Patents

Literature

113 results about "Black oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Black oxide or blackening is a conversion coating for ferrous materials, stainless steel, copper and copper based alloys, zinc, powdered metals, and silver solder. It is used to add mild corrosion resistance, for appearance and to minimize light reflection. To achieve maximal corrosion resistance the black oxide must be impregnated with oil or wax. One of its advantages over other coatings is its minimal buildup.

Surface treatment process for circuit board

ActiveUS20090191329A1Prevent overflowPrinted circuit aspectsSoldering apparatusEngineeringProtection layer

A surface treatment process for a circuit board is provided. The circuit board includes a substrate, a first circuit layer disposed on an upper surface of the substrate, and a second circuit layer disposed on a lower surface of the substrate. The first circuit layer is electrically connected to the second circuit layer. In the surface treatment process for the circuit board, a first oxidation protection layer and a second oxidation protection layer are respectively formed on a portion of the first circuit layer and a portion of the second circuit layer by immersion. Afterwards, the first circuit layer exposed by the first oxidation protection layer is subjected to black oxidation to form a black oxide layer. The thickness of the first oxidation protection layer is thinner than or equal to the thickness of the black oxide layer.

Owner:ADVANCED SEMICON ENG INC

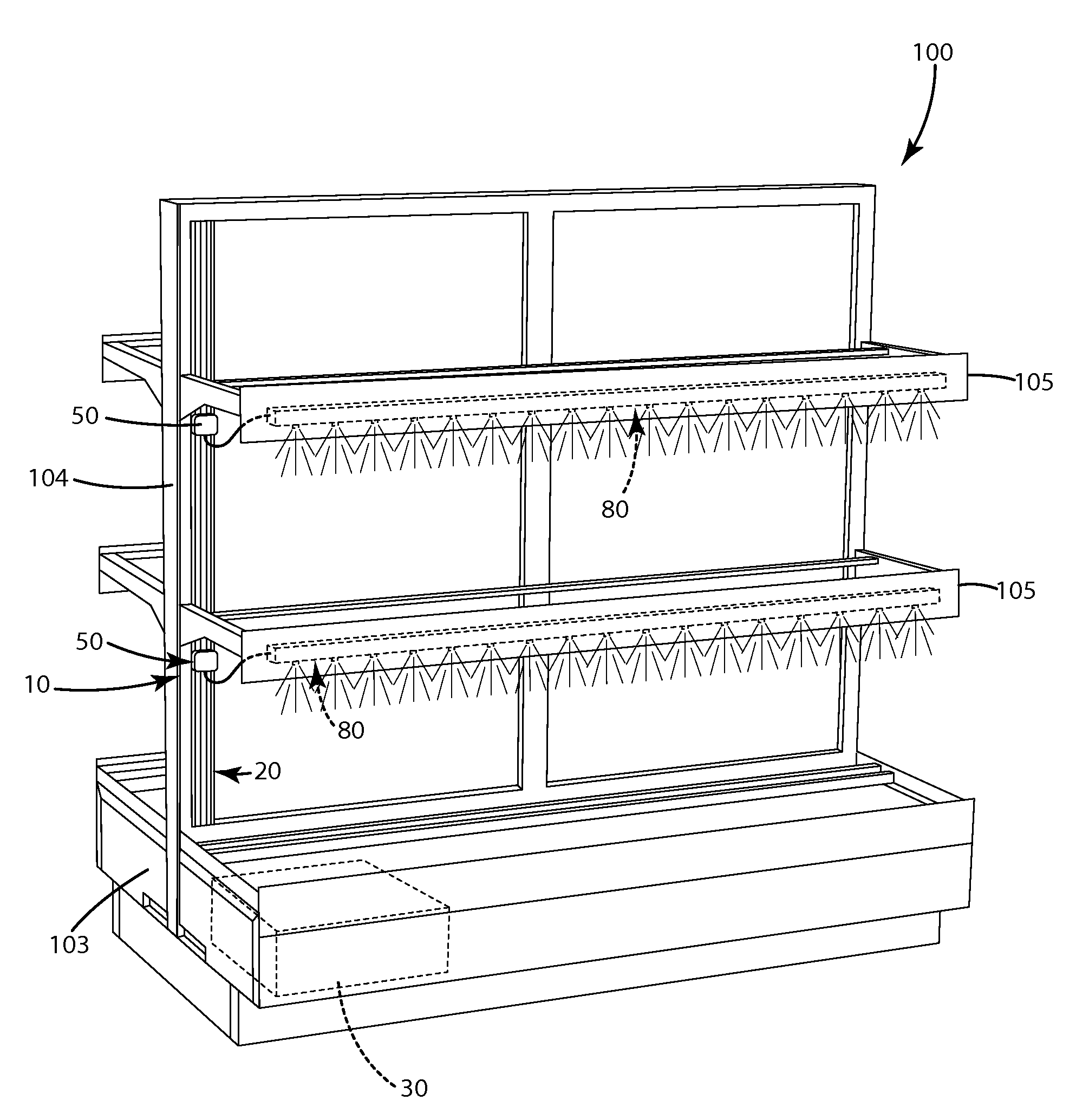

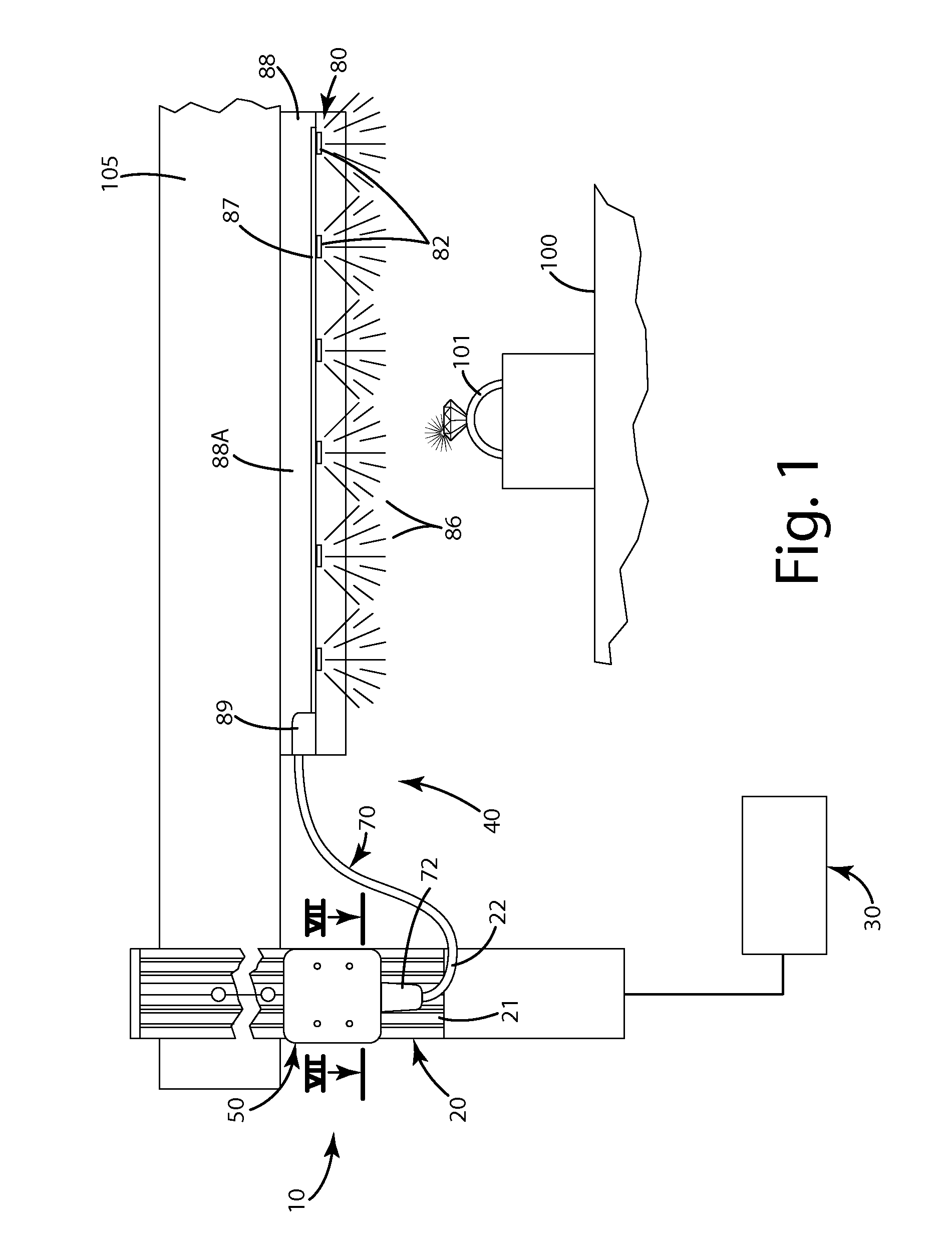

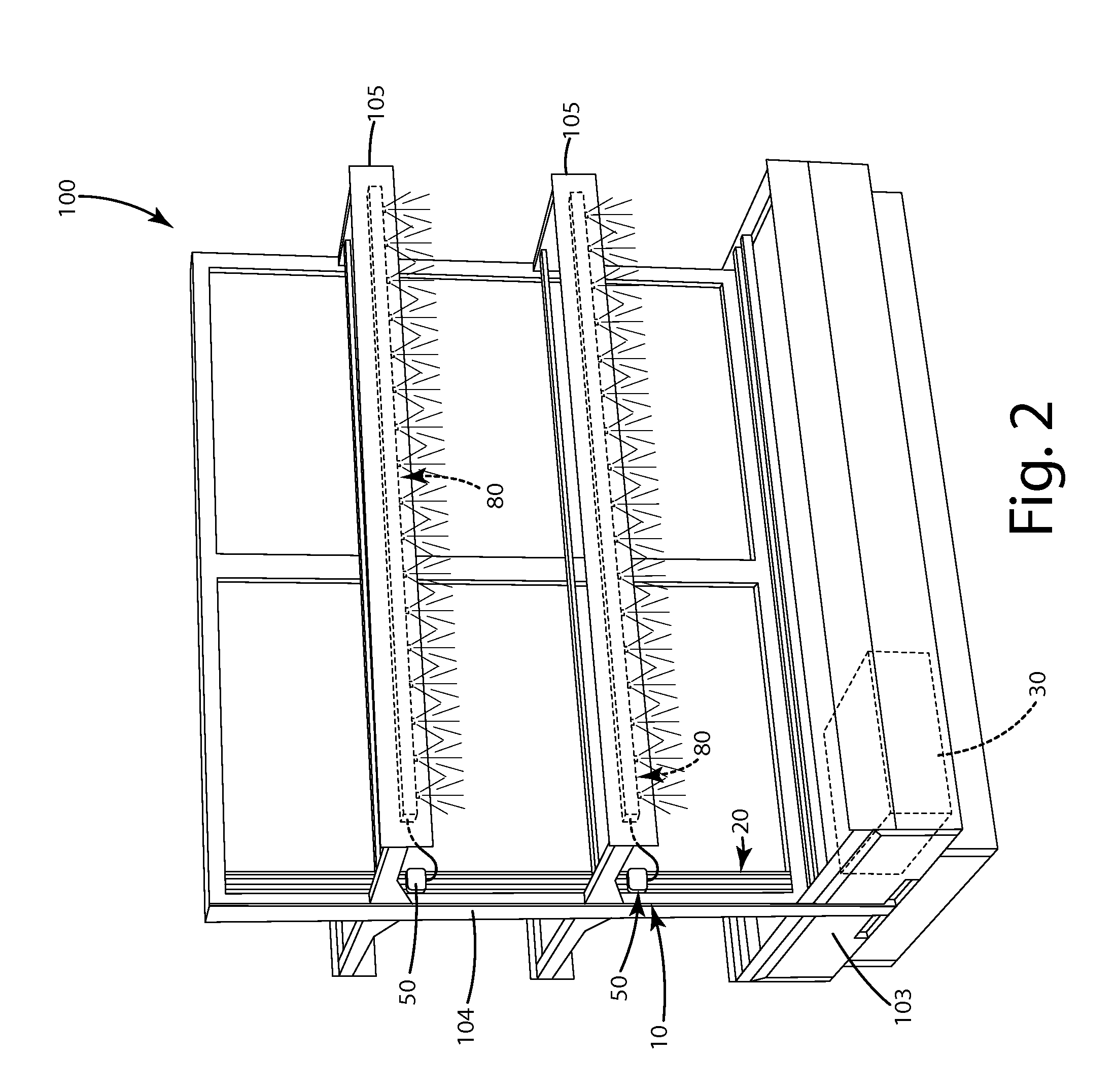

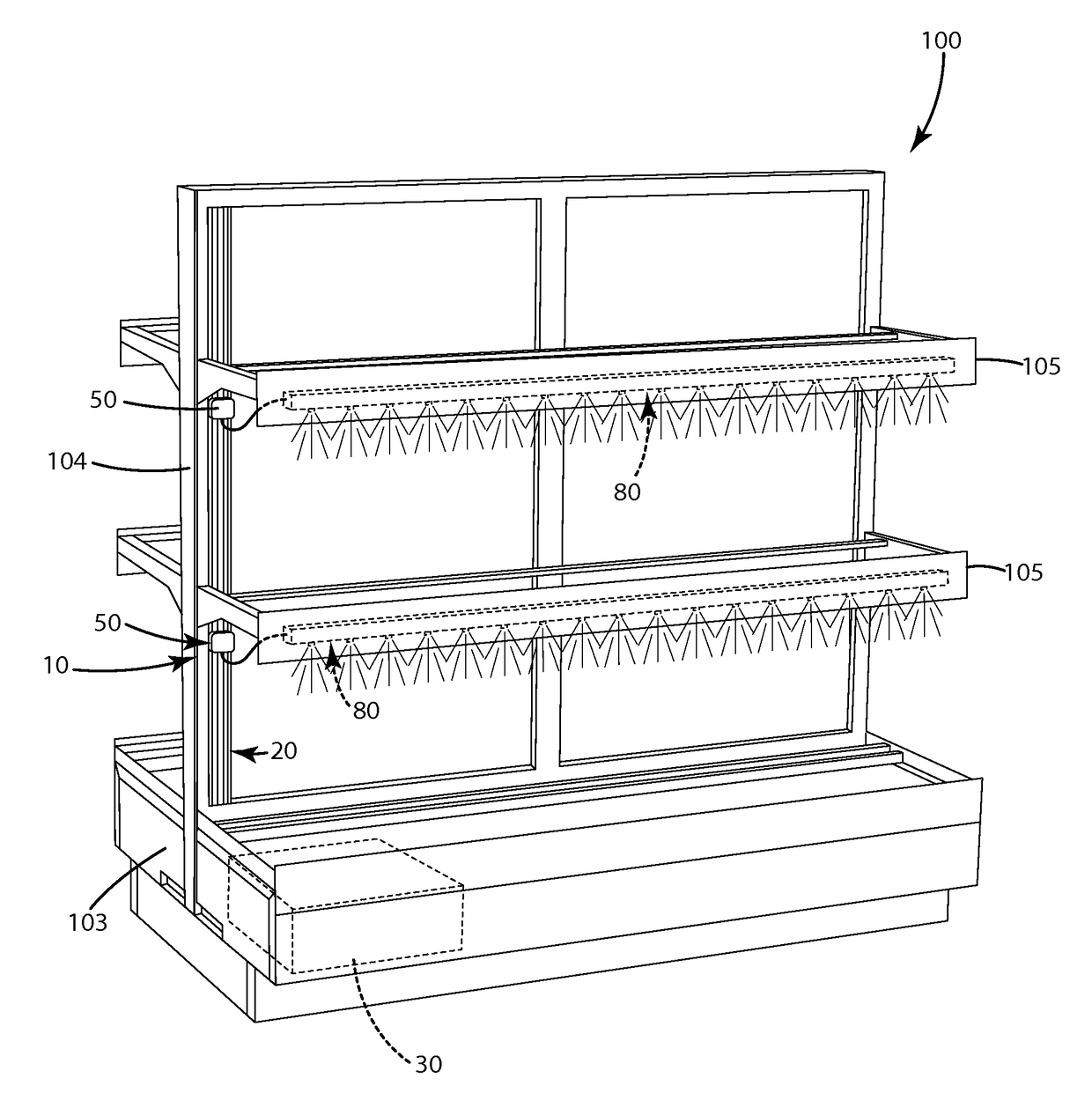

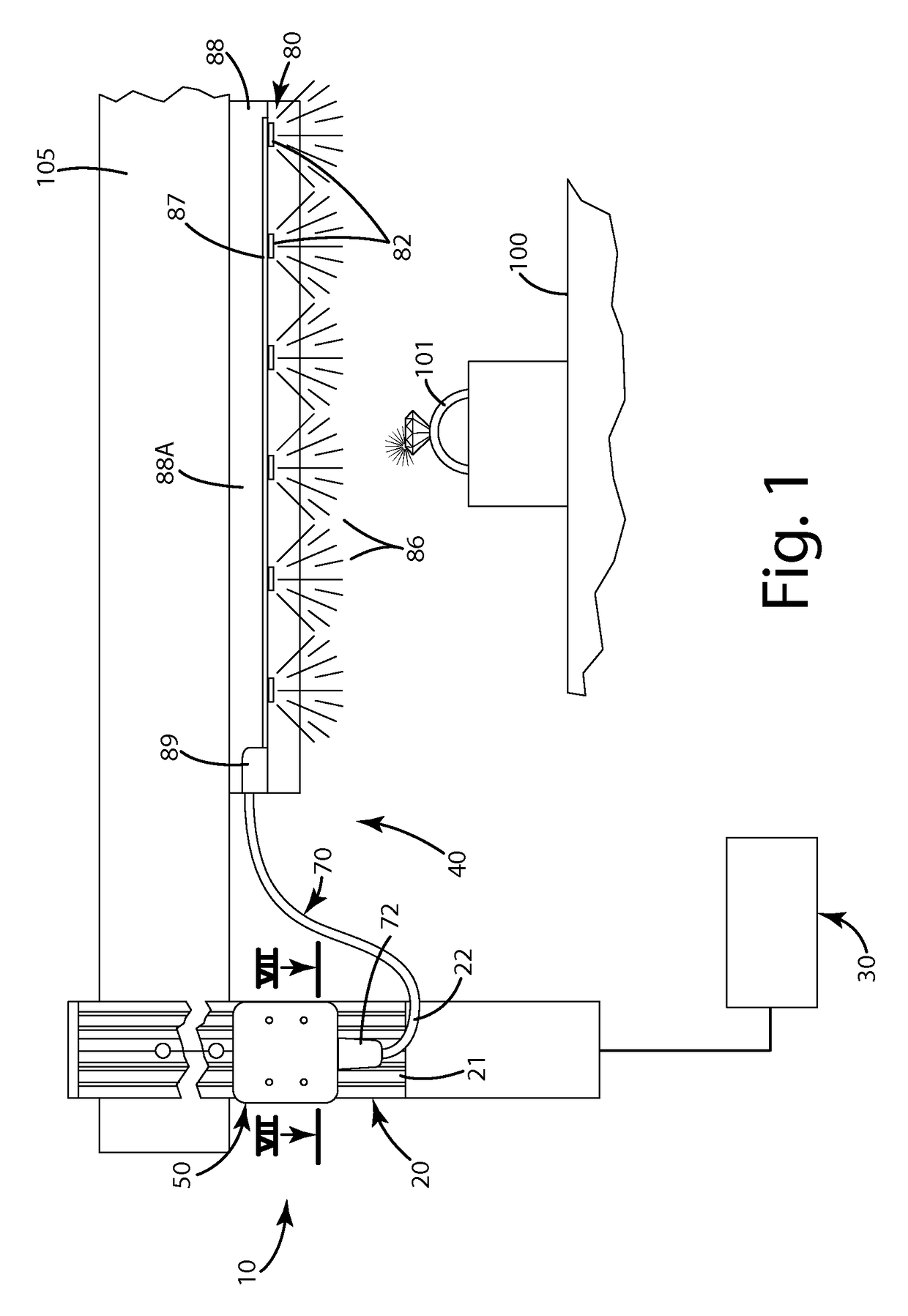

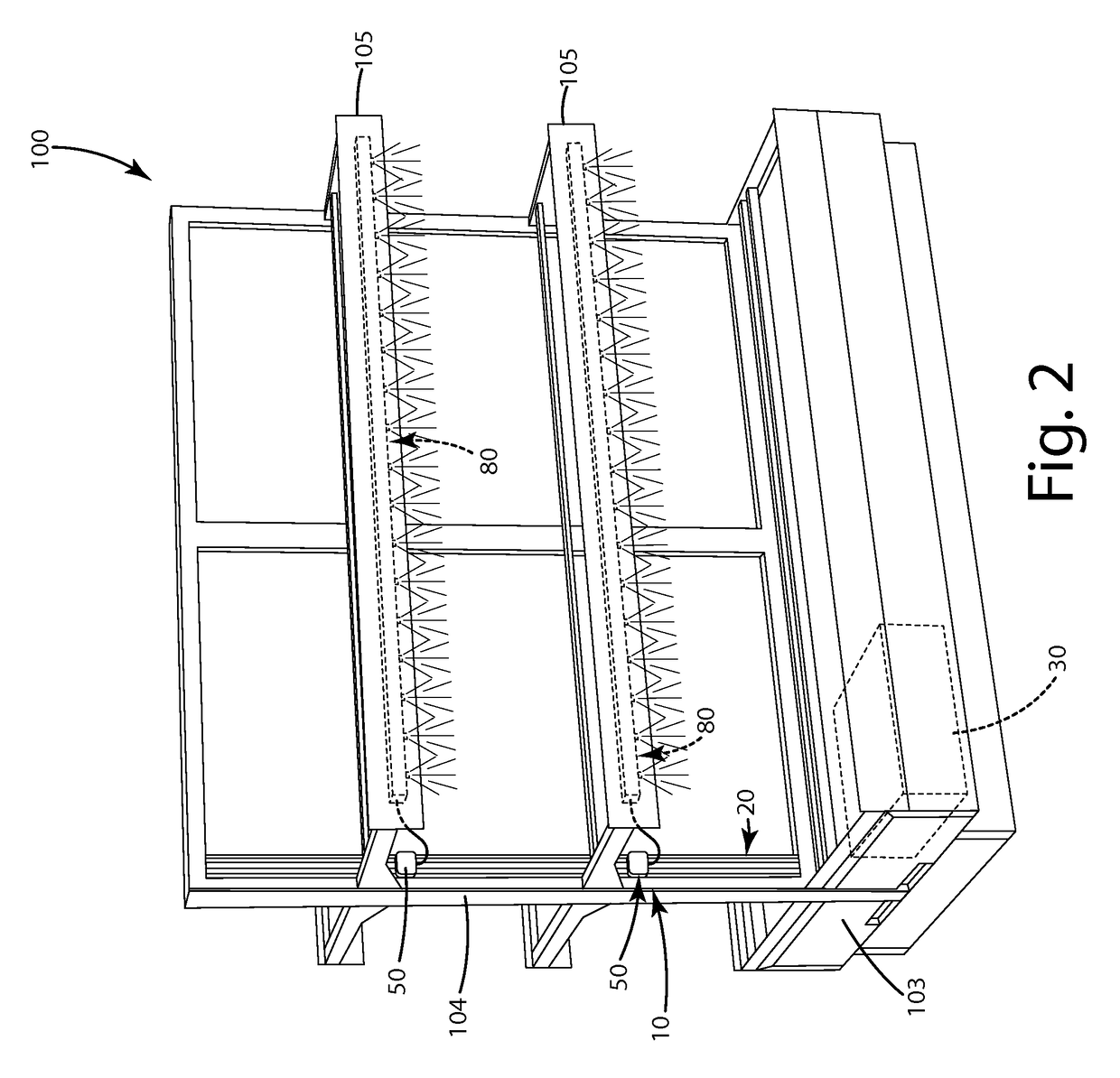

Display lighting system

ActiveUS20160061429A1Reduce orientation errorPrecise positioningMechanical apparatusLighting support devicesElectricityLow voltage

A lighting system including a low voltage frame, a puck magnetically joinable with the frame, a lighting array, and an elongated electrical connector joining the puck and the lighting array. The puck can be selectively positioned along the low voltage frame in a variety of different locations. The puck can be constructed from a polymeric material molded over electrical connectors, and optionally a power feed, such as a cable jack. The electrical connectors can be magnetized so that the electrical connectors are magnetically attracted to power rails on the low voltage frame to establish electrical coupling of the connectors to the power rails, while physically securing the puck in a fixed location along the low voltage frame. The power rails can be constructed from magnetic stainless steel, optionally coated with black oxide from a hot black oxide coating process.

