Patents

Literature

30results about How to "Guaranteed reserves" patented technology

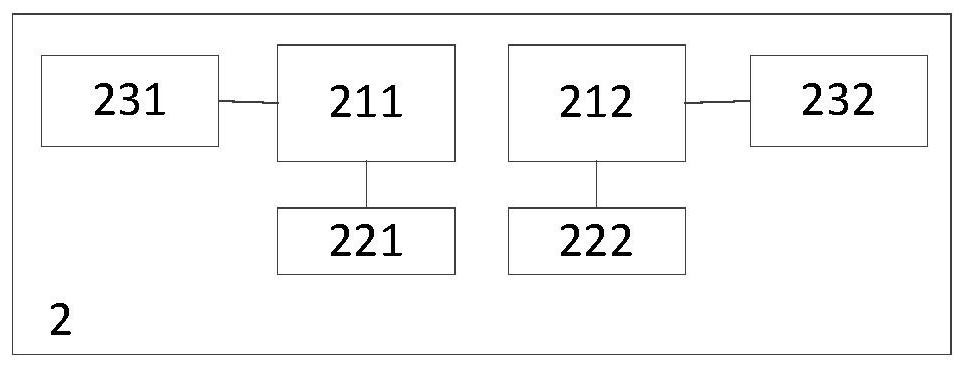

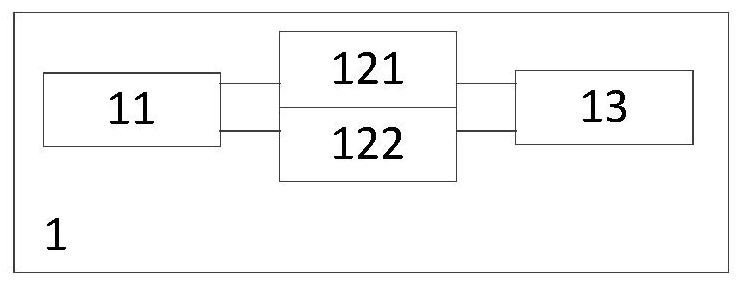

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

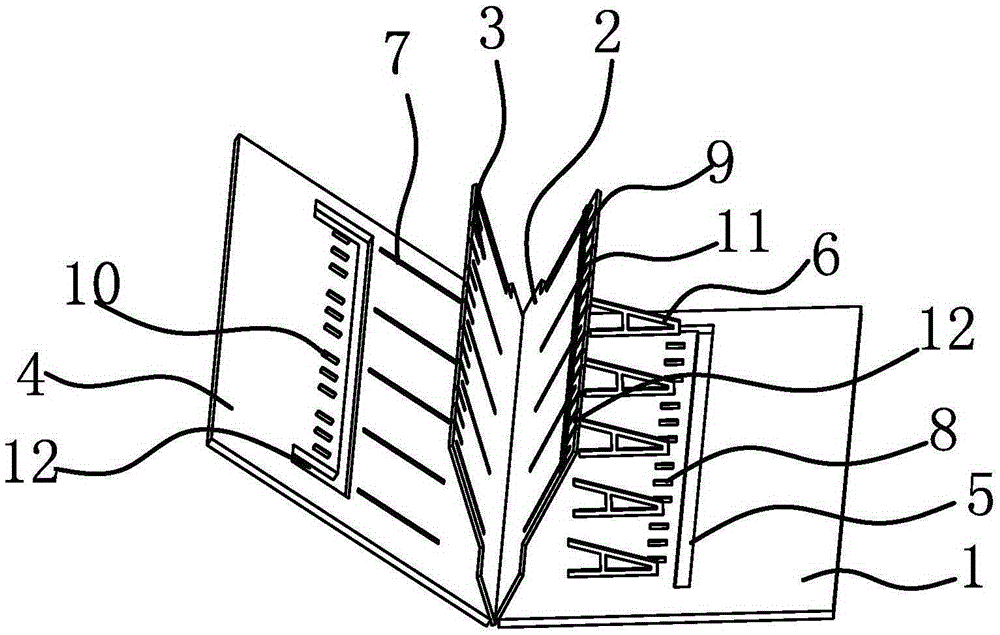

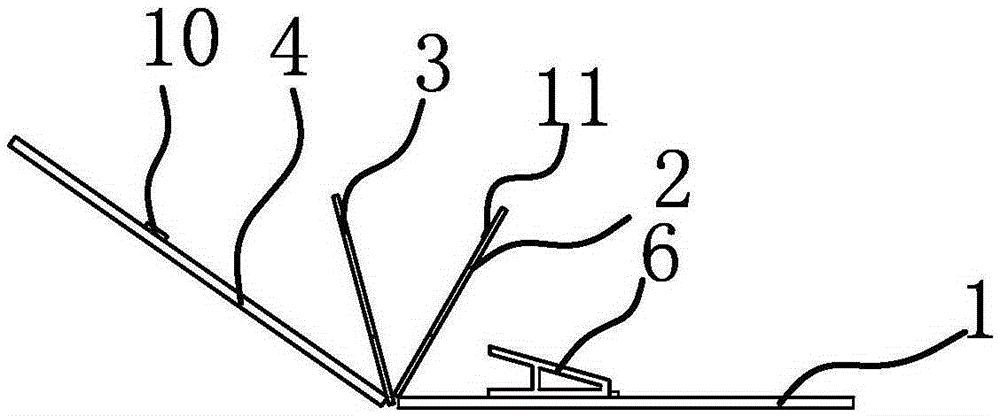

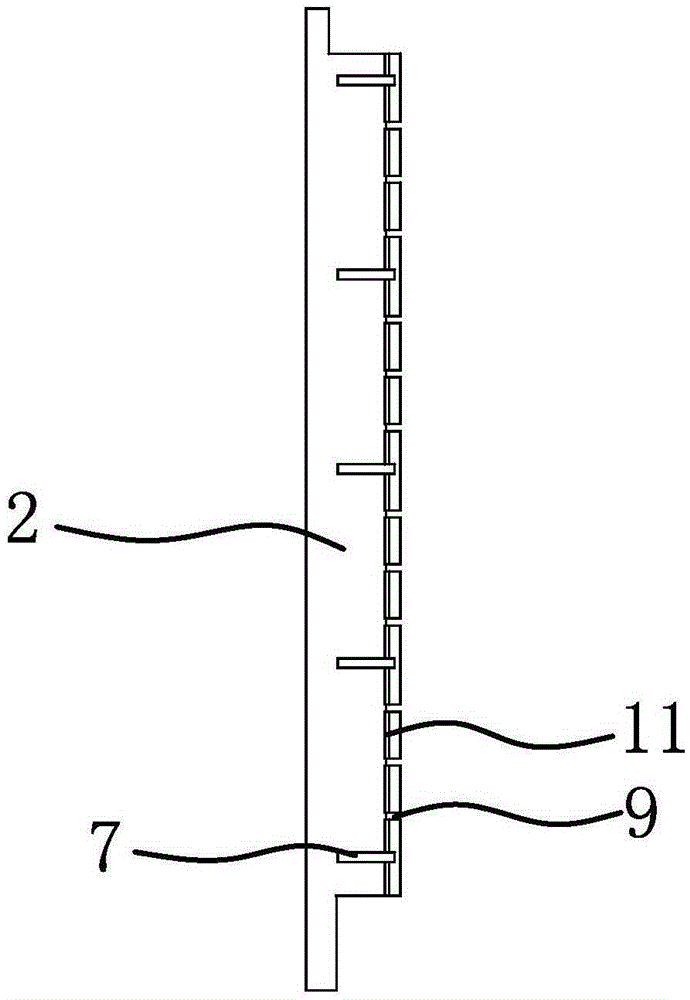

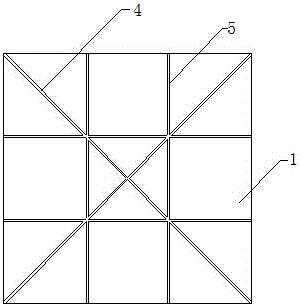

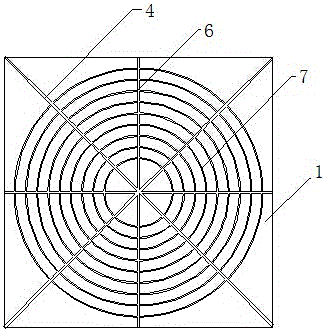

