Patents

Literature

58results about How to "Guaranteed production speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

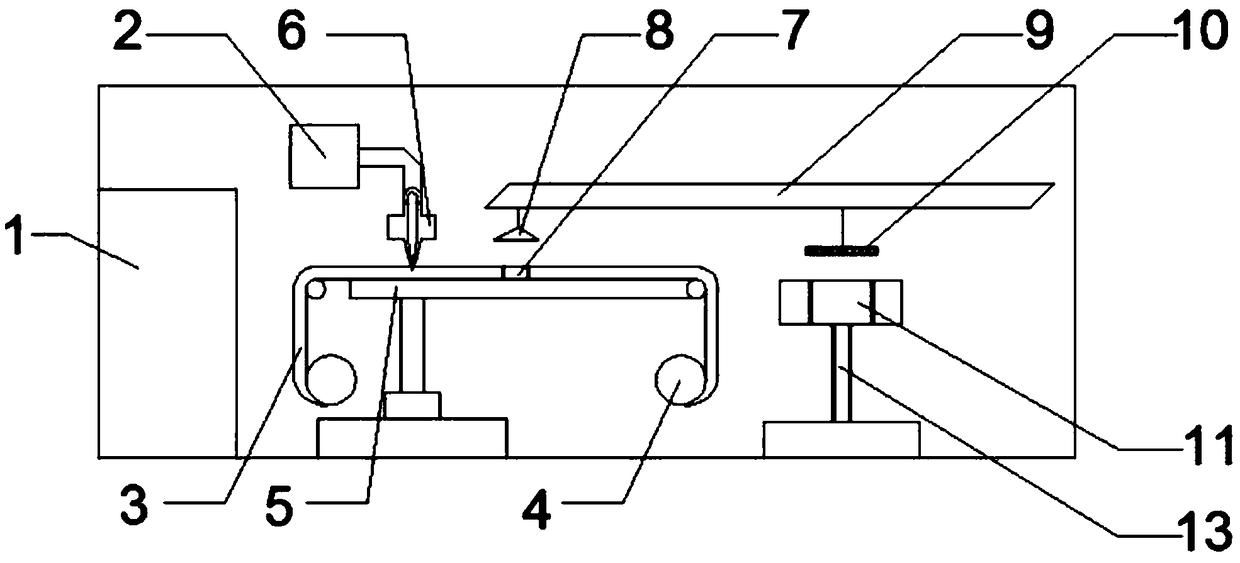

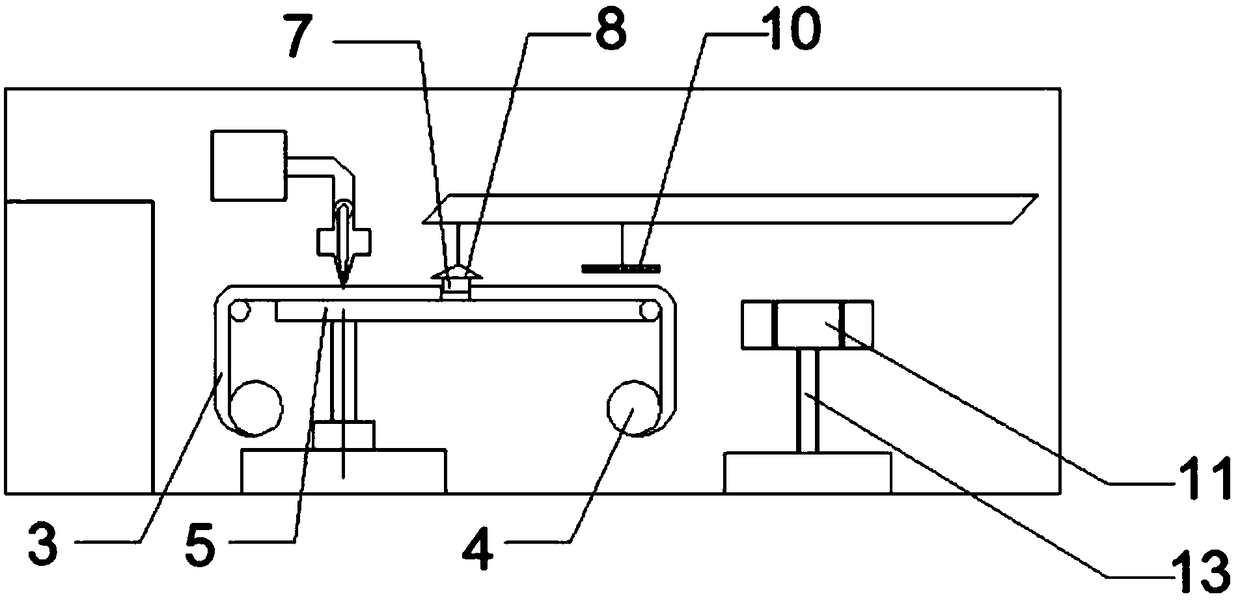

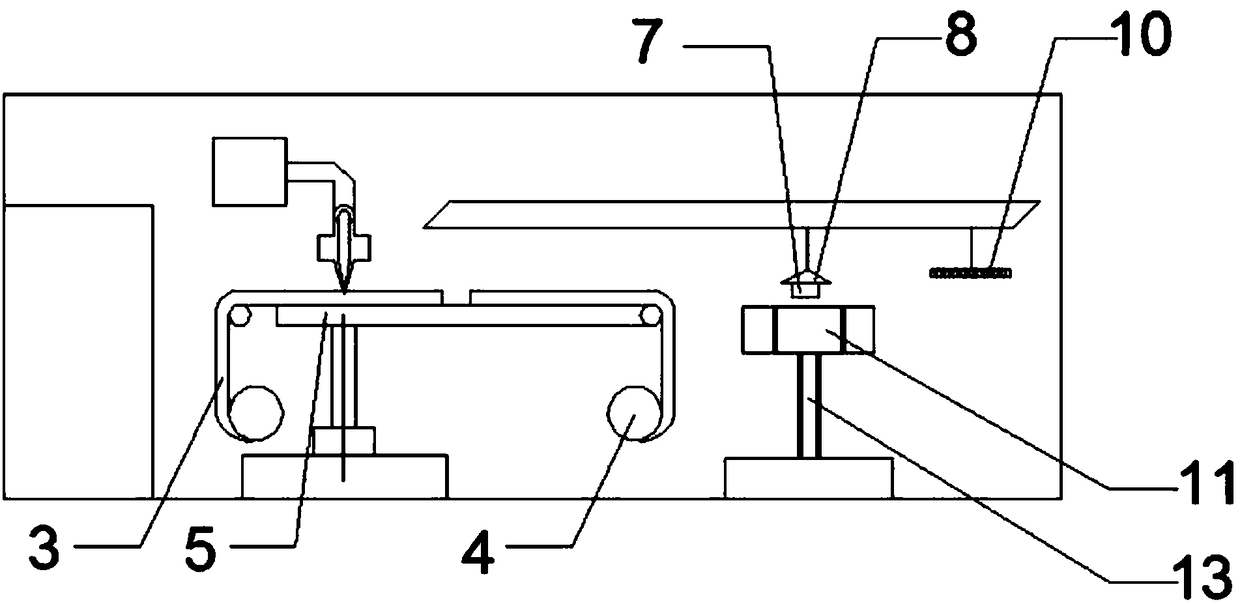

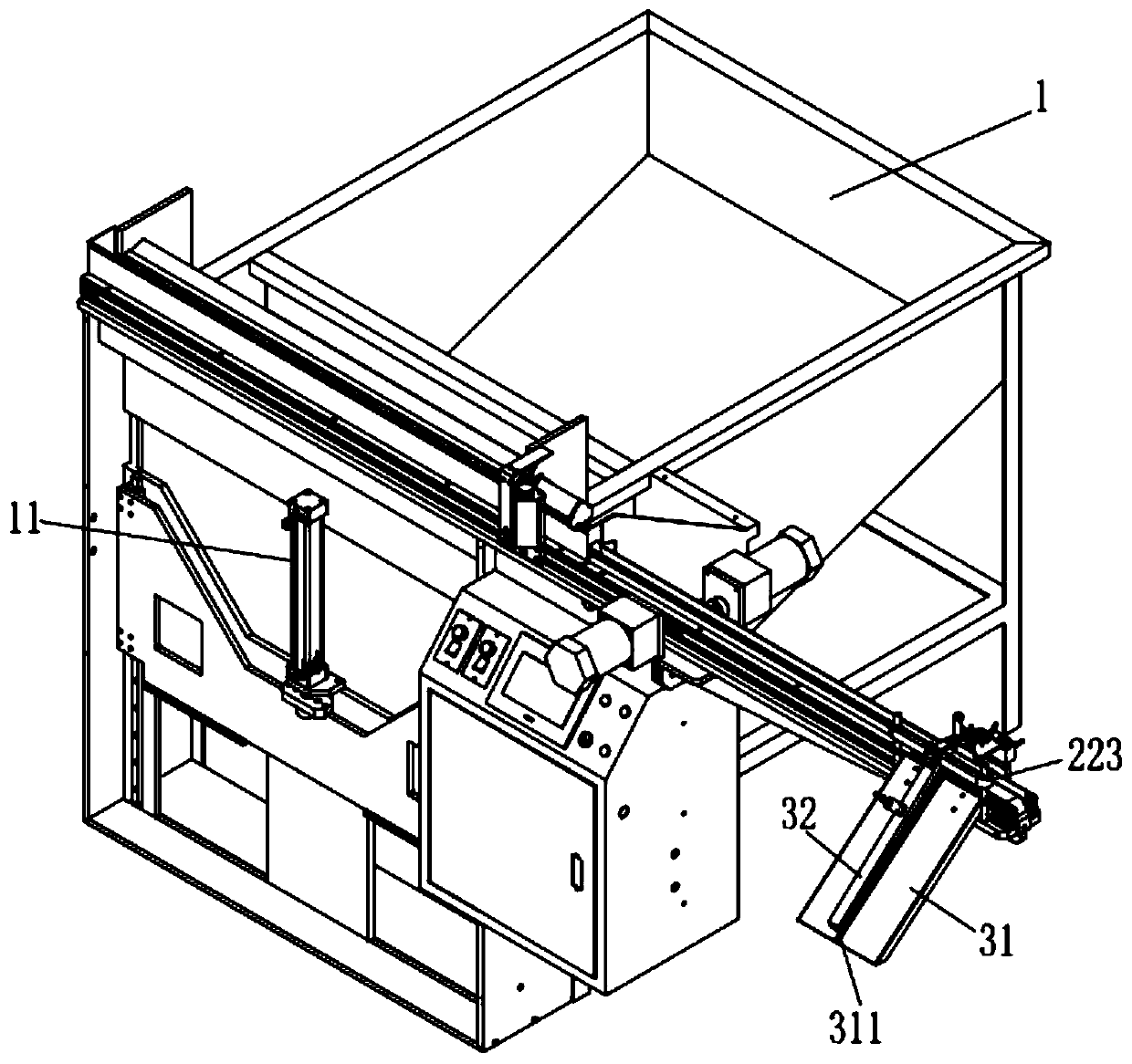

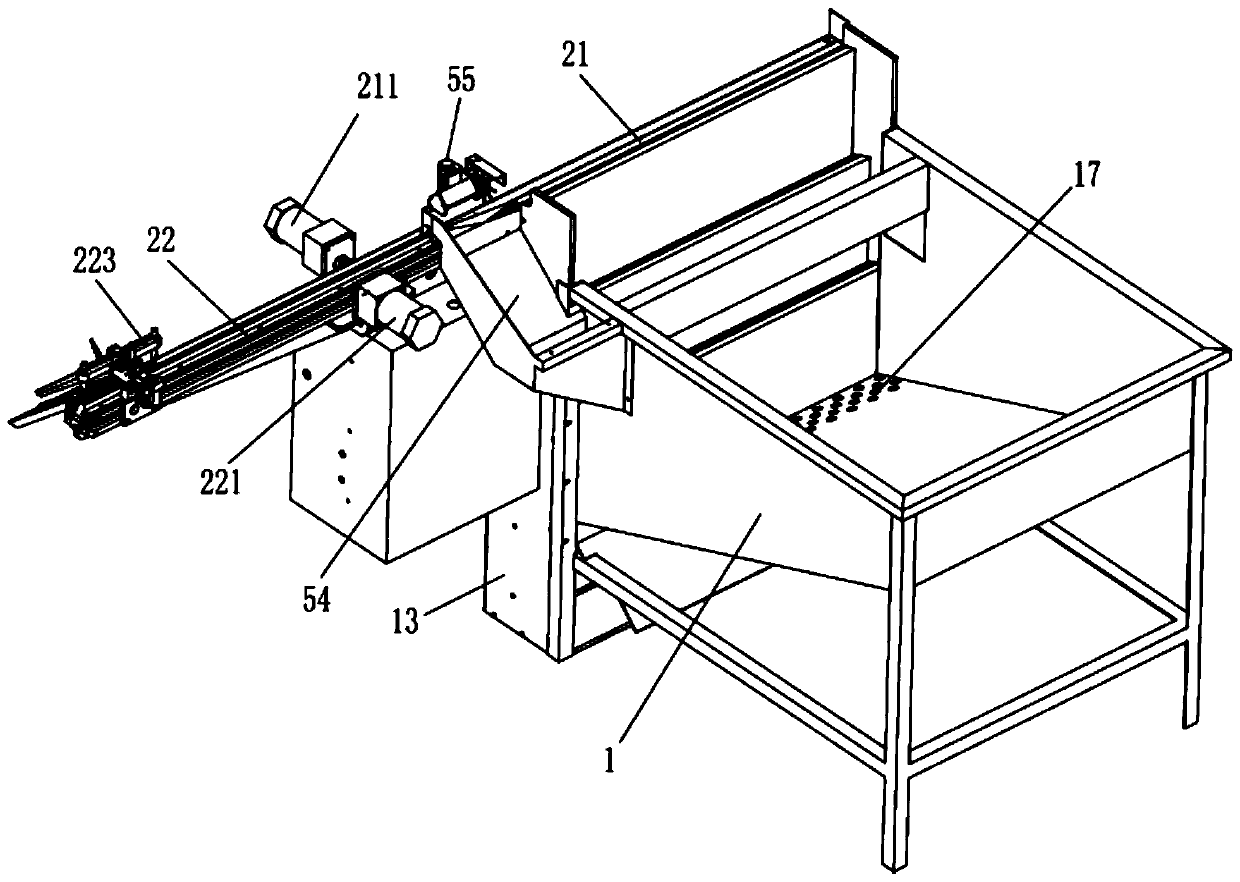

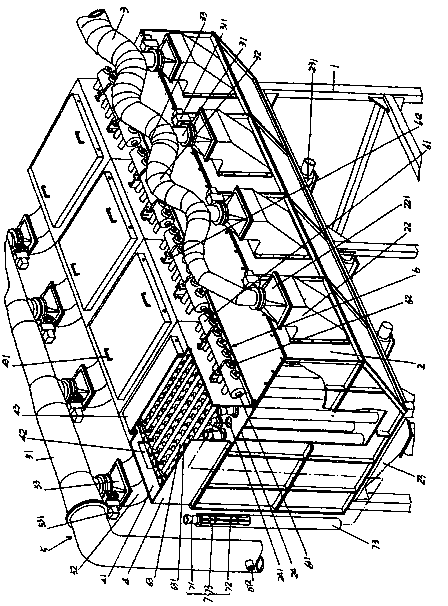

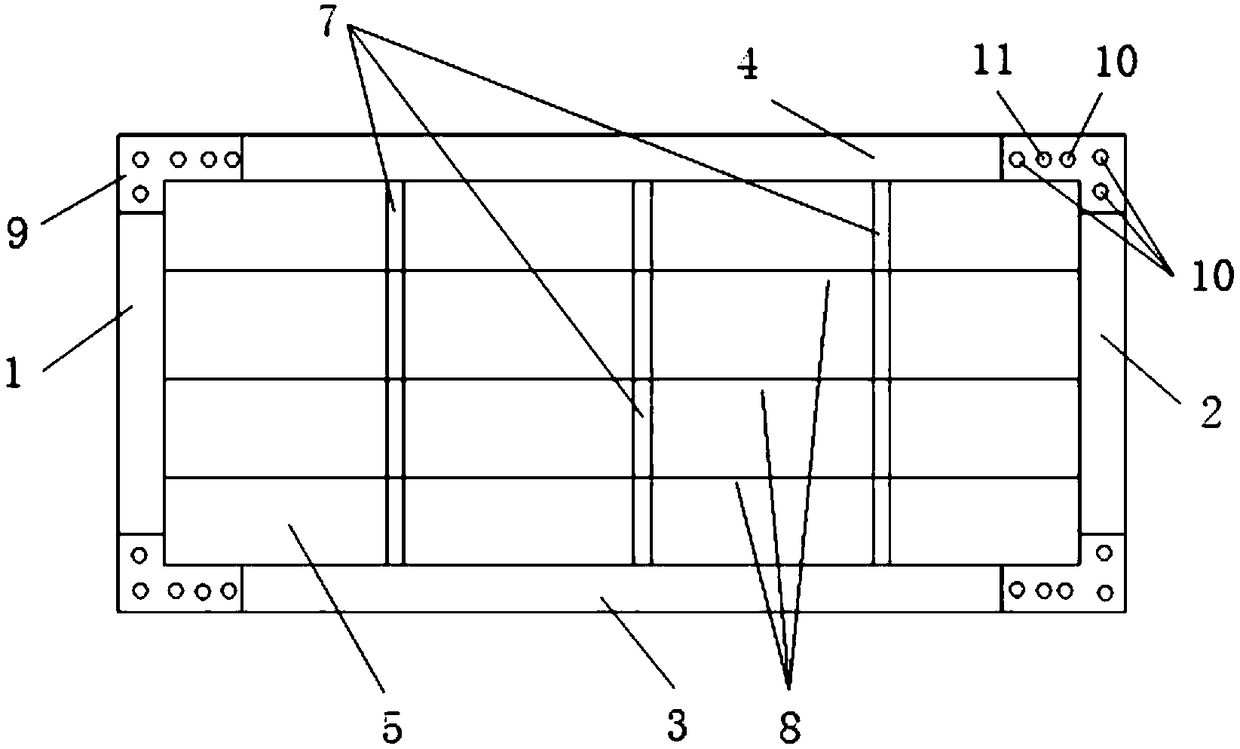

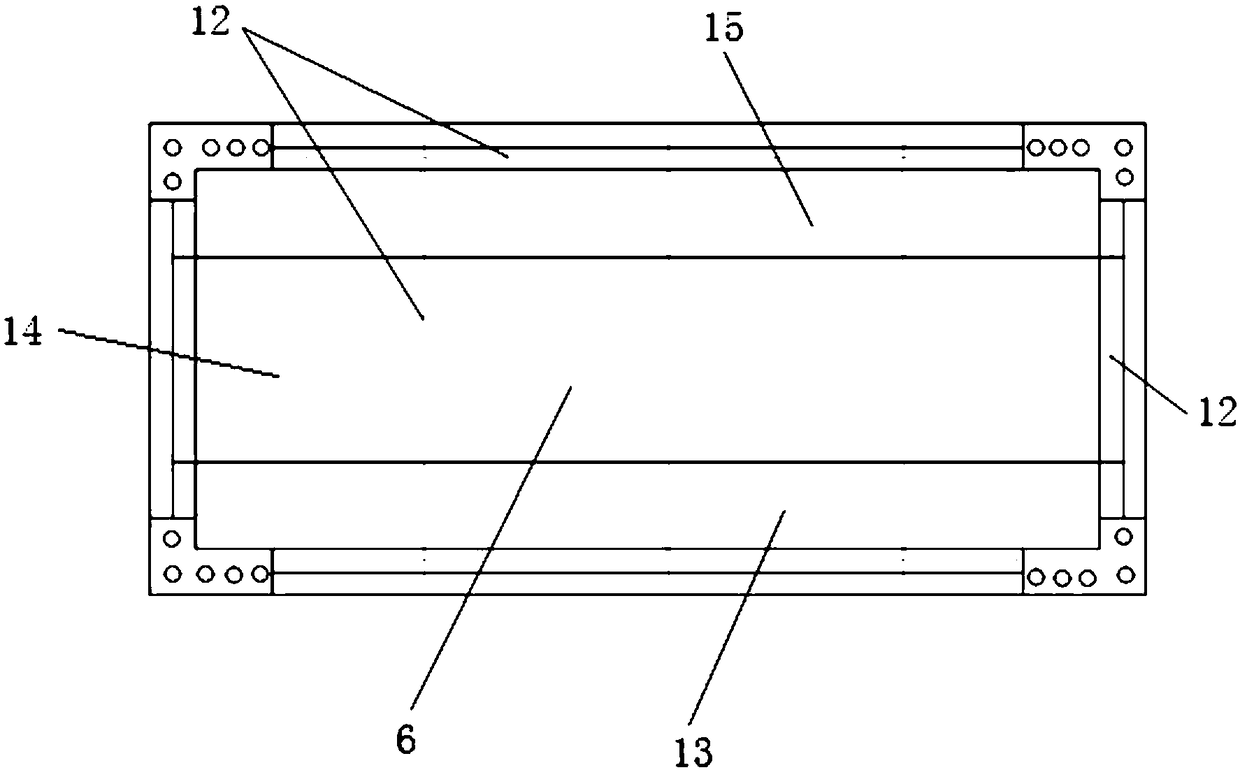

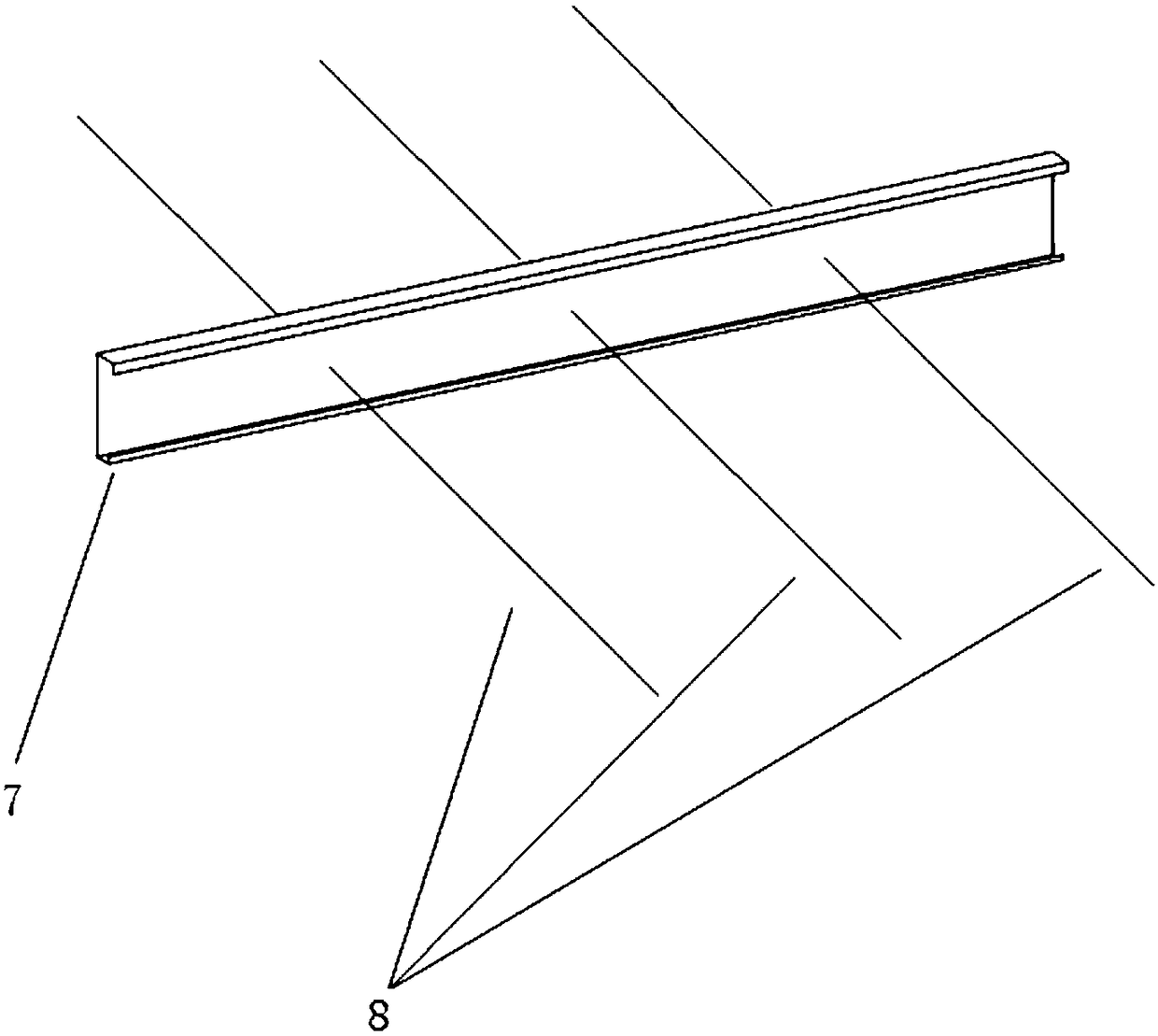

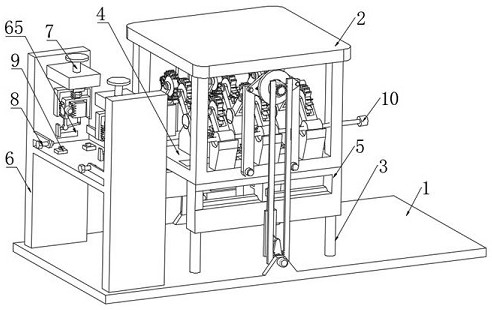

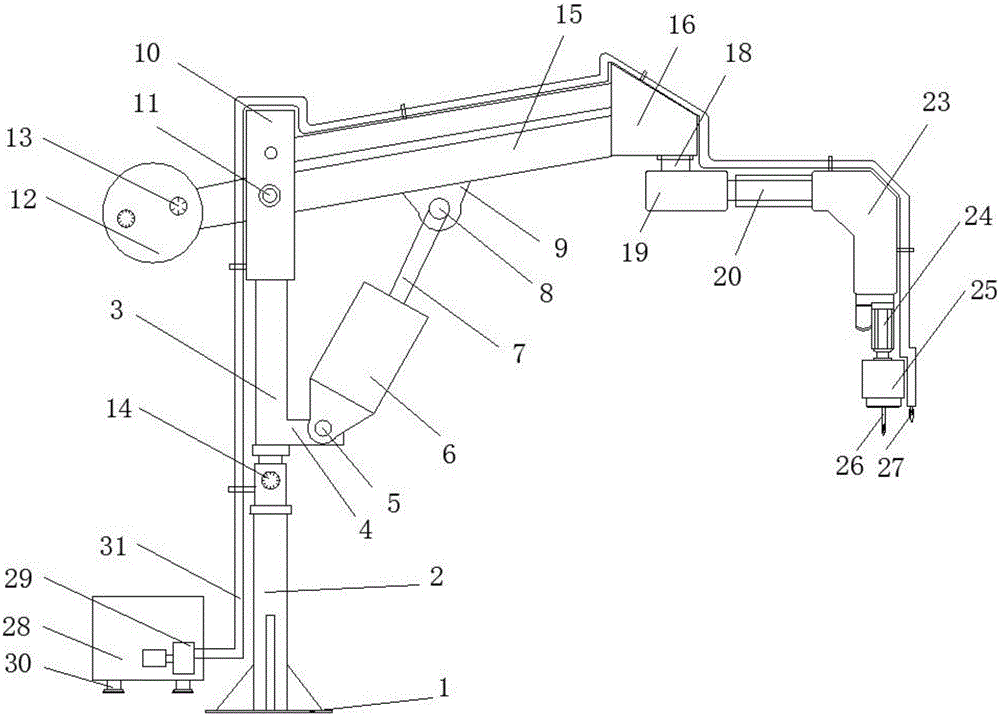

