Patents

Literature

35results about How to "Guaranteed production output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

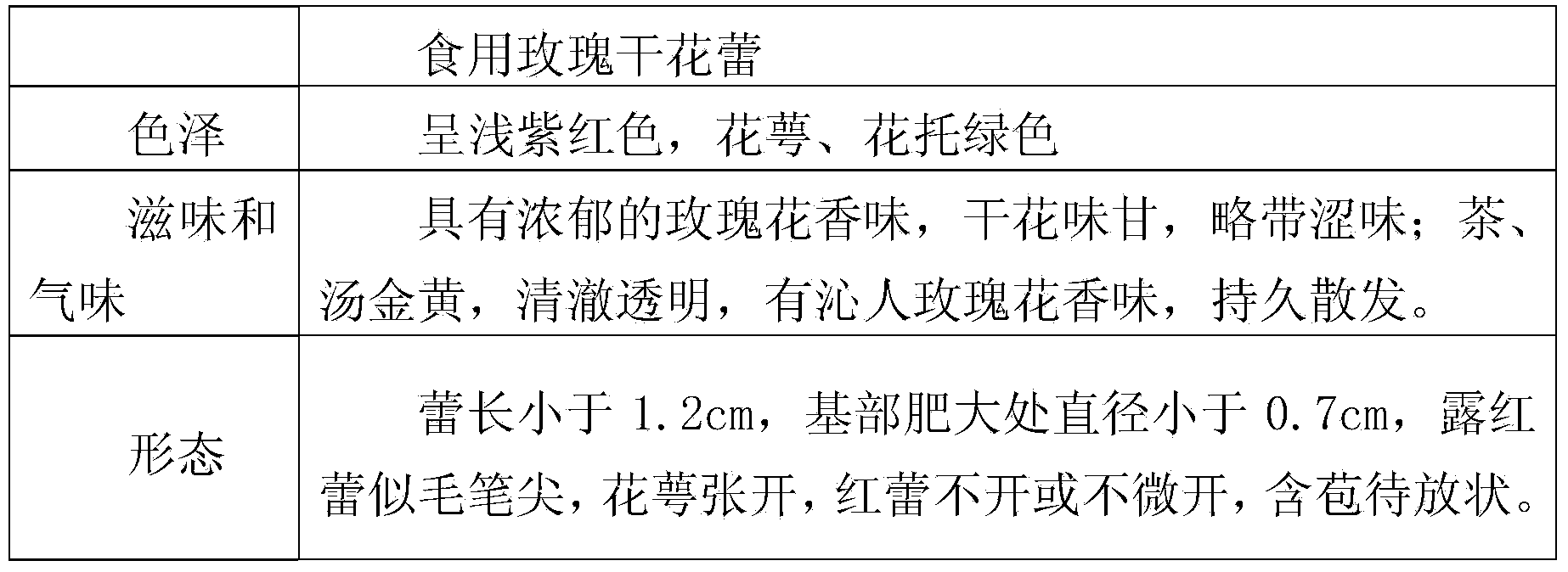

Comprehensive method for drying rosebuds through microwave vacuum and heated air circulation

ActiveCN103504448AEasy to useHumidity removalFood thermal treatmentFloral handlingEngineeringMicrowave

The invention discloses a method for drying rosebuds and belongs to the technical field of rosebud drying through microwave vacuum and heated air circulation. A comprehensive method for drying rosebuds through microwave vacuum and heated air circulation comprises the following steps: (1) feeding the rosebuds to a heated air circulation dryer for drying; (2) feeding the rosebuds obtained in the step (1) to a microwave vacuum drier for drying. According to the comprehensive method, the temperatures are low during the drying processes, the drying time is short, the product quality is high, meanwhile energy consumption is lowered, and the production efficiency is improved. Besides, microwaves can effectively sterilize the rosebuds and kill worms' eggs attached to the rosebuds, and are beneficial for prolonging product shelf lives.

Owner:银谷芳香科技有限公司

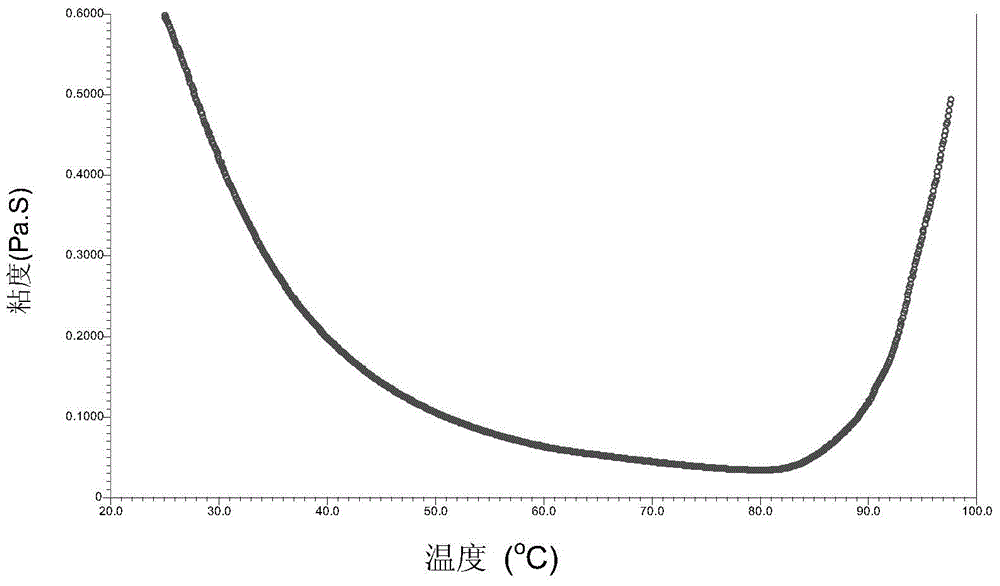

Underfill composition and packaging process using the same

ActiveCN104937027APrevent overflowImprove liquiditySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceFirming agent

Provided is a one part liquid underfill composition comprising an epoxy resin, a latent epoxy curing agent, a photocurable resin or monomer, a photoinitiator, an optional filler, and an optional thermal initiator. Also provided is a packaging process using the underfill composition.

Owner:HENKEL KGAA

Planting method for honeysuckle used as traditional Chinese medicine

InactiveCN104604460AIncrease productionGuaranteed production outputPlant cultivationCultivating equipmentsLand preparationChinese drug

The invention relates to a planting method for honeysuckle used as traditional Chinese medicine. The method comprises the following steps: (1) seed propagation; (2) land selection and preparation; (3) land preparation and transplanting; (4) topdressing; (5) intertillage and weeding; (6) shaping; (7) pruning; (8) topping; and (9) subsequent pruning. The honeysuckle planting method provided by the invention strictly controls every production element and key link in the flowering phase from the source of seeds, so the yield of the honeysuckle is effectively improved.

Owner:TIANJIN PANYU MEDICAL HERB PLANTING SPECIALIZED COOP

Steel pipeline anticorrosive material and preparation method of steel pipeline anticorrosive material

ActiveCN102850857AHigh temperature indentation hardnessGuaranteed productionAnti-corrosive paintsSteel qualityPolypropylene

The invention discloses a steel pipeline anticorrosive material and a preparation method of the steel pipeline anticorrosive material. The steel pipeline anticorrosive material comprises the following ingredients in proportion by weight: 44 to 54 parts of polypropylene, 3 to 12 parts of high-density polyethylene powder, 0.3 to 2.4 parts of anti-aging agents, 0.06 to 1.2 parts of antioxidant, 0.06 to 1.2 parts of lubricating agents, 0.06 to 0.6 parts of degradation inhibitors and 0.06 to 0.6 parts of initiators, wherein all ingredients are uniformly mixed in a highly mixed pot and are then extruded out through a reactive double-screw-rod extruding machine with the length-diameter ratio being 52:1, the extruded ingredients are subjected to strip pulling, air cooling and grain cutting, the temperature is set to be 180 DEG C to 220 DEG C, and the rotation speed of screw rods is set to be 180 to 400 turns per minute. Compared with the anticorrosive material in the market, the steel pipeline anticorrosive material has the advantages that the processing applicability is wide, high Vicat, high hardness and good low-temperature toughness are realized, and long service life at high temperature and requirements on the anticorrosive material when passing through specific districts such as water, sand and stone soil and oceans are met.

Owner:四川仁智新材料科技有限责任公司

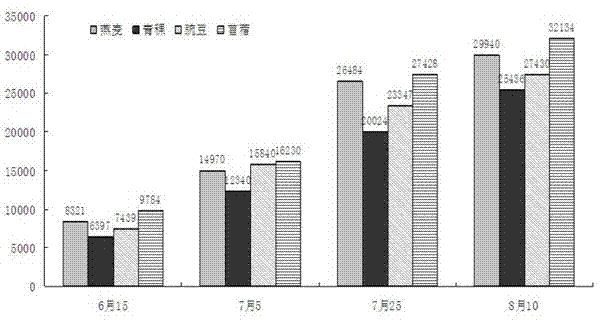

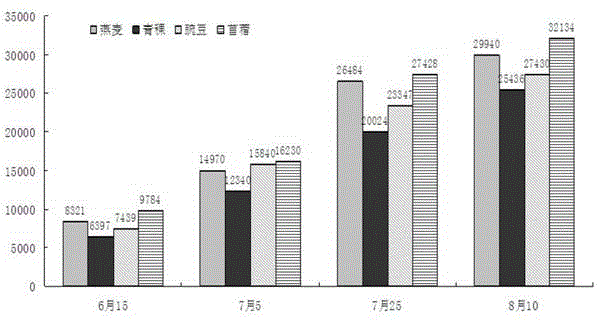

Qinghai-Tibet plateau high-cold pasturing area greenhouse grass planting technology

The invention discloses Qinghai-Tibet plateau high-cold pasturing area greenhouse pasture planting technology which comprises the following steps: (1) a greenhouse is prepared; (2) grass seeds and base fertilizers are respectively mixed standby; (3) ploughed fallowing is carried out; (4) preparation before broadcast sowing and planting is carried out; (5) a ditching method is prepared; (6) sowing is carried out; (7) soil is covered manually and smoothed, and manual suppression is carried out; (8) preparation before a rainy season comes is carried out; (9) treatment of 7-8 months at a high temperature is carried out; and (10) mowing and overwintering treatment are carried out. The Qinghai-Tibet plateau high-cold pasturing area greenhouse pasture planting technology integrates annual grass cultivation, perennial grass cultivation and cold season-warm season grass cultivation, is strong in flexibility and adaptability, simple, easy to operate, and low in cost, is the technology which is popularized and used by nations and local residents, provides a technological approach for forage grass production of extreme high altitude areas in China, and provides technological support for grass supply.

Owner:LANZHOU UNIVERSITY

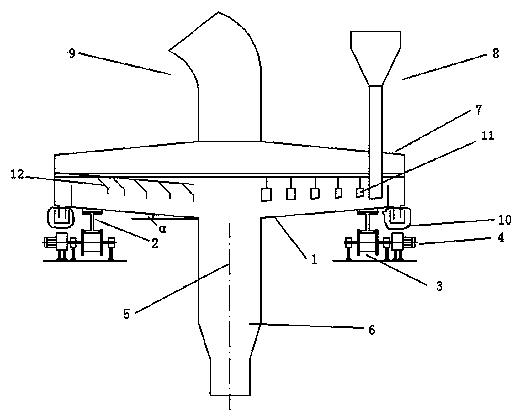

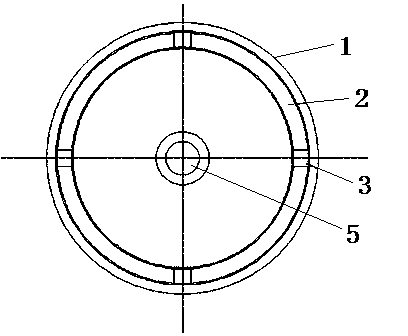

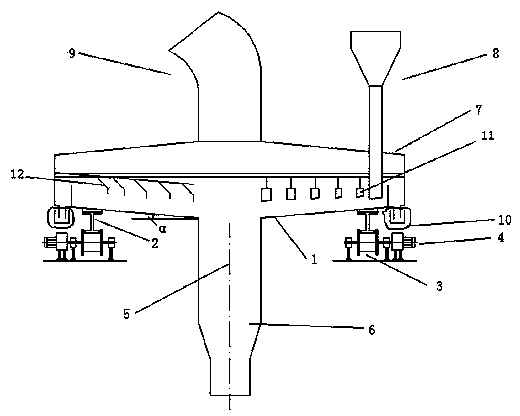

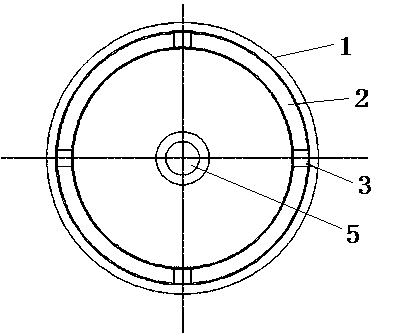

Rotary disc heating device for drying or pyrolyzing coal

InactiveCN103423984AOvercoming the inability to fully meshImprove stabilityIndirect heating destructive distillationHeating arrangementElectric machineEngineering

The invention discloses a rotary disc heating device for drying or pyrolyzing coal. The rotary disc heating device comprises a rotary disc, a feed port, a heating component, a plurality of rotating wheels, an annular track, a rotating shaft and a top cover, wherein the feed port is formed in the rotary disc; the heating component is used for heating a material in the rotary disc; the rotating wheels are connected with a motor; the motor is used for driving the rotating wheels to rotate; the annular track is arranged at the bottom of the rotary disc; the rotating wheels are fixedly arranged below the annular track along the annular track; the annular track is suitable for sliding along the rotating wheels and driving the rotary disc to rotate; the rotating shaft is arranged in the center of the rotary disc; the top cover is arranged above the rotary disc. The rotary disc heating device has the advantages of high stability, large loading capacity and strong environmental adaptability, and is more suitable for being applied to a drying or pyrolysis process of the coal.