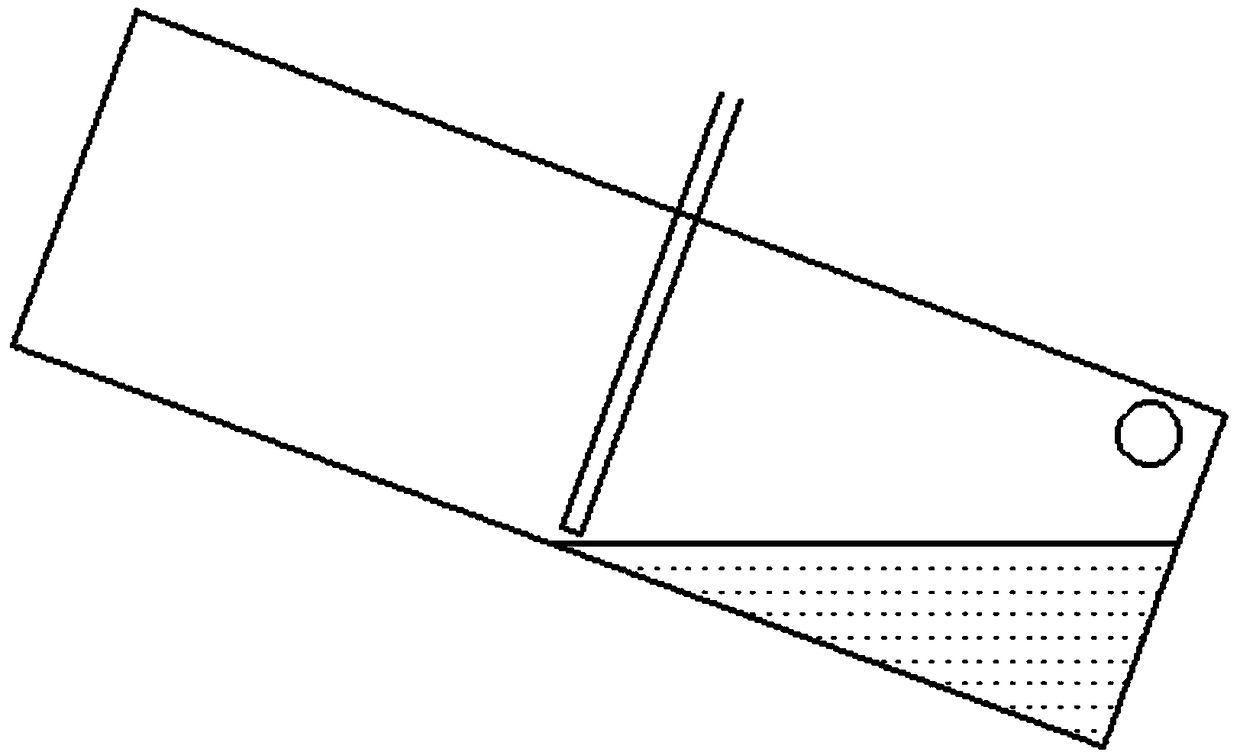

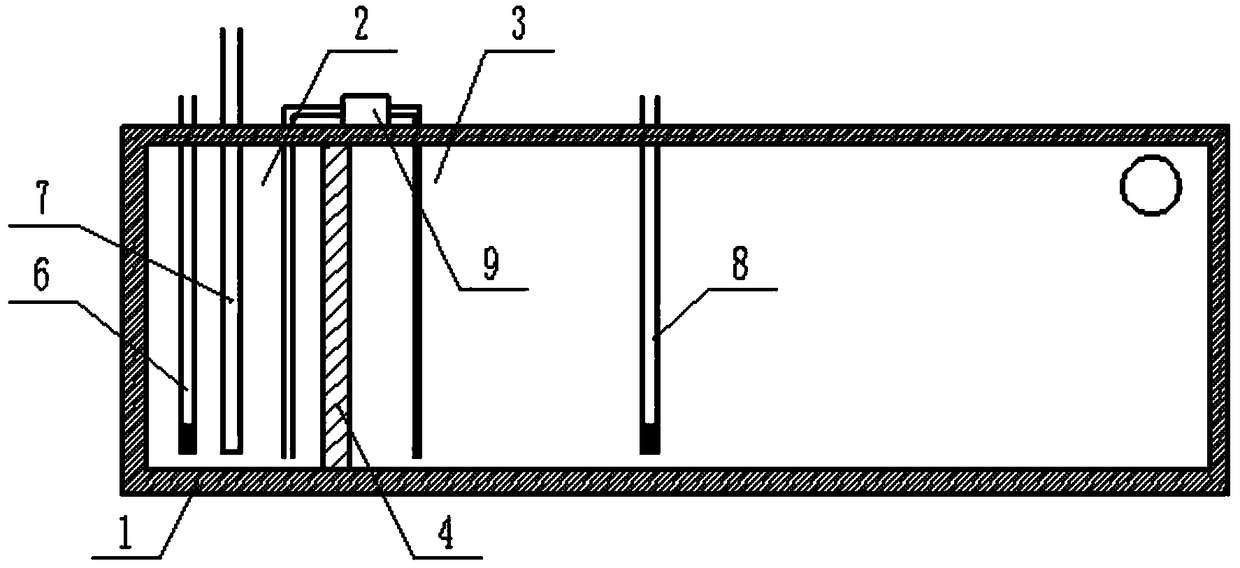

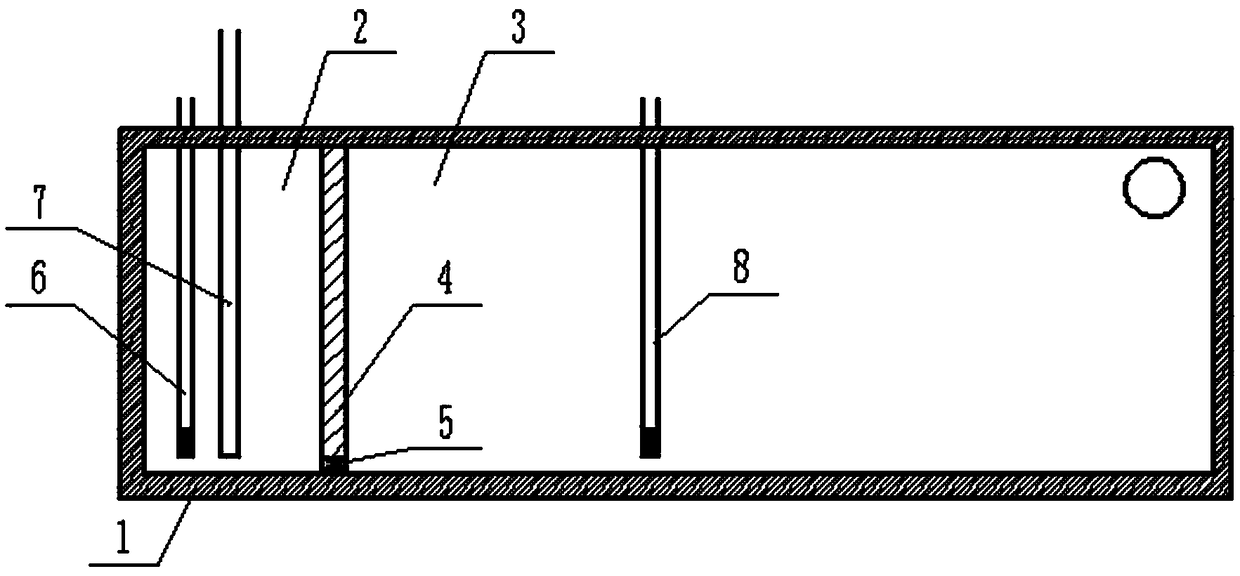

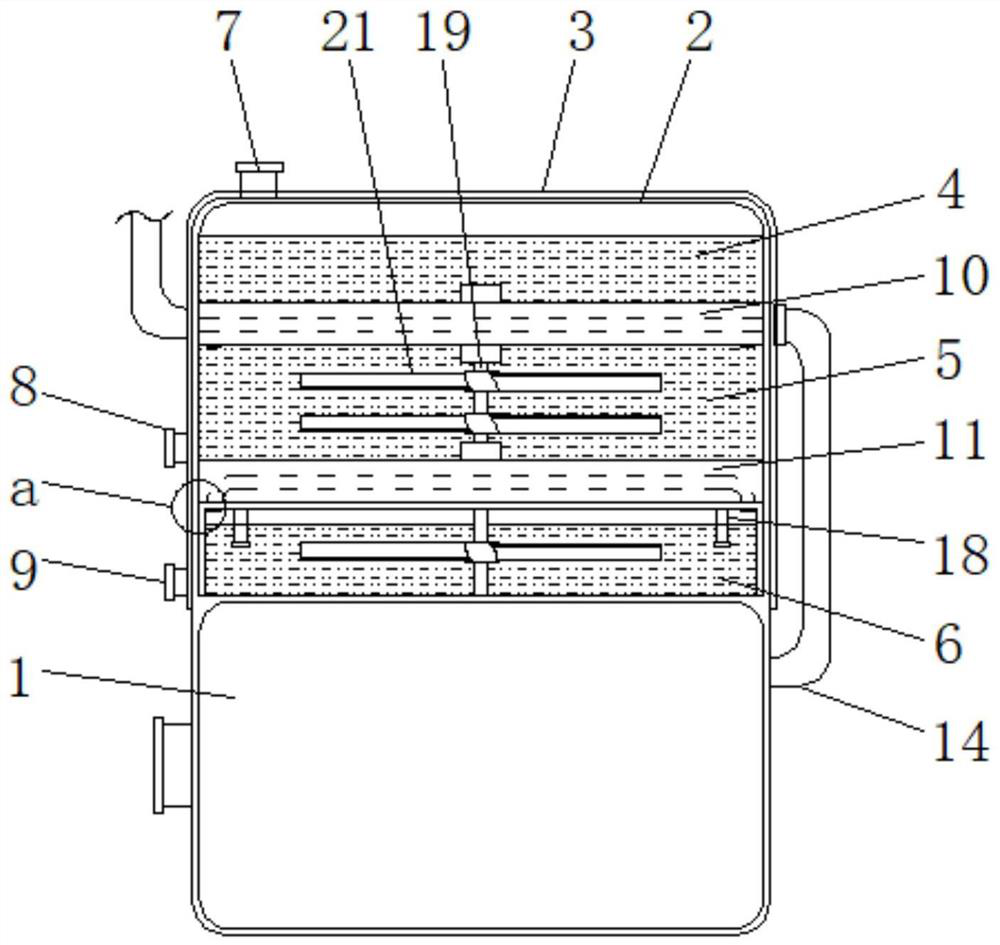

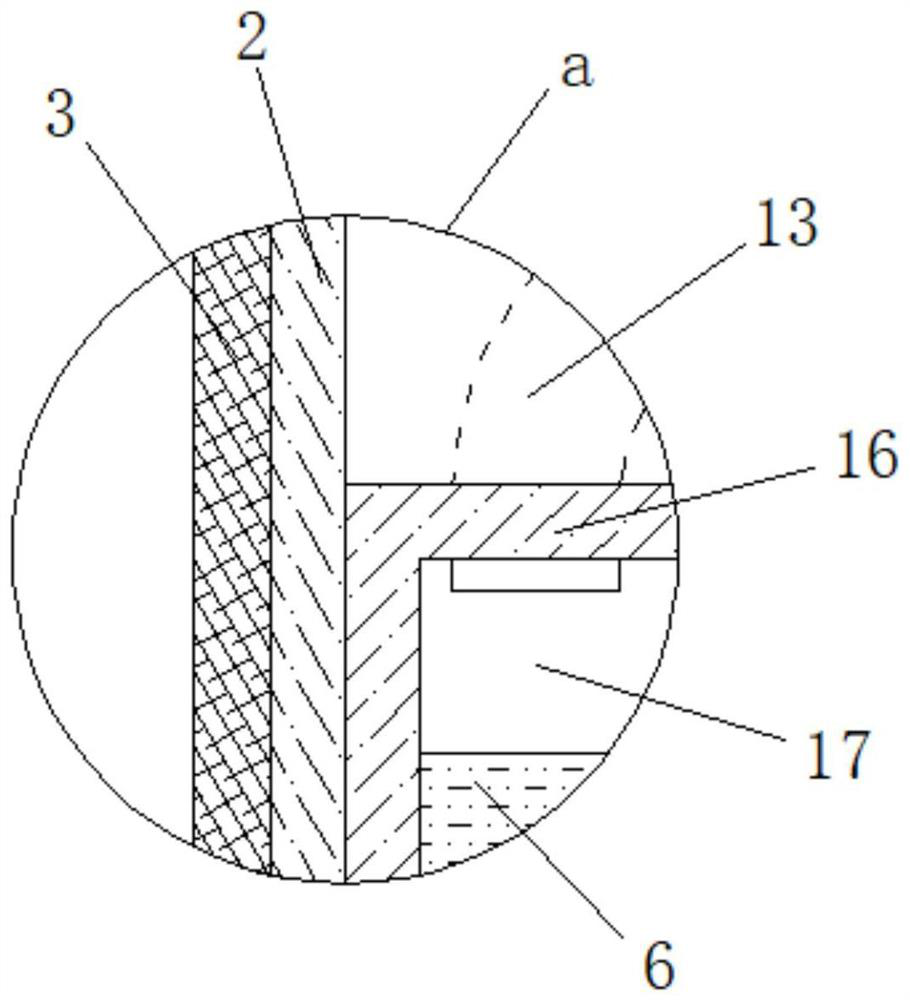

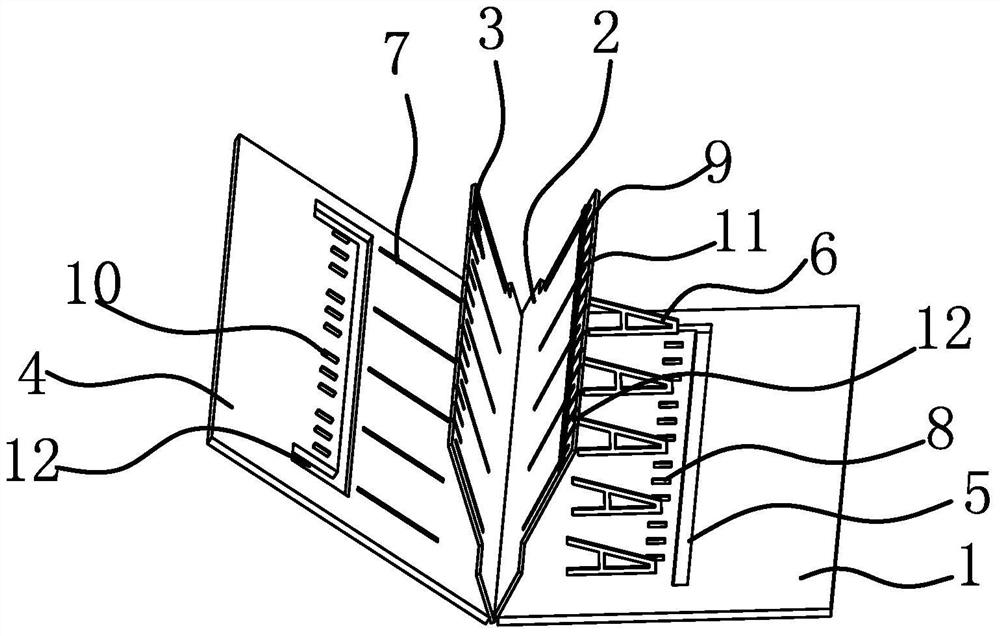

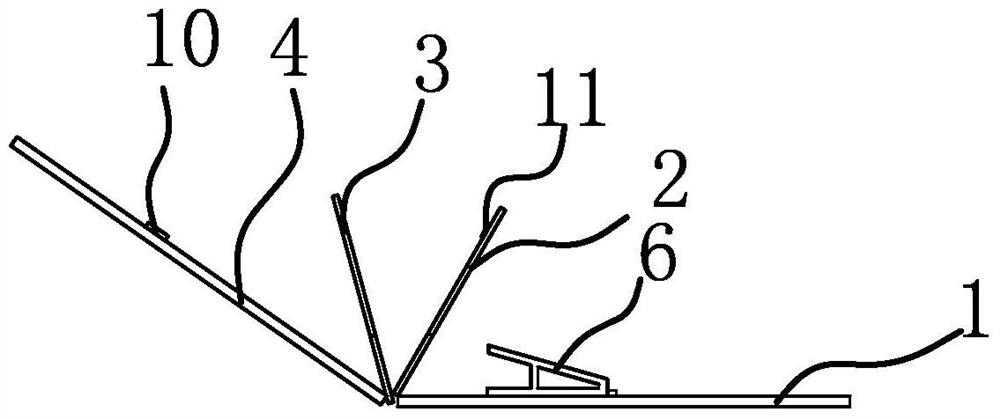

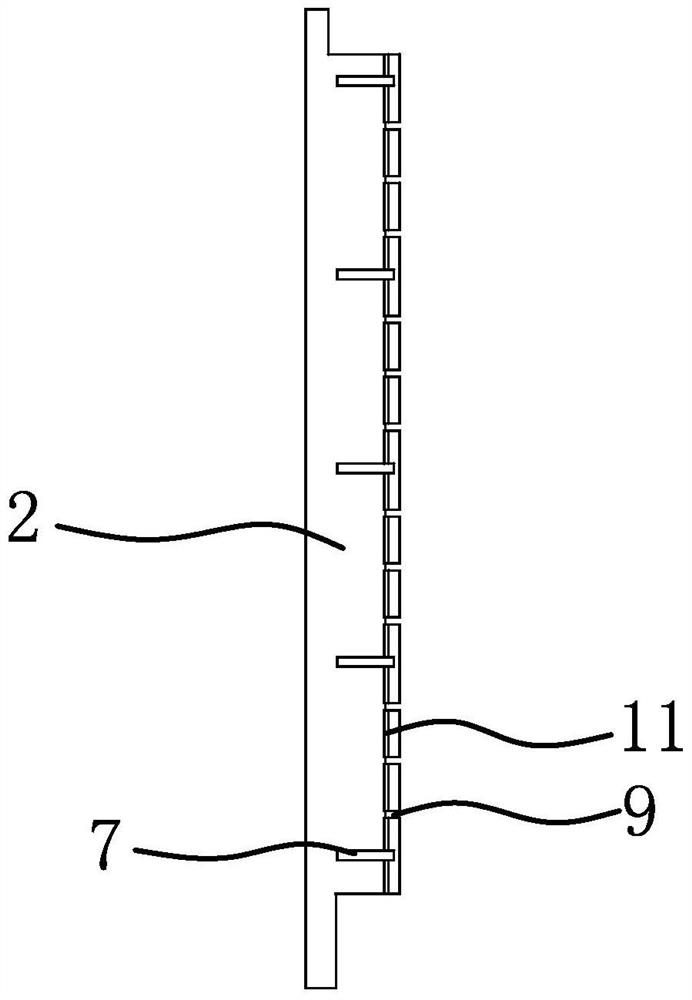

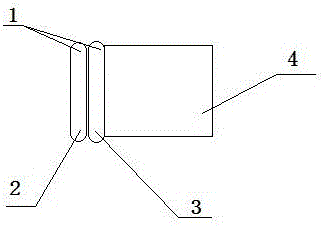

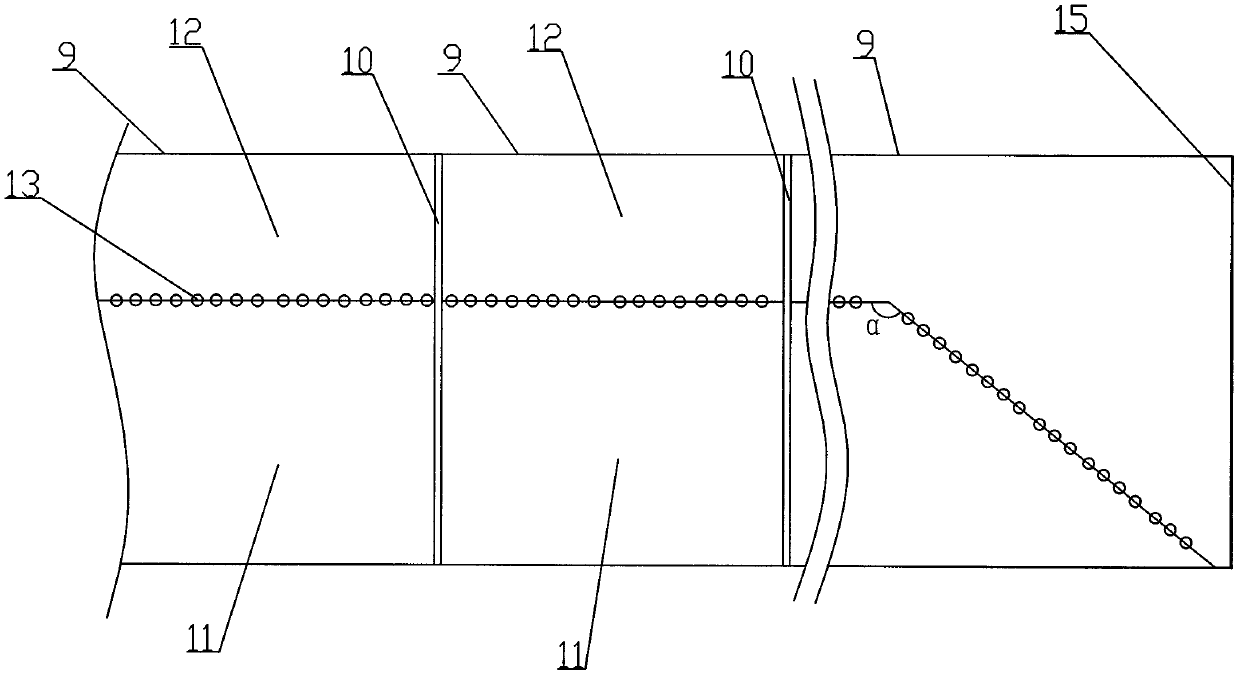