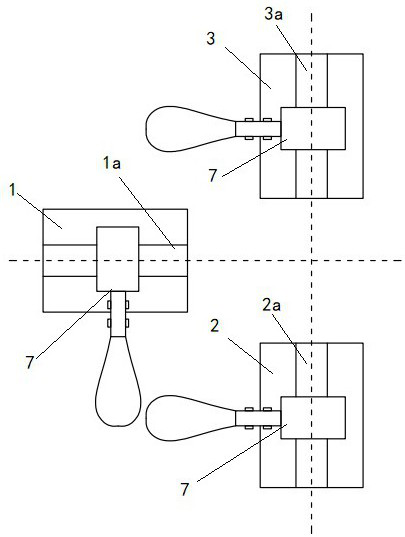

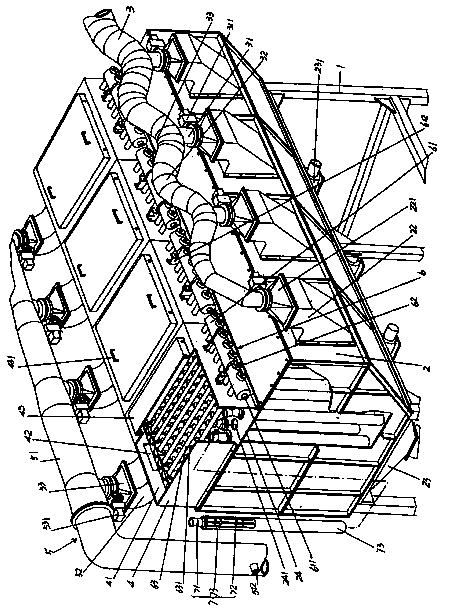

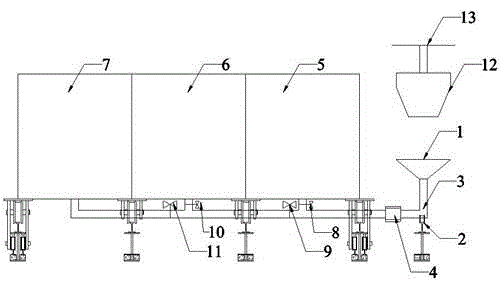

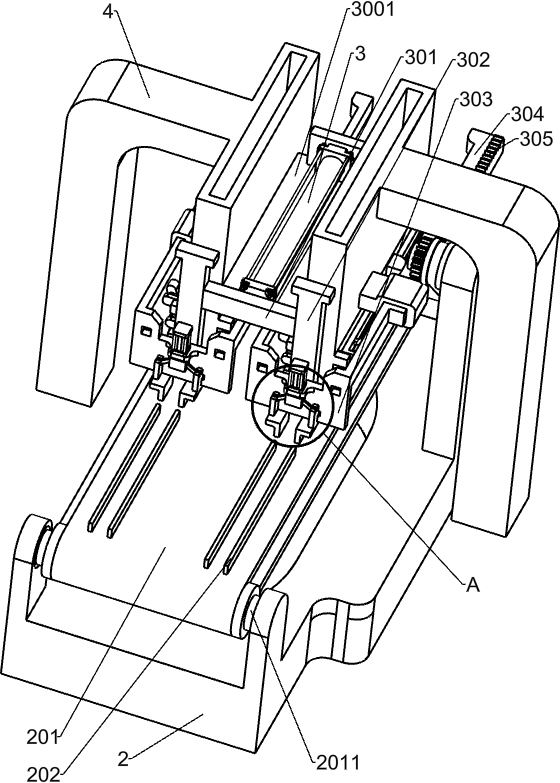

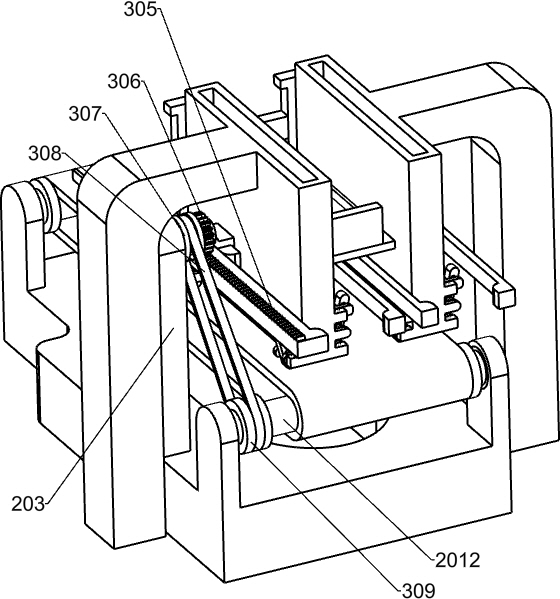

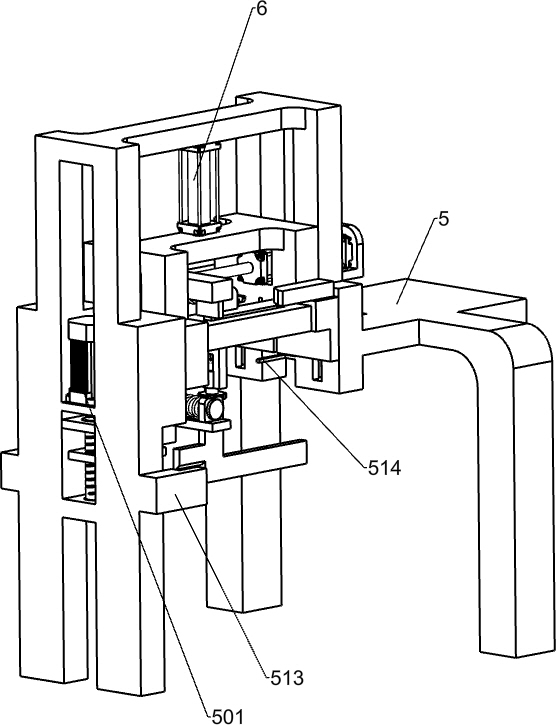

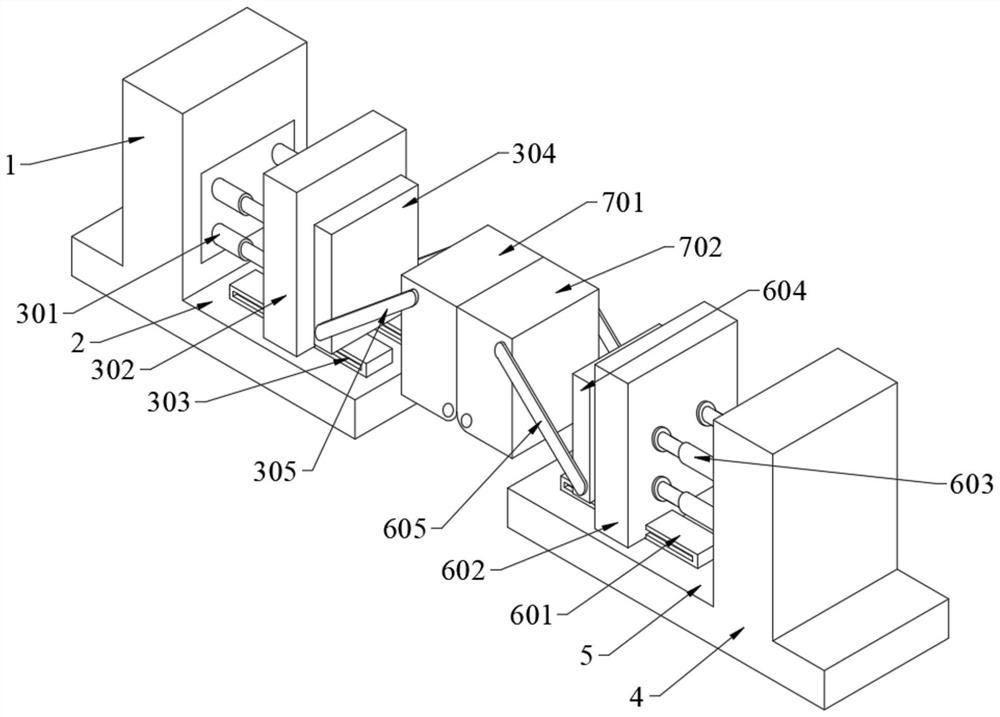

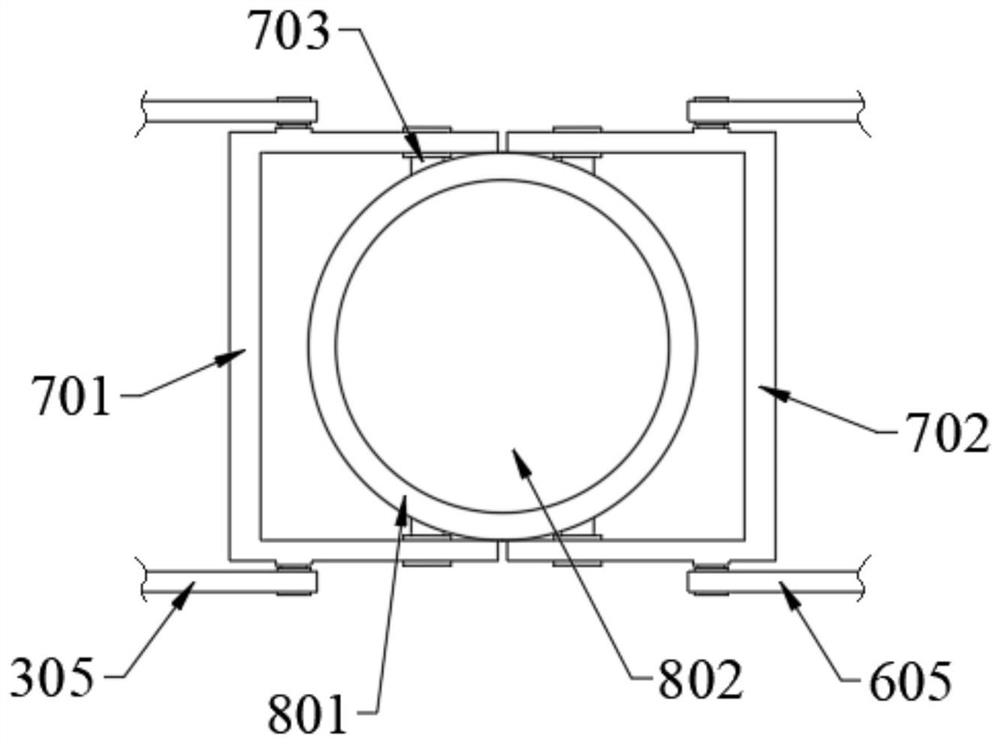

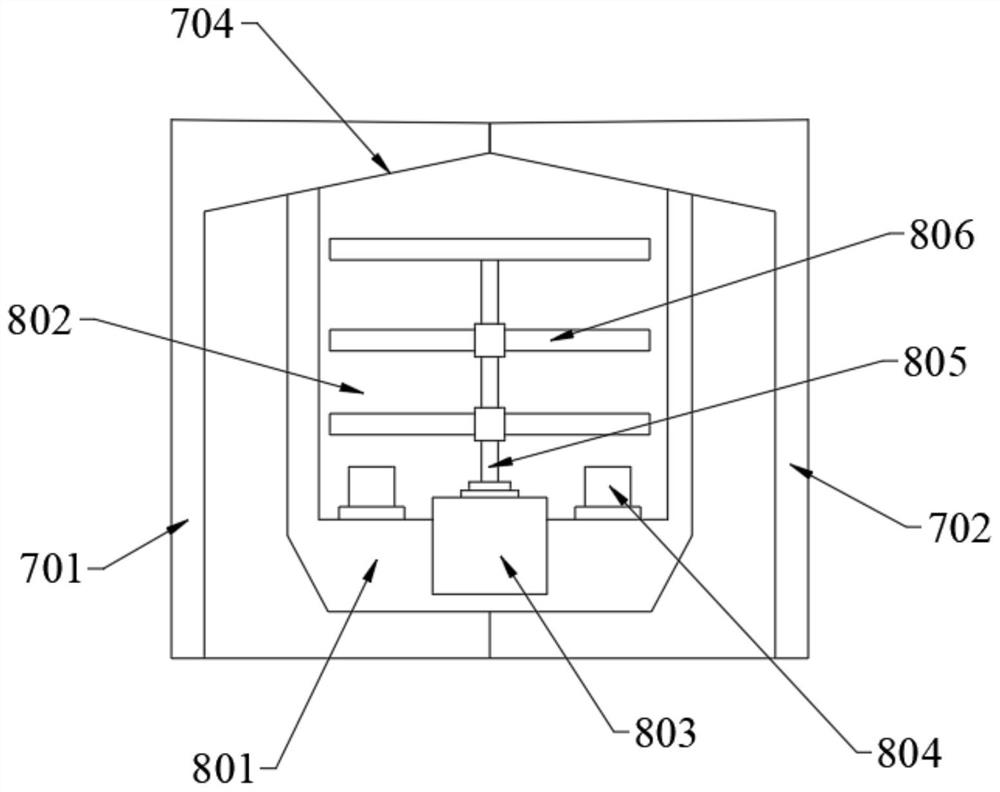

Fully-automatic assembly line after glass toughening

ActiveCN106890796AGuaranteed production speedIncrease productivitySortingGlass productionOff TreatmentEngineering