Owner:AMSTORE

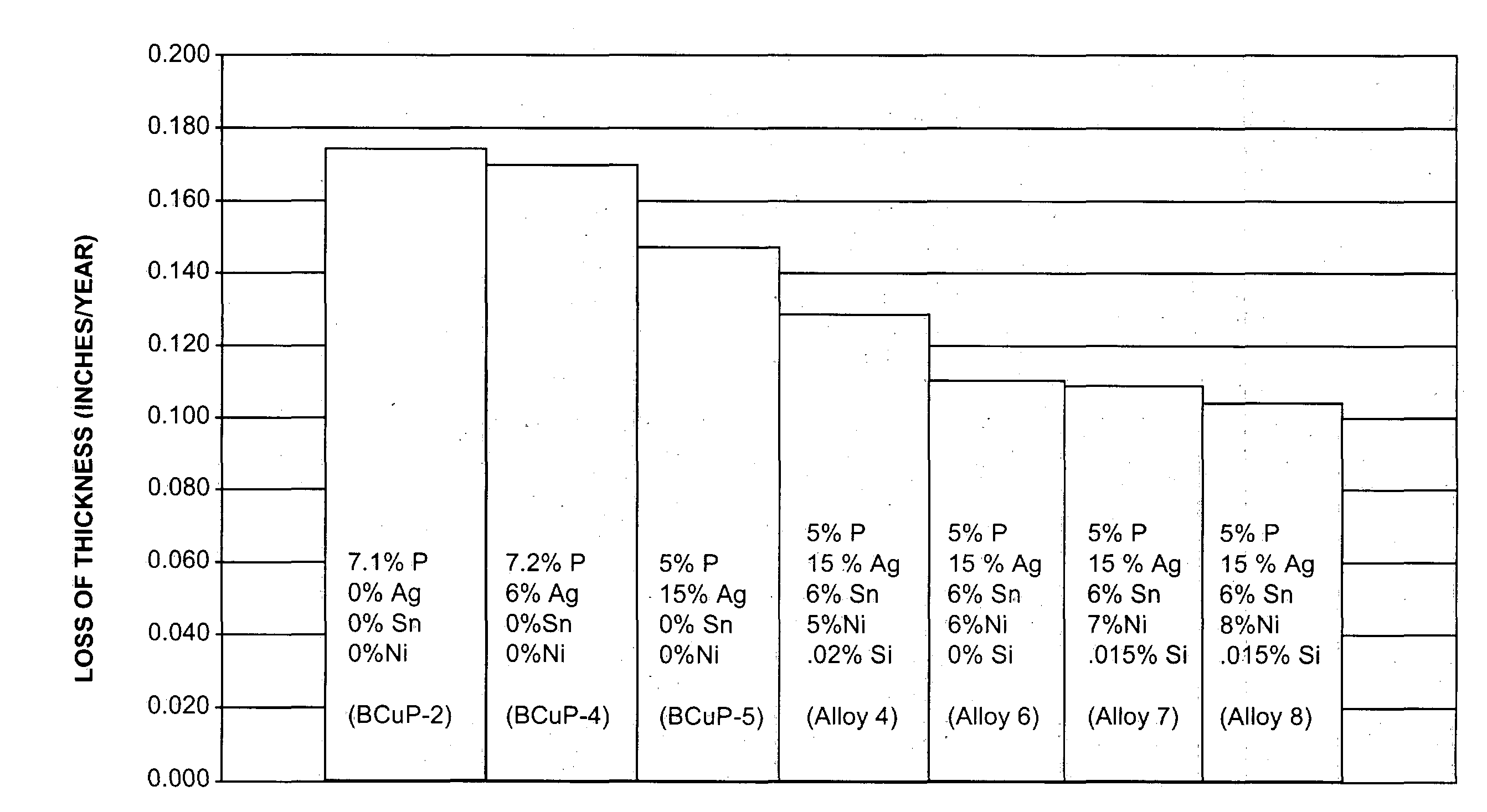

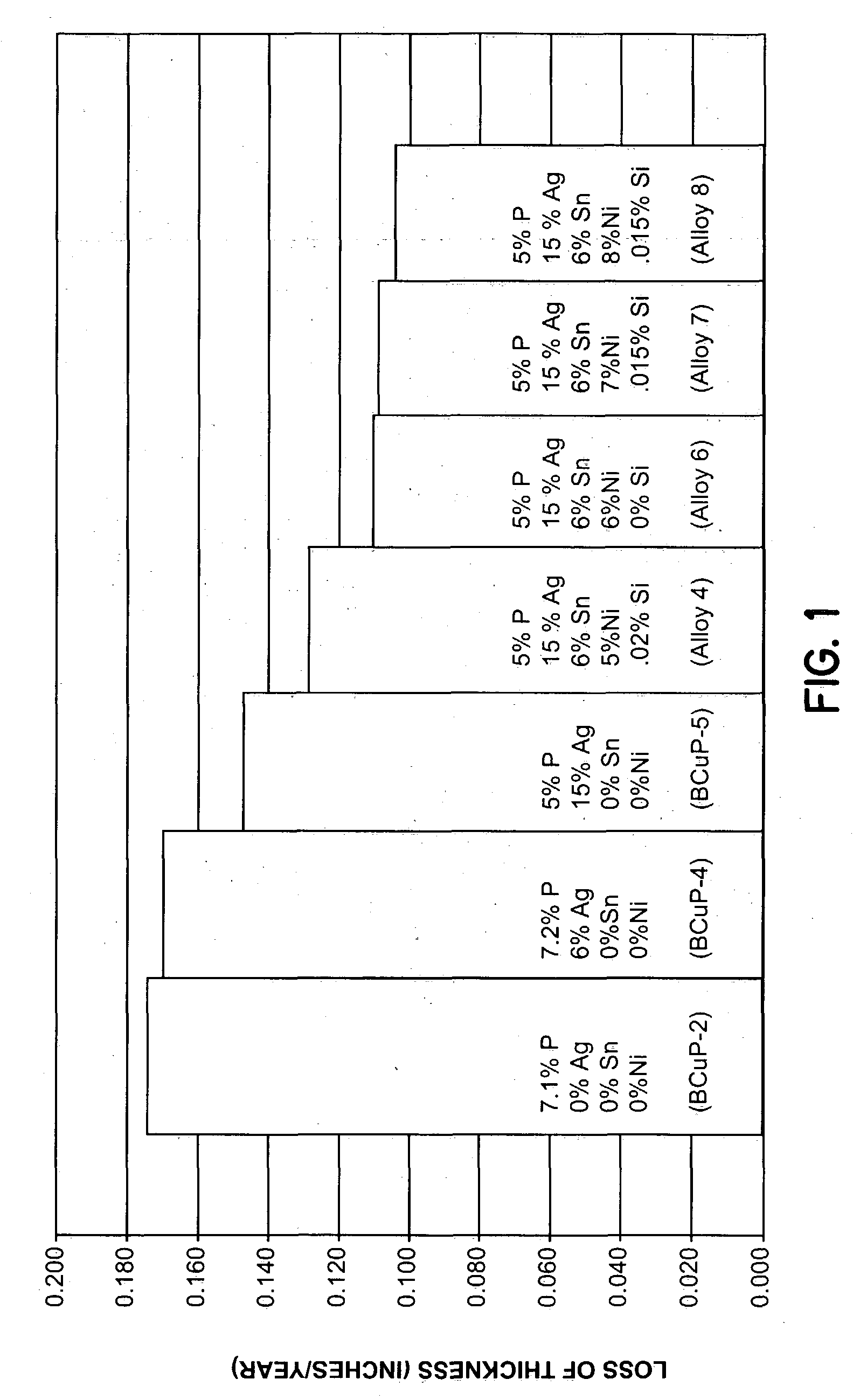

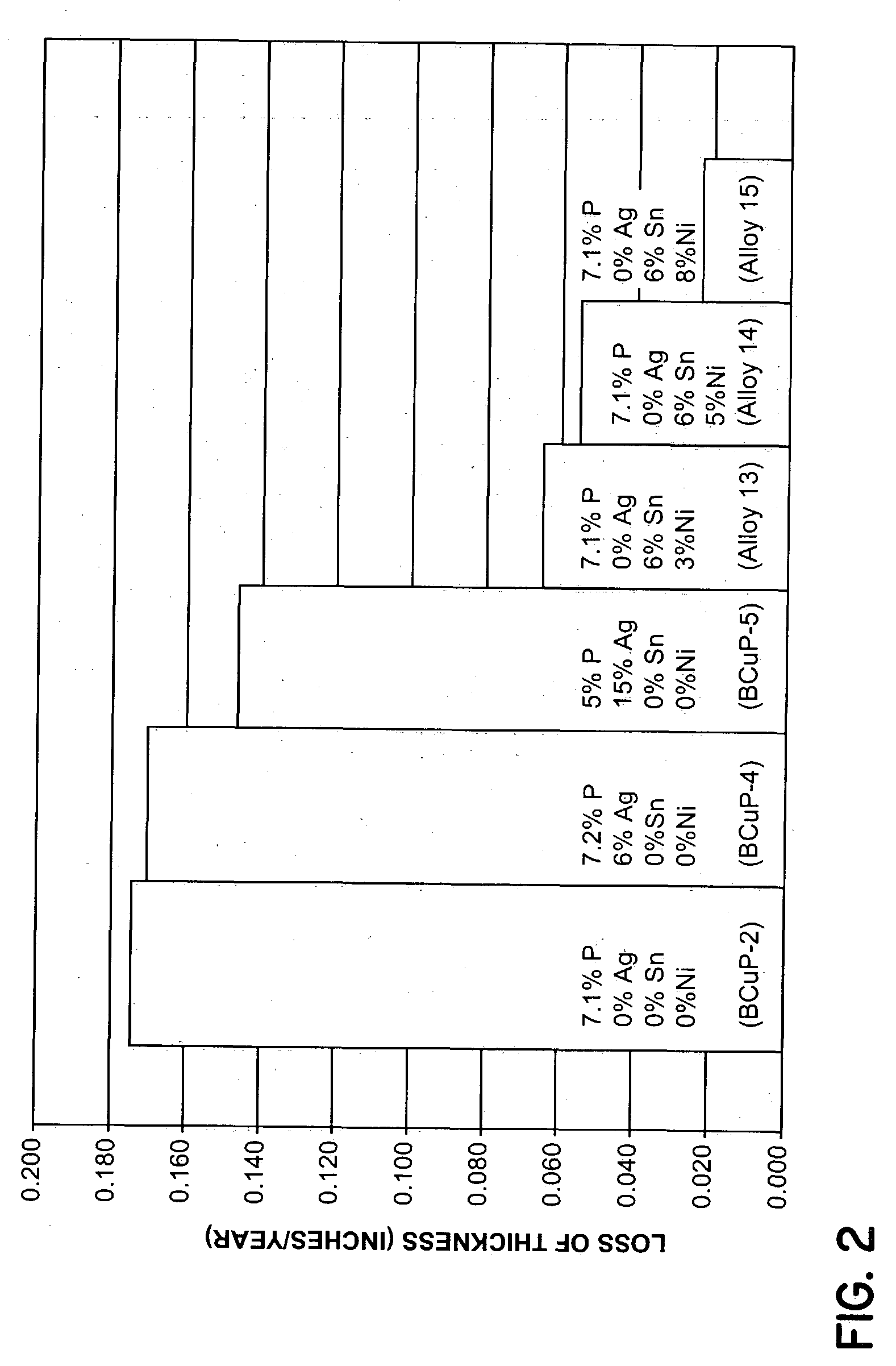

Phosphorous-copper base brazing alloy

InactiveUS20050249629A1Reduces melting rangeHigh hardnessWelding/cutting media/materialsSoldering mediaManganeseBraze alloy

A solid phos-copper base or silver-phos-copper base brazing alloy component for forming a brazed joint with a raised shoulder, little to no black oxide, and improved corrosion resistance. The brazing alloys of the present invention are visually distinguishable from copper and copper alloy parts. The solid brazing components of the present invention may be used in forming brazed joints at low brazing temperatures and result in a joint that is strong, ductile, smooth and corrosion resistant. The solid brazing components are provided in the form of wire, strip, foil or preform, and thus are advantageously used in a wide variety of brazing applications including copper tubing. The brazing components of the present invention are made of an alloy having a liquidus temperature above 840° F. and consist essentially of about 4-9% phosphorus, about 0.1-10% tin, up to about 4% antimony, about 0.1-15% nickel, up to about 3% silicon, up to about 18% silver, up to about 3% manganese, with the balance being copper. Exemplary embodiments include about 6-15% silver and / or 5-8% nickel.

Owner:LINCOLN GLOBAL INC

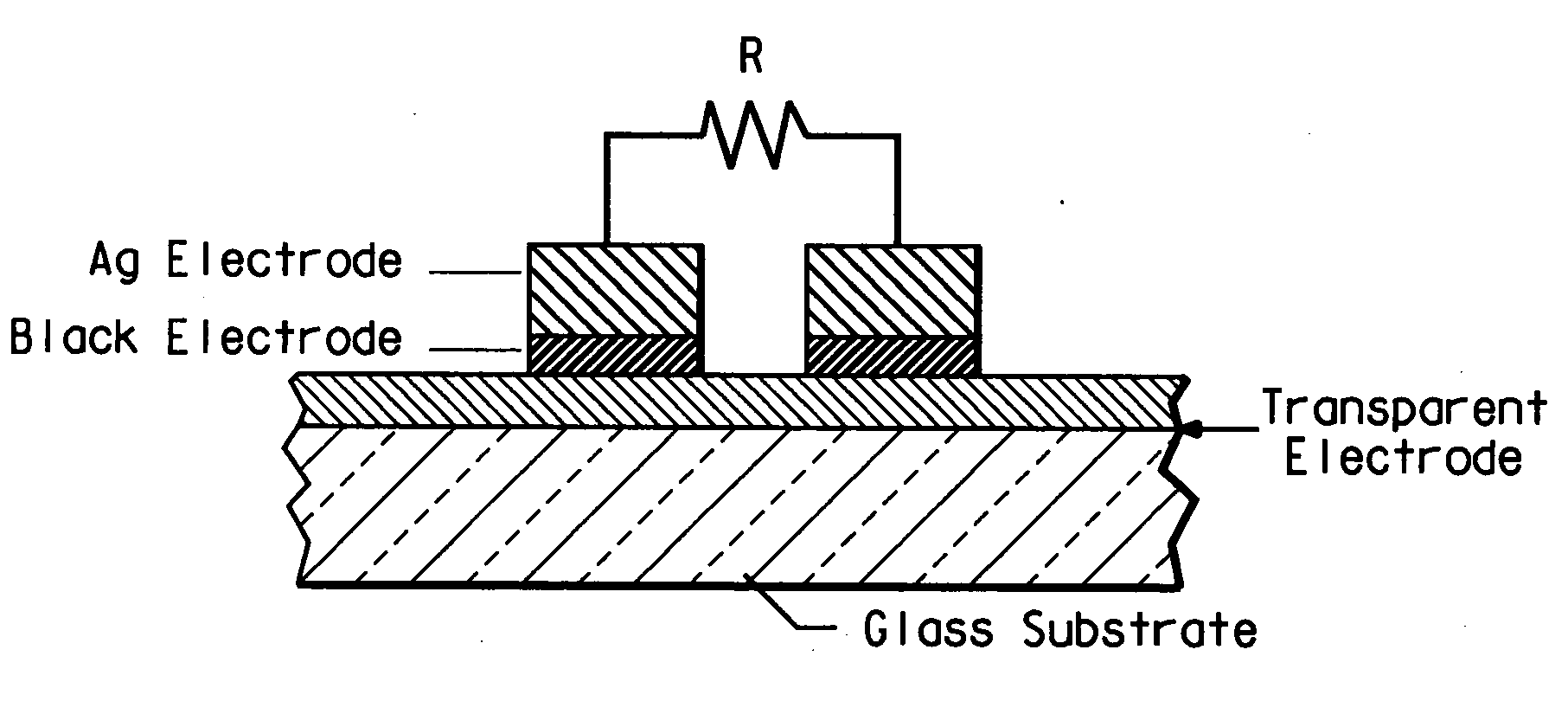

Black conductive thick film compositions, black electrodes, and methods of forming thereof

The present invention provides a method for forming a black electrode by performing sintering at a temperature in the range of 500-600° C. after applying a lead-free black conductive composition to a substrate. The aforementioned black electrode comprises a binder comprising a crystallized glass component. The aforementioned black conductive composition comprises conductive particles of black RuO2, lead-free black ruthenium-based polyoxide, and mixtures thereof in an amount of 4-30 wt %, based on the total weight of the composition, a lead-free non-conductive black oxide in an amount of 0-30 wt %, based on the total weight of the composition, and a lead-free bismuth-based glass binder in an amount of 10-50 wt %, based on the total weight of the composition.

Owner:EI DU PONT DE NEMOURS & CO

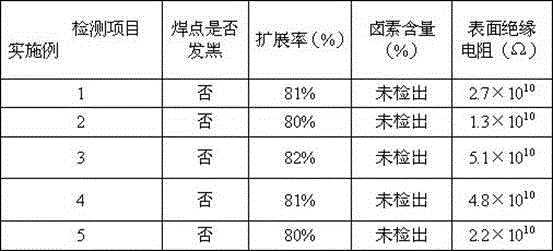

Halogen-free soldering agent for tin bismuth system unleaded tin paste and preparation method thereof

ActiveCN104858571ASolder joints are less corrosiveHigh surface insulationWelding/cutting media/materialsSoldering mediaActive agentEthyl group

The invention provides a halogen-free soldering agent for tin bismuth system unleaded tin paste and a preparation method thereof. The halogen-free soldering agent for the tin bismuth system unleaded tin paste consists of 20-47% of rosin, 8-20% of thickening agent, 0.5-12% of antioxidant, 4-15% of organic acid, 0.2-3% of ethylhexyl isocaprylic acid, 6-14% of organic amine, 0.5-8% of surface active agent,4-10% of thixotropic agent and the balance solvent. By optimizing selection of an active system of the soldering agent, the halogen-free soldering agent for the tin bismuth system unleaded tin paste enables the tin paste prepared from the halogen-free soldering agent for the tin bismuth system unleaded tin paste and tin bismuth system unleaded tin powder to not only contain no halogen element such as fluorine, chlorine, bromine, iodine and astatine, but also have good welding ability in soldering, and then generates full and bright soldering spots, does not generate black oxides, and is high in surface insulation resistance after the soldering, and is specially suitable for assembly welding of electronic parts and components, which require low soldering temperature.

Owner:深圳市同方电子新材料有限公司 +1

Composite black oxide particle, method for producing same, black coating material and black matrix

InactiveUS20070128438A1Good blacknessIncrease resistancePigmenting treatmentMolten spray coatingManganeseCopper

Disclosed is a composite black oxide particle which is composed of oxide of cobalt, copper and manganese. The copper / cobalt molar ratio is 0.1-0.5, and the manganese / cobalt molar ratio is 0.2-1.0. The composite black oxide particle further contains silicon, and the silicon content to the total oxide particle is 0.1-3 mass %. The surface of the composite black oxide particle is coated with aluminum oxide. The Al content in the surface coating to the entire particle is 0.05-3 mass %.

