineeringMechanical design

The embodiment of the invention provides a mounting component, which relates to the field of mechanical design and has the advantages that the complexity and the time of maintenance of an antenna device can be reduced. The mounting component comprises at least one group of fasteners and an adapter component, wherein the fasteners comprise a main fastener and an auxiliary fastener, and the main fastener is matched with the auxiliary fastener for installation of the antenna device on a pole in an embracing way or on a wall in a hanging way; and the adapter component is respectively connected with the main fastener and the antenna device and is provided with a Y-axis rotating component, the antenna device can rotate around a Y axis due to the Y-axis rotating component, and the Y-axis direction is parallel to the length direction of the antenna device. The mounting component provided by the embodiment of the invention is applied to installation of the antenna device.

Owner:HUAWEI TECH CO LTD

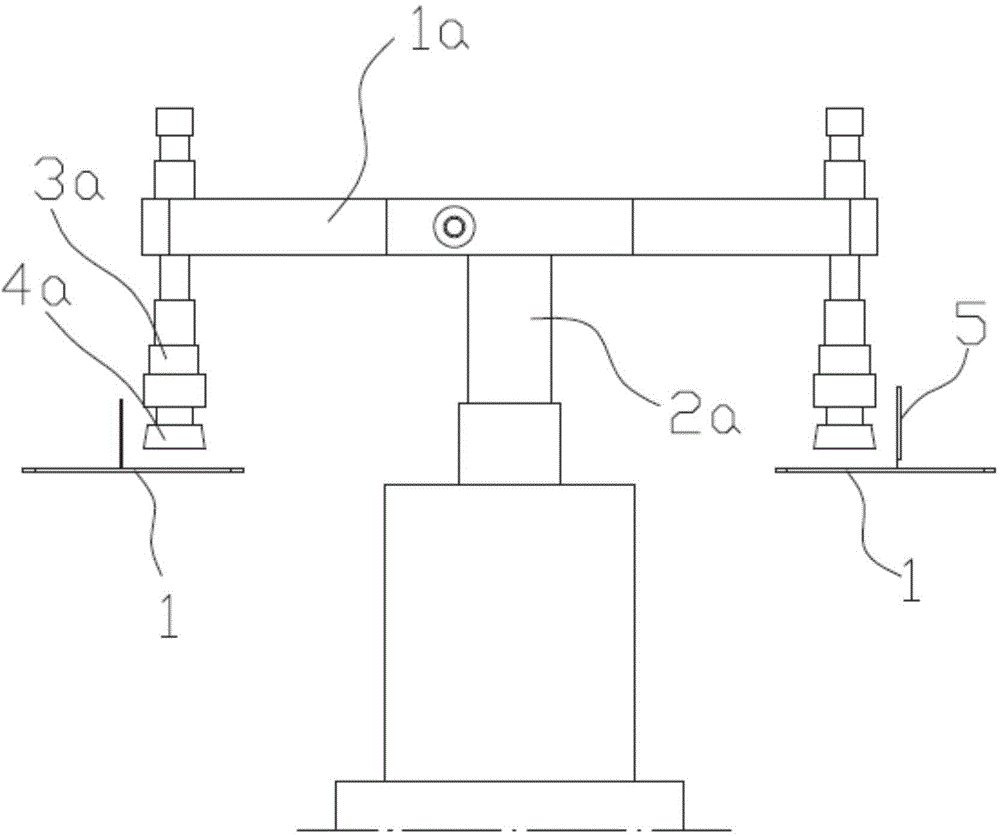

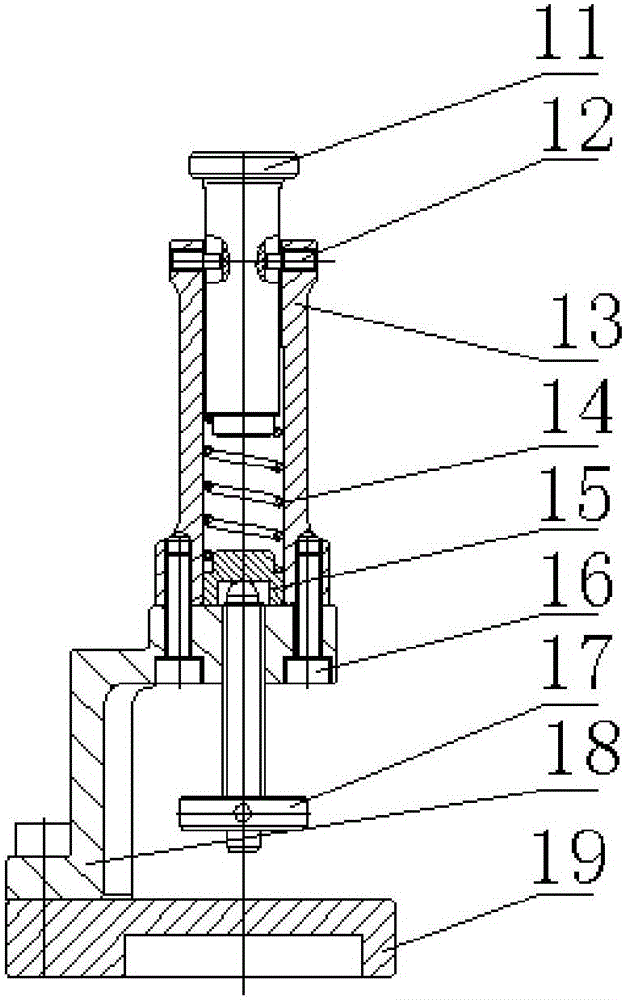

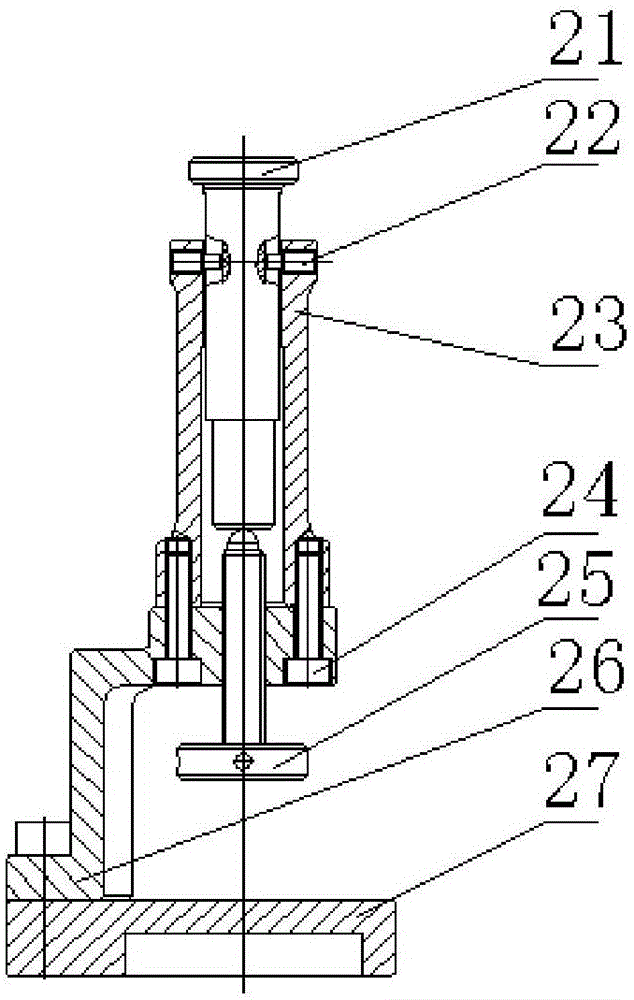

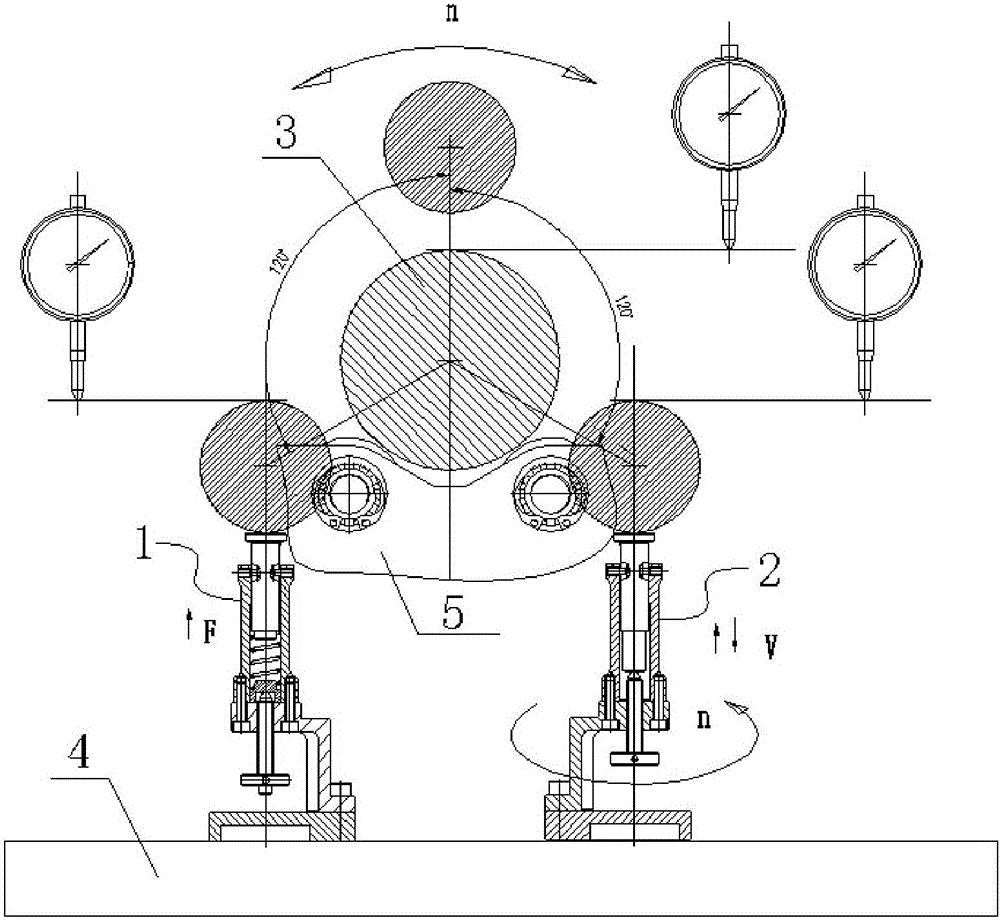

Auxiliary supporting component for detecting crank throw included angle of crank shaft

ActiveCN105115405AStable and precise stopOperational securityAngles/taper measurementsTurn angleMechanical engineering

The invention discloses an auxiliary supporting component for detecting a crank throw included angle of a crank shaft. The auxiliary supporting component comprises an elastic support and a rigid support, wherein the elastic support comprises a first C-shaped bracket, a first sliding sleeve and a first sliding shaft; a first base is arranged at the bottom of the first C-shaped bracket and is used for being placed on a detection platform; the first sliding sleeve is arranged at the upper end of the first C-shaped bracket; a pressure spring is arranged in the first sliding sleeve; the first sliding shaft is arranged in the first sliding sleeve and is driven by the pressure spring to slide up and down; the rigid support comprises a second C-shaped bracket, a second sliding sleeve, a second sliding shaft and a first adjusting screw; a second base is arranged at the bottom of the second C-shaped bracket and is used for being placed on the detection platform; the second sliding sleeve is arranged at the upper end of the second C-shaped bracket; the second sliding shaft is arranged in the second sliding sleeve; the first adjusting screw is used for adjusting the height of the second sliding shaft in the second sliding sleeve. According to the supporting component, the crank throw height of the crank shaft can be adjusted, and the crank shaft can be stably and accurately stopped in a certain corner phase position.