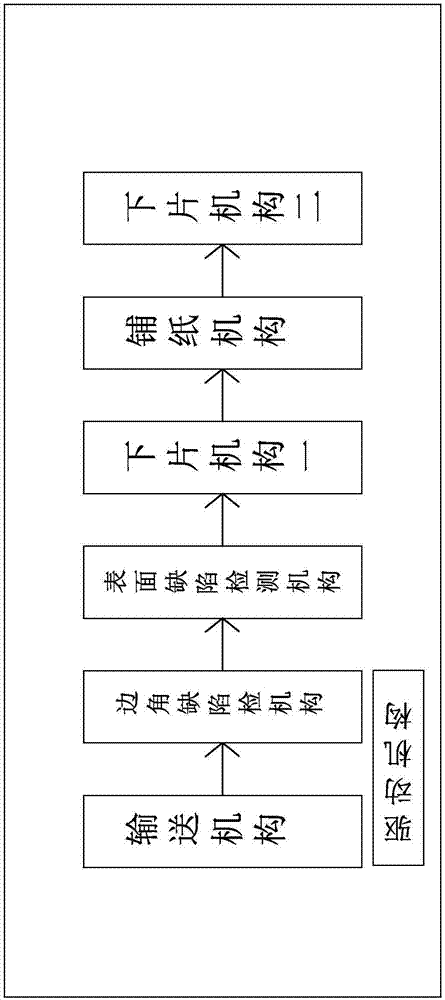

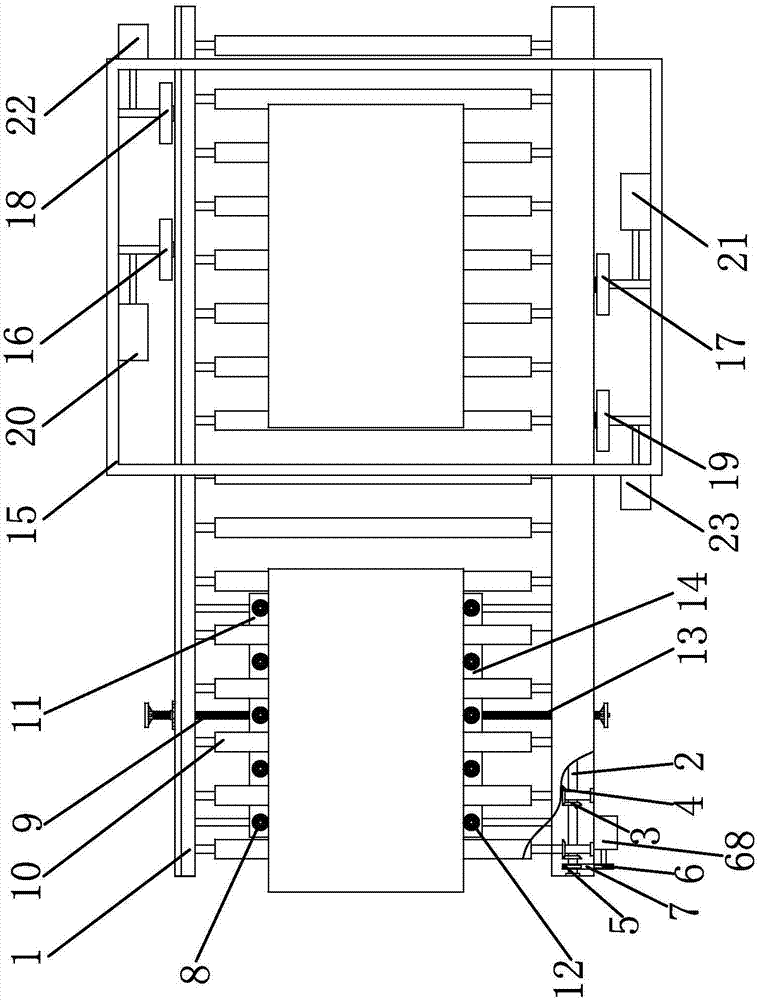

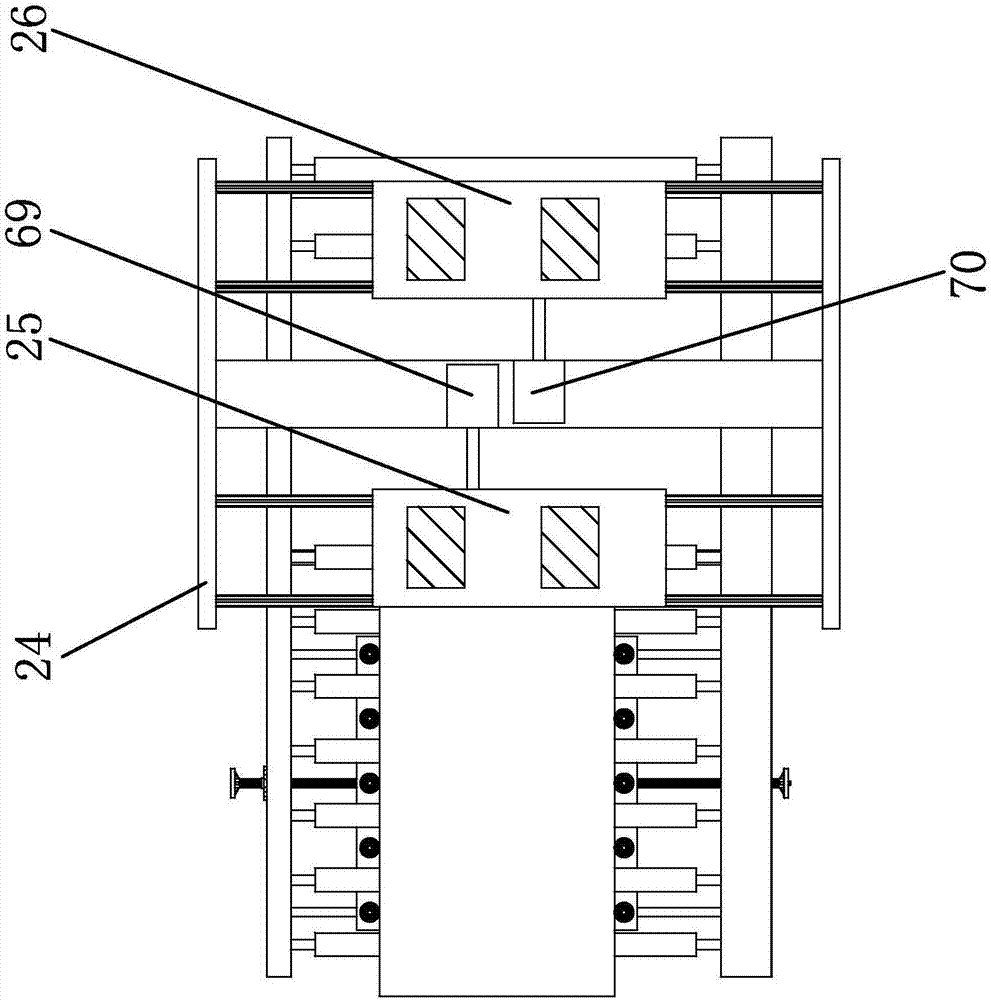

The invention provides a fully-automatic assembly line after glass toughening, belongs to the technical field of machinery, and solves the problem of low production efficiency in the prior art. The fully-automatic assembly line after glass toughening comprises a rack, wherein a strip-shaped guide rail is fixed to the rack; a conveying mechanism capable of automatically conveying glass to move forwards is arranged on the guide rail; the conveying mechanism comprises a plurality of conveying rolls; the conveying rolls are arranged on the guide rail in a manner of circumferentially rotating and being axially fixed; a drive mechanism enabling the conveying rolls to synchronously rotate is arranged at one side of the rack; the guide rail is provided with an inlet end and an outlet end; and an anti-deflection mechanism for preventing the glass from deflection, a corner defect detection mechanism capable of carrying out corner defect detection on the glass, a surface defect detection mechanism capable of carrying out surface defect detection on the glass, a batch-off mechanism I capable of carrying out batch-off treatment on glass defective products, and a paper laying mechanism capable of carrying out online automatic paper laying on qualified glass are sequentially arranged from the inlet end to the outlet end. The fully-automatic assembly line after glass toughening has the advantage of being efficient.

Owner:FLAT GLASS GROUP CO LTD

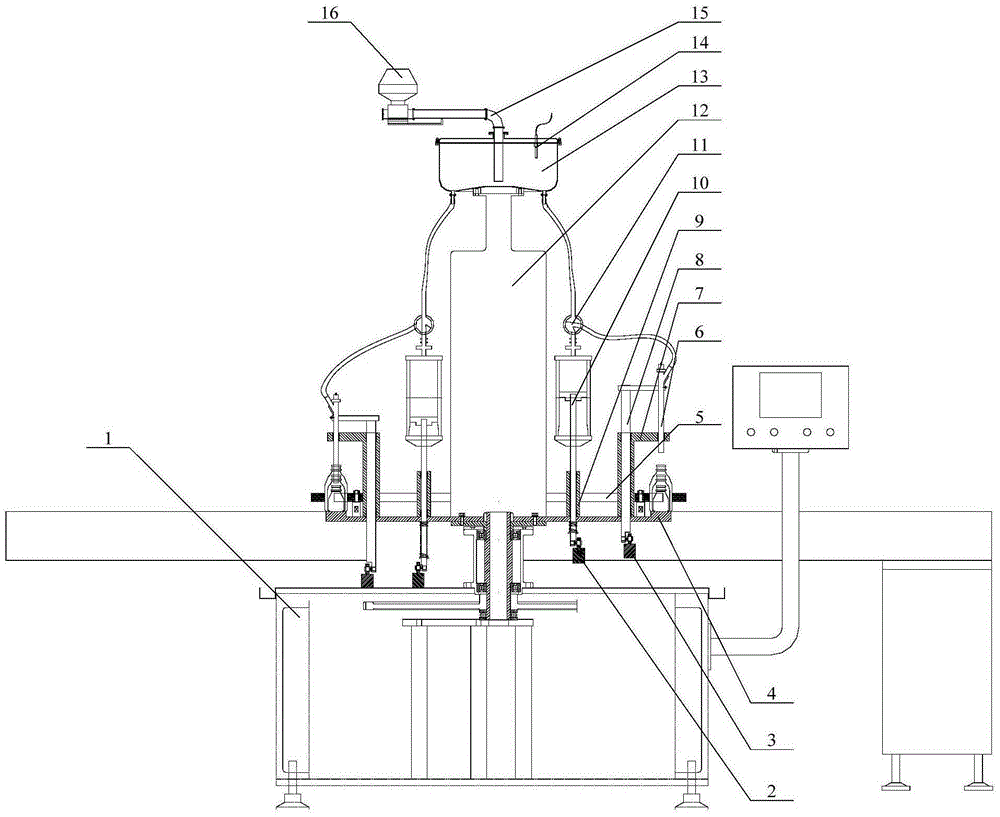

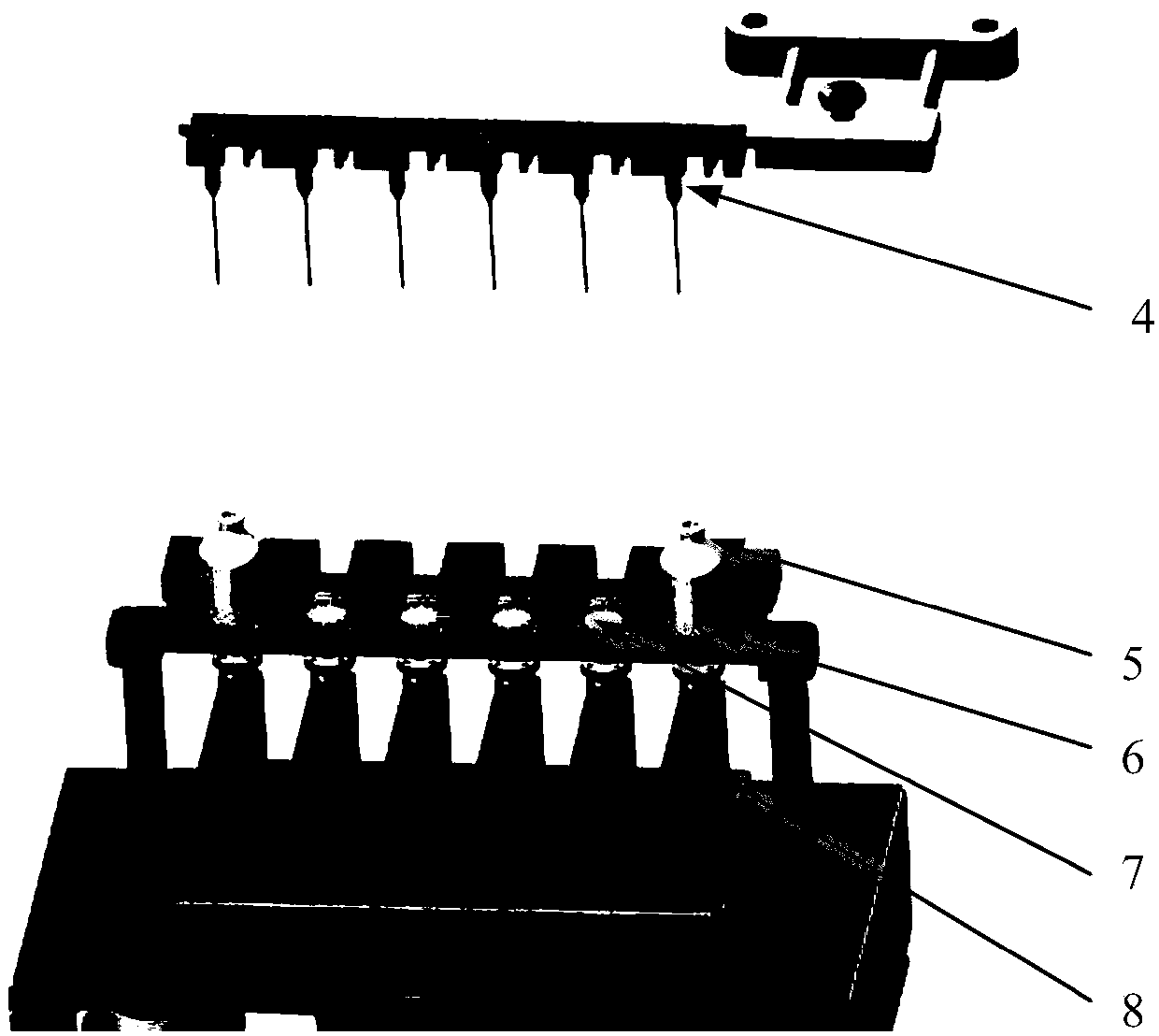

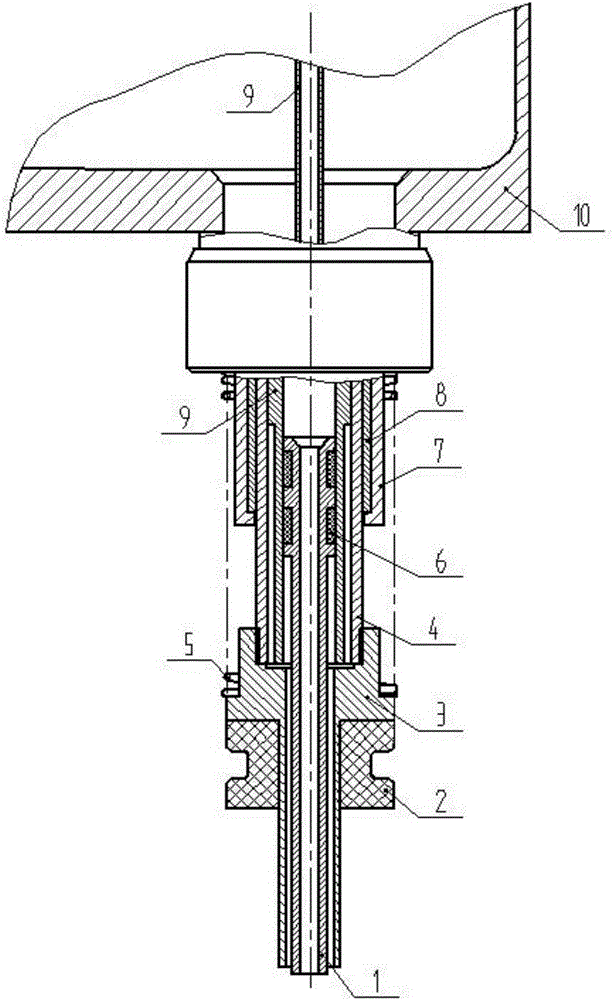

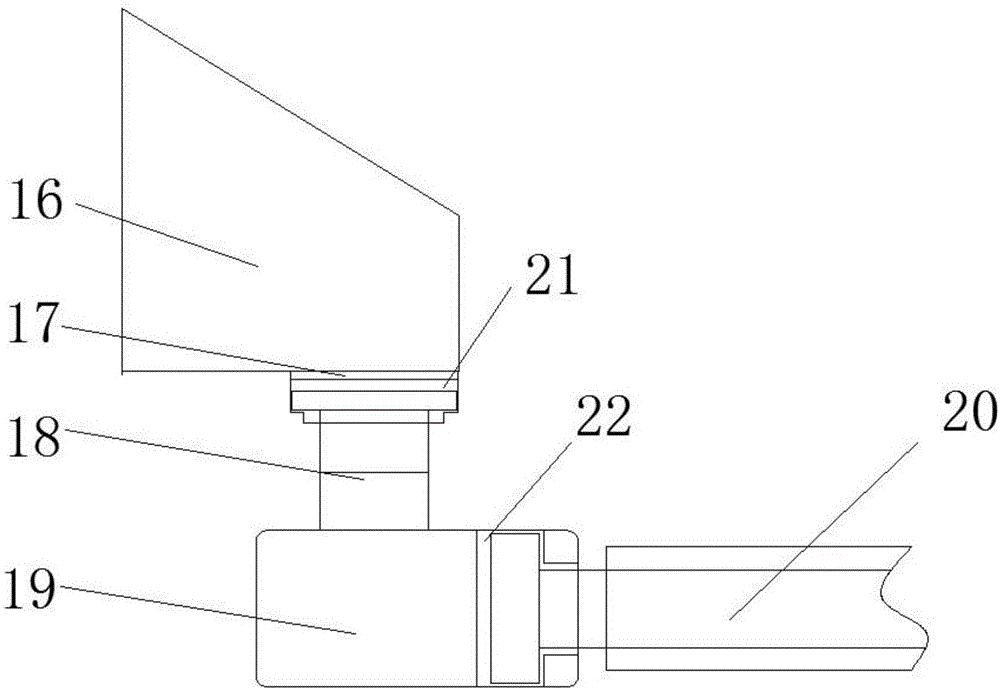

Filling machine

ActiveCN105174169AAchieve dischargeEfficient dischargeFilling using suctionLiquid storage tankEngineering

The invention discloses a filling machine. The filling machine comprises a filling station located on a machine frame. The filling station comprises a plunger pump, a filling device and a pneumatic corner valve, wherein a pump body of the plunger pump is fixed to a rotary base plate, and a piston rod of the plunger pump is connected with a first lifting device; a filling nozzle of the filling device is aligned with a bottle opening of a preparation bottle; the pneumatic corner valve comprises an inlet and two outlets, the inlet is communicated with a high-position liquid storage tank, one outlet is communicated with an opening in the pump body of the plunger pump, and the other outlet is communicated with the filling nozzle. Liquid medicine is sucked in and pressed out through the plunger pump, the requirement for the preparation bottle is not strict, and the filling machine can be adaptive to most preparation bottles; the quantity of liquid medicine sucked in and discharged by the plunger pump can be accurately controlled by adjusting the expansion amount of the piston rod, so that the filling quantity is accurately controlled. By controlling the lifting frequency of the first lifting device, the first lifting device can be matched with other equipment on a production line, the production speed is guaranteed, and production efficiency is improved. Moreover, the filling machine is simple in structure, convenient to disassemble, wash and maintain, and low in manufacturing and using cost.