Owner:MITSUI MINING & SMELTING CO LTD

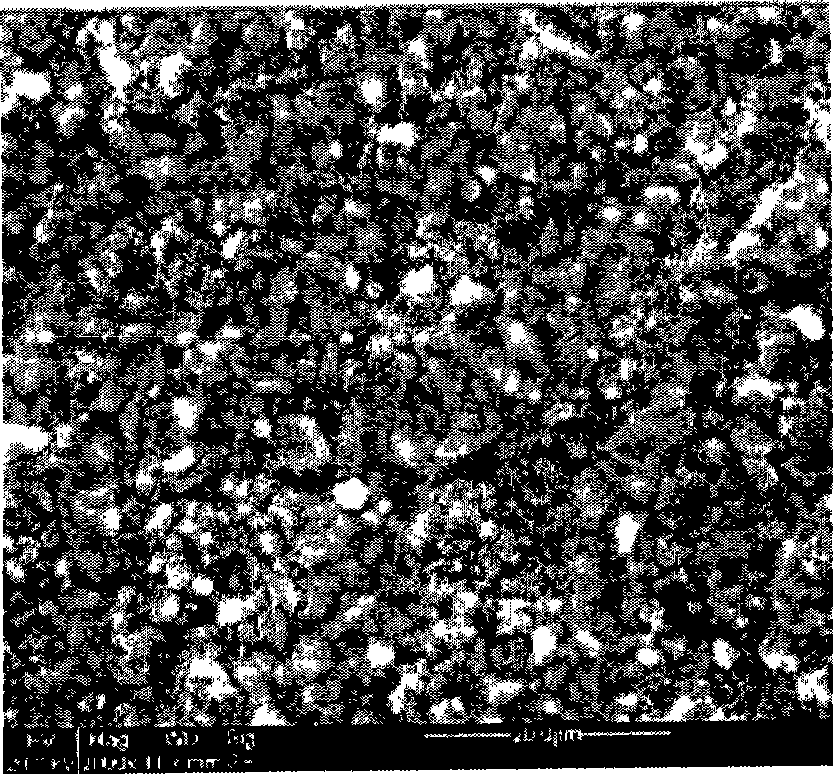

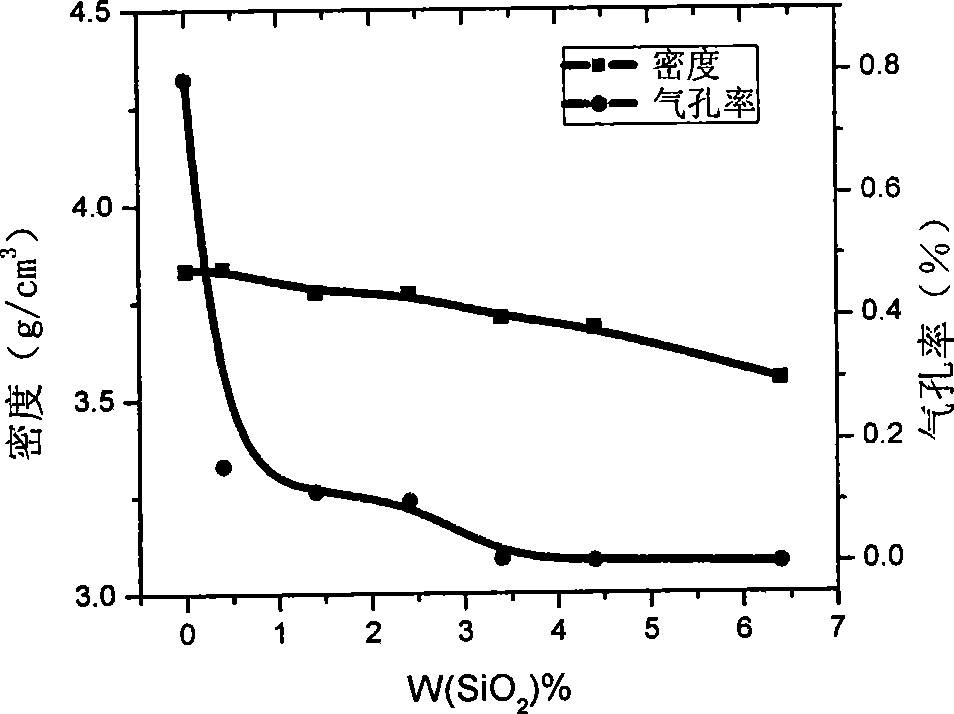

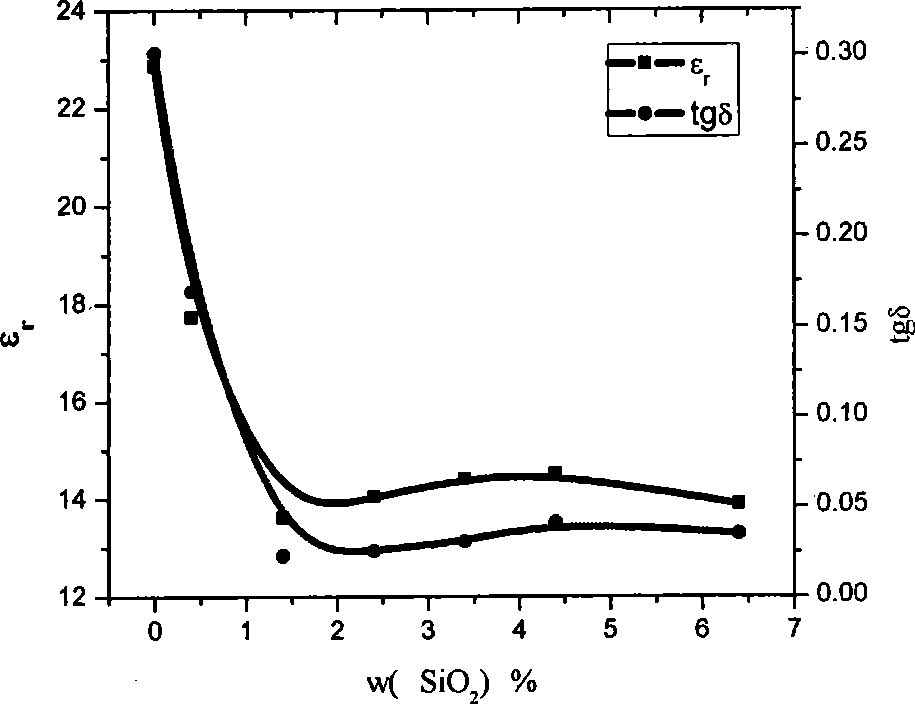

Preparation of black alumina substrate for multilayered wiring

InactiveCN101483417ALower sintering temperatureLower firing temperatureImpedence networksBasal laminaPlasticizer

The present invention discloses a method for preparing material of black alumina substrate used in multilayer wiring, namely adopts solid phase method, adds elements of Co, Mn, Cr, Si, Ti, B, V etc. into principal crystalline phase Al2O3 powder, modify oxide of alumina through adulterating, which recedes firing temperature, and brings out a black oxide of alumina organic doctor-blade casting method on the basis of modified powder, selects doctor-blade casting agent, double solvent and composite plasticizer that suitable for oxide of alumina; uniform and stable slurry with high solid content is obtained, bisque forming quality is enhanced; use doctor blade method for tape-casting, equipment simple and operational, natural drying process convenient, drying process will not lead rupture of billet body and phenomenon of unable stripping; obtained film body compact, and use mechanical drilling method to prepare stack basal lamina and obtain black alumina substrate used in multilayer wiring.

Owner:HUAZHONG UNIV OF SCI & TECH

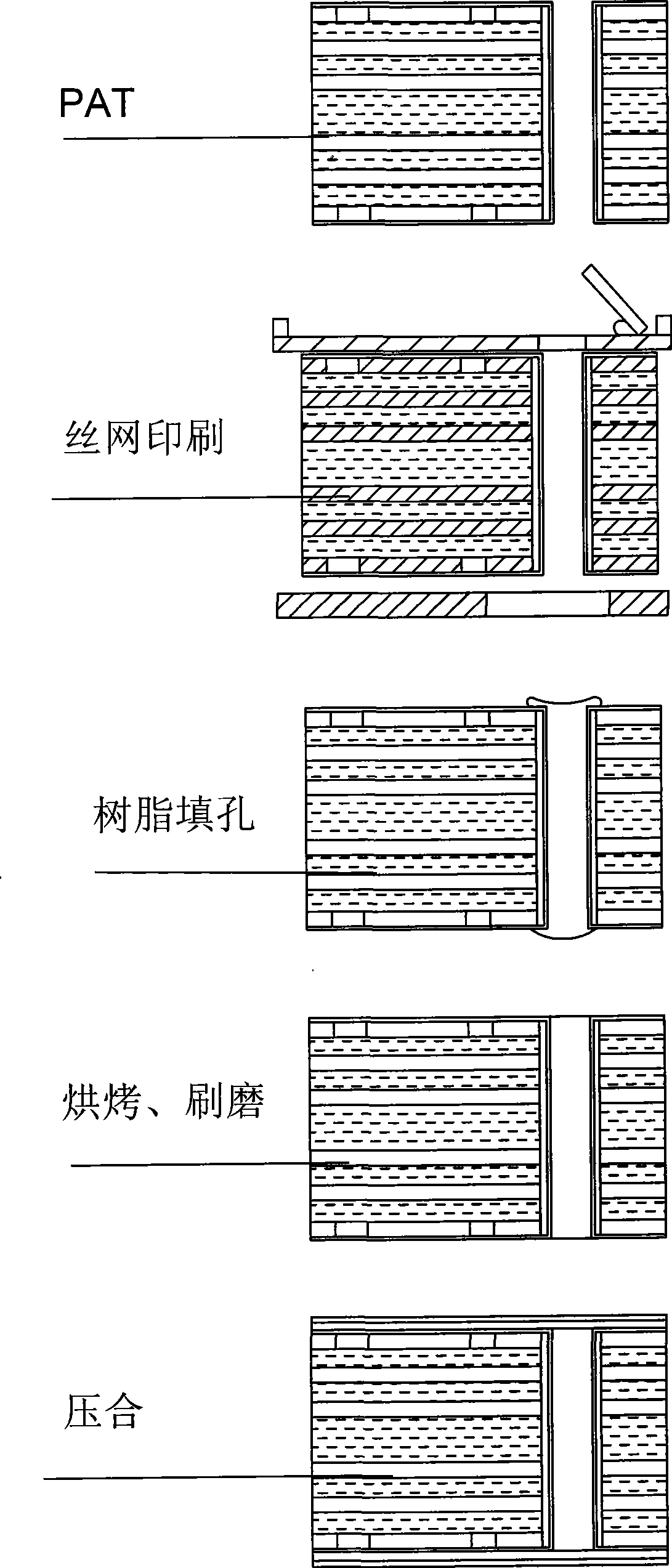

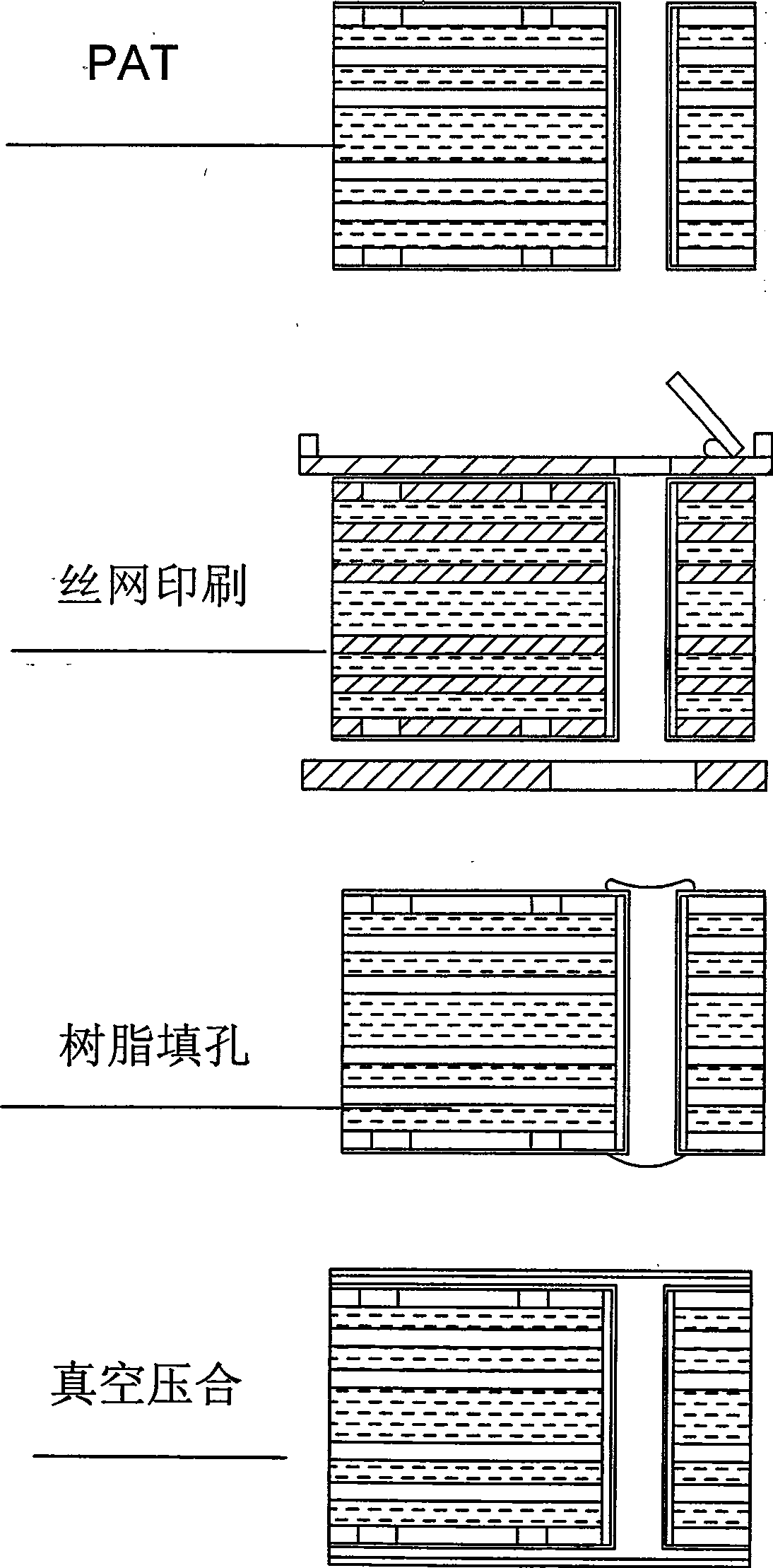

Process for blind hole, buried hole, and filled hole of multi-layered high density interconnected printed circuit board

InactiveCN101478862AShorten production timeShorten production hoursMultilayer circuit manufacturePrinted element electric connection formationScreen printingHigh density

The invention relates to a blind hole, buried hole, and porefilling craft for a multi-layer high-density interconnect printed circuit board, which is characterized in that the blind hole, buried hole, and porefilling craft for a multi-layer high-density interconnect printed circuit board firstly generates even brick red or black oxide layer on the copper surface of a printed circuit board provided with bores utilizing liquid medicine; with roughness of the generated oxide layer, the oxide layer can be closely connected with an adhesive tablet and can avoid an influence on reliability of the product from the surface of pig copper and cuprous chloride formed by a pressing high temperature reaction; then a traditional screen printing is carried out. The craft is characterized in that resin is filled into an appointed hole and laminating of the adhesive tablet is carried out within a time limit, then a vacuum compressing craft is carried out. The blind hole, buried hole, and porefilling craft for a multi-layer high-density interconnect printed circuit board can shorten the production labor hour and improve productivity.

Owner:HONGYUAN TECH HANGZHOU

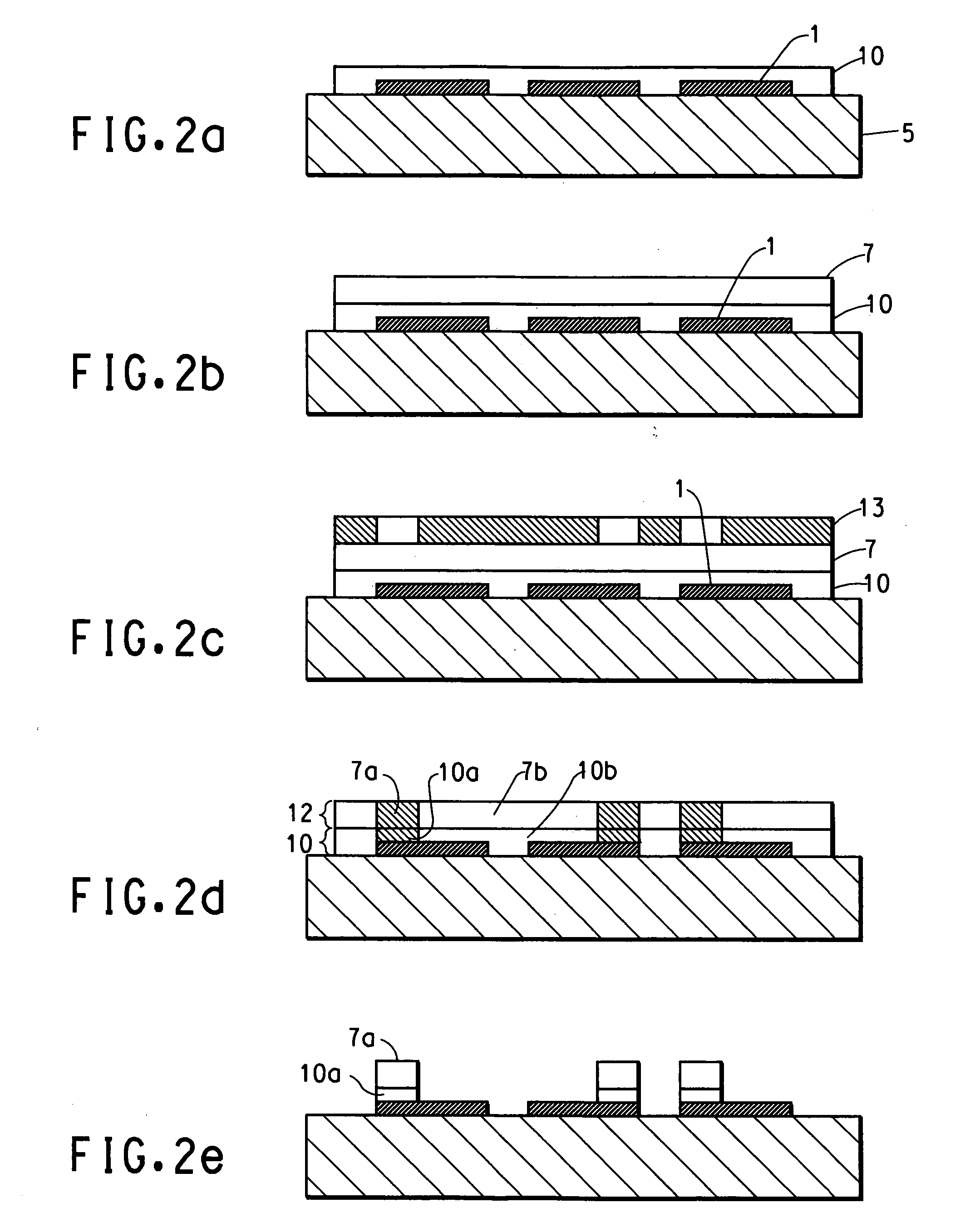

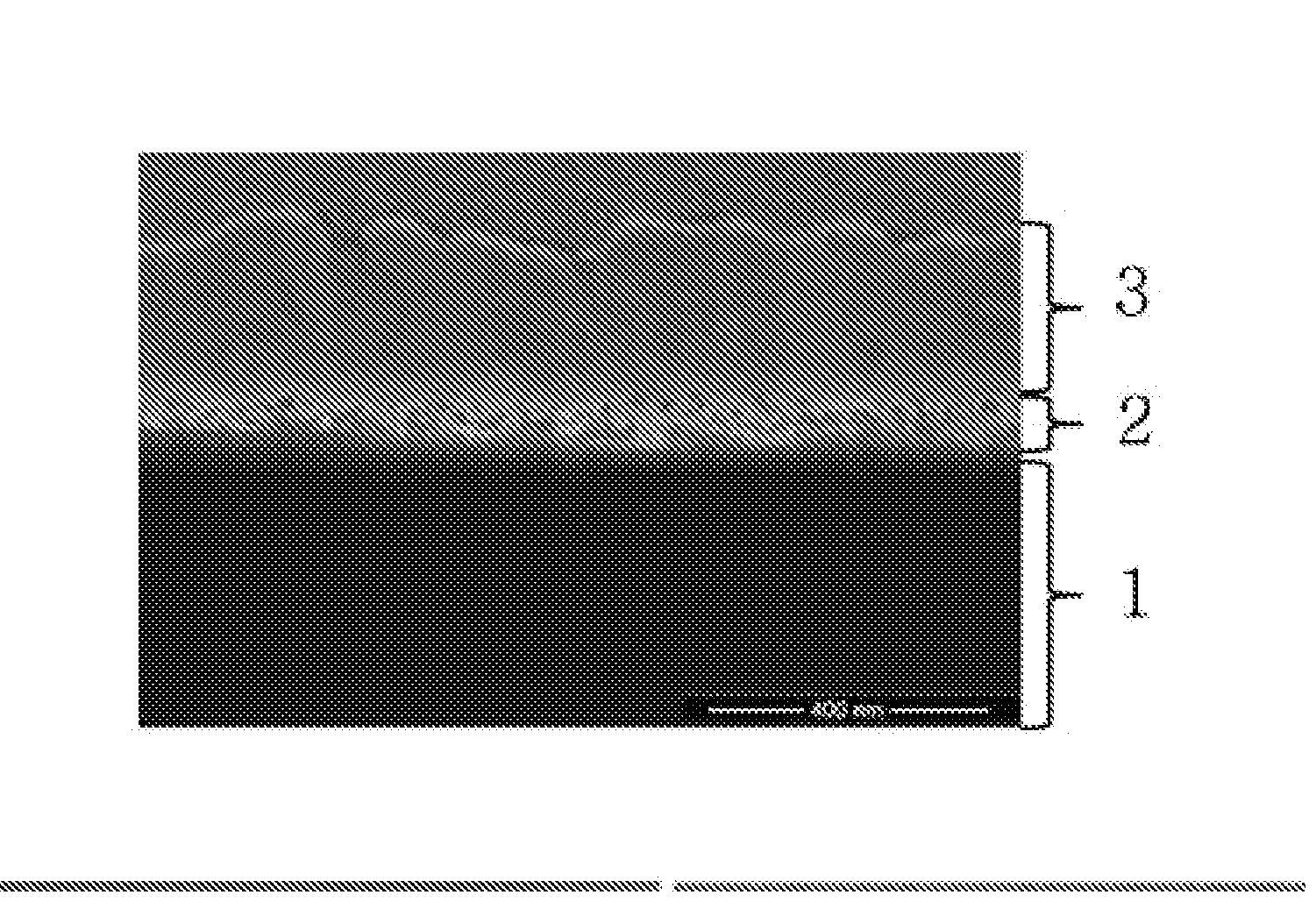

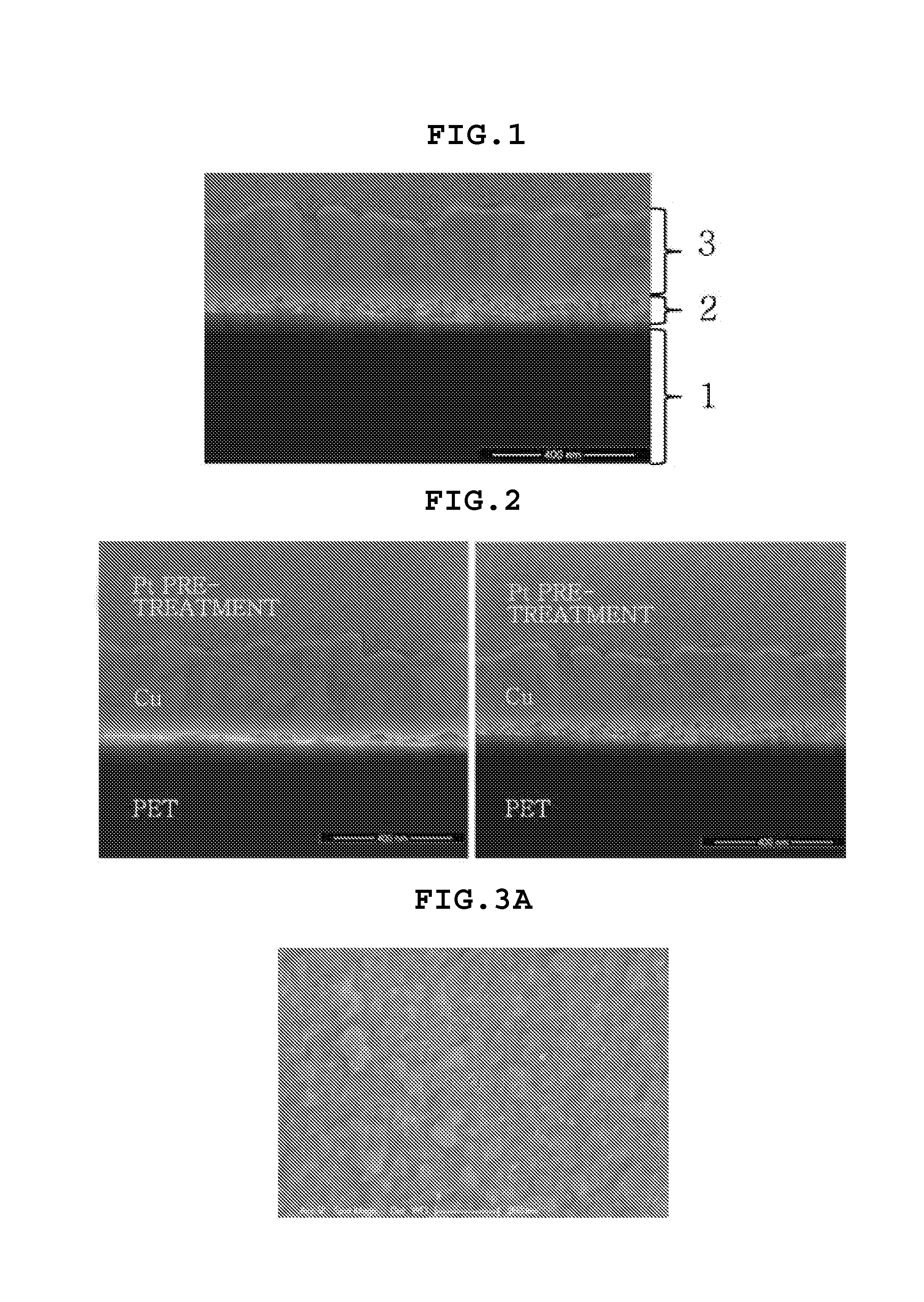

Insulating base plated with metal layer, plating method thereof, and transparent electrode including insulating base

