Piezoelectric-type three-dimensional printing forming system and forming method thereof

A three-dimensional printing, piezoelectric technology, applied in printing, typewriters, etc., can solve the problems of expensive powder and binder, large application constraints, complex structure, etc., to improve the convenience and efficiency of operation, and facilitate connection and movement , Improve the effect of forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

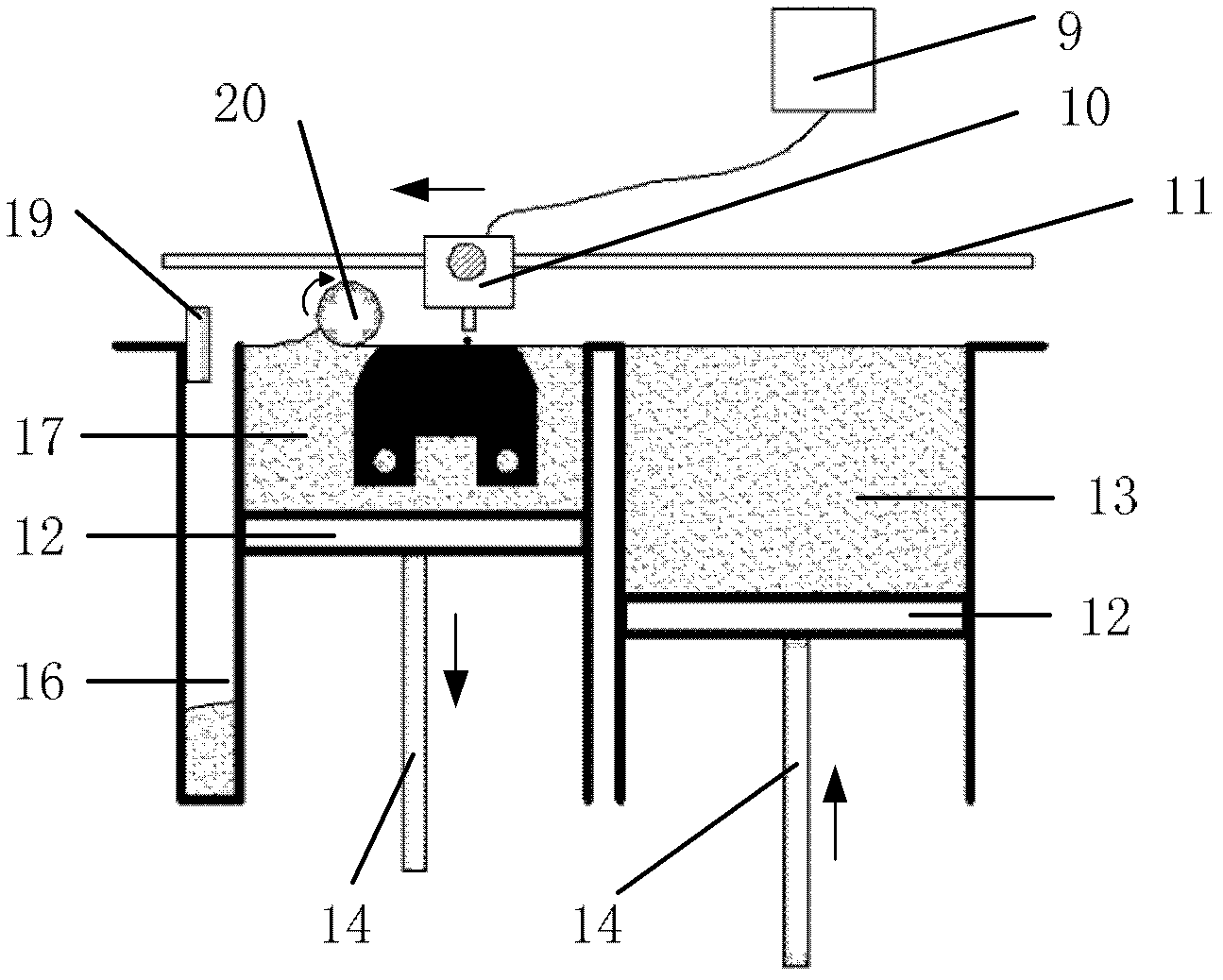

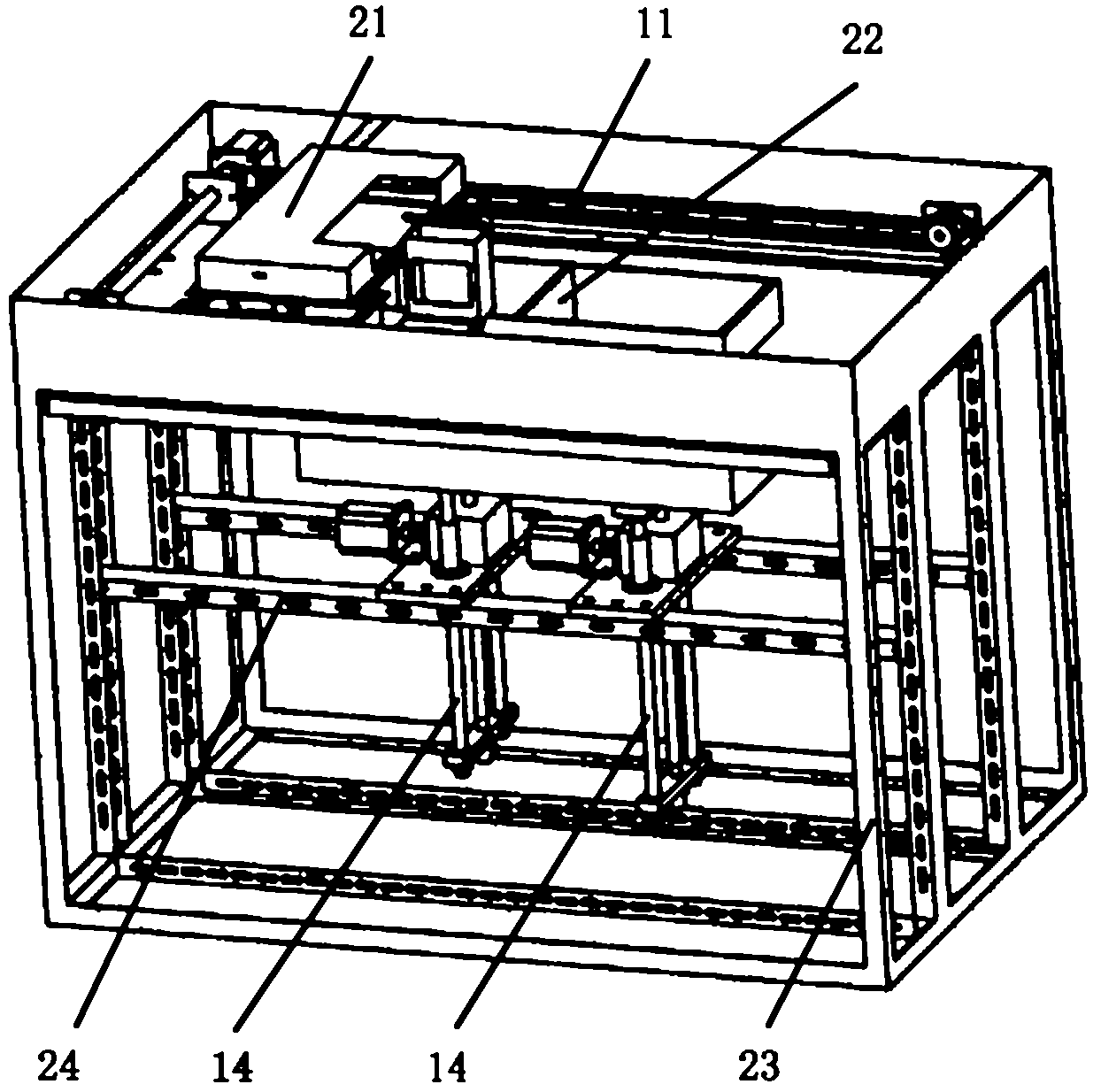

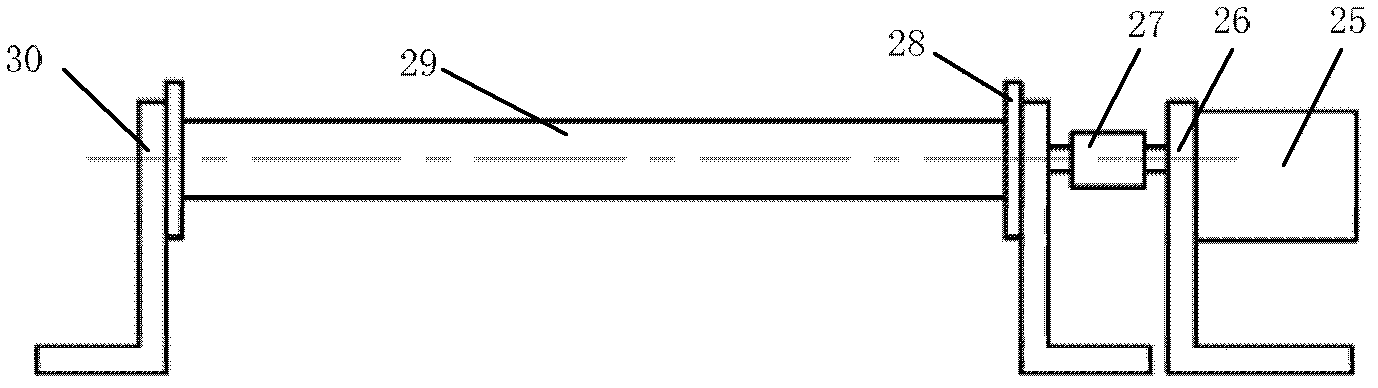

[0041] See also Figure 1 to Figure 2 , The three-dimensional printing molding system of the present invention includes a piezoelectric nozzle 10, a powder chamber 22, a powder spreading mechanism 20, a bearing structure 21, an X-direction movement mechanism 11, a negative pressure adsorption mechanism 12, a powder chamber lifting mechanism 14, and a powder scraping device 19 , casing and supporting frame 23 thereof, and automatic control device (not shown) and other components.

[0042] The piezoelectric nozzle 10 is transformed from a piezoelectric inkjet printer, retaining the piezoelectric noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com