Patents

Literature

120results about How to "Ensure production stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microemulsion preconcentrate

InactiveUS20050118254A1Ensure production stabilityBiocideCarbohydrate active ingredientsActive componentMicroemulsion

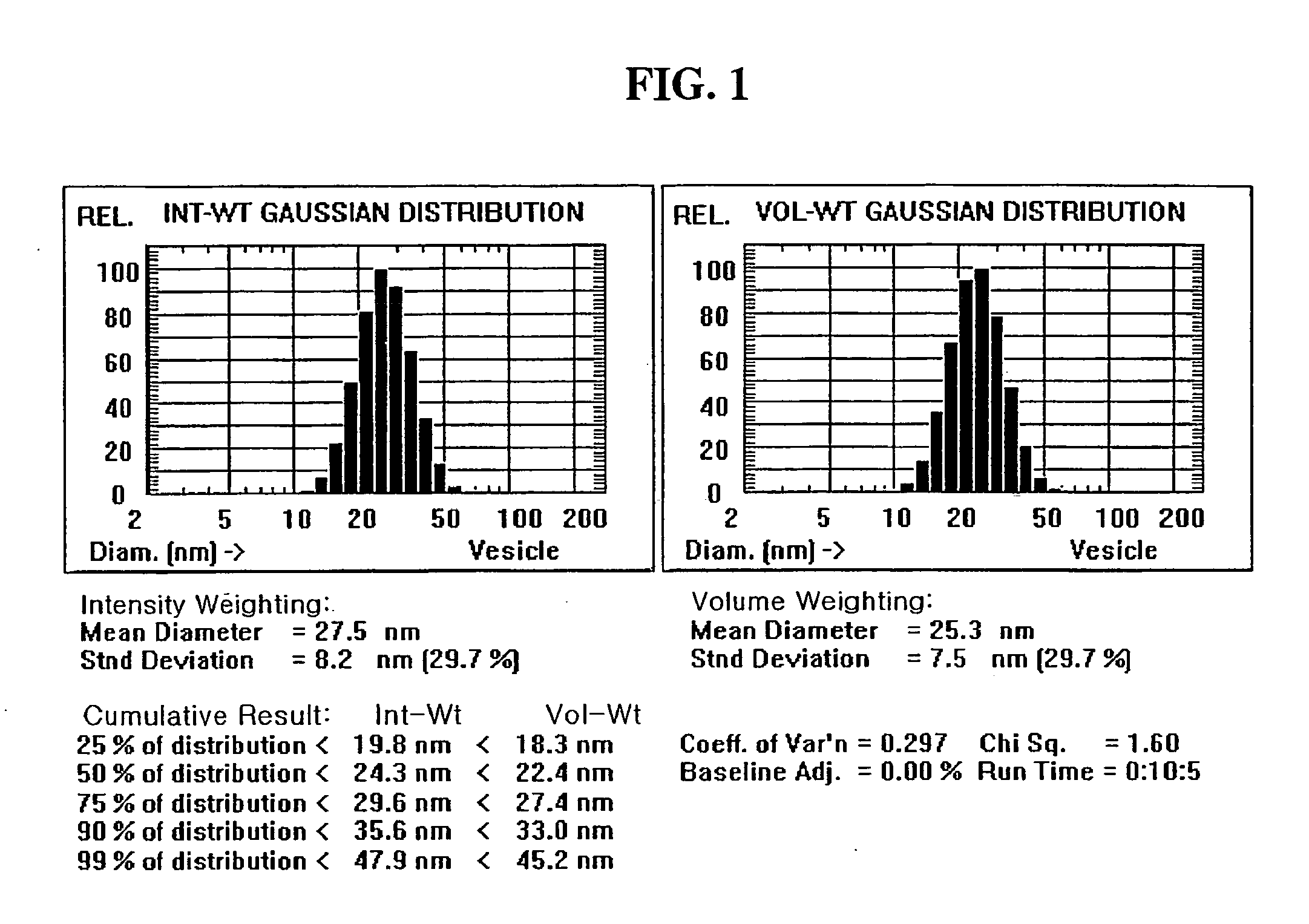

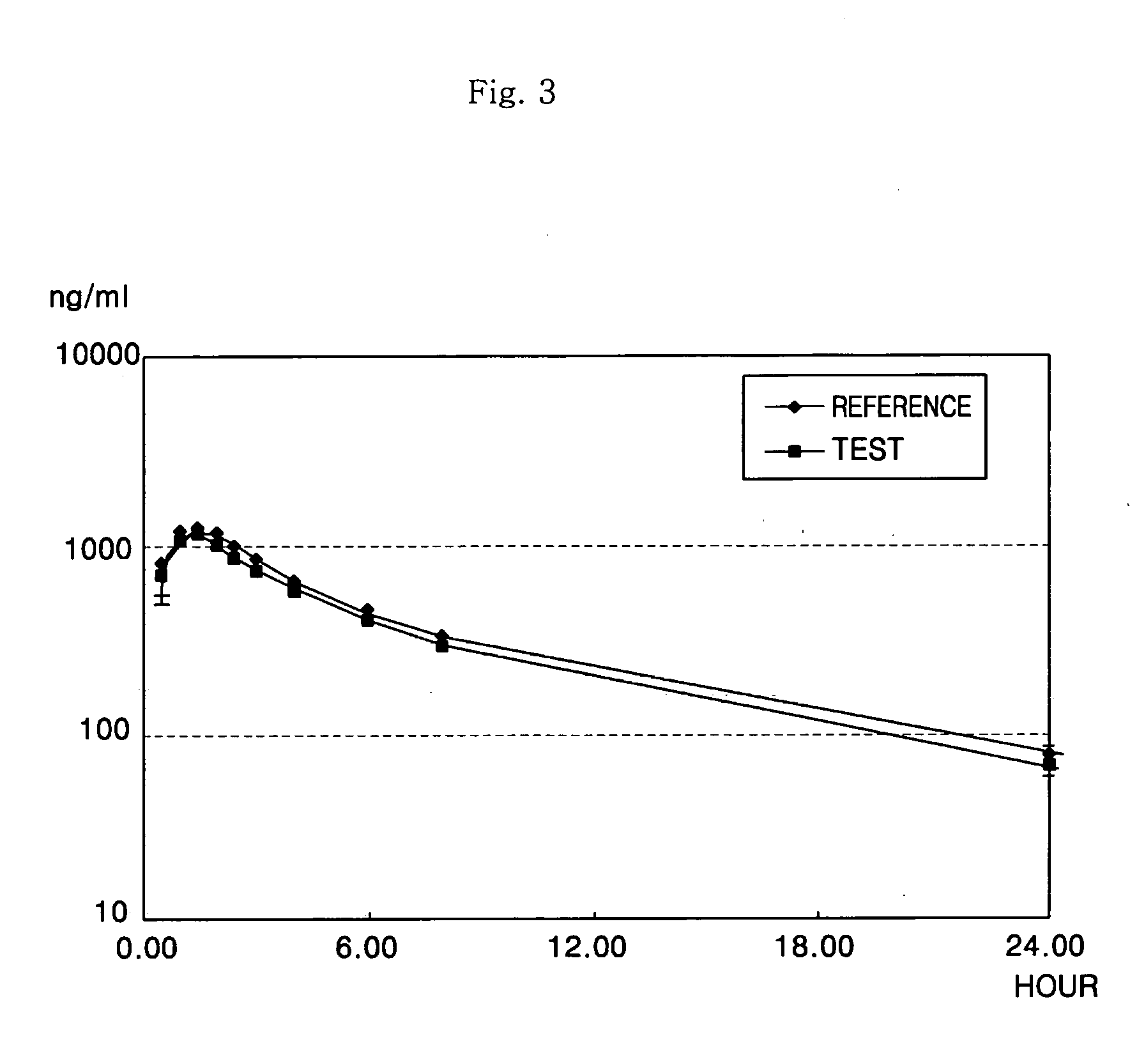

A microemulsion preconcentrate is provided, which comprises an active component, an oil, a surfactant, and a hydrophilic solvent selected from the group consisting of propylene glycol diacetate, propylene glycol monoacetate, and salts of the forgoing materials.

Owner:CJ CORPORATION

Production process of 65 Mn spring steel wire rod and 65 Mn spring steel wire rod

ActiveCN102912101AImprove metallographic structureImprove performanceHeat treatment process controlWire rodSpring steel

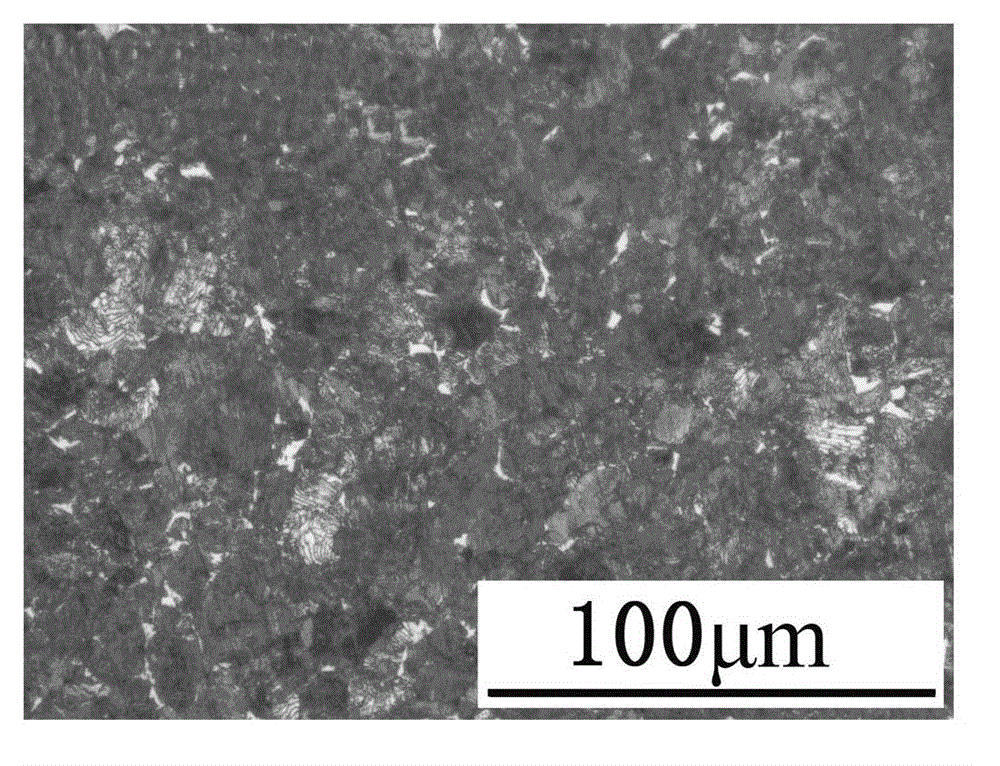

The invention discloses a production process of a 65 Mn spring steel wire rod and a 65 Mn spring steel wire rod. According to the invention, advantages of a device of a high line set are utilized, a finish rolling and reducing-sizing mills adopt 8+4 type, through optimization of a heating cycle process before rolling, a rolling control process and a cooling control process, only 8 front finish rolling machines and 2 reducing-sizing mills are utilized, so that surface decarburization of a spring is reduced and is even removed, and the fatigue life of a finished spring is prolonged; the amount of scales is reduced and the metal yield is improved; a metallographic structure is improved and a high sorbite rate is obtained, so that the production process has conditions to cancel a lead patenting process at the earlier drawing stage, the production processing cost is reduced, and the metallographic structure and the comprehensive performance of a hot-rolled wire rod for the 65 Mn spring steel are optimized. According to the invention, the microstructure quality and the mechanical property of the produced hot-rolled wire rod with phi6.5 mm for the 65 Mn spring steel reach the standard of the conventional 65 Mn spring steel after lead hot-rolled wire rod for the 65 Mn spring steel, the conditions to cancel the lead patenting process at the earlier drawing stage by a downstream user can be satisfied, a processing process is reduced for a user, and the production cost is reduced.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

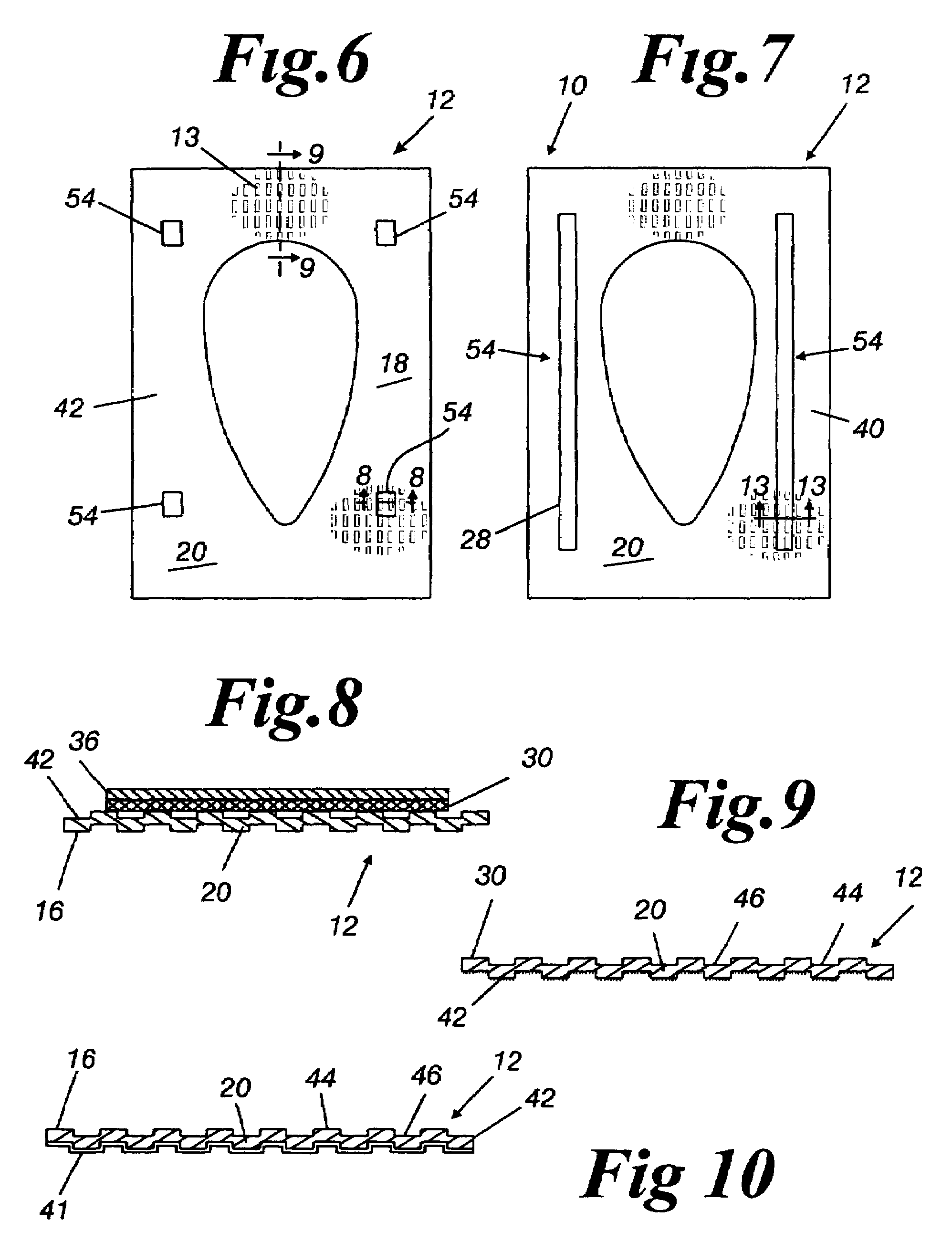

Sanitary, portable and disposable toilet seat cover, with attached wipe

InactiveUS7247360B1Improve absorbencyAdd to thicknessStampsFlexible coversTowelettesBiomedical engineering

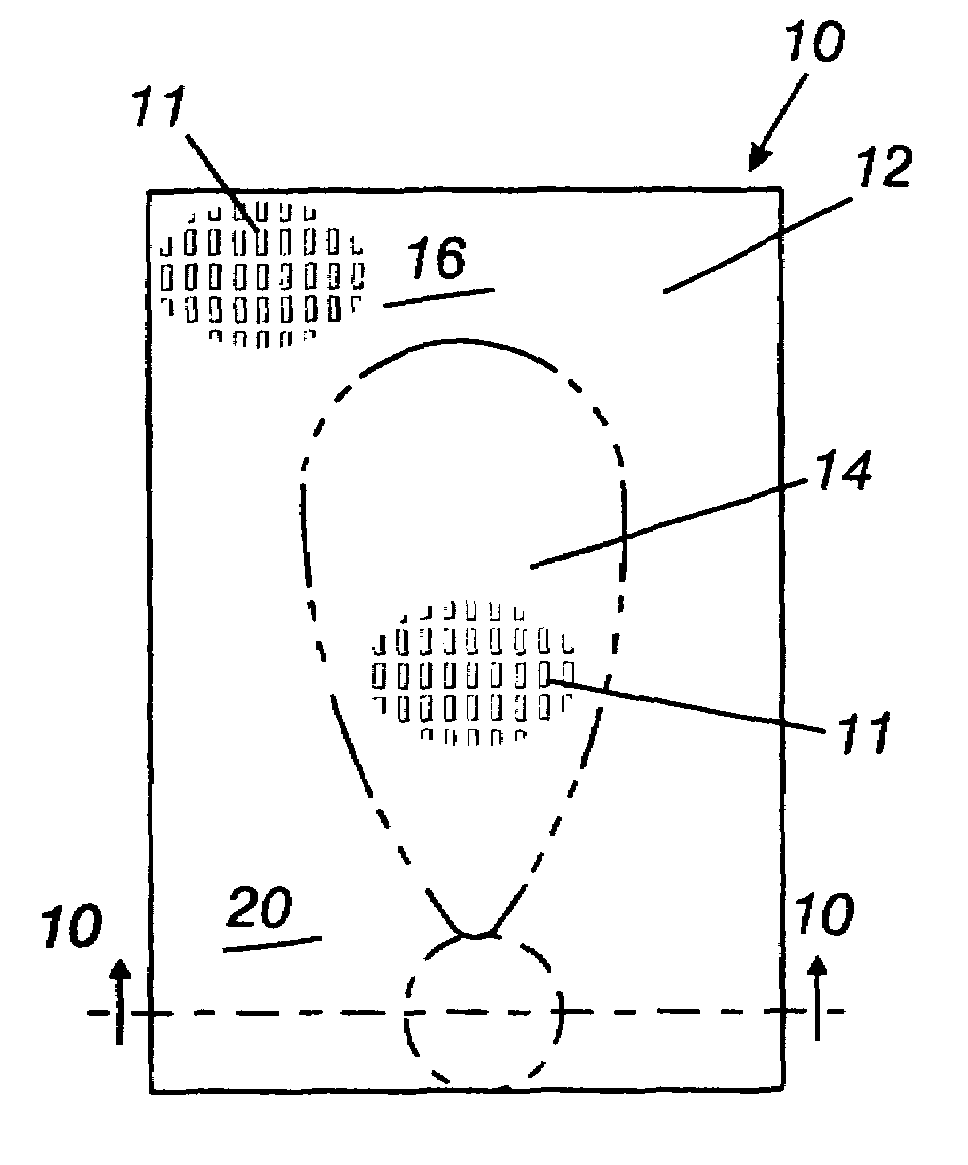

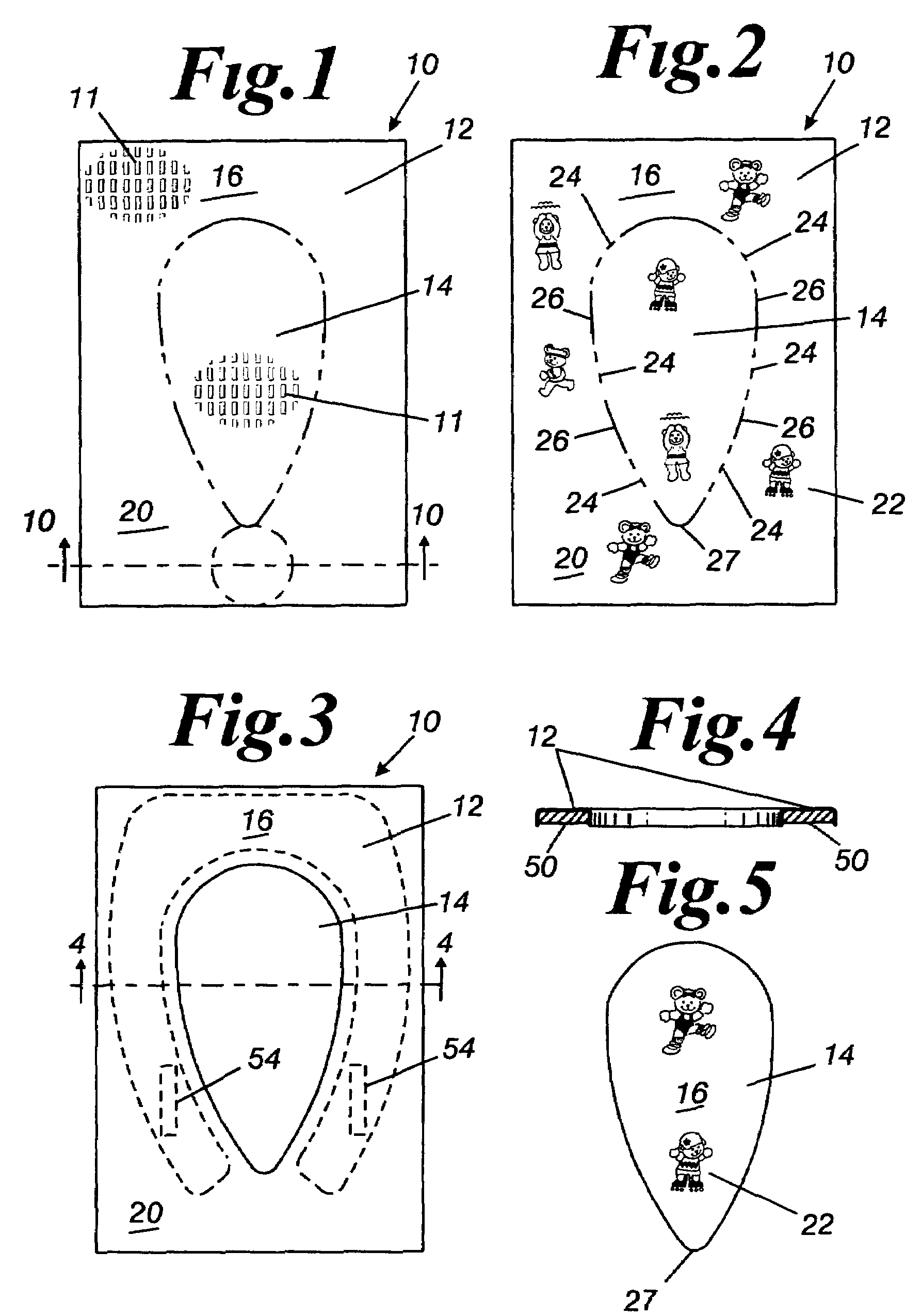

The invention is an easy to fold sanitary toilet seat cover for preventing direct contact between an individual's skin and the top and the side surfaces of a toilet seat. When unfolded, the toilet seat cover is sufficiently large to not only cover the entire elongated toilet seat, but also cover the sides of the seat. The disposable toilet seat cover comprises a polygonal annulus that is comprised of a quilted multilayer sheet having a water impervious layer and an absorbent layer, a wipe that is a detachable inner oval section that provides an opening to the toilet, and an adhesive fastening means for temporarily securing the polygonal annulus toilet seat. The water impervious layer comprises a coated layer and / or a filmic layer. The wipe detaches from an inner ovalled edge of the annulus, and is functional as a sanitary wipe or towel.