InactiveUS20140017508A1Improve adhesionLiquid/solution decomposition chemical coatingSupporting insulatorsInterface layerElectroplating

Disclosed herein are an insulating base plated with a metal layer, a plating method thereof, and a transparent electrode including the insulating base. During the manufacture of a polymer layer, a structure of an interface layer between a surface of the polymer layer and a metal layer is modified, adhesion with metal is excellent and the polishability of the interface layer is reduced, and thus, the reflectivity of the metal layer is reduced and particular color impression of metal is reduced to obtain black-oxide treated properties. When the metal layer formed on the insulating base is used in a mesh-type transparent electrode having a fine pattern, sufficient adhesion with metal for forming a pattern is obtained and the reflectivity of an adhesion layer of the metal layer is reduced, thereby increasing the visibility. Accordingly, the insulating base may be suitable for products such as transparent electrodes or touch panels.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Technique for manufacturing vehicle door bonnet lock nut plate

The invention discloses a manufacturing process of a lock nut panel for a vehicle door. The lock nut panel is a baseplate provided with two lug bosses, each lug boss is provided with a screw hole, and the baseplate is provided with a hem and two square holes; and the lock catch nut panel for a front door uses Type 45 steel. The manufacturing process comprises the following steps: feeding sheet materials, stretching 1, stretching 2, stretching 3, stretching 4, stretching 5, molding, punching, shaping, ripping edges, punching the square holes, folding the hem, grinding the platform, tapping thread, quenching, tempering in low temperature and black oxide coating. By adopting the structure, the invention ensures the quality of components and the security of the whole vehicle, avoids the problem of high scrap rate of components due to instable quality, and effectively saves the cost.

Owner:SAIC MOTOR

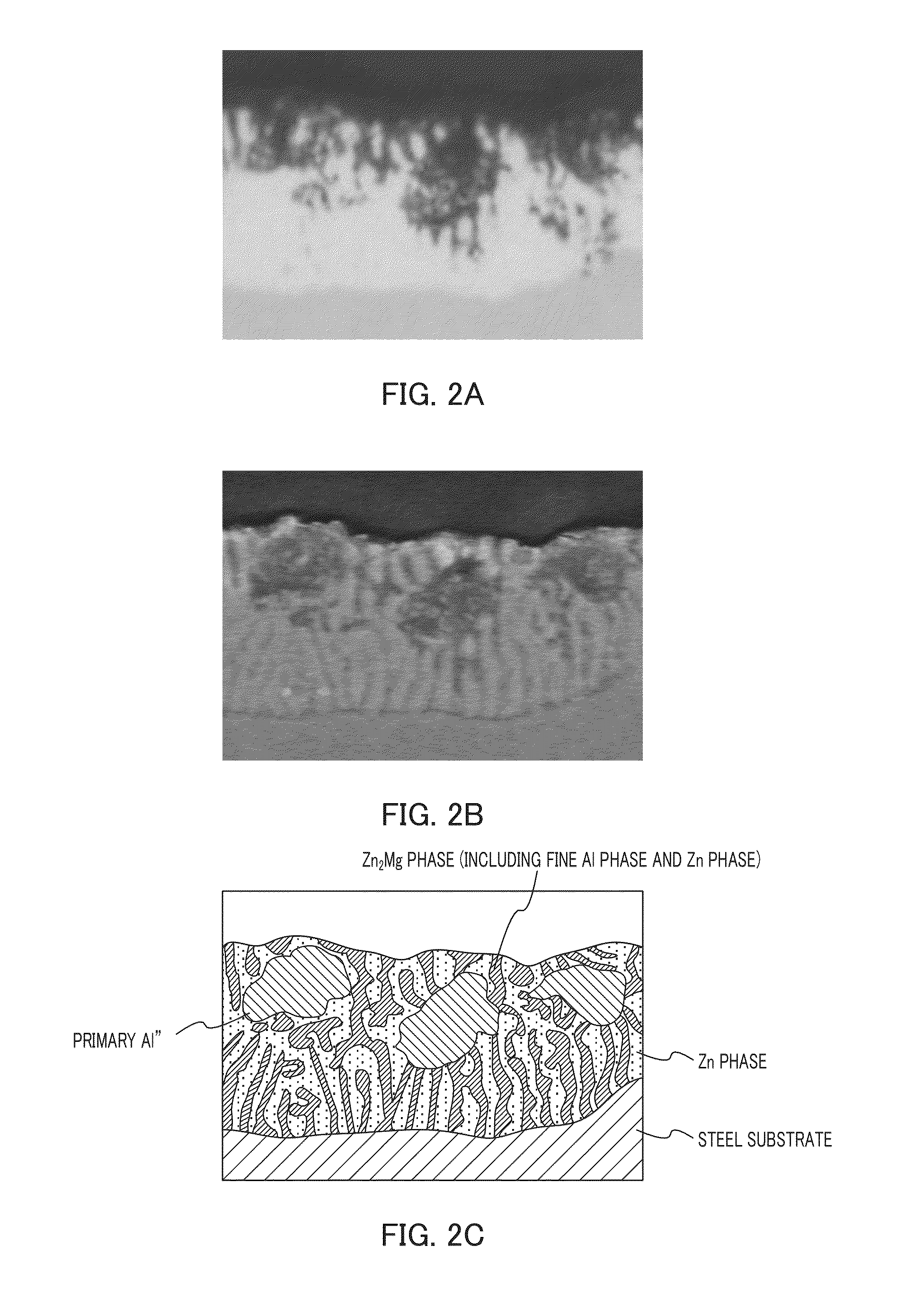

Black-plated steel sheet

A black-plated steel sheet has a Zn-plating layer containing molten Al and Mg, containing Al in the amount of 1.0-22.0 mass %, containing Mg in the amount of 1.3-10.0 mass %, and having a Zn black oxide distributed in a lamella pattern in the plating layer. The Zn black oxide is a Zn oxide derived from a Zn2Mg phase. The brightness of the surface of the Zn-plating layer containing the molten Al and Mg has an L* value of 60 or less.