Owner:GUANGXI YUCHAI MASCH CO LTD

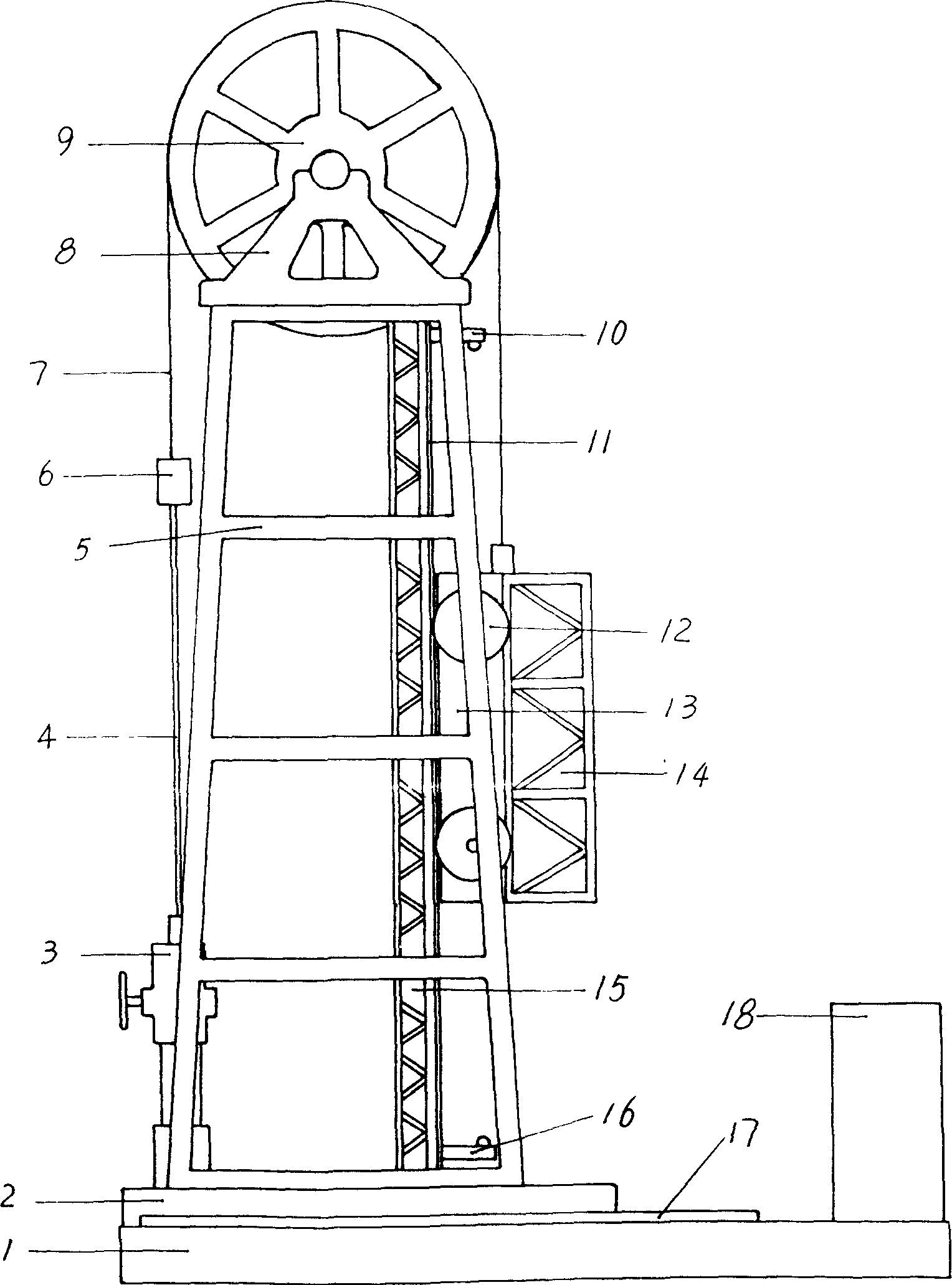

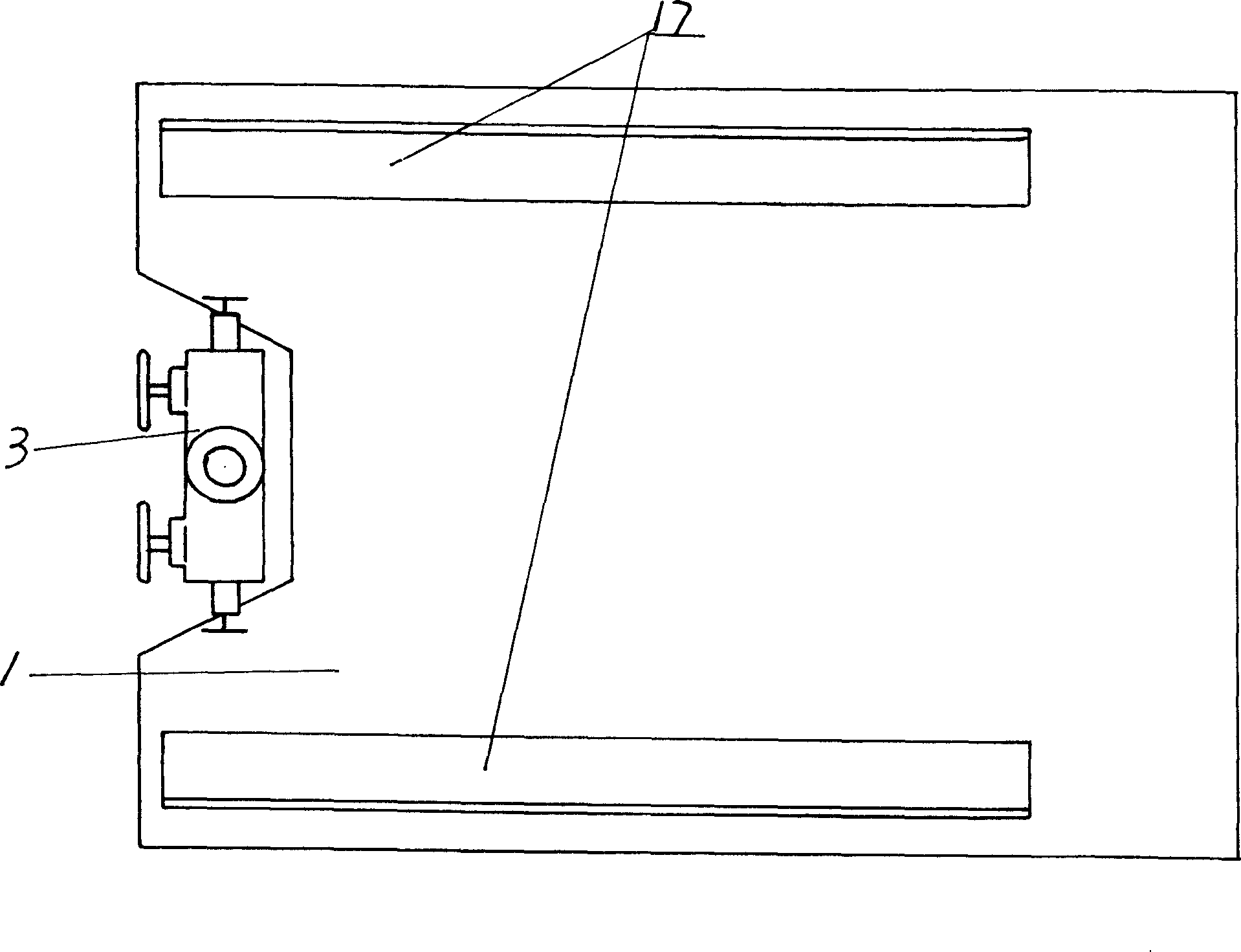

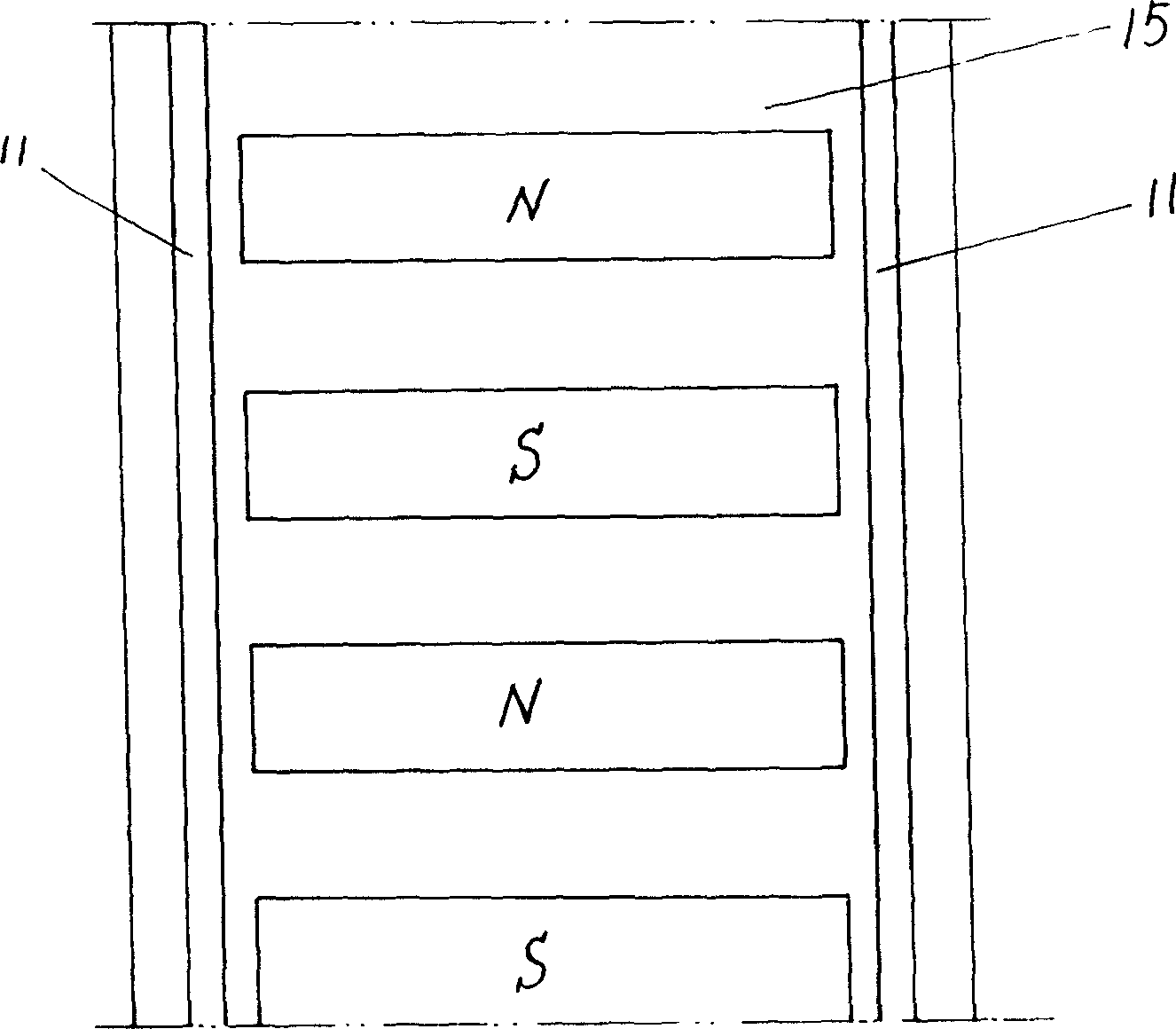

Non walking beam linear motor pumping unit

InactiveCN1525039AEasy to installStable structureFluid removalPropulsion systemsElectric machineLinear motor

The invention provides a beam-free linear electric-machine oil pump, having characters of stable structure, smooth working, high-efficiency energy saving and convenient use and maintenance, applied to oil pumping work in oil field and oil well. Its technical project: it includes main frame, stator fixed on the main frame, rope and rotor linked with the rope, as well as rotor guide rail, rotor guide wheel and spacing commutator, and its character: the stator is a unilateral structure and the rotor adapts to the stator. The rotor is fixed with balance weight box, there is a wind circulating cooling device in the cavity of the rotor, the spacing commutator can movably position, the top end of the main frame is set with head sheave and the main frame can move with the moving base.