Owner:HAMCO

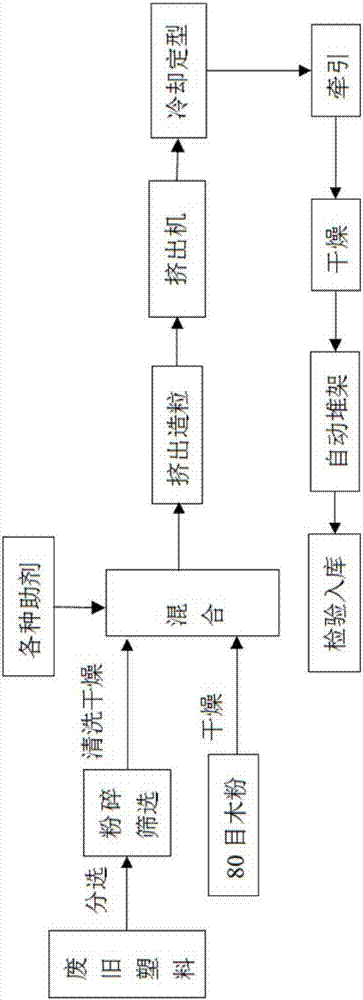

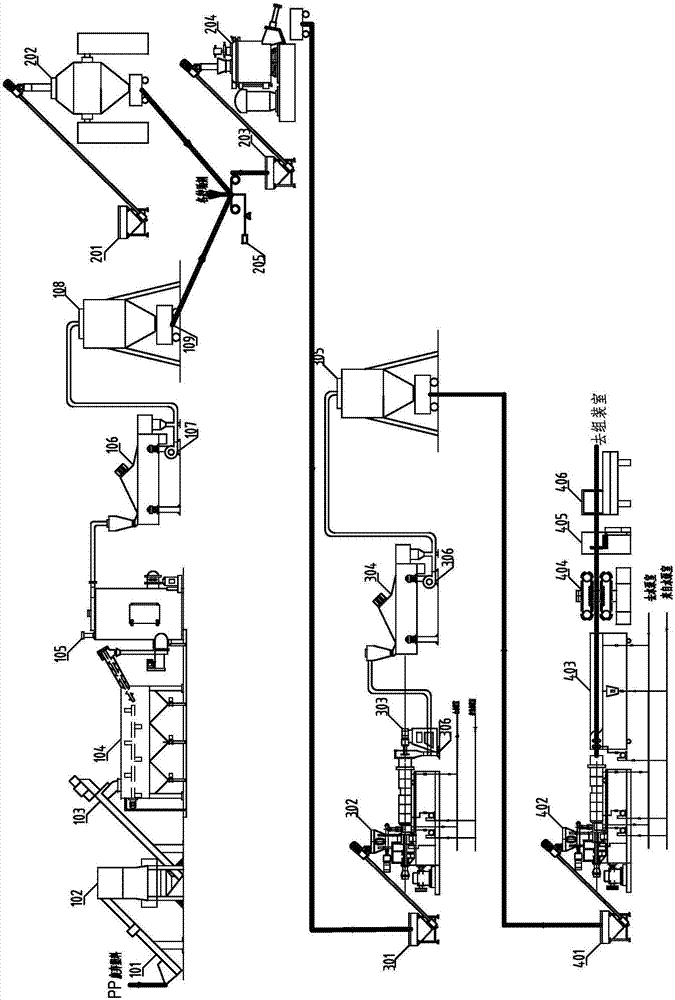

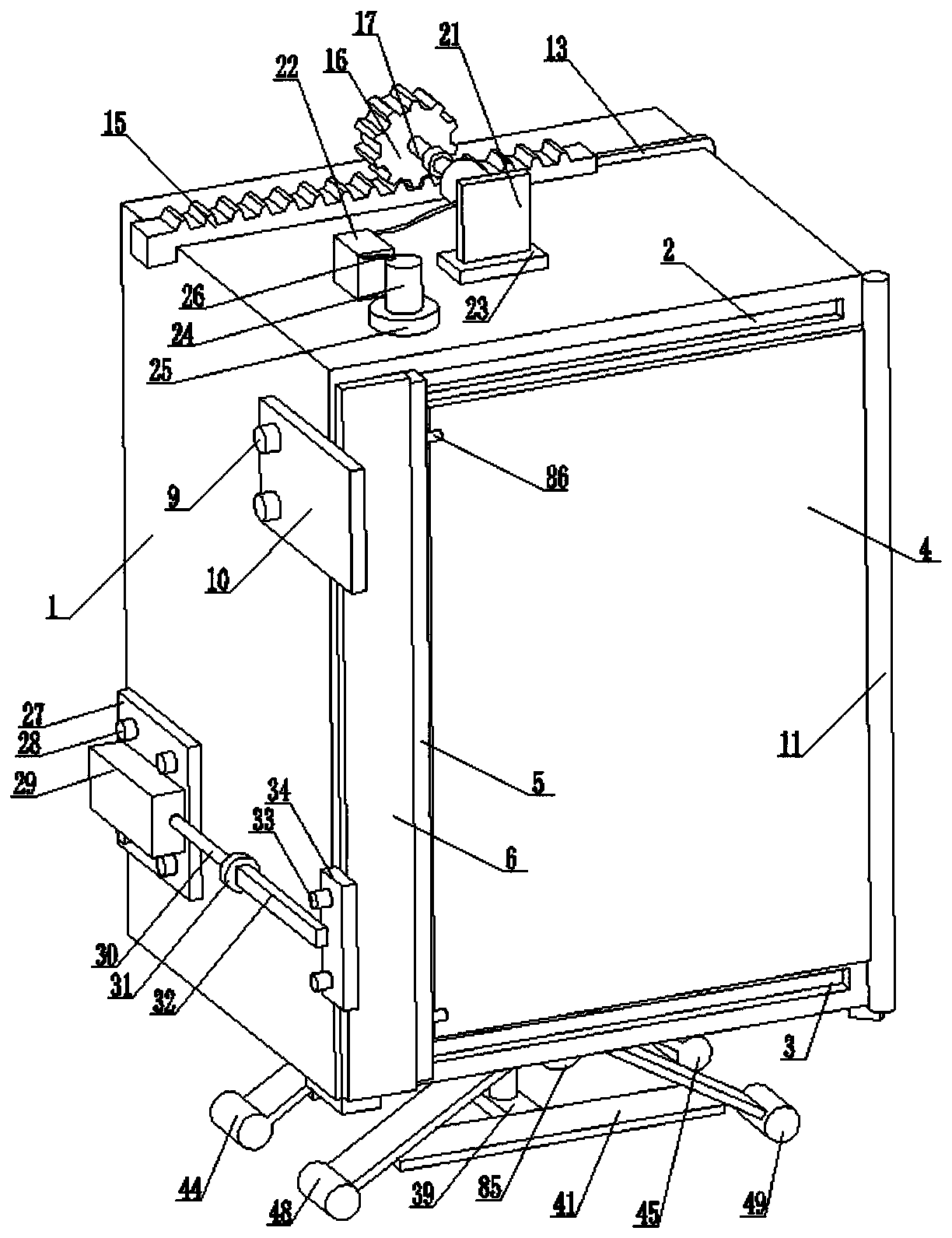

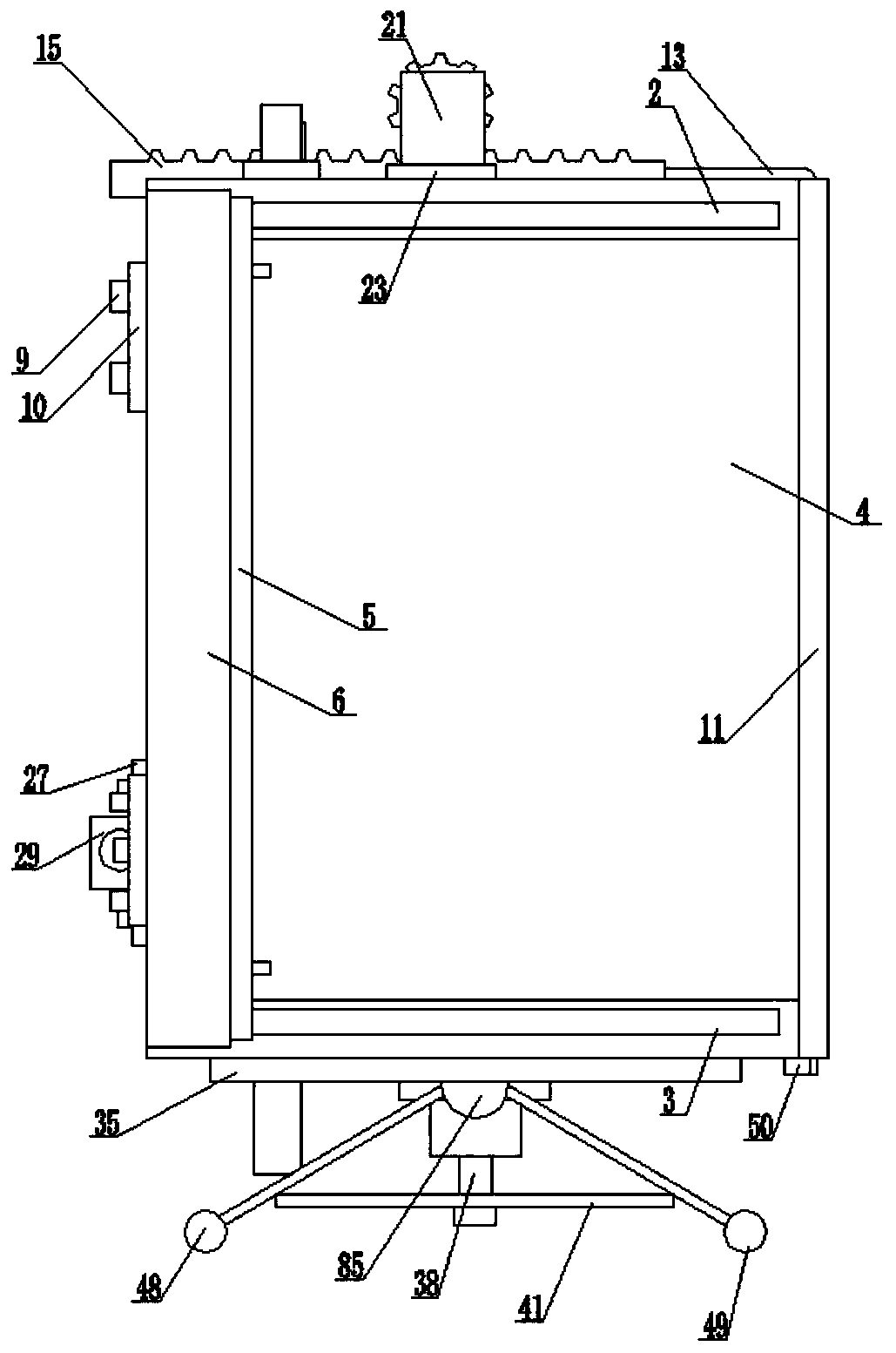

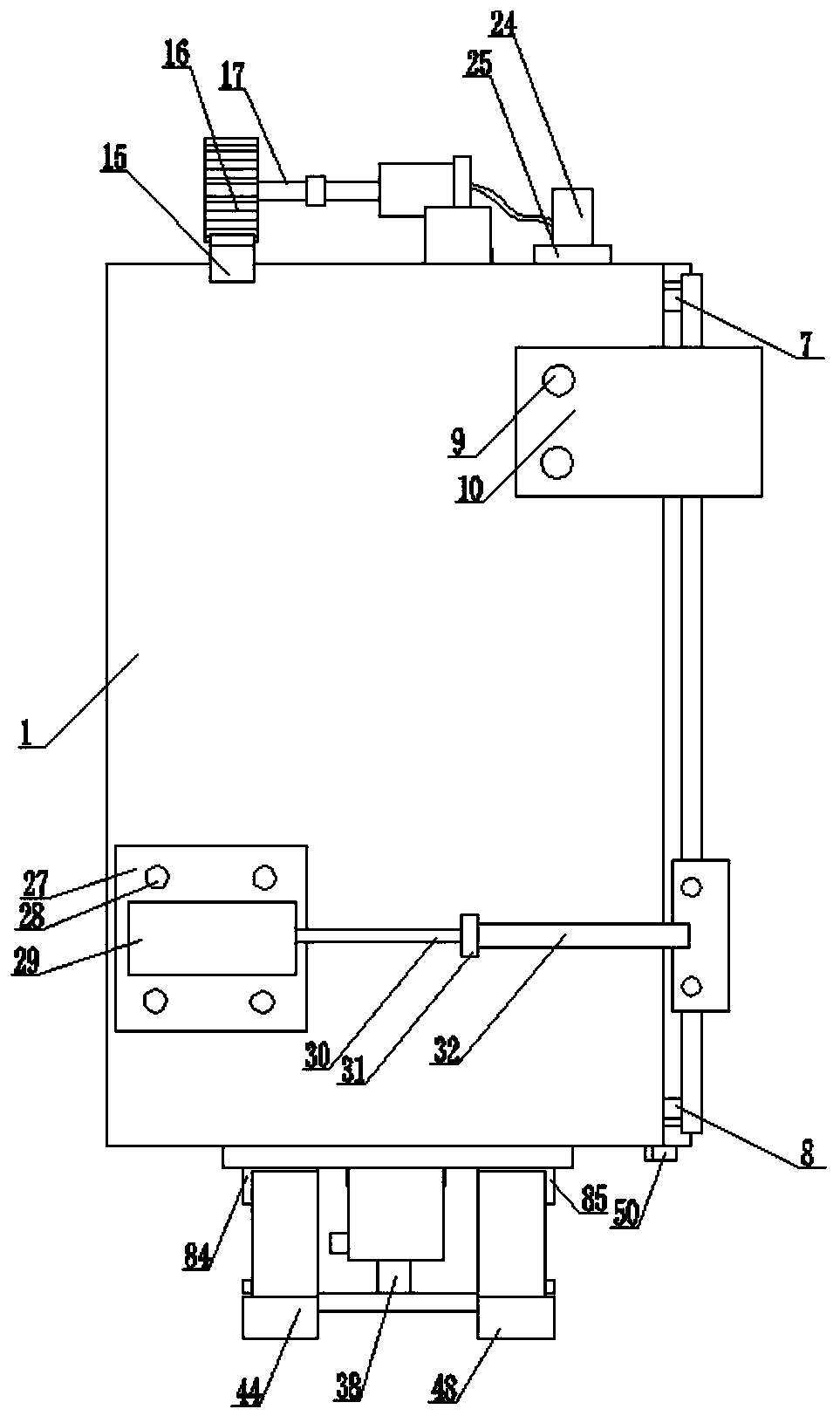

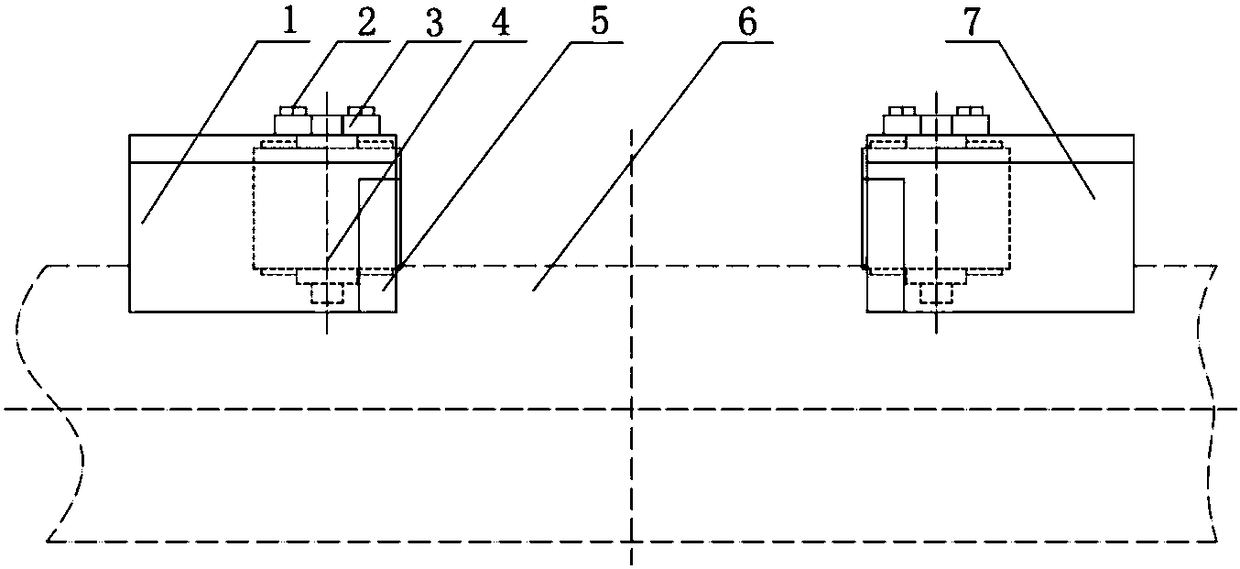

Formulation of wood-plastic profile as well as preparation method and manufacturing device thereof

InactiveCN107189216AImprove impact performance at room temperatureHigh low temperature impact resistanceHeat resistanceAntioxidant

The invention particularly relates to a formulation of wood-plastic profile as well as a preparation method and a manufacturing device thereof. The formula is characterized by being prepared from the following raw materials in parts: 100 parts of PP waste plastic with good mobility, 20 to 75 parts of wood powder, 5 to 15 parts of flexibilizer; 2 to 10 parts of compatibilizer; 1 to 10 parts of lubricant; 0.1 to 1 part of main antioxidant; 0.1 to 0.5 part of auxiliary antioxidant; 0.02 to 0.5 part of light stabilizer and 0.1 to 4 parts of antibacterial agents; the preparation method is characterized by comprising the following steps:(1) recycling the PP waste plastic with good mobility; (2) cleaning, crushing and drying; 3) drying the wood powder; 4) extruding and granulating; and 5) extruding and molding; and the manufacturing device is characterized by comprising a plastic cleaning device, a wood powder drying device, a weighing device, a mixing device, an extrusion granulation device and an extrusion molding device. The invention has the advantages of low cost, durability, long life, good heat resistance, good resistance to ultraviolet rays, high hardness and high load capacity.