Owner:NISSHIN STEEL CO LTD

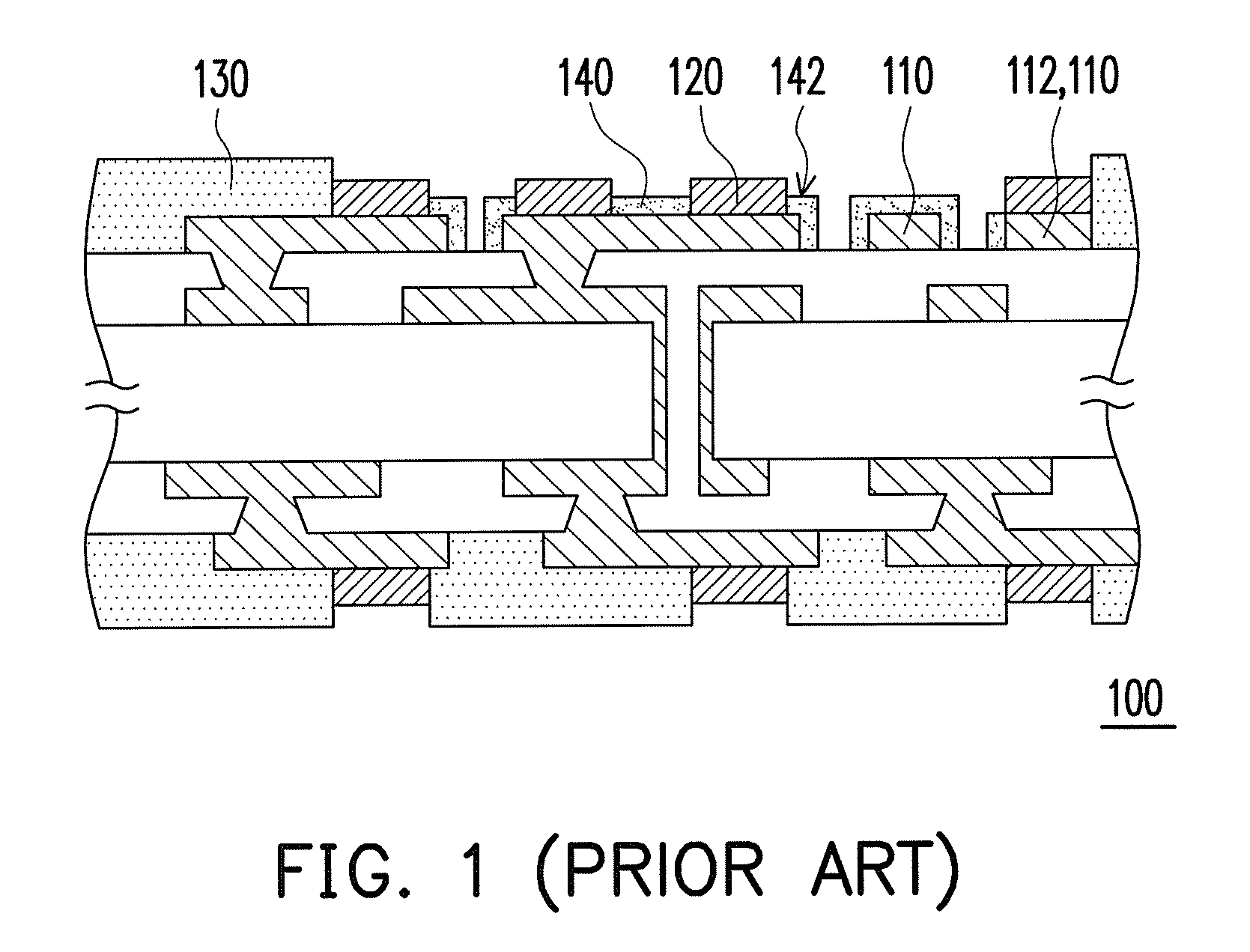

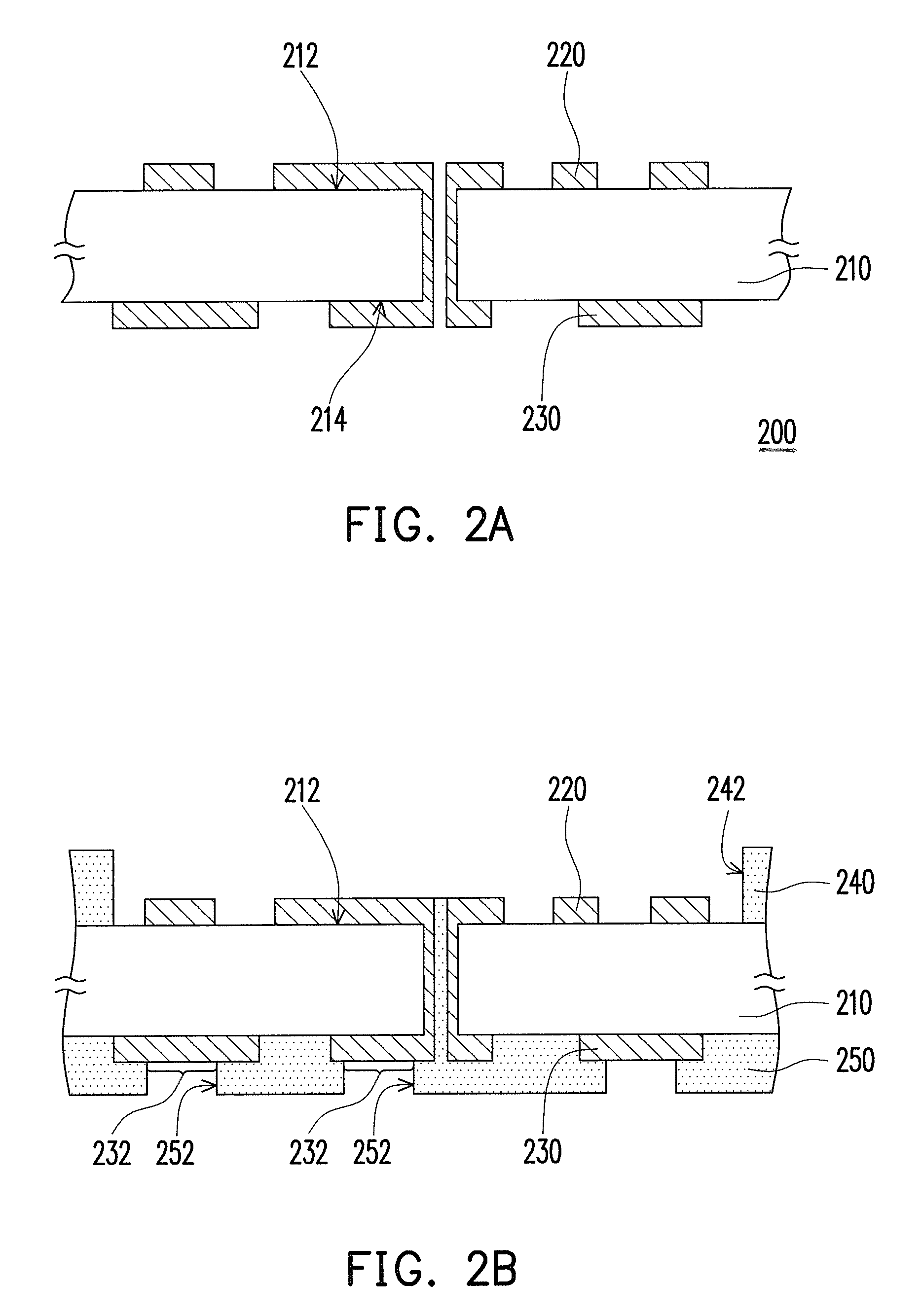

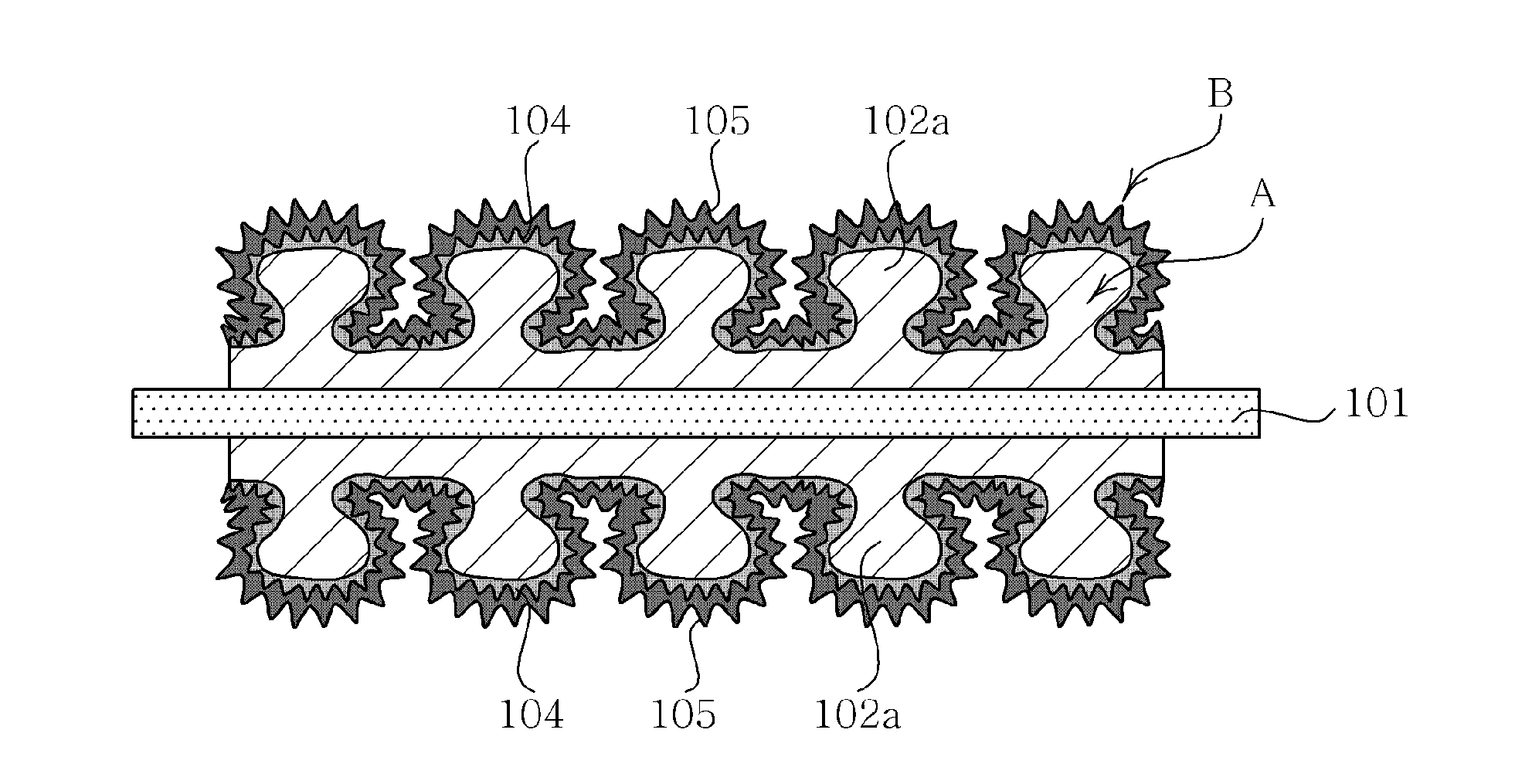

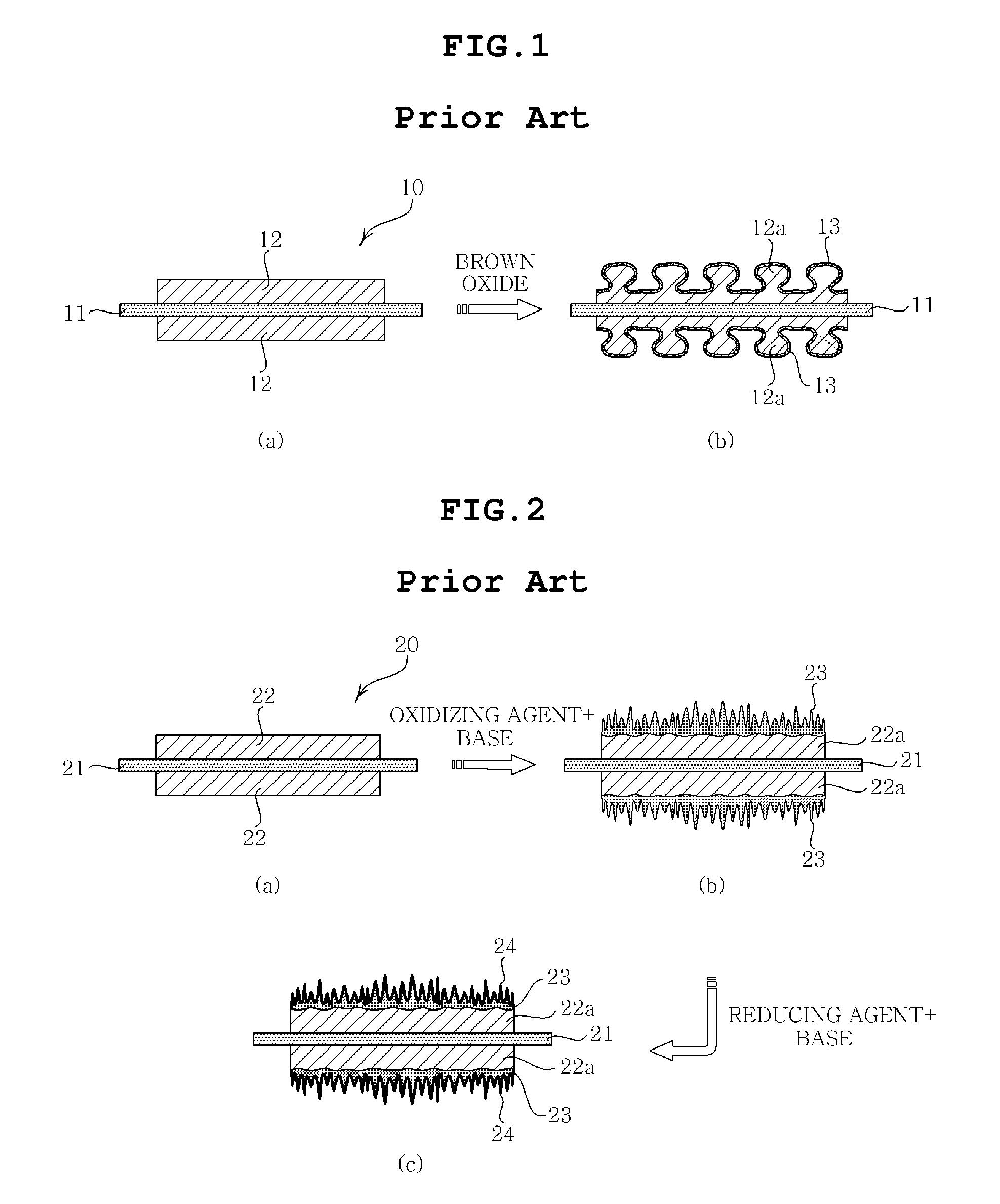

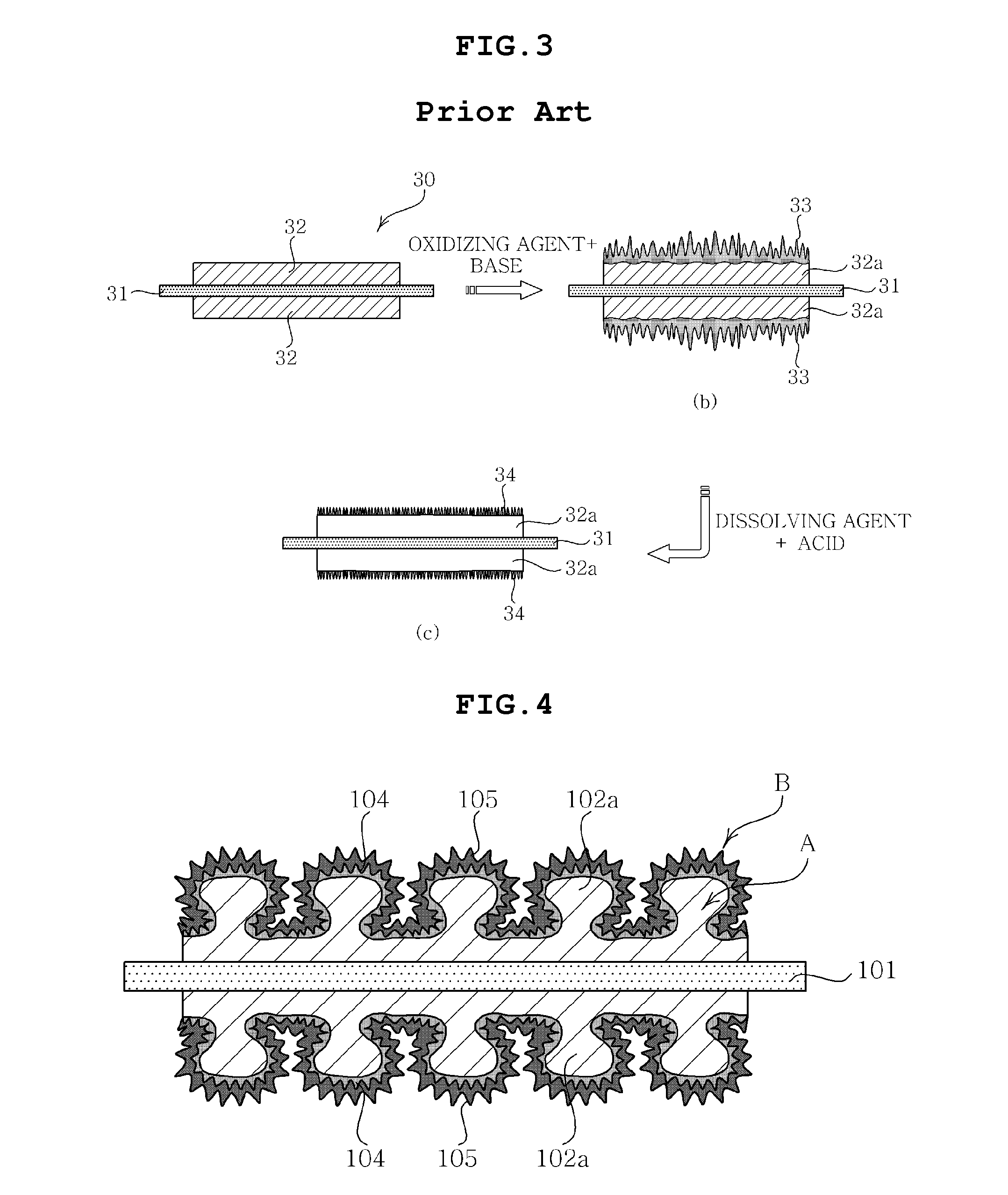

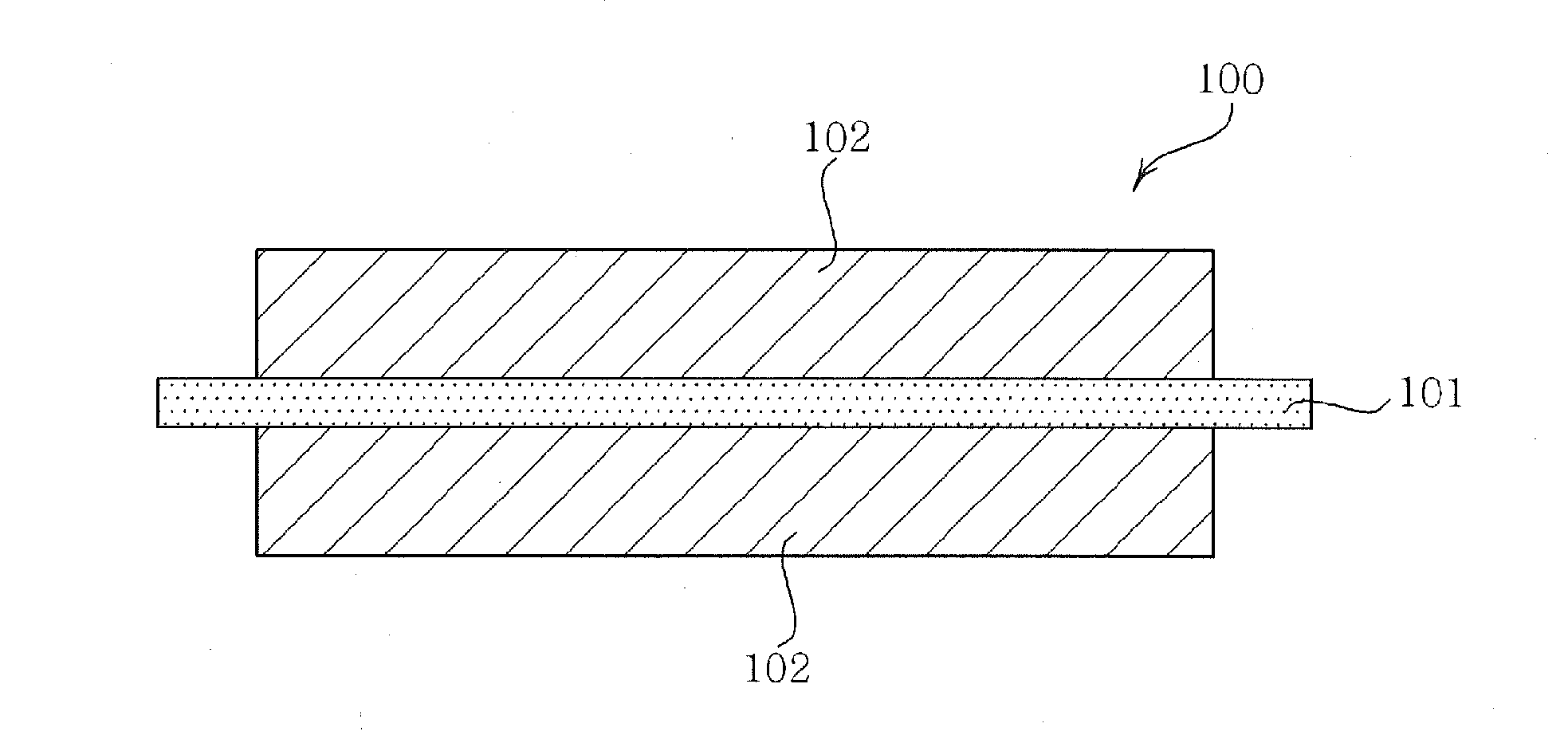

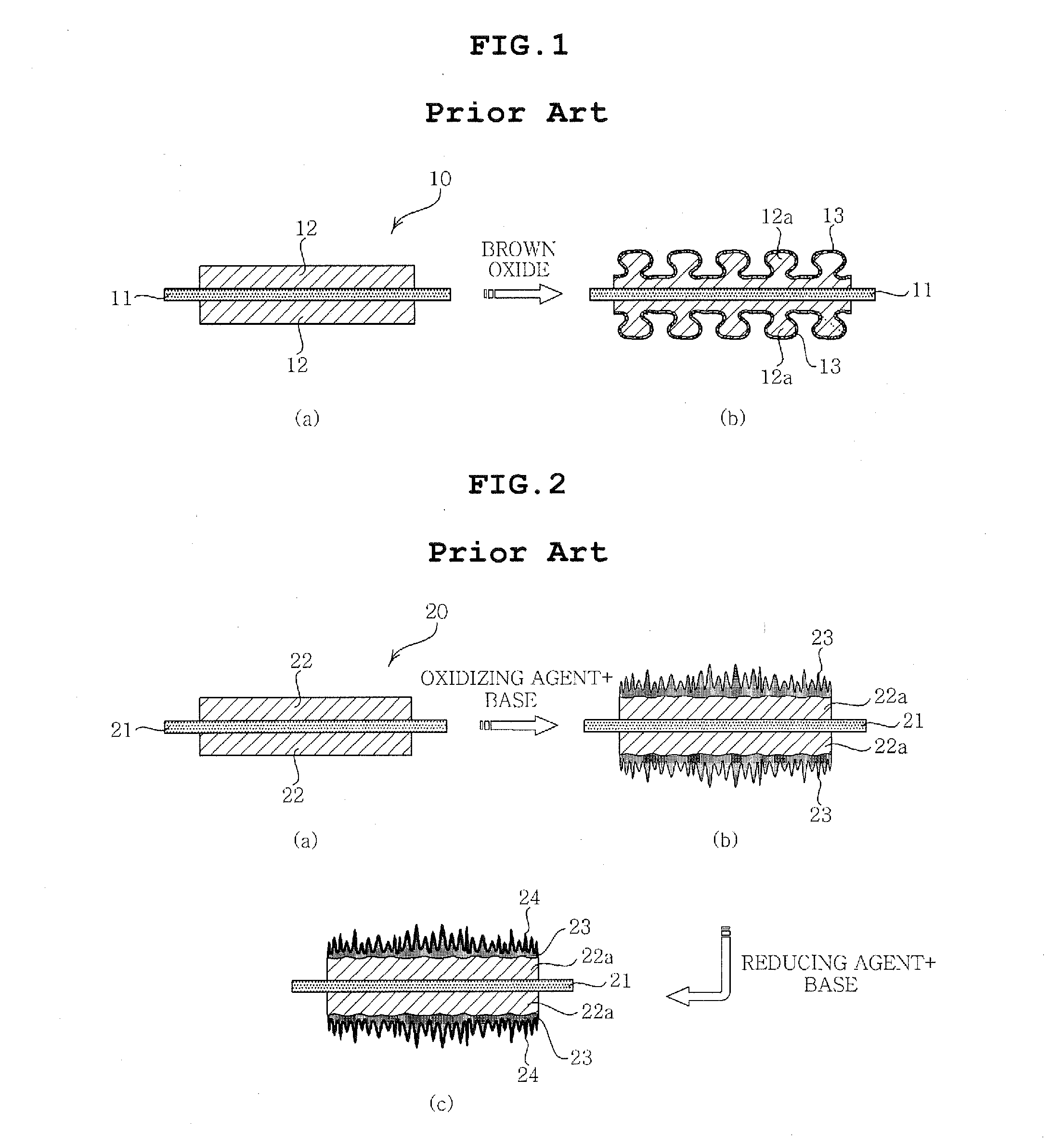

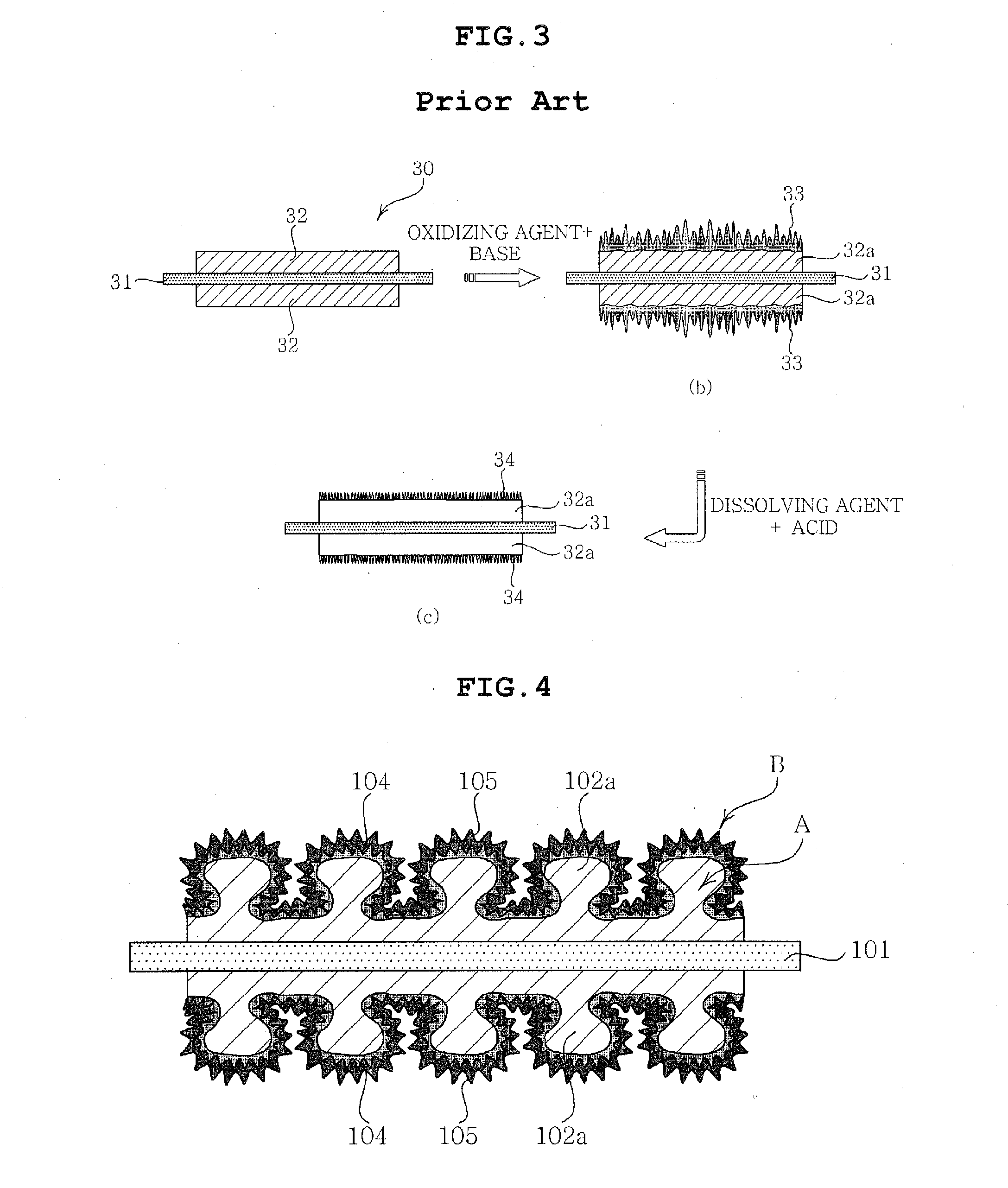

Printed circuit board and method for manufacturing the same

ActiveUS20120168212A1Improve interlayer adhesionMaintain good properties3D rigid printed circuitsPrinted circuit aspectsSurface roughnessEngineering

