Rotating-sector-laser-based position and pose measurement method of cantilever excavator

A cantilever roadheader and fan laser technology, which is applied in the directions of measuring devices, measuring instruments, surveying and navigation, etc., can solve problems such as poor visibility, calibration of inertial navigation systems, and miscellaneous equipment, and achieves low cost and high automation. Measure and improve the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

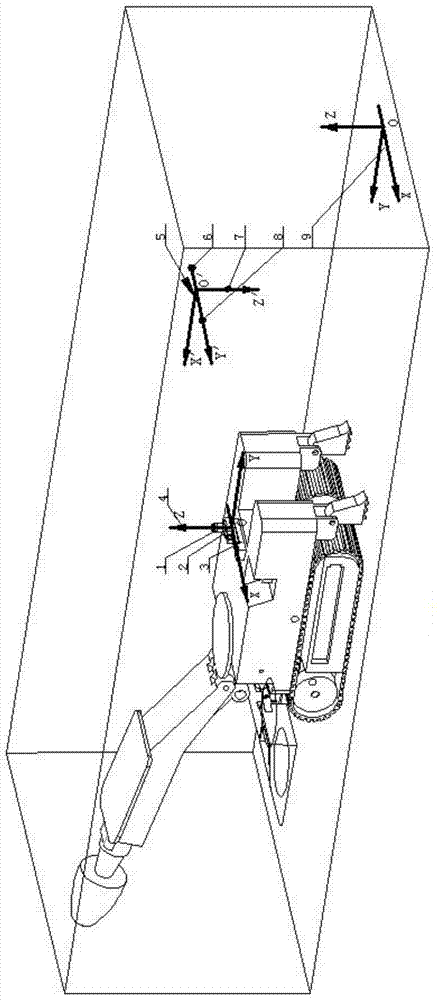

[0025] Such as figure 1 As shown, the method of measuring the pose of a cantilever roadheader using a space point three-dimensional coordinate measurement system based on sector laser angle measurement, the pose measurement process includes the following steps:

[0026] (1) Install the sector laser transmitter on the cantilever roadheader so that it is fixedly connected with the cantilever roadheader. The fan laser receiving end is installed in the formed roadway, that is, 3 non-collinear fan laser receivers.

[0027] (2) A coordinate system is constructed by the sector laser transmitter, which is called the fuselage coordinate system (O-XYZ). The fan laser transmitter is composed of a high-precision slide table, a high-precision turntable, a fan laser transmitter, and an initial reference. The initial position rotation axis of the fan laser transmitter is the Z axis, and the moving direction of the high-precision slide table is the X axis.

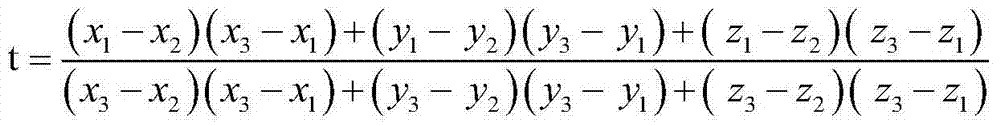

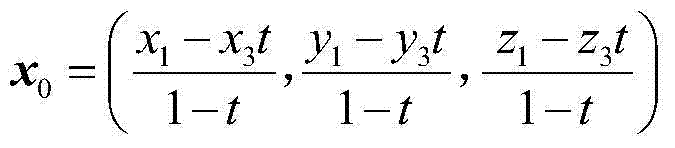

[0028] (3) A coordinate system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com