Owner:YANTAI UNIV

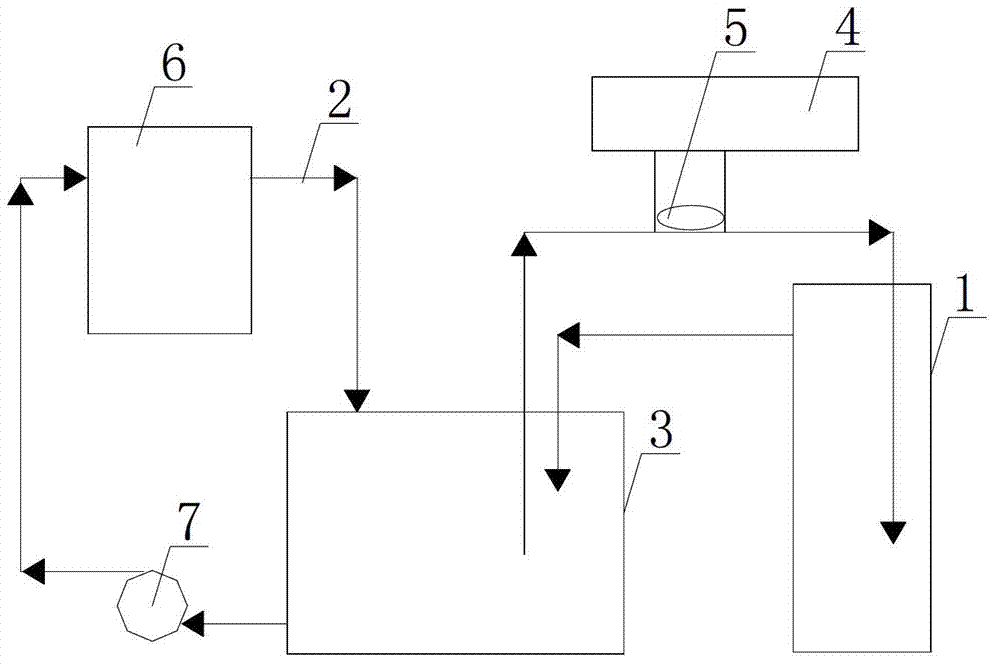

Automatic control technology of black oxidation copper foil in supplying copper ions and equipment used thereby

The invention discloses an automatic control technology of a black oxidation copper foil in supplying copper ions. The invention also discloses equipment used by the technology, in order to provide an automatic control technology that when electrolytic copper foil is subjected to black oxidation, parameters are set according to different technologies, the copper ions are compensated automatically, thereby achieving the aim of stabilizing the copper concentration, the technology is ensured to be stable, and color quality of the copper foil caused by unstable copper ions is prevented from being abnormal. The technical point comprises the following steps of: 1) starting up a liquid supplying circulating pump, thus the black oxidation electrolytic liquid passes through a black oxide electrolytic groove, and then backflows to a black oxidation liquid storage tank; 2) detecting the copper concentration of the black oxidation liquid storage tank after the circulating is determined to be normal, and meanwhile determining the electroplating current; and then detecting the copper concentration of the black oxidation liquid storage tank and the copper concentration of a copper dissolving tank; 3) collecting data, and calculating the consumption quantity of the copper ions per hour; and 4) starting up a micro type diaphragm pump, setting the time, and thereby achieving quantitative uniform supplement. The automatic control technology of the black oxidation copper foil in supplying the copper ions and the equipment used by the method belong to the technical field of copper foil manufacturing.

Owner:梅州市梅县区金象铜箔有限公司

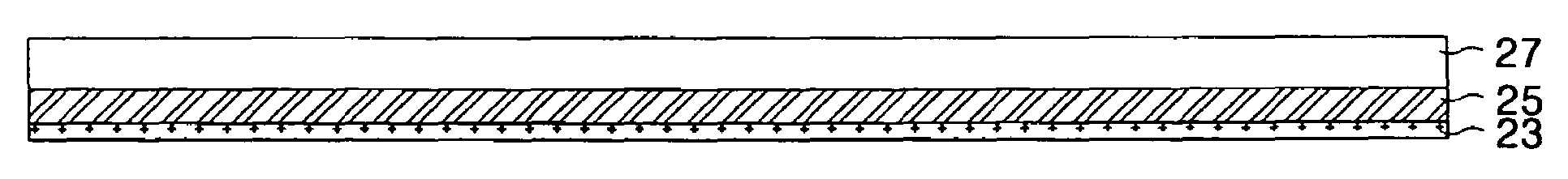

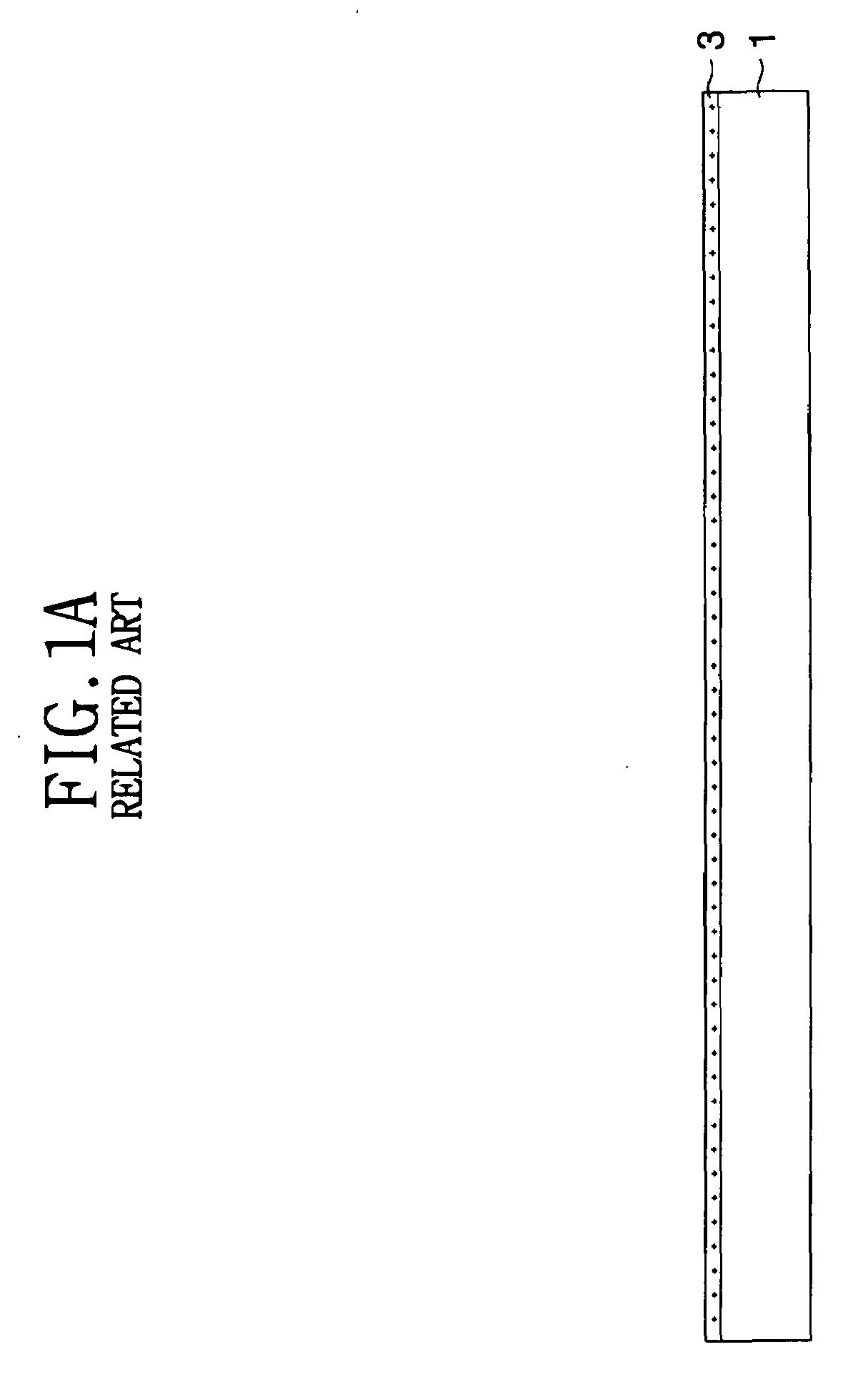

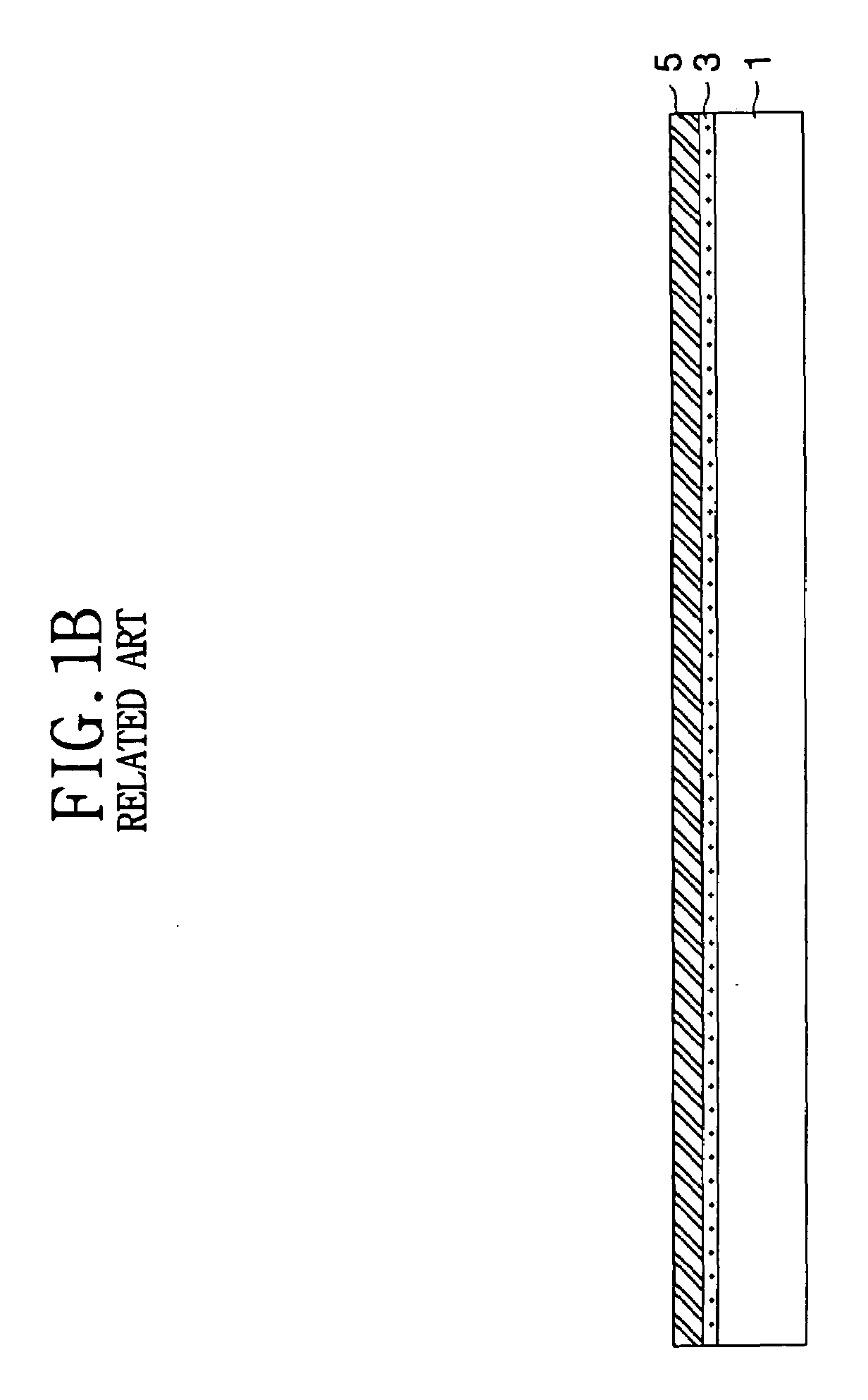

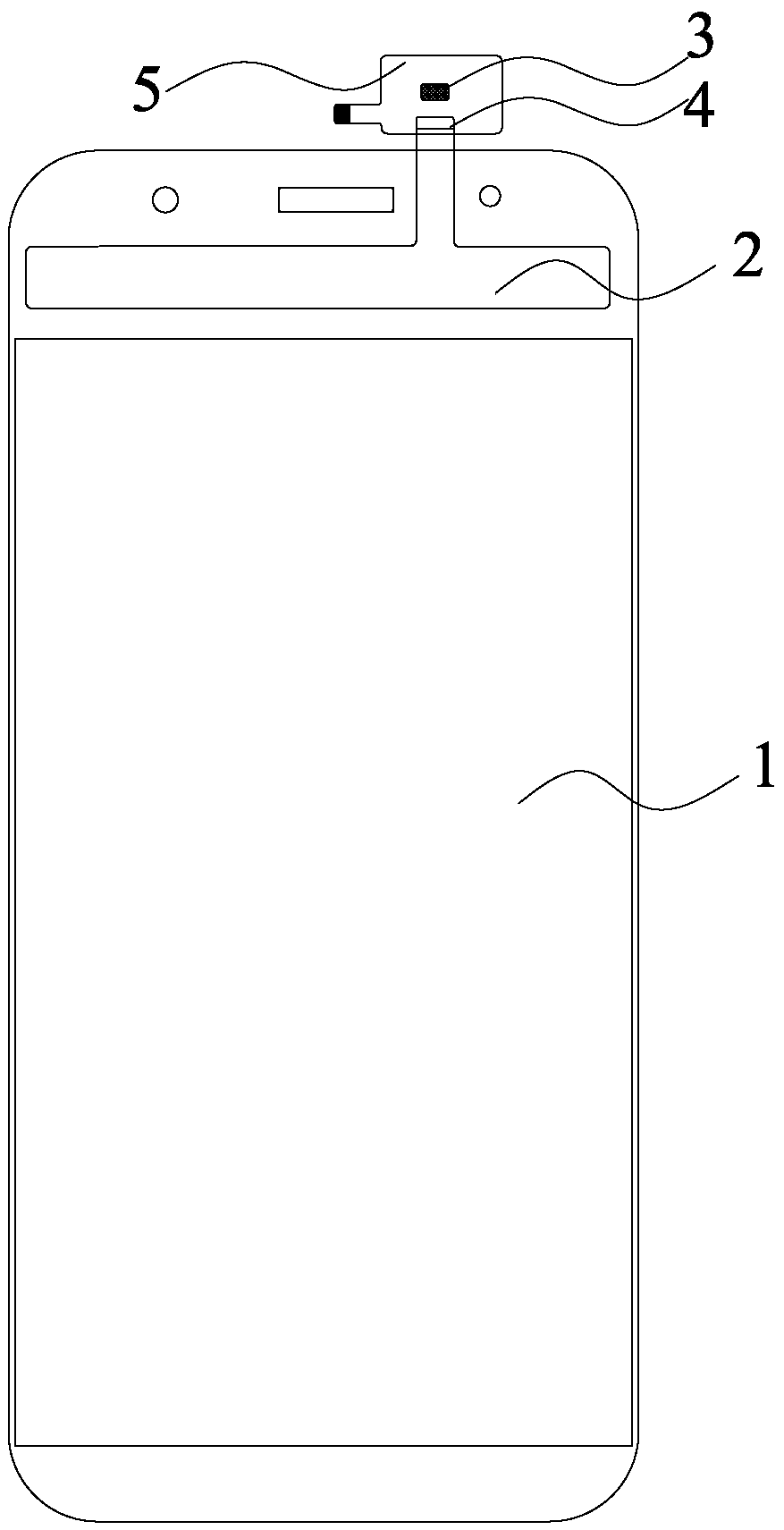

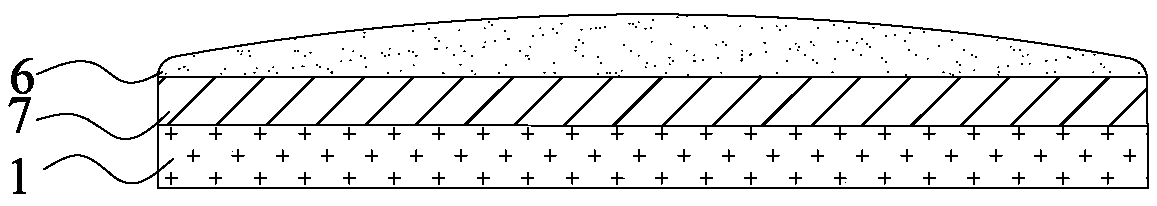

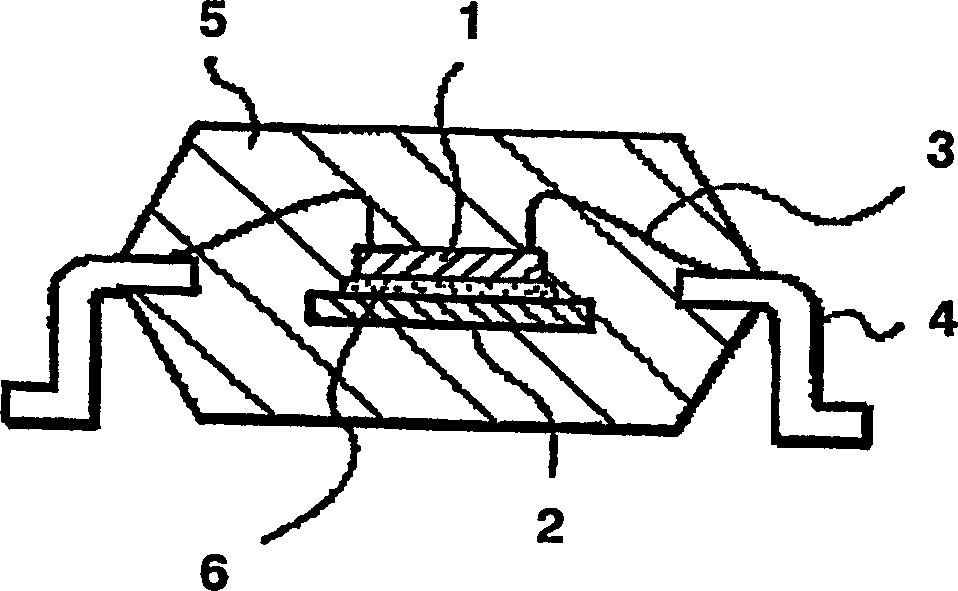

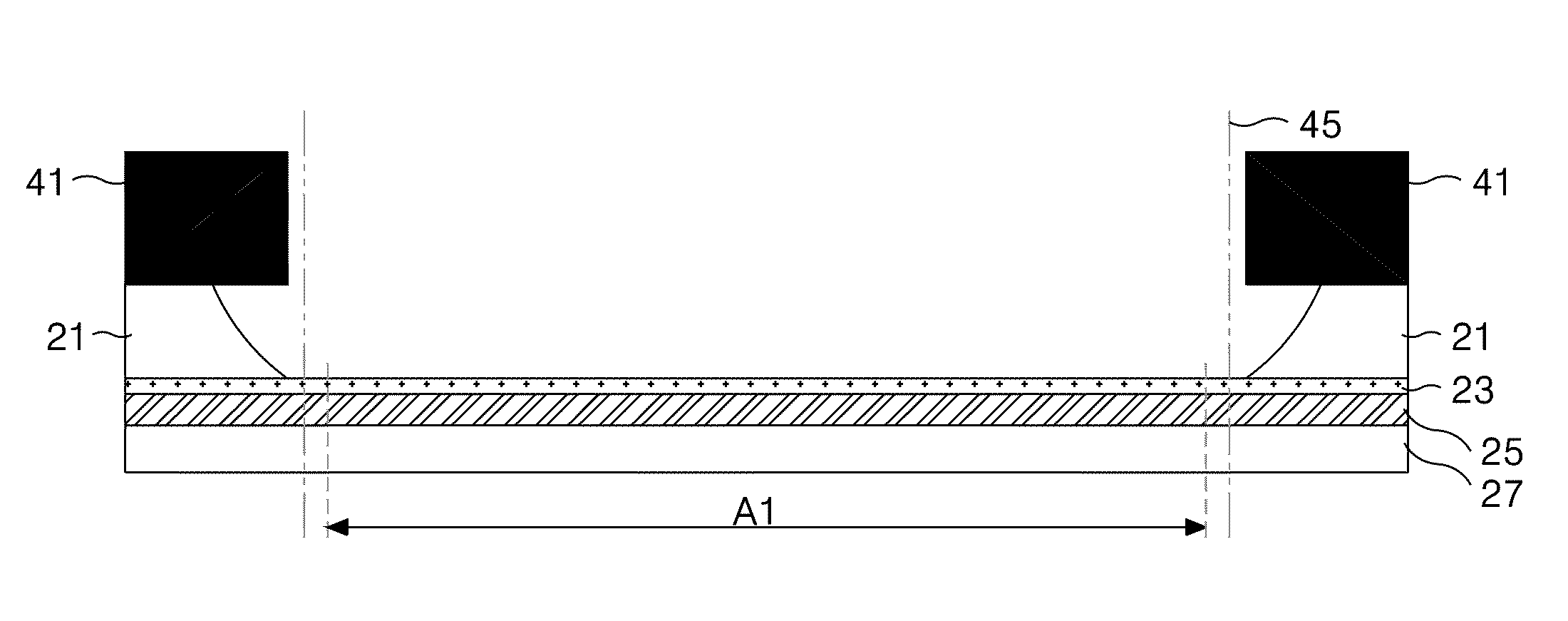

Method for manufacturing flexible display device and flexible display device

ActiveUS20080121415A1Stable productionEnsure production stabilityDischarge tube luminescnet screensPrinted circuit detailsEngineeringFlexible display

A flexible display device and a method for manufacturing a flexible display are provided. The flexible display device includes a flexible substrate, a display element layer formed on the flexible substrate; an insulating protective layer covering the display element layer; and a rigid substrate. The rigid substrate has an etching selectivity at least 20 times greater than that of the insulating protective layer.