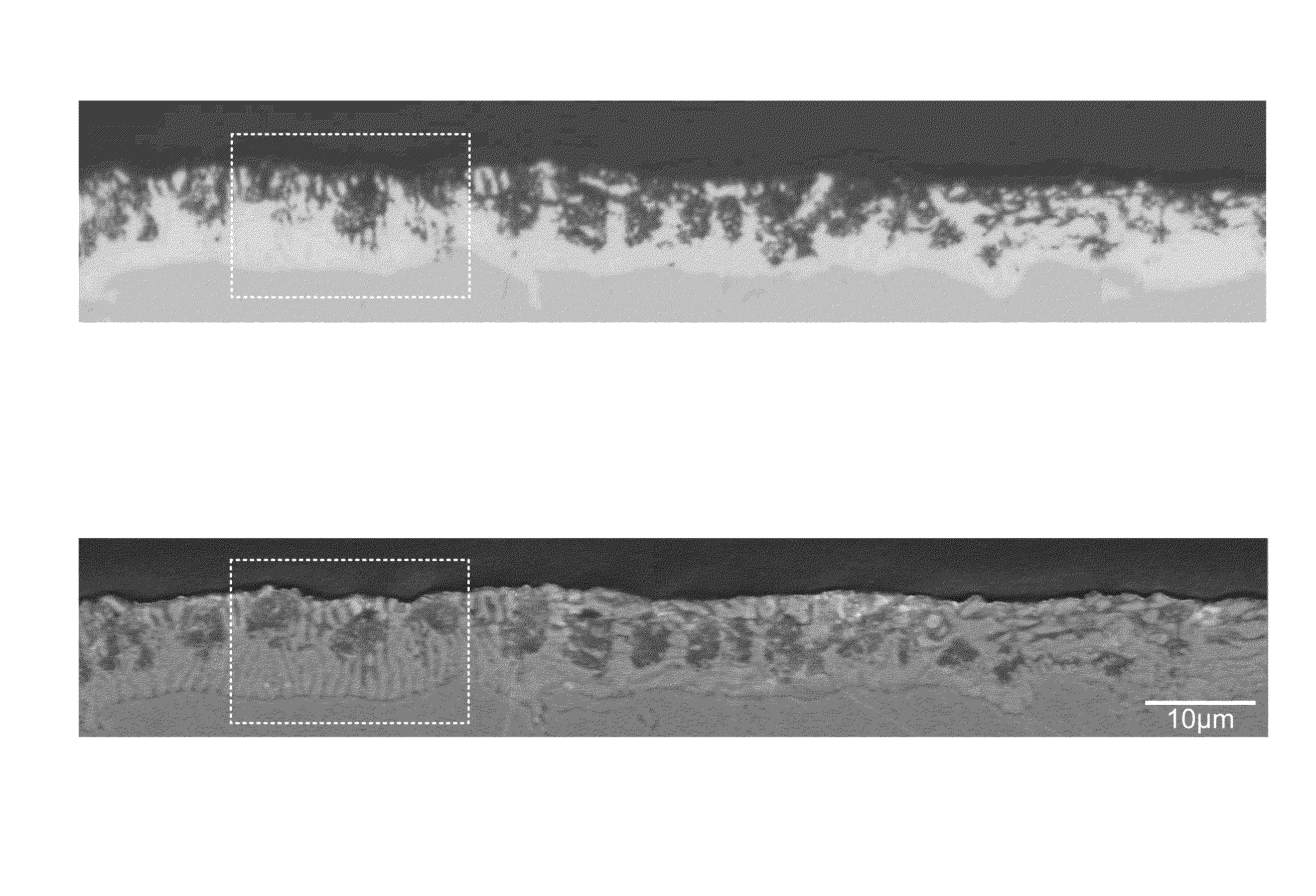

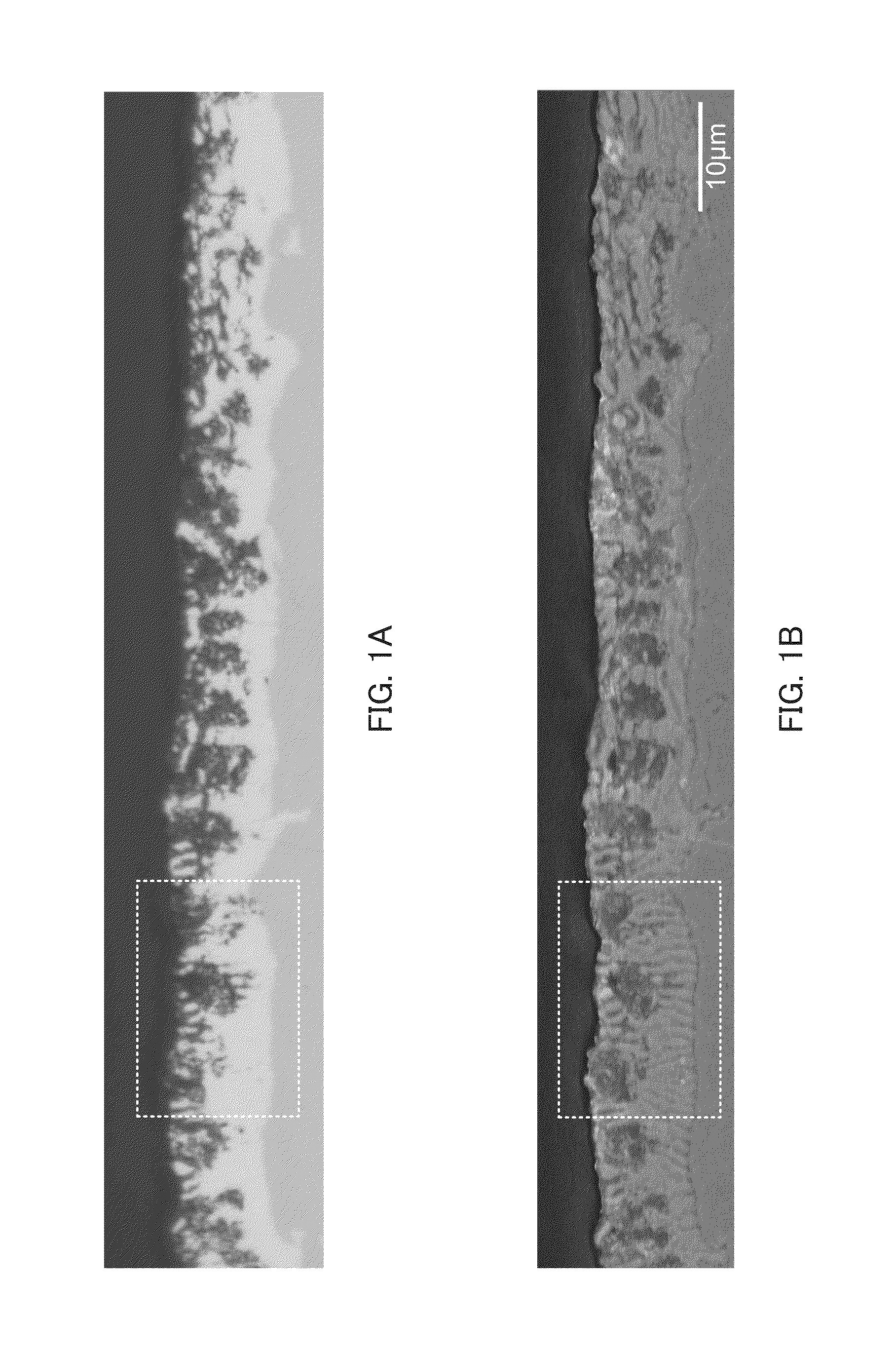

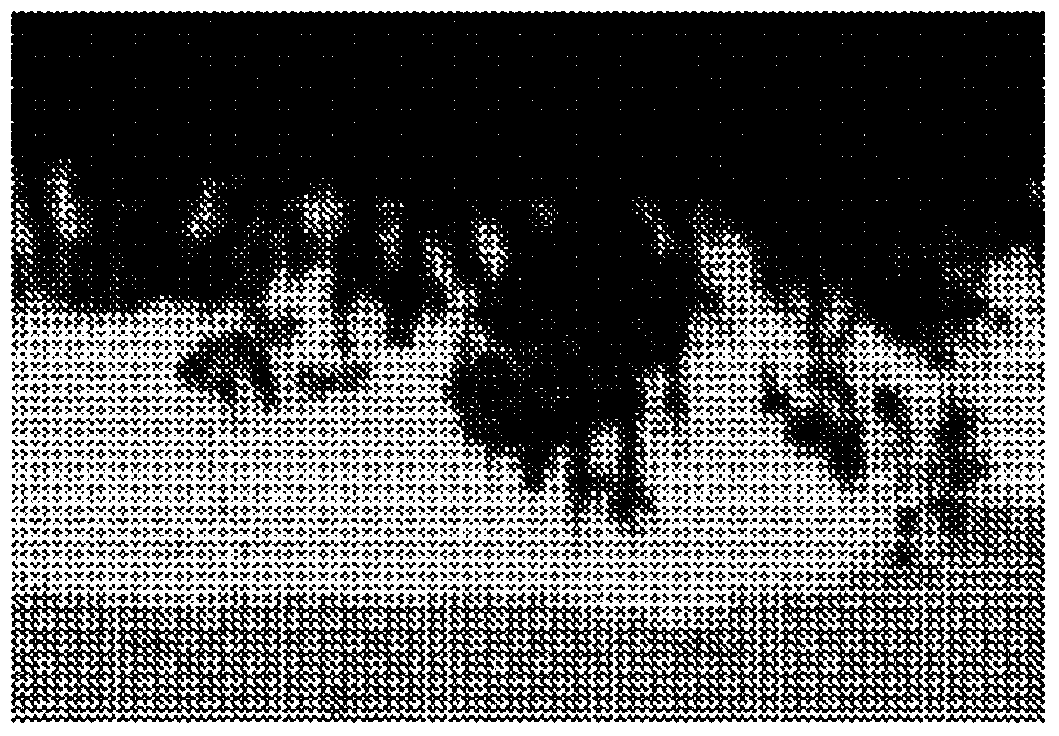

Disclosed herein are a printed circuit board and a method for manufacturing the same. The printed circuit board includes: a base substrate having a metal pattern for a circuit; and a surface roughness provided on the metal pattern, wherein the surface roughness has a first surface roughness in an anchor structure and a second surface roughness having a black oxide layer in a needle structure formed on the first surface roughness.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