Owner:北京予知环境工程有限公司

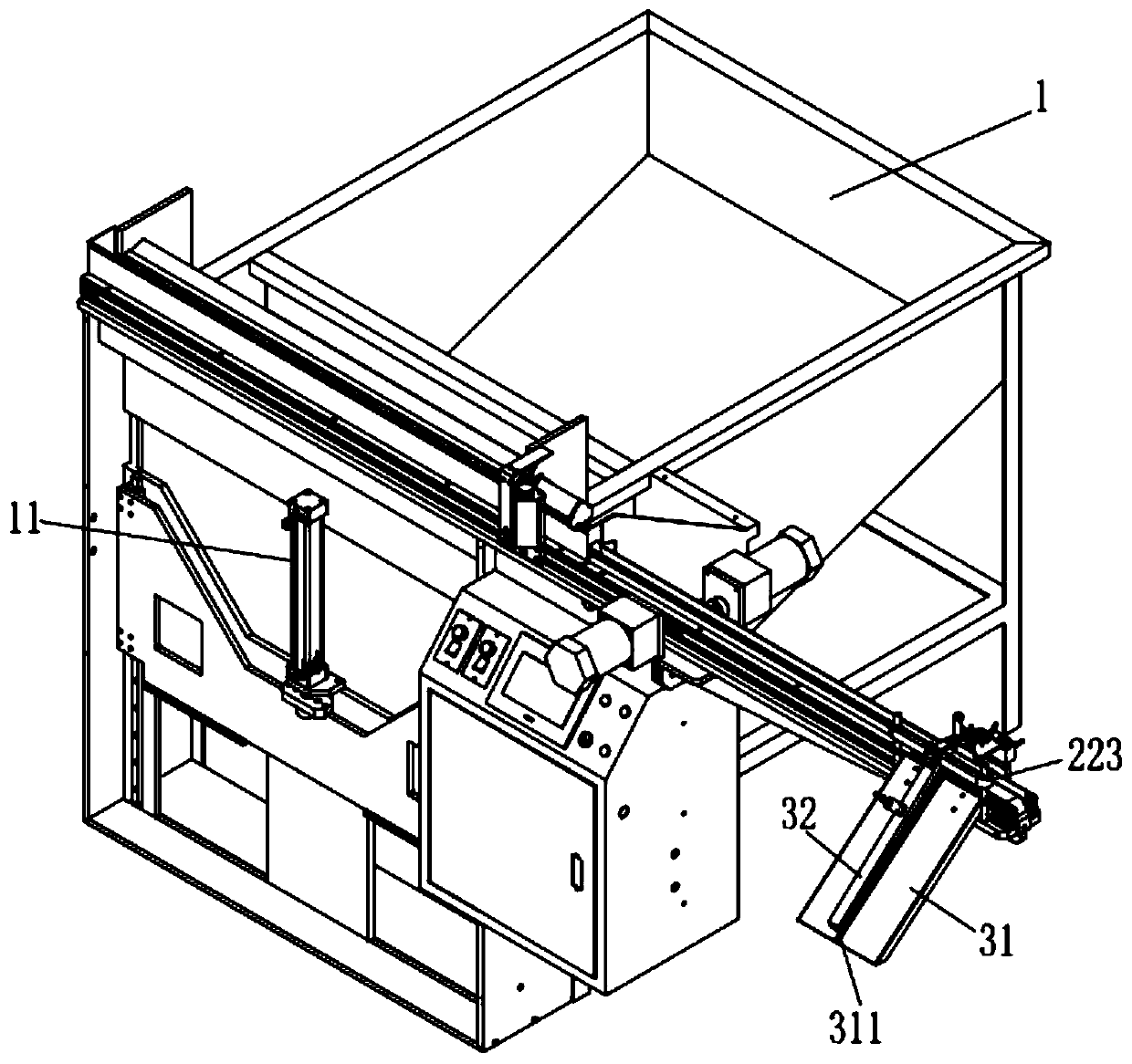

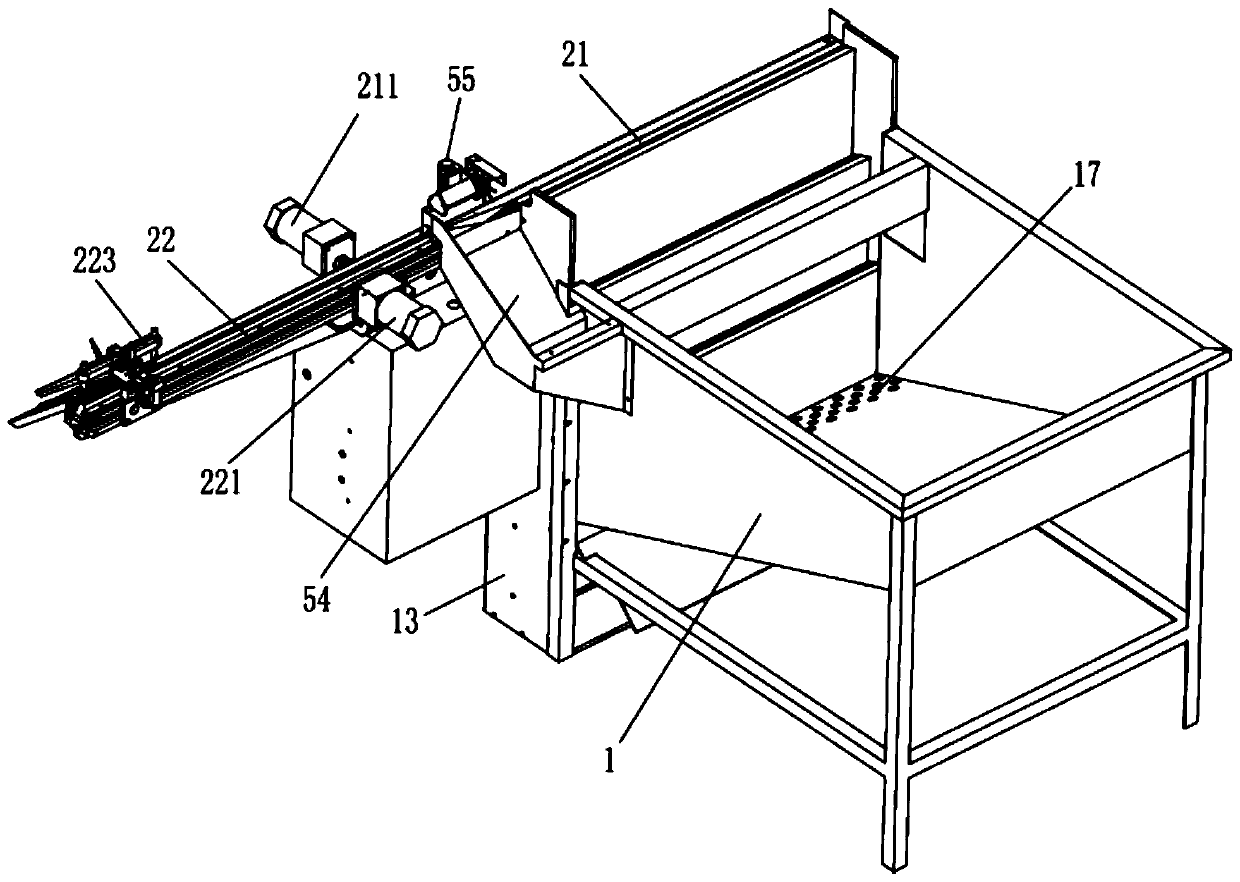

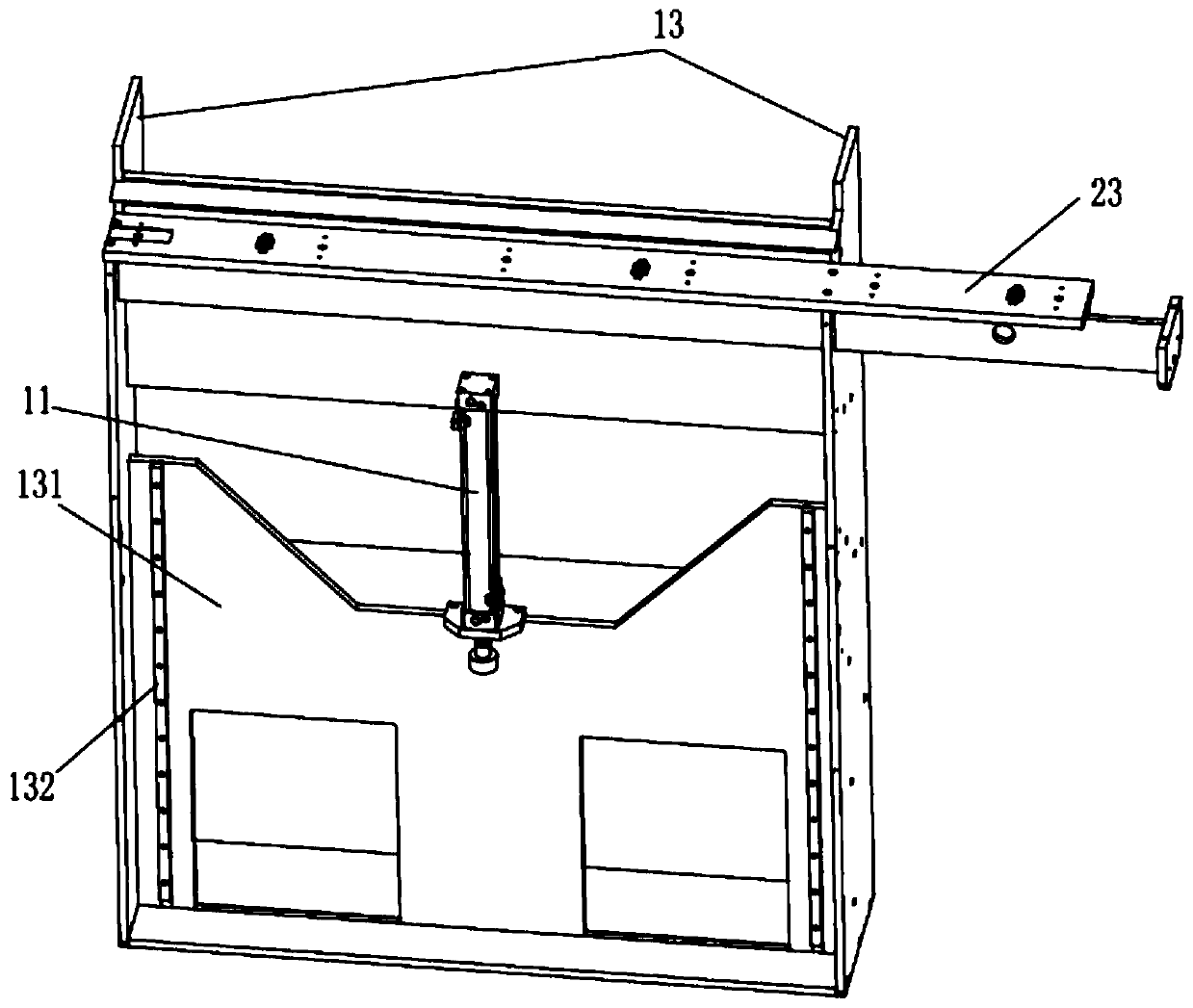

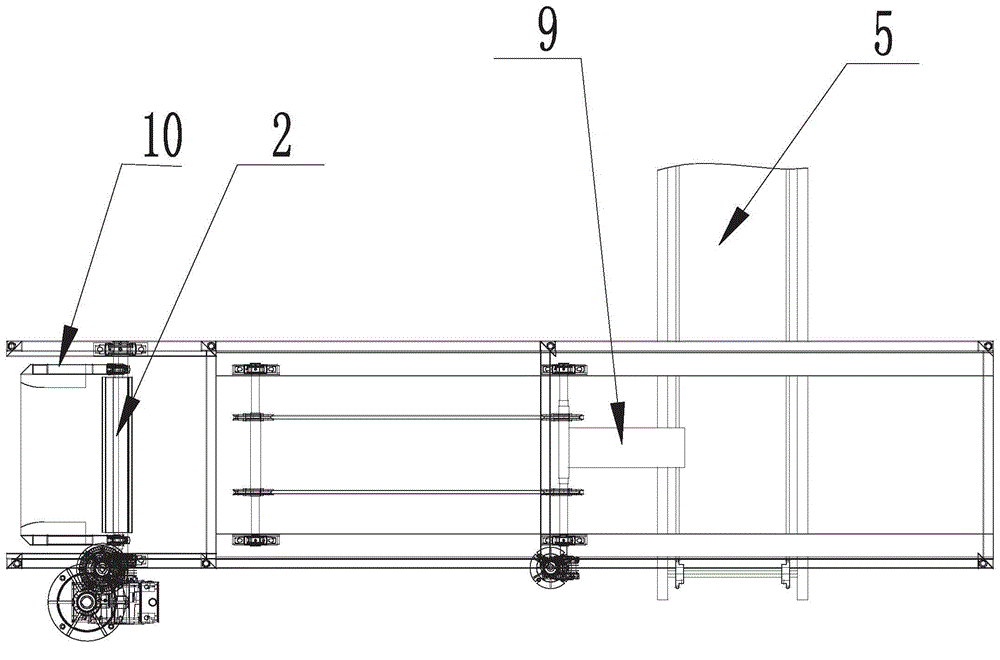

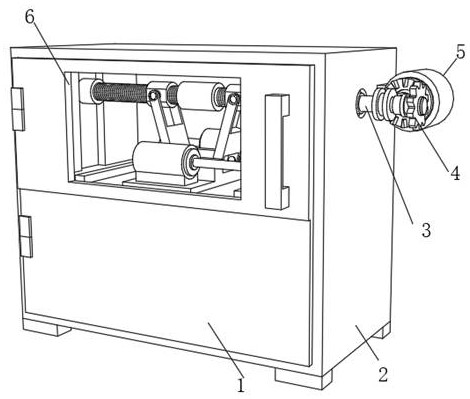

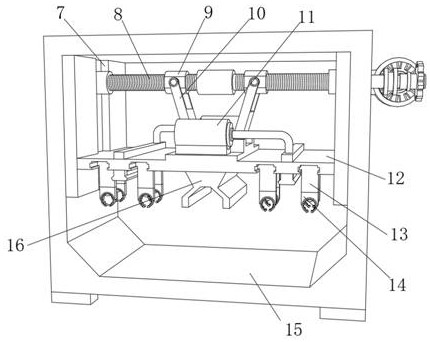

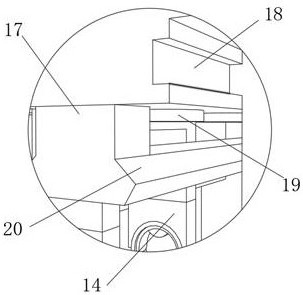

Automatic arranging and feeding device for firework cylinders

PendingCN109704017APrevent fallingShorten the ascent distanceConveyorsControl devices for conveyorsFireworksEngineering

Owner:广州胜美智能设备有限公司

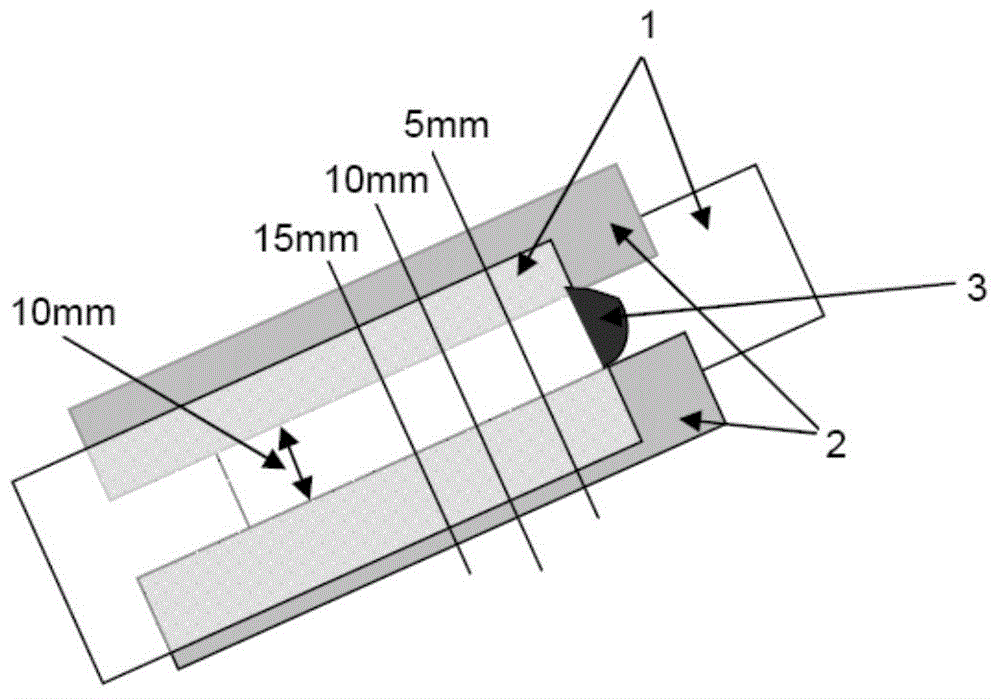

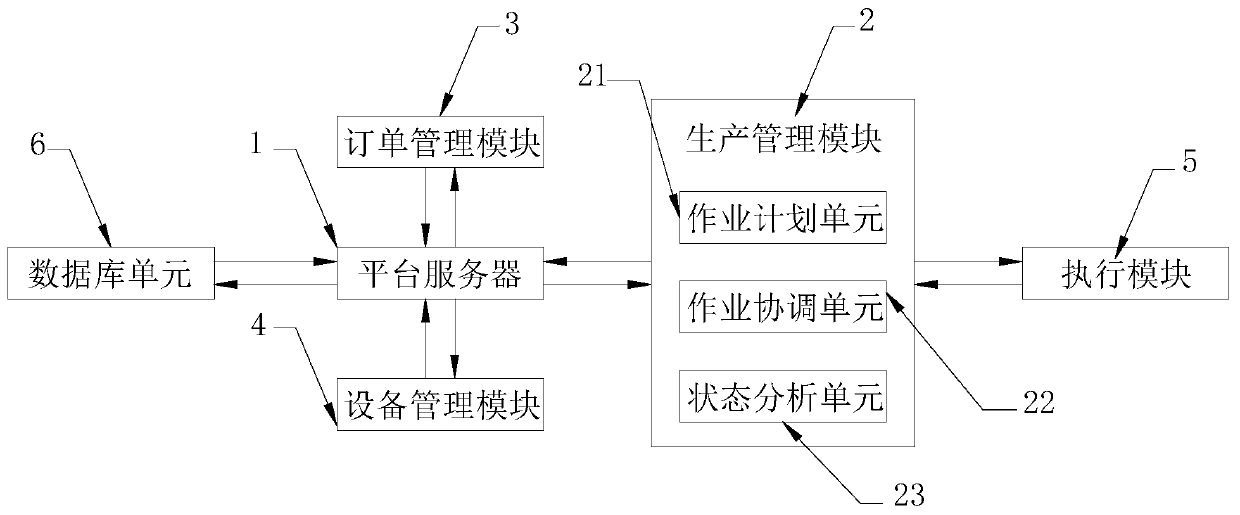

Intelligent production management platform for T-shaped profiles

InactiveCN111507563ARealize intelligent managementImprove processing efficiencyOffice automationBuying/selling/leasing transactionsIntelligent managementWorkload

The invention relates to the technical field of intelligent production, and particularly discloses an intelligent production management platform for T-shaped profiles which comprises a platform server, a production management module, an order management module, an equipment management module, an execution module and a database unit. The platform server is used for regulating, controlling and managing a production process; wherein the production management module is used for distributing, regulating and controlling the machining process of profile products, the order management module is used for arranging and distributing product orders, the equipment management module is used for collecting parameter states of machining and production equipment, the execution module is used for issuing aproduction instruction and controlling the equipment to work, and the database unit is used for storing platform information; intelligent management of T-shaped profile production and machining can beachieved, the profile machining efficiency is effectively improved, the time needed by production is shortened, the production cost is saved, and the workload of workers is reduced to a certain extent.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Turnplate heating device used for drying or pyrolyzing coal material

ActiveCN103615879AOvercoming the inability to fully meshImprove stabilityIndirect heating destructive distillationHeating arrangementMechanical engineeringCoal

The invention discloses a turnplate heating device used for drying or pyrolyzing a coal material. The turnplate heating device comprises a turnplate, a feeding port, a heating part used for heating a material in the turnplate, multiple runners connected with motors, an annular rail arranged at the bottom of the turnplate, a rotating shaft arranged at the center of the turnplate, and a top cover arranged above the turnplate, the feeding port and the heating part are arranged on the turnplate, the motors are used for driving the runners to rotate, the runners are fixedly arranged below the annular rail along the circumference of the annular rail, and the annular rail is suitable for sliding along the runners and driving the turnplate to rotate. The turnplate heating device has the advantages of high stability, large loading capacity and high environmental suitability and is more suitable for being applied to drying or pyrolyzing processes of the coal material.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

