Trolley for construction of rectangular box culvert and tunnel

A technology for tunnel construction and box culverts, which is applied in tunnels, tunnel linings, road bottom layers, etc. It can solve problems such as high equipment manufacturing and maintenance costs, uncertainty of side formwork trajectory, misplacement and gaps in axillary formwork, etc., to achieve Concrete pouring has good molding quality, large transformable space, and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

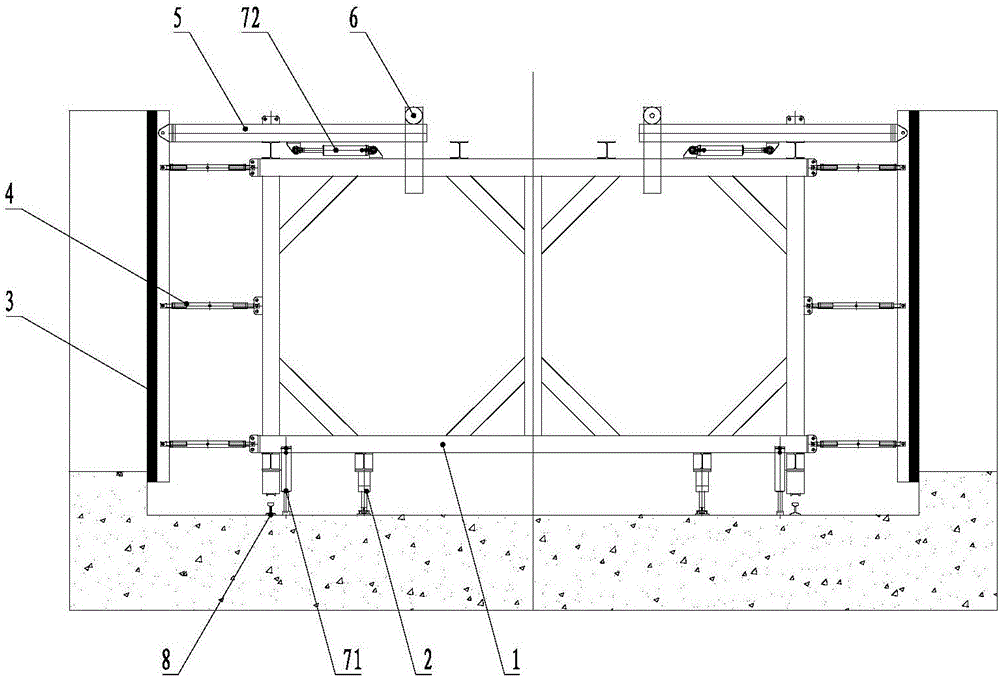

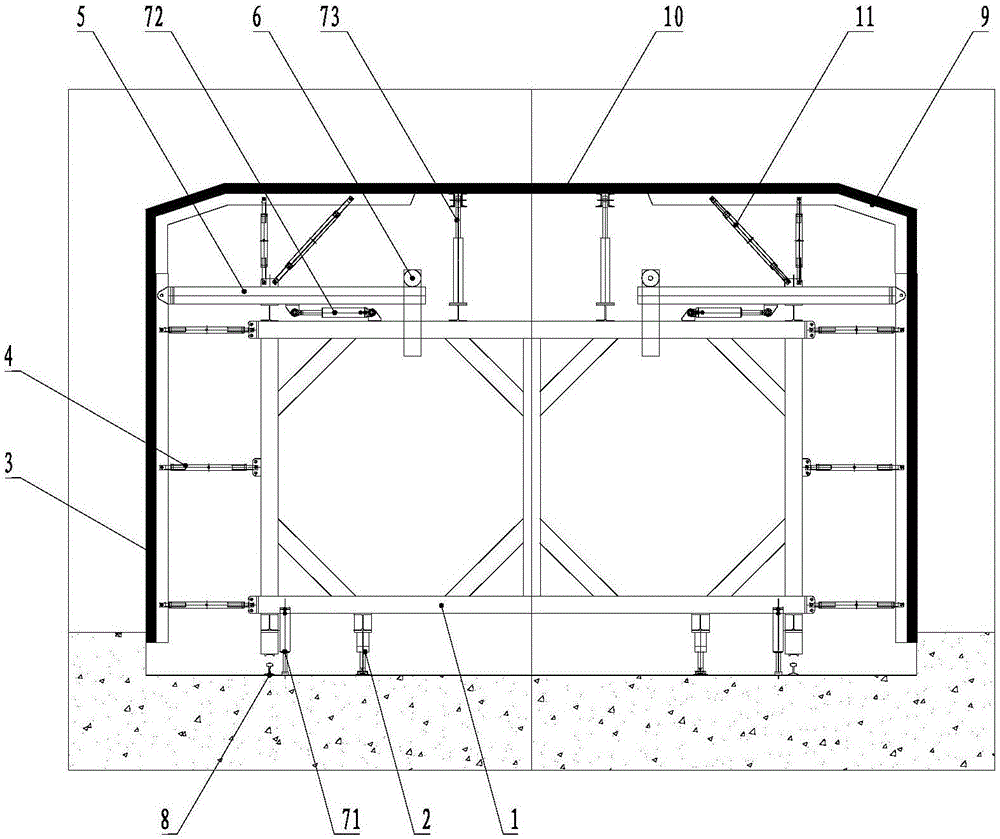

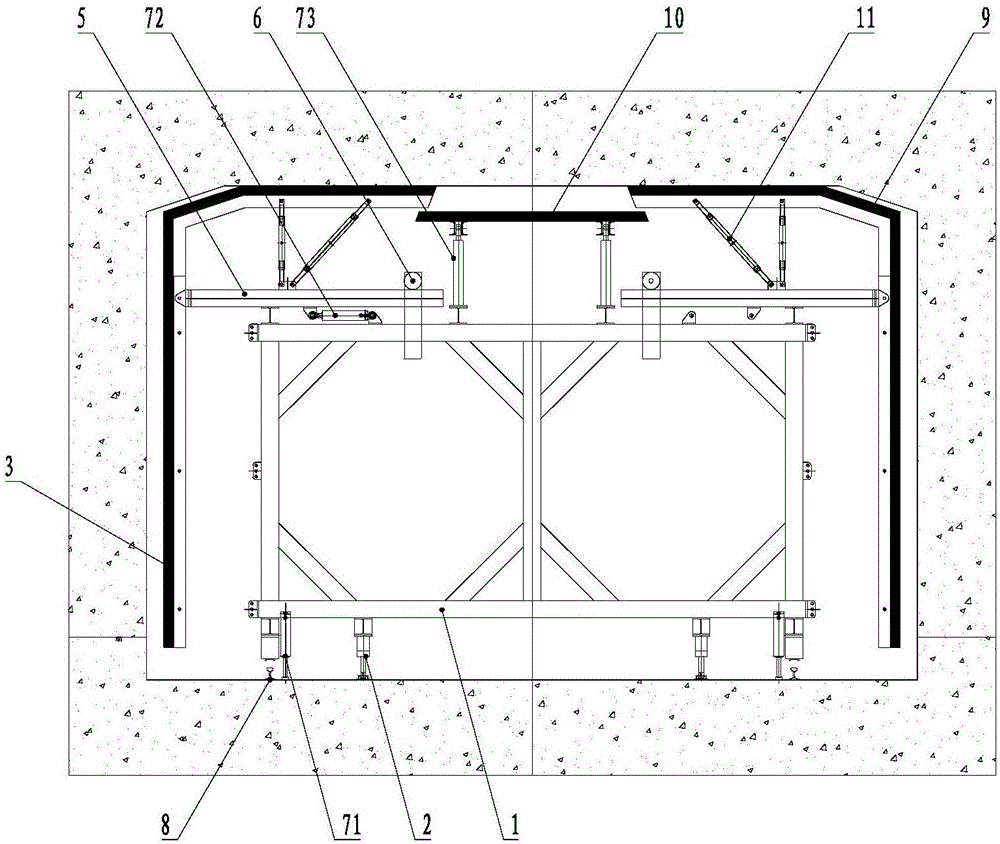

[0022] Such as figure 1 As shown, in the rectangular box culvert provided by the present invention and the trolley for tunnel construction, the side plate formwork 3 is connected with the steel bracket 1 through the lateral strut 4, and the top of the steel bracket 1 is provided with a counterforce sliding frame 6, and the traverse beam One end of 5 is connected with the side plate form 3, and the other end is inserted into the reaction carriage 6, and a traversing power device is provided between the traversing beam 5 and the top of the steel support 1, specifically, the traversing power device is a traversing oil cylinder The bottom of the 72 steel bracket 1 is provided with a vertical support screw rod 2 . The steel support 1 is supported on the concrete surface of the bottom slab through the vertical support screw 2.

[0023] Further, a traveling system is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com