Preparation of black alumina substrate for multilayered wiring

A technology of black alumina and multi-layer wiring, applied in the direction of electrical components, impedance networks, etc., can solve the problems of high cost, demanding processing technology, high alumina sintering temperature, etc., to reduce equipment requirements, simple process, reduce The effect of firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of Wu electrode slurry is: adding Al to metal tungsten powder 2 o 3 Base ceramic powder and add a little organic carrier dropwise, and grind while adding dropwise. The amount of organic carrier should be such that a small amount of the ground slurry can be pulled out of fine sticky filaments or a large amount can be pulled into a film. Among them, the mass percentage of metal tungsten powder is 83wt% ~ 86wt%, Al 2 o 3 The mass percentage of the base ceramic powder is 12wt%-15wt%, the mass percentage of the organic vehicle is 1wt%-3wt%, and the Wu electrode slurry is finally prepared by fully grinding in a mortar. The organic carrier is composed of ethyl cellulose, terpineol, and dibutyl phthalate, among which, 19ml~21ml terpineol and 2ml~5ml dibutyl phthalate are added to each 1g of ethyl cellulose, and the water bath Heat and stir evenly to dissolve all the ethyl cellulose to make an organic carrier.

[0039] (5) Multi-layer co-firing:

[00...

example 1

[0042] Doping modification reduces the sintering temperature of alumina to prepare the process of casting powder: Weigh the total mass of powder as 10g, Al 2 o 3 8.69g, Co 2 o 3 0.05g, MnO 2 0.37g, Cr 2 o 3 0.21g, SiO 2 0.45g,TiO 2 0.2g, V 2 o 50.03g. Put the weighed powder into a ball mill jar, add alcohol as a medium for planetary ball milling, and mix well for 3 hours. Then dry and pass through an 80-mesh sieve. Add an appropriate amount of 10% PVA polyvinyl alcohol for granulation, put it into a tablet press for tablet molding at a pressure of 15 MPa, and then sinter in air at 1350°C for 2 hours to obtain a dense black alumina ceramic body.