Owner:LG DISPLAY CO LTD

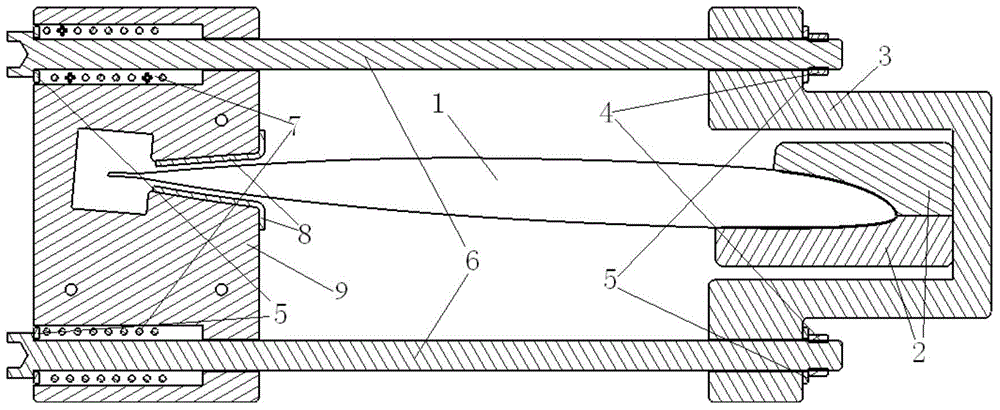

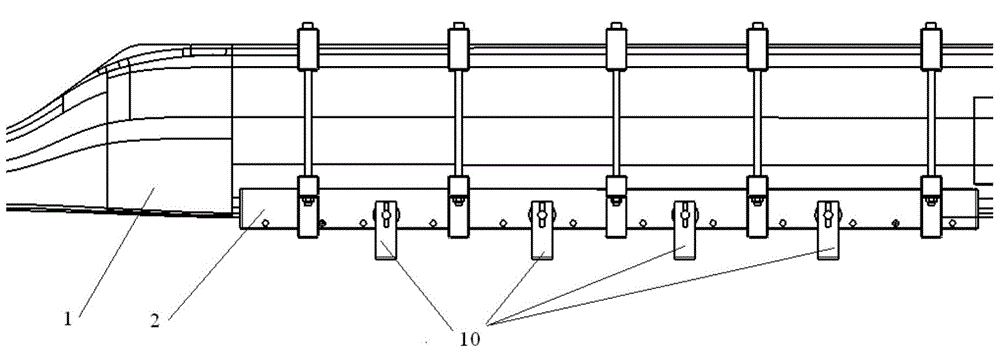

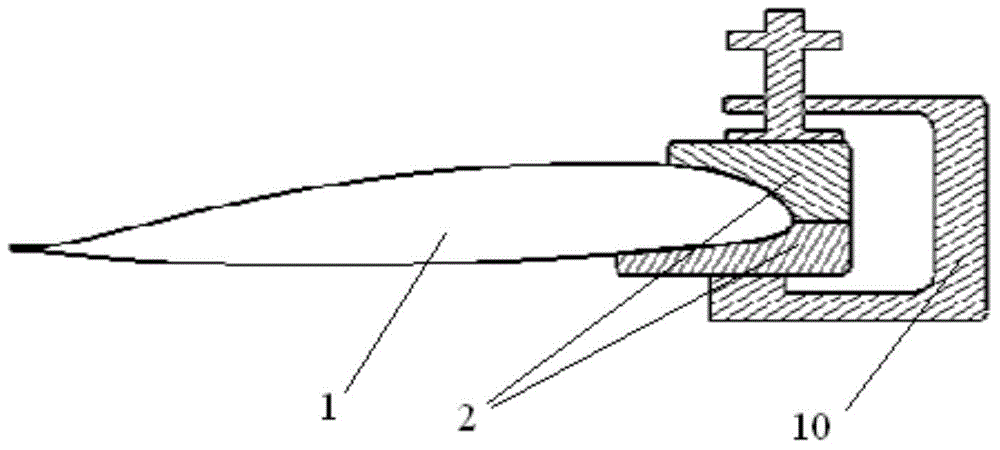

Process method for replacement and repair of iron clad of main blade made of composite material

InactiveCN104691779AImprove repair efficiencyIncrease success rateAircraft maintainanceAdhesion strengthPolyresin

The invention belongs to the technique of repair of aircrafts, and relates to a process method for replacement and repair of an iron clad of a main blade made of a composite material. The surface of the blade is marked in a spanwise position where the iron clade needs to be replaced, and the iron clad is separated from the main blade; an original resin system is selected and used, dry glass cloth is dipped in glue with 45% glue content, the glass cloth after glue dipping is cut according to the size of the glass cloth, and the layers of the laid glass cloth are one more than those of the stripped glass cloth; a tooling is fixed by adhesive tape and vacuumized, and a upper wing surface and a lower wing surface of the iron clad are pressurized; finally, the method that the blade is fully packaged with a vacuum bag is adopted, so that the iron clad of the blade can be replaced and repaired. The repair quality of the iron clad of the main blade is improved after ungluing, the theoretical appearance and the adhesion strength of the blade are guaranteed, the blade scrap rate caused by faults of the iron clade is effectively reduced, the repair efficiency and the repair success rate of the blade are increased, and the repair quality and the product stability are guaranteed.

Owner:HARBIN

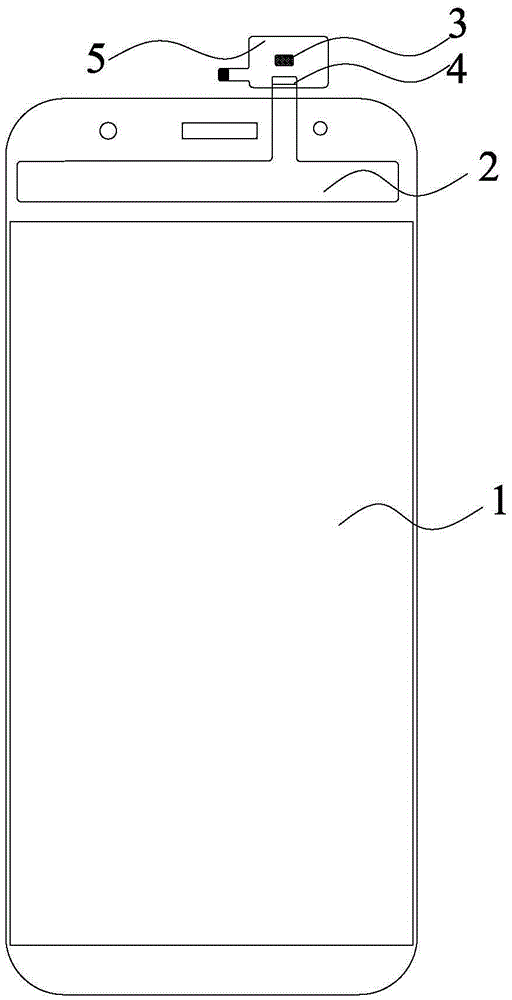

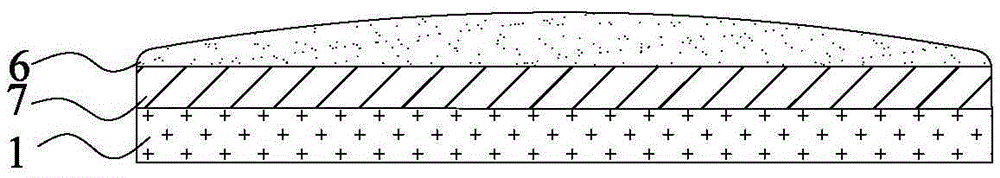

GG monolayer multipoint borderless touch screen and preparation process thereof

InactiveCN105511681AGood light transmissionImprove clarityInput/output processes for data processingSputteringGlass cover

The invention relates to the technical field of touch screens and particularly relates to a GG monolayer multipoint borderless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical adhesive layer and ITO conductive glass, wherein a border wiring area of the ITO conductive glass comprises a transverse wiring area arranged at one end of the touch screen, the ITO conductive glass is provided with a monolayer multipoint electrode pattern of single-end outgoing line, and an FPC is mounted in the transverse wiring area in a press-fitting manner and is connected with an IC chip. According to the GG monolayer multipoint borderless touch screen and the preparation process thereof, the FPC is mounted in the transverse wiring area at one end of the touch screen in the press-fitting manner, and original left and right longitudinal wiring areas are canceled, so that longitudinal sides of the touch screen do not need wiring, and thus, a borderless visual effect is built; ultraviolet illumination is adopted during magnetron-sputtering ITO film plating, so that the photoelectric properties of the ITO conductive glass are improved, only one-time FPC press-fitting is required during preparation, the process is simple, the yield of products is high, and excellent properties and production stability for the touch screen can be guaranteed.

Owner:深圳市欣联科技有限公司

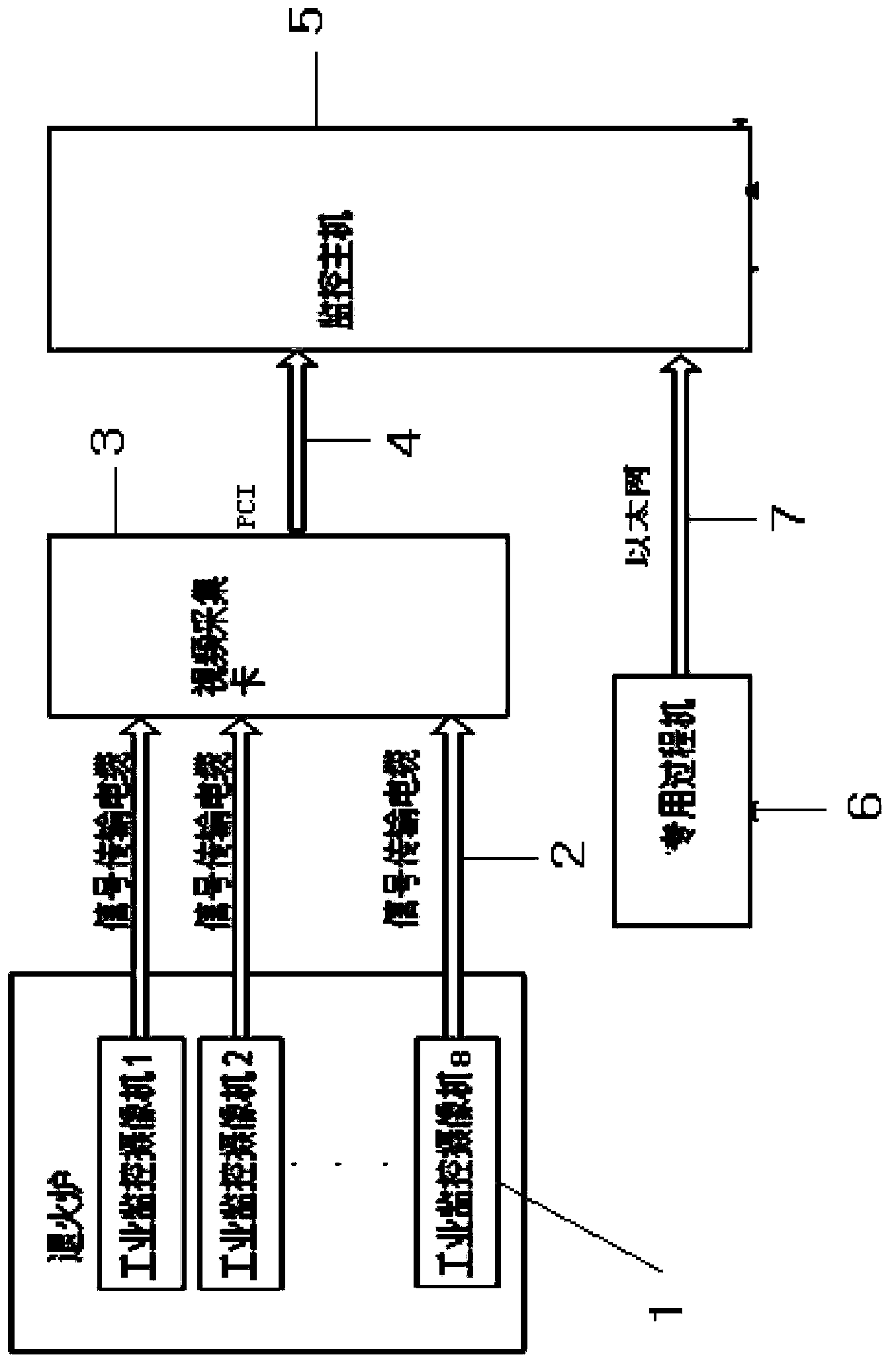

Method for online recognition of deviation of strip steel in furnace

ActiveCN103834796AAvoid missing detectionAvoid false detectionFurnace typesHeat treatment process controlStrip steelSquare error

The present invention discloses a method for online recognition of deviation of a strip steel in a furnace. The method comprises: 1) collecting multiple strip steel images including a strip steel edge position; 2) adopting an attention selection method to treat the collected strip steel images to obtain the significant feature pictures of the strip steel images, wherein the significant feature pictures comprise the edge position information of the strip steel; 3) carrying out a gray stretching treatment on the significant feature pictures, and then carrying out a binaryzation treatment, wherein all the taken values in the value taking range are adopted to calculate the corresponding classes square error r2 so as to determine the first optimal gray threshold T1 and the second optimal gray threshold T2, the pixels in the pictures requiring the binaryzation treatment are divided into the target class, the background class and the interference class according to the first optimal gray threshold T1 and the second optimal gray threshold T2, the gray value of the target class pixels is set to 1, and the grey values of the background class pixels and the interference class pixels are set to 0; and 4) judging whether the deviation of the edge position of the strip steel in the binaryzation picture is more than the preset value. The technical scheme has characteristics of easy and accurate use.

Owner:BAOSHAN IRON & STEEL CO LTD +2

GF single-layer multi-touch frameless touch screen and preparation process thereof

ActiveCN105426014AImprove antiknock performanceReduce reflectionInput/output processes for data processingGlass coverEngineering

The invention relates to the technical field of touch screens, in particular to a GF single-layer multi-touch frameless touch screen and a preparation process thereof. The touch screen comprises a tempered glass cover plate, a transparent optical glue layer and an ITO conductive film, wherein the wiring area of an ITO conductive film frame comprises a transverse wiring area arranged at one end of the touch screen, single-layer multi-touch electrode patterns realizing single-end wiring are formed on the ITO conductive film, a FPC (flexible printed circuit) is pressed on the transverse wiring area, an outgoing line of the ITO conductive film is connected with an IC (integrated circuit) chip through the FPC, and the tempered glass cover plate is provided with an anti-explosion layer and an anti-reflective layer. According to the GF single-layer multi-touch frameless touch screen, the FPC is pressed on the transverse wiring area at one end of the touch screen, so that wires are not required to be arranged on longitudinal edges of the touch screen, and a flameless visual effect is realized; the GF single-layer multi-touch frameless touch screen has good photoelectric performance, stability and anti-explosion capacity, FPC pressing only needs to be performed once in the preparation process, the process is simple, the yield of products is high, and the good performance and the production stability of the touch screen can be guaranteed.

