Punching die

A punching and mold technology, applied in the field of mold equipment, can solve the problems of low hole quality, lower product qualification rate, metal pipe deformation, etc., and achieve the effects of high molding quality, low manufacturing cost, and processing cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

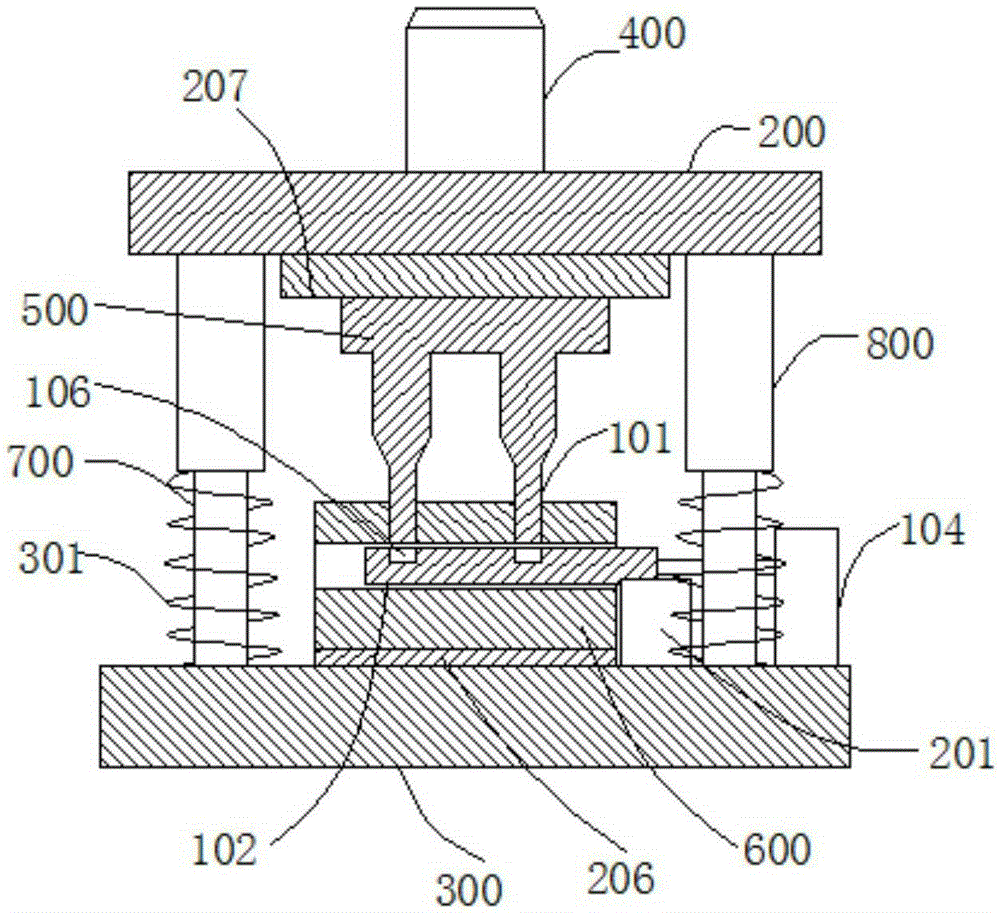

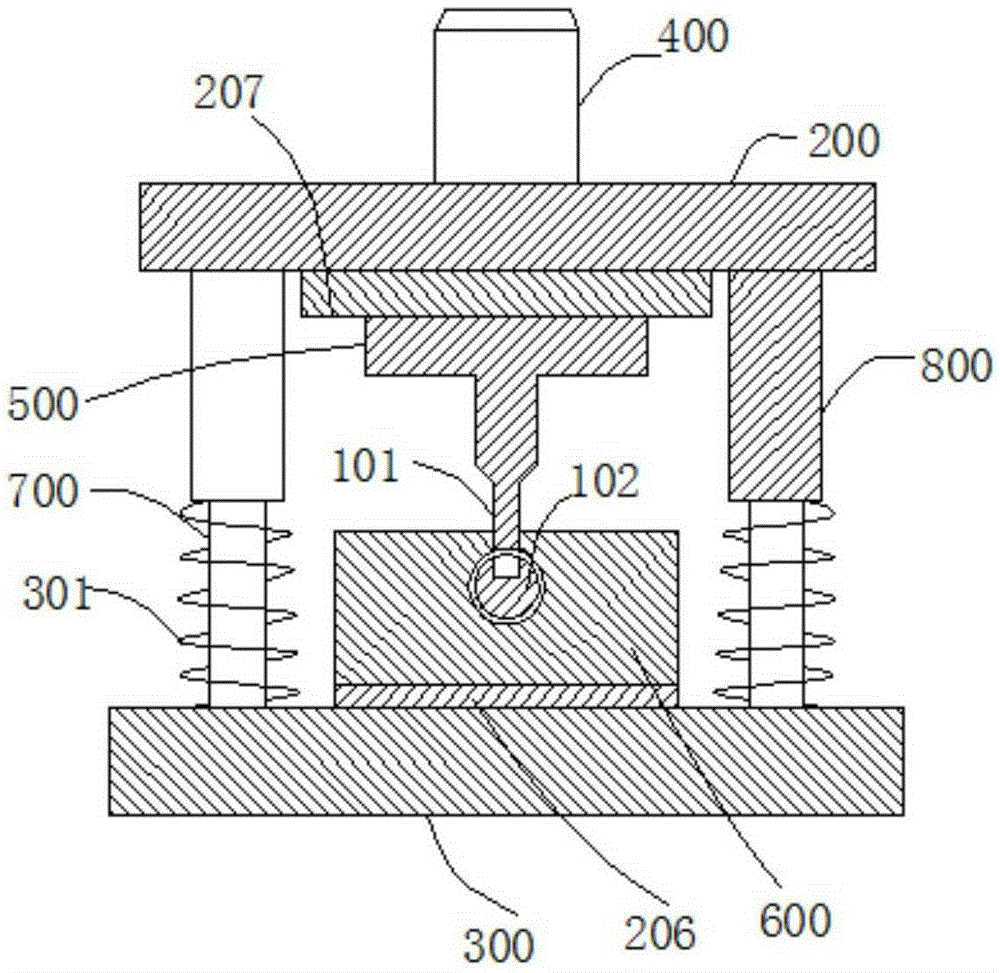

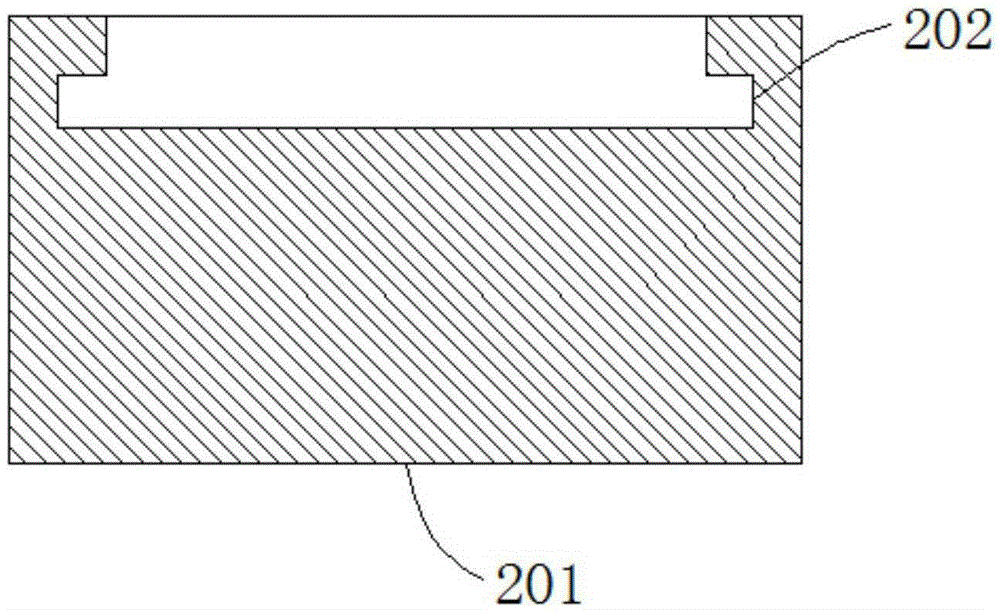

[0035] Using the punching die for punching can improve productivity, and the product quality is stable and safe, but there are some defects in the existing punching die. The existing punching die has only one punch, and only one hole can be punched at a time. , If multiple continuous holes are punched on the metal pipe, the metal pipe needs to be installed repeatedly, which reduces the production efficiency and increases the installation error, and then the punching accuracy of the hole is low, the qualified rate of the product decreases, and the cost increases.

[0036] In view of this, the designer of the present invention has designed a kind of punching die, and when punching, the core-pulling slide block is positioned at the lumen of metal tubing, and when the punch presses downwards, the core-pulling slide block can bear the impact of the punch. The force on the metal pipe, the metal pipe is not easy to deform, will not affect the quality of punching, and can form multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com