Owner:高旺

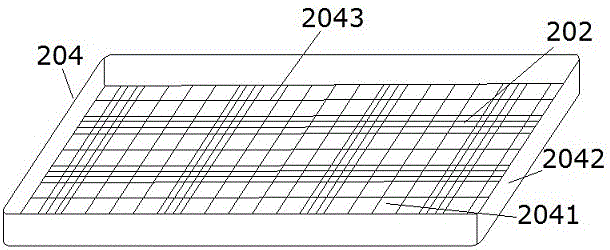

Mobile seedbed capable of being used for three-dimensional planting

InactiveCN105815147AEfficient use of water resourcesEasy to pushSelf-acting watering devicesCultivating equipmentsBiologyPulley

The invention discloses a mobile seedbed that can be used in the interplanting mode. The mobile seedbed that can be used in the interplanting mode is sleeved on a seedling raising device. The seedling raising device is provided with a seedling raising groove. Horizontally juxtaposed slideways; the mobile seedbed includes a seedbed and a support, the support is arranged below the seedbed, the bottoms of both sides of the support are equipped with the pulleys, and the seedbeds are placed horizontally and juxtaposed by the pulleys on the slide. Using the above technical scheme, the mobile seedbed is socketed on the seedling raising device, and the mobile seedling bed and the seedling raising device can respectively plant different Chinese herbal medicines, thereby realizing the interplanting mode; the seedling raising device is provided with a seedling groove for planting Chinese herbal medicines, and the seedbed passes through the bottom of the support The pulley and the slideway above the seedling raising device can realize the movement of the seedbed, and it is more convenient to manage the Chinese medicinal materials planted in the seedling raising device when interplanting.

Owner:JIANGSU DAOCHENG BIOTECH CO LTD

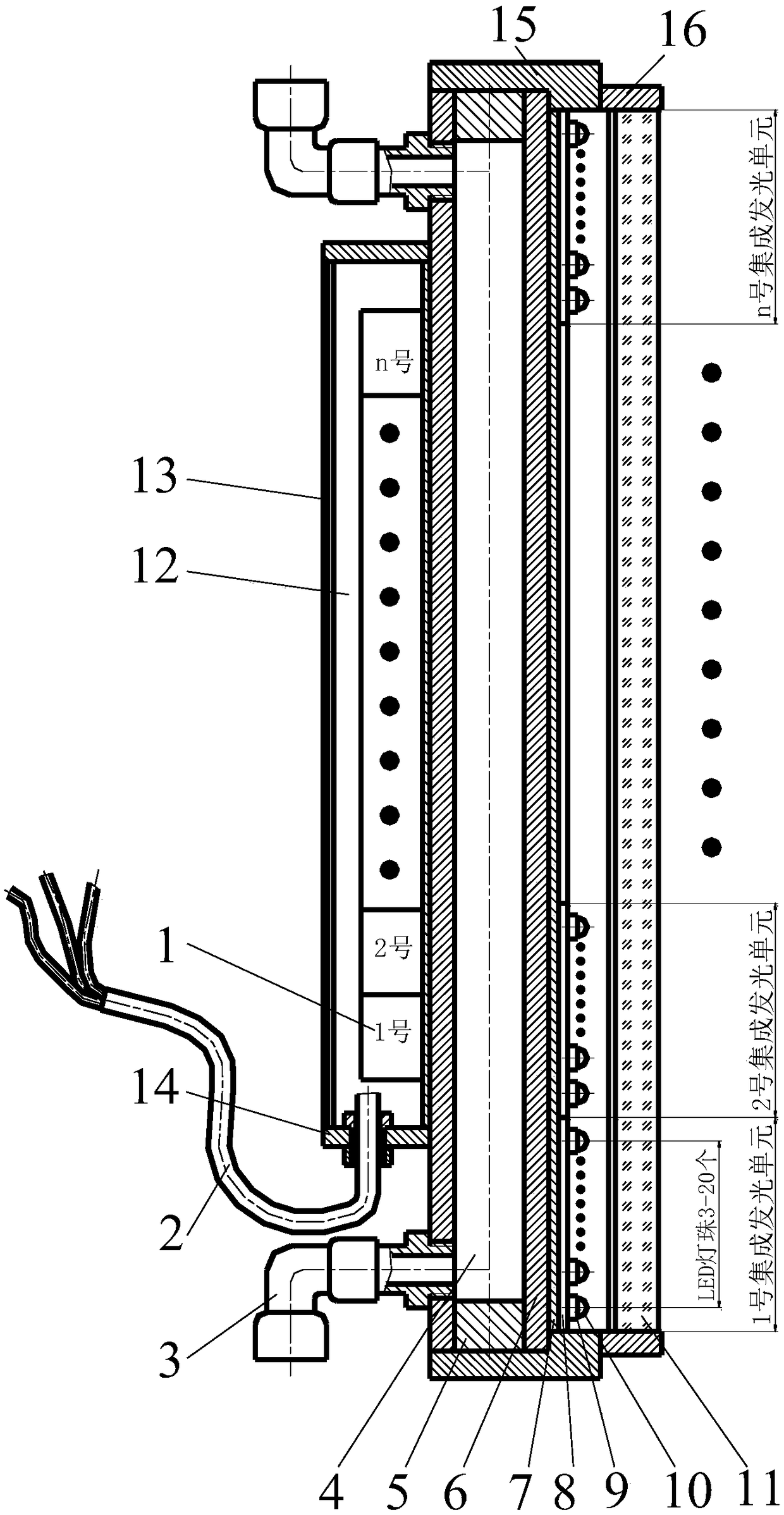

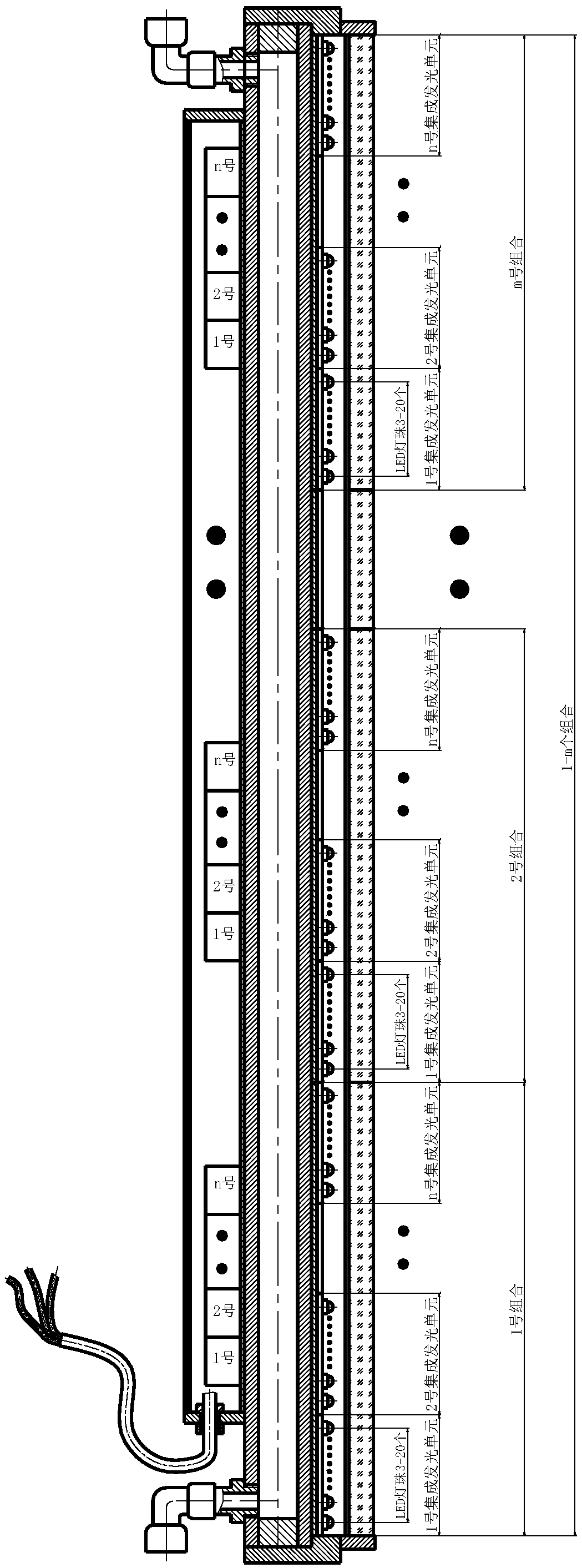

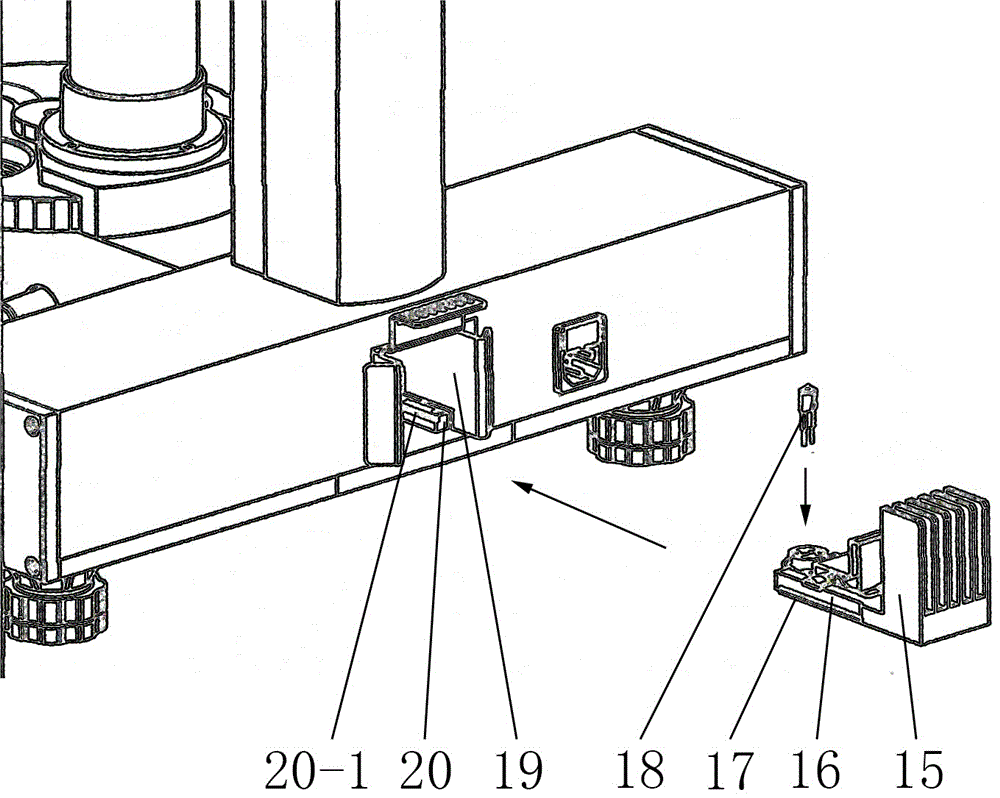

Ultraviolet light LED generating device, processing method and ultraviolet light irradiating device

ActiveCN109297003AExtended service lifeImprove protectionLighting heating/cooling arrangementsCable/conductor manufactureCross-linkLight beam

The invention relates to an ultraviolet light LED generating device, a processing method and an ultraviolet light irradiating device. The irradiating device comprises an ultraviolet LED irradiating cavity, a transmission member and a rack. The ultraviolet LED irradiating cavity is composed of a plurality of light emitting components. Each light emitting component is formed by assembling fixing pieces and a plurality of LED light emitting sources. Each LED light emitting source is composed of LED lamp beads, an LED substrate, a driving power supply, an optical element and a cooling seat. The fixing pieces at two ends are connected to realize the positioning and fixing of the LED light emitting sources, so that the LED light emitting sources are parallel to each other in the axial directionand have included angles in the transverse direction, and the emitted light beams are irradiated to the same axis. According to the ultraviolet light LED generating device, the processing method and the ultraviolet light irradiating device, the component parts of the irradiating cavity can be quickly separated, so that sufficient operation space is provided among the components, and fast cleaningand maintaining are facilitated; and an cross-linked object in a light spot column of the ultraviolet light irradiating device can meet the requirement of uniform ultraviolet light irradiating intensity on the circumferential surface of the cross-linked object, and the product quality is improved.