Owner:长沙汇一制药机械有限公司

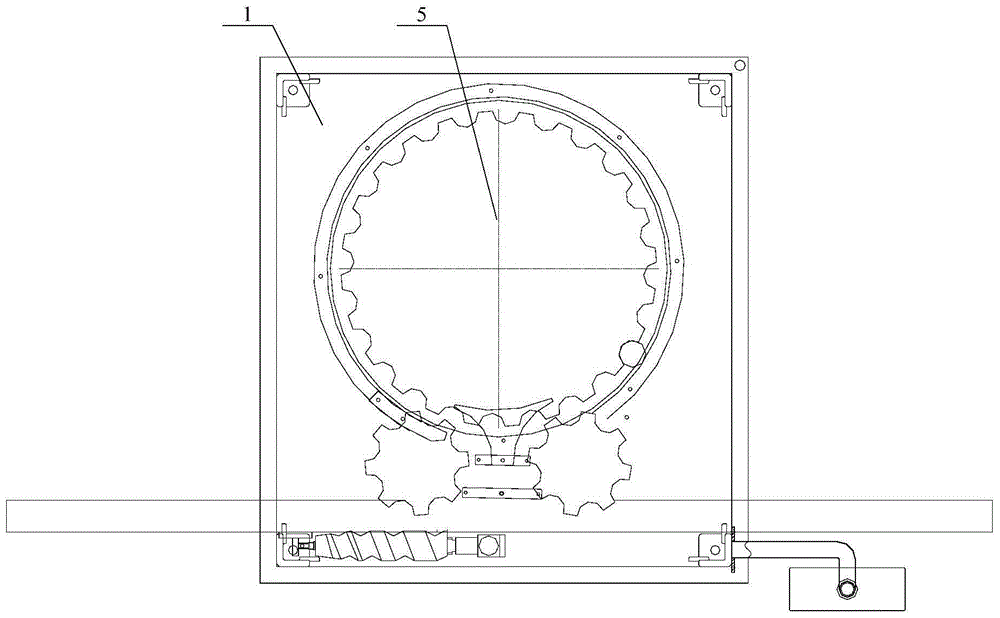

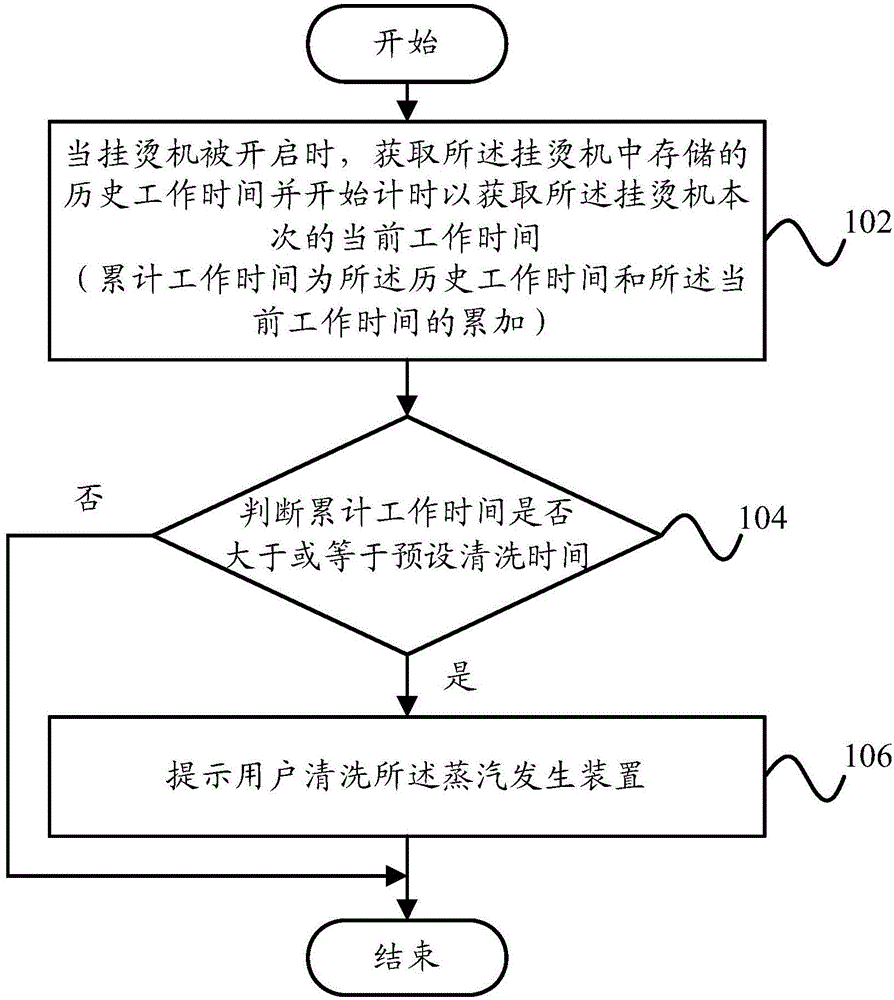

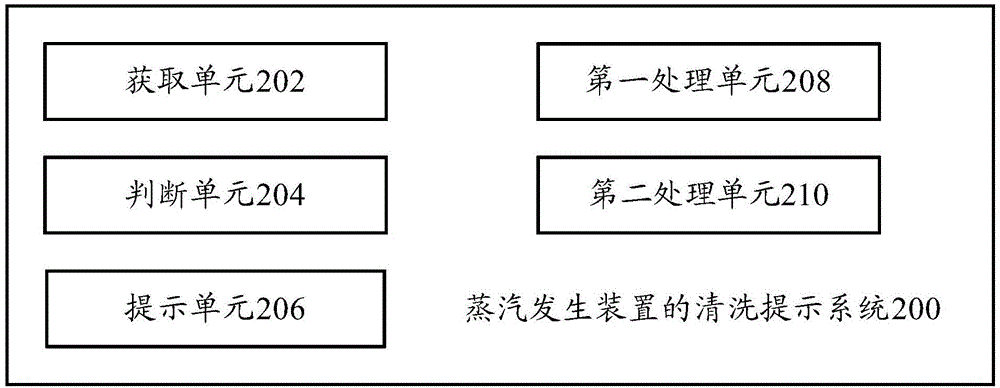

Cleaning prompt method and system for steam generation device, and garment steamer

ActiveCN105696293AGuaranteed production speedExtended service lifeIroning apparatusTextiles and paperWork periodSoftware engineering

The invention provides a cleaning prompt method for a steam generation device, a cleaning prompt system for the steam generation device, and a garment steamer. The cleaning prompt method for the steam generation device includes the following steps: acquiring the historical work time stored in the garment steamer and starting to time to acquire the current work time of the garment steamer when the garment steamer is enabled; determining if the accumulative work time of the garment steamer is greater than or equal to the preset cleaning time of the steam generation device or not, and prompting a user to clean the steam generation device if so, wherein the accumulative work time is equal to the sum of the historical work time and the current work time. According to the technical scheme, the method and the system can timely and accurately prompt the user to clean the steam generation device, and thereby prolonging the service life of the steam generation device.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

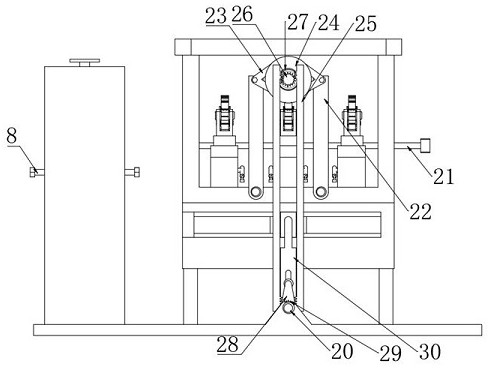

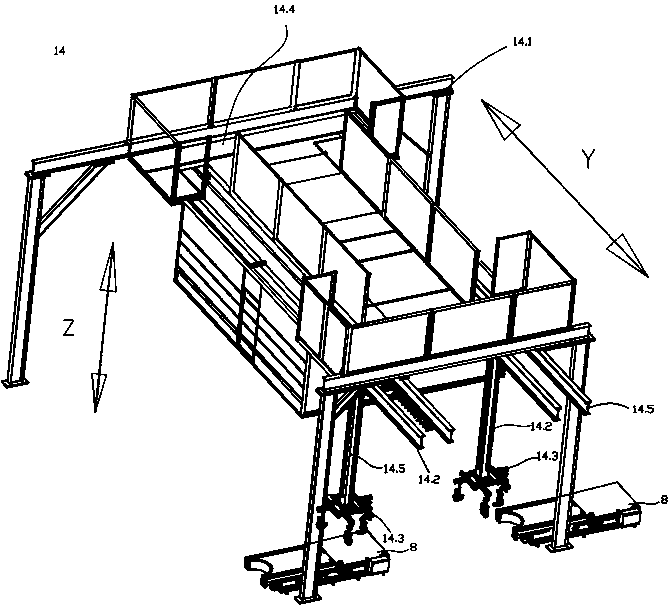

Part manufacturing equipment and method combining laser cutting with electromagnetic welding

ActiveCN108188606AGuaranteed production speedGuarantee product qualityAdditive manufacturing apparatusWelding apparatusControl systemEngineering

The invention discloses part manufacturing equipment and method combining laser cutting with electromagnetic welding. The part manufacturing equipment comprises a laser cutting system, a raw materialconveying and recovery system, a transportation system, an electromagnetic welding system and a control system; the laser cutting system comprises a laser and a cutting platform, and the laser is located over the cutting platform; the raw material conveying and recovery system comprises a raw material reel and a recovery reel, the raw material reel and the recovery reel are located on the two sides of the cutting platform correspondingly, and metal material strips penetrate through the cutting platform and are driven by the recovery reel to move forwards on the cutting platform; the transportation system comprises a three-axis track and a suction cup assembly, and the suction cup assembly can freely move on the three-axis track; and the electromagnetic welding system comprises an electromagnetic coil device and a welding worktable, the electromagnetic coil device can freely move on the three-axis track, and the welding worktable is a lifting table and gradually declines along with increasing of the number of welding layers. According to the part manufacturing equipment and method combining laser cutting with electromagnetic welding, the cost can be reduced, the machining time duration can be shortened, and applicability on parts with various size ranges is good.

Owner:HONG KONG PRODUCTIVITY COUNCIL

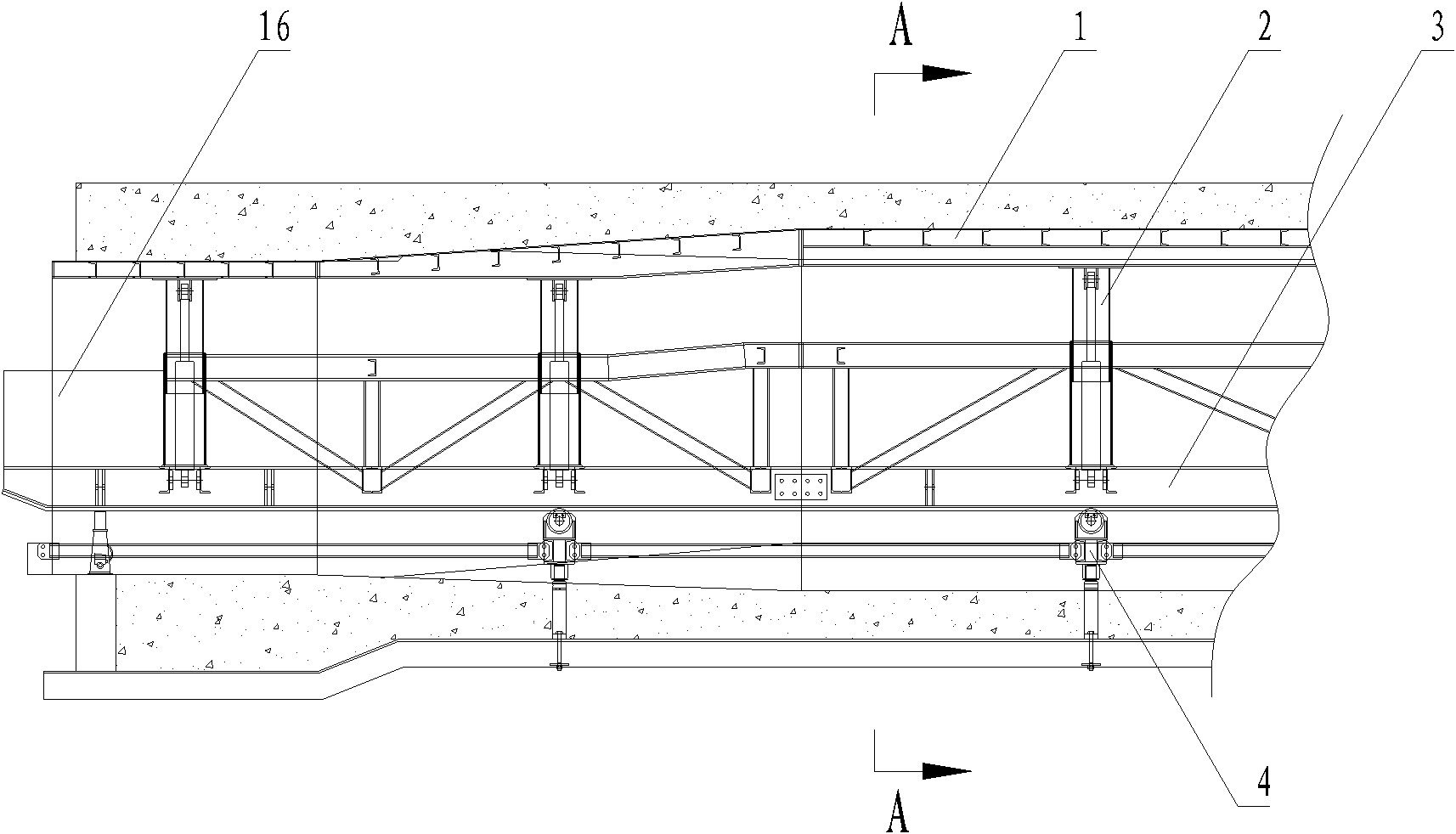

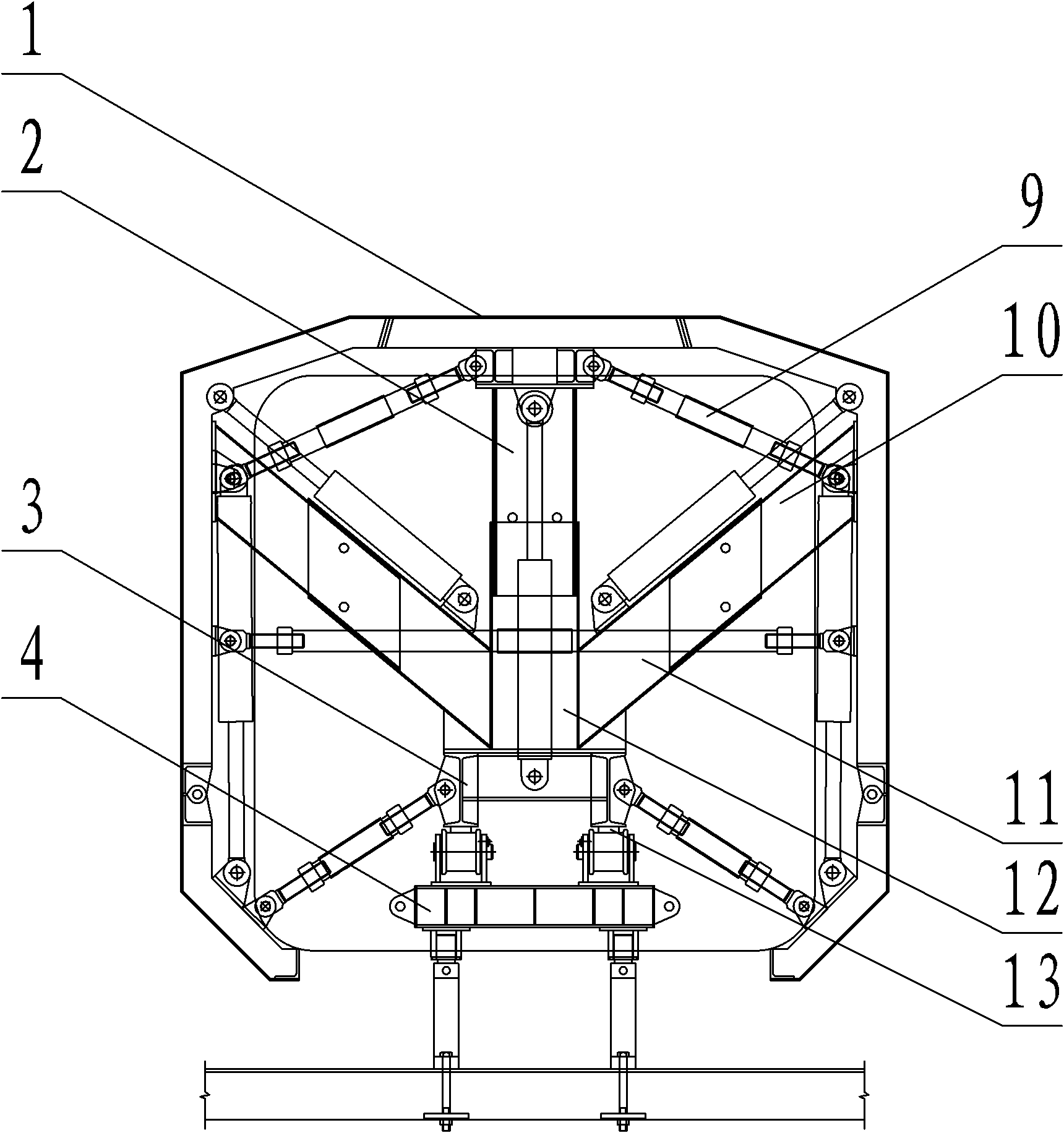

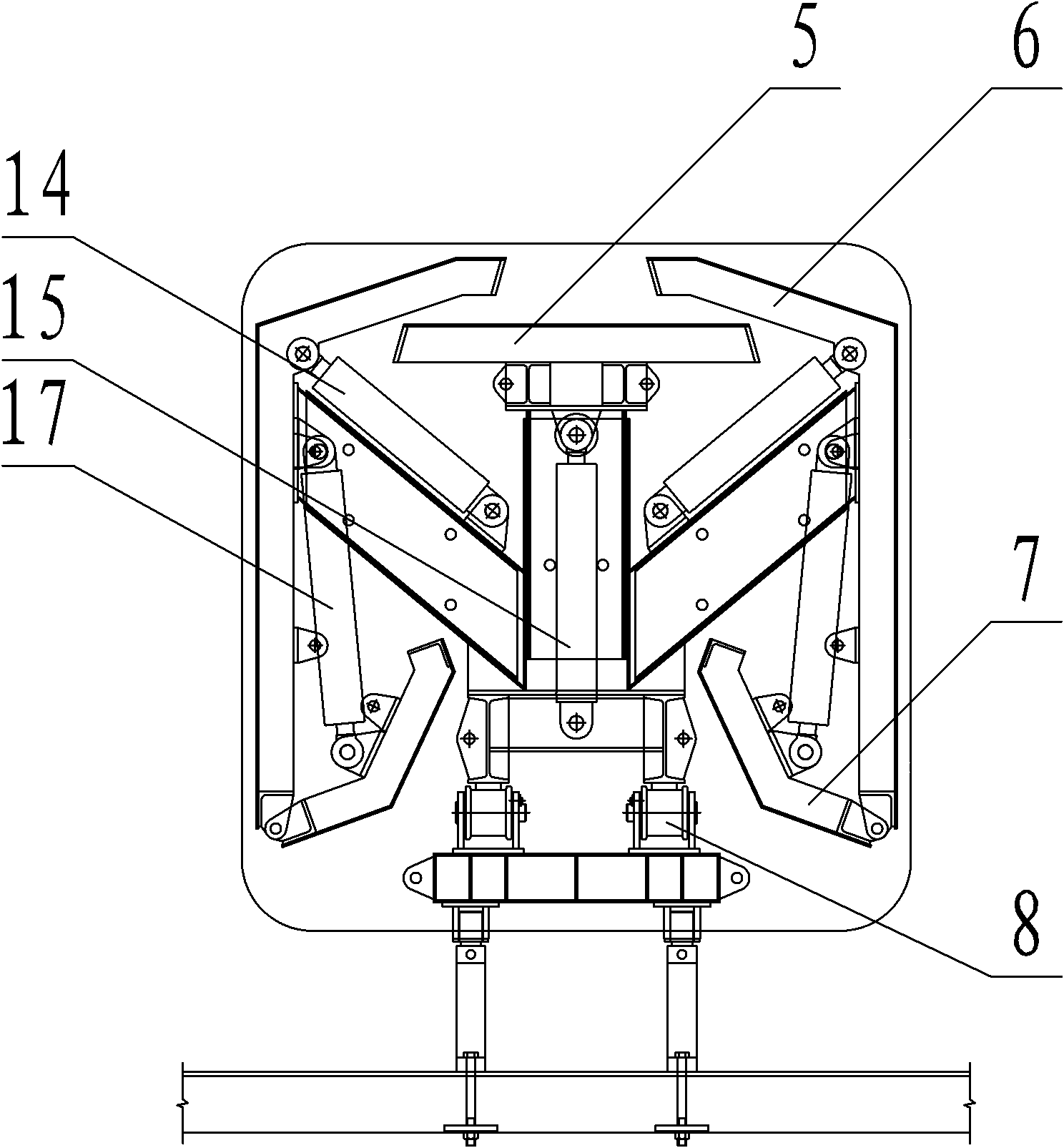

Guide pillar type hydraulic internal mold for straight web plate box girder

InactiveCN102189595ALoading and unloadingShorten the prefabrication periodMouldsHigh volume manufacturingPulp and paper industry

The invention discloses a guide pillar type hydraulic internal mold for a straight web plate box girder. The internal mold comprises a template, a jacking guide pillar, a main girder, a supporting base, a telescopic supporting rod, sideward oil tanks and a jacking oil tank, wherein both sides above the main girder are provided with a sideward guide sleeve symmetrically; sideward guide pillars are sleeved in sideward guide sleeves; the end parts of the side guide pillars are fixedly arranged on the inner side of an upper movable template; the sideward oil tanks are parallelly arranged on the sideward guide sleeves; and the piston ends of the sideward oil tanks are also arranged on the inner side of the upper movable template. By the hydraulic internal mold, the template can be more quickly and conveniently assembled and disassembled, labor intensity is reduced, and the prefabrication construction period of the box girder is greatly reduced, so that production speed is ensured; and the mold is suitable for mass production of prefabricated box girders and can be popularized to be used for designing box girder internal molds of the same type.