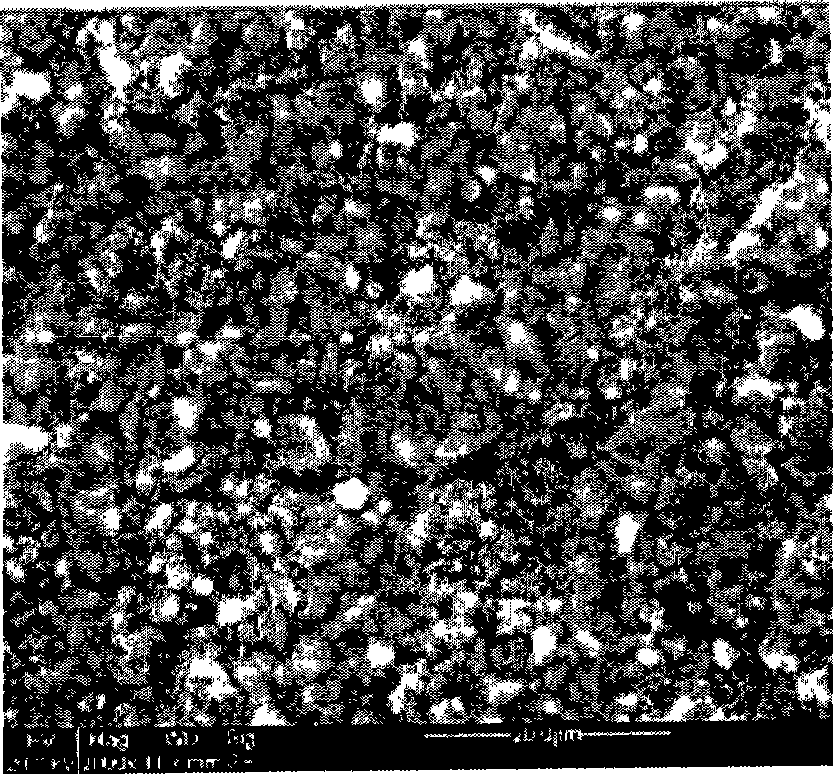

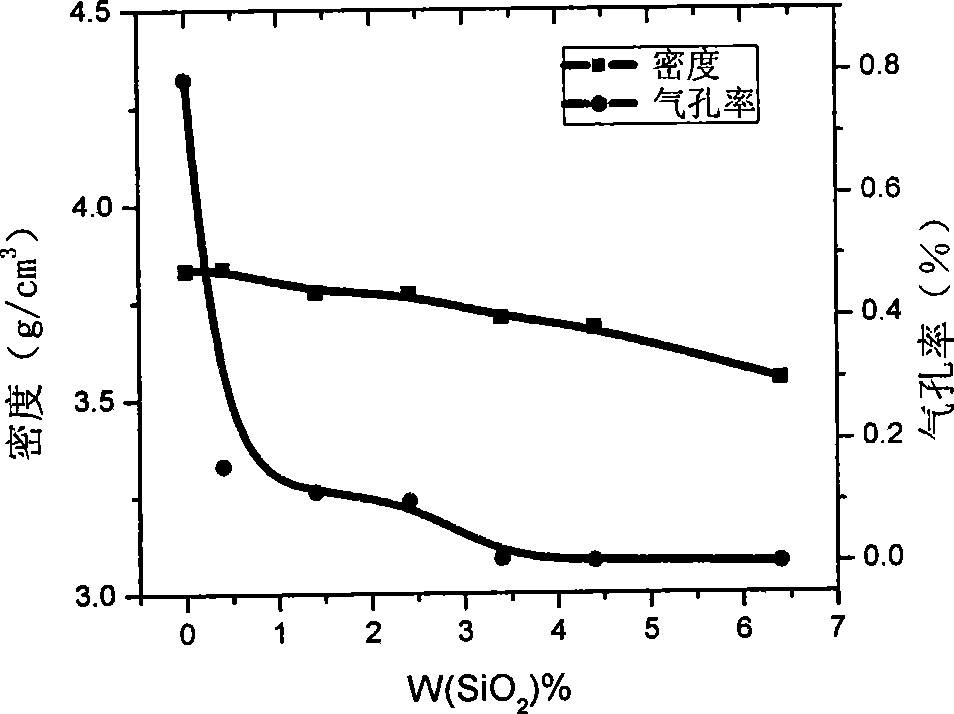

[0043] SiO 2 The SEM picture when the content is 4.5% figure 1 . It can be seen that the grains are fine and uniform, the average grain size is about 2.5 μm, and no flaky grains are formed. Test its physical and electrical properties to get SiO 2 The relationship between content and density and porosity is as fol...

example 2

[0045] The same technological process as scheme 1, the total mass of the powder is weighed to be 10g, Al 2 o 3 8.99g, Co 2 o 3 0.05g, MnO 2 0.37g, Cr 2 o 3 0.21g, SiO 2 0.15g, TiO 2 0.2g, V 2 o 5 0.03g. Put the weighed powder into a ball mill jar, add alcohol as a medium for planetary ball milling, and mix well for 3 hours. Then dry and pass through an 80-mesh sieve. Add an appropriate amount of 10% PVA for granulation, put it into a tablet press for tablet molding at a pressure of 15 MPa, and then sinter in air at 1350°C for 2 hours to obtain a dense black alumina ceramic body.

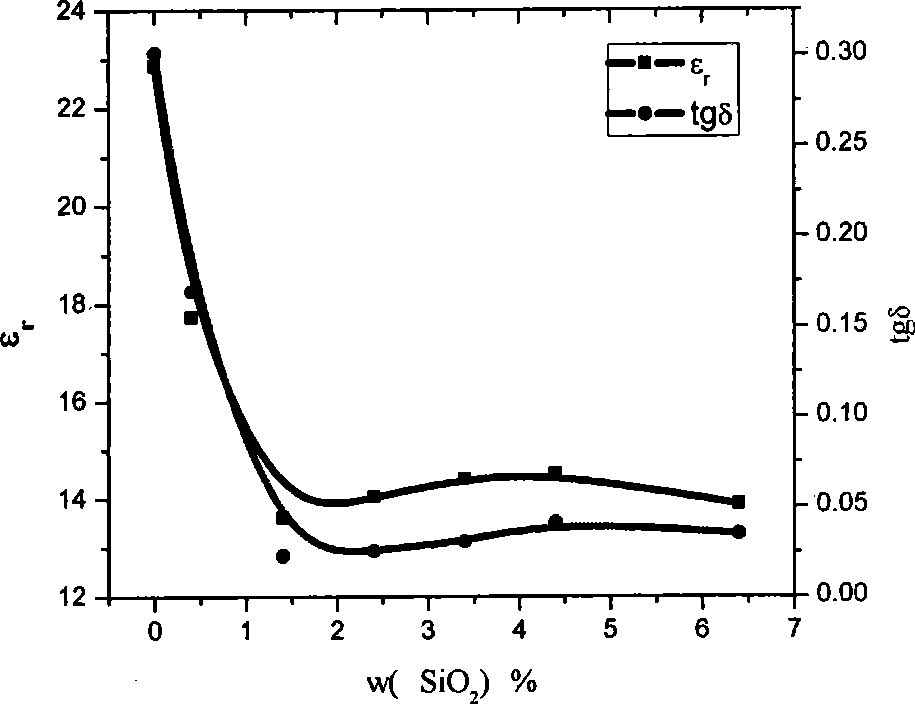

[0046] SiO 2 When the content of SiO is in the range of 0.5wt%-6.5wt%, SiO 2 The addition of black Al 2 o 3 The effect of ceramic porcelain body color is minimal. W(SiO 2 )% = 1.5%, the density of sintered porcelain is 3.78g / cm 3 , the porosity is 0.12%, and the insulation resistivity is 2.5×10 10 Ω.cm, when the frequency is 10kHz, the measured relative permittivity ε r =13.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com