Assembly line capable of enabling fruits to be fed by automatically overturning basket and conveying vacant basket

A technology of automatic turning and assembly line, which is applied in the direction of conveyor objects, emptying containers, transportation and packaging, etc., to reduce labor, save costs, and avoid fruit damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

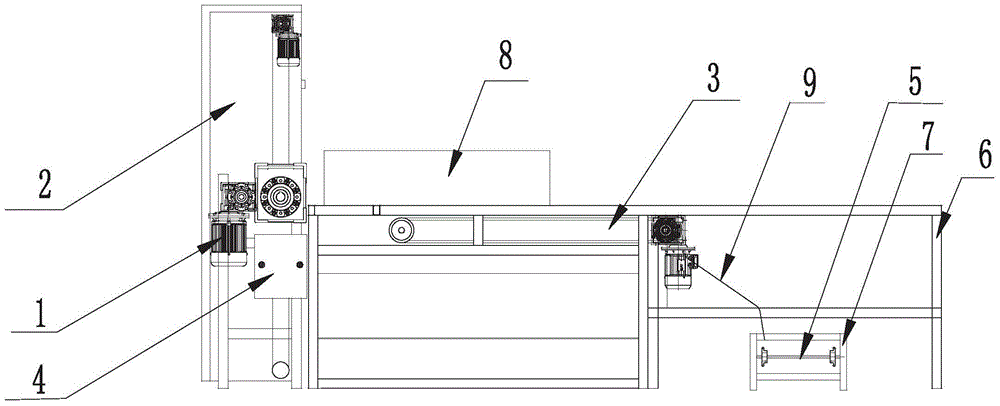

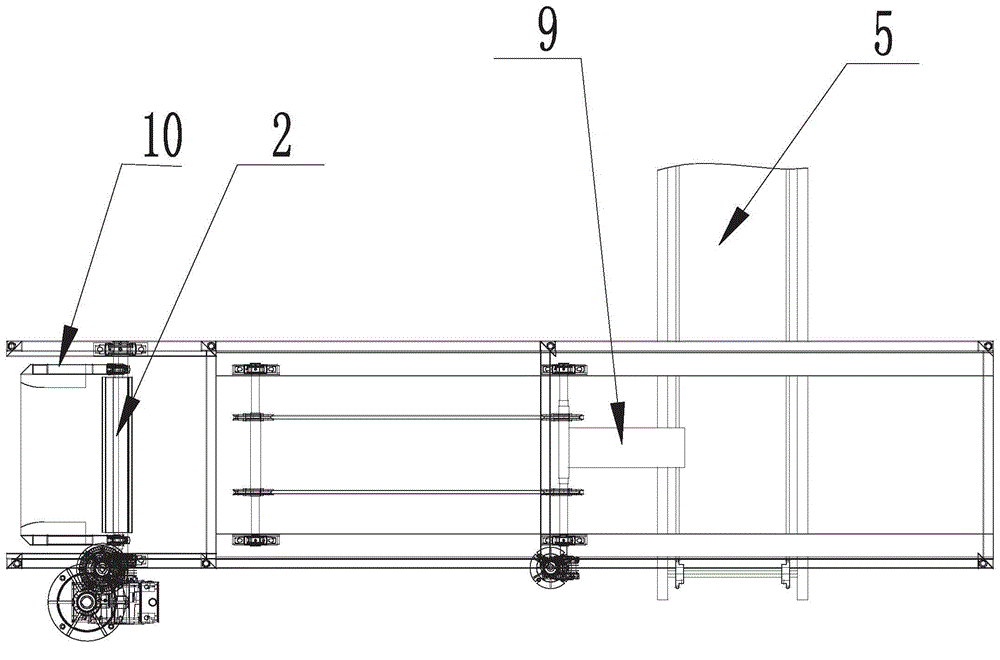

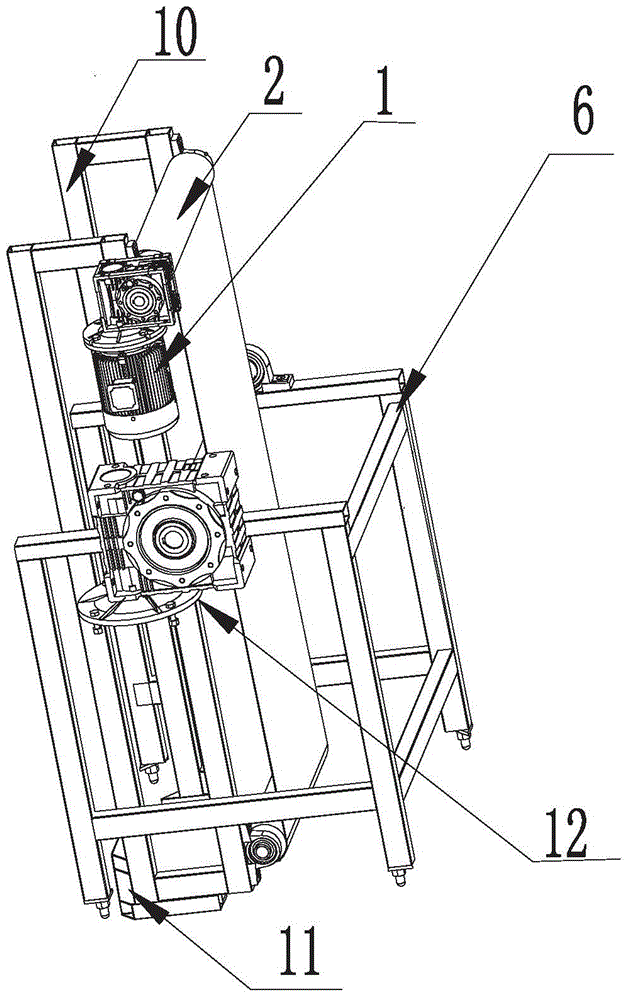

[0021] Such as Figure 1~3 Shown, a kind of automatic fruit turning basket fruit and empty basket conveying assembly line, comprise first frame 6, second frame 7, the first frame 6 end is equipped with a fruit belt conveyor 2, the first frame 6 A belt conveyor 3 is installed in the middle, and the belt conveyor 3 is used to transport turnover baskets. A second frame 7 is arranged under the other end of the first frame 6. The second frame 7 is vertically arranged with the first frame 6. A chain conveyor 5 is installed on the second frame 7, and the chain conveyor 5 is used for transporting turnover baskets. The end of the belt conveyor 3 is provided with a folding plate 9, and the end of the belt conveyor 3 is connected to the second frame 7 through the folding plate 9. The folding plate 9 plays the role of fixing the first frame 6 and the second frame 7 which are perpendicular to each other.

[0022] One end of the first frame 6 is equipped with a control box 4 , and the fru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com