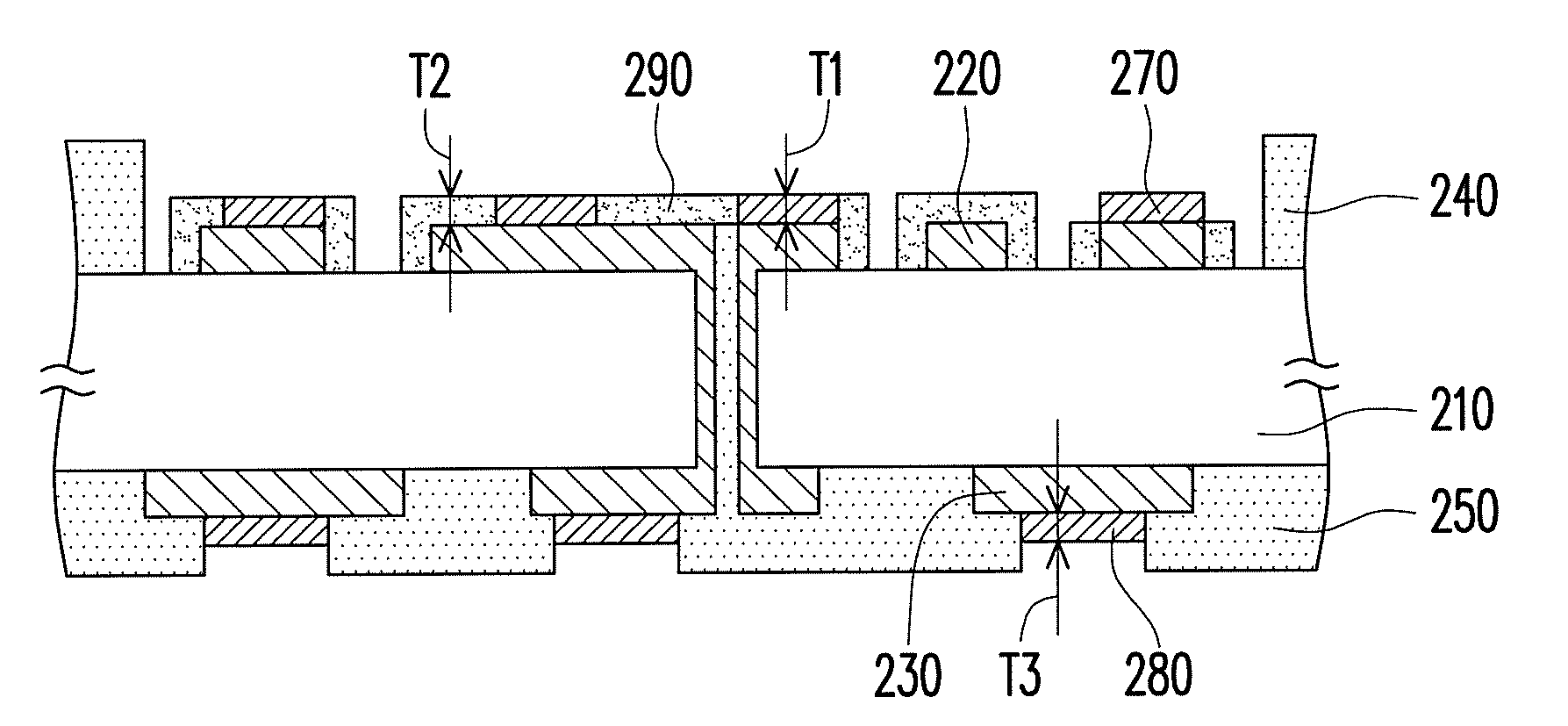

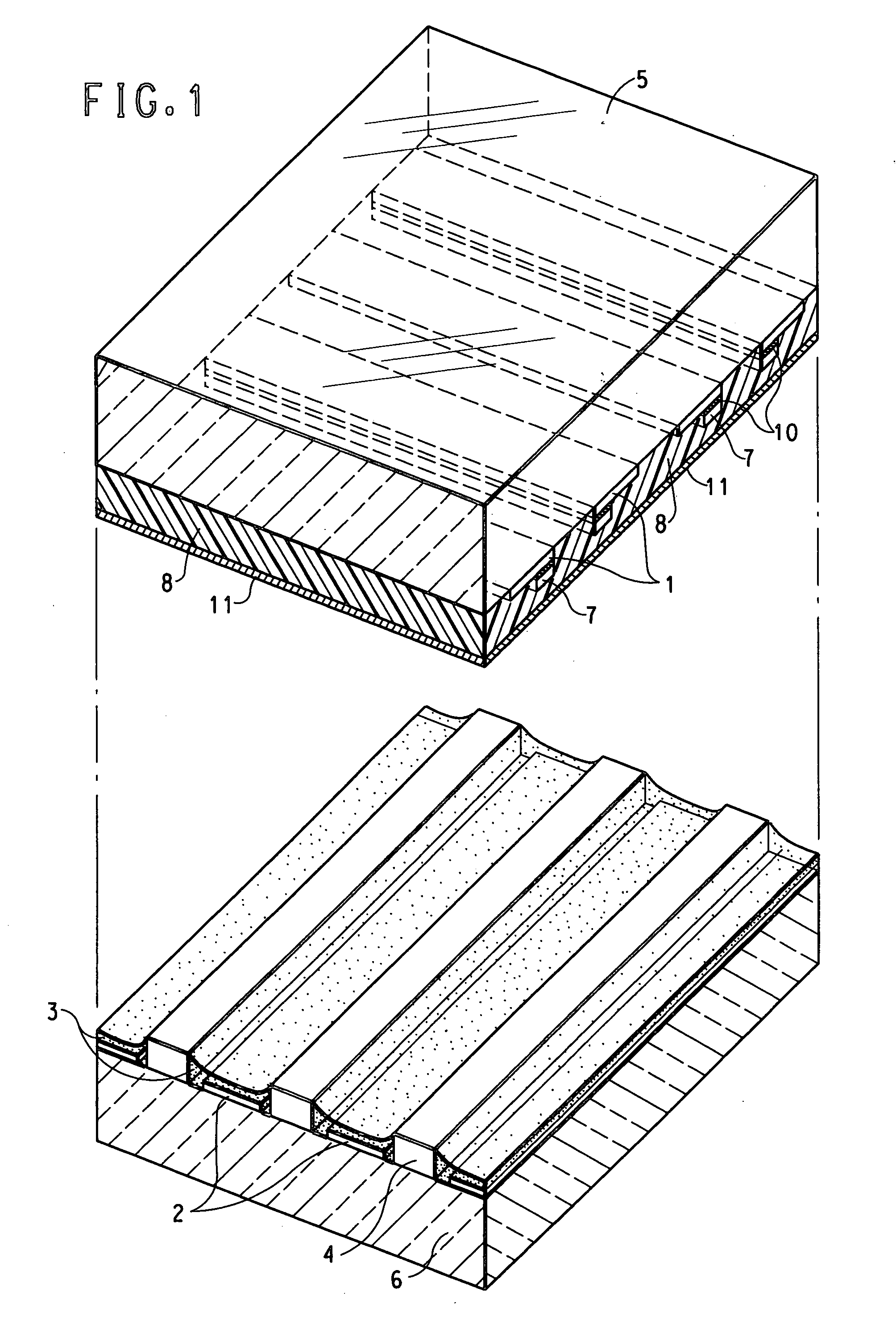

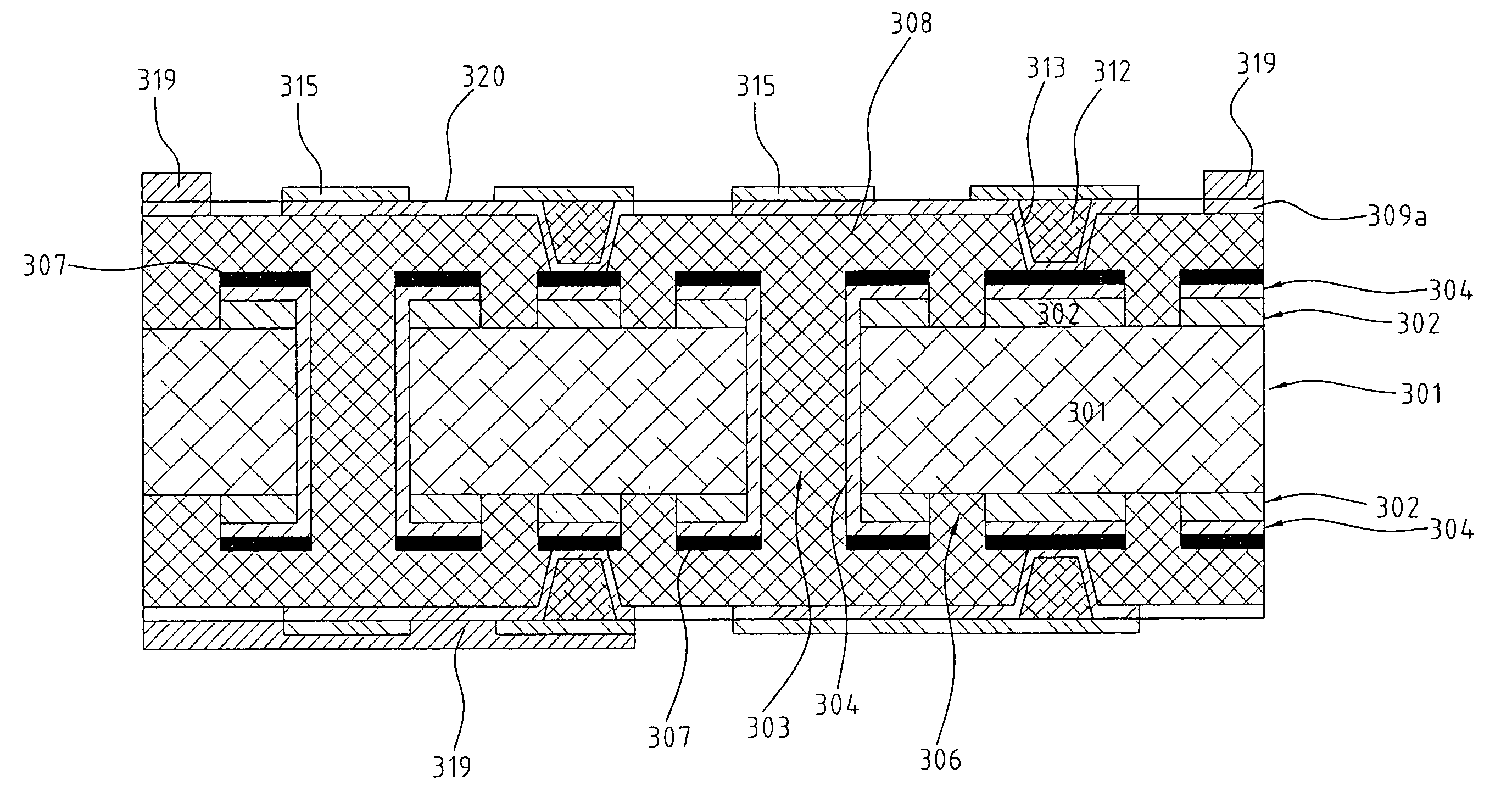

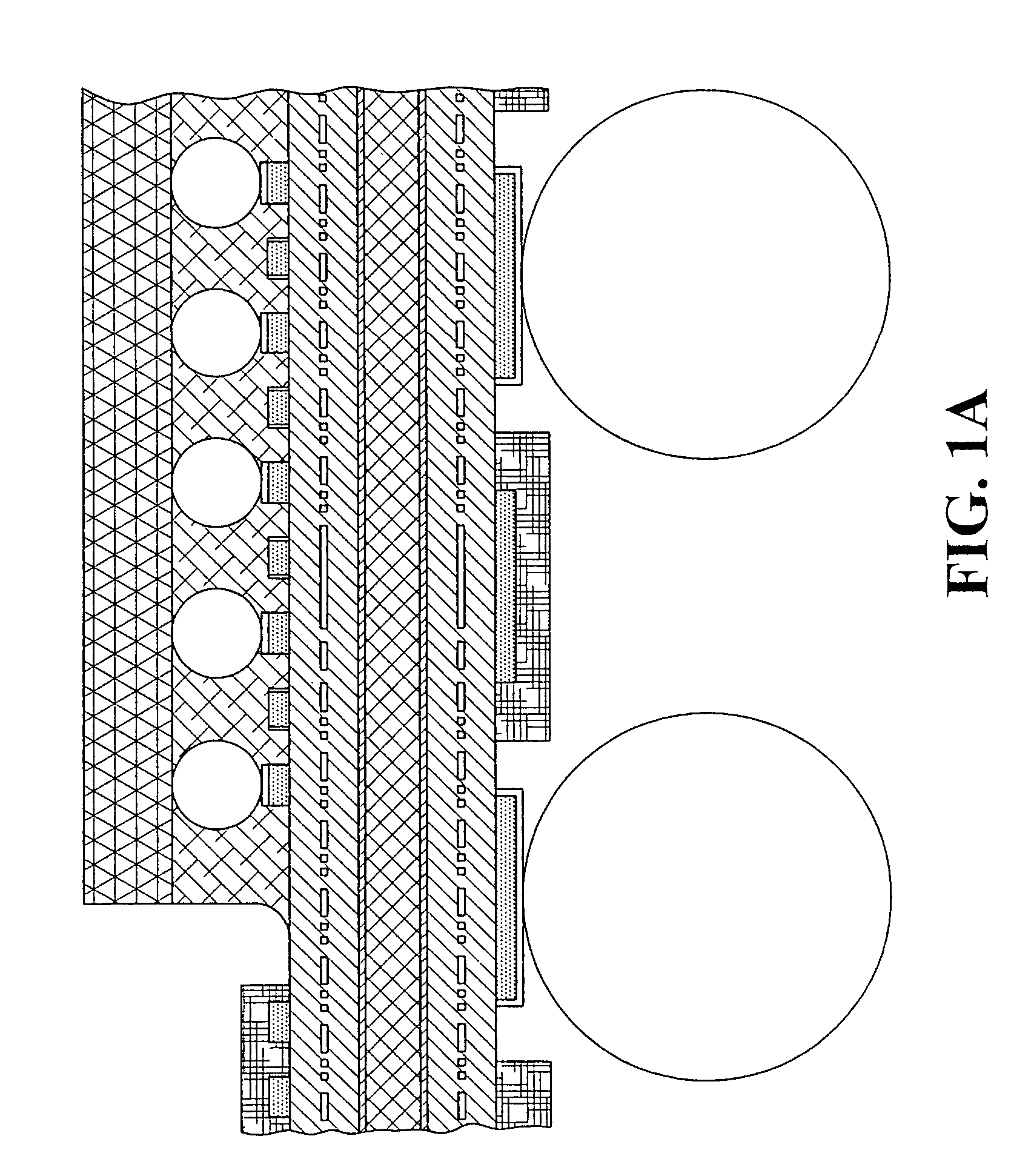

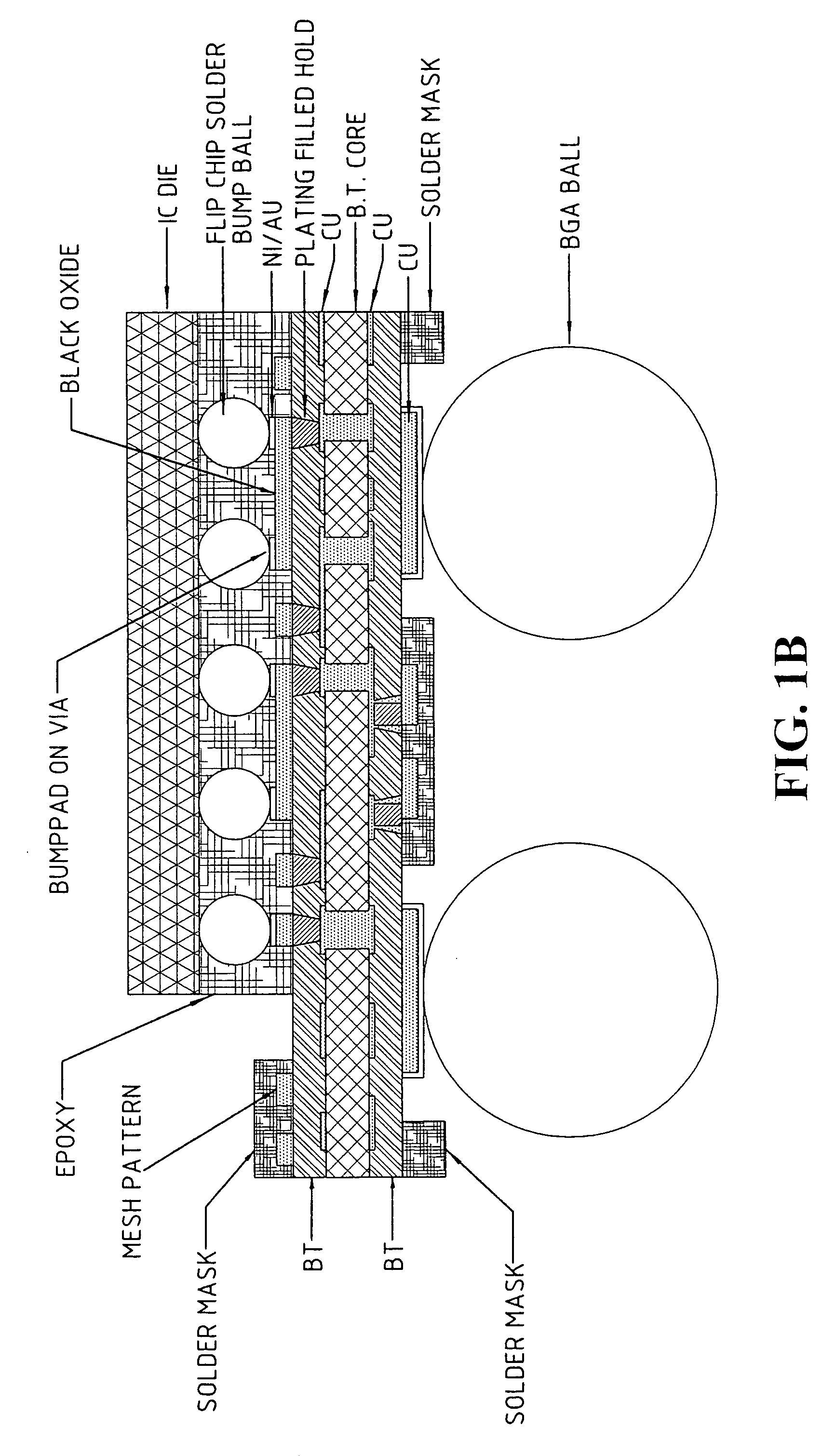

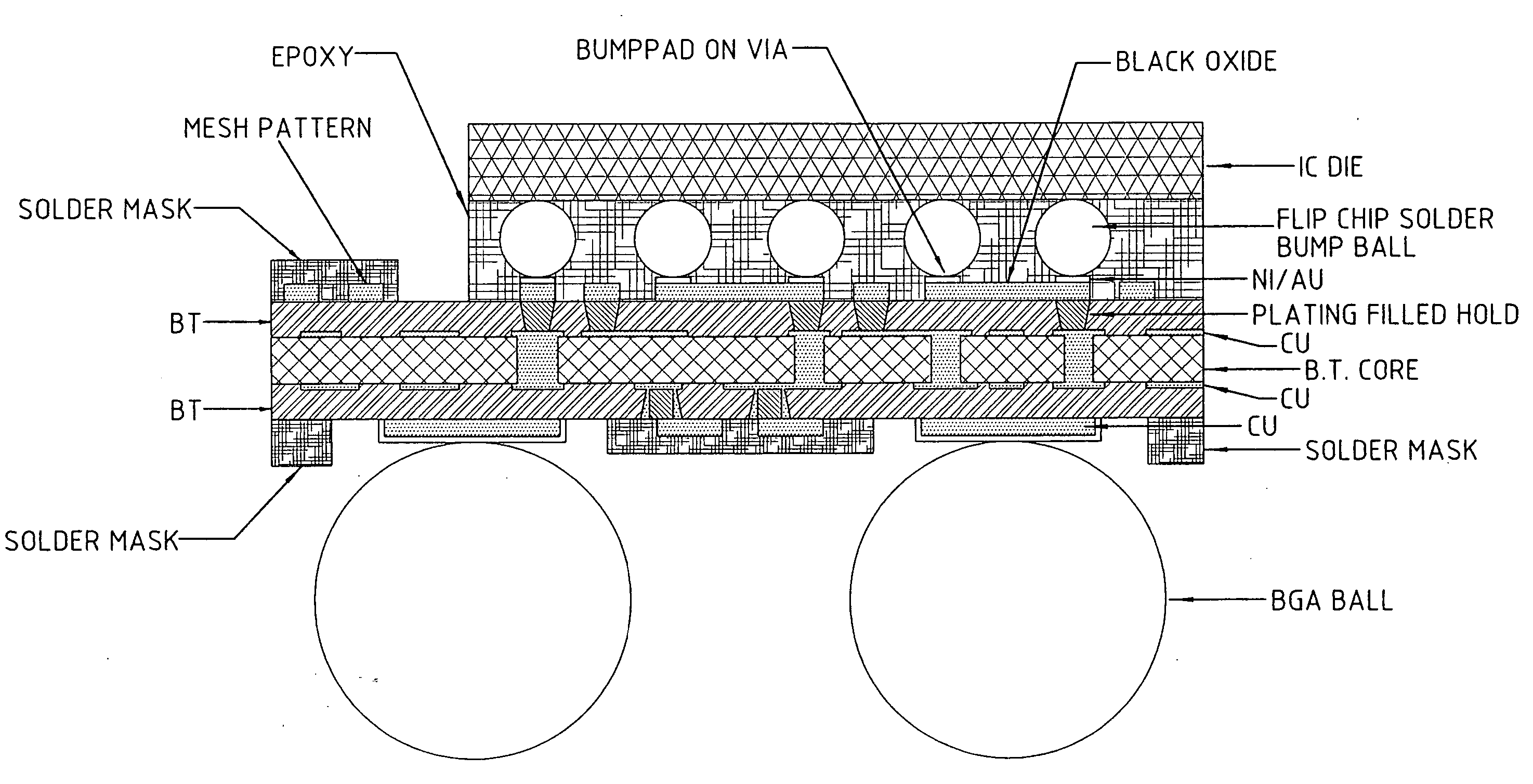

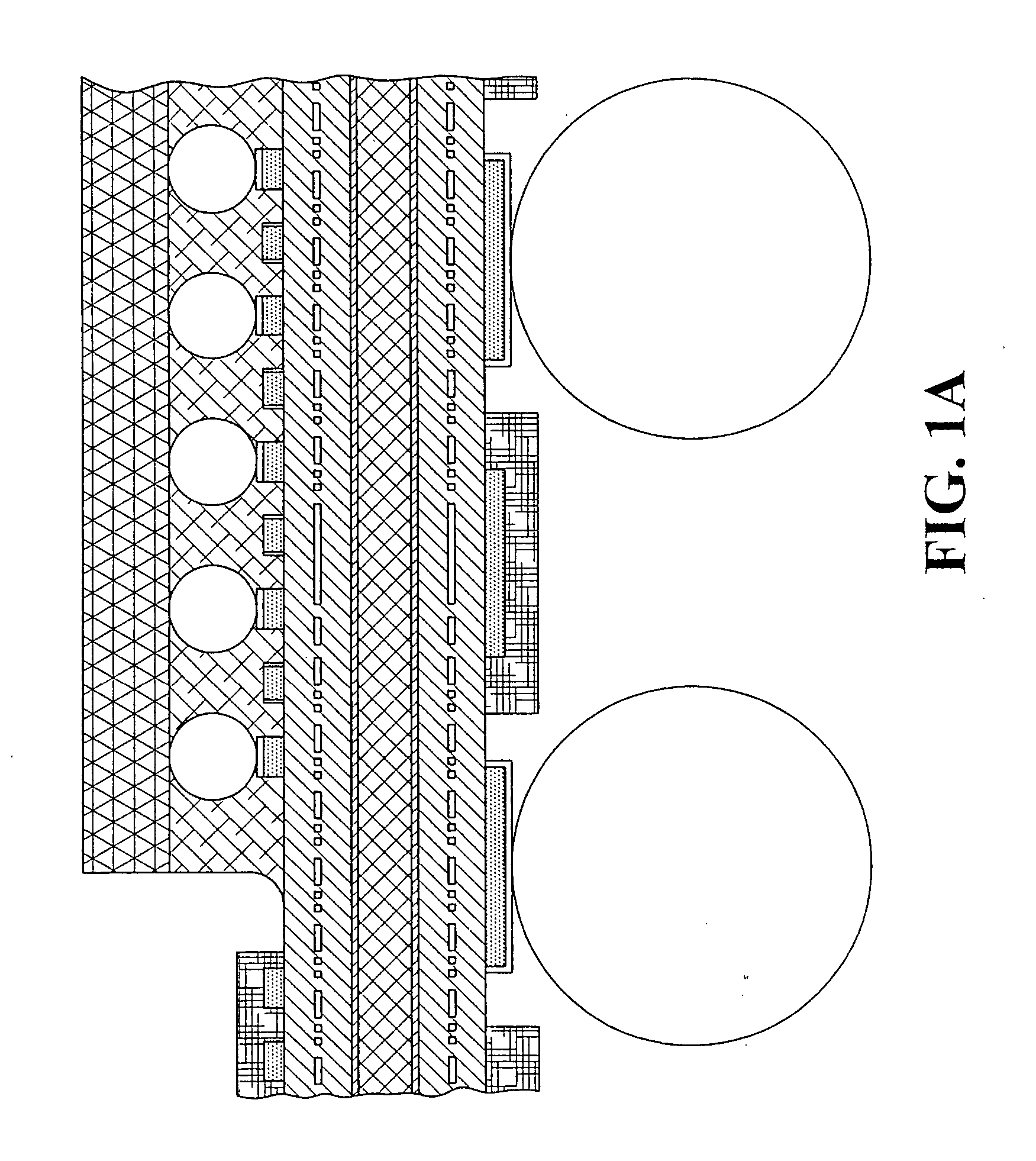

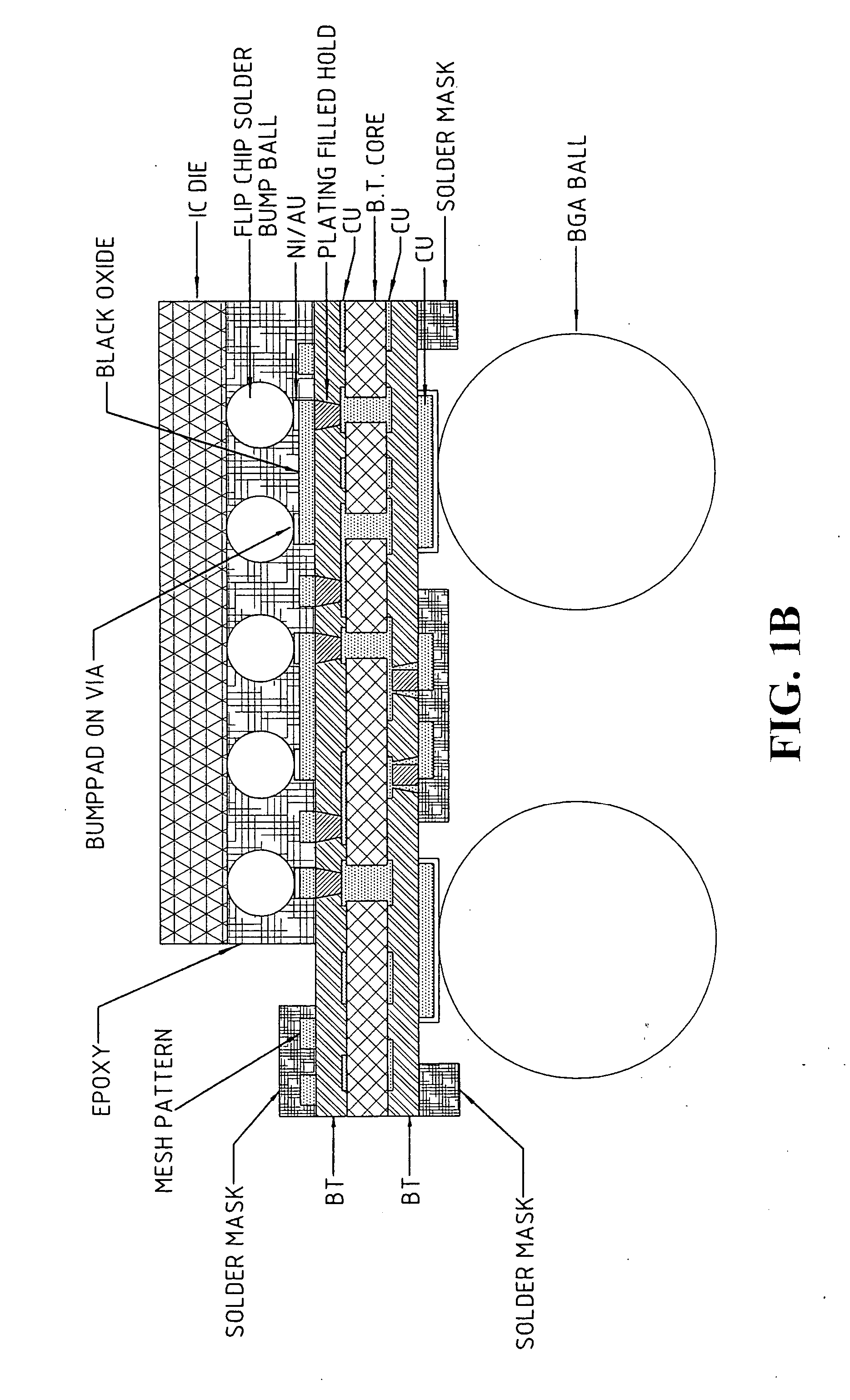

Structure and method for fine pitch flip chip substrate

InactiveUS6969674B2Increasing the thicknessImprove adhesionPrinted circuit assemblingInsulating substrate metal adhesion improvementResistEngineering

The present invention relates to a Fine Pitch flip chip substrate. A black oxide dam is made on the metal circuit between bump pads to replace the conventional solder resist so that the bump pads will not be buried in the solder resist. A small via is drilled by laser drilling and plated filled with copper to be used as the connection between the circuits. By this way, the density and the flexibility of routing could be improved. A mesh pattern can be made in the limited space to increase the stiffness of the substrate.

Owner:KINSUS INTERCONNECT TECH

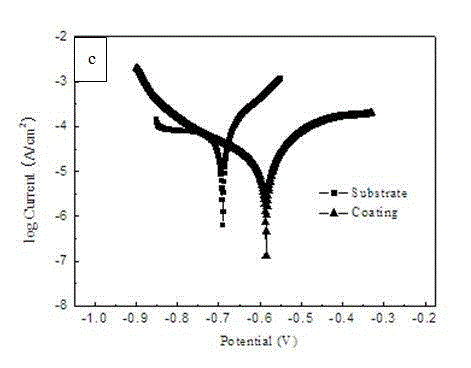

Non-toxic corrosion-protection rinses and seals based on cobalt

InactiveUS7235142B2Optimized formulaAvoid corrosionSurface reaction electrolytic coatingSolid state diffusion coatingSolubilityPhosphate

Rinsing or sealing solutions based on cobalt are described for barrier films such as anodic coatings, phosphate coatings, or “black oxide” coatings. The treated films contain a trivalent or tetravalent cobalt / valence stabilizer complex. The rinsing or sealing bath may also contain an optional preparative agent or an optional solubility control agent. The oxidized cobalt is present in the coating in a “sparingly soluble” form. The valence stabilizers can be either inorganic or organic in nature. Cobalt / valence stabilizer combinations are chosen based on the well-founded principles of cobalt coordination chemistry. A number of cobalt / valence stabilizer combinations that match the performance of conventional hexavalent chromium systems are presented.

Owner:UNIV OF DAYTON

Method for directly generating black corrosion-resistant micro-arc oxidation film layer on steel surface

InactiveCN104831332AAchieving Micro-arc OxidationImprove corrosion resistanceAnodisationMicro arc oxidationSodium aluminate

The present invention relates to the steel surface intensified machining technique, and specifically refers to a method for directly generating a black corrosion-resistant micro-arc oxidation film layer on the steel surface. Firstly, the surface of a steel product is mechanically polished, and then is cleaned to remove oil and stains. After that, the steel product is placed in an electrolyte solution to serve as an anode for the micro-arc-oxidation treatment. In this way, the steel product with the black micro-arc oxidation film on the surface thereof is simply cleaned and dried. The method is characterized in that the electrolyte solution basically comprises the following components: 6-32 g / l of sodium aluminate, 2-96 g / l of sodium silicate, and 0.05-10 g / l of sodium dihydrogen phosphate. According to the technical scheme of the invention, a black oxide ceramic film is directly generated on the steel surface.

Owner:JIANGSU UNIV

Black-plated steel sheet

ActiveCN104245997AStrong designImprove retentionHot-dipping/immersion processesSolid state diffusion coatingBrightness perceptionBlack oxide

A black-plated steel sheet has a Zn-plating layer containing molten Al and Mg, containing Al in the amount of 1.0-22.0 mass%, containing Mg in the amount of 1.3-10.0 mass%, and having a Zn black oxide distributed in a lamella pattern in the plating layer. The Zn black oxide is a Zn oxide derived from a Zn2Mg phase. The brightness of the surface of the Zn-plating layer containing the molten Al and Mg has an L* value of 60 or less.

Owner:NISSHIN STEEL CO LTD

Automatic control technology of black oxidation copper foil in supplying copper ions and equipment used thereby

The invention discloses an automatic control technology of a black oxidation copper foil in supplying copper ions. The invention also discloses equipment used by the technology, in order to provide an automatic control technology that when electrolytic copper foil is subjected to black oxidation, parameters are set according to different technologies, the copper ions are compensated automatically, thereby achieving the aim of stabilizing the copper concentration, the technology is ensured to be stable, and color quality of the copper foil caused by unstable copper ions is prevented from being abnormal. The technical point comprises the following steps of: 1) starting up a liquid supplying circulating pump, thus the black oxidation electrolytic liquid passes through a black oxide electrolytic groove, and then backflows to a black oxidation liquid storage tank; 2) detecting the copper concentration of the black oxidation liquid storage tank after the circulating is determined to be normal, and meanwhile determining the electroplating current; and then detecting the copper concentration of the black oxidation liquid storage tank and the copper concentration of a copper dissolving tank; 3) collecting data, and calculating the consumption quantity of the copper ions per hour; and 4) starting up a micro type diaphragm pump, setting the time, and thereby achieving quantitative uniform supplement. The automatic control technology of the black oxidation copper foil in supplying the copper ions and the equipment used by the method belong to the technical field of copper foil manufacturing.

Owner:梅州市梅县区金象铜箔有限公司

A blackening agent for the inner layer of a printed circuit board multilayer board and its preparation method and application

InactiveCN102286739AAvoid layeringImprove uneven black oxidationInsulating substrate metal adhesion improvementMetallic material coating processesSodium chlorateSodium chlorite

The invention discloses a blackening agent for the inner layer of a printed circuit board multilayer board, a preparation method and application thereof. The blackening agent for the inner layer of a printed circuit board multilayer board, its raw material components are calculated by per kilogram of raw materials, consisting of 300~400g of sodium hydroxide, 200~300g of sodium chlorite, 5~15g of It consists of stabilizer, 0.005-0.01g wetting agent and water. Its preparation method is to completely dissolve the solid drug with water, then add a wetting agent until it is completely dissolved, and then add water to the calculated amount to finally obtain a blackening agent for the inner layer of a printed circuit board multilayer board. The obtained blackening agent for the inner layer of the printed circuit board multilayer board can oxidize the copper surface of the inner layer of the printed circuit board multilayer board into a dense oxide layer, thereby combining with the resin to form a large bonding force to avoid circuit Layering of boards. It also improves the unevenness of black oxidation, makes the black oxide layer denser, improves the anti-stripping strength, and the copper surface after micro-etching is cleaner and more uniform.

Owner:SHANGHAI INST OF TECH

One-step method for making colour oxide film on surface of aluminium and aluminum alloy

InactiveCN1873059AUniform and dense surfaceImprove wear resistanceSurface reaction electrolytic coatingAlloySodium silicofluoride

This invention discloses a technique for forming a color oxide film on the surface of aluminum and aluminum alloy products. The technique comprises: oxidizing aluminum or aluminum alloy in an aqueous solution of sodium silicate 2-10 g / L, sodium hydroxide 0.5-3 g / L, sodium molybdate 0.2-4 g / L, sodium silicofluoride 0.1-9 g / L, sodium tungstate 0.2-10 g / L, and potassium permanganate 0.5-4 g / L at 10-50 deg.C and current density of 0.08-2 A / cm2 for 0.5-3 h to obtain a yellow / brown / black oxide film. The oxide film is uniform and compact, and has a thickness of 20-200 mum. Besides, the oxide film also has good wear and corrosion resistance. The technique has such advantages as simple process, and no pollution.

Owner:YANSHAN UNIV

Structure and method for fine pitch flip chip substrate

InactiveUS20050032273A1Misalignment problemImprove adhesionPrinted circuit assemblingInsulating substrate metal adhesion improvementResistEngineering

The present invention relates to a Fine Pitch flip chip substrate. A black oxide dam is made on the metal circuit between bump pads to replace the conventional solder resist so that the bump pads will not be buried in the solder resist. A small vias is dilled by laser drilling and plated filled with copper to be used as the connection between the circuits. By this way, the density and the flexibility of routing could be improved. A mesh pattern can be made in the limited space to increase the stiffness of the substrate.

Owner:KINSUS INTERCONNECT TECH

Preparation method of calcined alumina powder for black ceramics

The utility model provides a preparation method of calcined alumina powder for black ceramics and relates to a preparation method of calcined alumina powder suitable fore preparing bright high alumina black ceramics. The preparation method of the calcined alumina powder is characterized by comprising the following preparation steps: mixing activated alumina with salt solution of black oxide in proportion, drying and adding an additive capable of refining a crystal grain and uniformly mixing, adding mixed power into a crucible and adding into a high-temperature furnace for calcining to obtain black calcined alumina; and grinding the black calcined alumina to obtain the calcined alumina powder for the black ceramics. Through the method, as the activated alumina is uniformly mixed with the salt solution of the black oxide, the reaction area is increased, and the reaction activity is increased. Meanwhile, the additive capable of refining the crystal grain is added and is calcined into black powder at a proper temperature, the alumina and the black oxide form discontinuous solid solution, and the discontinuous solid solution can stably exist in the ceramic sintering process and is uniformly colorated. The preparation method is high in sintering activity, is suitable for low-temperature sintering and is convenient to operate.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Display lighting system

ActiveUS9596950B2Reduce errorsPrecise positioningMechanical apparatusLighting support devicesElectricityLow voltage

A lighting system including a low voltage frame, a puck magnetically joinable with the frame, a lighting array, and an elongated electrical connector joining the puck and the lighting array. The puck can be selectively positioned along the low voltage frame in a variety of different locations. The puck can be constructed from a polymeric material molded over electrical connectors, and optionally a power feed, such as a cable jack. The electrical connectors can be magnetized so that the electrical connectors are magnetically attracted to power rails on the low voltage frame to establish electrical coupling of the connectors to the power rails, while physically securing the puck in a fixed location along the low voltage frame. The power rails can be constructed from magnetic stainless steel, optionally coated with black oxide from a hot black oxide coating process.