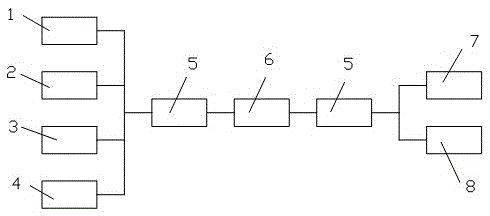

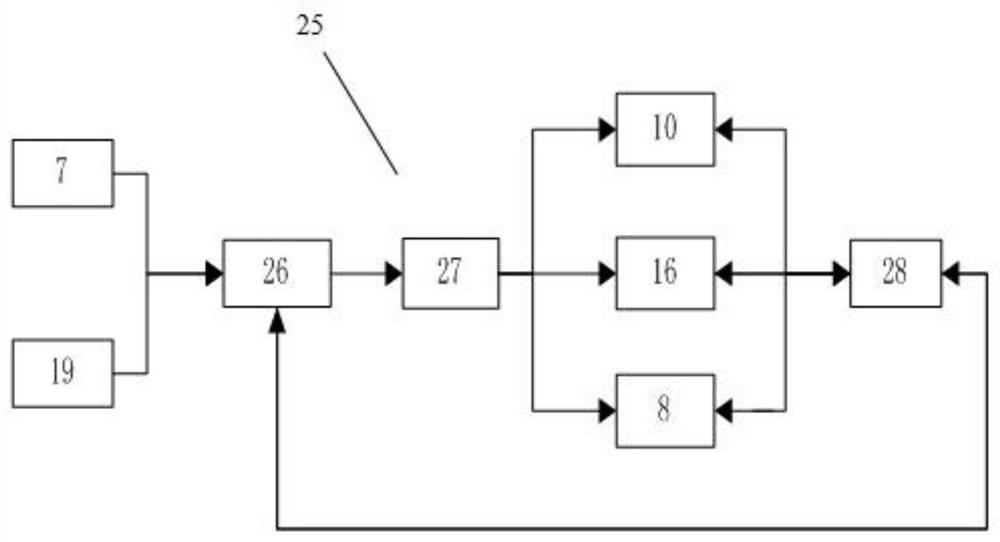

Agricultural internet of things control device

InactiveCN105118273AGuaranteed production outputImprove developmentTransmission systemsFertilizerAgricultural engineering

The invention discloses an agricultural internet of things control device which comprises a pH sensor, an optical sensor, a carbon dioxide sensor, a fertilizer distributor, an irrigation valve, a communication network and a data platform. The pH sensor is located in soil of an agricultural greenhouse, and the optical sensor and the carbon dioxide sensor are located in the agricultural greenhouse. The pH sensor, the optical sensor and the carbon dioxide sensor are connected with the data platform through the communication network. The fertilizer distributor and the irrigation valve are located in the agricultural greenhouse, and the data platform is connected with the fertilizer distributor and the irrigation valve through the communication network. Through data collection of the sensors, the concrete problems in agricultural production can be found timely, the specific location where the problems occur is timely located so as to facilitate timely treatment, so that the agricultural production yield is guaranteed, the production with information and software as the center can be achieved, the problems occurring in an existing agricultural internet of things are solved, and accordingly the agricultural development and application are promoted.

Owner:SUZHOU DALIKE AUTOMATION TECH

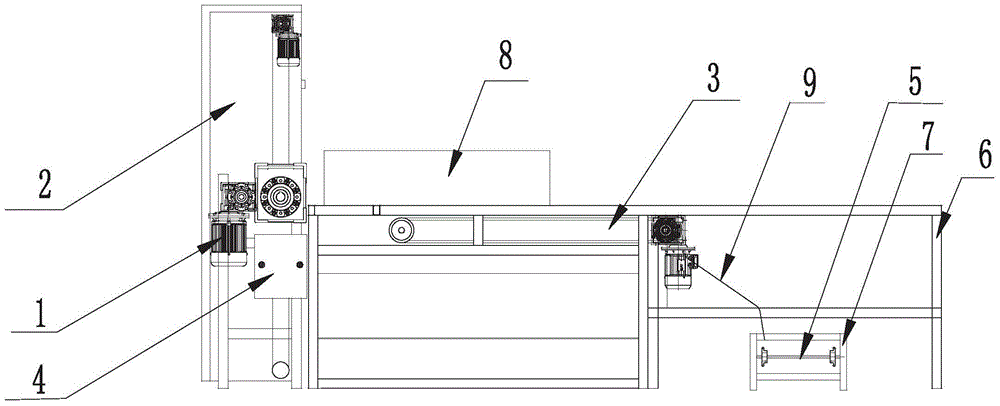

Assembly line capable of enabling fruits to be fed by automatically overturning basket and conveying vacant basket

InactiveCN106697871APrevent fallingAvoid damageBottle emptyingConveyor partsChain conveyorAssembly line

An assembly line capable of enabling fruits to be fed by automatically overturning a basket and conveying the vacant basket comprises a first rack and a second rack. A fruit feeding belt conveyor is arranged at one end of the first rack; a belt conveyor is mounted in the middle of the first rack; the second rack is arranged below the other end of the first rack; the second rack and the first rack are arranged vertically; and a chain conveyor is mounted on the second rack. A folding plate is arranged at the tail end of the belt conveyor, and the tail end of the belt conveyor is connected with the second rack through the folding plate. The assembly line capable of enabling fruits to be fed by automatically overturning the basket and conveying the vacant basket is matched with a fruit cleaning, waxing and sorting device, and the problems of automatic feeding fruits, overturning the basket and automatically conveying the vacant basket are solved. The manual work of workers is reduced, meanwhile, the labor productivity is greatly improved, the cost is saved, and fruit damage caused by manual fatigue operation can be avoided.