Clothes tail-splitting type zipper sewing template and sewing method thereof

The invention, which belongs to the technical field of the clothes production, relates to a clothes tail-splitting type zipper sewing template. With the template, problems of low clothes zipper sewing efficiency and poor quality in the prior art can be solved. The template comprises a base plate, a lining pressing plate, a zipper pressing plate, and a panel, wherein the units are arranged in sequence. The base plate and the panel are superposed and sewing slots with shapes consistent with a sewing shape of a zipper are formed in the same positions. A plurality of clamping elements are arranged on the base plate. Clamping element avoiding holes where the clamping elements pass are formed in the panel, the lining pressing plate, and the zipper pressing plate. A plurality of lining adjusting bosses are arranged on the base plate; adjusting holes corresponding to the adjusting bosses are formed in the lining pressing plate; a plurality of fabric adjusting bosses are arranged on the panel; and adjusting holes corresponding to the fabric adjusting holes are formed in the zipper pressing plate. According to the template, staggering is formed during compression of the lining part and the fabric part, thereby guaranteeing the enough margin during sewing of the lining / fabric part; and thus a good flat effect after zipper sewing can be realized and the zipper sewing quality is effectively improved.

Owner:JIAXING UNIV

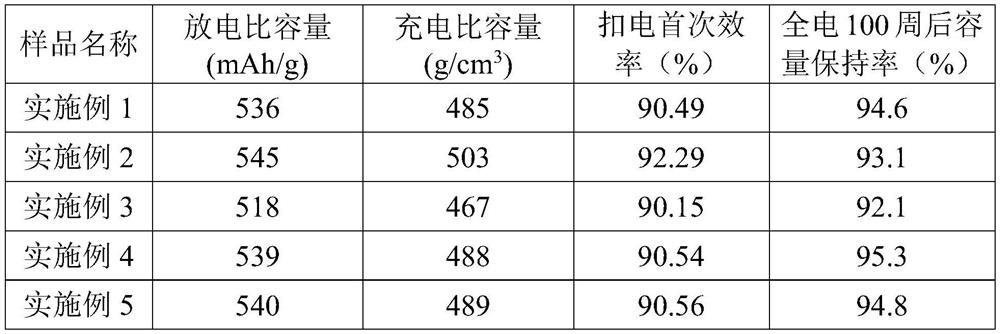

Hard carbon negative electrode composite material and preparation method and application thereof

InactiveCN113184827AMake up for consumptionReduce generationNegative electrodesCarbon preparation/purificationCarbon coatingElectrolytic agent