Owner:DONGGUAN PINGBO ELECTRONICS

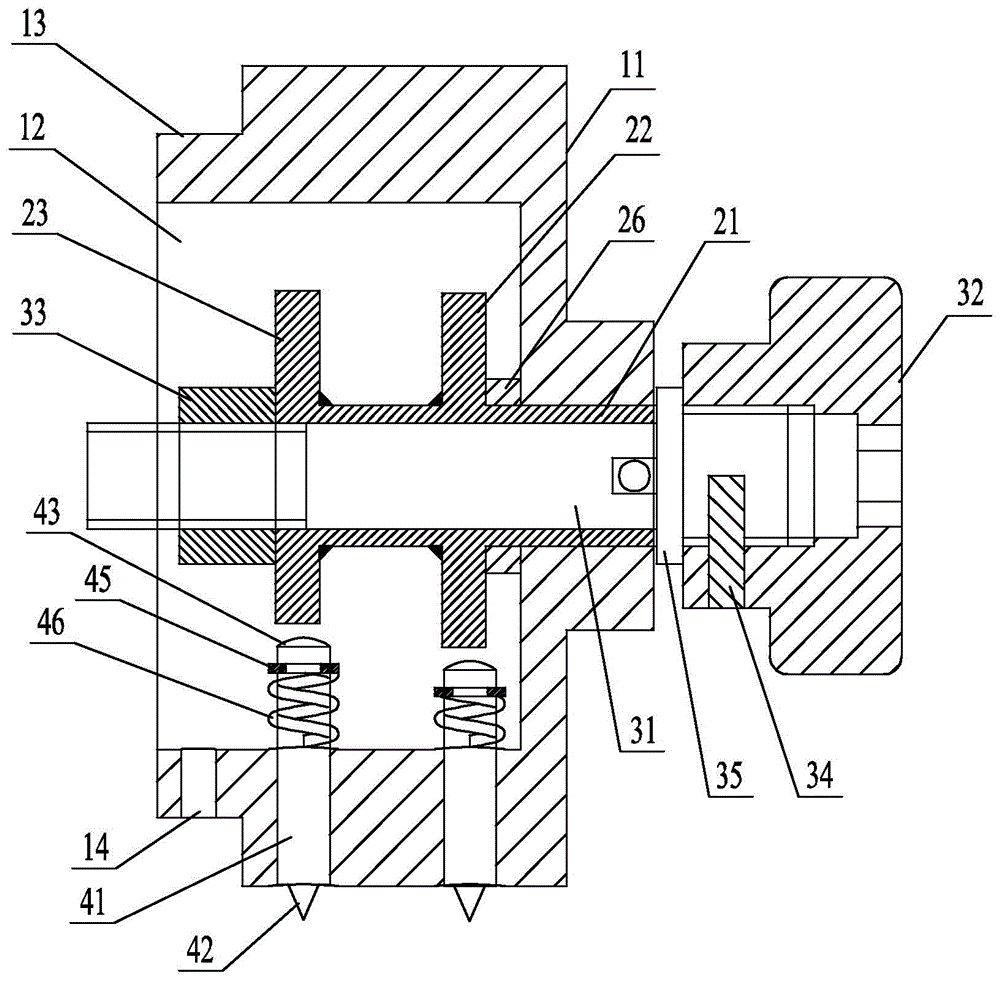

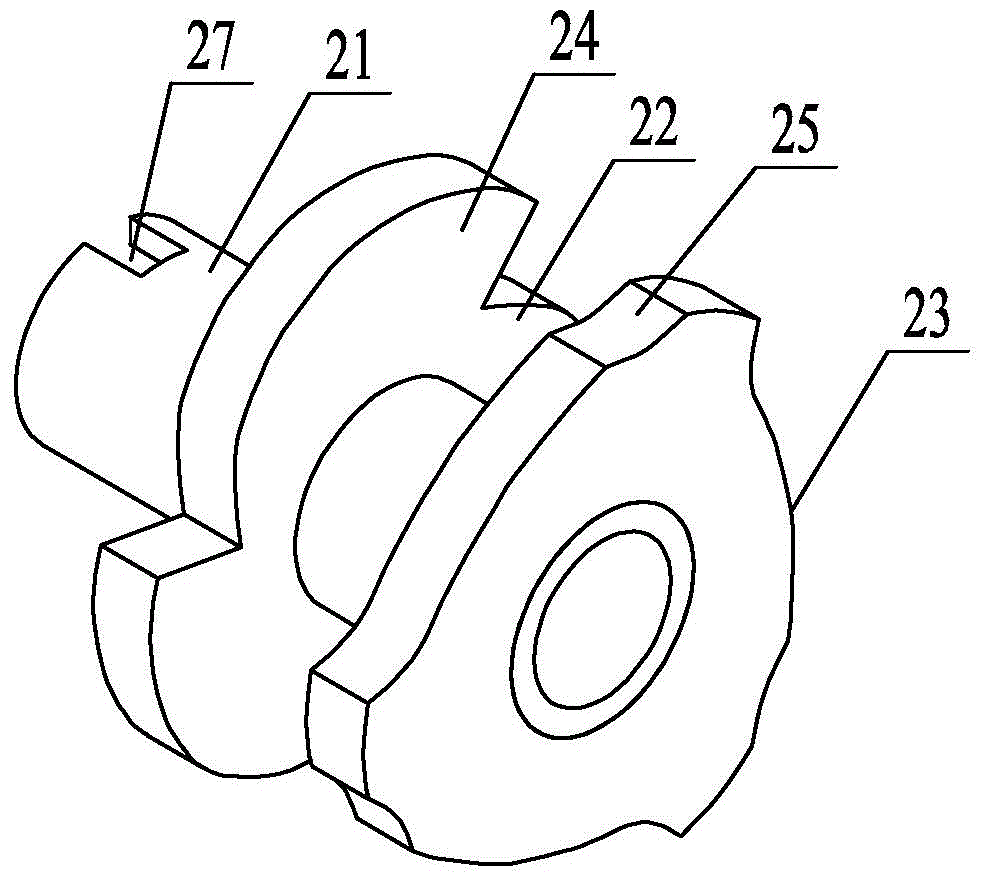

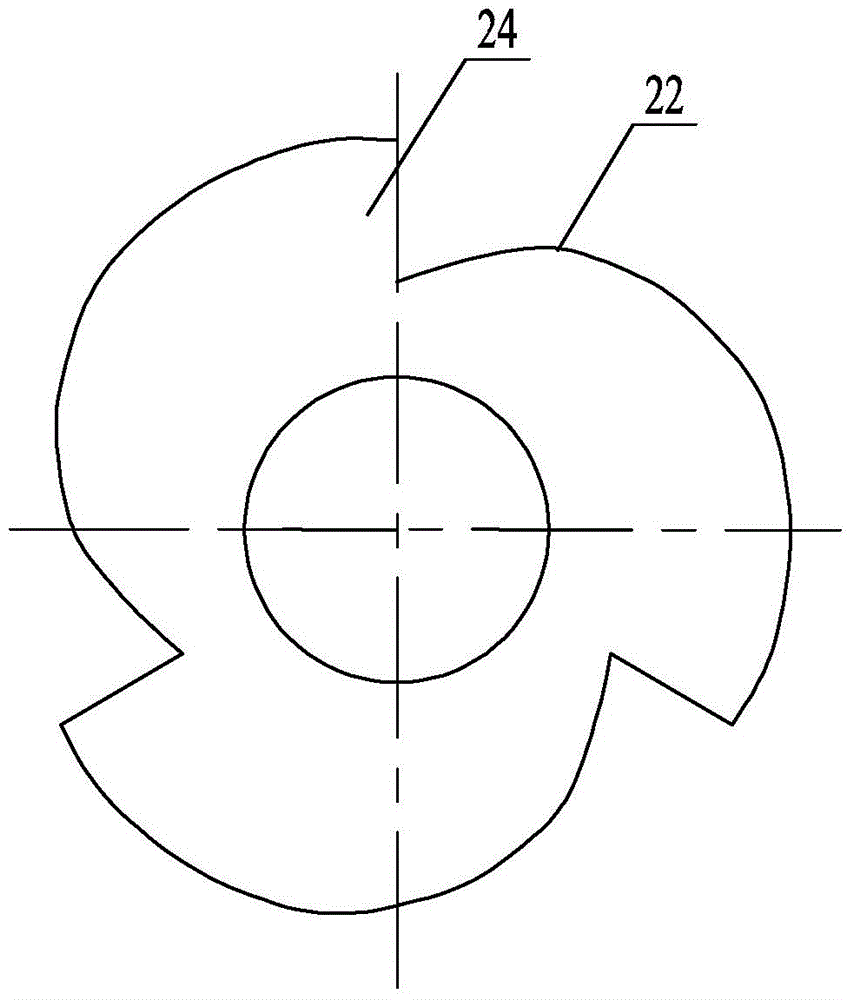

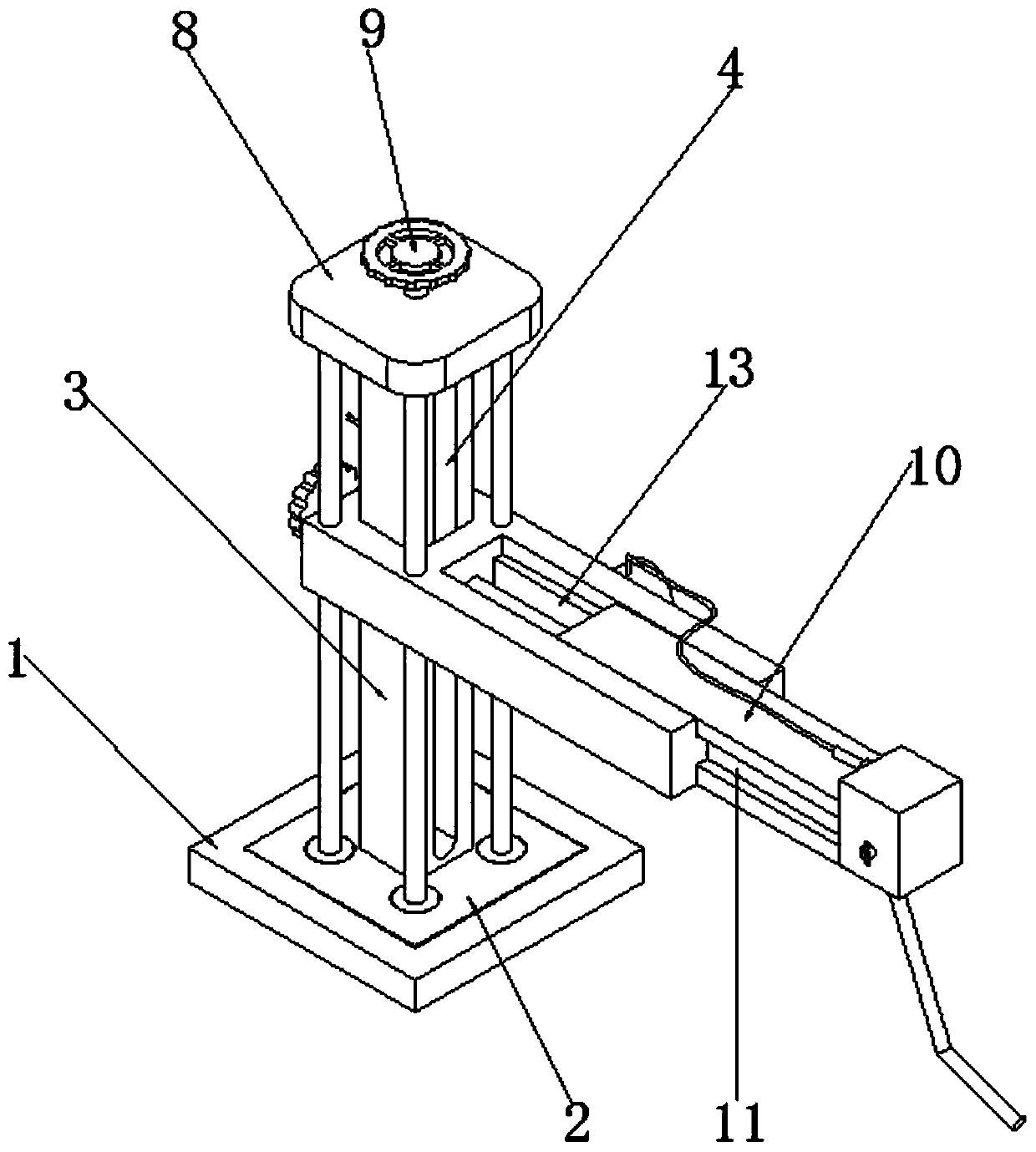

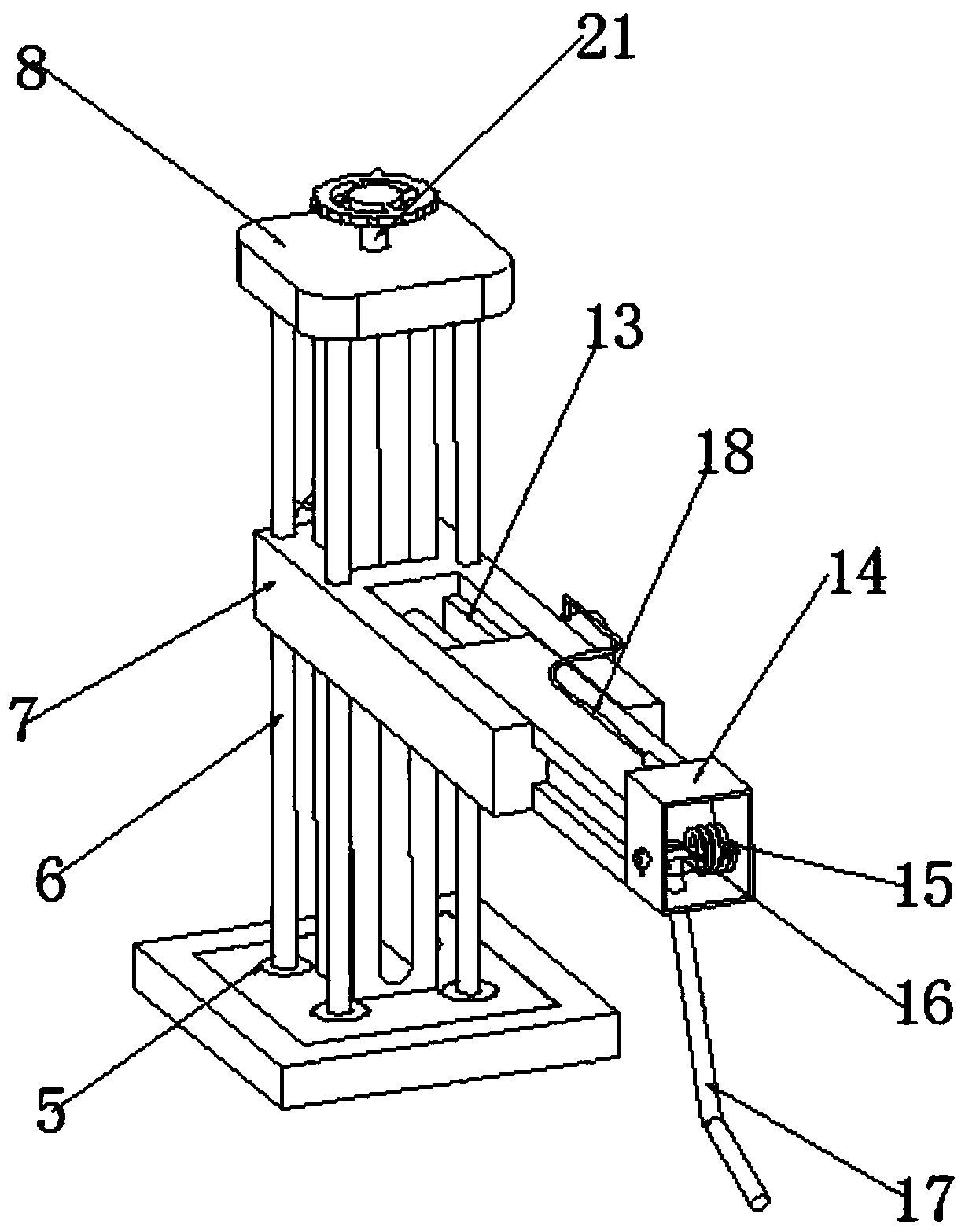

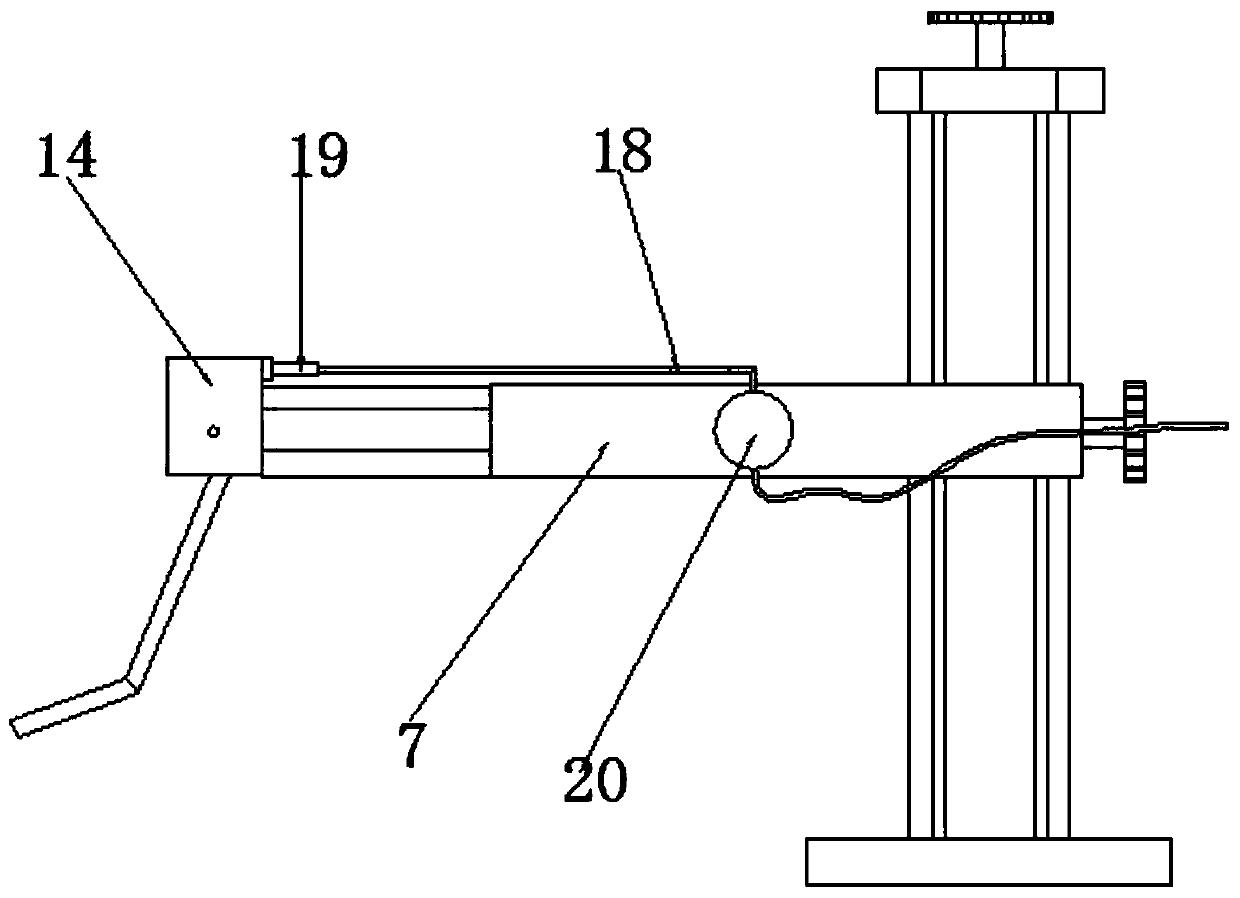

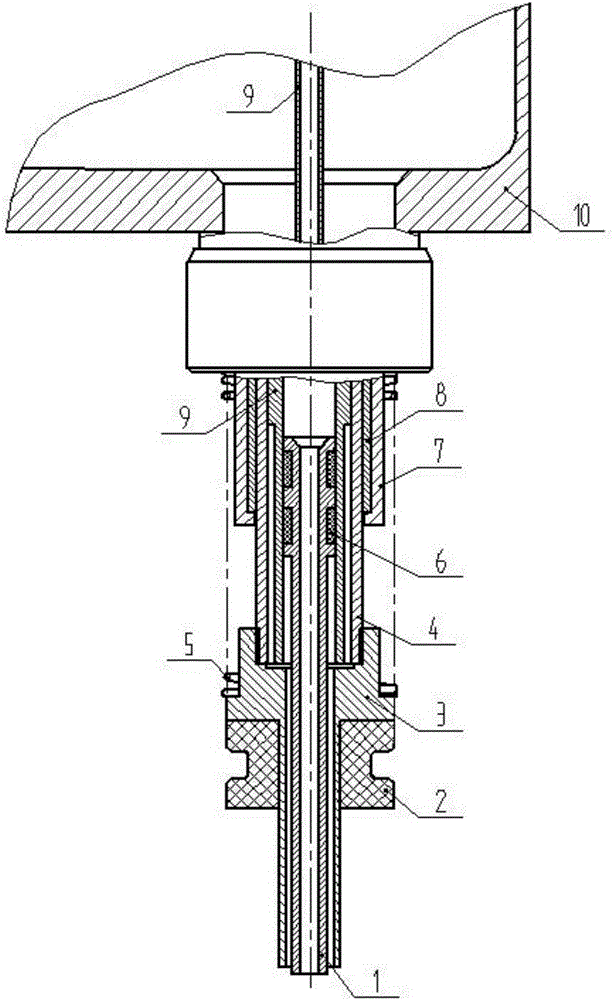

Yarn barrel locking device for aramid yarn of optical cable

The invention discloses a yarn barrel locking device for aramid yarn of an optical cable and relates to the field of nonmetallic reinforcing pieces of communication optical cables. The yarn barrel locking device for the aramid yarn of the optical cable comprises a column-shaped cam seat, the front end hollows towards the inside to form a hollow cavity, a hollow shaft is axially arranged in the hollow cavity, and a first cam and a second cam sleeve the hollow shaft; a rotating shaft is co-axially arranged in the hollow shaft, and the end thereof runs through the rear end of the cam seat and is fixed with a handle wheel; at least one pair of through holes corresponding to the two cams are arranged in the side wall of the cam seat, a column body is through arranged in each pair of through holes, the end of the column body running through the cam seat is a pointed end, the end located in the hollow cavity is a ball head end, and a spring sleeves the part of each column body in the hollow cavity; each cam is provided with cam pieces, wherein the number of the cam pieces is larger than the pair number of the through holes, when two cams rotate, the column bodies corresponding to the cams telescopically move in the through holes along with the rotation of the cam pieces. The yarn barrel locking device for the aramid yarn of the optical cable prevents the yarn barrel generating axial and radial jump in the production process, the optical cable bending, yarn break and cable break due to the yarn barrel loosening are avoided, and the production efficiency is improved.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