Owner:吴家波

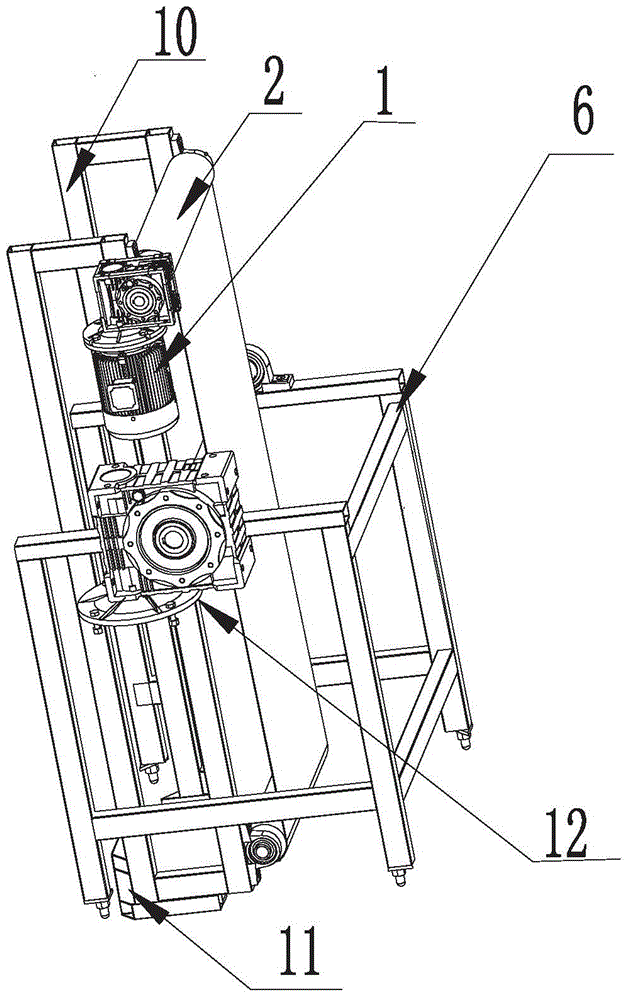

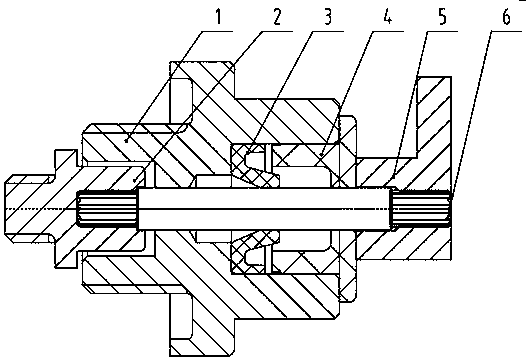

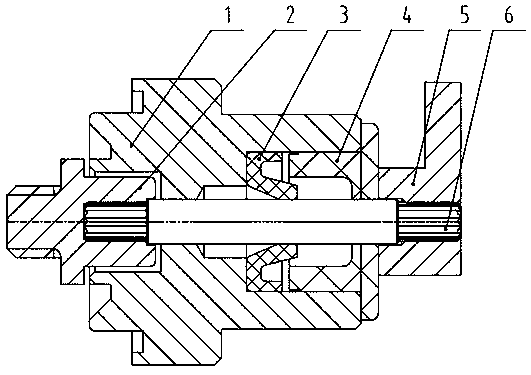

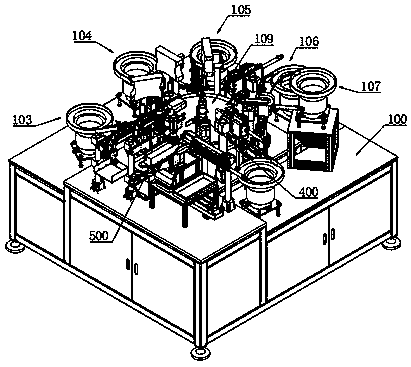

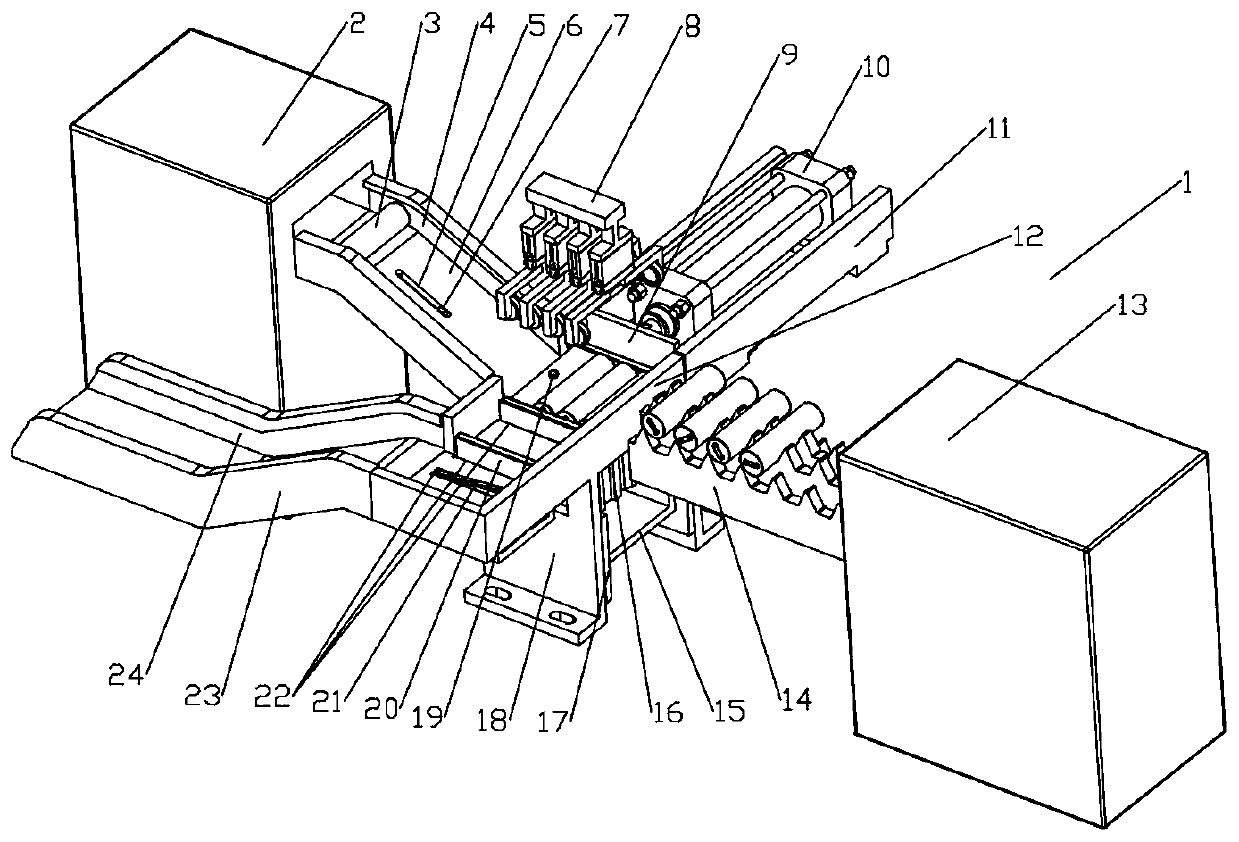

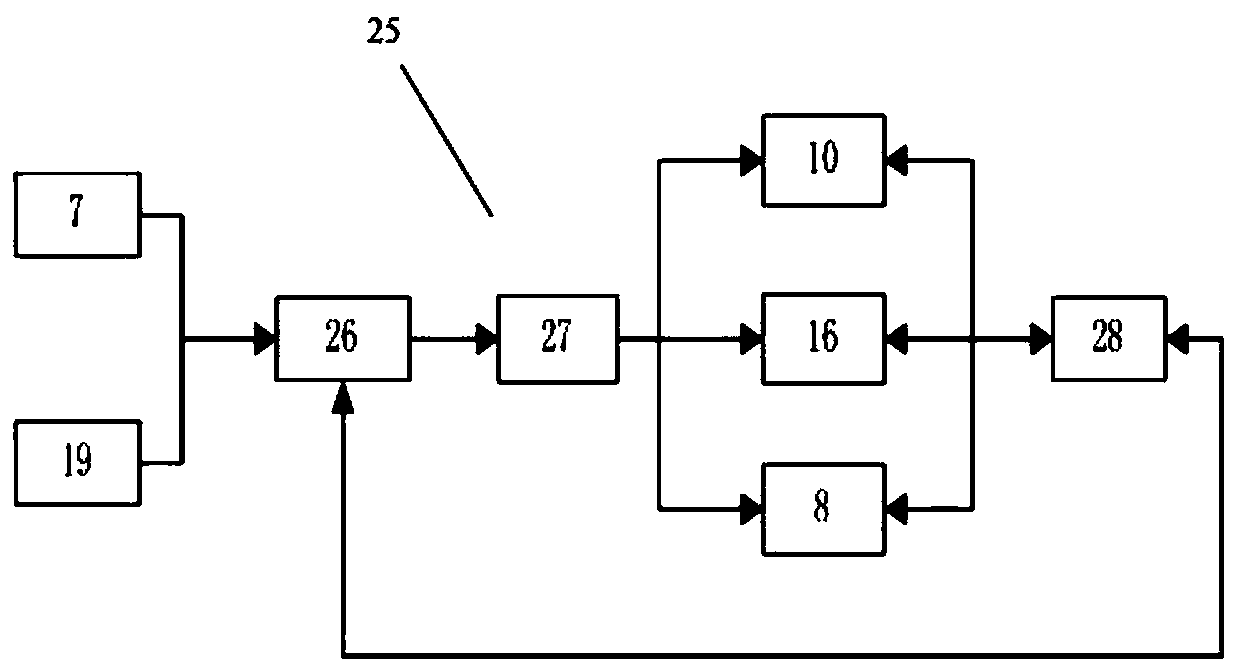

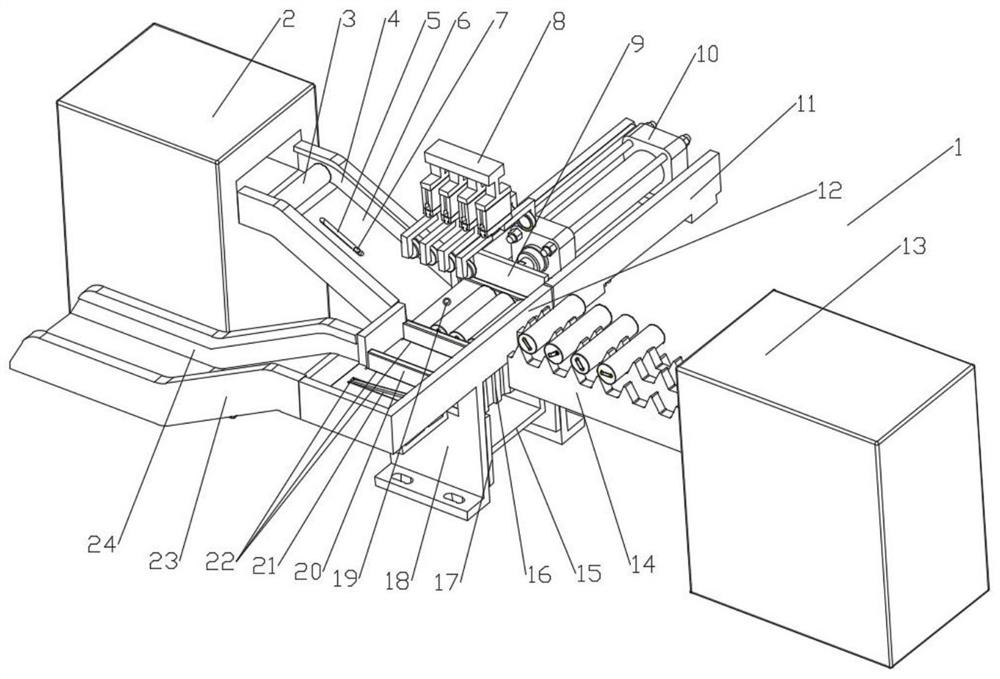

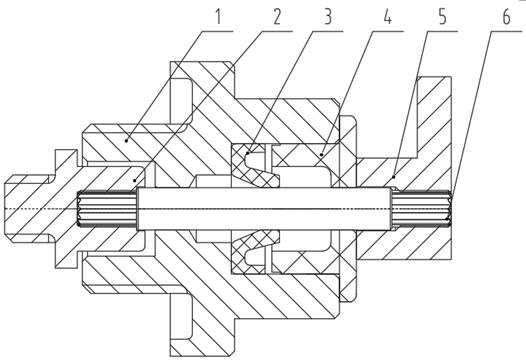

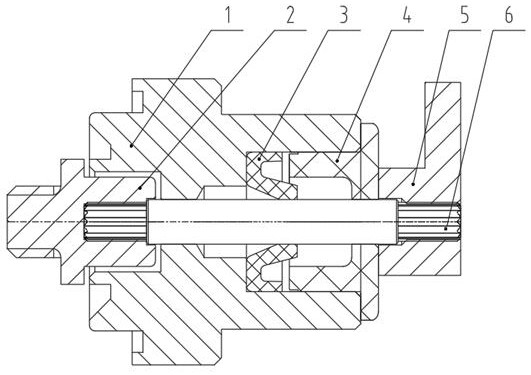

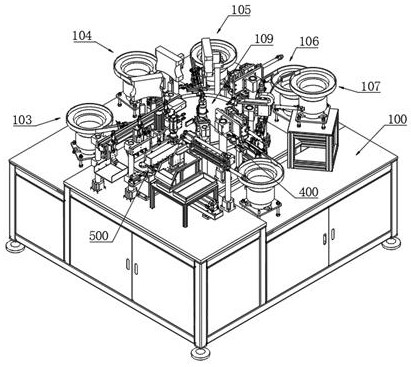

Direct transmission set assembling device

The invention discloses a direct transmission set assembling device. The direct transmission set assembling device is characterized by comprising an assembling table and an assembling rotary disc, wherein an assembling base is fixedly mounted on the upper surface of the assembling rotary disc. The direct transmission set assembling device further comprises six assembling mechanisms, wherein the six assembling mechanisms are a connecting piece assembling mechanism, a shaft sleeve assembling mechanism, a leather cup assembling mechanism, an end cover assembling mechanism, a transmission shaft assembling mechanism and a shifting rod assembling mechanism which are sequentially arranged in the rotating direction of the assembling rotary disc, and six charging point positions are formed; each assembling mechanism comprises a vibration disc, a material receiving positioning base and a transplanting mechanism; the vibration discs are used for conveying parts stored inside to the material receiving positioning bases one by one; and the transplanting mechanisms are used for conveying the parts in the material receiving positioning bases to the adjacent charging point positions and can load the parts into the assembling base. According to the direct transmission set assembling device, assembling of a direct transmission set can be automatically completed, non-stop continuous production isachieved, and the production efficiency and the yield can be better guaranteed.

Owner:深圳市睿荔科技有限公司

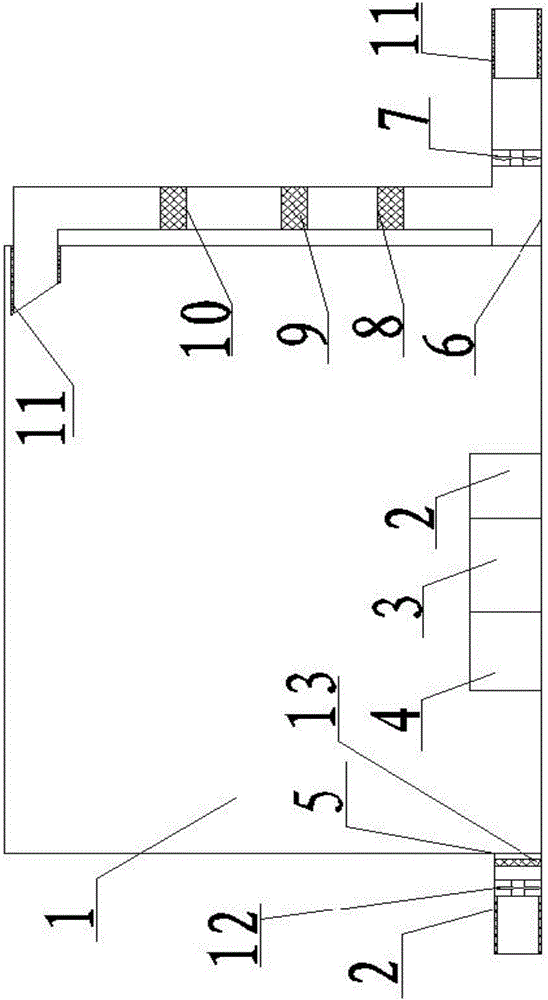

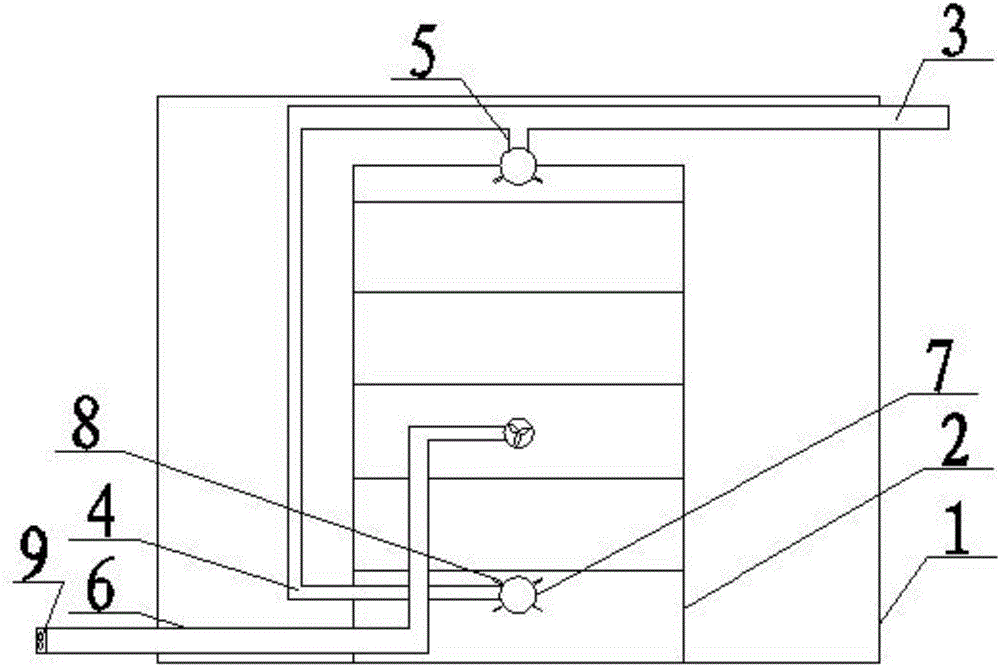

Gas supply system of full closed fungus production workshop

PendingCN106718070AGuaranteed ventilationSmooth ventilationLavatory sanitoryDeodrantsInlet channelEngineering

The invention discloses a gas supply system of a full closed fungus production workshop. The system comprises the production workshop, the bottom face of one side wall of the production workshop is provided with a waste gas exhausting channel exhausting waste gas, a clean air inlet channel which makes the clean air enter is arranged at the other side of the production workshop, the clean air inlet channel comprises a bottom end horizontal air inlet pipeline arranged outside the production workshop and located at the bottom face, a vertical channel communicated with the bottom end horizontal air inlet pipeline and located on the outer wall of the production workshop, and a top end horizontal air inlet channel which is arranged on the top end of the production workshop and communicated with the vertical channel and extends into the inner side of the production workshop from the outer side of the production workshop, the bottom end horizontal air inlet pipeline is provided with a blower, and a first layer filter screen, a second layer filter screen and a third layer filter screen are alternately arranged on the vertical channel from a near-end of air inflow to a far-end of air inflow in sequence.

Owner:冯广胜 +1

Quick falling and collecting device of cylindrical cells after being covered with films

ActiveCN110654653AImprove equipment utilizationGuaranteed productionPackagingConveyor partsPhysicsElectrical control

