Halogen-free soldering agent for tin bismuth system unleaded tin paste and preparation method thereof

A lead-free solder paste and flux technology, used in welding equipment, welding media, manufacturing tools, etc., can solve problems such as adverse effects on mechanical properties and electrical properties of solder joints, reducing surface insulation resistance, solder joints and substrate corrosion, etc. Achieve high mechanical strength after welding, prevent blackening of solder joints, and reduce corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

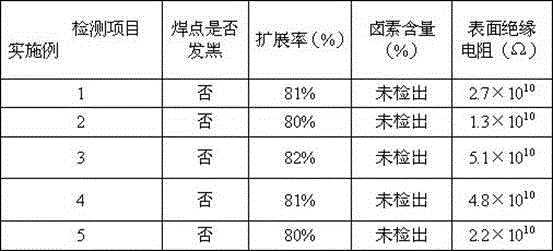

Examples

Embodiment 1

[0038] Flux raw materials: 20g perhydrogenated rosin, 20g P-105 resin, 0.5g imidazole, 4g malonic acid, 3g ethylhexyl isooctanoic acid, 3g ethanolamine, 3g diethanolamine, 8g monooctyl phosphate, modified hydrogenated castor oil 4g, ethyl octane glycol 34.5g;

[0039] Preparation method: Put 4g of malonic acid, 3g of ethylhexylisooctanoic acid, 3g of ethanolamine and 3g of diethanolamine into a reaction vessel, heat to 100°C, stir for 20 minutes, make it fully react, and prepare acid ammonium salt; Add 20g of perhydrogenated rosin, 20g of P-105 resin, 0.5g of imidazole and 34.5g of ethyl octane glycol into another reaction vessel, heat to 140°C, stir for 15 minutes to make it evenly mixed; then cool the mixture to 100 ℃, add the above-mentioned acid ammonium salt and 8 g of monoisooctyl phosphate, stir for 15 minutes, and mix well; continue to cool down to 50 ℃, add 4 g of modified hydrogenated castor oil, and use a high-speed emulsifier to emulsify at high speed for 10 minute...

Embodiment 2

[0041] Flux raw materials: water white rosin 20g, colorless rosin 10g, P-105 resin 4g, polybutene 4g, 2-ethylimidazole 6g, 2,6-di-tert-butyl-4-methylphenol 6g, dibutylene 5g glutaric acid, 5g ethylhexyl isooctanoic acid, 0.2g ethylhexyl isooctanoic acid, 8g triethanolamine, 0.2g phenyl glycidyl ether, 0.3g polyoxyethylene glyceryl ether, 10g ethylene stearic acid amide, ethyl hexanediol 10g and methylpentanediol 11.3g;

[0042] Preparation method: put 5g of succinic acid, 5g of glutaric acid, 0.2g of ethylhexylisooctanoic acid, and 8g of triethanolamine into a reaction vessel, heat to 120°C, stir for 30 minutes, and make it fully react to prepare ammonium acid Salt; add 20g of water-white rosin, 10g of colorless rosin, 4g of P-105 resin, 4g of polybutene, 6g of 2-ethylimidazole and 2,6-di-tert-butyl-4-methyl in another reaction vessel 6g of phenol, 10g of ethyl hexanediol and 11.3g of methylpentanediol, heated to 180°C, stirred for 20 minutes, and mixed evenly; then the mixtu...

Embodiment 3

[0044]Flux raw materials: 685 rosin 10g, 610 rosin 20g, 604 rosin 17g, polyisobutylene 8g, imidazole 0.5g, adipic acid 1g, sebacic acid 2g, benzoic acid 2g, ethylhexyl isooctanoic acid 3g, diethylenetriamine 14g , monoisooctyl phosphate 2g, modified hydrogenated castor oil 2g, ethylene stearic acid amide 3g, tetraethylene glycol dimethyl ether 5g, diethylene glycol monohexyl ether 5g and triethyl carbitol ether 5.5 g;

[0045] Preparation method: Put 1g of adipic acid, 2g of sebacic acid, 2g of benzoic acid, 3g of ethylhexylisooctanoic acid and 14g of diethylenetriamine into a reaction vessel, heat to 110°C, and stir for 25 minutes to make it fully react , prepared into acid ammonium salt; in another reaction vessel, add 685 rosin 10g, 610 rosin 20g, 604 rosin 17g, polyisobutylene 8g, imidazole 0.5g, tetraethylene glycol dimethyl ether 5g, diethylene glycol monohexyl ether 5g and 5.5g of triethyl carbitol ether, heated to 160°C, stirred for 18 minutes, and mixed uniformly; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com