Owner:HARBIN HAPRO ELECTRIC TECH

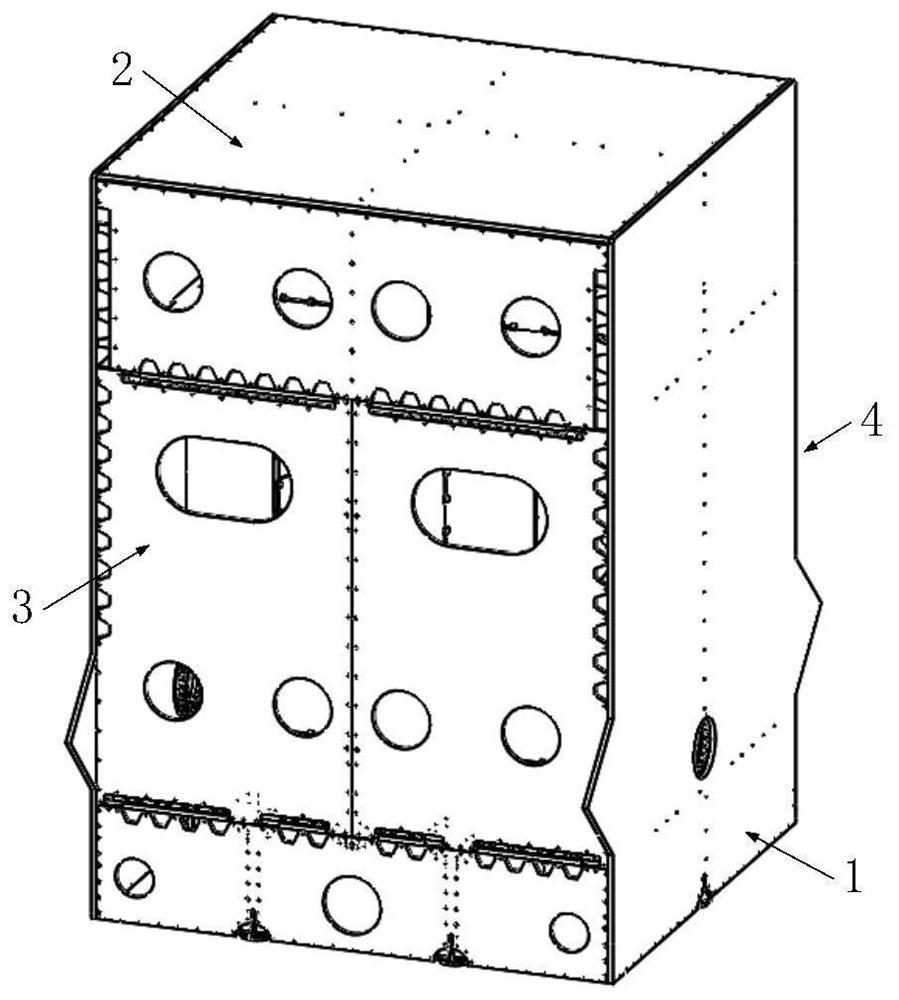

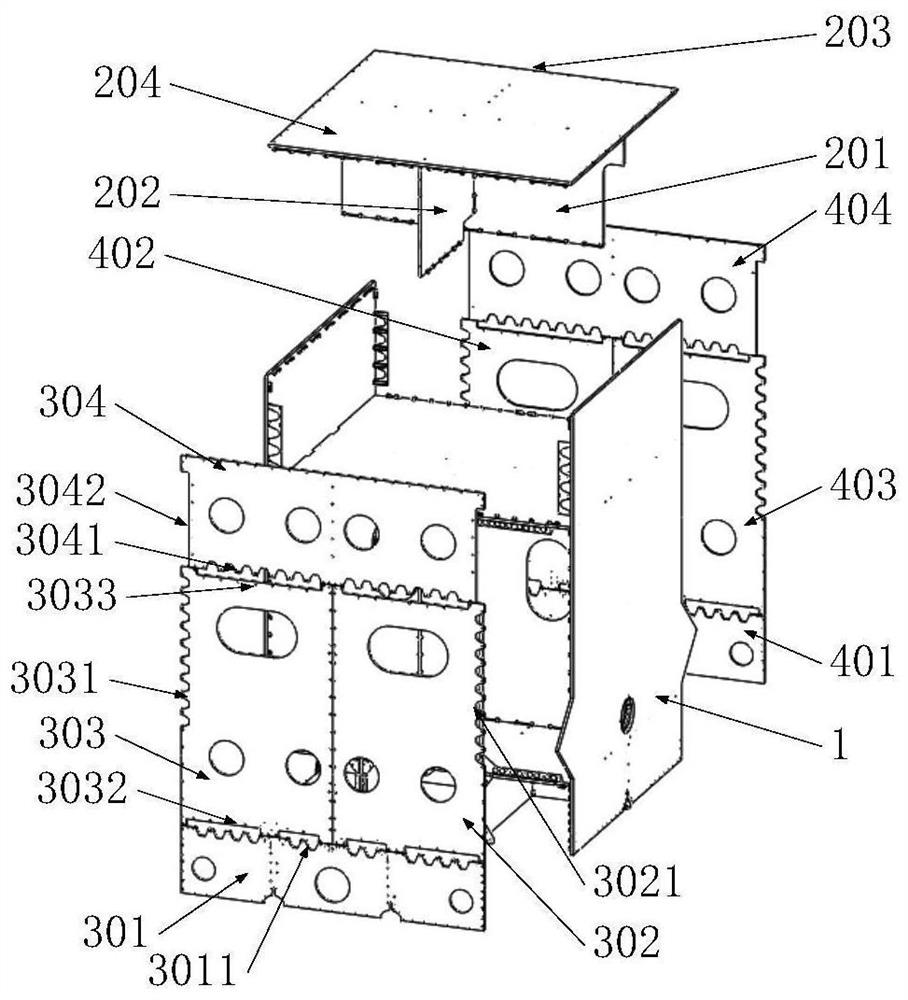

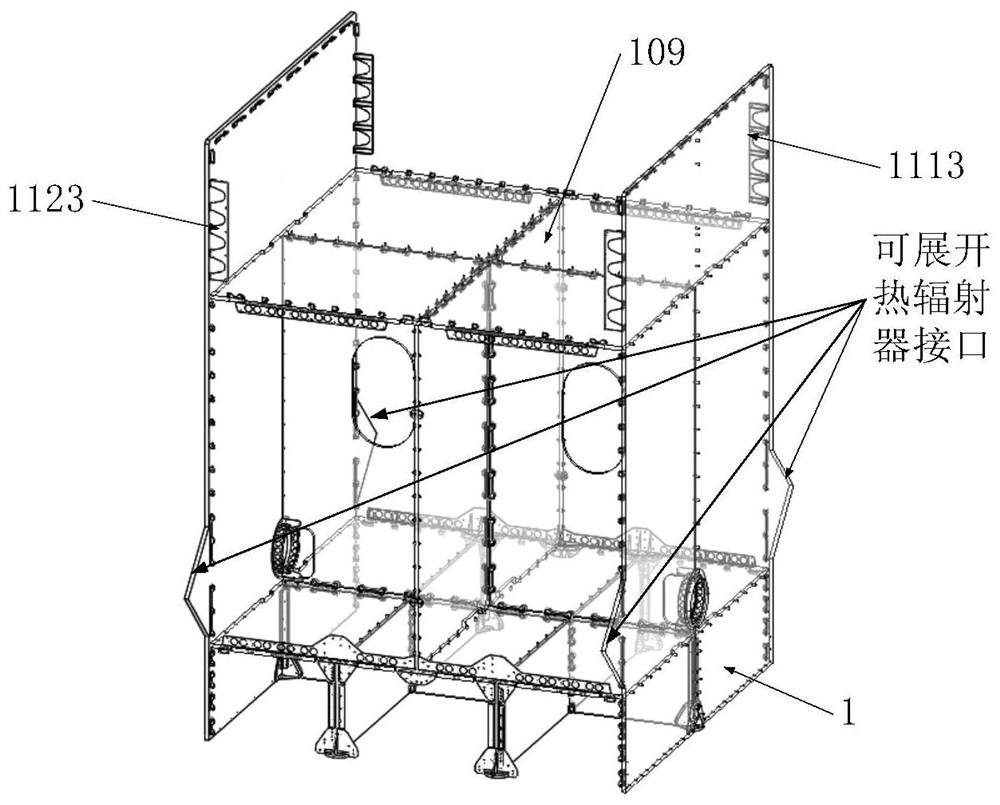

Large box plate type communication cabin structure

ActiveCN112319851AMeet structural lightweight requirementsHigh structural efficiencyCosmonautic partsArtificial satellitesClassical mechanicsMechanical engineering

A large box plate type communication cabin structure is geometrically divided into partition plates and outer plates from inside to outside, and a cabin space is divided into a lower cabin, a middle cabin and an upper cabin from bottom to top by two layers of horizontal plates. From the assembling relation, the lower cabin partition plate, the middle cabin partition plate, the two layers of horizontal plates and the south and north outer plates are not detachable, and an inner framework with the general assembly modularization manufacturability is formed. The upper cabin partition plate and the opposite floor are non-detachable, so that an antenna cabin structure with local general assembly modularization manufacturability is formed; ten east-west plates, the antenna cabin structure and the inner framework are mutually detachable; in the aspect of a force transmission system, large-mass loads of the communication cabin are mainly distributed on east, west, south, north and earth outerplates, and the large-mass dispersed loads are gradually concentrated from the outer plates and finally gathered to platform cabin connectors of the communication cabin. The communication cabin structure provided by the invention provides a cabin body outer surface load mounting area of up to 40m<2>, and ensures the connection requirements of large-area load, large-path transponders and large-areaload cabin heat dissipation.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