A quick falling and collecting device of cylindrical cells after being covered with films can solve the technical problems that a film covering machine is low in equipment utilization rate, and then production efficiency of products is influenced in the prior art. The quick falling and collecting device of the cylindrical cells after being covered with the films comprises a quick falling device machinery transmission system, and further comprise an electrical control system and a cylindrical cell recycle device. The quick falling and collecting device of the cylindrical cells after being covered with the films is used for quickly collecting and temporarily storing the applicable targets which are the cylindrical cells after being accumulated on all stations of a variety of cylindrical cellproduction lines. The quick falling and collecting device of the cylindrical cells after being covered with the films timely collects the fallen cylindrical cells which are accumulated after film covering, prevents normal output of the devices in the current procedure from being influenced by fault or low efficiency of devices in the next procedure, meanwhile alleviates the problem that underfeeding or device fault in the current procedure causes insufficient feed and wait to the next procedure, and then the materials are temporarily stored, and can make great contributions to improvement ofcomprehensive equipment utilization rate and production efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

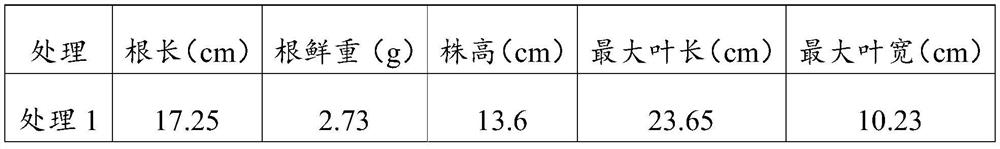

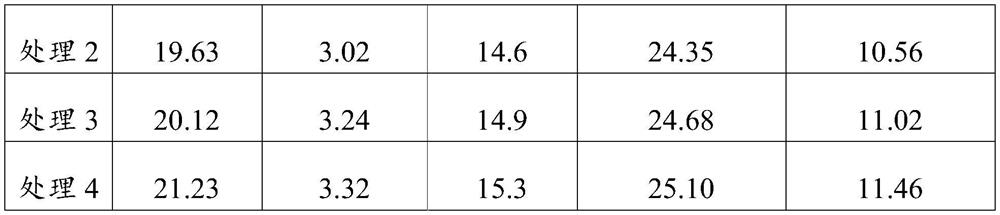

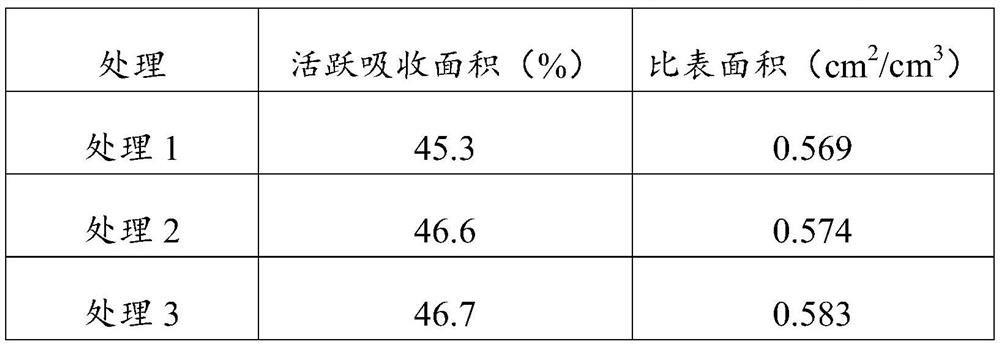

Microbial fertilizer with function of promoting growth of tobacco plants as well as preparation method and application of microbial fertilizer

PendingCN114657087AGrowth-promoting functionPromote growth and developmentMagnesium fertilisersBacteriaBiotechnologyMicroorganism

The invention discloses a microbial fertilizer with a function of promoting growth of tobacco plants as well as a preparation method and application of the microbial fertilizer. The preparation method of the microbial fertilizer with the function of promoting the growth of the tobacco plants comprises the following steps: respectively preparing fermentation broth of bacillus amyloliquefaciens YWF-17-0001 and fermentation broth of bacillus subtilis D23; mixing the fermentation liquor of the bacillus amyloliquefaciens YWF-17-0001 and the fermentation liquor of the bacillus subtilis D23 to prepare a compound microorganism bacterium solution with the function of promoting the growth of tobacco plants; and mixing the compound microbial bacterial liquid with an auxiliary agent to prepare the microbial bacterial fertilizer with the function of promoting the growth of tobacco plants, wherein the effective viable count in each gram of the microbial bacterial fertilizer is 2.0 * 10 < 8 > cfu / g-4. 0 * 10 < 8 > cfu / g. The microbial fertilizer disclosed by the invention is applied as a base fertilizer, has rooting and root strengthening effects on tobacco plants, and can improve the rooting quantity of the tobacco plants and promote the root system to develop robustly, so that the nutrient absorption of the tobacco plants is improved, the risk of root diseases caused by weak root system development of the tobacco plants is reduced, the nutrition resistance of the tobacco plants is improved, and the production quality and yield of tobacco leaves are ensured.

Owner:MICROBIAL FERMENTATION ENG RES CENT CO LTD OF YUNNAN PROVINCE

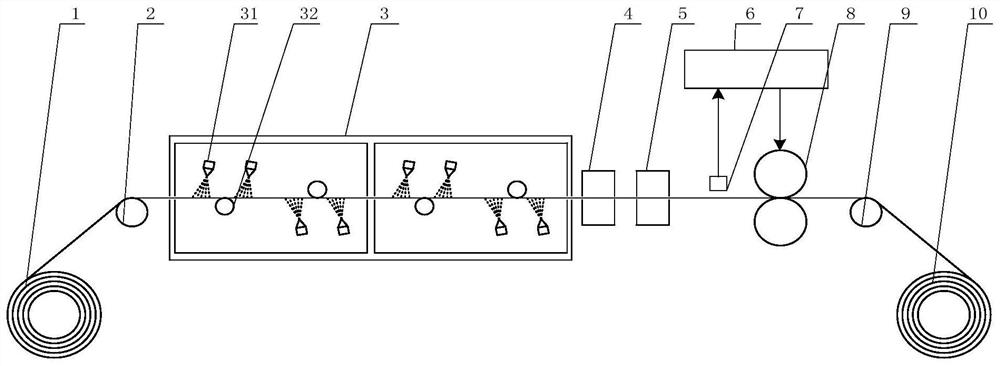

BMD production line speed control method based on strip steel surface brightness detection

ActiveCN111992589AGuaranteed production outputGuaranteed reliabilityWork treatment devicesRoll mill control devicesProduction lineAutomatic control

The invention discloses a BMD production line speed control method based on strip steel surface brightness detection, and relates to the technical field of strip steel surface brightness detection. The method comprises the steps that firstly, the gray value deviation is obtained, and an automatic control gain coefficient is calculated; then, the gray value deviation is multiplied by the control gain coefficient to obtain the adjustment amount of the pinch roll speed, and the amplitude of the adjustment amount is limited; and finally, the amplitude-limited adjustment amount is added to the pinch roll speed calculated last time, and the current pinch roll speed is obtained and stored at the same time. According to the BMD production line speed control method based on strip steel surface brightness detection, the descaling, flushing, purging and drying functions of the whole BMD production line are comprehensively considered, the reliability and descaling effect of an injection system canbe guaranteed, and the production yield of the BMD production line can be guaranteed as well.