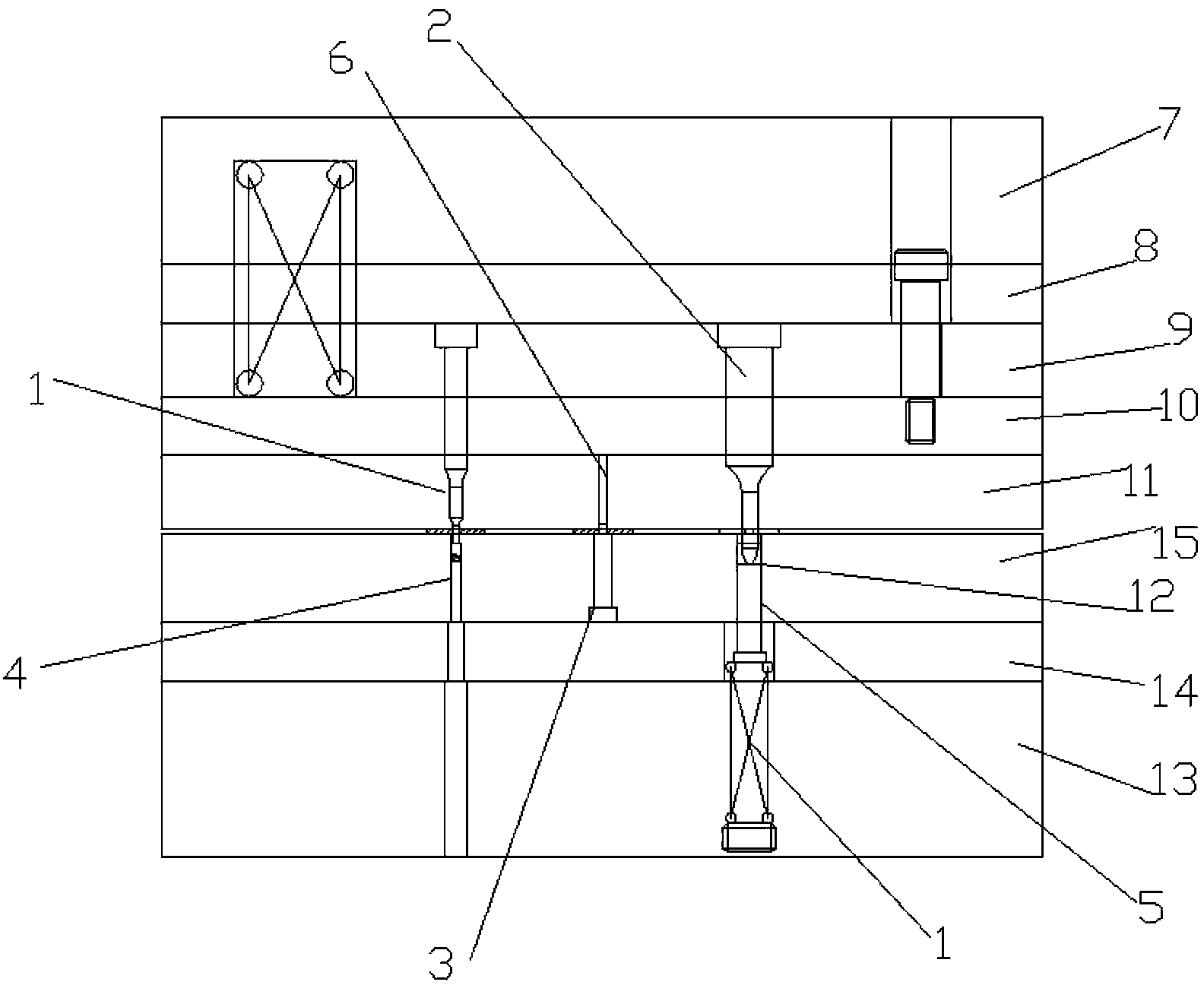

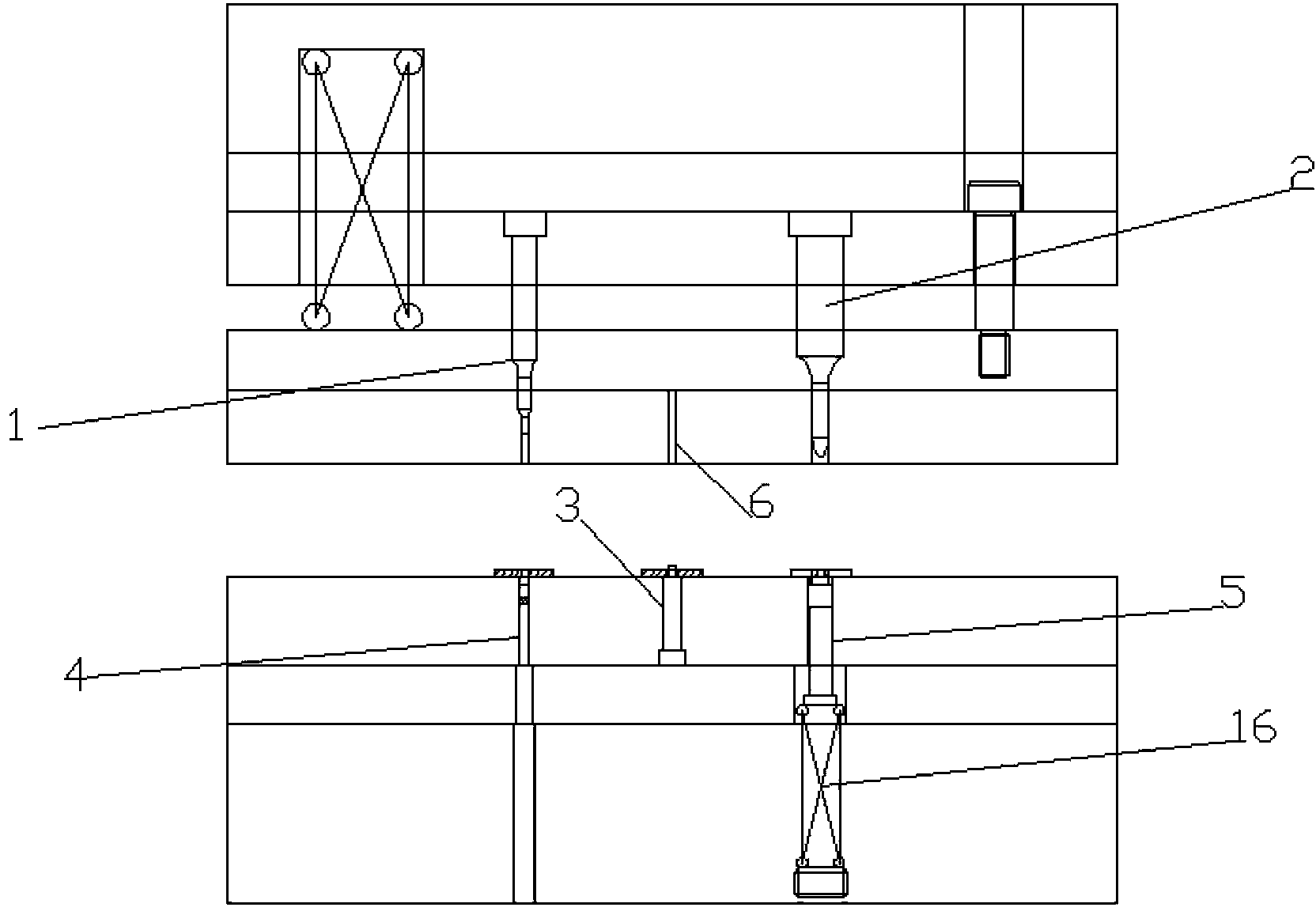

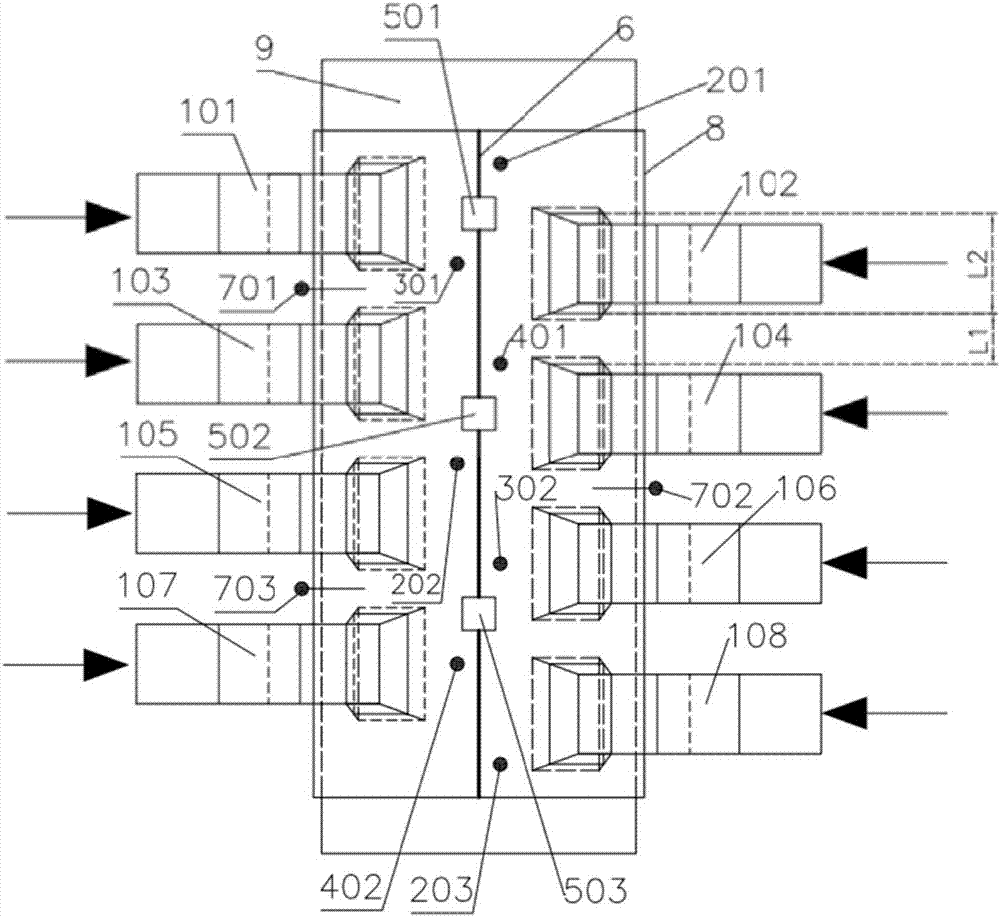

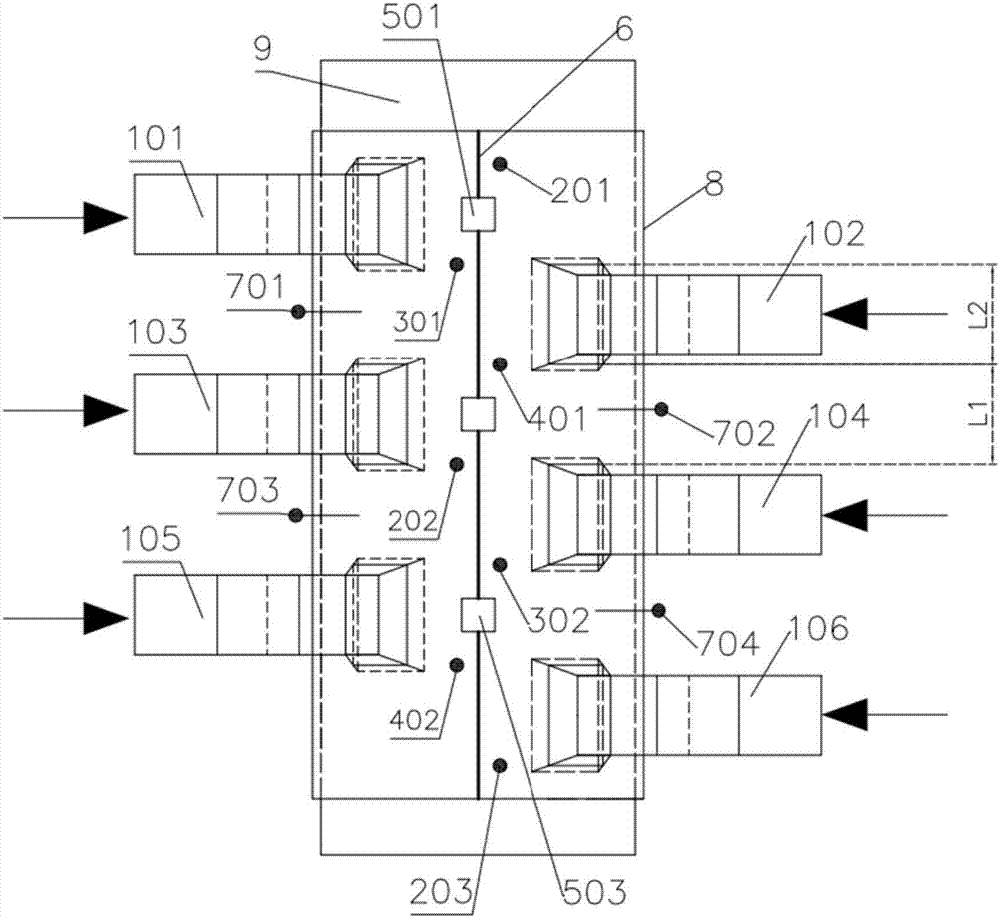

Cracking-free stamping die for hole flanging of stainless steel thick plate

ActiveCN104338848AGuaranteed production effectEnsure production stabilityShaping toolsPerforating toolsThick plateCrack free

The invention discloses a cracking-free stamping die for hole flanging of a stainless steel thick plate. The cracking-free stamping die comprises an upper die and a lower die, wherein a hole punching punch and a hole flanging punch are arranged on the upper die in a spaced positioning manner; a hole extruding punch is arranged on the lower die in a positioning manner; a waste via hole which corresponds to the hole punching punch and is matched with the hole punching punch in size is formed in the lower die; a hole flanging inner jack which corresponds to the hole flanging punch and is matched with the hole flanging punch in size is arranged on the lower die; an avoiding hole which corresponds to the hole extruding punch and is matched with the hole extruding punch in size is formed in the upper die. According to the cracking-free stamping die disclosed by the invention, the problem that the stainless steel thick plate is cracked during hole flanging can be effectively solved, so that the phenomenon that normal production cannot be realized caused by cracking is reduced, the productibility of the die and the stability of products are guaranteed, the production efficiency is improved, and extra waste of production cost of products is reduced.

Owner:JIANGSU BOJUN IND TECH

Method for preparing alpha-alumina powder for liquid crystal substrate glass

ActiveCN101767808AImprove crystallinity and sphericityHigh purityAluminates/aluminium-oxide/aluminium-hydroxide purificationLiquid crystalAmmonium chloride mixture

The invention discloses a method for preparing alpha-alumina powder for liquid crystal substrate glass, which is prepared from the following raw materials in part: 90 to 99 parts of first class industrial alumina or / and first class industrial aluminium hydroxide, 0.3 to 5 parts of boric acid, 0.2 to 5 parts of ammonium chloride and 0.2 to 2 parts of barium fluoride. The method comprises the following steps: firstly, mixing the raw materials uniformly, placing the mixture in a tunnel kiln, calcining the mixture at the calcination temperature of 1450 DEG C and keeping the temperature for 6 hours; secondly, sorting and grading the quality of a product of the first step, crushing, grinding and grading the product by placing the product in a continuous ball-grinding grading production line to obtain alumina powder with the required grain size distribution; and thirdly, putting a product of the second step into purified water, washing the product to make a pH value of the alumina powder between 7.5 and 8.5, and drying the product to obtain the alpha-alumina powder. The alpha-alumina powder for the liquid crystal substrate glass prepared by the method has the following specific indexes: Al2O3 content of more than or equal to 99.8 percent, alpha-phase transformation rate of more than or equal to 98 percent, SiO2 content of less than or equal to 0.03 percent, Fe2O3 content of less than or equal to 0.02 percent, Na2O content of less than or equal to 0.02 percent, C content of less than or equal to 0.01 percent, Cl<-> content of less than or equal to 0.001 percent, SO3 content of less than or equal to 0.01 percent, ignition loss of less than or equal to 0.01 percent and alpha-alumina grain size of between 30 and 75 micrometers.

Owner:河南天马新材料股份有限公司

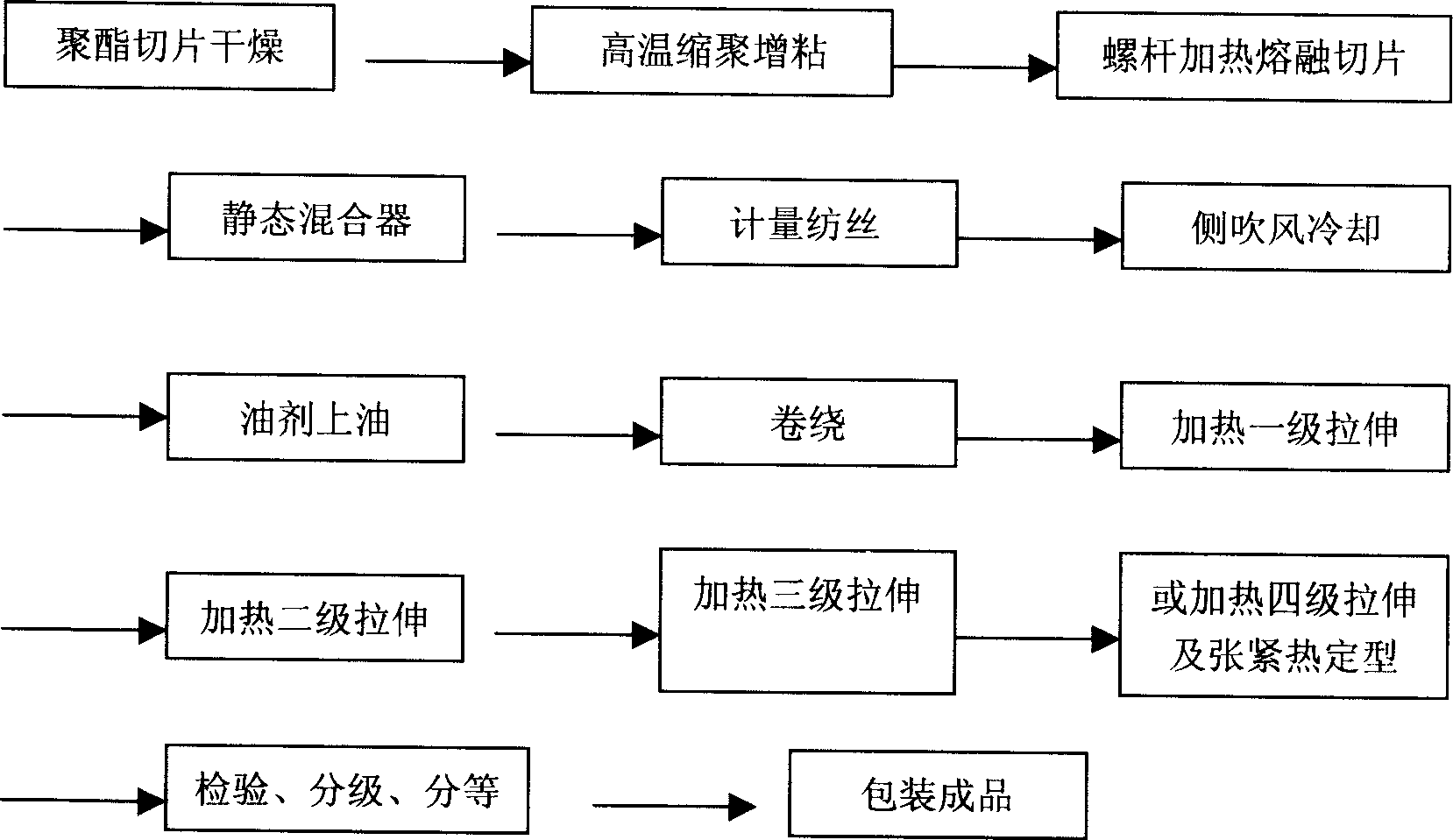

Production process and application of polyester filament

InactiveCN1811023AGuaranteed structural uniformityEnsure production stabilityScreen printersMelt spinning methodsPotentiometerFlat panel display

The present invention is the production process and application of polyester filament. The production process includes the following steps: 1. spinning polyester chip in conventional process in a spinning machine; and 2. sectional heating to stretch the wound filament. The polyester filament is applied in weaving high grade polyester printing screen, making high density multilayer printed circuit board, miniature printed resistor, printed potentiometer, etc. The present invention can produce polyester filament with high homogeneity, low coefficient of variation, controllable boiling shrinkage and capacity of making high quality printing screen.

Owner:DONGHUA UNIV +1

Power distribution cabinet

InactiveCN111555142AFirmly connectedEasy inspection and maintenanceSubstation/switching arrangement casingsArrangements responsive to excess currentStructural engineeringInductor

The invention provides a power distribution cabinet. The power distribution cabinet comprises a box body, an action bottom plate, an inductor, an intelligent circuit breaker and an intelligent currentstabilizer, and a baffle is fixed to the left side face of the box through a second series of bolt sets. An upper guide groove and a lower guide groove are respectively formed in the upper and lowersides of the rear side surface of the box body; an upper limiting column and a lower limiting column are respectively arranged in the upper guide groove and the lower guide groove; and a connecting strip is fixed to the right side face of the driving plate through a first series of bolt sets. The right portion of the flexible plate penetrates through the passing column to be connected with the rear end of the middle column, the bottom of the passing column is fixedly connected with the bottom of the box body through the fixing connecting arm, the front end of the middle column is fixedly connected with the rear end of the pull belt, a fixing column is arranged on the right side face of the box body, and the top of the pull belt is fixedly connected with the right end of the rack. Accordingto the technical scheme, the technical problems that in the prior art, the box door automatic opening function is not achieved, the capacity of rising when meeting water, intelligent power failure, intelligent current stabilization and the like are effectively solved, and application and popularization are facilitated.

Owner:吴娟

Ore flotation activator and its preparation method

InactiveCN1911528ARaise the gradeIncrease the error rate of beneficiationFlotationFoaming agentFish oil

The present invention relates to one kind of mineral floating activating agent and its preparation. The mineral floating activating agent is prepared with the materials including water, gypsum, animal oil, fish oil and sodium carbonate in the weight ratio of 0.2-2 to 0.2-0.5 to 0.1-1.0 to 0.2-2.0 to 0.1-1.0 and through several technological steps. It is white water soluble powder of grain size 0.02 mm. The mineral floating activating agent is used as catalyst in sulfide mineral floating operation, and can activate collecting agent and foaming agent to reach effective separation of adhered gangue and non-sulfide mineral and ensure high floating effect.