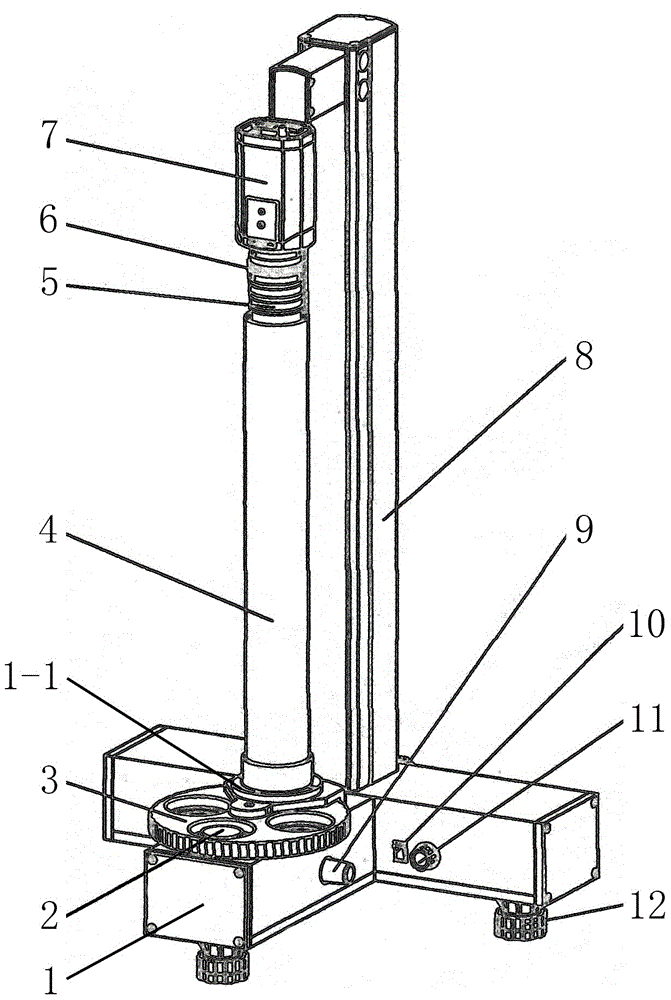

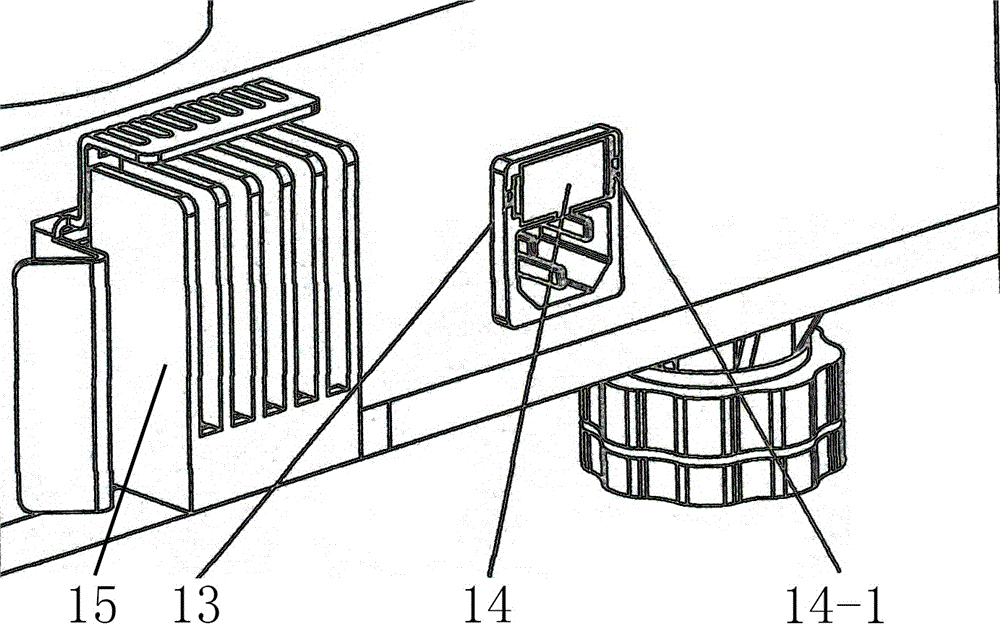

Micropore detection instrument

InactiveCN106017539ARealize complete and clear imagingDetermine the transparent stateMeasurement devicesOptical pathCamera lens

The invention discloses a micropore detection instrument, and relates to the technical field of optical detection equipment. The micropore detection instrument comprises a base and an object table and a rack which are installed on the base. The rack is provided with a camera. A workpiece to be detected is arranged on the object table. A light source is arranged below the detection position of the workpiece to be detected. The workpiece to be detected is arranged in an imaging light path of the light source and the lens of the camera in detection. The lens is provided with an out-of-focus adjustment ring. An image space telecentric flat field lens is used as the lens. A light shading cylinder is arranged between the lens and the detection position. The light source is arranged in the base. The light source is a light-emitting member which is installed in a heat radiation base of which one end is inserted in the base. The other end of the heat radiation base is provided with heat radiation fins which are exposed out of the base. The problems that the transparent state of all the micropores of the workpiece cannot be judged by the existing micropore detection instrument in one time of imaging can be solved.

Owner:WUZHOU OKA OPTICAL INSTR

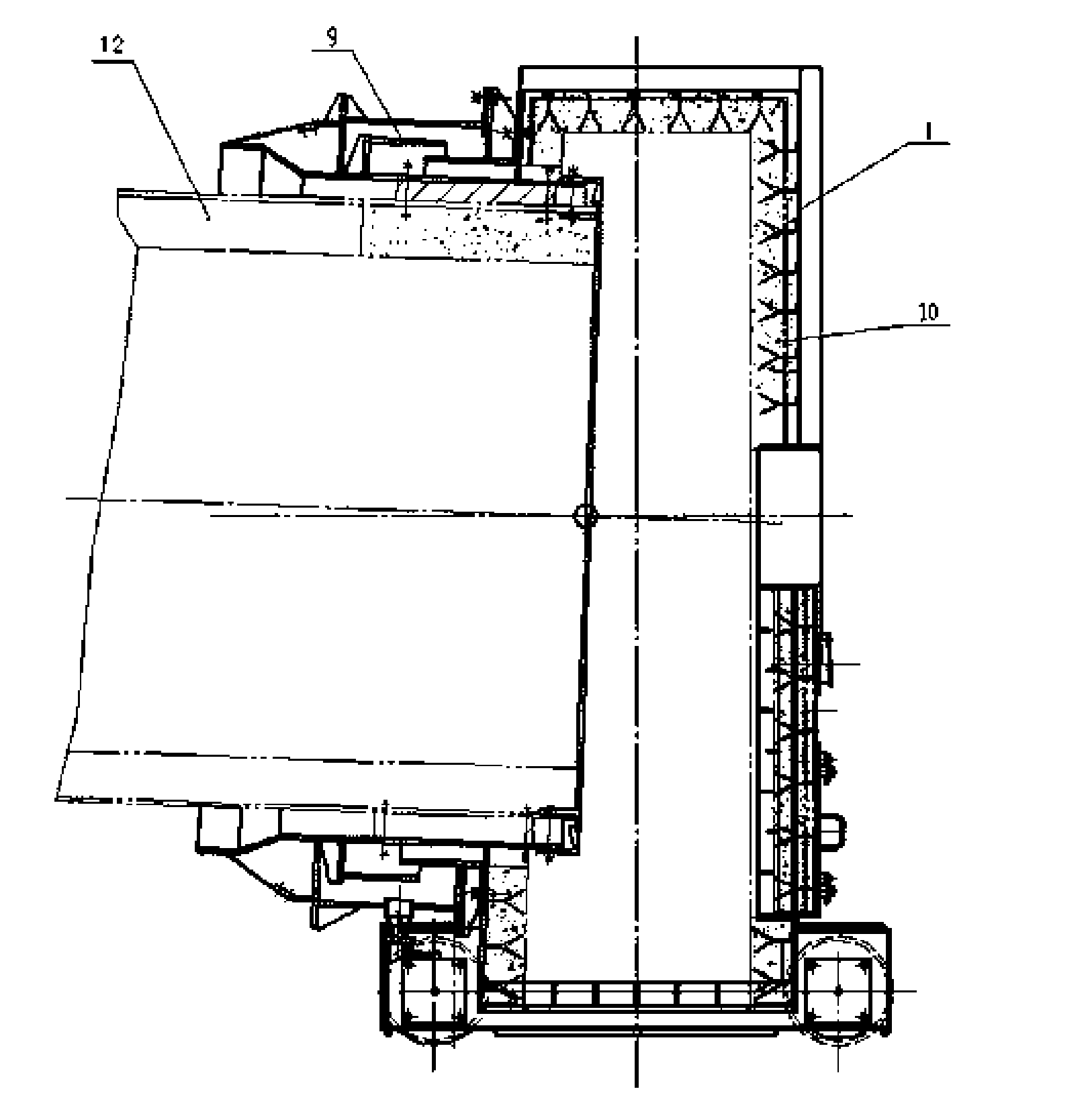

Kiln head cover of rotary kiln

The invention discloses a kiln head cover of a rotary kiln, comprising a kiln head sealing device (9) welded with a kiln cylinder (12) into a whole, wherein the other side of the kiln head sealing device (9) is coupled with a kiln head cover body (1), the inner side of the kiln head cover body (1) is provided with a lining (10) made of a refractory material, a rectangular cover gate (2) is arranged on the front side of the kiln head cover body (1), a gate bolt (3) is installed on the cover gate (2), the kiln head cover body (1) and the kiln head sealing device (9) can be mutually disconnected, two sides of the kiln head cover body (1) are respectively provided with a wheel group, and a steel rail (11) is arranged below the wheel groups. Compared with the prior art, the invention ensures that a maintenance worker can enter through the cover gate to perform minor repair on the rotary kiln head, and when major repair is needed, larger maintenance tools and materials can be carried by the maintenance worker and a enough operation space is allowed for the worker to perform maintenance through disconnecting the cover body and the kiln head sealing device and moving the wheel groups by a certain distance on the steel rail.

Owner:GUIYANG AL-MG DESIGN & RES INST

Method for pouring ABR (Acrylate Butadience Rubber) reaction tank baffle

ActiveCN102635237AGood molding qualityGuaranteed impermeabilityTreatment with anaerobic digestion processesBuilding material handlingRebarSteel tube

The invention discloses a method for pouring an ABR (Acrylate Butadience Rubber) reaction tank baffle. The method comprises the following steps: 1) binding reinforcing bar nets: binding double-layer reinforcing bar nets by using reinforcing bars and binding stirrups between the double-layer reinforcing bar nets; 2) bracing formworks: respectively bracing beam supporting formworks on two sides of a beam reinforcing bar net, bracing plate supporting formworks on two sides of a plate reinforcing bar net, bracing an axilla supporting formwork outside an axilla reinforcing bar net, and meanwhile, supporting and fixing by using a longitudinal supporting rod and a horizontal supporting rod of a scaffold, and fixing and supporting the bottom of the plate reinforcing bar net on a steel tube of the scaffold; 3) pouring concrete: pouring a part below a preformed hole, a part from the preformed hole to the axilla and the beam with concrete layer by layer in turn; and 4) dismounting the formworks: dismounting the formworks when the concrete strength is 100%. The beam and plate of the ABR reaction tank baffle are integrally poured according to the method disclosed by the invention, so that the construction cold seam does not exist between the beam and plate and the forming quality is excellent.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