Owner:BAOSHAN IRON & STEEL CO LTD

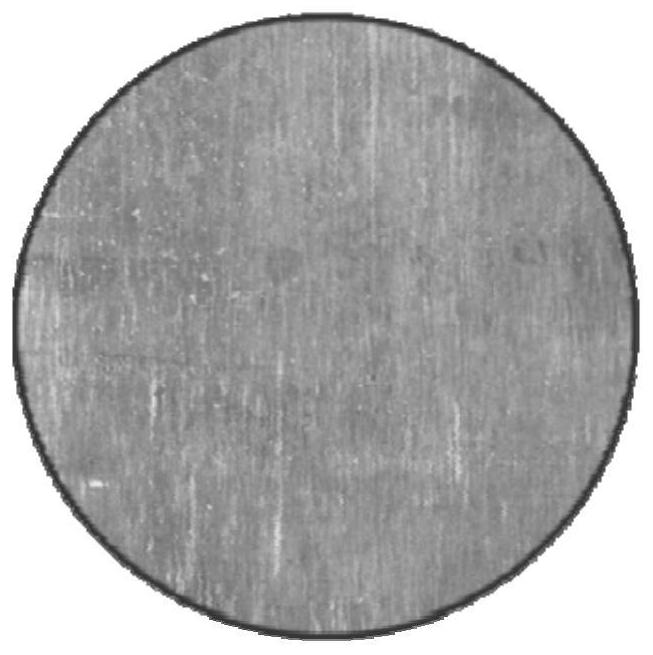

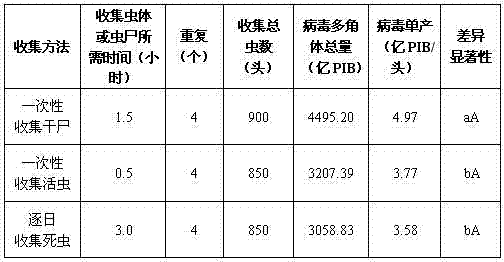

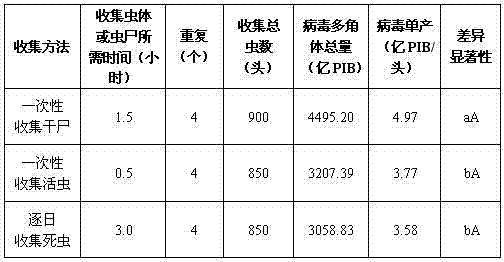

Production method for euproctis pseudoconspersa nuclear polyhedrosis virus

ActiveCN103589691AAvoid allergiesLower hatch rateMicroorganism based processesViruses/bacteriophagesSkin sensitizationMicroorganism

A production method for euproctis pseudoconspersa nuclear polyhedrosis virus belongs to the technical field of microbial pesticide production. The production method comprises the following technological steps: 1) large-scale breeding of larva; 2) virus propagation; 3) virus collection; and 4) virus extraction. The production method comprises the following beneficial effects: firstly, skin allergy caused by toxic hair of euproctis pseudoconspersa is prevented, because the probability of euproctis pseudoconspersa toxic hair contamination is substantially reduced by exchanging forage in a fume cupboard and collecting euproctis pseudoconspersa dead bodies, and allergy is effectively avoided; secondly, the virus production yield is improved, by employing potted tea trees for producing overwintering spawns, the hatching rate of the overwintering spawns is substantially improved from 10-15% to 65-80%, so that first-generation larva breeding number and virus productivity in next year are ensured; and also, the virus dried dead body collection method is employed, helps to reduce the loss of virus during collection, and is improved in efficiency by 52.7% and in virus productivity by 38.8% compared with a conventional collection method.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Qinghai-Tibet plateau high-cold pasturing area greenhouse grass planting technology

The invention discloses Qinghai-Tibet plateau high-cold pasturing area greenhouse pasture planting technology which comprises the following steps: (1) a greenhouse is prepared; (2) grass seeds and base fertilizers are respectively mixed standby; (3) ploughed fallowing is carried out; (4) preparation before broadcast sowing and planting is carried out; (5) a ditching method is prepared; (6) sowing is carried out; (7) soil is covered manually and smoothed, and manual suppression is carried out; (8) preparation before a rainy season comes is carried out; (9) treatment of 7-8 months at a high temperature is carried out; and (10) mowing and overwintering treatment are carried out. The Qinghai-Tibet plateau high-cold pasturing area greenhouse pasture planting technology integrates annual grass cultivation, perennial grass cultivation and cold season-warm season grass cultivation, is strong in flexibility and adaptability, simple, easy to operate, and low in cost, is the technology which is popularized and used by nations and local residents, provides a technological approach for forage grass production of extreme high altitude areas in China, and provides technological support for grass supply.

Owner:LANZHOU UNIVERSITY

Ventilation system of all-closed fungi production workshop

PendingCN106813347ASmooth ventilationImprove ventilation efficiencyLighting and heating apparatusCultivating equipmentsEnvironmental engineeringMechanical engineering

The invention discloses a ventilation system of an all-closed fungi production workshop. The ventilation system comprises a production workshop and a fungi bag storage rack; an air intake main pipe is arranged at the top end of an inner cavity of the production workshop; a clean air inlet for enabling clean air to enter is formed in the outer end, extending out of the production workshop, of the air intake main pipe; a bottom end clean air exhaust pipe is arranged at the bottom end of the fungi bag storage rack, and is communicated with the air intake main pipe through a communicating pipe; a top end clean air exhaust pipe is arranged at the top end of the fungi bag storage rack, and is communicated with the air intake main pipe; a waste gas exhaust pipe communicated with an external atmospheric environment is arranged at the bottom end of the production workshop; and a waste gas sucking pipe is arranged at the middle part of the fungi bag storage rack, and is communicated with the waste gas exhaust pipe through a communicating pipe.

Owner:冯广胜 +1

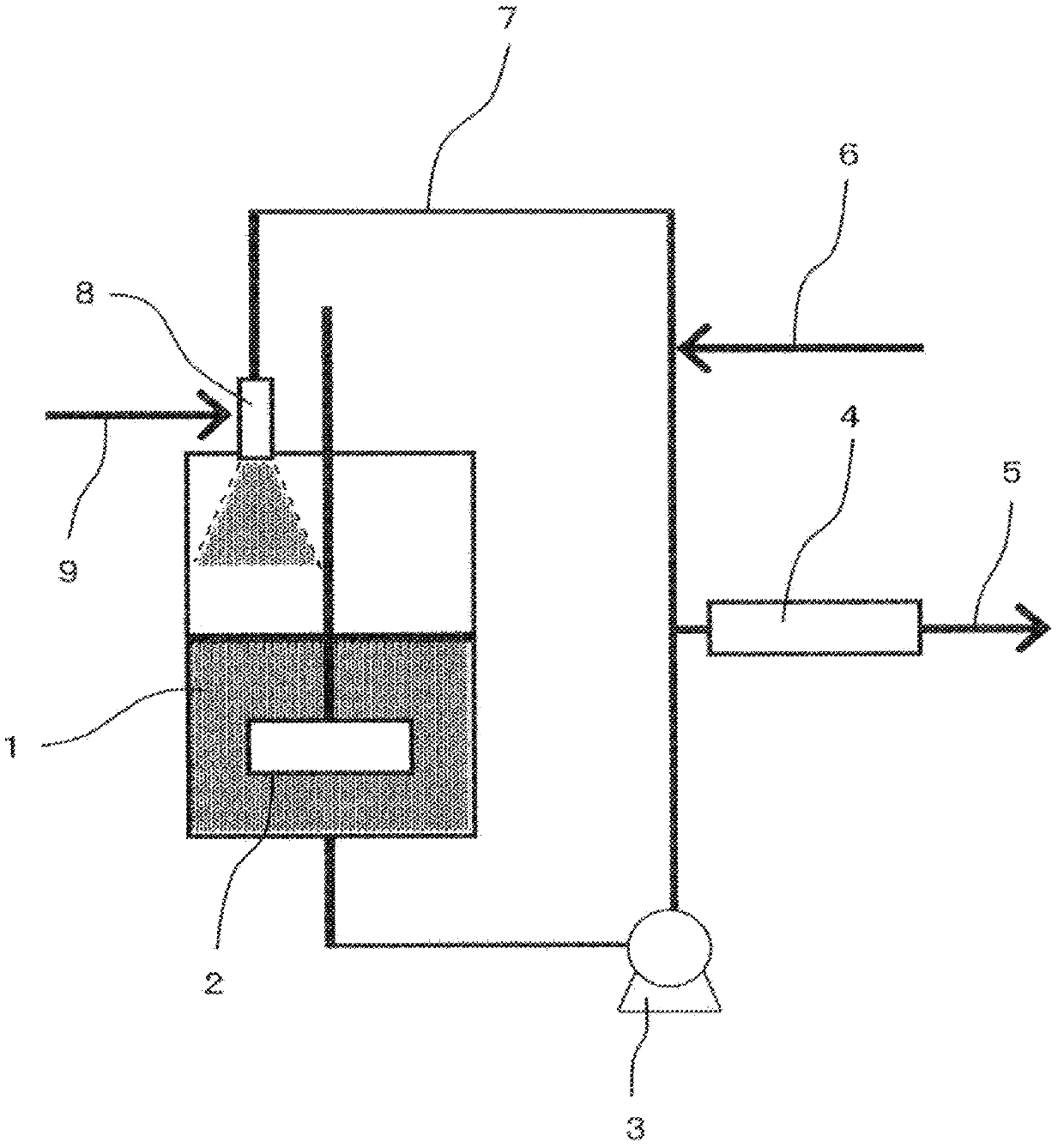

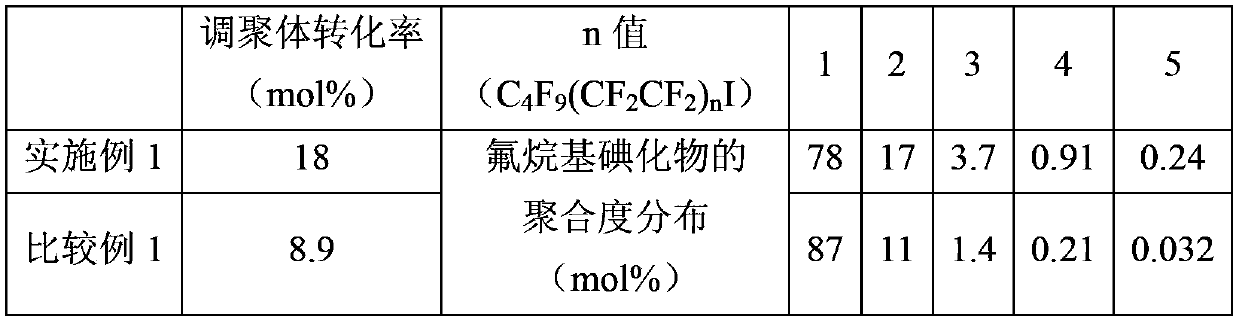

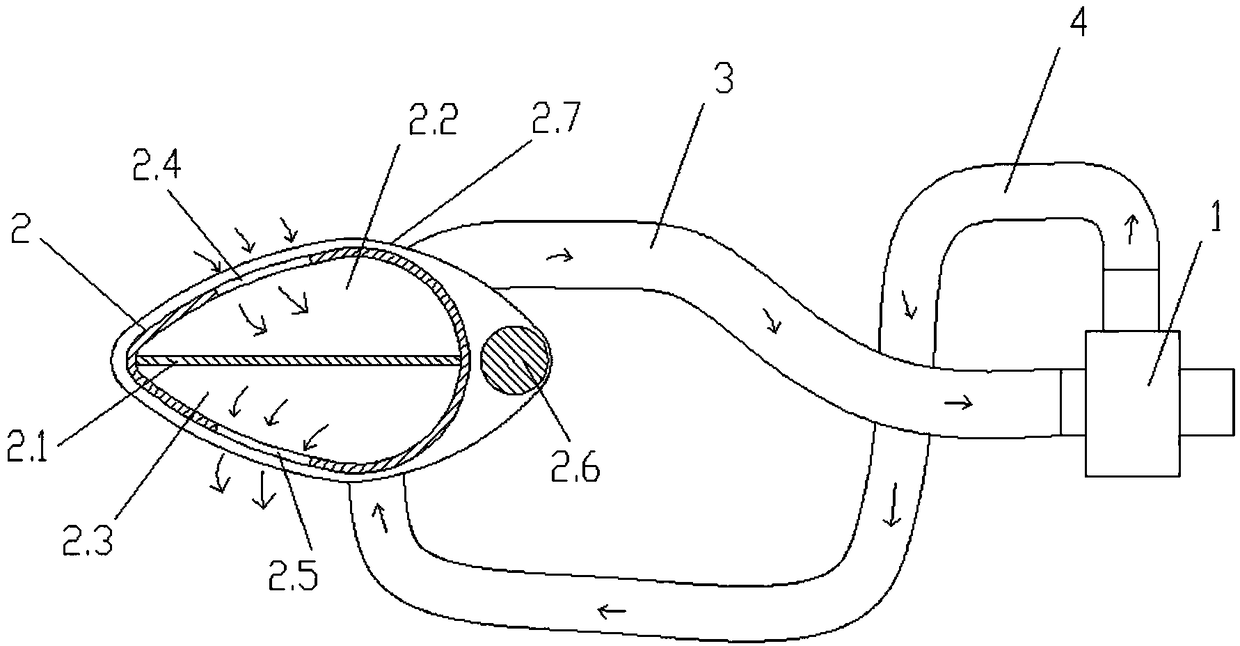

The manufacture method of fluoroalkyl iodide

ActiveCN103373895BImprove contact efficiencyHigh selectivityHalogenated hydrocarbon preparationTetrafluoroethyleneGas phase