Owner:湖南五新智能科技股份有限公司

Automatic arranging and feeding device for firework cylinders

PendingCN109704017APrevent fallingShorten the ascent distanceConveyorsControl devices for conveyorsFireworksEngineering

Owner:广州胜美智能设备有限公司

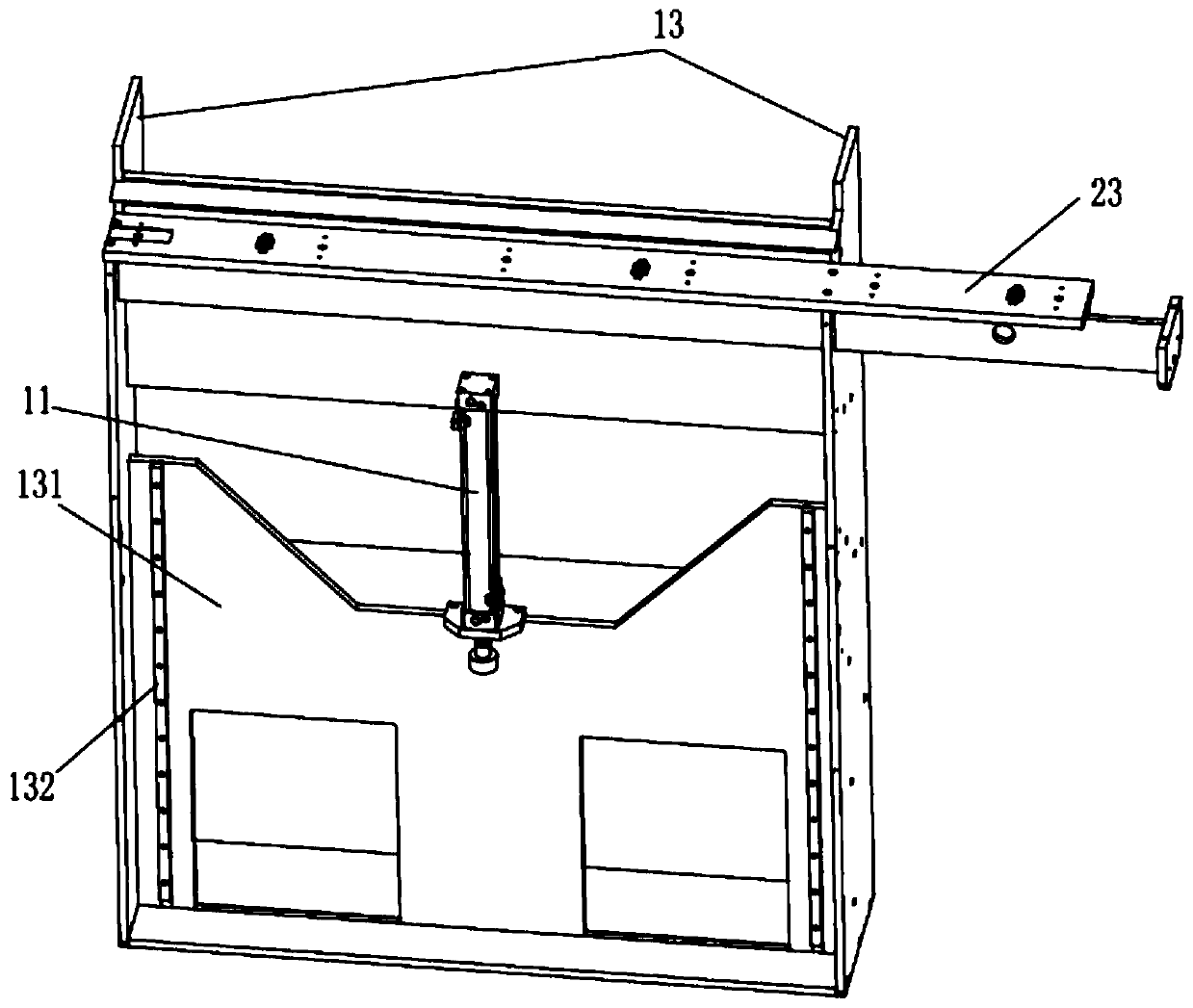

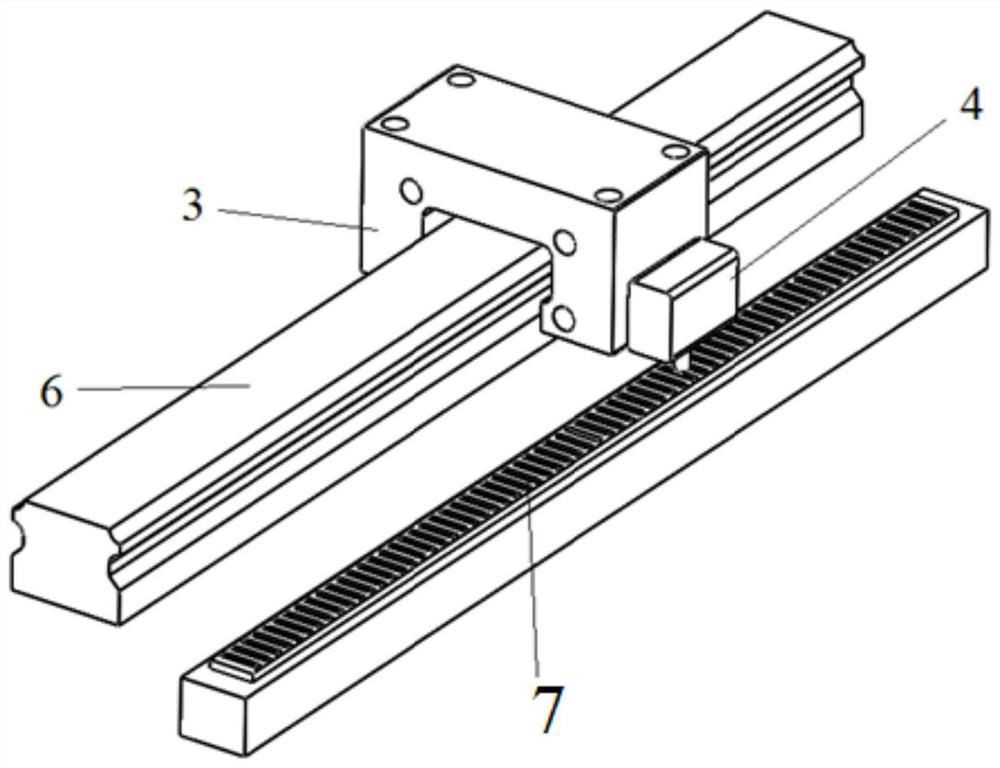

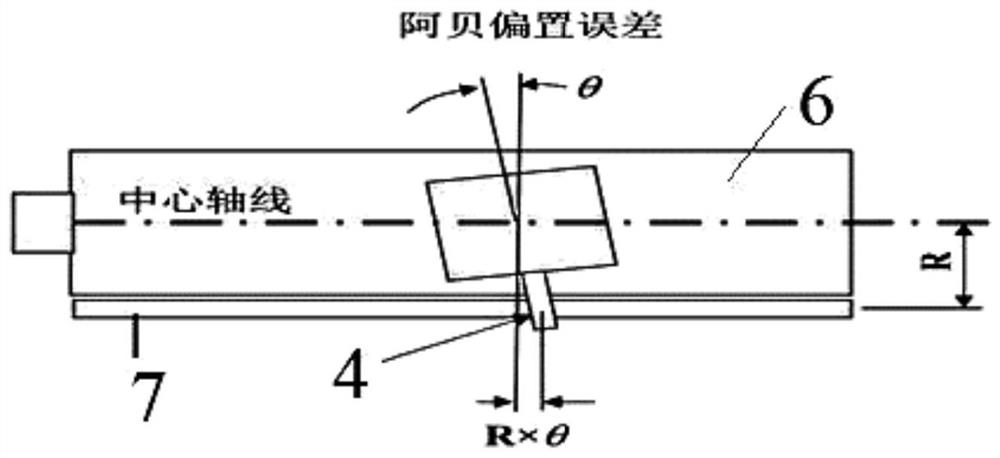

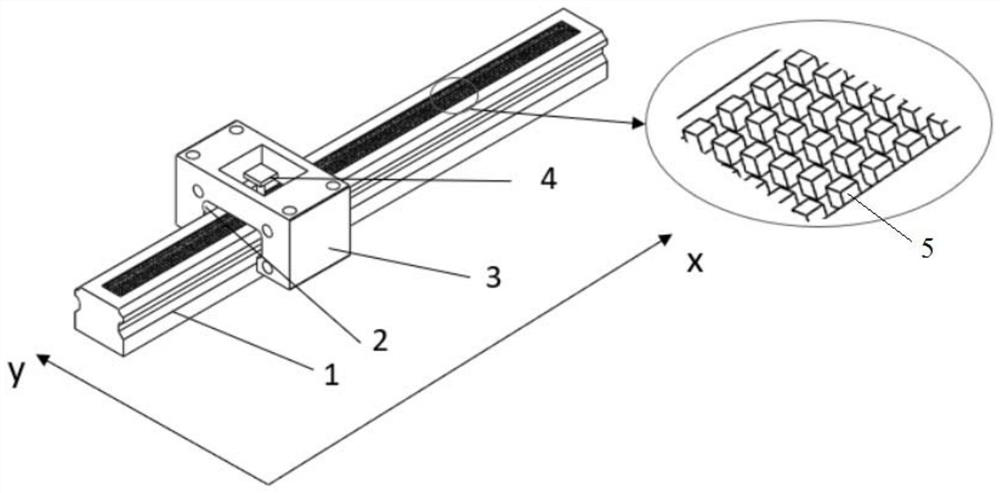

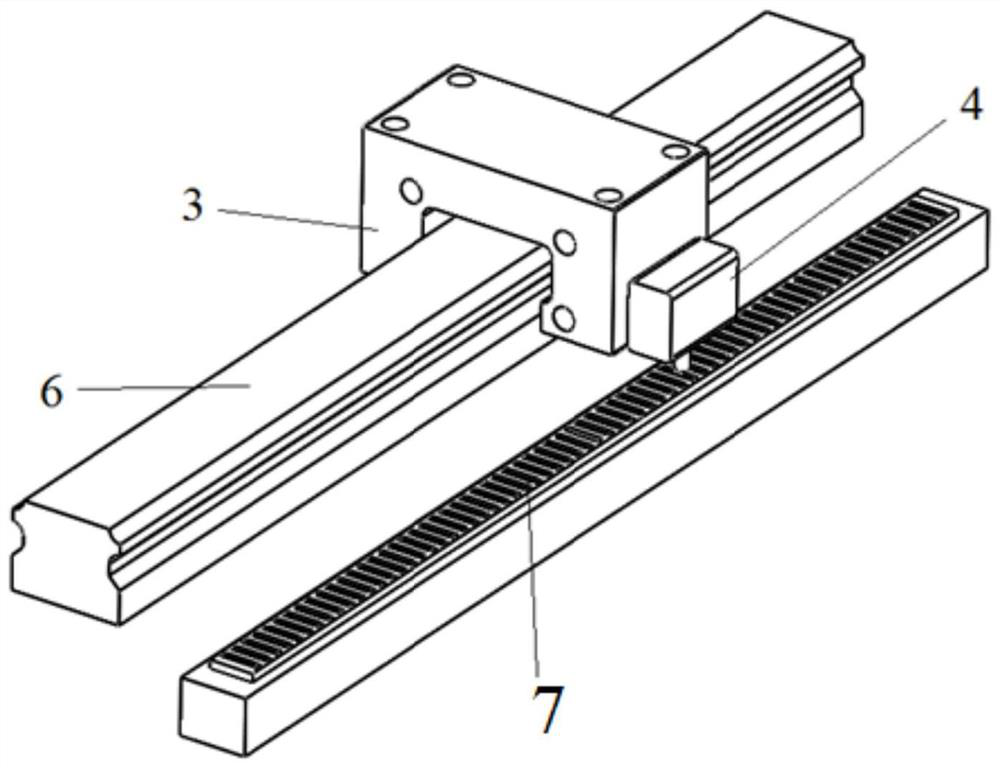

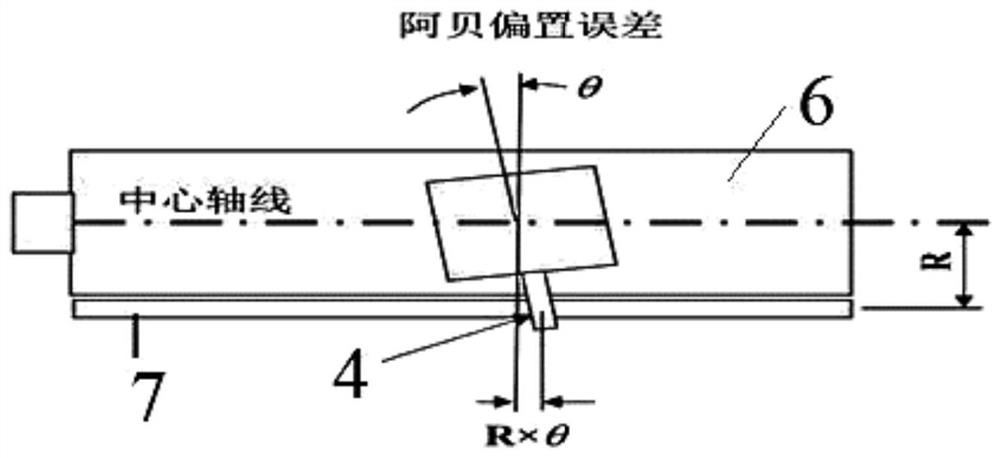

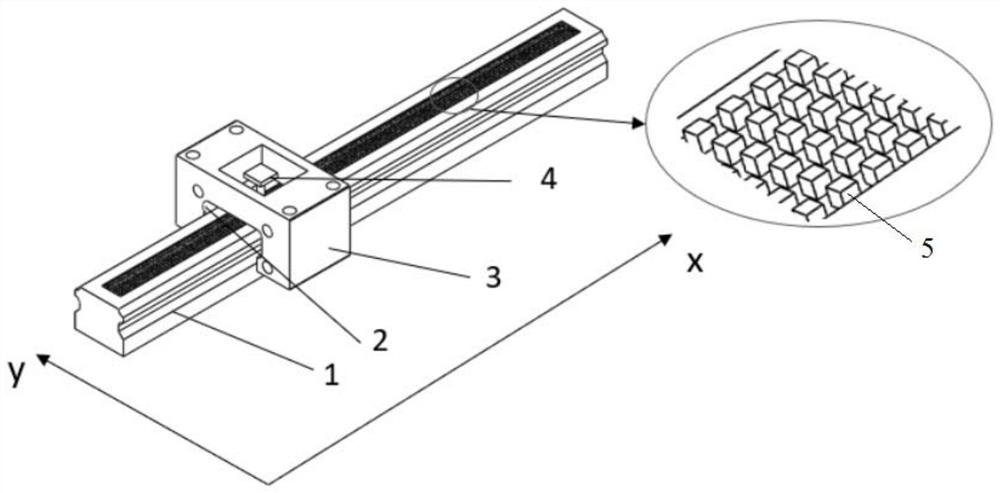

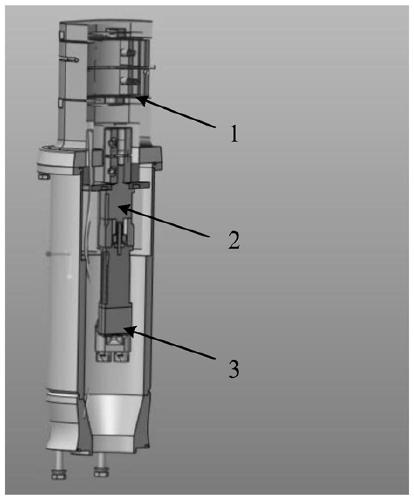

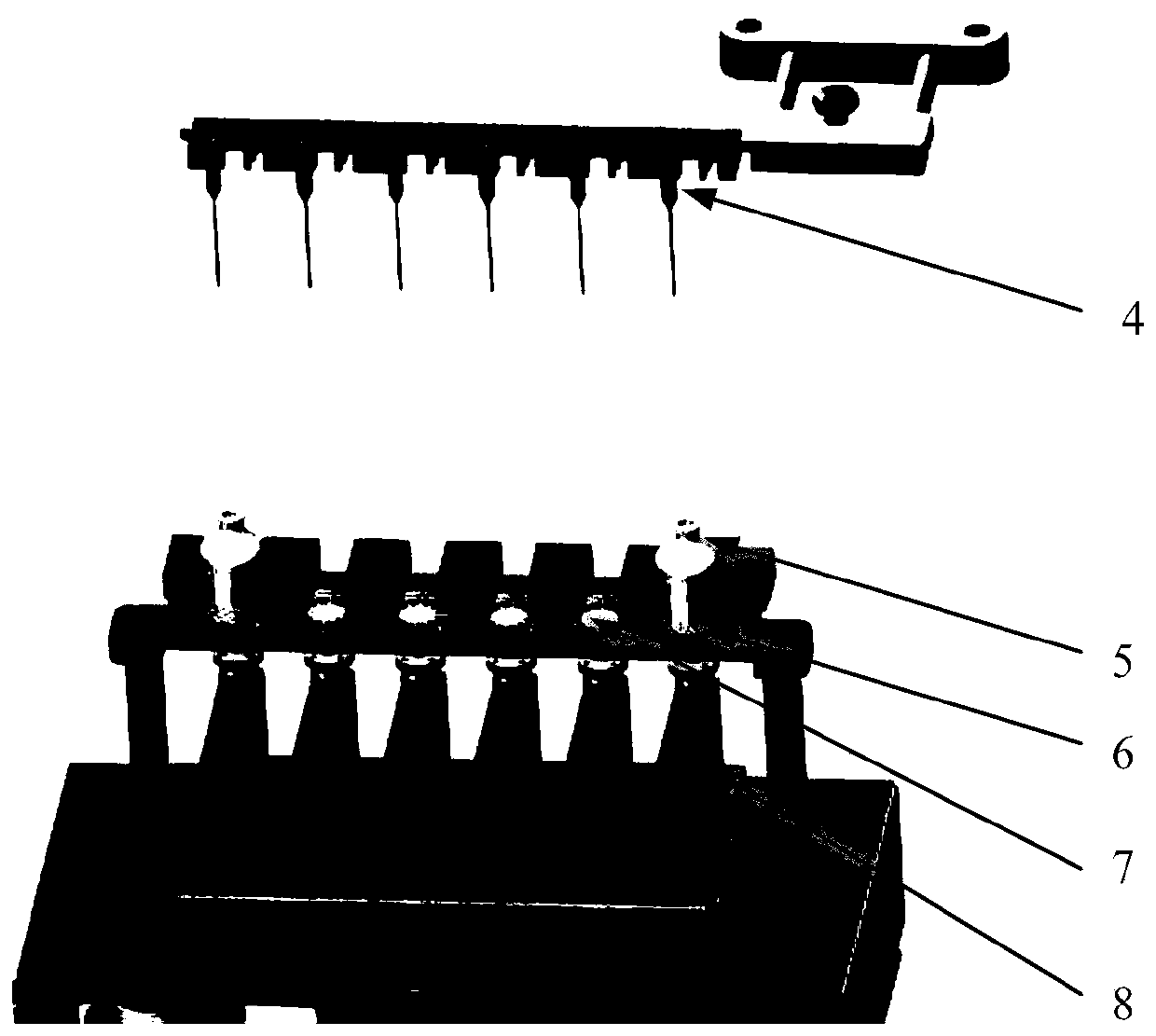

Device and method for synchronous in-situ measurement of linear displacement and straightness of guide rail

ActiveCN111735393AAbbe's error is smallReduce nonlinear errorUsing optical meansGratingMechanical engineering

The invention discloses a device and a method for synchronous in-situ measurement of linear displacement and straightness of a guide rail. For an integrated two-dimensional grating and guide rail, a two-dimensional grating is etched on the upper surface of a linear guide rail, and a reading head is embedded in a sliding block. The specific measurement method comprises the steps that when the sliding block moves on the guide rail, the reading head outputs two pairs of orthogonal sine and cosine signals at the same time, the sine and cosine signals are transmitted to an upper computer through anacquisition card after being subjected to filtering and analog-digital conversion, and displacement and straightness are solved on the upper computer through a method of counting edges through high-frequency pulses, wherein the linear displacement of the guide rail is solved through orthogonal signals generated by the grid lines perpendicular to the x axis, and the straightness of the guide railis solved through orthogonal signals generated by the grid lines perpendicular to the y axis. The method has the advantages of small guide rail pair mounting size, high positioning precision, multi-parameter synchronous in-place measurement and the like, and a new method is provided for displacement and straightness measurement of the guide rail.