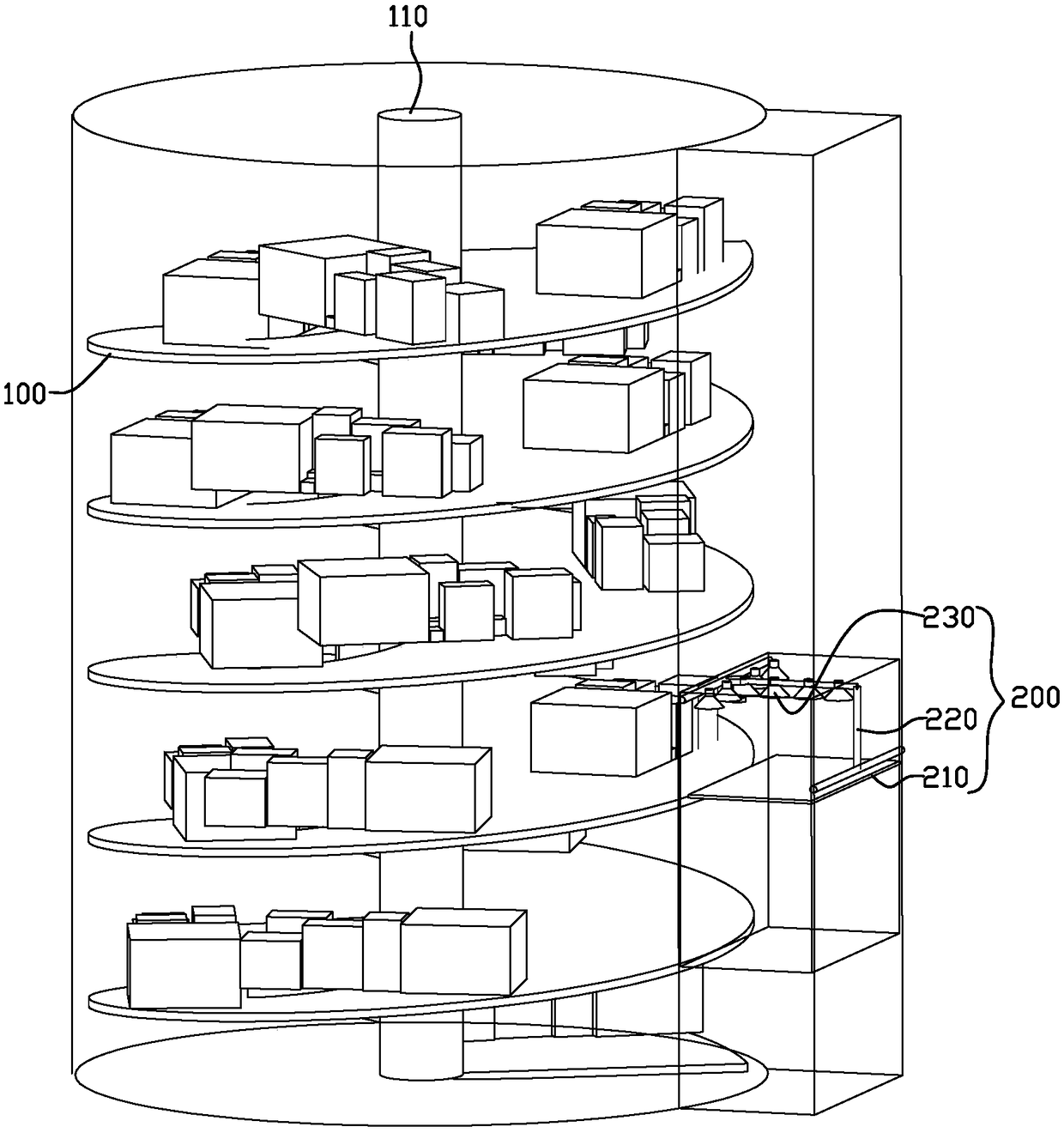

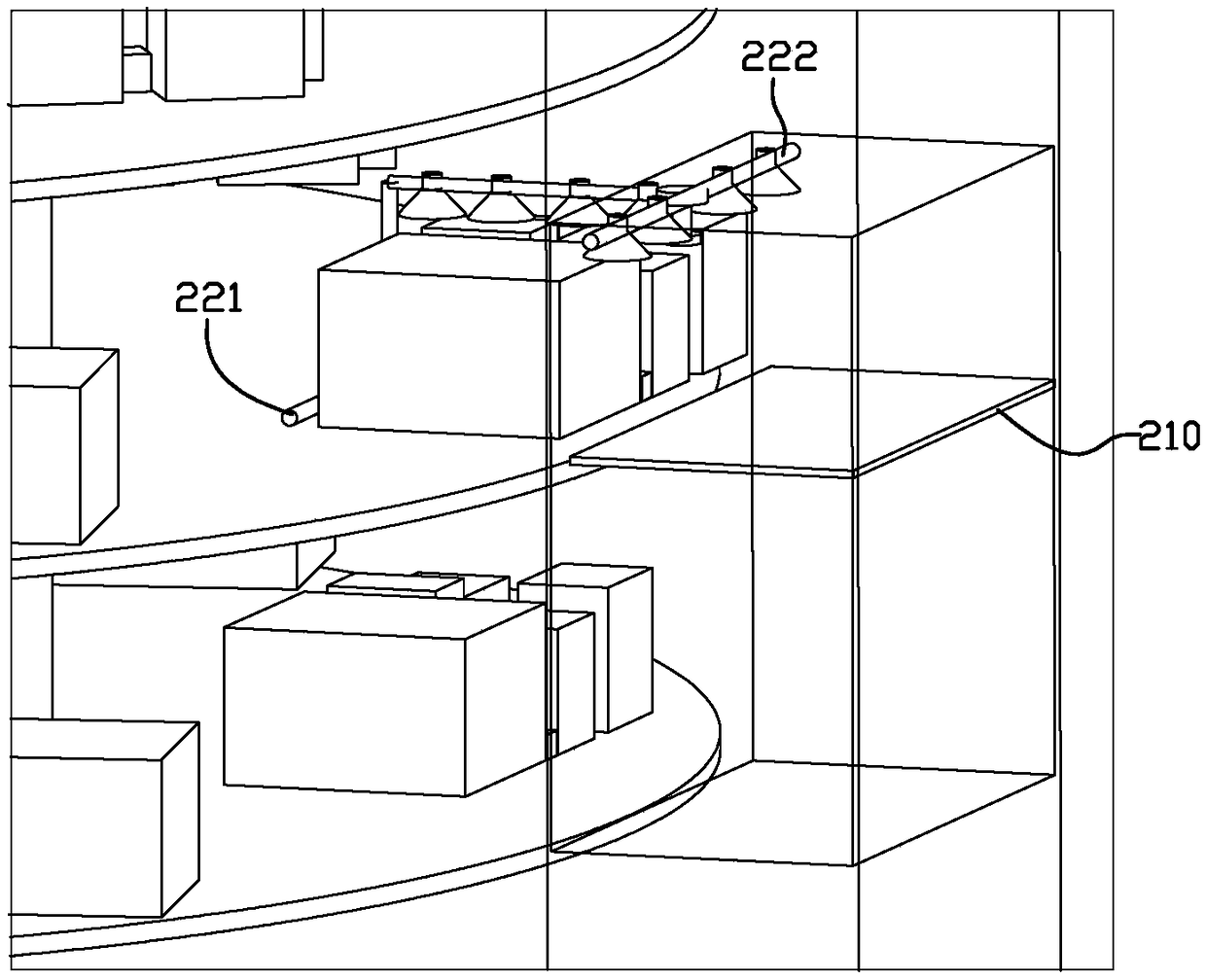

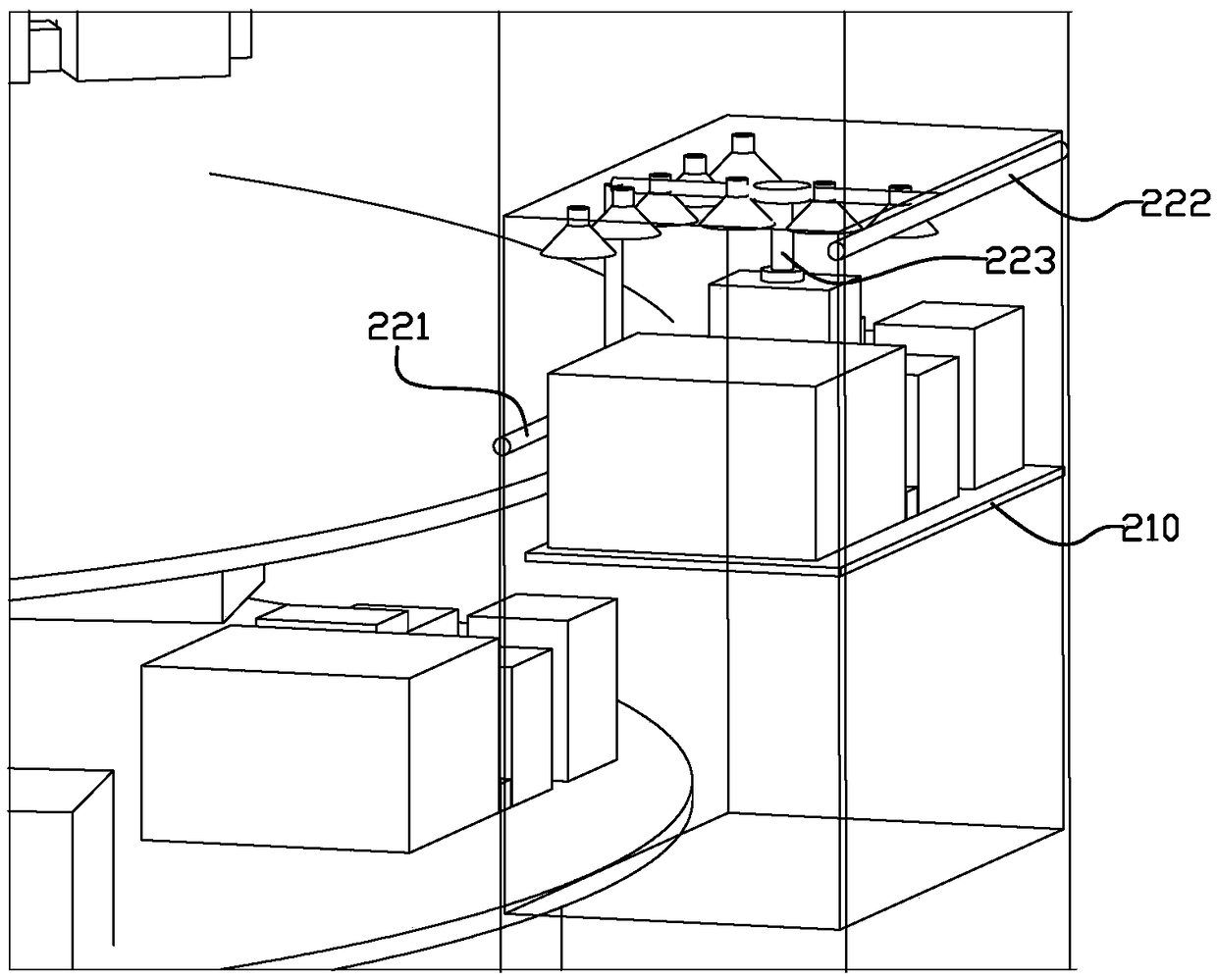

Self-service terminal and cargo sorting method

PendingCN108974747AEnough operating spaceSmall footprintStorage devicesLogistics managementReciprocating motion

The invention relates to the field of logistics transportation, and discloses a self-service terminal and a cargo sorting method. The self-service terminal comprises a spirally-distributed storage rack, and further comprises a lifting device capable of axially reciprocating along the storage rack. The lifting device comprises a transfer storage device, a cargo acquisition device and an informationacquisition device, wherein the cargo acquisition device can realize transfer of bulk cargos between the transfer storage device and the storage rack, the information acquisition device obtains the information of transferred bulk cargos, and the cargo acquisition device selects the required cargos from the bulk cargos in the transfer storage device on the basis of the information. The sorting place of the cargos is transferred to the outside of the storage rack, so that the corresponding sorting device has enough operating space. The transfer process does not involve sorting, so the corresponding sorting device can achieve the goal of transfer only through simple actions, the occupied space in the self-service terminal is greatly reduced, and the storage capacity of the self-service terminal is helped to be improved.