The present invention provides a novel preparation method of fluoroalkyl iodile, which can prepare fluoroalkyl iodile with high selection rate, and furthermore a small-size reactor can be used and excellent production efficiency is obtained. Particularly the invention provides the preparation method of the fluoroalkyl iodile, which is characterized in that: in a reactor, telomerization between fluoroalkyl iodile which is used as telogen and is represented by a formula (I) and tetrafluoroethylene that is used as backbone material is caused for preparing the fluoroalkyl iodile represented by the formula (II). In the RfI formula (I), Rf is a fluoroalkyl of which the number of carbon atoms is 1-6. In the Rf-(CF2CF2)n-I formula (II), Rf is same with that in the formula (I), and n is an integer selected from 1-4. Reaction solution in the reactor is extrated and is fed from an ejector inlet on the reactor to the inner part of the ejector. When the reaction solution passes through the ejector, gas which contains tetrafluoroethylene in the reactor is sucked from the suction port of the ejector to the inner part of the ejector. Mixture of the reaction solution and the gas which comprises tetrafluoroethylene is sprayed from the outlet of the ejector into the reactor, thereby causing reaction between the fluoroalkyl iodile represented by the formula (I) and tetrafluoroethylene.

Owner:DAIKIN IND LTD

A device for quickly unloading and collecting cylindrical battery film

ActiveCN110654653BIncrease profitGuaranteed production outputPackagingConveyor partsProduction lineElectrical battery

The invention discloses a device for quickly unloading and collecting cylindrical batteries after film covering, which can solve the technical problem of low equipment utilization rate of film covering machines in the prior art, which further affects the production efficiency of products. It includes the mechanical transmission system of the fast unloading device, and also includes the electrical control system and the cylindrical battery recovery device; the applicable object of the device of the present invention is the rapid collection and temporary storage of cylindrical batteries at various stations on various cylindrical battery production lines. Collect the accumulation of the material after the coating in time to avoid the failure of the equipment in the next process or the accumulation of low-efficiency batteries to affect the normal output of the equipment in the previous process, and at the same time reduce the shortage of materials or equipment failure in the previous process. The device can make a great contribution to improving the comprehensive utilization rate of equipment and improving production efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

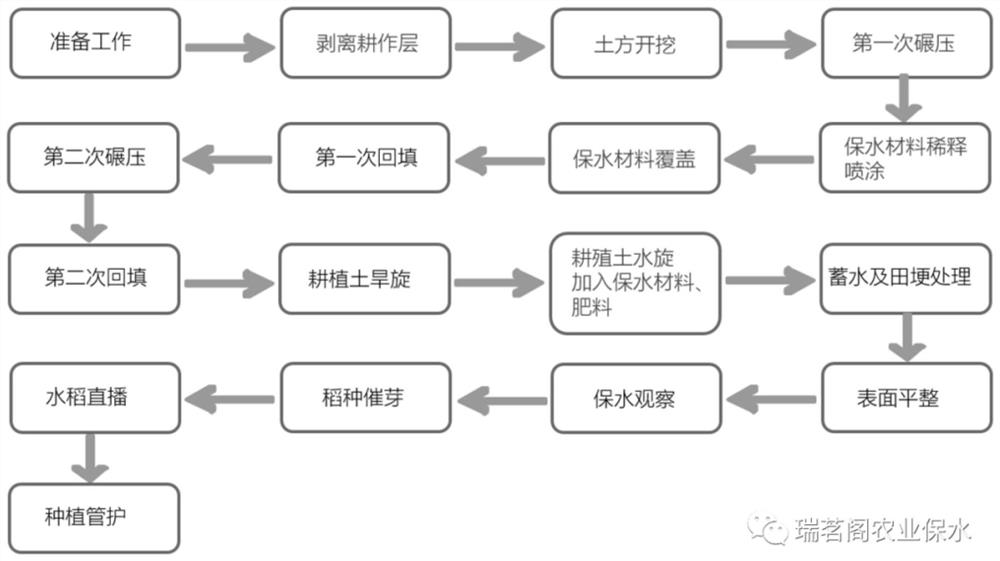

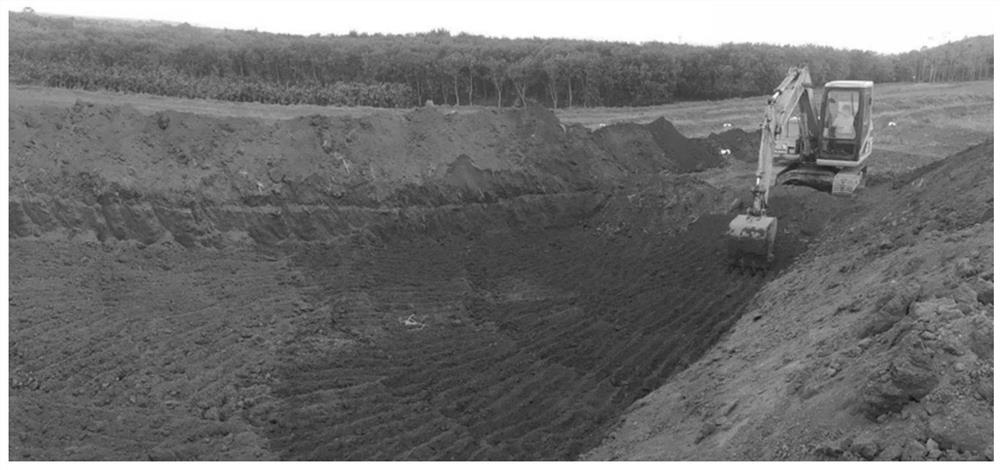

A treatment method for water conservation, water conservation and fertilizer conservation by transforming dry and sandy land into paddy fields

ActiveCN111642167BExcellent adhesionGood anti-leakage performanceExcrement fertilisersBioloigcal waste fertilisersWater usePlant roots

The invention provides a treatment method for water conservation, water conservation and fertilizer conservation and fertilizer conservation for transforming dry and sandy land into paddy fields, comprising: 1) peeling off the cultivated layer, and the peeling height is ≥ 30 cm; 2) first rolling: the first time 2 to 3 The first round of compaction treatment, the compaction degree is ≥85%, forming the plow bottom layer, and the water-retaining material is diluted and sprayed; 3) Water-retaining material covering: dry-laying water-retaining material; 4) The second backfill: backfill with 10-20% of the original soil, cover Soil improvement additives; backfill with 15-25% of the original soil; 5) second rolling: second 2-3 times of compaction; 6) second backfill: backfill with 55-75% of the original soil; 7 ) Rotary tillage: add organic fertilizer, trace element raw materials and water-retaining materials, perform dry rotation and 2 times of water rotation to form a plowing soil layer; the method for transforming dry and sandy land into paddy fields in the present invention can effectively maintain the long-term water retention of the transformed paddy fields Fertilizer function, saving irrigation water and planting fertilizer costs, and promoting plant root growth, increasing crop production.

Owner:海南瑞茗阁实业有限公司

A kind of production method of tea caterpillar nuclear polyhedrosis virus

ActiveCN103589691BAvoid allergiesLower hatch rateMicroorganism based processesViruses/bacteriophagesSkin sensitizationAnimal science

