Filling head of low vacuum filling machine

A filling machine and filling head technology, applied in the fields of food machinery and pharmaceutical machinery, can solve problems affecting product quality, filling speed and filling accuracy, and filling volume, so as to ensure quality and production stability , Guaranteed accuracy and production speed, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

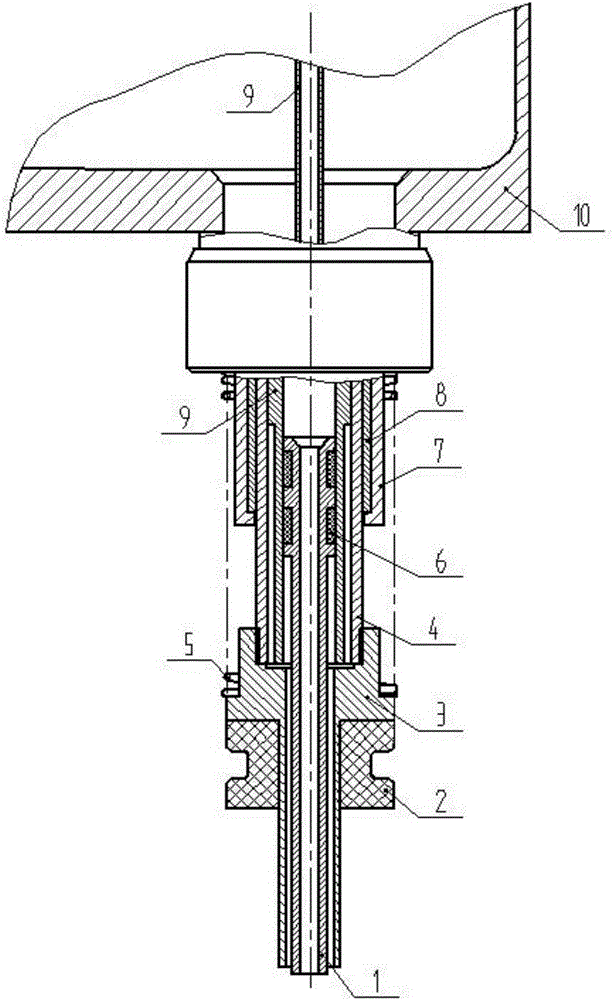

[0023] Such as figure 1 As shown, the filling head of a negative pressure filling machine provided by the present invention includes a filling tube 1, a bottle mouth gasket 2, a vacuum tube 3, a valve core 4, a coupling nut 7, a guide sleeve 8, and a ventilation tube 9 , spring 5 and guide sealing ring 6, the upper end of the vacuum pumping tube 3 is connected with the lower end of the valve core 4, the vent pipe 9 is sleeved on the inner wall of the valve core 4, and the outer wall of the valve core 4 is sleeved The guide sleeve 8, the outer wall of the guide sleeve 8 is sleeved with the coupling nut 7, the outer wall of the vacuum tube 3 is sleeved with the bottle mouth seal 2, and the upper end surface of the bottle mouth seal 2 withstands the The step surface of the vacuum tube 3; the filling tube 1 is penetrated on the inner wall of the vacuum tube 3 and the vent tube 9, the outer wall of the upper end is matched with the inner wall of the vent tube 9, and the groove of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com