Owner:AMSTORE

Production method for chemically coloring low-chromium stainless steel into black

InactiveCN103031552AAchieve corrosion resistanceHigh in ironMetallic material coating processesHigh concentrationHigh energy

The invention discloses a production method for chemically coloring low-chromium stainless steel into black. In the conventional stainless steel chemical coloring, a chromium-iron alloy of which the chromium content is over 13 percent is selected mostly, and a process for using high-temperature and high-concentration chromic acid and sulfuric acid is adopted, so that defects on the aspects of the performance of a black film and color control and the defects of high energy consumption, high pollution, high cost and the like exist. Stainless steel of which the chromium content is 11.7-13 percent is taken as a substrate material, and a chemical coloring liquid of a low-temperature, low-concentration and nontoxic oxidant is adopted; and a black oxide film which is dense on the appearance and has luster is formed on the surface of low-chromium stainless steel, and a corrosion resisting effect which is the same as that of high-chromium stainless steel is achieved.

Owner:张晓波

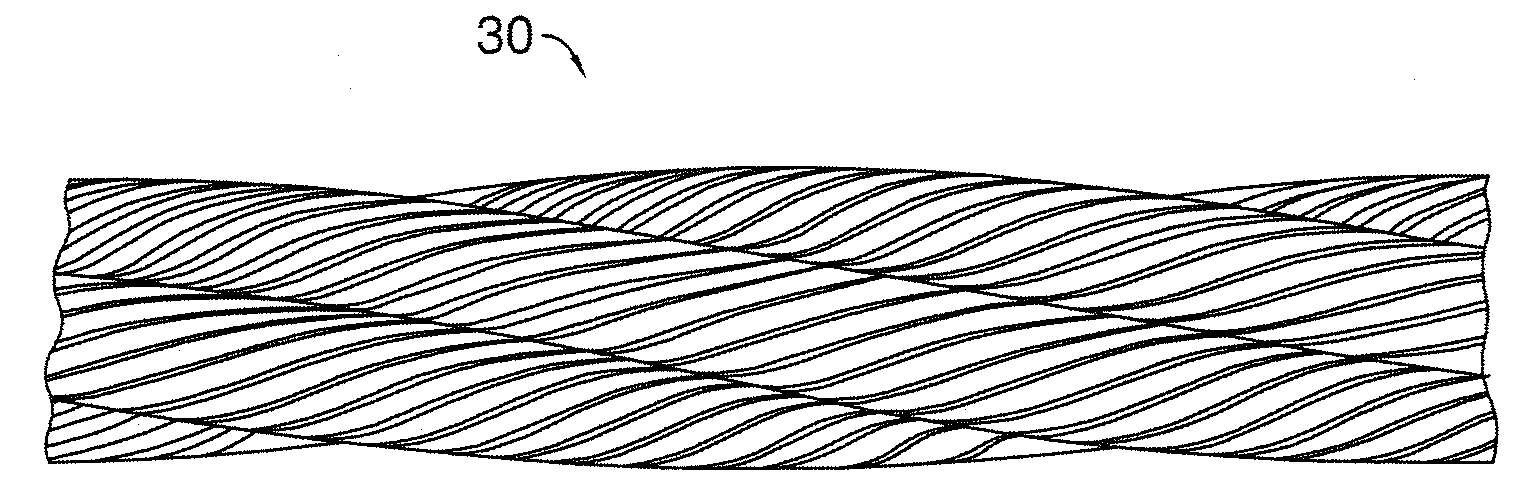

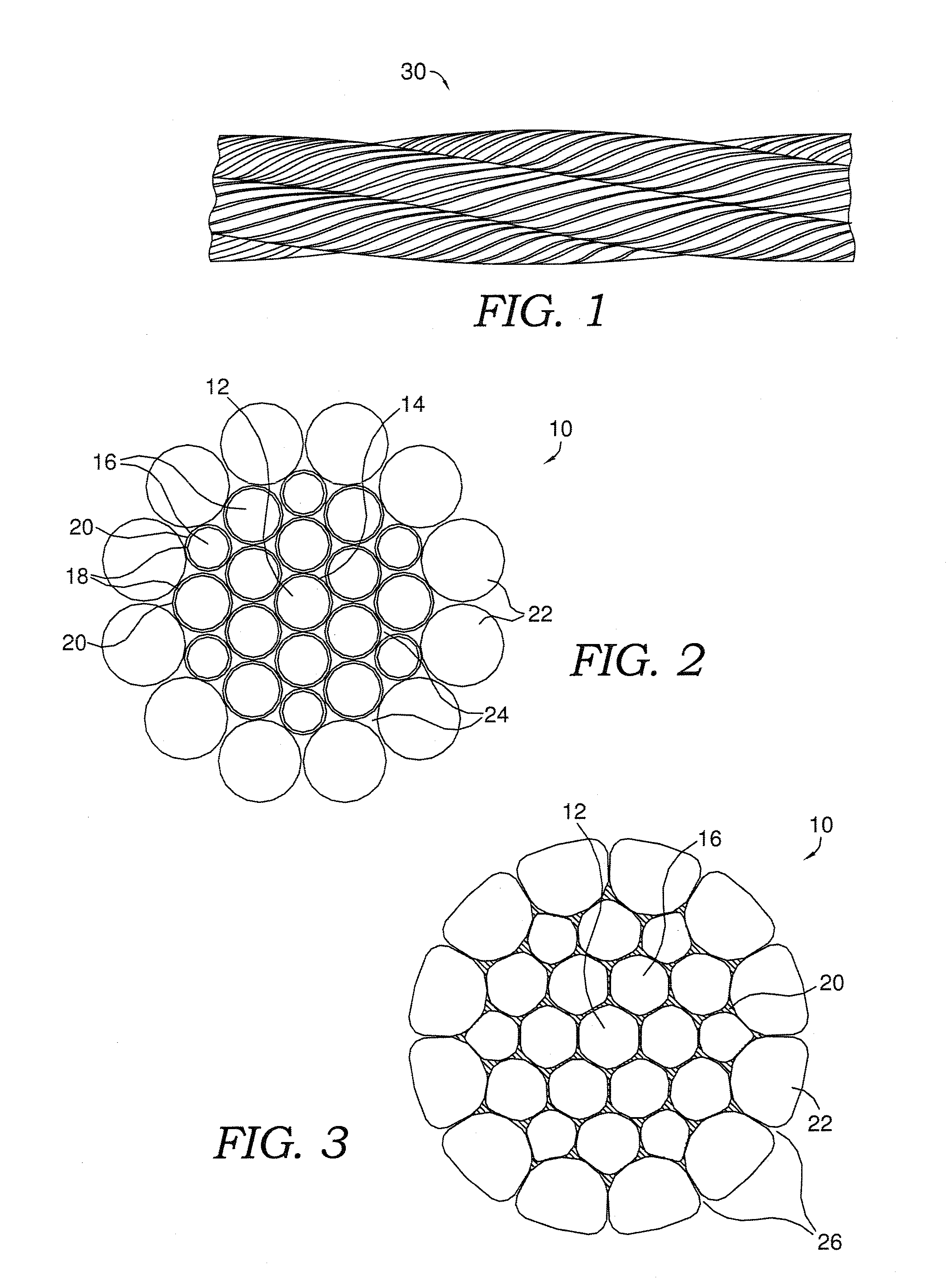

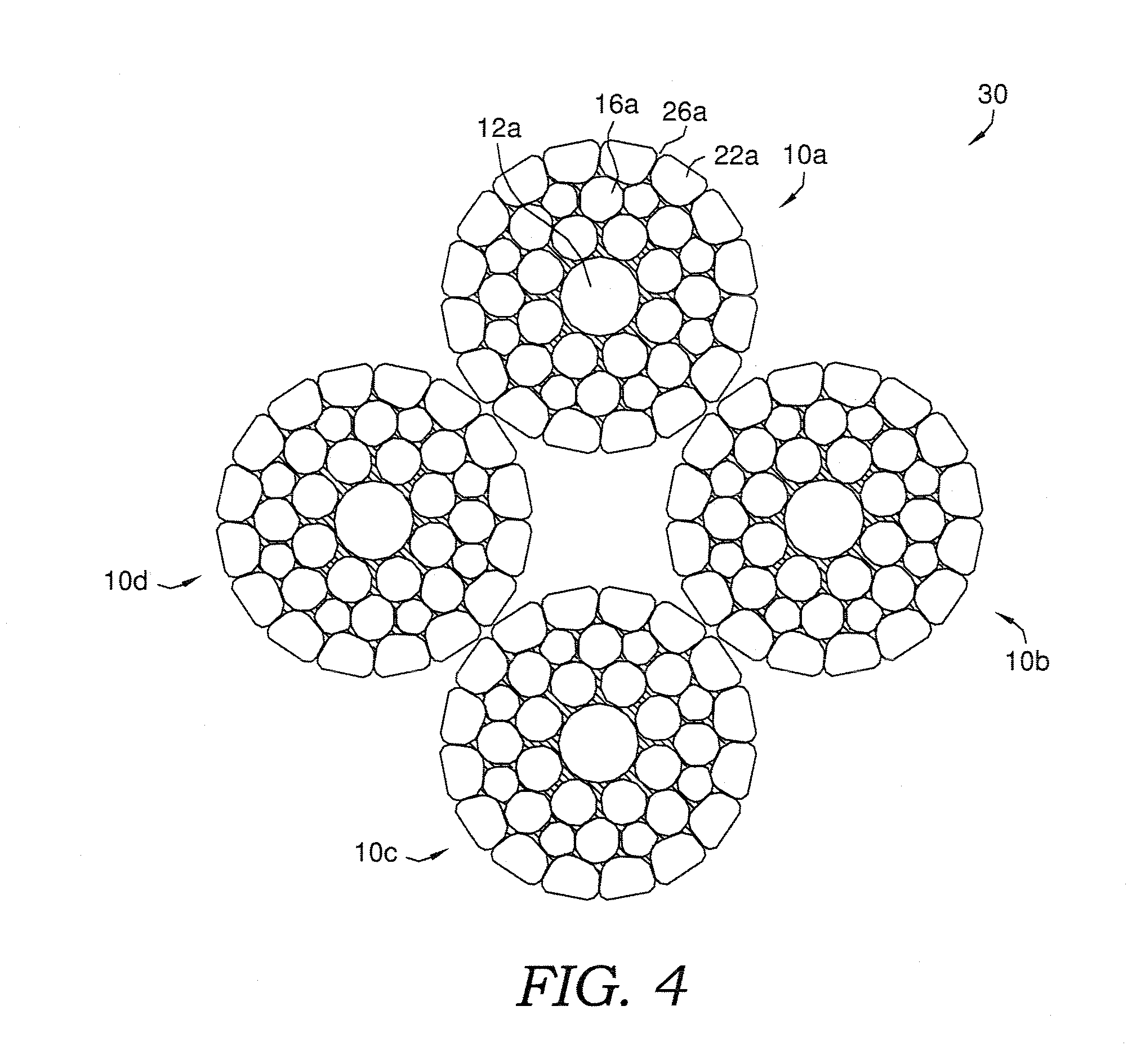

Four strand blackened wire rope

The present invention is directed to a wire rope having a blackened finish designed for theatrical productions. The wire rope includes a plurality of strands that have a closed spiral arrangement with each other and are compacted. Each strand includes a center wire spirally surrounded by a plurality of inner wires that are spirally surrounded by a plurality of outer wires so that the outer wires completely encompass the inner wires. The center wire and the inner wires are made from a galvanized material and coated with a lubricant. The outer wires are made from a non-coated steel material. Each strand is compacted so the outer wires create a tight mechanical seal to protect the inner wires. The blackened finish on the wire rope is due to a black oxide coating treatment and provides for low visibility of the wire rope during theatrical performances.

Owner:WIRECO WORLDGROUP INC

A graphic plating method for dual-side and multi-layer flexible printed circuit board

The invention discloses a method of electroplating double-face and multilayer flexible printed circuit board diagrams, which is characterized that: after the process step of drilling black oxide treatment, arranging a whole board electroplating covering thin copper step which includes immersing the via hole internal wall surface, a hole disk and a diagram part of the circuit to be arranged of whole copper clad board, depositing a thin copper layer on the surface thereof, the current density of electroplating is 1.6A / dm<2>-2.6A / dm<2>, the electroplating time is in 0.5 hours. Comparing with the prior art, the invention has the beneficial effects that: the method electroplates thin copper on the whole board after the process step of drilling black oxide treatment, the via hole internal wall surface which is adhesived with carbon powder is covered by the copper layer to form hole copper, which prevents alkaline developer contacting with carbon powder, inferior products with open circuit disadvantage can not be generated, the product qualified rate is improved markedly.

Owner:华德环科暖通工程(泰州)有限公司

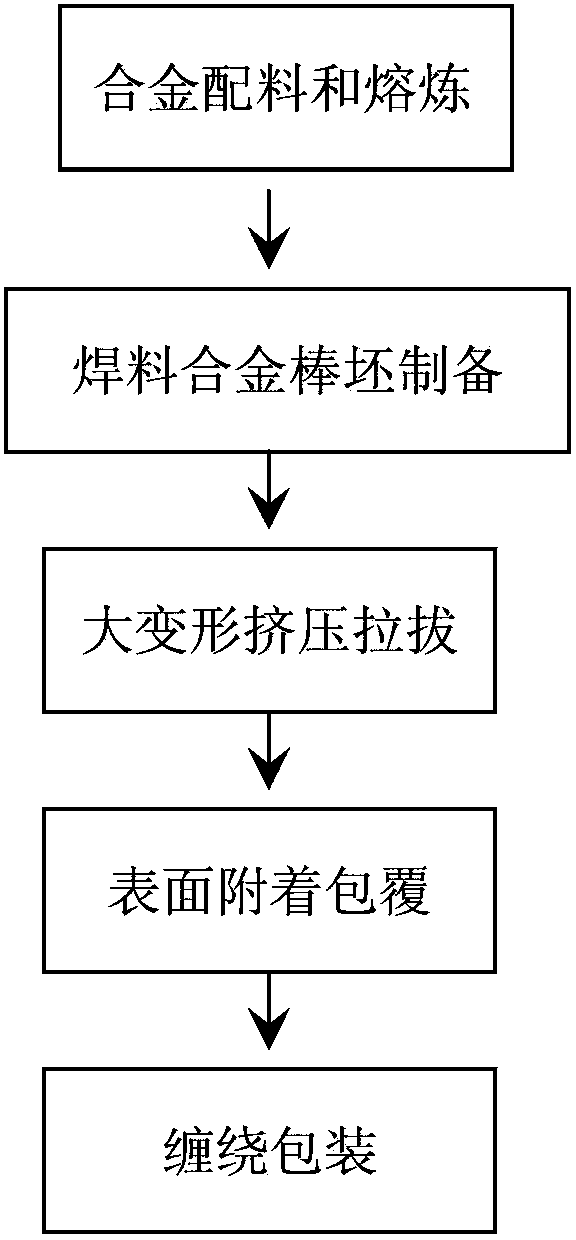

Anti-oxidation high-temperature soft-solder solid wire and manufacturing method thereof

InactiveCN104070303AImprove mechanical propertiesImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaManufacturing technologyConductor Coil

The invention relates to an anti-oxidation high-temperature soft-solder solid wire and a manufacturing method thereof and belongs to the technical field of solder production. The anti-oxidation solid wire comprises a high-temperature soft-solder solid wire and an anti-oxidation protective layer covering the solid wire. The high-temperature soft-solder solid wire comprises, by weight, Sn 2-15wt%, Ag 0-5wt%, one or multiple of P, Ge, Ga, Bi, Sb and Zn 0.01-1wt% and the balance Pb. Solder wires manufactured by the method effectively solve the problems such as black oxide of a surface layer of a lead-based solder, poor wetting during brazing without soldering flux and clamminess and damage to the surface of the solder wires in winding and use. The solder wires have the advantages of strong bonding strength, round welding spot, bright halation, good sealing performance, high reliability, long service life and the like in brazing and use.

Owner:BEIJING COMPO ADVANCED TECH

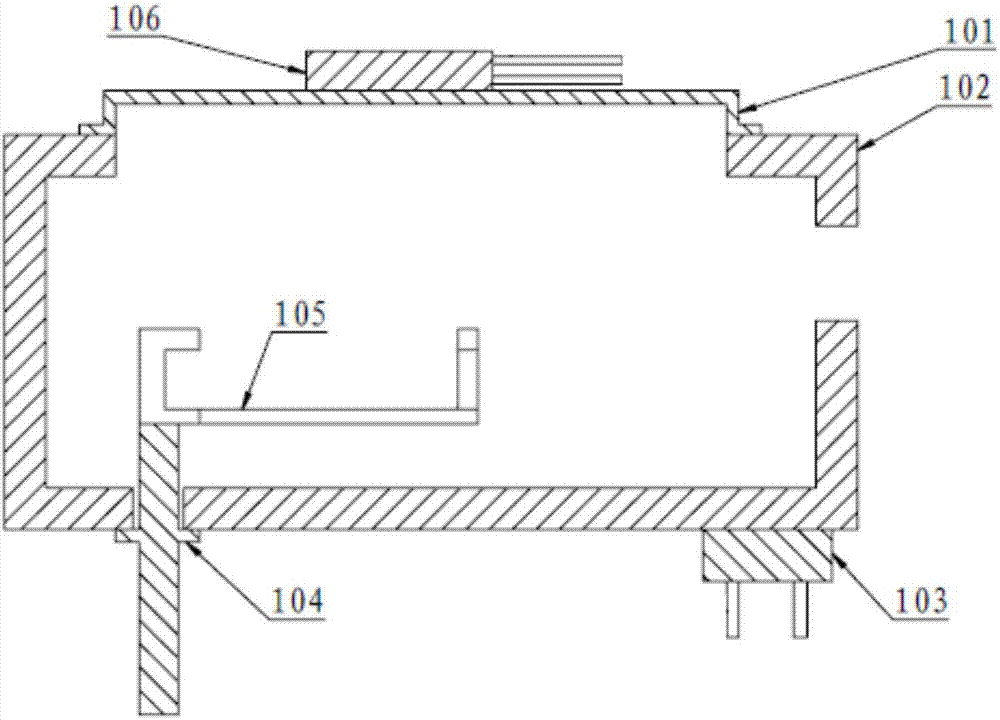

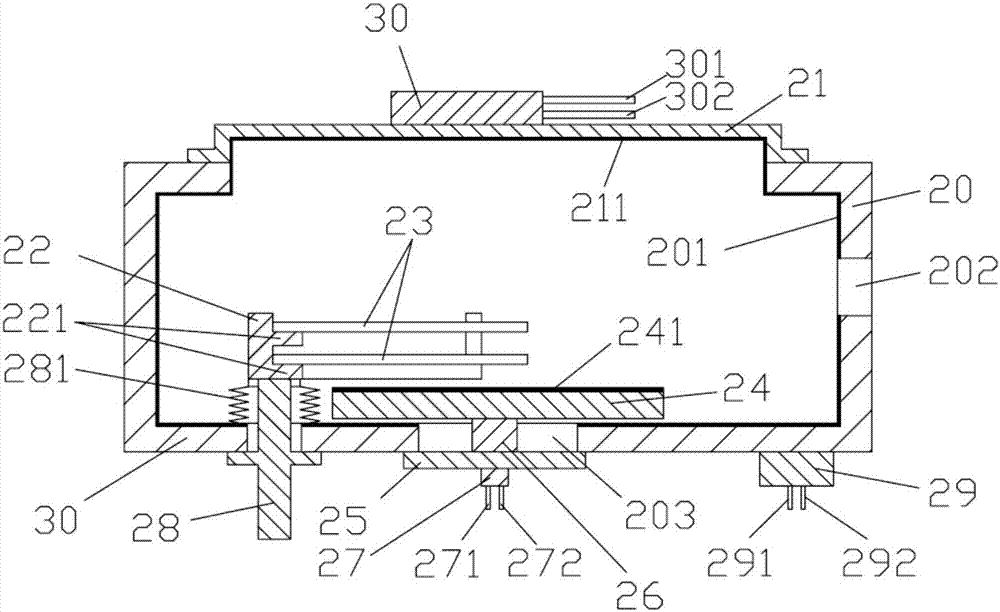

Cooling chamber and semiconductor processing equipment

ActiveCN107195567AImprove cooling efficiencyIncrease heat absorptionSolid-state devicesSemiconductor/solid-state device manufacturingCooling chamberEngineering

The invention provides a cooling chamber and semiconductor processing equipment. The chamber wall of the cooling chamber is internally provided with a first cooling channel, and the cooling medium is piped into the first cooling channel so as to cool the chamber wall. Besides, the cooling chamber is internally provided with a bracket which is used for bearing a tray, and the tray is used for bearing a processed workpiece. Furthermore, a black oxide layer is formed on at least partial internal surface of the chamber wall of the cooling chamber. According to the cooling chamber, the cooling efficiency of the tray can be enhanced so as to enhance the productivity of equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Hot-rolling steel plate cleaning agent

The invention publishes a kind of hot rolled steel plate and metal strip cleaning agent to clean black oxide film and rust on them. The cleaning agent is composed by 15-28% sulphuric acid (proportion is 1.84), 13-20% chloride ion and 31-71% water, the total acidity is 40-60 points and the work temperature is 20-80 degree. It can take place of thick hydrochloric acid to do cleaning. The chloride ion can be gotten from lithium chloride, sodium chloride, hydrochloric and so on. the noxious gas the cleaning agent, such as hydrogen chloride, can be reduced by 80%. So it can reduce the pollution and can prolong the dish life of arrangement.

Owner:文锐君 +1

Brass surface chemical blackening method

InactiveCN106222645AUniform colorImprove corrosion resistanceMetallic material coating processesPhysical chemistryRoom temperature

The invention discloses a brass surface chemical blackening method. The core is that brass is reacted with blackening liquid to form a layer of black oxide film on the surface. Firstly, a brass basal body is deoiled, polished, activated and cleaned; then, the brass basal body is put in the blackening liquid consisting of copper salt and ammonium salt, and is reacted with solution at a room temperature; and after the black film layer with uniform and stable color is generated on the surface of the brass, the brass basal body is taken out for related subsequent treatment to prevent pollution of the surface of the film layer. The brass surface chemical blackening method has the following advantages: the process is simple in flow; the cost is low; the prepared film layer is high in corrosion resistance and bonding force; and the decorating and corrosion resisting effects are excellent.

Owner:SHENYANG LIGONG UNIV

Printed circuit board and method for manufacturing the same

ActiveUS20150382461A1Improve interlayer adhesionMaintain good properties3D rigid printed circuitsPrinted circuit aspectsSurface roughnessPrinted circuit board

Disclosed herein are a printed circuit board and a method for manufacturing the same. The printed circuit board includes: a base substrate having a metal pattern for a circuit; and a surface roughness provided on the metal pattern, wherein the surface roughness has a first surface roughness in an anchor structure and a second surface roughness having a black oxide layer in a needle structure formed on the first surface roughness.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com