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

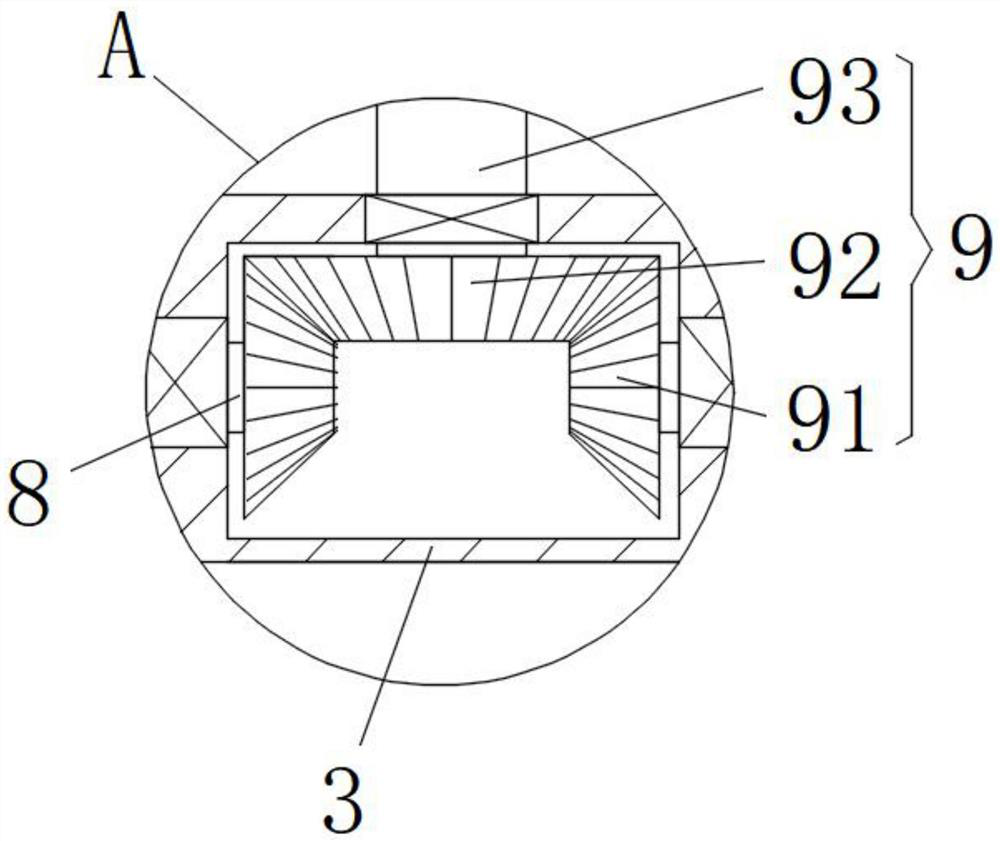

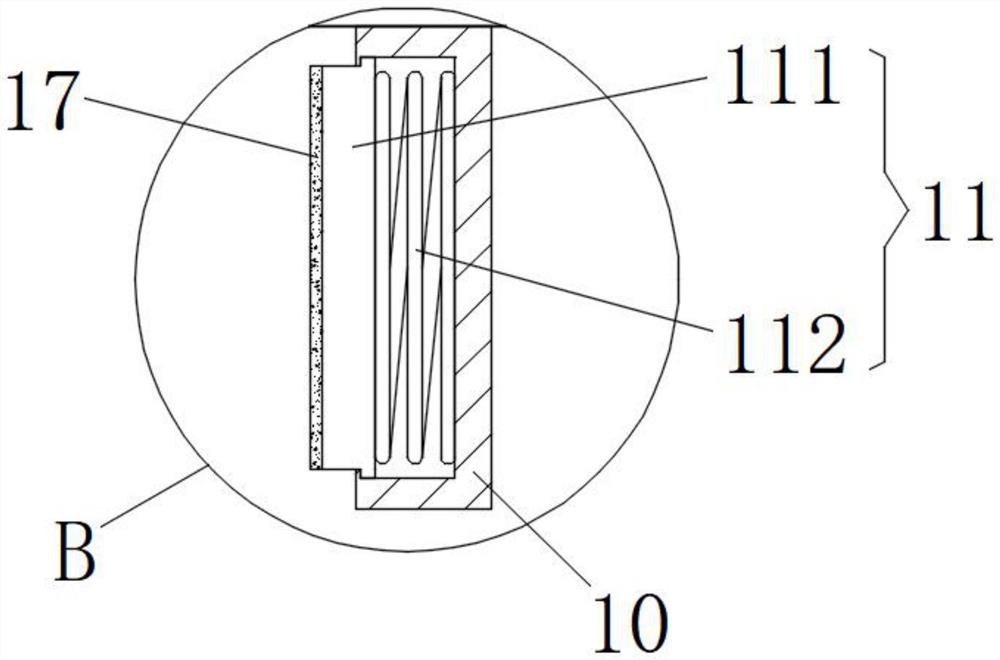

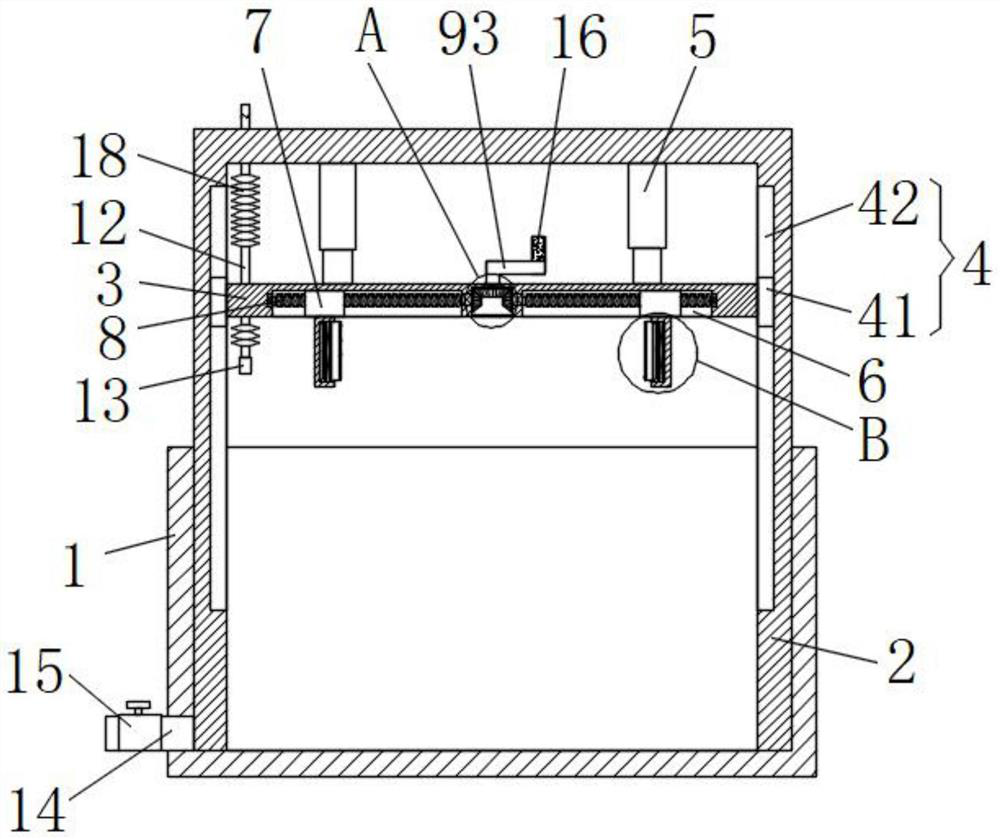

Compact spinning lattice apron anti-blocking fiber removal system

The invention relates to a compact spinning lattice apron anti-blocking fiber removal system. The system comprises a draught fan, an air pipe, an air suction flexible tube and an exhaust flexible tube, wherein the air pipe is internally provided with an air pipe partition plate, and the air pipe partition plate divides the air pipe into an air suction cavity and an air supply cavity; one end of the air suction flexible tube is communicated with the air suction cavity, and the other end of the air suction flexible tube is communicated with an air inlet end of the draught fan; one end of the exhaust flexible tube is communicated with the air supply cavity, and the other end of the exhaust flexible tube is communicated with an air outlet end of the draught fan; the air pipe is provided with an air suction groove communicated with the air suction cavity; and the draught fan is provided with an air blowing groove communicated with the air supply cavity. Compared with the prior art, the compact spinning lattice apron anti-blocking fiber removal system has the advantages that dust and short fibers can be prevented from blocking off meshes to avoid machine halt for cleaning; the productionis ensured, and the labor-hour is reduced; because air blowing and air suction are performed by using a same draught fan, energy consumption is not needed to be increased.

Owner:柳州市卓洋纺织有限公司

Air tightness detection device for ground washing vehicle water tank production

PendingCN114323468AEasy to detectImprove detection efficiencyDetection of fluid at leakage pointAgricultural engineeringAir tightness

The invention relates to the technical field of ground washing vehicles, and discloses a ground washing vehicle water tank production air tightness detection device, which comprises a box body, the inner wall of the box body is in bolted connection with a U-shaped frame, a lifting plate is slidably connected between the inner walls of the U-shaped frame, and a sliding mechanism is arranged between the lifting plate and the inner wall of the U-shaped frame. An air cylinder is connected between the top of the lifting plate and the U-shaped frame in a bolted mode, and a first sliding groove is formed in the surface of the lifting plate. According to the water tank detection device, the lifting plate moves along the first sliding groove under the action of the air cylinder to enable the water tank to enter the position below the water surface, the purpose of convenient detection can be achieved, the detection efficiency is improved, the labor amount is reduced, and the production yield is guaranteed; the water tank detection device can achieve the purpose of detecting water tanks with different sizes, improves the flexibility and applicability of the device, reduces the labor amount, and reduces the production cost.

Owner:广东浩海环保设备有限公司

Steel pipeline anticorrosive material and preparation method of steel pipeline anticorrosive material

ActiveCN102850857BImprove impact toughnessHigh molecular weightAnti-corrosive paintsAnoxomerPolypropylene

The invention discloses a steel pipeline anticorrosive material and a preparation method of the steel pipeline anticorrosive material. The steel pipeline anticorrosive material comprises the following ingredients in proportion by weight: 44 to 54 parts of polypropylene, 3 to 12 parts of high-density polyethylene powder, 0.3 to 2.4 parts of anti-aging agents, 0.06 to 1.2 parts of antioxidant, 0.06 to 1.2 parts of lubricating agents, 0.06 to 0.6 parts of degradation inhibitors and 0.06 to 0.6 parts of initiators, wherein all ingredients are uniformly mixed in a highly mixed pot and are then extruded out through a reactive double-screw-rod extruding machine with the length-diameter ratio being 52:1, the extruded ingredients are subjected to strip pulling, air cooling and grain cutting, the temperature is set to be 180 DEG C to 220 DEG C, and the rotation speed of screw rods is set to be 180 to 400 turns per minute. Compared with the anticorrosive material in the market, the steel pipeline anticorrosive material has the advantages that the processing applicability is wide, high Vicat, high hardness and good low-temperature toughness are realized, and long service life at high temperature and requirements on the anticorrosive material when passing through specific districts such as water, sand and stone soil and oceans are met.

Owner:四川仁智新材料科技有限责任公司

Direct Drive Assembly Assembly

ActiveCN110712037BGuaranteed production efficiencyGuaranteed production outputAssembly machinesDrive shaftPhysics

Owner:深圳市睿荔科技有限公司

Vanadium nano electrothermal material

PendingCN111304590AImprove securityGuaranteed reservesMaterial nanotechnologyVacuum evaporation coatingSputteringVanadium atom

The invention provides a vanadium nano electrothermal material, belongs to the technical field of branch nanomaterials of new material large classes, and particularly provides a vanadium nano electrothermal material body mainly formed by vanadium. The nanomaterial is formed in the manner that vanadium, nickel, tungsten and chromium at the mass percent of 40%-80%-10%-30%-5%-16%-0%-15% are embed-plated on base materials with different sizes and shapes such as the pipe shape, the plate shape, the piece shape, the strip shape and the round shape made of quartz glass, ceramic and other materials with specially-treated surfaces through sputtering. The thickness of a film is 5,000-20,000 nanometers, the material has the properties that the electrothermal conversion rate is high, heating is extremely rapid, the heating surface temperature is high, the durability is long, the material is resistant to scratching and does not disengage, the power is not attenuated, and the magnetic radiation is low, and power can be supplied through 10 V-220 V alternating and direct currents. The material is prepared into various heating assemblies and designed into various novel electric appliances and equipment, the beneficial effects that instant heating is achieved, the cost performance is high, energy is saved, and environmental friendliness is achieved are achieved, use is easy, and the applicationrange is wide. The vanadium nano electrothermal material fills up the blank of the world in the field of electrothermal heating application and has extremely high use value and broad application prospects.

Owner:彭文婷

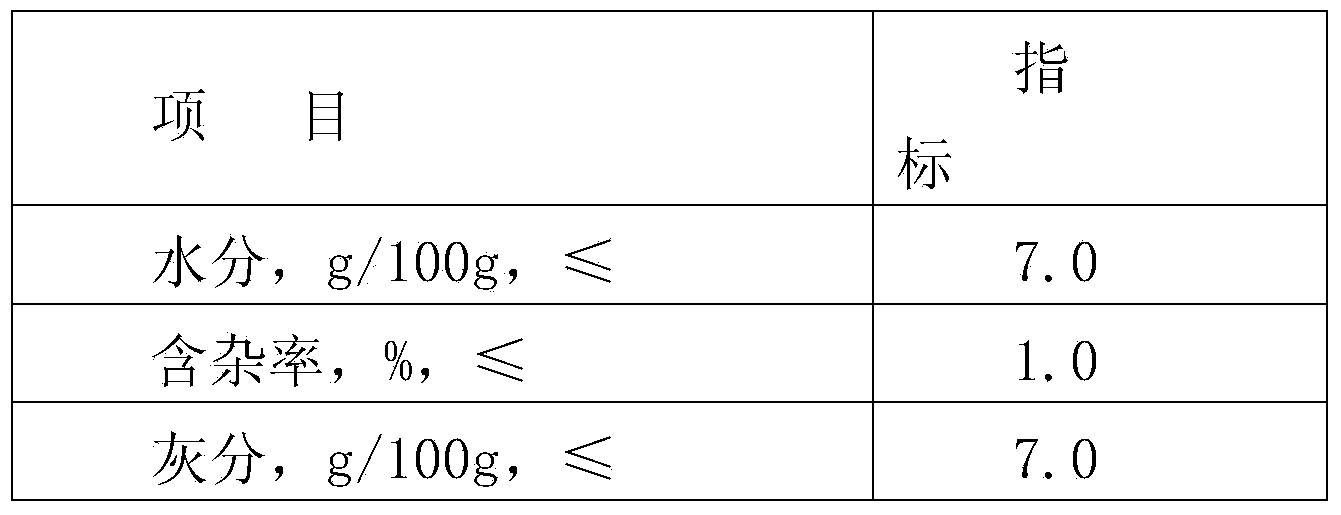

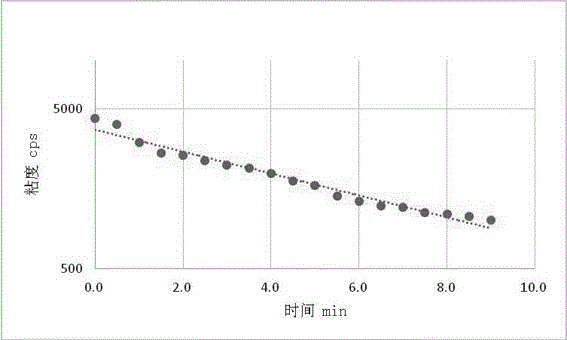

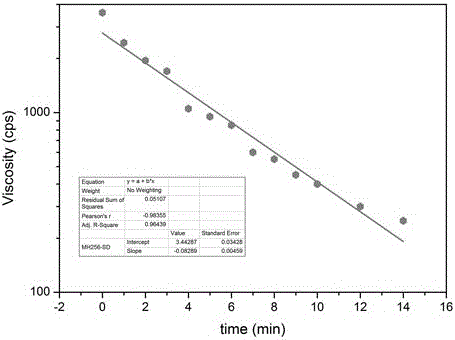

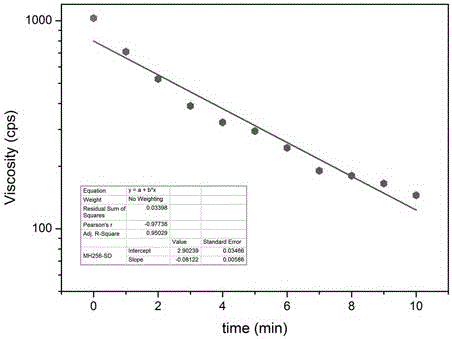

Method for rapidly detecting cellulose-ether anti-mold performance

InactiveCN106338453ADetection of enzyme resistanceShort detection cycleFlow propertiesEtherDistilled water

The invention relates to a method for rapidly detecting the cellulose-ether anti-mold performance. The method includes the following steps that (1) cellulose powder is put into distilled water, the mixture is stirred, the cellulose is fully suspended, and standing is carried out till supernatant is completely clarified; (2) a to-be-detected cellulose-ether sample is dried, then a solution is prepared with distilled water, the constant temperature is kept in a constant temperature groove, and the initial viscosity is detected through a viscosity meter; (3) a cellulose solution is movably taken into a to-be-detected cellulose-ether solution, timing and stirring are carried out, an enzyme solution is evenly dispersed, large bubbles do not exist in the solution, the viscosity is detected, time is recorded, the viscosity is detected once every 30 s to 60 s, operating is repeated till the viscosity is reduced to be below 200 cps to 300 cps, or operating is stopped after 10 min to 15 min. According to the method, detection is carried out in the mode that cellulose ether is cut through cellulose, the anti-enzyme capacity of the cellulose ether can be rapidly detected, the detection period is quite short, the detection accuracy is high, the production efficiency and the annual yield are guaranteed, and the basis is provided for large-scale production.

Owner:浙江海申新材料有限公司

Electronic rotor paint dipping device with relatively high efficiency

InactiveCN112756188AOvercome the disadvantages of dipping paintImprove the efficiency of dippingPretreated surfacesManufacturing dynamo-electric machinesElectric machineGear wheel

Owner:龚爽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com