Owner:XI AN JIAOTONG UNIV

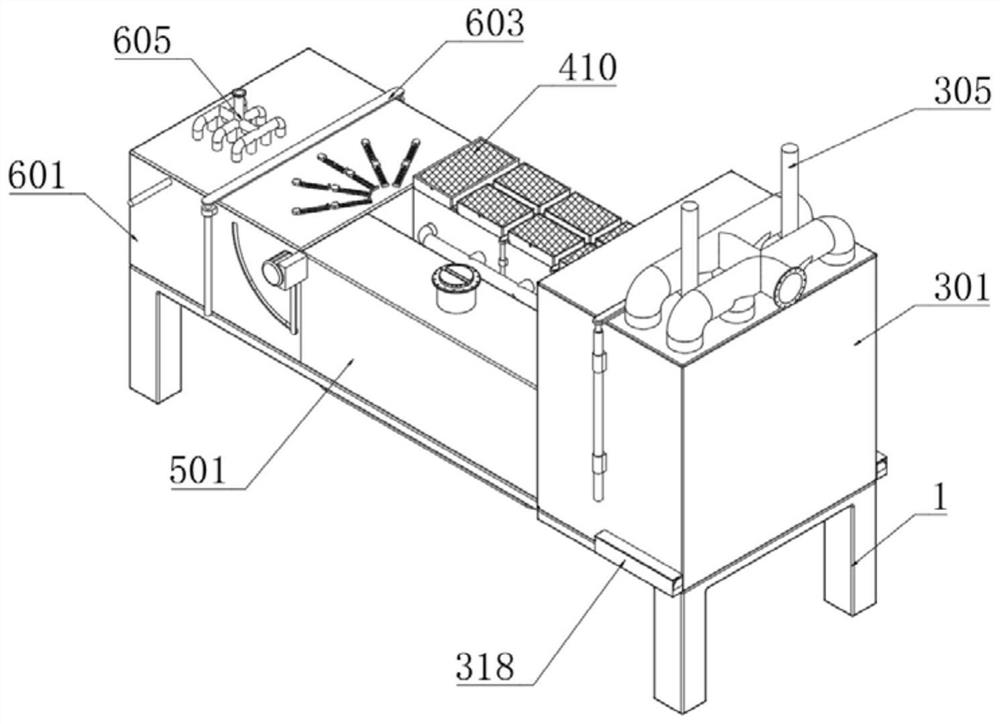

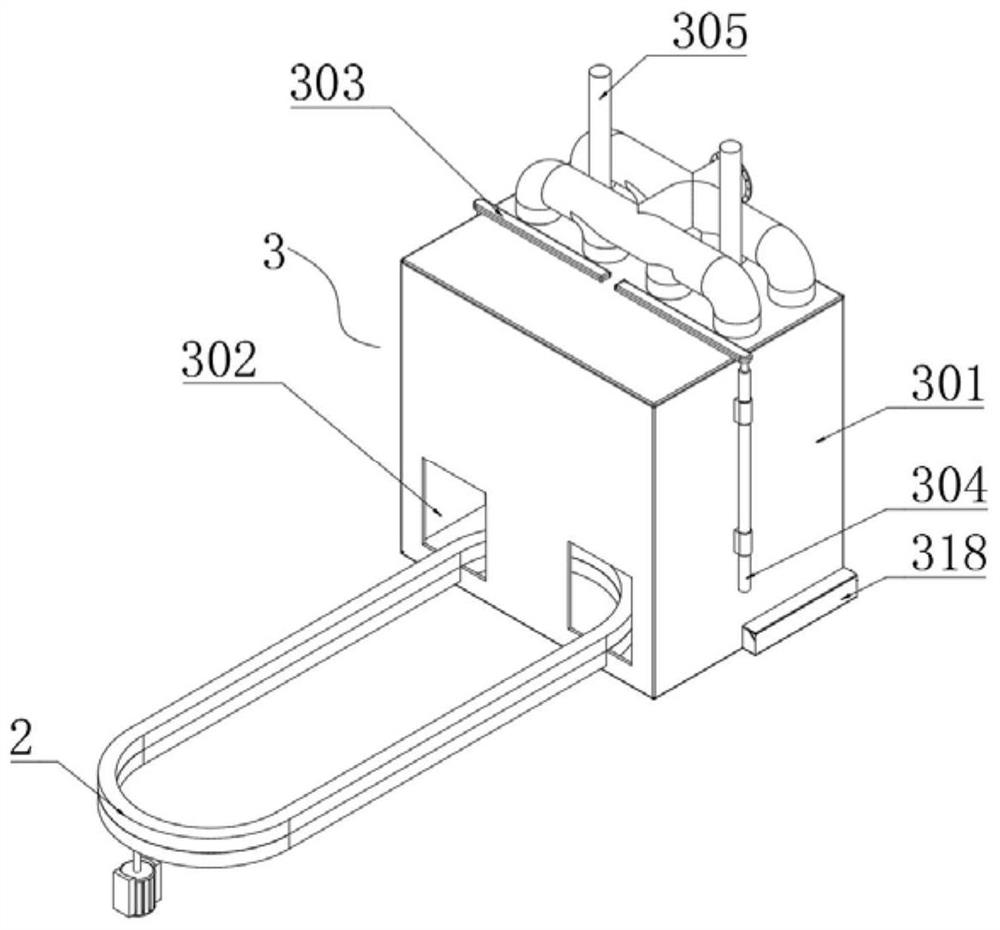

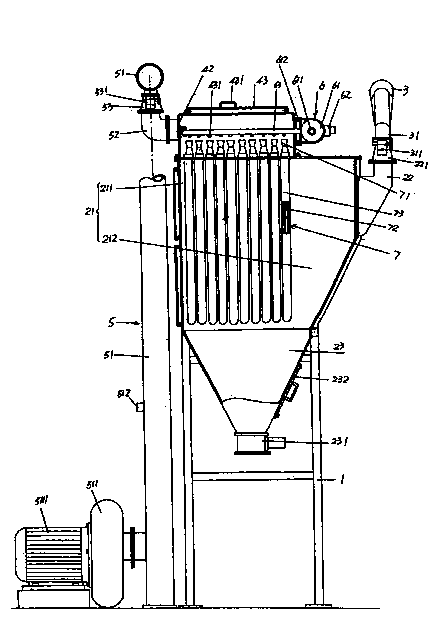

Zinc oxide collecting device

InactiveCN104212980AImprove efficiencyZinc oxide product classification effect is goodMaterial SeparationEngineering

The invention relates to a zinc oxide collecting device, and belongs to the technical field of a facility for producing metallic oxides by a dry method. The zinc oxide collecting device comprises a machine frame, a collecting box, a feeding pipe, an air return box, an air extracting mechanism, a compressed air leading-in mechanism and a zinc material separation mechanism, wherein a collecting box separation cavity is arranged in the collecting box and consists of a recovery cabin and a collecting cabin; a collecting hopper is arranged on the outer wall of the collecting box; the bottom of the collecting box is provided with a discharging hopper; the discharging hopper is communicated with the recovery cabin and the collecting cabin; a discharging hopper discharging control valve is arranged in a position of a discharging opening of the discharging hopper; a feeding pipe discharging opening control valve is arranged on a feeding pipe discharging opening in a cooperated way; the air return box corresponds to the recovery cabin; the air extracting mechanism is connected with the back side of the air return box and is communicated with an air return box cavity; the compressed air leading-in mechanism is arranged at the front side of the air return box; the zinc material separation mechanism is positioned in the separation cavity of the collecting box and is fixed with a zinc material separation mechanism installing hole. Zinc oxide products in different grades can be obtained; the collecting efficiency is improved, the production speed of zinc oxide is guaranteed, and the energy-saving effect is achieved; and the efficiency is high, and the grading effect of zinc oxide products is good.

Owner:徐州市正峰锌业有限公司

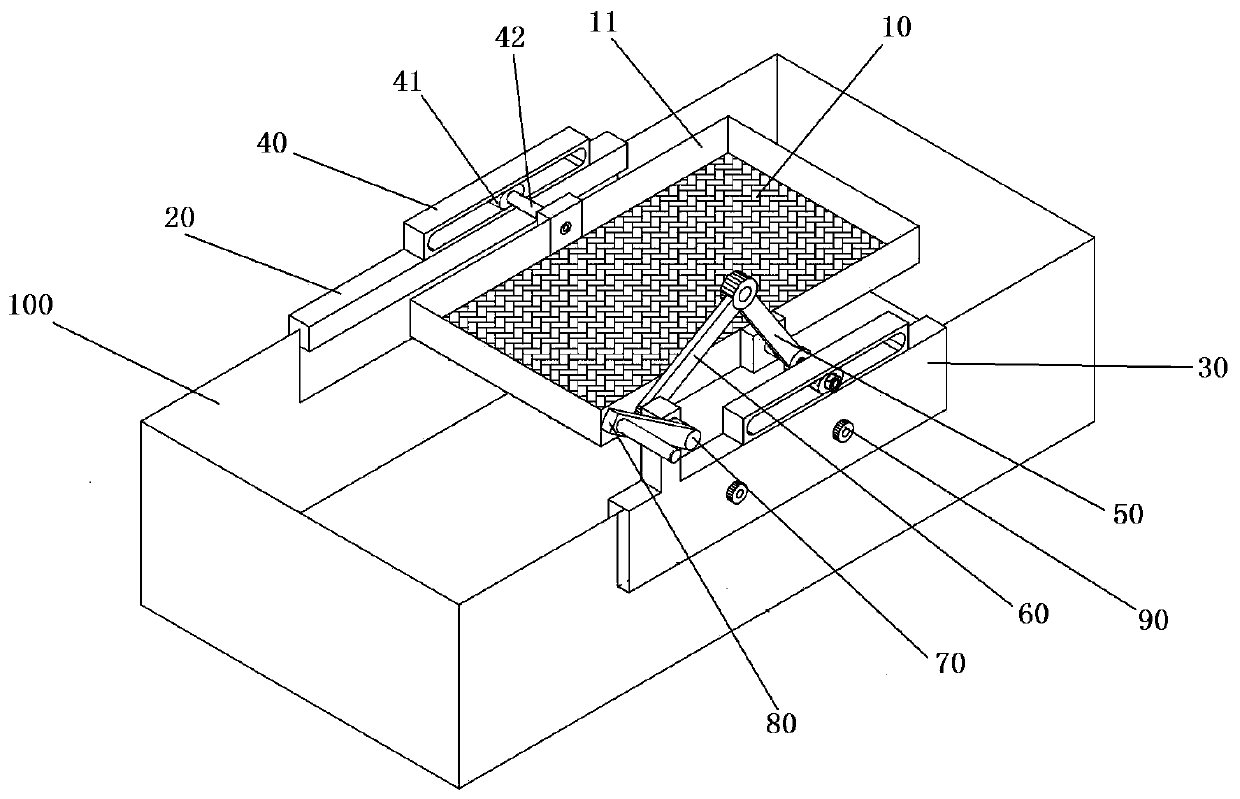

Fiber material dispersing and feeding device

InactiveCN110712298AGuaranteed production speedGuaranteed StrengthSievingScreeningFiberControl theory

The invention discloses a fiber material dispersing and feeding device which comprises a screen, a first fixed frame and a second fixed frame; the first fixed frame and the second fixed frame are oppositely arranged and are provided with sliding rails respectively; each sliding rail is provided with a slider; one side of the screen is fixedly connected with the slider on the first fixed frame through a connecting shaft; the other side of the screen is fixedly connected with the slider on the second fixed frame through a connecting shaft; the first fixed frame or the second fixed frame is provided with a drive mechanism; and the drive mechanism drives the screen to freely slide along the sliding rails. By adopting the fiber material dispersing and feeding device disclosed by the invention,the fiber material unloading efficiency and quality can be effectively improved, the fiber material unloading is more rapid and labor-saving, and fiber materials are more uniform in distribution without clumping, so that a preparation speed, the strength and the quality of the concrete and the like are guaranteed.

Owner:GUANGDONG UNIV OF TECH

Assembly type light steel-foam concrete composite floor and construction method thereof

The invention discloses an assembly type light steel-foam concrete composite floor and a construction method thereof. The floor comprises a floor frame and panels, wherein the floor frame comprises afirst transverse channel steel and a second transverse channel steel which are arranged along the longitudinal direction, a first longitudinal channel steel and a second longitudinal channel steel arearranged between the first transverse channel steel and the second transverse channel steel, the lap joint portion of the end portions of the first transverse channel steel, second transverse channelsteel, first longitudinal channel steel and second longitudinal channel steel is provided with a connecting part, the connecting part connects the first transverse channel steel, the second transverse channel steel, the first longitudinal channel steel and the second longitudinal channel steel integrally, a plurality of rebars are arranged between the first longitudinal channel steel and the second longitudinal channel steel along the longitudinal direction, a first panel and a second panel are paved on the rebars at the both sides of the floor frame, and a cavity formed by the first panel, the second panel and the floor frame is filled with foam concrete. The assembly type light steel-foam concrete composite floor and the construction method thereof have the advantages that the self-weight of the floor is light, the strength is high, the effects of heat preservation, sound insulation, heat insulation and water resistance are good, and the construction is convenient; all floors are produced in plants, thereby being capable of ensuring the quality requirements, producing in batch, guaranteeing the production speed, and achieving green production, not only are materials used reasonably, but also the environment is protected, and the floor is economic and practical.

Owner:SHENYANG JIANZHU UNIVERSITY

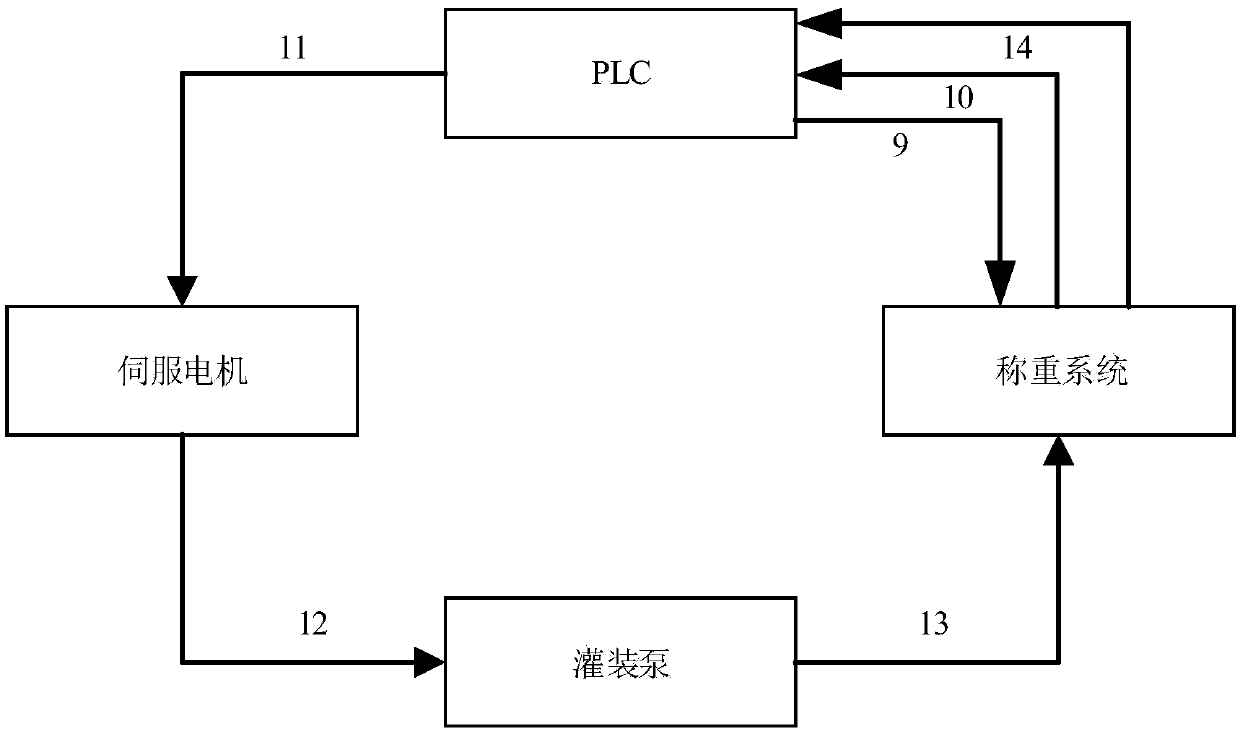

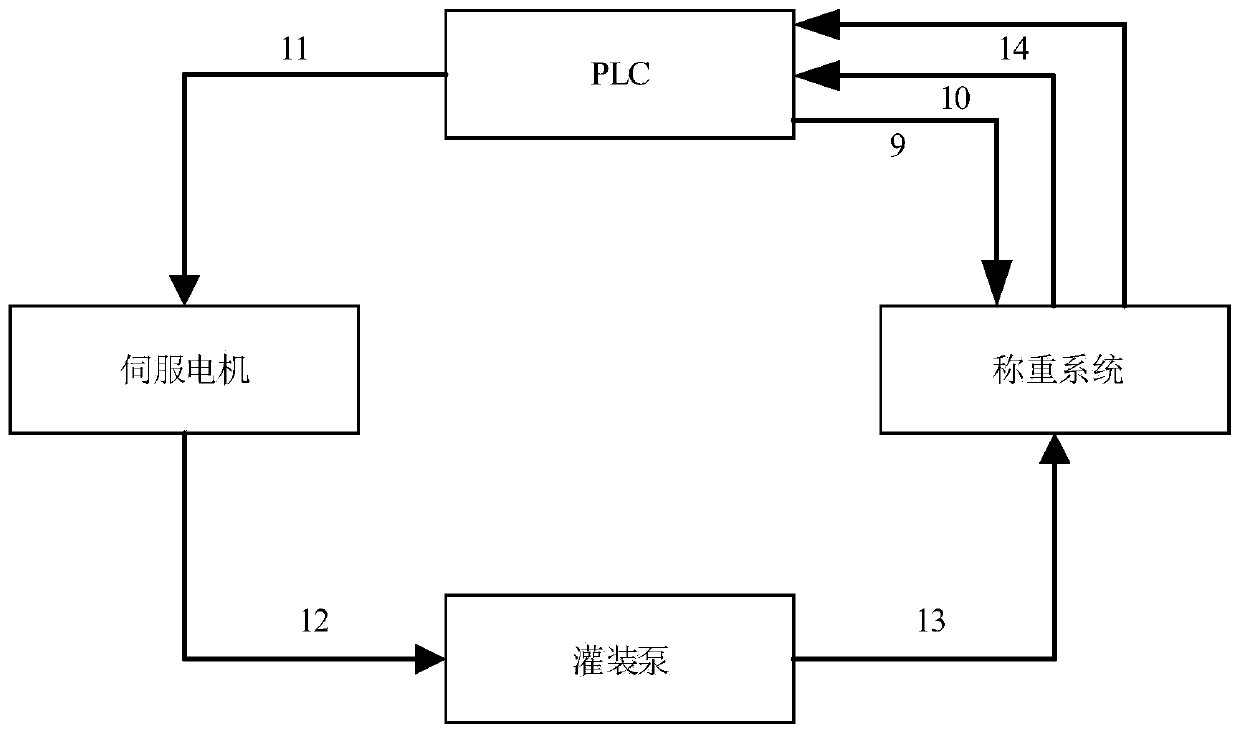

Method and equipment for controlling filling accuracy

ActiveCN109592095AAvoid interferenceGuaranteed production speedLiquid materialEngineeringTarget weight

The invention provides a method and equipment for controlling filling accuracy. By using a controlling method including a system initiation stage, a rough filling stage, a refined filling stage and aclosing stage, the filling accuracy is controlled; in the refined filling stage, low-speed filling is carried out by using a filling pump; after second predetermined time T16, the weight of liquid isdetected in real time until the weight reaches a second predetermined value G2 and then the detection is stopped; and the size of the second predetermined value G2 is determined according to a difference value between target weight G1 of a container and the weight of a less amount of surplus liquid which does not flow into the container during closing of the filling pump. According to the method and equipment for controlling the filling accuracy disclosed by the invention, rough filling and refined filling are separately carried out and sectional control is carried out, the rough filling is used for ensuring the production speed and the refined filling is used for ensuring the filling accuracy; the pump-rear pipe storage amount is taken into consideration between a refined filling value and a predetermined value; and through calibrating the matching of the refined filling value and the pump-rear pipe storage amount in real time, the situation that the final filling amount is almost consistent with the predetermined value is ensured.