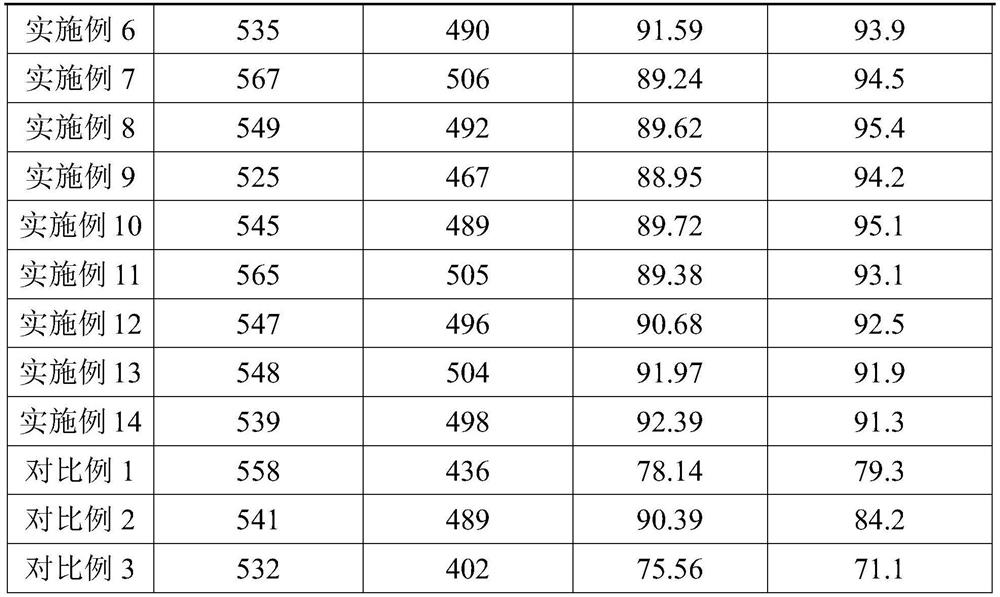

The invention relates to a hard carbon negative electrode composite material and a preparation method and application thereof, and the preparation method comprises the following steps: pretreating a carbon-containing raw material to prepare a hard carbon precursor; mixing the hard carbon precursor with a lithium-containing compound and a binder to prepare a solid pre-lithiated hard carbon precursor; carrying out sintering treatment on the pre-lithiated hard carbon precursor to prepare pre-lithiated hard carbon; and carrying out carbon coating treatment on the pre-lithiated hard carbon to form a carbon coating layer on the surface of the pre-lithiated hard carbon. Exogenous lithium is introduced into the surface and the bulk phase of hard carbon to form a lithium-carbon compound, so that a certain amount of lithium is filled in a stable structure and pores of the hard carbon in advance, and the consumption of effective lithium in the battery caused by first formation is made up. A carbon coating layer is matched to reduce the defects of the hard carbon surface and cover the lithium-carbon compound with relatively high chemical activity, so that the lithium supplement effect can be achieved, the side reaction of an active substance and an electrolyte can be reduced, the first coulombic efficiency can be synergistically improved, and the cycle life of the battery can be prolonged.