Owner:BEIJING WUTAI HUANQIU SCI & TECH DEV

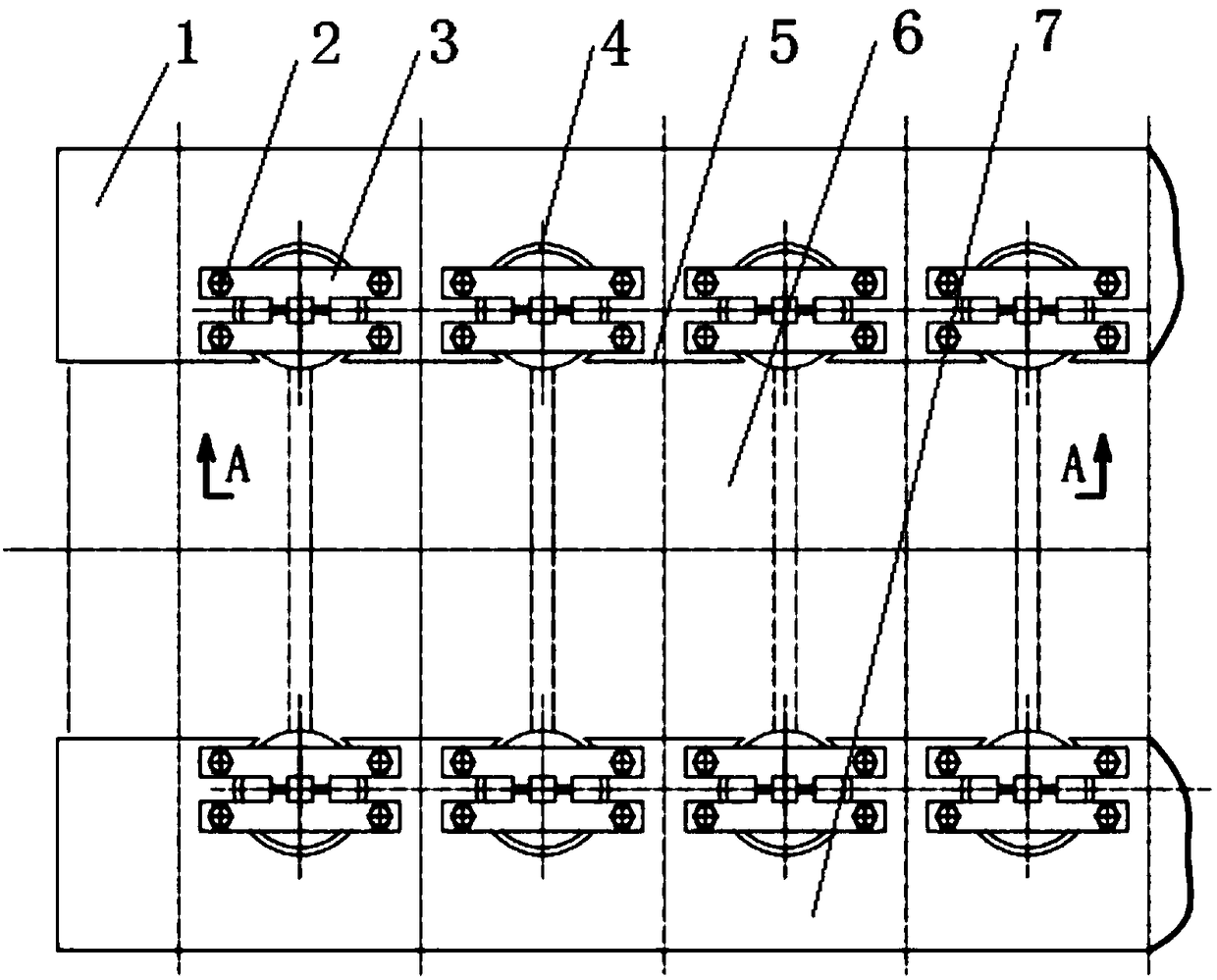

Coiling machine side guide plate with long service life

InactiveCN108580582AExtend the service life of a machineReduce replacement frequencyRolling resistanceRolling-element bearing

The invention relates to a coiling machine side guide plate with long service life. The coiling machine side guide plate comprises a side guide plate body and an idler wheel assemblies, wherein the side guide plate body comprises a left side guide plate body and a right side guide plate body; a plurality of idler wheel assemblies are arranged on the inner sides of the side guide plate body; each of the idler wheel assemblies comprises an idler wheel, a rolling bearing, a penetrating cover and a sealing element; the upper ends of the rolling bearings of the idler wheel assemblies are assembledon a fixed chuck plate; the fixed chuck plate is fixed on the side guide plate body through a bolt; and lower ends of the rolling bearings of the idler wheel assemblies are mounted on a guide plate body lower plate. According to the coiling machine side guide plate, the idle wheels can rotate freely, and as the rolling friction coefficient of the idler wheels is small, the generated friction forceis small, scratch to two side faces of a steel strip and burr generation are greatly reduced, and product quality and productions stability are ensured; and in addition, as the friction force is lowered, the abrasion loss is reduced, onetime looming service life of the side guide plate is greatly prolonged, the changing frequency of the side guide plate is reduced, the operating efficiency of a production line is improved and the operating cost is lowered.

Owner:SD STEEL RIZHAO CO LTD

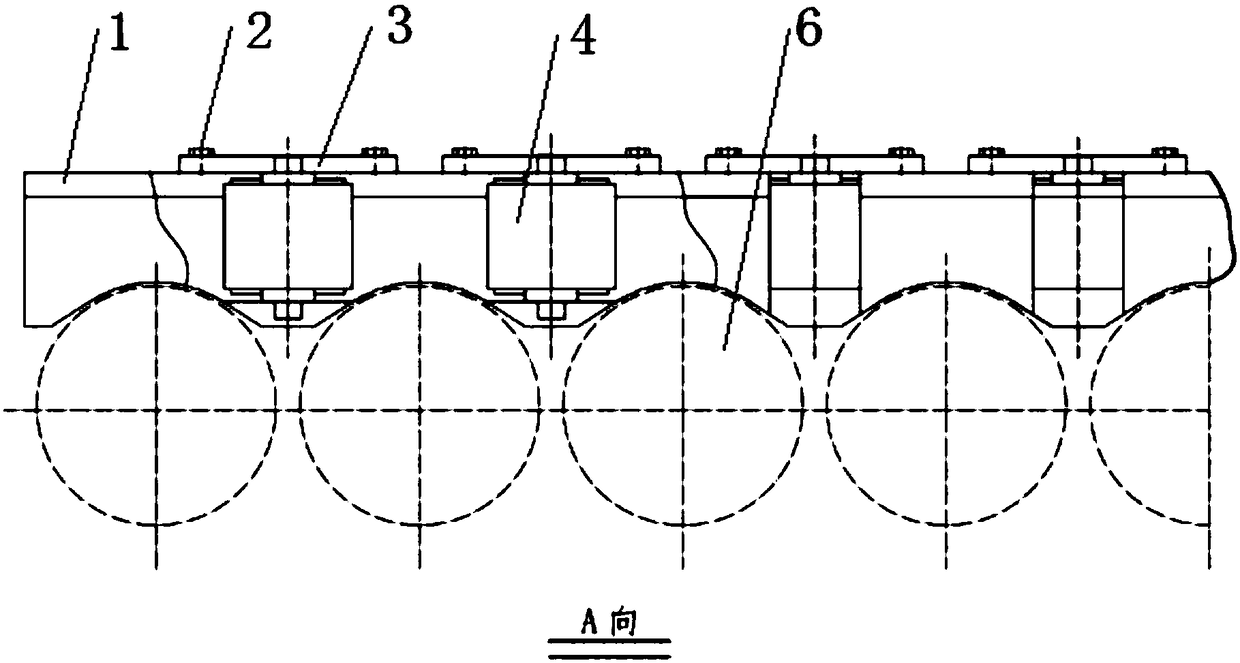

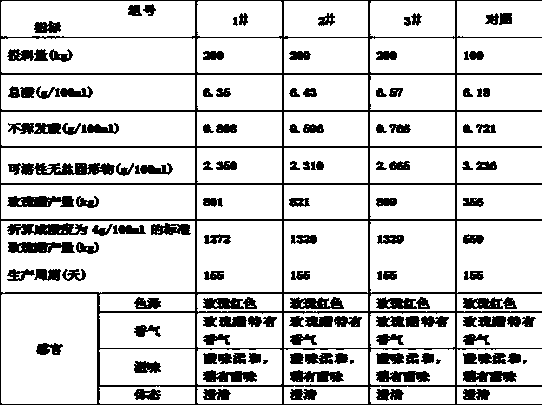

Method for producing rose vinegar by pump reflux method

ActiveCN107904133AReduce labor intensityHigh degree of mechanizationVinegar preparationRefluxBiochemical engineering

The invention discloses a method for producing rose vinegar by a pump reflux method. The method comprises the following steps: rinsing rice; steaming rice; cooling cooked rice; putting the cooked ricein a tank and erecting a nest; floating; adding water; fermenting; aging; squeezing; and sterilizing. The tank is cylindrical, the upper end of the tank is open while the lower end of the tank is provided with a cone-shaped or arc-shaped bottom; a mash discharge hole is formed in the lowest part of the cone-shaped or arc-shaped bottom of the tank; the mash discharge hole is connected to a refluxspray hole in the upper end hole of the tank through a pipeline; a liquid pump is arranged on the pipeline; and a grass cover is arranged on the upper end hole. The fermenting step comprises the following steps: (1) medium frequency large reflux fermentation control in early stage; (2) high frequency medium reflux fermentation control in middle stage; and (3) low frequency small reflux fermentation control in later stage. According to the method for producing rose vinegar by the pump reflux method disclosed by the invention, the production scale of the rose vinegar can be expanded, the yield of the rose vinegar is increased, the quality of the rose vinegar is stabilized and improved, and the labor intensity is alleviated.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

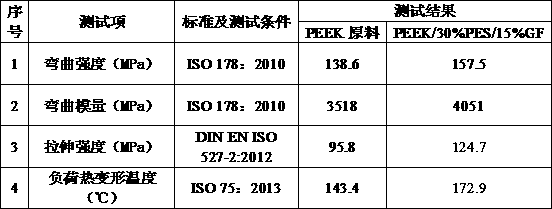

Glass fiber reinforced PEEK/PES composite material

InactiveCN108164923AHigh crystallinityIncrease heat deflection temperature under loadMolten stateCross-link

The invention provides a glass fiber reinforced PEEK / PES composite material and a preparation method thereof, wherein the PEEK composite material comprises glass fiber (GF), polyether sulfone (PES), polyether ether ketone (PEEK), a coupling agent and an antioxidant. The preparation method comprises: first drying, high-speed mixing, extrusion granulation, and second drying and injection molding. According to the present invention, by adding the polyether sulfone (PES) resin and the glass fiber (GF) to the medium-viscosity polyether ether ketone (PEEK) resin, the bending resistance of the composite material is remarkably improved; by adding the coupling agent and the antioxidant, the interfacial bonding between the glass fiber and the resin is increased, and PEEK can be prevented from self-molecular chain degradation cross-linking in the molten state; and the bending performance and the temperature resistance of polyether ether ketone are improved while the cost of the PEEK composite material is reduced.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

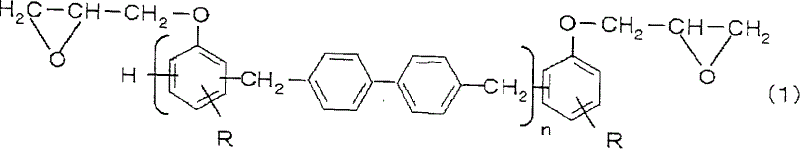

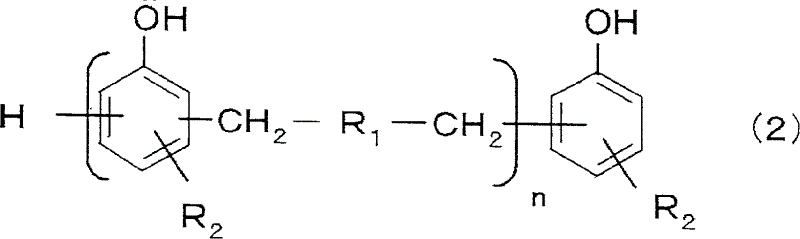

Resin composition for encapsulating semiconductor chip and semiconductor device therewith

ActiveCN1761692AFully curableFull liquiditySemiconductor/solid-state device detailsSolid-state devicesEpoxySemiconductor chip

An epoxy resin composition for encapsulating a semiconductor chip, which has good flowability without deterioration in curability. Specifically, a resin composition is disclosed for encapsulating a semiconductor chip containing a phenol aralkyl type epoxy resin containing biphenylene structure(A), a phenol aralkyl type resin containing phenylene or biphenylene structure (B), an inorganic filler (C) and a curing accelerator (D) as main components, further containing a silane coupling agent (E) in 0.01 wt % to 1 wt % both inclusive of the total amount of the epoxy resin composition and a Compound (F) containing two hydroxyl groups combined with each of adjacent carbon atoms on a naphthalene ring in more than or equal to 0.01 wt % of the total amount of the epoxy resin composition.

Owner:SUMITOMO BAKELITE CO LTD

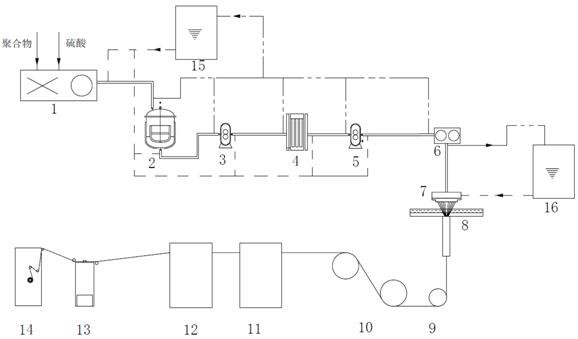

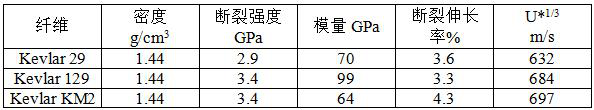

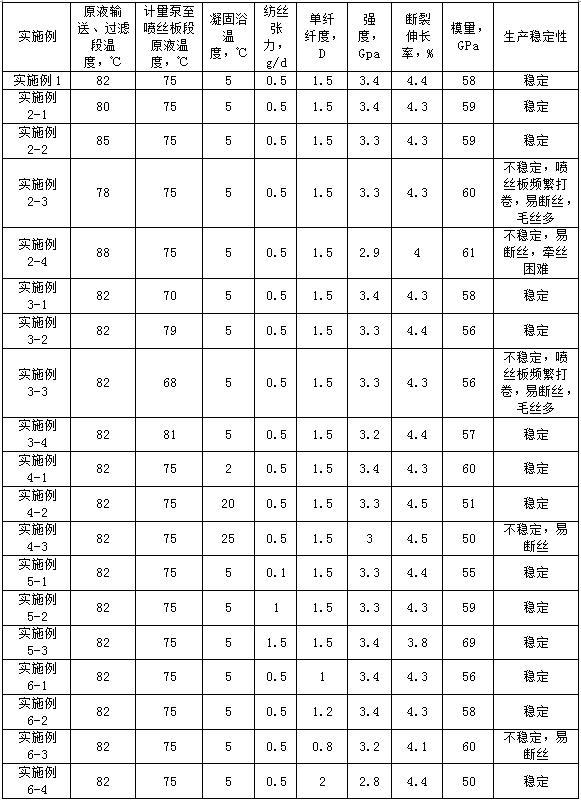

High-strength and high-toughness para-aramid fibers and preparation method thereof

ActiveCN112281223AGood orientationHigh strengthSpinning head liquid feederArtificial filament washing/dryingPolymer scienceSpinning

The invention discloses high-strength and high-toughness para-aramid fibers and a preparation method thereof. The high-strength and high-toughness para-aramid fibers have the breaking elongation of 4.0-4.7% and the breaking strength of greater than or equal to 3.3 GPa. The preparation method comprises the steps that a para-aramid spinning solution enters an air layer through a spinneret plate andthen enters a coagulating bath to form nascent fibers, and the nascent fibers are sequentially washed, dried, oiled and wound to prepare the finished high-strength and high-toughness para-aramid fibers, wherein the temperature of the spinneret plate passed by the spinning solution is 70-79 DEG C, the temperature of the coagulating bath is 0-20 DEG C, and low-tension control is adopted for washingand drying. The para-aramid fibers prepared by the method have the characteristics of high strength and high toughness, can meet the higher-level weight reduction requirements of bulletproof vests andbulletproof armors, and fill up the domestic blank.

Owner:中蓝晨光化工有限公司

Shunting system of sintering smoke circulating loop

The invention discloses a shunting system of a sintering smoke circulating loop. The shunting system comprises a smoke cover mounted on a sintering machine trolley; more than two shunting pipes are respectively arranged on two sides of the width direction of the smoke cover; baffle plates are arranged in the smoke cover of a sintering machine in the middle positions of orifices of the shunting pipes on two sides; and the heights of the baffle plates are lower than the distance from the top of the smoke cover of the sintering machine to the surface of a sintered material. Through use of multiple measures, a sintering smoke circulating process achieves the technical purposes of effectively relieving the hedging of circulating smoke on two sides of the width direction of the smoke cover, effectively inhibiting the bias of circulating smoke in the width direction of the sintering machine, effectively accelerating the dispersion of the circulating smoke in different directions in the smoke cover and adjusting the openness of a skylight valve in real time.

Owner:HUATIAN ENG & TECH CORP MCC +1

Dry net deviation detector

PendingCN110258166AEnsure safetyEnsure production stabilityPaper-making machinesDrive wheelThreaded rod

The invention discloses a dry net deviation detector. The dry net deviation detector comprises a mounting seat, a base, a support arm, a slide arm, a branch arm, a detecting seat and a winding reel. The base is mounted in the mounting seat. The support arm is mounted at the center of the top of the base. A first insertion groove is formed in one side of the support arm. A gear box is mounted at the top end of the support arm. First threaded rods are mounted at the top of the base and on the periphery of the support arm. The top ends of the first threaded rods penetrate the slide arm, and driven wheels located in the gear box are mounted at the top ends of the first threaded rods. A rotating shaft is mounted at the internal center of the gear box. The dry net deviation detector has the advantages that dry net deviation interference signals generated by limited vibration sources can be effectively prevented, and accordingly, safety and production stability of dry nets are ensured; height and length adjustment of detected portions is rapidly completed, local adjustment after mounting of the detector is facilitated, re-disassembly and re-assembly are not needed, and the length of a guide line is adjusted conveniently during overall adjustment of the detector.

Owner:SHANYING INT HLDG CO LTD

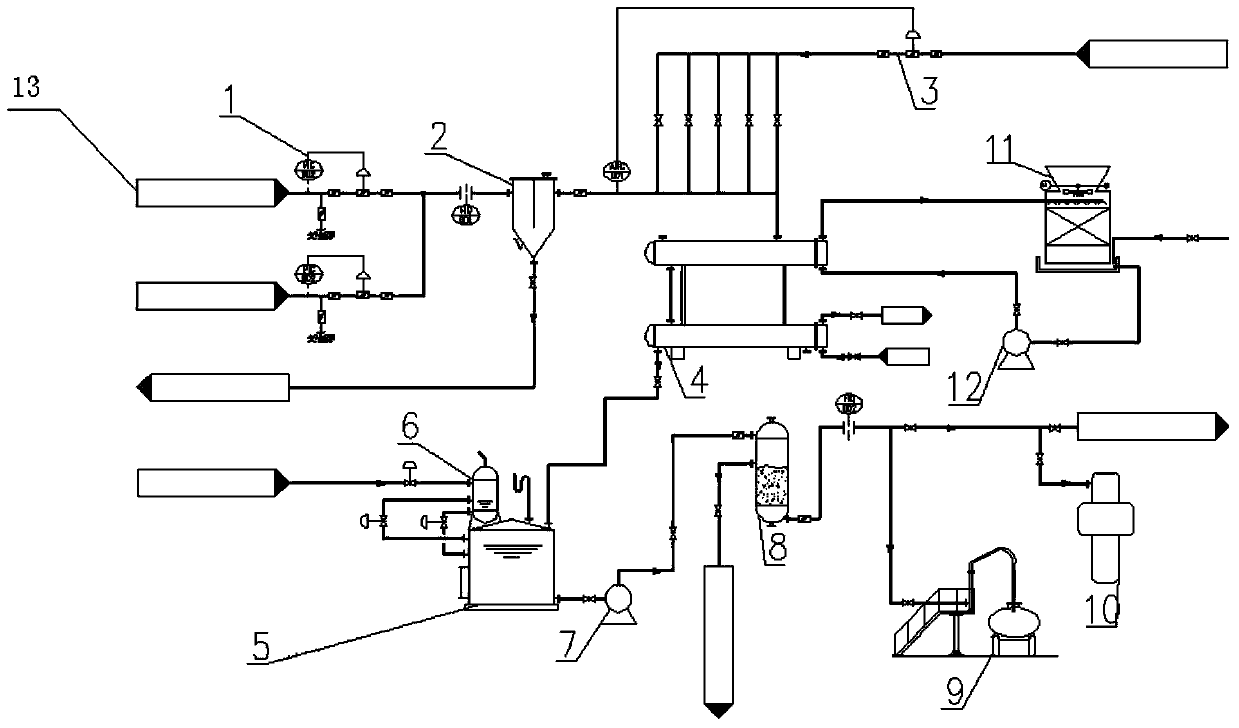

Device and method for recycling waste ammonia gas in arsenic coking process

ActiveCN104003419ADoes not affect normal operationGuaranteed purityAmmonia preparation/separationAmmonium hydroxideTower

The invention discloses a device and method for recycling waste ammonia gas in an arsenic coking process, and belongs to the technical field of ammoniation desulfuration and coking. The method for recycling the waste ammonia gas in the arsenic coking process comprises the following steps that 1, the waste ammonia gas at the top of a fixed ammonia tower is guided out; 2, pressure of the top of the ammonia tower is regulated; 3, liquid and solid which are carried in the waste ammonia gas are separated; 4, the concentration of ammonium hydroxide is regulated; 5, the ammonia gas is condensed and cooled to the temperature suitable for storage and conveying, and then the ammonia gas is conveyed to a strong ammonium hydroxide storage tank; 6, diffusion ammonia gas at the top of the strong ammonium hydroxide storage tank is recycled; 7, a little of oil matter included in the ammonium hydroxide is filtered out; 8, the ammonium hydroxide with the standard quality is recycled. According to the method for recycling the waste ammonia gas in the arsenic coking process, the ammonia gas including the waste ammonia gas can be recycled, and production cost is saved.

