Automatic arranging and feeding device for firework cylinders

An automatic arrangement and automatic feeding technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of slow feeding speed, rising cost, laborious and laborious, etc., to ensure production speed and output, The effect of improving production efficiency and shortening the ascent distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Such as Figure 10 As shown, the rubber cartridge 10 includes a barrel body 101 and nozzles 102 provided at both ends of the barrel body, and a circular waist groove 103 is provided in the middle of the barrel body.

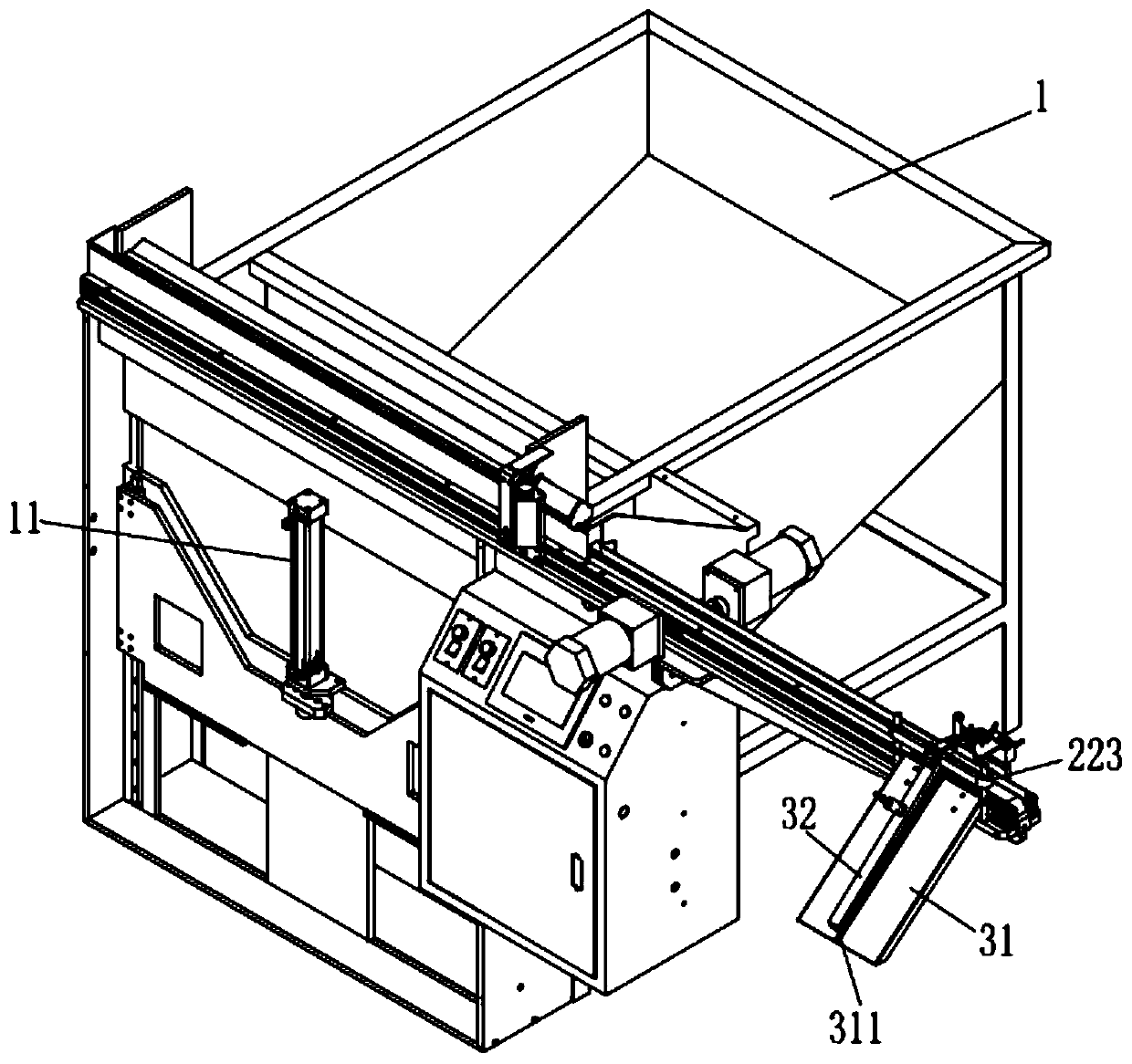

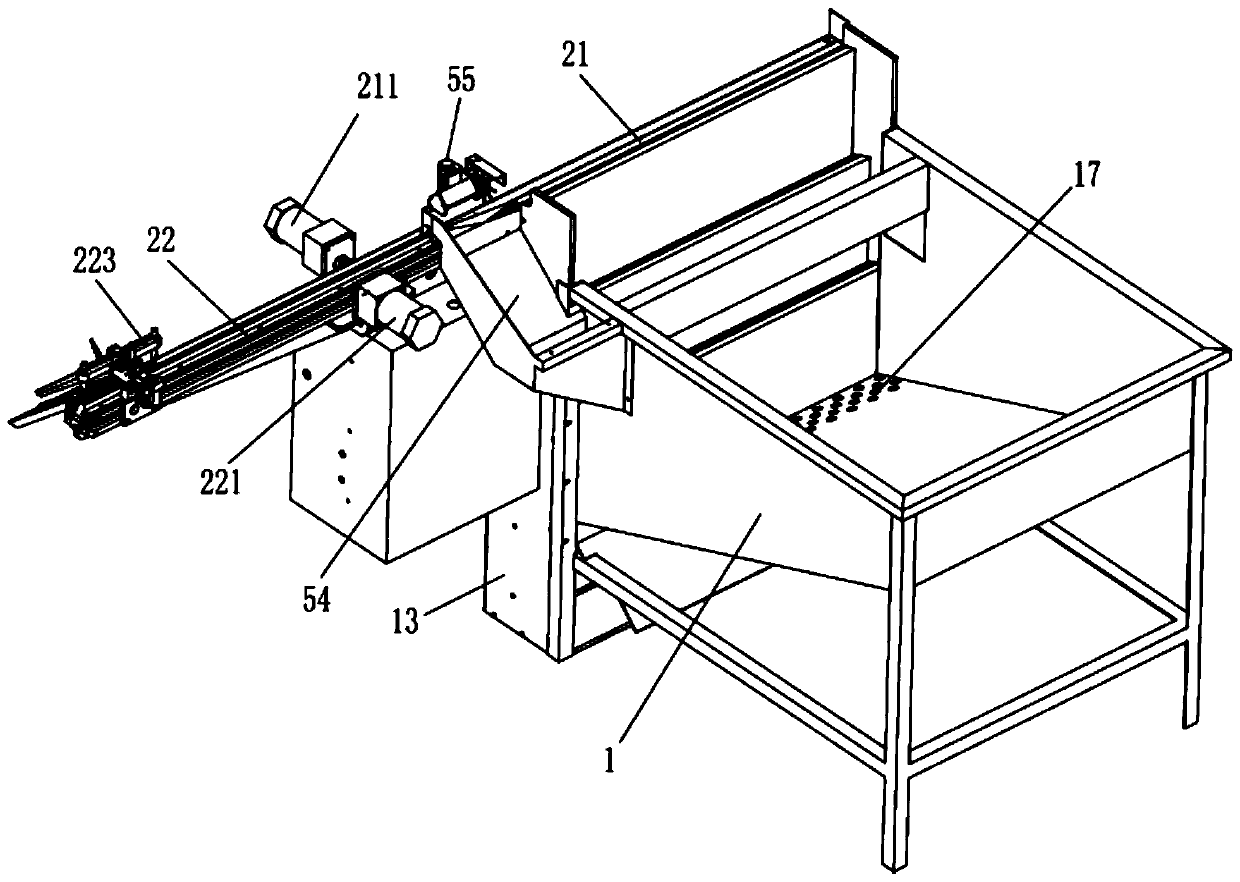

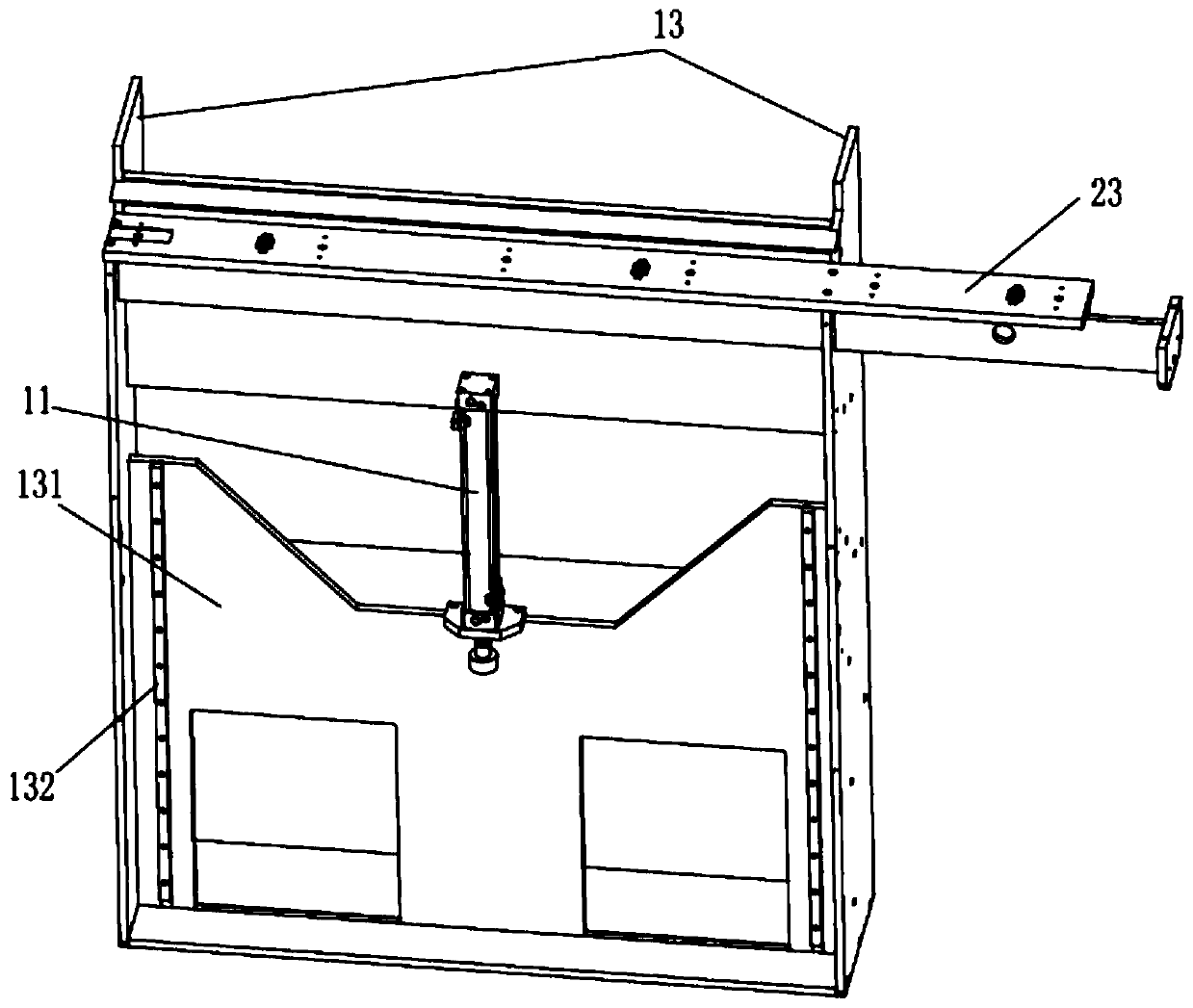

[0033] Such as Figure 2 to Figure 12As shown, the automatic arrangement and feeding device for fireworks tubes shown in this embodiment is used for automatic loading and arrangement and unloading of rubber tubes, and specifically includes an automatic feeding mechanism, a transmission mechanism and an arrangement and unloading mechanism. The automatic feeding mechanism includes The hopper 1 and the lifting part arranged at one end of the hopper 1, the lifting part includes a bracket connected to one end of the hopper 1, a first cylinder 11 vertically arranged on the bracket, and an upper cylinder connected vertically with the piston rod of the first cylinder 11. Material push pedal 12, the feeding push pedal 12 is positioned at an end of the hopper 1; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com