BMD production line speed control method based on strip steel surface brightness detection

A technology of line speed control and surface brightness, which is applied in the direction of rolling mill control devices, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of poor reliability of the nozzle clamping mechanism, and achieve descaling effect, reliability, and The effect on production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

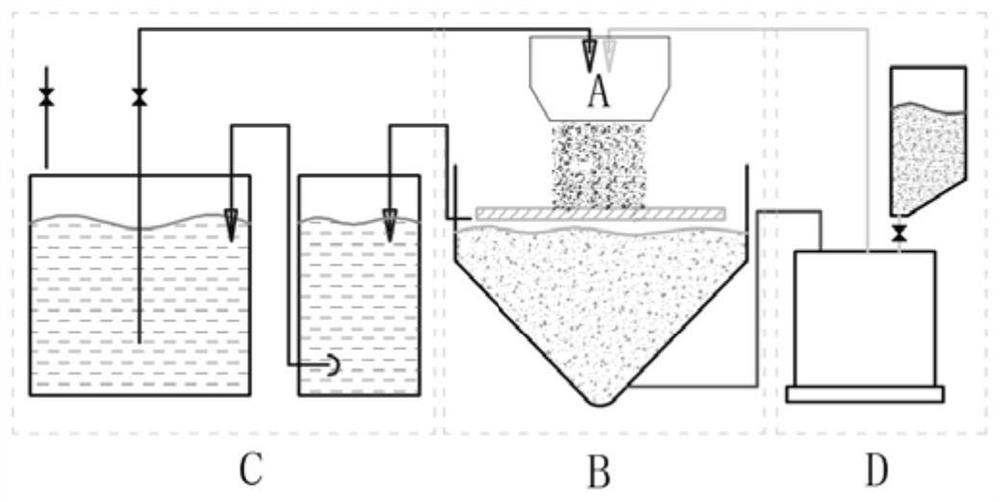

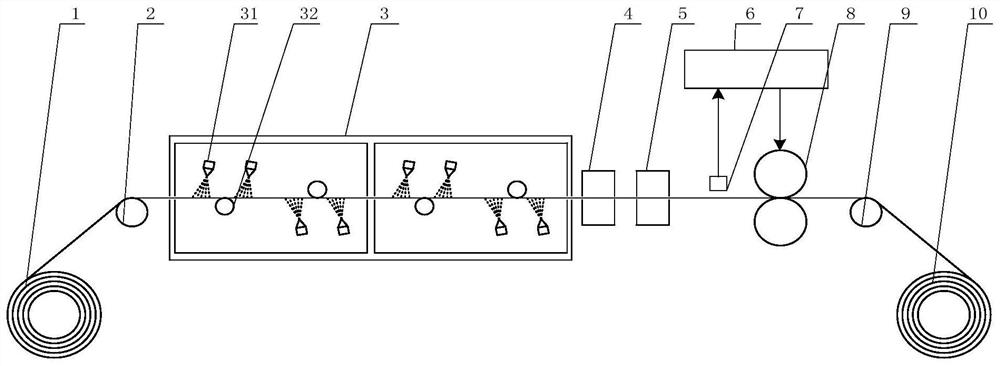

Method used

Image

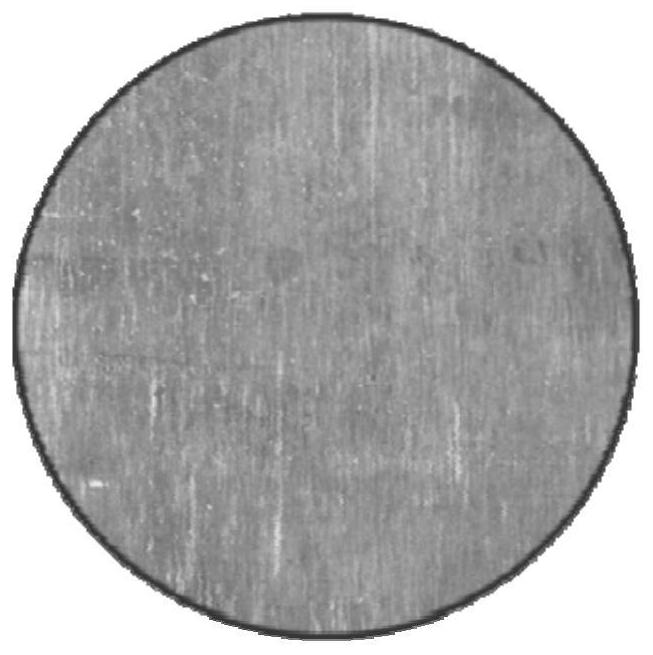

Examples

Embodiment 1

[0054] S1. Set the target gray value G set =200;

[0055] S2, the received actual gray value G act = 160;

[0056] S3. Gray value deviation ΔG=160-200=-40;

[0057] S4, the pinch roller speed S calculated last time old =0.3m / s, calculate the gain coefficient k G

[0058] S5. Calculate the pinch roller speed adjustment ΔS, ΔS=0.001125×(-40)=-0.045;

[0059] S6. Limit the adjustment amount, when ΔS>ΔS max , ΔS=ΔS max ; when ΔSmax , ΔS=-ΔS max ; where, ΔS max Indicates the maximum adjustment amount, unit: m / s;

[0060] S7, calculating the current pinch roller speed S new = 0.3-0.045 = 0.255m / s;

[0061] S8. Save the current pinch roller speed S old = 0.255m / s.

Embodiment 2

[0063] S1. Set the target gray value G set =200;

[0064] S2, the received actual gray value G act =130;

[0065] S3. Gray value deviation ΔG=130-200=-70;

[0066] S4, the pinch roller speed S calculated last time old =0.25m / s, calculate the gain coefficient k G

[0067] S5. Calculate the pinch roller speed adjustment ΔS, ΔS=0.0009375×(-70)=-0.065625;

[0068] S6. Limit the adjustment amount, when ΔS>ΔS max , ΔS=ΔS max ; when ΔSmax , ΔS=-ΔS max ; where, ΔS max Indicates the maximum adjustment amount, unit: m / s; because the calculation result is less than -ΔS max , after limiting ΔS=-0.05

[0069] S7, calculating the current pinch roller speed S new = 0.25-0.05 = 0.2m / s;

[0070] S8. Save the current pinch roller speed S old = 0.2m / s.

[0071] In summary, adopting the technical solution of the present invention, the BMD production line speed control method based on strip steel surface brightness detection first obtains the size of the gray value deviation and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| greyscale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com