Owner:TRUKING TECH LTD

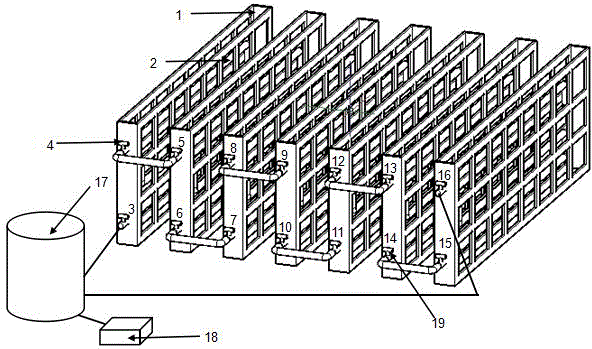

Maintaining technology for heat-conduction oil of combined mould

The invention provides a maintaining technology for heat-conduction oil of a combined mould. Maintaining pipelines are installed in each set of frames of the combined mould and arranged in a zigzag shape. A pipeline inlet of the first frame is formed in the bottom of the left side of the frame, and a pipeline outlet of the first frame is formed in the top of the left side of the frame. A pipeline inlet of the second frame is formed in the top of the left side of the frame, and a pipeline outlet of the second frame is formed in the bottom of the left side of the frame, and so on. The pipeline outlet of the first frame is connected with the pipeline inlet of the second frame through a connecting pipeline. The pipeline outlet of the second frame is connected with a pipeline inlet of the third frame through a connecting pipeline, and so on. The heat-conduction oil is adopted as heating media in the pipelines. The heat-conduction oil is connected to the pipeline inlet of the first frame from a storage tank, sequentially flows through the maintaining pipelines in the first frame, the second frame, the third frame, the fourth frame and the like, flows out of a pipeline outlet of the frame at the most tail end and enters the storage tank again, and the heat-conduction oil is used for circulating heating in the maintaining pipelines in this way. A controller is arranged, and large-batch, phased and partial maintaining of prefabricated wallboards can be conducted.

Owner:RENQIU YONGJI CONSTR & INSTALLATION ENG

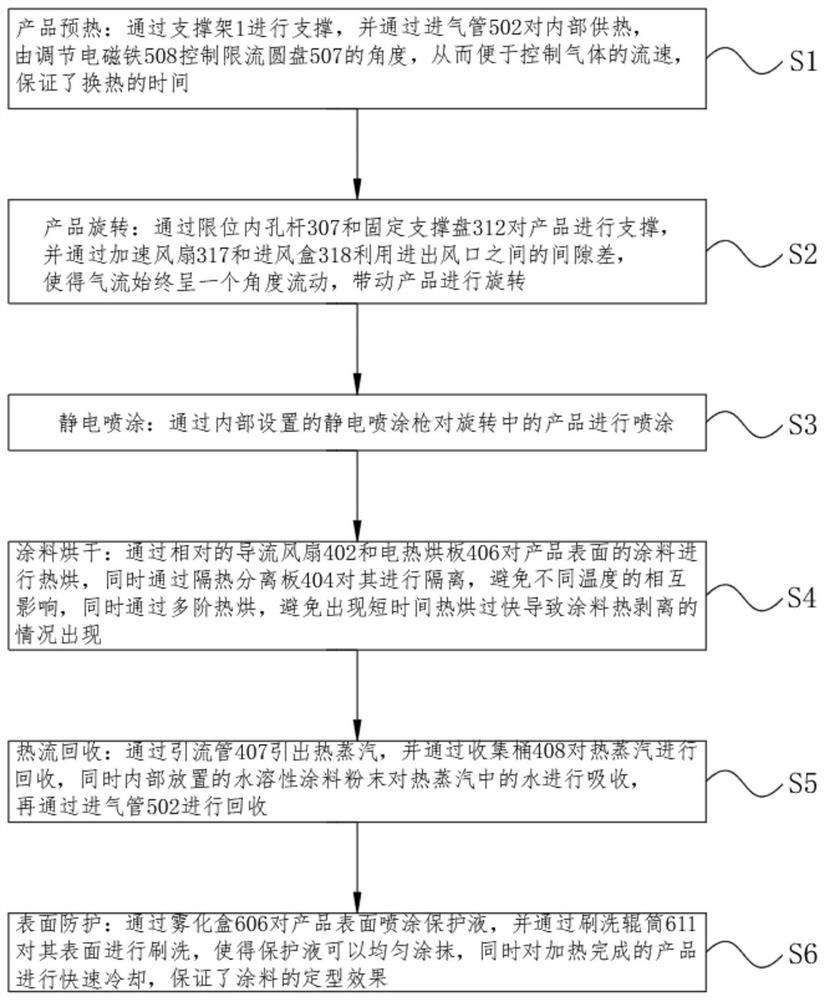

Vertical intelligent multidirectional electrostatic paint spraying method

InactiveCN113198698AFirmly attachedUniform adhesionLiquid spraying plantsPretreated surfacesHeat flowProcess engineering

The invention discloses a vertical intelligent multidirectional electrostatic paint spraying method. The vertical intelligent multidirectional electrostatic paint spraying method comprises the following steps: S1, product preheating, S2, product rotating, S3, electrostatic spraying, S4, paint drying, S5, heat flow recovery and S6, surface protection. According to the invention, products are preheated, so that the situation of non-uniform electrostatic charge distribution caused by direct spraying for the cold products is avoided, and then the uniformity of the products during spraying is ensured; by rotating the products, excessive paint is prevented from being accumulated on the surfaces of the products, and then orange-stripe-shaped stripes on the surfaces of the products caused by flowing of the paint are avoided, so that the spraying quality for the products is ensured; the products are subjected to hot drying after the spraying is completed, and through symmetrical hot drying at the two ends, the paint is prevented from flowing during the hot drying, so that orange-stripe-shaped flowing marks are further avoided while paint distribution is ensured; and meanwhile, the products gradually adapt to different temperatures through multi-step hot drying, so that hot stripping caused by instant high temperature is avoided.

Owner:刘华

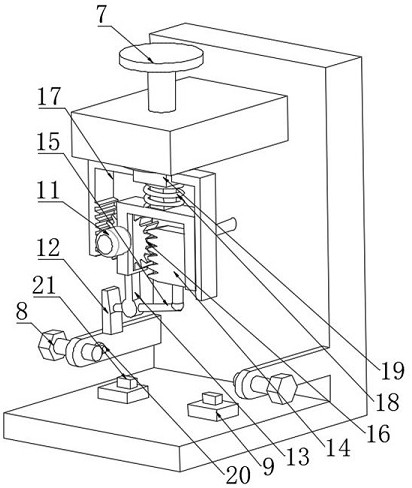

Straightening machine with downward pressing starting point detection function

ActiveCN113319155AReduce distanceAvoid over straighteningShaping toolsMetal-working feeding devicesStructural engineeringMachine

The invention belongs to the technical field of workpiece straightening, and particularly relates to a straightening machine with a downward pressing starting point detection function. The straightening machine comprises a base, a plurality of mounting seats are arranged at the upper side of the base, and a containing plate is arranged between every two front and back adjacent mounting seats; bearing seats and straighteners are arranged at the opposite sides of the front and back adjacent mounting seats and above the containing plates, sliding columns capable of being matched with the bearing seats to be in up-down sliding connection are arranged on the bearing seats, limiting caps are arranged at the top ends of the sliding columns, and limiting blocks and connecting blocks are arranged on the sliding columns and below the bearing seats; and the sliding columns are in threaded connection with the connecting blocks and the bearing seats in a matched manner, and transmission seats are arranged at the two sides of each connecting block. By means of the straightening machine, a workpiece can be straightened in all directions under the condition that the rust removal efficiency is guaranteed, the automation degree is high, and safety and reliability are achieved.

Owner:常州海特赐仁传动科技有限公司

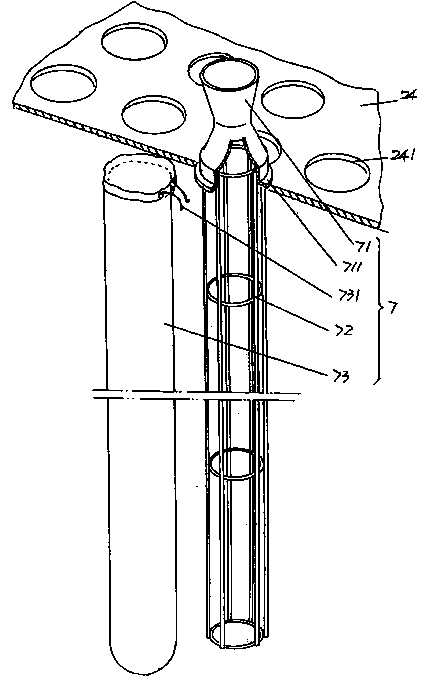

Filling head of low vacuum filling machine

InactiveCN105197863AGuaranteed accuracy and production speedReduce difficultyLiquid bottlingVacuum tubeBottle

The invention discloses a filling head of a low vacuum filling machine. The filling head of the low vacuum filling machine comprises a filling pipe, a bottle opening sealing pad, a vacuumizing pipe, a valve core, a connection nut, a guide sleeve, a ventilation pipe, a spring and a guide sealing ring, wherein the upper end of the vacuumizing pipe is connected with the lower end of the valve core; the inner wall of the valve core is sleeved by the ventilation pipe; the outer wall of the valve core is sleeved by the guide sleeve; the outer wall of the guide sleeve is sleeved by the connection nut; the outer wall of the vacuumizing pipe is sleeved by the bottle opening sealing pad; the filling pipe penetrate through the inner walls of the vacuumizing pipe and the ventilation pipe; the spring is mounted on the outer wall of the upper end of the vacuumizing pipe; the spring is mount in a manner of extending to the outer wall of the connection nut; a liquid outlet in the lower end of the filling pipe protrudes from an air extraction opening in the lower end of the vacuumizing pipe. According to the filling head of the low vacuum filling machine, the phenomenon that the liquid is pumped out during filling is avoided; the filling part is small in size of the outer diameter; the centering difficulty is reduced; the production speed and the product quality are improved; the production cost is reduced.

Owner:长沙铭盛科技发展有限公司

Mechanical arm type efficient and rapid dust-prevention drilling machine

InactiveCN107433345AQuick positioning and controlEnsure safetyMaintainance and safety accessoriesBoring/drilling machinesDrilling machinesControl engineering

Owner:合肥恩腾电子科技有限公司

Nickel-plated diamond micro-powder enhanced babbitt metal and preparation process

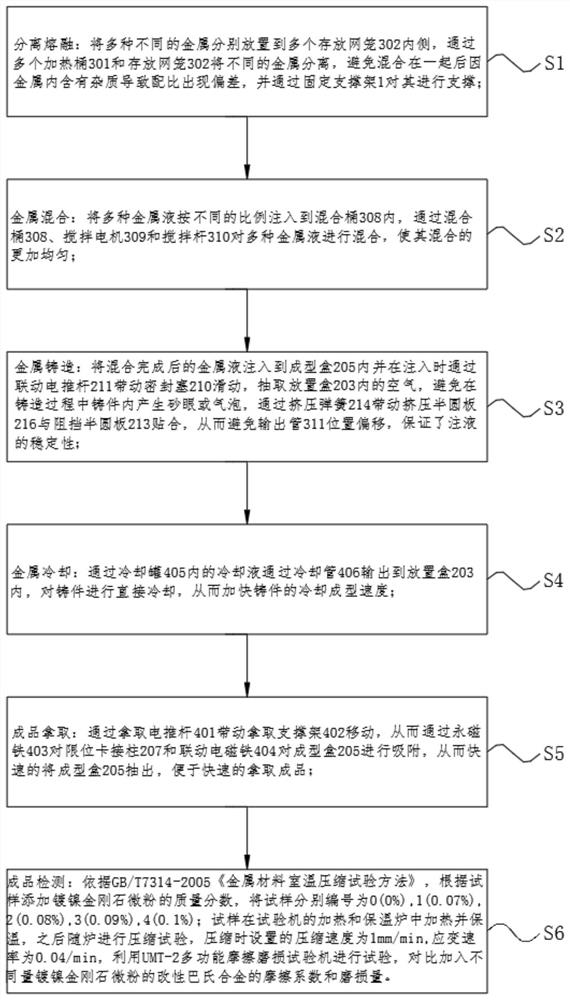

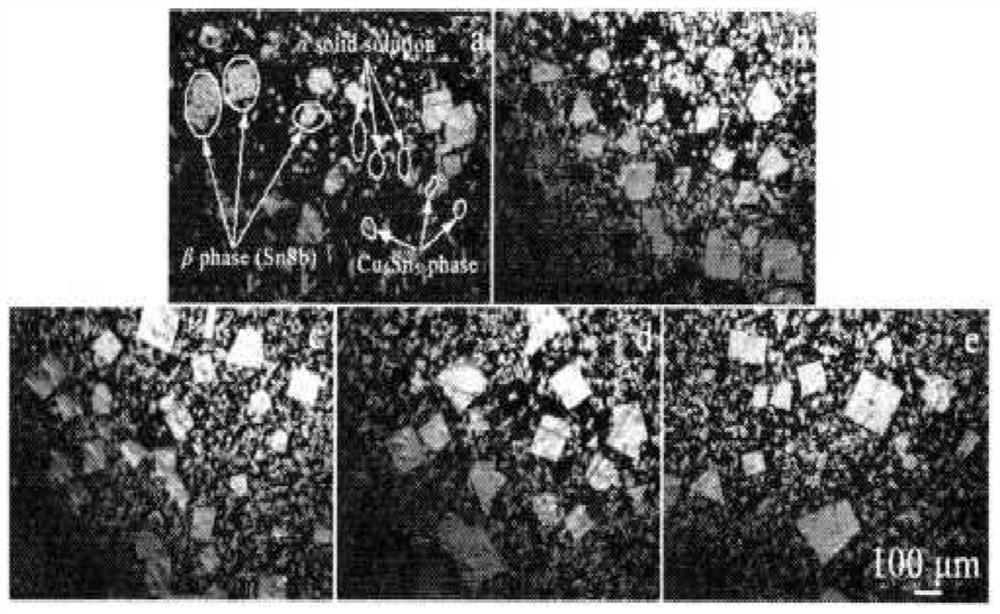

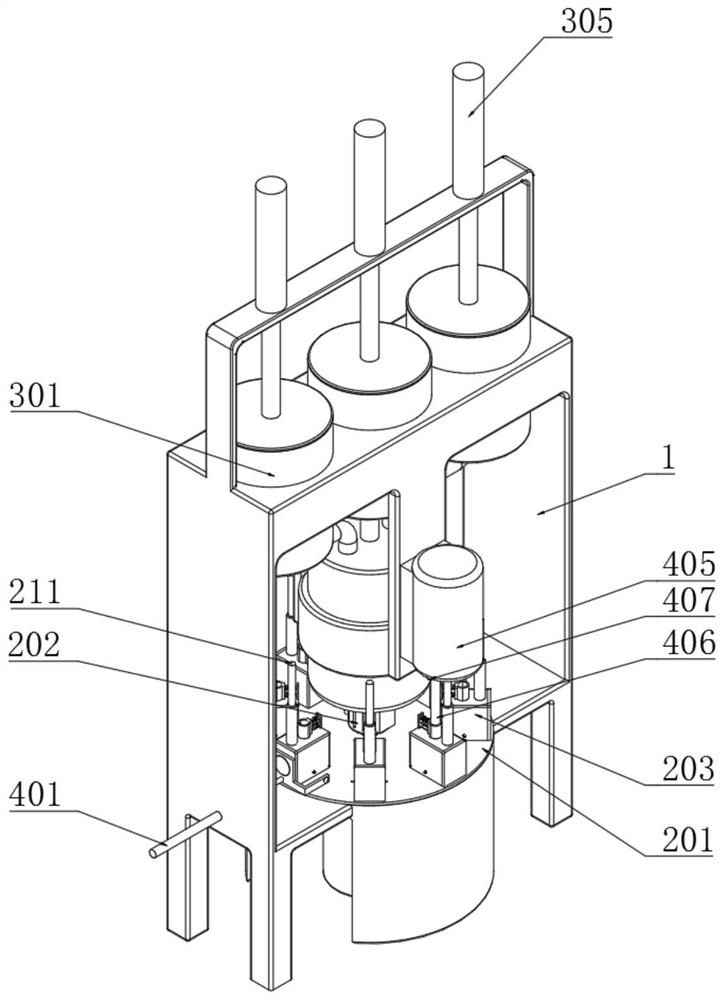

PendingCN113441680AScientific and reasonable structureEasy to useRotary stirring mixersFoundry mouldsMetal impuritiesMolten metal

The invention discloses nickel-plated diamond micro-powder enhanced babbitt metal and a preparation process. The preparation process comprises the steps of S1, separating and melting; S2, metal mixing; S3, metal casting; S4, metal cooling; and S5, finished product taking. According to the nickel-plated diamond micro-powder enhanced babbitt metal and the preparation process, multiple kinds of metal are separated and molten, the situation that the final proportion is affected by metal impurities is avoided, and therefore the stability of the proportion is guaranteed; various molten metal is mixed through a mixing barrel, so that the mutual mixing uniformity of the molten metal is guaranteed, the situation of metal precipitation is avoided, and the product quality is guaranteed; vacuum extraction is carried out on a forming box, so that the situation of sand holes in products is avoided; castings are directly and rapidly cooled, so that the forming speed of the castings is increased; and a taking electric push rod drives a taking supporting frame to directly and rapidly take the products, so that rapid collection of the products is facilitated, the production speed of the products is increased through multi-step treatment, and the quality of the products is guaranteed.

Owner:NANJING TIN REFINING CO LTD

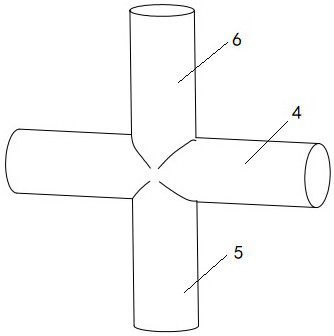

Circular tube cross-shaped welding auxiliary clamping method

InactiveCN111644746AReduce energy consumptionEasy Axial AlignmentMetal working apparatusLaser beam welding apparatusStructural engineeringSkelp

The invention discloses a circular tube cross-shaped welding auxiliary clamping method. The circular tube cross-shaped welding auxiliary clamping method includes the steps that a guide rod is axiallysleeved with a first short tube in a penetrating manner, transversely penetrates through a long tube from a welding position and is axially sleeved with a second short tube in a penetrating manner insequence, so that the first short tube, the long tube and the second short tube form a cross-shaped structure; cap pillars are arranged at the two ends of the guide rod, and the relative positions ofthe cap pillars and the guide rod are fixed so that the first short tube and the second short tube are stressed axially; and the cross-shaped structure is clamped by a clamping device and then welded.According to the circular tube cross-shaped welding auxiliary clamping method, the deformation of the short tube welding position is avoided on the premise that the clamping efficiency is not affected, and the welding qualification rate of a product is greatly improved.

Owner:江苏统联科技股份有限公司

Pleurotus eryngii culture material prepared from rice bran as raw material

InactiveCN104193444AGuaranteed production speed and colorHigh nutritional valueFertilizer mixturesProtein proteinPleurotus eryngii

The invention discloses a pleurotus eryngii culture material prepared from rice bran as a raw material. The mixed culture material in a dry state comprises the following raw materials in percentage by weight: 10%-20% of miscellaneous wood chips, 35%-40% of rice bran meal, 12%-27% of bagasse, 16%-30% of wheat bran, 3%-8% of corn powder and 1%-5% of calcium carbonate; the pre-wetted mixed culture material has the water content of 65%+ / -1 and the pH value of 4-5; the rice bran meal is prepared by leaching out grease and removing a solvent from wet meal. According to the pleurotus eryngii culture material prepared from rice bran as the raw material, the production speed and color of pleurotus eryngii can be ensured, and the nutritional value of the pleurotus eryngii can be improved; meanwhile, the preparation process of the rice bran meal is simple and relatively low in energy consumption, a method for preparing low-denaturation rice bran meal by adopting a leaching process can be carried out at the normal temperature, and the obtained rice bran meal is low in denaturation rate and residual oil rate and high in protein content and nitrogen soluble index.

