Direct Drive Assembly Assembly

A technology of assembly device and transmission group, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty and inefficiency of manual assembly, and achieve the effect of high labor intensity, ensuring consistency and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] one

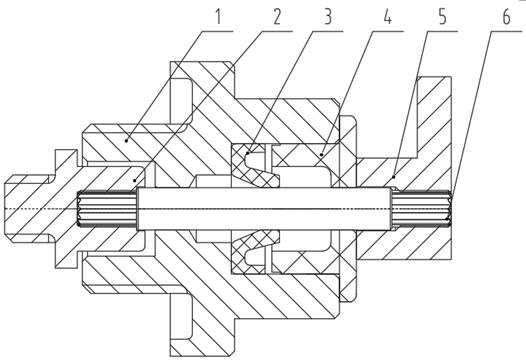

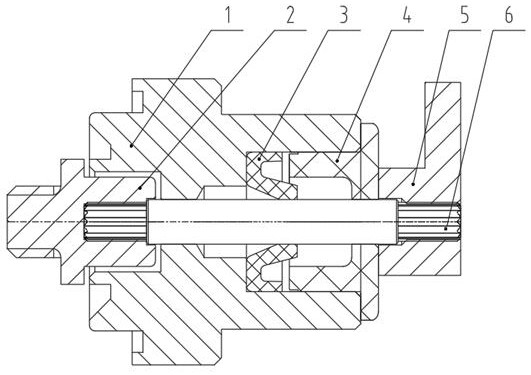

[0048] Such as figure 1 and figure 2 Shown: direct drive group, including drive shaft 6, bushing 1, dynamic seal structure, connecting piece 2 and lever 5;

[0049] The transmission shaft 6 is rotatably inserted in the sleeve 1; one axial end of the transmission shaft 6 is a transmission input end, and the other end is a transmission output end; the transmission input end is fixedly provided with the dial A rod 5, the shifting rod 5 has a shifting portion protruding outward along the radial direction of the transmission shaft 6; the transmission output end is coaxially fixed with the connecting piece 2;

[0050] The interior of the shaft sleeve 1 is provided with the dynamic sealing structure near the transmission input end, and the outer surface of the shaft sleeve 1 is provided with an assembly and fixing structure of the shaft sleeve 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com