Owner:坎德拉(深圳)科技创新有限公司

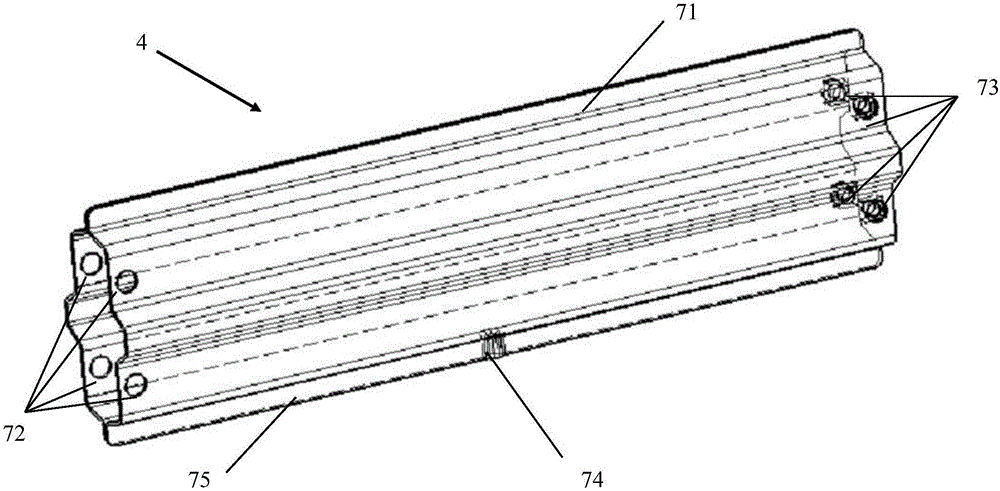

Independent adaptor piece used for plastic scintillator detector array environment test

ActiveCN106370371AGood force transmission performanceIncrease stiffnessStatic/dynamic balance measurementMaterial thermal analysisDetector arrayTransmission performance

The invention relates to an independent adaptor piece used for a plastic scintillator detector array environment test. The independent adaptor piece comprises an I-beam force transmission structure, the two opposite sides of the I-beam force transmission structure are respectively provided with an upper planar portion and a lower planar portion, the width of the upper planar portion is smaller than the width of the lower planar portion, four upper installation holes are arranged at four corners of a rectangular of the upper planar portion, the lower planar portion is symmetrically provided with two columns of lower installation holes, and each column is uniformly provided with three. According to the invention, the independent adaptor piece structurally utilizes an I-beam force transmission performance feature and realizes large rigidity and good mechanical vibration spectrum transmission performance. Four connection holes in the upper surfaces of adaptor pieces are connected with a plastic scintillator detector array, six connection holes in the lower surfaces are connected with a vibration table expansion bench or a shock testing machine expansion bench, through open design at two sides, the operation space is sufficient, the application is facilitated, the installation moment requirement of a product is satisfied, and the environment test can also be conveniently mounted and dismounted.

Owner:TIANJIN AEROSPACE RELIA TECH +2

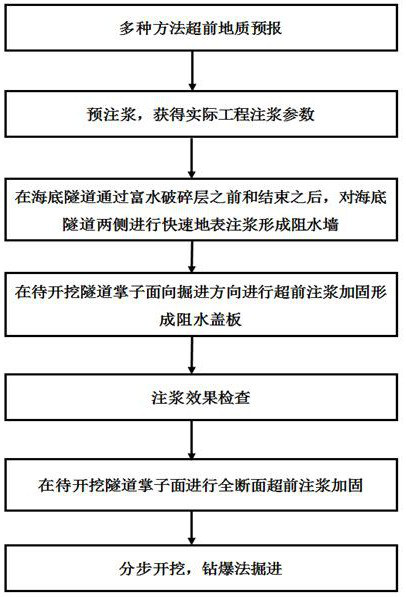

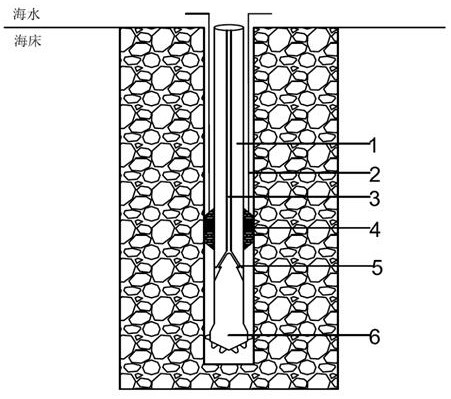

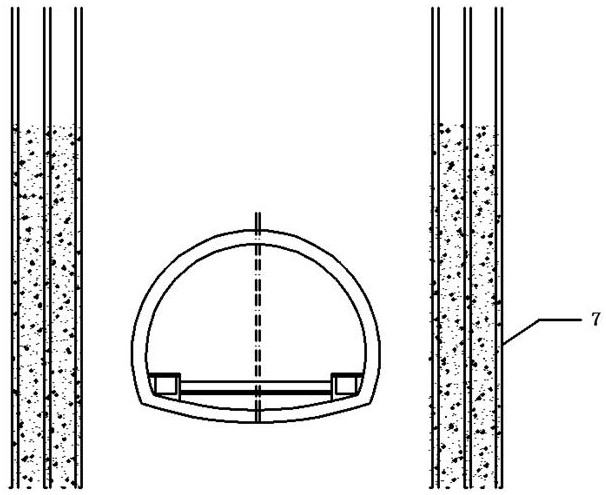

Fence type grouting construction method for subsea tunnel to pass through water-rich fault fracture zone

ActiveCN113073983AEnsure excavation safetyShort construction periodTunnelsFracture zoneStructural engineering

The invention discloses a fence type grouting construction method for a subsea tunnel to pass through a water-rich fault fracture zone. The fence type grouting construction method comprises the following steps that advanced geology forecast is carried out; pre-grouting is carried out to obtain grouting related parameters; fracture zone water-blocking walls are constructed on the two sides of the tunnel; advanced grouting reinforcement is carried out to form a water-blocking cover plate; a grouting effect is inspected; full-section grouting reinforcement of a tunnel face is carried out; and tunneling is carried out by a drilling and blasting step method. According to the fence type grouting construction method for the subsea tunnel to pass through the water-rich fault fracture zone, grouting is innovatively carried out from the seabed surface from top to bottom, the water blocking cover plate is combined, a fence type water blocking structure is formed, the safety coefficient in the subsea tunneling process is improved, and the application range is wide.

Owner:OCEAN UNIV OF CHINA

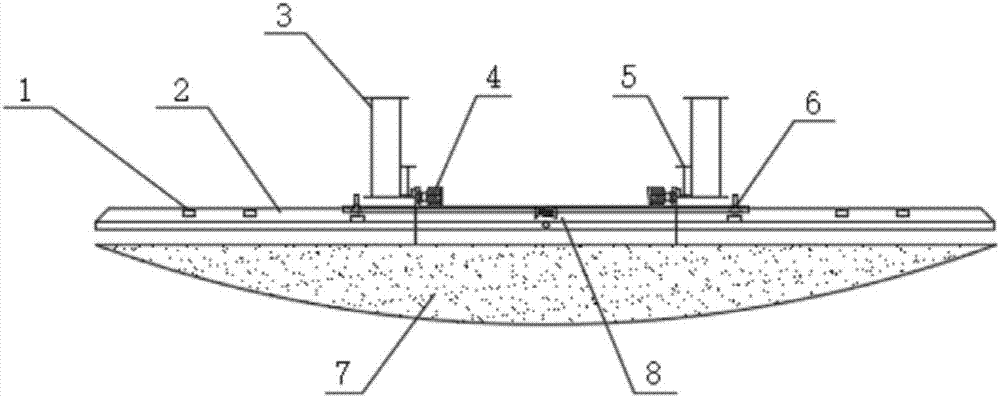

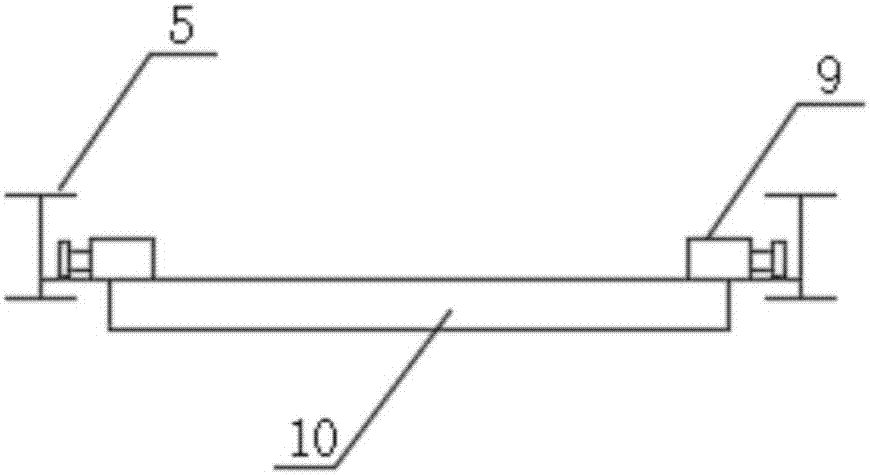

Improvement equipment for vibrating and leveling inverted-arc filling part

PendingCN107420116AIncrease coverageImprove leakage vibrationUnderground chambersTunnel liningStructural engineeringElectric consumption

The invention discloses improvement equipment for vibrating and leveling an inverted-arc filling part. The improvement equipment comprises vibrators, a leveling plate, trestle girders, a walking part, I-shaped beams, a lifting rod, the inverted-arc filling part, a middle adjusting camber part, motors and an ironing plate. The improvement equipment has the advantages that a full-automatic leveling machine is added on the basis of a full-automatic hydraulic inverted-arc trestle, the equipment is easy to operate, after inverted-arc filling, quick vibration and compacting are conducted, the leveling effect is good, and the problems that vibration missing and excessive vibration exist in original filling concrete vibration can be effectively solved. Conventional inverted-arch surface finishing is conducted through the adoption of the coordination of labor and an electric trowelling machine, 12 m inverted-arcs need to be provided with three electric trowelling machines, and it take about 2.5 h for two people to complete the work, and the electricity consumption amount is 16.5 degrees; meanwhile, when the full-automatic leveling machine is adopted, the 12 m inverted-arcs need to be provided with one set of XDSZ-100 type full-automatic leveling machine, the consumed time is about 0.4 h, the electricity consumption amount is 1.3 degrees, the leveling time is then shortened, and the labor investment is reduced.