Owner:武汉华德环保工程技术有限公司

Method for manufacturing flexible display device having an insulative overcoat and flexible display device having the same

ActiveUS8257129B2Stable productionEnsure production stabilityFinal product manufactureSolid-state devicesEngineeringFlexible display

Owner:LG DISPLAY CO LTD

Filling head of low vacuum filling machine

InactiveCN105197863AGuaranteed accuracy and production speedReduce difficultyLiquid bottlingVacuum tubeBottle

The invention discloses a filling head of a low vacuum filling machine. The filling head of the low vacuum filling machine comprises a filling pipe, a bottle opening sealing pad, a vacuumizing pipe, a valve core, a connection nut, a guide sleeve, a ventilation pipe, a spring and a guide sealing ring, wherein the upper end of the vacuumizing pipe is connected with the lower end of the valve core; the inner wall of the valve core is sleeved by the ventilation pipe; the outer wall of the valve core is sleeved by the guide sleeve; the outer wall of the guide sleeve is sleeved by the connection nut; the outer wall of the vacuumizing pipe is sleeved by the bottle opening sealing pad; the filling pipe penetrate through the inner walls of the vacuumizing pipe and the ventilation pipe; the spring is mounted on the outer wall of the upper end of the vacuumizing pipe; the spring is mount in a manner of extending to the outer wall of the connection nut; a liquid outlet in the lower end of the filling pipe protrudes from an air extraction opening in the lower end of the vacuumizing pipe. According to the filling head of the low vacuum filling machine, the phenomenon that the liquid is pumped out during filling is avoided; the filling part is small in size of the outer diameter; the centering difficulty is reduced; the production speed and the product quality are improved; the production cost is reduced.

Owner:长沙铭盛科技发展有限公司

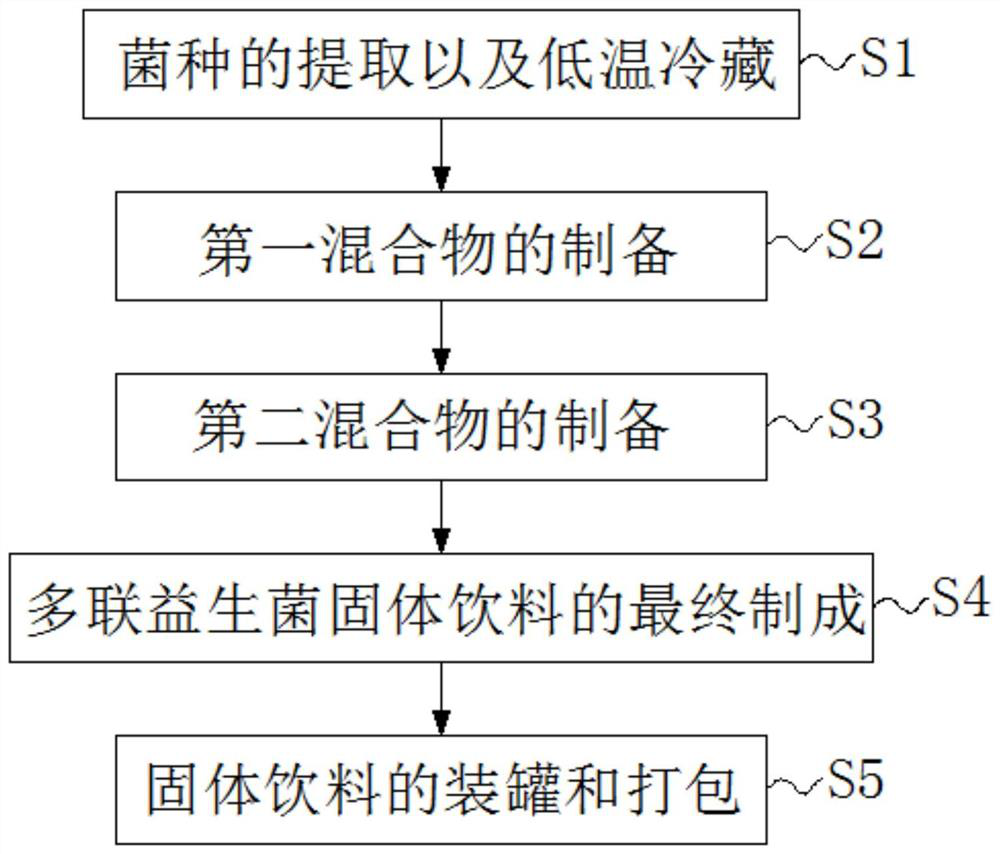

Multi-probiotic solid beverage and preparation method thereof

InactiveCN111838493AStir in the same directionUnique tasteLactobacillusBifidobacteriumBiotechnologyLactobacillus rhamnosus

The invention discloses a multi-probiotic solid beverage which comprises the following raw materials in parts by weight: 12-14 parts of lactobacillus casei, 10-12 parts of lactobacillus acidophilus, 15-17 parts of lactobacillus rhamnosus, 10-12 parts of bifidobacterium longum, 10-15 parts of fructo-oligosaccharide and 2-4 parts of a flavoring agent, and relates to the technical field of preparation of solid beverages. The invention discloses the multi-probiotic solid beverage and the preparation method thereof. A plurality of probiotics (such as lactobacillus casei, lactobacillus acidophilus,lactobacillus rhamnosus and bifidobacterium longum) are added into the solid beverage, multi-connected use is realized, mutual promotion of the effects of various strains is realized, the effects of improving the intestinal environment of a human body and enhancing the immunity are achieved, meanwhile, the water-soluble dietary fibers and the flavoring agent are added, so that the solid beverage has unique flavor and taste, and the sterile water can prevent bacteria in the water from influencing the activity and efficacy of probiotics, so that the number of viable bacteria is increased, and the valuing capacity and survival rate in intestinal tracts are enhanced.

Owner:江苏碧清园食品科技有限公司

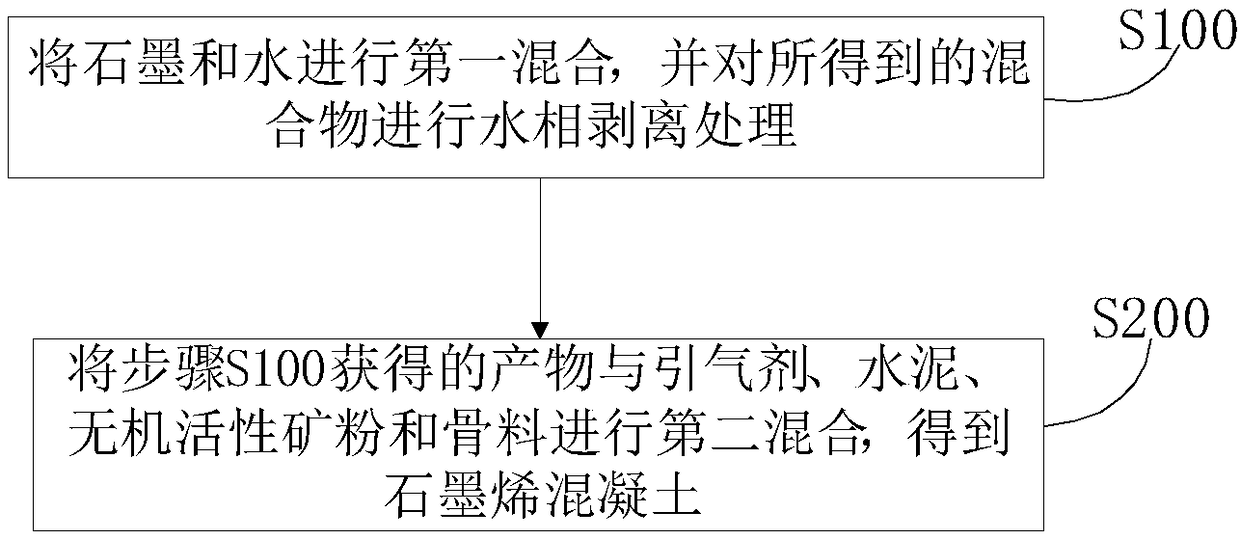

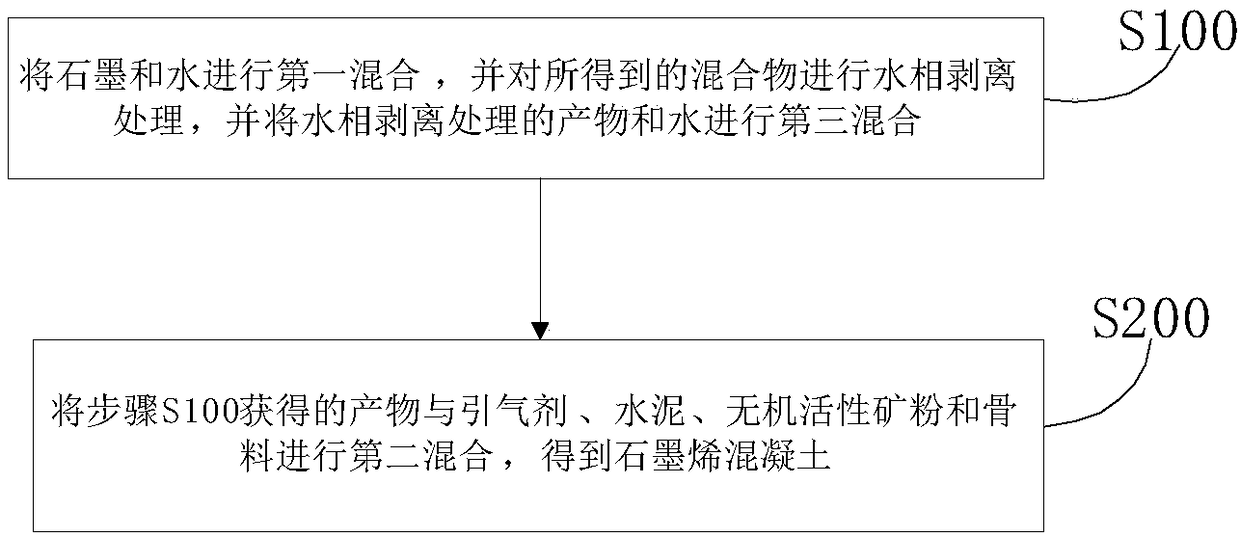

High-performance graphene concrete and preparation method thereof

The invention provides high-performance graphene concrete and a preparation method thereof. The method for preparing the high-performance graphene concrete comprises the following steps: (1) carryingout first mixing on graphite and water, and carrying out aqueous phase stripping processing on the obtained mixture; (2) carrying out second mixing on a product obtained in (1), air entraining agent,cement, inorganic active mineral powder and aggregate to obtain in situ dispersion graphene concrete. Therefore, the preparation method has the advantages of simple preparation technology, small pollution, low energy consumption and low cost and is easy for industrial production, major engineering and infrastructure construction can be favorably guaranteed, the compressive strength and the freeze-thaw resistance of the graphene concrete can be obviously improved, so that the mechanical property of the graphene concrete is slowly lowered under a cold hash condition, and surface denudation and elasticity modulus losses are small.

Owner:内蒙古信敏惠纳米科技有限公司

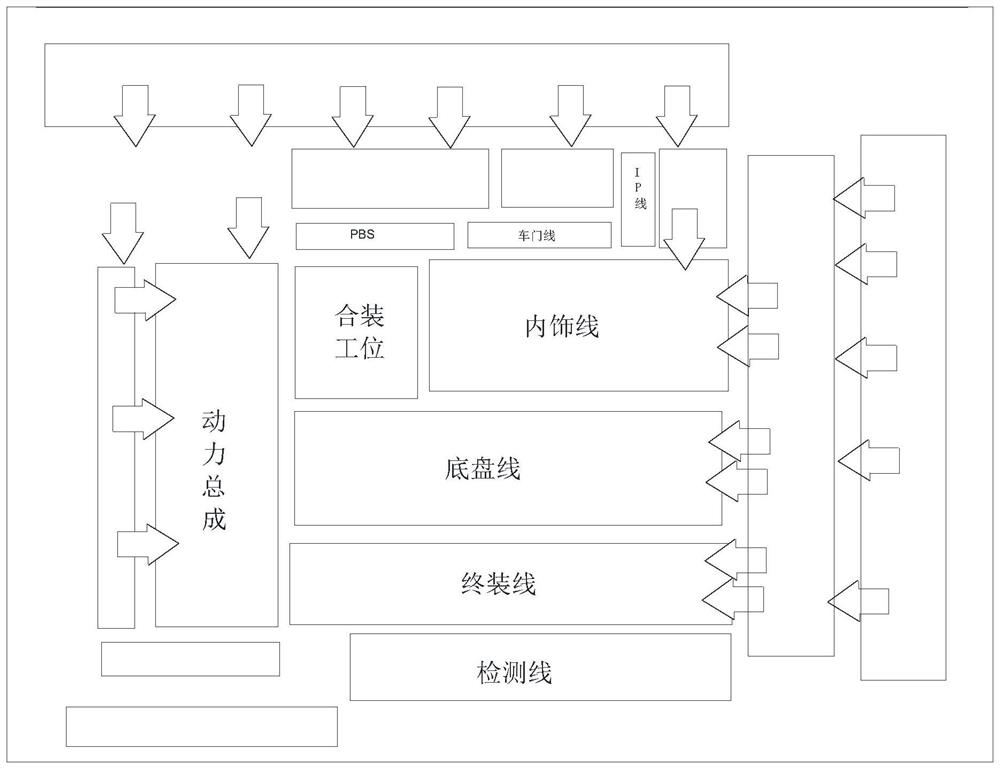

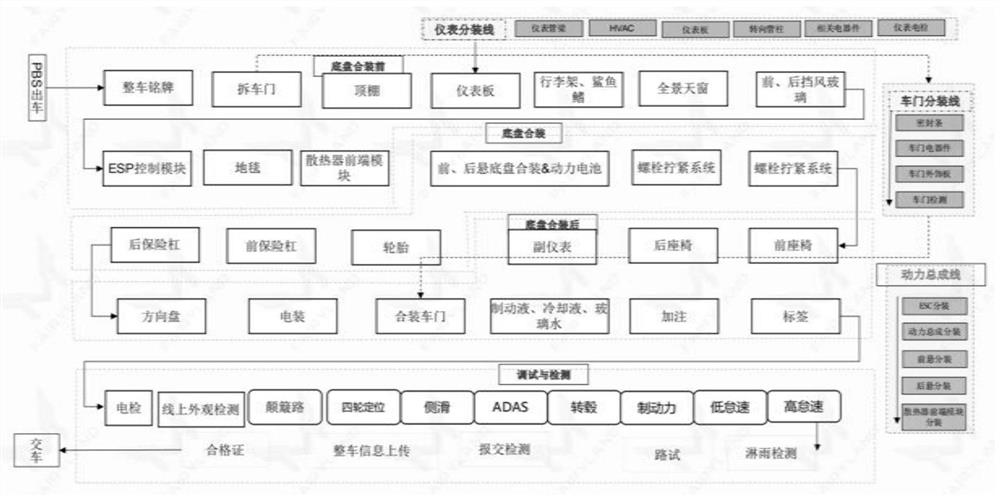

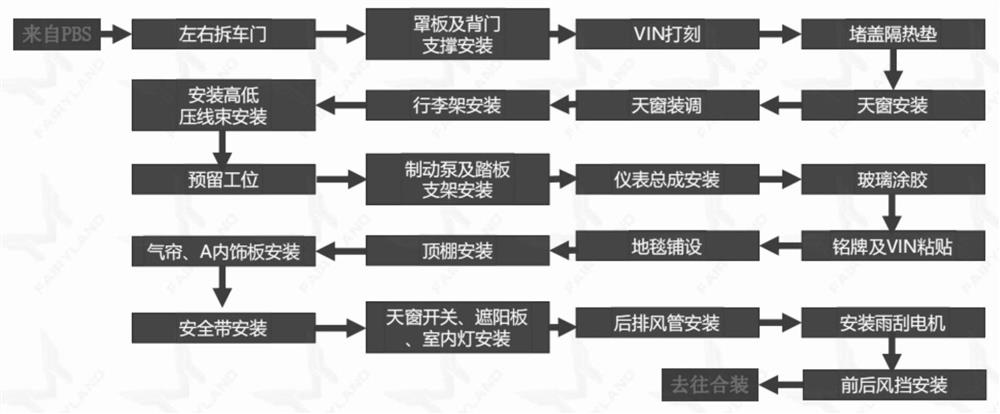

Flexible automobile production line and production method

PendingCN114013537ARealize flexible designImprove good performanceVehiclesAssembly lineMaterial transfer

The invention discloses a flexible automobile production line and a production method. The flexible automobile production line is reasonably divided into an interior trim line, a power assembly line, a chassis line, a combined assembly station and a final assembly line. Installation of an interior trim, a power assembly and a chassis is completed on each branch line at present, finally fixed-point combined assembly is completed on the combined assembly station, and finally, final loading is completed through a final loading line, products are conveyed to the detection line to be detected and then leave a factory. The whole-process material transfer is completed through flexible transportation provided with an AGV trolley, reasonable station arrangement and flexible design of the position relation of three-face surrounding and inward pushing between all branch lines are supplemented, and cooperative operation of various AGV devices and automation devices is added, so that the overall flexible design of the automobile production line is realized, and space rationalization, path minimization, inventory minimization and error minimization are realized, so that subsequent expansion and transformation are facilitated; and meanwhile, the assembling reliability and the production stability are guaranteed, and meanwhile the advantages of high station utilization rate and mechanical logic limitation are achieved.

Owner:法睿兰达科技(武汉)有限公司

Composite heat-preservation light autoclaved aerated concrete and preparation method thereof

InactiveCN111606626AUniform sizeImprove thermal insulation performanceCeramicwareAutoclaved aerated concreteLime

The invention discloses composite heat preservation light autoclaved aerated concrete. The invention discloses a preparation method of the composite thermal-insulation lightweight autoclaved aerated concrete. The preparation method comprises the following steps: mixing and ball-milling fluorite mine tailings, quartz sand, building solid waste and water to obtain mortar; adding lime, cement, composite sepiolite and aluminum powder into the mortar, uniformly stirring, pouring into a mold, pouring, and carrying out gas forming to form a green body; and demolding the green body, cutting, and steaming to obtain the composite heat-preservation light autoclaved aerated concrete. The composite sepiolite is prepared by the following process: feeding sepiolite powder into a sulfuric acid solution, stirring for 1-2 hours at 50-60 DEG C, filtering, washing to be neutral, drying, then adding sodium alginate, microcrystalline cellulose and water, fully and uniformly mixing, carrying out hydrothermalcarbonization for 2-4 hours at 160-180 DEG C, filtering, washing, drying and crushing to obtain the composite sepiolite. The autoclaved aerated concrete is low in density, low in heat conductivity coefficient and good in sound insulation and compressive strength.

Owner:安徽筑园景新型建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com