Owner:SHUYANG SU HE AGRI PROD SALES PROFESSIONAL COOP ASSOC

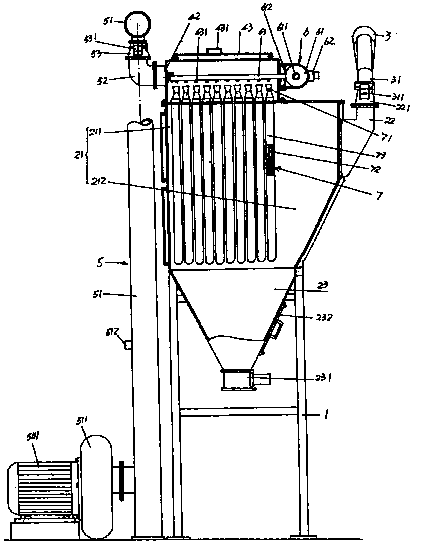

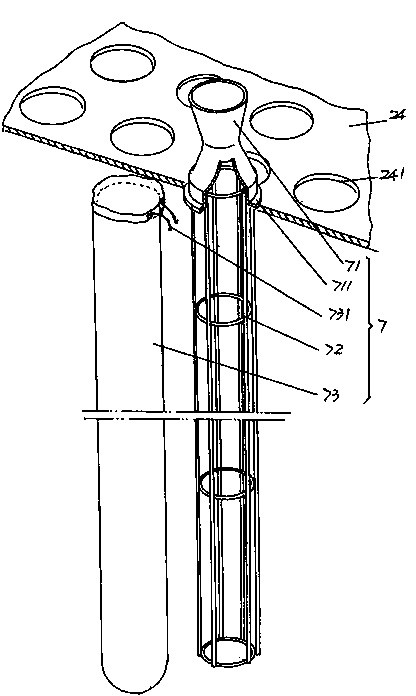

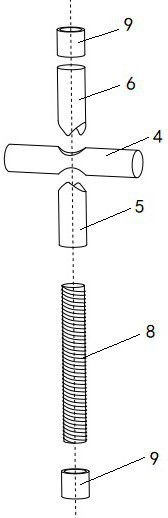

Environment-friendly and energy-saving zinc oxide graded collecting device

ActiveCN104226595AGuaranteed production speedImprove grading effectGas current separationEngineeringControl valves

The invention discloses an environment-friendly and energy-saving zinc oxide graded collecting device and belongs to the field of a facility for producing a metal oxide by a dry method. The device comprises a rack, a collecting box, a material feeding pipe, air-returning boxes, an air pumping mechanism, a compressed air introducing mechanism and a zinc material separating mechanism, wherein collecting box separating cavities are formed in the collecting box; each collecting box separating cavity consists of a reclaiming cabin and a collecting cabin; a collecting hopper is arranged on the outer wall of the collecting box; a material discharging hopper is arranged at the bottom of the collecting box; a material feeding pipe material outlet is formed in the material feeding pipe; a material feeding pipe material outlet control valve is arranged on the material feeding pipe material outlet; the air-returning boxes correspond to the reclaiming cabins; a zinc material separating mechanism mounting hole is formed in the top plate of the collecting box; the air pumping mechanism is connected with the rear sides of the air-returning boxes; the compressed air introducing mechanism is arranged on the front sides of the air-returning boxes and comprises a compressed air bag, a pulse electromagnetic valve and a pulse air-outtake pipe; the zinc material separating mechanism comprises a Venturi tube, a mouse cage type framework and a sleeving bag. Different using requirements are met; the collecting efficiency is improved, and the production speed of zinc oxide is guaranteed; the grading effect of a zinc oxide product is good; the quality of exhausted air is guaranteed, and a zinc oxide resource is saved.

Owner:河北长力环保科技有限公司

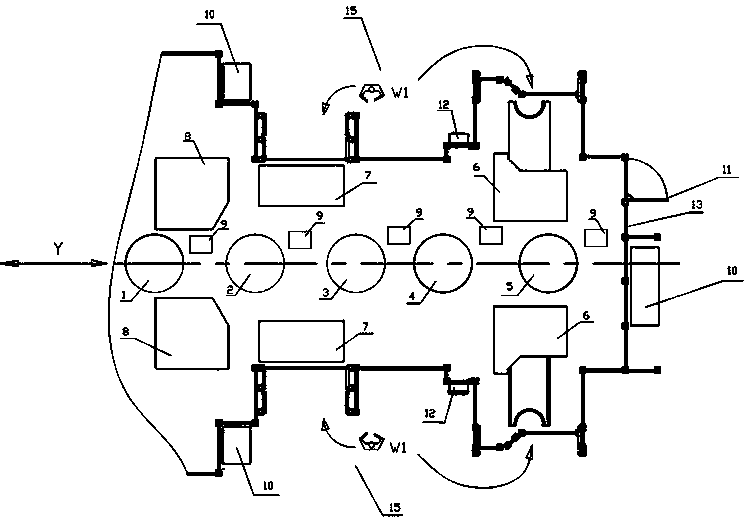

C column welding production line and C column welding processing method

ActiveCN108284289AIncrease profitLow costWelding/cutting auxillary devicesAuxillary welding devicesProduction lineControl system

The invention discloses a C column welding production line and a C column welding processing method. The C column welding production line comprises an operation area, a control system and a maneuvering area formed by surrounding a protective fence. The operation area is located on the outer side of the maneuvering area; the maneuvering area comprises a transportation system, and an inner plate assembly welding working area, a C column welding working area and a rear side wall assembly welding working area arranged sequentially; the inner plate assembly welding working area comprises a robot Aand an inner plate assembly welding working table; the C column welding working area comprises a robot C and a C column welding working table; the rear side wall assembly welding working area comprises a robot D, a robot E and a rear side wall assembly welding working table; the robot B is arranged between the robot A and the robot C; the transportation system is erected above the inner plate assembly welding working area and the rear side wall assembly welding working area; and the control system controls and monitors actions and states of various devices in the maneuvering area. The C columnwelding production line is high in device utilization rate, high in welding speed and high in productivity of the production line.

Owner:成都锐升科技有限责任公司

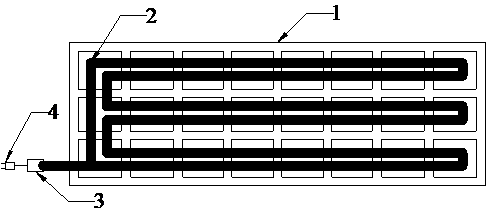

Maintenance technology of carbon fiber tube for combination mold core

InactiveCN105984027AQuality assuranceGuaranteed production speedCeramic shaping apparatusFiberMaterials science

The invention provides a maintenance technology of a carbon fiber tube for a combination mold core. The technology is to mount the carbon fiber tube in a frame of a combination mold; the carbon fiber tube is bent like a snake in the frame of the combination mold; finally, two ends of the carbon fiber tube are connected; the carbon fiber tube is connected to a controller; and the controller is connected with a plug out of the frame. When a prefabricated wall board needs to be maintained, the plug is connected into a power supply; the controller is arranged to adjust a maintenance temperature for maintenance; or the maintenance temperature and time are set in a staged manner for staged maintenance.

Owner:RENQIU YONGJI CONSTR & INSTALLATION ENG

Self-compacted concrete pouring technique for assembling mold

InactiveCN105984016AQuality assuranceGuaranteed production speedFeeding arrangmentsWall platePeristaltic pump

The invention provides a combined mold self-compacting concrete pouring technology. The technology uses a walkable self-compacting concrete hopper arranged on one side of the combined mold to perform self-compacting concrete pouring on the combined mold. A walking gear is arranged under the hopper, and the hopper pipeline is connected with a Peristaltic pump, connected from the peristaltic pump, there are three sections of adjustable pipelines, which are respectively connected under the three parts of the combined mold, and are equipped with a stop valve; the self-compacting concrete is transported into the hopper by the automatic distribution machine, and the automatic distribution machine can automatically walk in the Aerial track to coordinate the production of prefabricated wall panels. The invention can make the self-compacting concrete be poured smoothly in the preparation process of the prefabricated wallboard without generating air bubbles, and avoids the vibration process, thereby ensuring the quality and speed of the prefabricated wallboard.

Owner:RENQIU YONGJI CONSTR & INSTALLATION ENG

Municipal sign propaganda frame welding device

PendingCN114378496AAvoid offsetPrevent splashWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWelding process

The invention discloses a welding device for a municipal sign propaganda frame. The welding device comprises a conveyor, a first supporting frame, a conveying belt, a first carrier roller, a second carrier roller, a storage frame and the like. The device is provided with a conveyor, a first supporting frame is arranged on the right side of the conveyor, a first carrier roller and a second carrier roller are rotationally connected to the left side and the right side of the top of the first supporting frame correspondingly, a conveying belt is wound around the first carrier roller and the second carrier roller jointly, and two storage frames are symmetrically arranged on the right half portion of the first supporting frame in the front-back direction; a second supporting frame is arranged above the conveyor and the first supporting frame. According to the automatic welding device, the propaganda frame and the propaganda frame supporting legs can be automatically welded together, manpower consumption is reduced, and the welding efficiency is improved; the feeding mechanism can clamp the supporting legs of the propaganda frame and automatically feed the supporting legs to the welding position, and the supporting legs of the propaganda frame can be prevented from deviating in the welding process.

Owner:周绍岭

High-temperature retting device for culture medium and use method of high-temperature retting device

ActiveCN114467685AGuaranteed high temperature retting timeHigh temperature retting time is the sameBio-organic fraction processingTransportation and packagingMechanical engineeringCulture mediums

Owner:江苏兴农基质科技有限公司

A device and method for synchronously measuring guide rail line displacement and straightness in situ

ActiveCN111735393BAbbe's error is smallReduce nonlinear errorUsing optical meansGratingMechanical engineering

The invention discloses a device and a method for synchronously measuring the line displacement and straightness of a guide rail in situ. The integrated two-dimensional grating guide rail is to etch the two-dimensional grating on the upper surface of the linear guide rail, and the reading head is embedded in the slide block. The specific measurement method is as follows: when the slider moves on the guide rail, the reading head outputs two pairs of orthogonal sinusine and cosine signals at the same time, and after filtering and analog-to-digital conversion, it is transmitted to the host computer through the acquisition card, and the edge is counted by high-frequency pulses. Methods Calculate the displacement and straightness on the host computer; the linear displacement of the guide rail is obtained by the orthogonal signal generated by the grid line perpendicular to the x-axis, and the straightness of the guide rail is obtained by the orthogonal signal generated by the grid line perpendicular to the y-axis. The invention has the advantages of small installation volume of the guide rail pair, high positioning accuracy, multi-parameter synchronous on-site measurement, etc., and provides a new method for the displacement and straightness measurement of the guide rail.

Owner:XI AN JIAOTONG UNIV

A method and device for controlling filling accuracy

ActiveCN109592095BAvoid interferenceGuaranteed production speedLiquid materialControl engineeringMechanical engineering

The invention provides a method and equipment for controlling filling accuracy. By using a controlling method including a system initiation stage, a rough filling stage, a refined filling stage and aclosing stage, the filling accuracy is controlled; in the refined filling stage, low-speed filling is carried out by using a filling pump; after second predetermined time T16, the weight of liquid isdetected in real time until the weight reaches a second predetermined value G2 and then the detection is stopped; and the size of the second predetermined value G2 is determined according to a difference value between target weight G1 of a container and the weight of a less amount of surplus liquid which does not flow into the container during closing of the filling pump. According to the method and equipment for controlling the filling accuracy disclosed by the invention, rough filling and refined filling are separately carried out and sectional control is carried out, the rough filling is used for ensuring the production speed and the refined filling is used for ensuring the filling accuracy; the pump-rear pipe storage amount is taken into consideration between a refined filling value and a predetermined value; and through calibrating the matching of the refined filling value and the pump-rear pipe storage amount in real time, the situation that the final filling amount is almost consistent with the predetermined value is ensured.

Owner:TRUKING TECH LTD

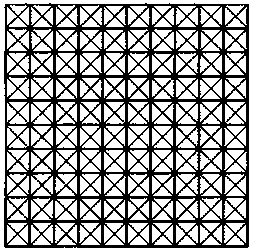

EVA (Ethylene-Vinyl Acetate) film

PendingCN107779112AIncrease productivityGuaranteed production speedFilm/foil adhesives without carriersPhotovoltaic energy generationAgricultural engineeringVinyl acetate

The invention provides an EVA (Ethylene-Vinyl Acetate) film. Mixed patterns are independently pressed on the upper surface and the lower surface; and the mixed patterns comprise geometrical patterns and frosted patterns. The EVA film provided by the invention has low shrinkage ratio, and the production speed of the production line can be effectively ensured, so that the production efficiency of the EVA film is greatly improved.

Owner:浙江利昌科技有限公司

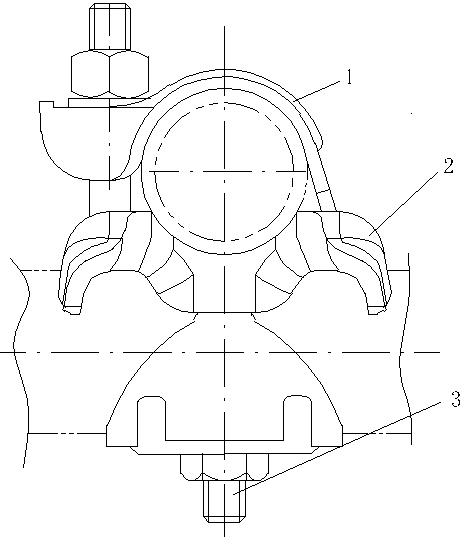

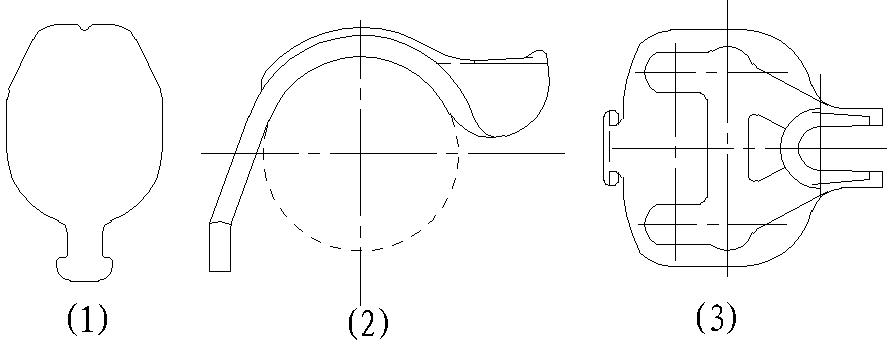

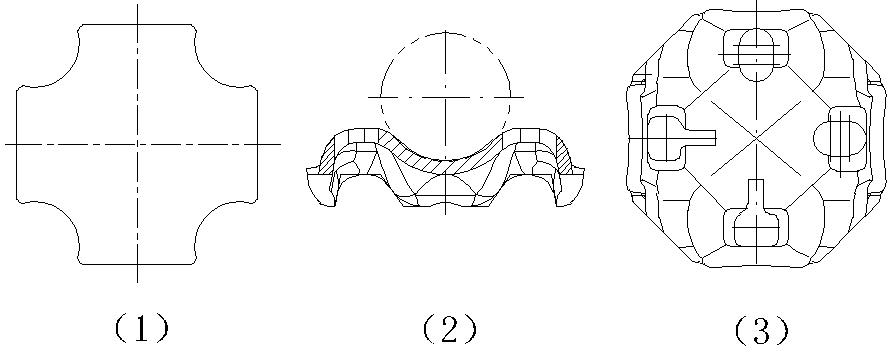

Steel plate hydraulic-forming production method and process of construction fastener

The invention provides a steel plate hydraulic-forming production method and process of a construction fastener. In the method, a common hot-rolled steel plate Q235 with the thickness of 5mm or more than 5mm is exclusively utilized as a production raw material of the fastener, and a special hydrostatic press with the pressure of not less than 200T is adopted for forming the innovatively designed fastener in a special hard die, which realizes continuous mechanized production operation of the fastener and innovation of the production method and process of the construction fastener. The fastener produced by the method and process provided by the invention has the advantages of good skid resistance, good breaking resistance, good tension resistance and good deformation resistance, and reaches and exceeds the national and international fastener quality standards; and meanwhile the production method and process can replace those of the cast-iron fastener which has the defects such as high energy consumption, high pollution, high carbon emission, low quality, low safety and low efficiency.

Owner:董国荣

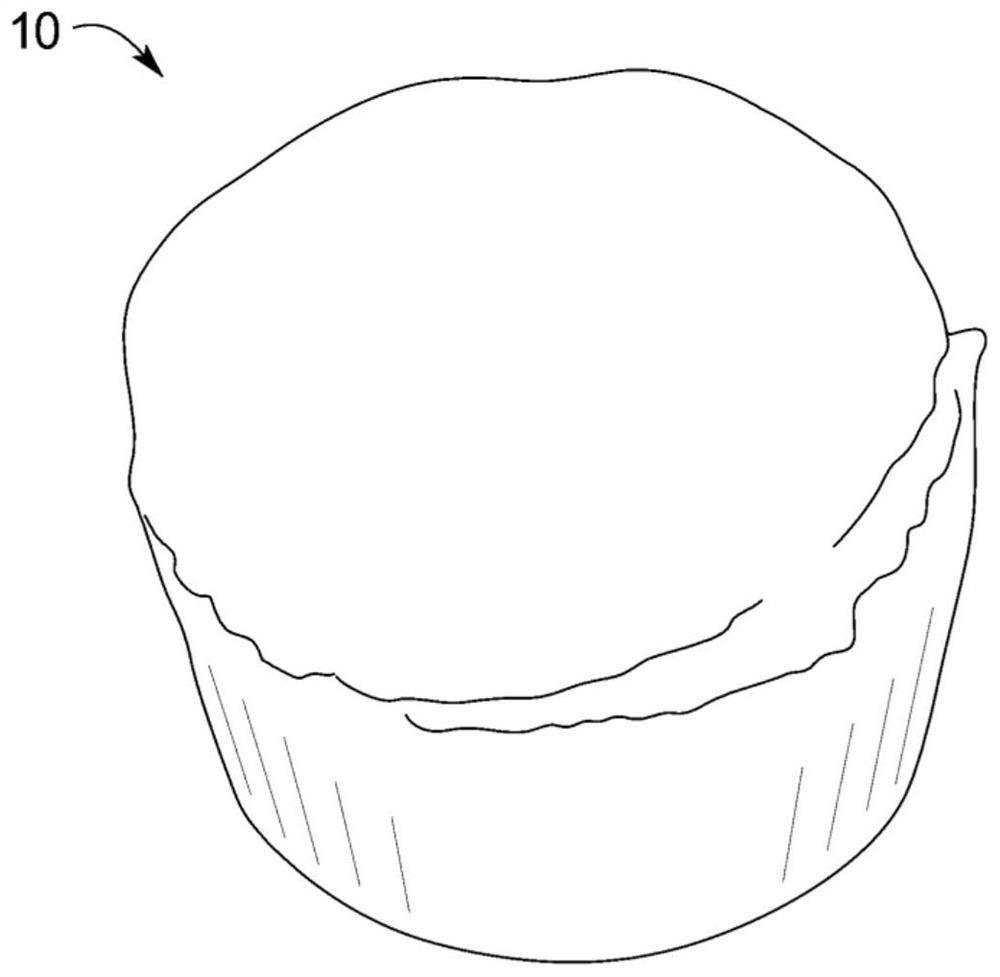

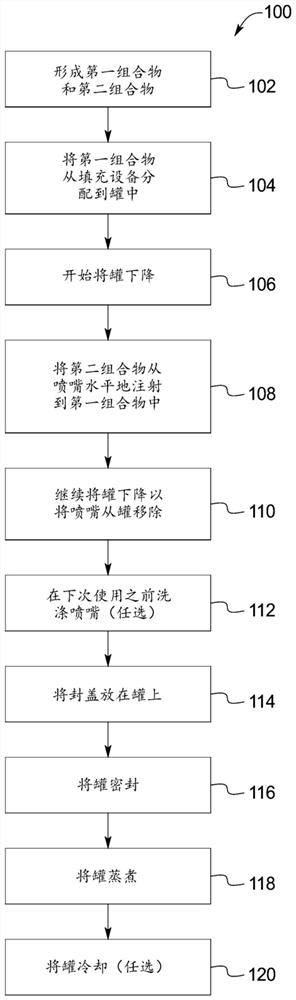

Apparatus and method for encapsulating fillers in food products

ActiveCN106659191BGuaranteed production speedAnimal feeding stuffWorking-up animal fodderPolymer sciencePneumatic valve

Owner:SOC DES PROD NESTLE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com