Owner:中交中南工程局有限公司

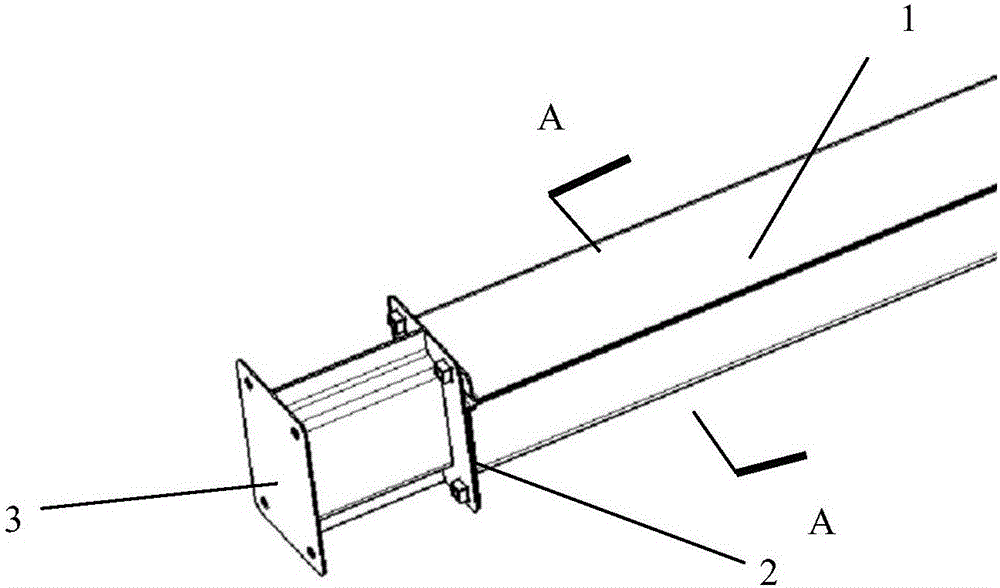

Front longitudinal beam applicable to automobile body

InactiveCN106114629ASmall amount of deformationImprove longitudinal strengthUnderstructuresBumpersAbsorbed energyEngineering

The invention provides a front longitudinal beam applicable to an automobile body. The front longitudinal beam comprises two weldments (7) same in structures. The weldments (7) are formed through sheet material stamping and comprise upper welding edges (71) and lower welding edges (75), bulges having trapezoid cross sections are arranged on the middles of the weldments (7) through stamping, the two weldments (7) are arranged in a manner the sunken sides of the bulges are opposite, so that the front longitudinal beam has a cavity having a cross-shaped section, energy absorbing box mounting holes (72) are formed in the positions, close to the ends, of the weldments (7) in the direction perpendicular to the front longitudinal beam, and the front longitudinal beam is in bolted connection with energy absorbing boxes (3). The front longitudinal beam is higher in longitudinal strength, small in deformation amount during front crash and capable of better protecting passengers in the automobile, the energy absorbing boxes can be assembled more conveniently through the front longitudinal beam, the assembled energy absorbing boxes can be well supported, and thus the energy absorbing boxes can play a good role in absorbing energy.

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

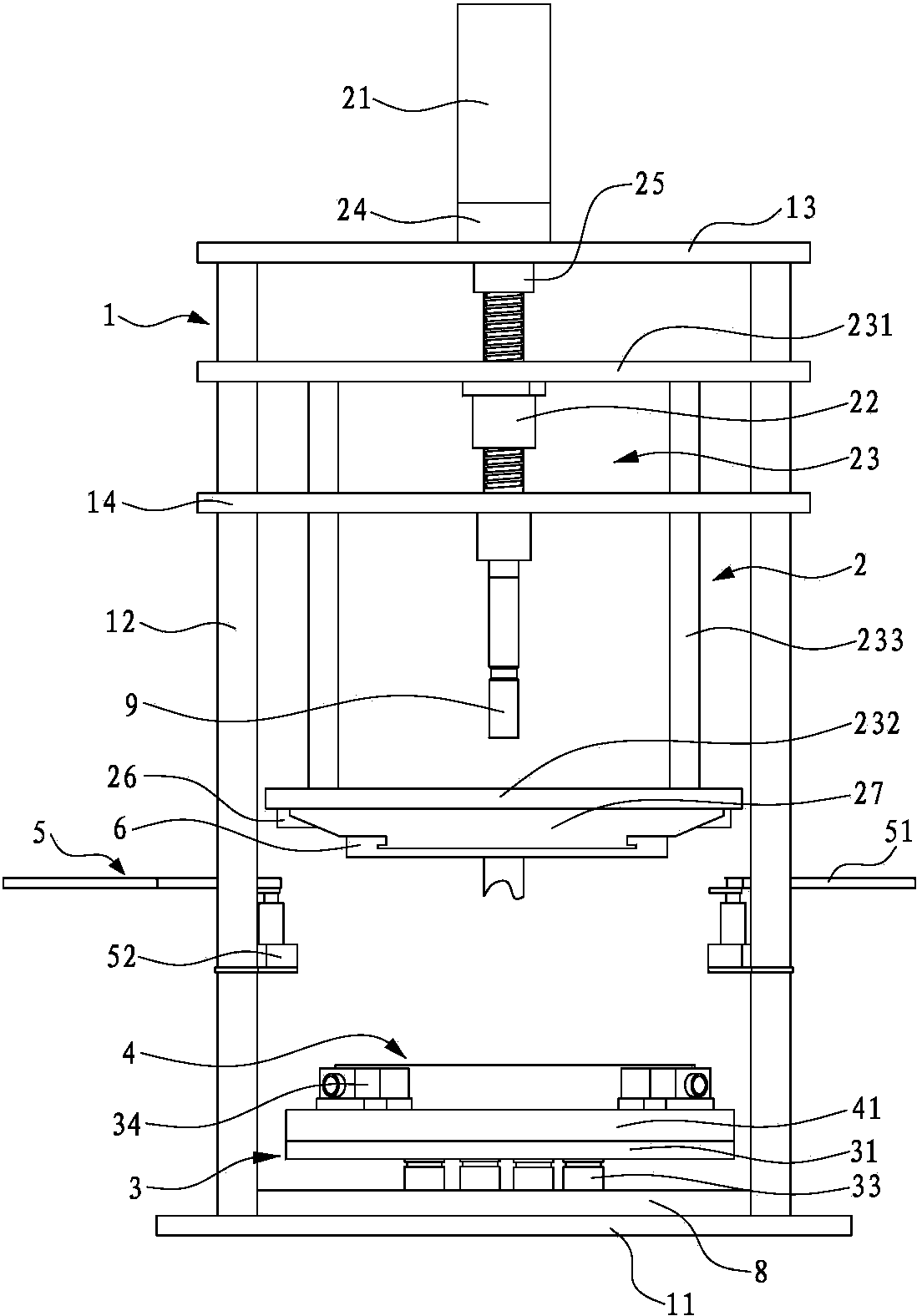

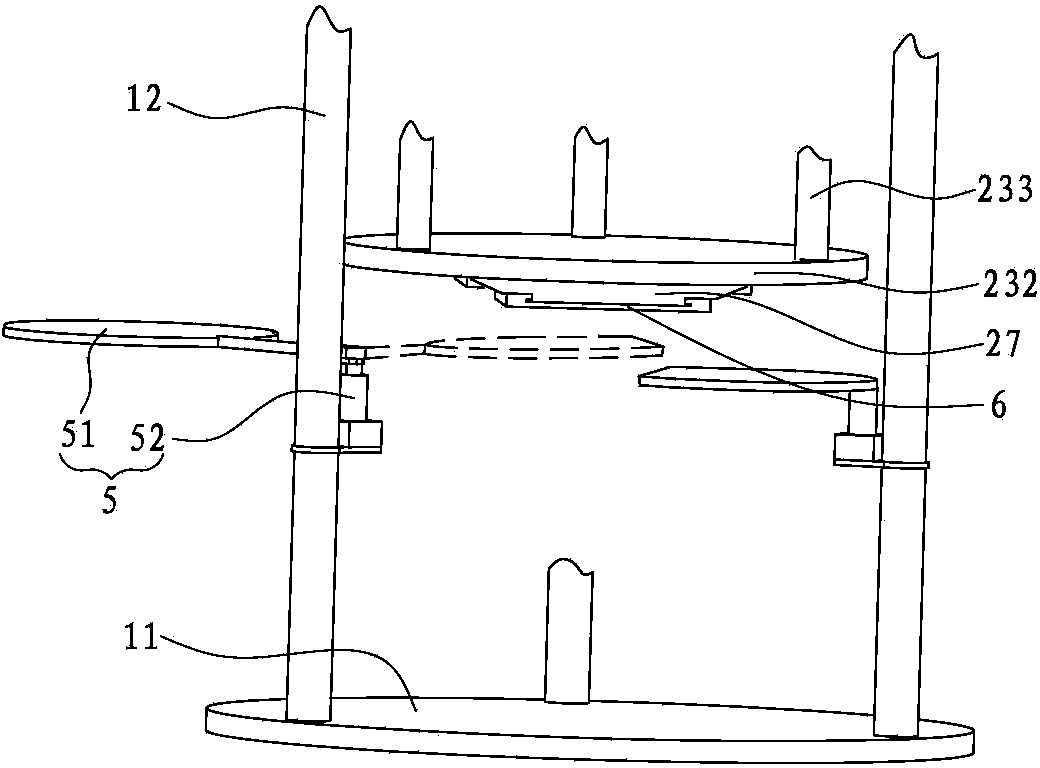

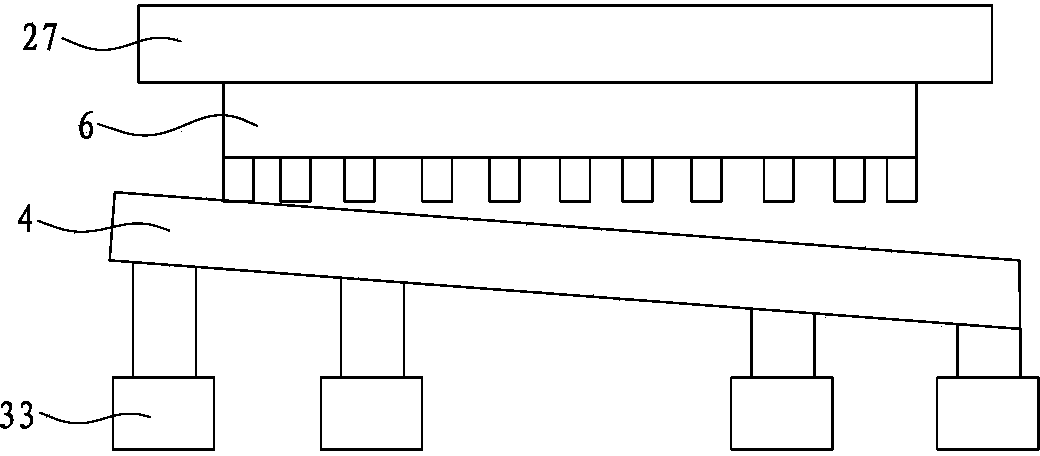

Micro contact printing device based on voice coil motors and work process thereof

ActiveCN103507451AImprove linearityQuick responseOther printing apparatusStampingMicrocontact printingControl manner

The invention discloses a micro contact printing device based on voice coil motors and a work process of the micro contact printing device. The micro contact printing device comprises a macro dynamic drive device, a micro dynamic leveling drive device, a printing device and an ink supplying device, wherein the macro dynamic drive device can achieve coarse positioning of a moulage and a printing platform in the vertical direction, and the micro dynamic leveling drive device is driven by the four voice coil motors. Firstly, an inclinometer is used for guaranteeing that the printing platform is in a horizontal position. Secondly, an optical component is used for detection, so that the voice coil motors are controlled to work to regulate the degree of parallelism between the moulage and printing materials, and fine leveling is achieved. Finally, the four voice coil motors are driven to work synchronously to carry out contact transfer printing between the moulage and the printing materials. The micro contact printing device is based on a positioning and constant force control method of the voice coil motors, the voice coil motors can be used for achieving the two steps of leveling and micro motion to guarantee uniform contact between the moulage and the printing materials, and high-accuracy, high-efficiency and pollution-free transfer printing can be realized.

Owner:XIAMEN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com