Automatic control technology of black oxidation copper foil in supplying copper ions and equipment used thereby

A technology of copper ion and blackened copper, which is applied in the field of copper foil manufacturing, can solve problems such as large product quality differences, unstable production processes, and lagging operation adjustments, so as to achieve stable quality, avoid abnormal color quality, and ensure production stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

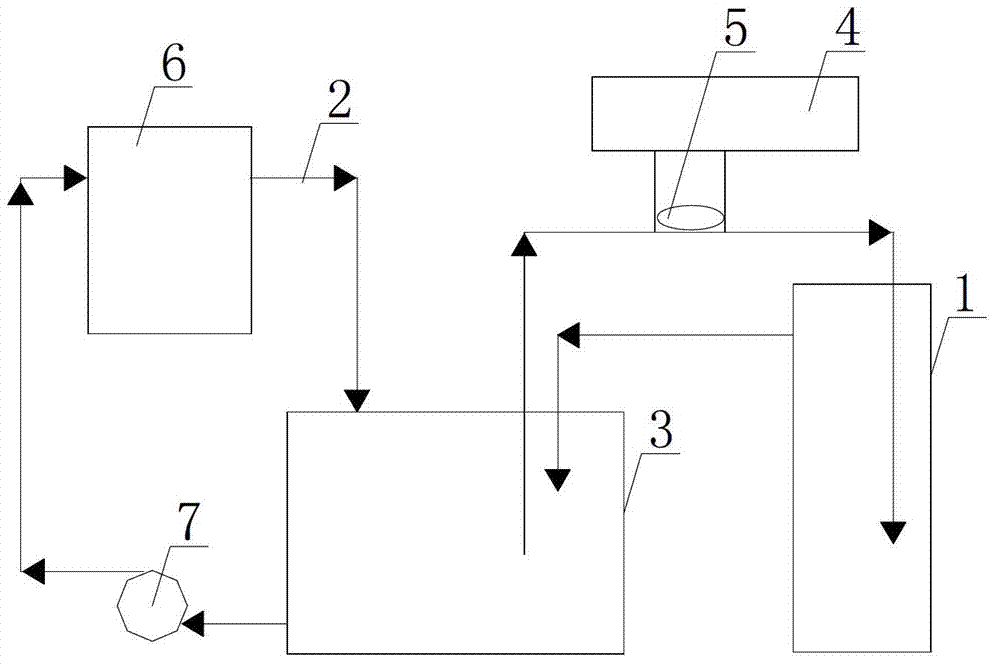

[0013] An automatic control process for supplementing copper ions in blackened copper foil. The equipment used in the automatic control process includes a copper melting tank 1, which is connected to a blackening storage tank 3 through a pipeline 2, and the copper melting tank 1 is connected to a blackening storage tank 3. Also be provided with micro-diaphragm pump 4 between liquid storage tank 3, be provided with time gauge electrical appliance 5 above micro-diaphragm pump 4, blackening storage tank 3 is also connected with blackening electroplating tank 6 by pipeline 2, between blackening storage tank 3 and A circulating pump 7 is arranged between the blackening electroplating tanks 6 .

[0014] The automatic control process includes the following steps: 1) Start the liquid supply circulation pump 7, so that the blackening electrolyte passes through the blackening electroplating tank 6, and then returns to the blackening liquid storage tank 3; 2) After confirming that the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com