Owner:KUNSHAN BAOTRON NEW ENERGY TECH CO LTD

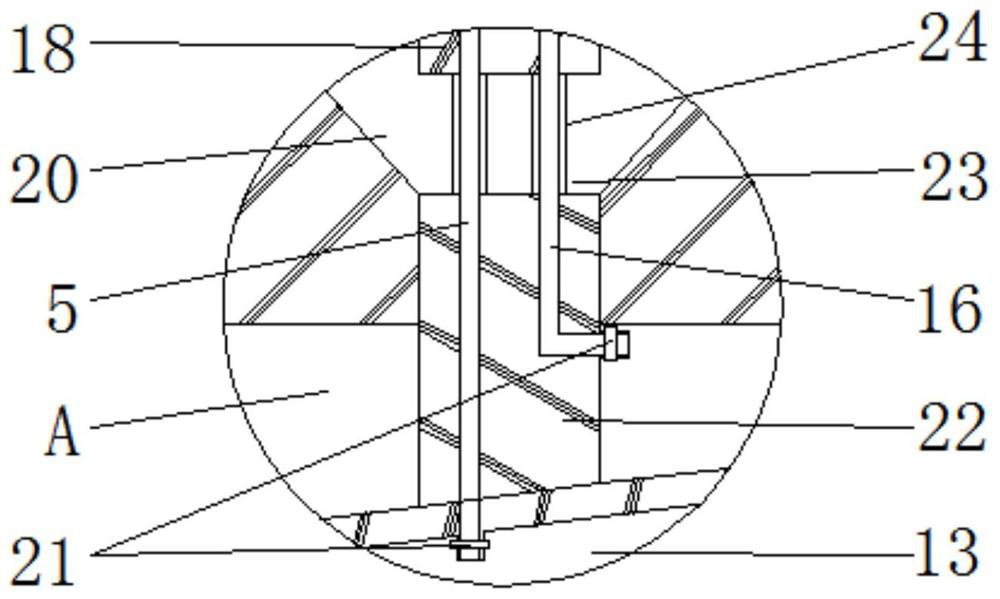

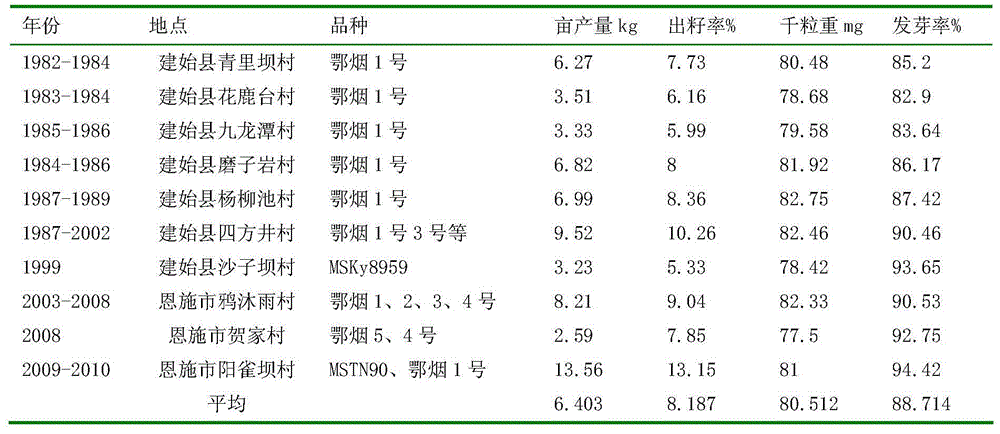

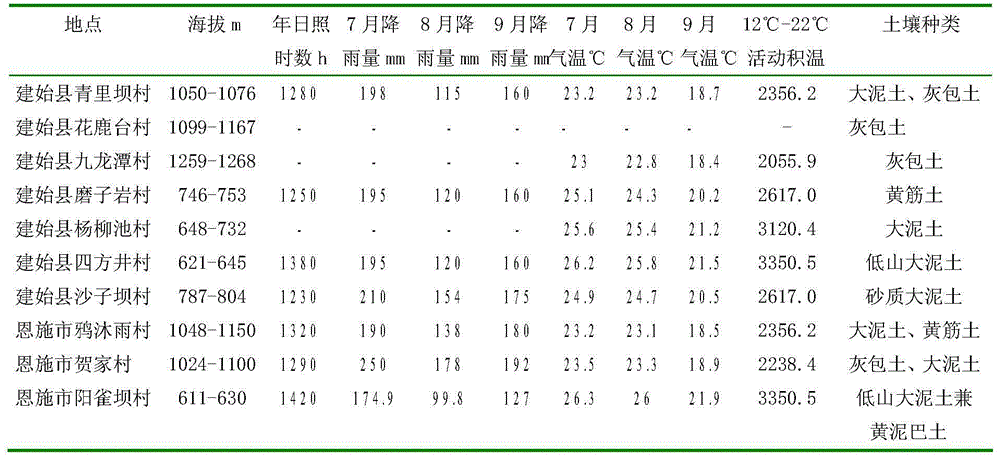

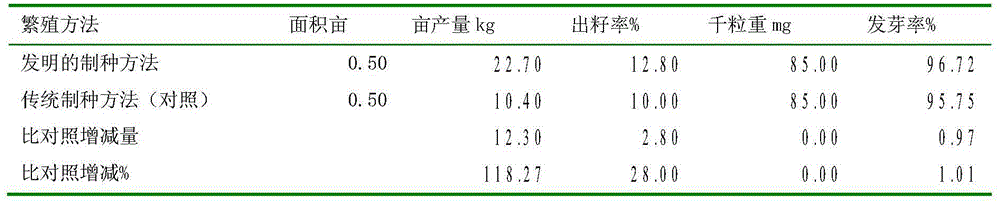

Economical and efficient production method of tobacco male sterile first generation hybrid seed

InactiveCN103348909AAvoid catastrophic lossReduce line spacingPlant genotype modificationHybrid seedNicotiana tabacum

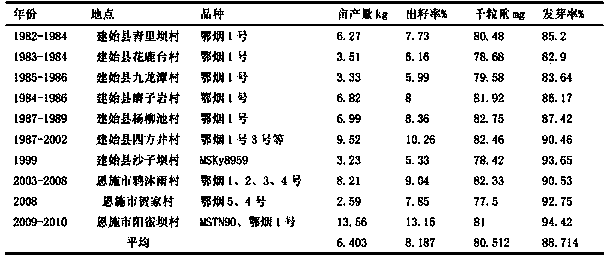

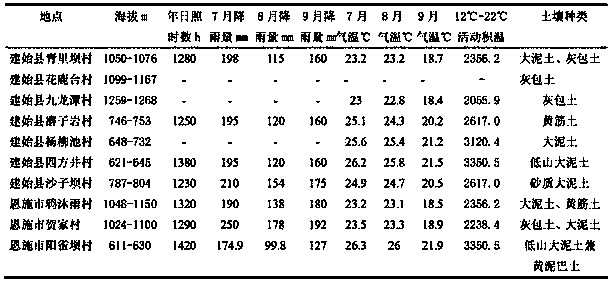

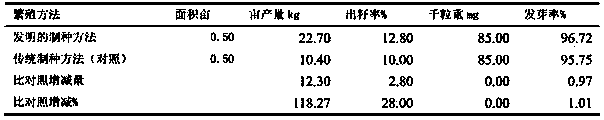

The invention provides an economical and efficient production method of a tobacco male sterile first generation hybrid seed. The method includes: at an altitude of less than 700 meters, under the climate conditions meeting the requirements of early vegetative growth and later reproductive growth of tobacco plants, conducting seedling culture on a maternal tobacco plant and a paternal tobacco plant separately, then employing isolation planting, performing topping on the maternal tobacco plant, then collecting paternal pollen and preparing pollination, during pollination, adding starch and blending them, adopting an artificial pollination pen or pollination gun to perform pollination, carrying out deblossoming on the maternal tobacco plant both before and after pollination, and when the capsule pericarp browning reaches more than 80%, conducting single fruit harvesting in batches and performing drying, then conducting threshing processing to obtain the male sterile first generation hybrid seed. The method provided in the invention has the advantages of reasonable design, low production investment, and high seed yield. On the basis of ensuring a variety purity (99%) and a seed germination rate (95%), maximization of a high-quality germplasm propagation coefficient is realized, the seed yield is greatly improved, and the seed production cost is decreased significantly.

Owner:TOBACCO RES INST OF HUBEI PROVINCE

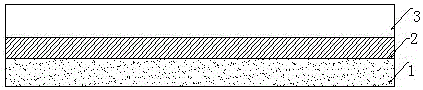

Processing method of marble composite board

InactiveCN105839882AImprove fitQuality improvementCovering/liningsLaminationComposite plateUltimate tensile strength

The invention relates to a processing method of a marble composite board, which includes substrate processing, material selection, lamination, drying, cooling, edge trimming, thickness setting and polishing, inspection and packaging and storage. Through the above steps, the processed substrate and Marble is compounded, and through the time and temperature environment required for drying glue, it is combined with the stone and ceramic tile composite board as a whole, and will not fall off due to residual air. After the stone and ceramic tile composite board is installed, the strength of the marble composite board can be guaranteed. The advantages of the present invention are: the processing method of the marble composite board of the present invention, the upper surface of the substrate is processed into exhaust grooves connected with the four sides of the substrate through the tooling, and then when the marble and the substrate are composited, the marble and the substrate are The air in the glue interlayer between them can not remain, so that the air bubbles can be quickly discharged and the large-area hollowing can be reduced. On the other hand, the exhaust groove on the substrate can also ensure the retention of glue, so as to obtain high-quality marble composite panels. Reduced defective rate.

Owner:江苏仁寿致尊建材发展有限公司

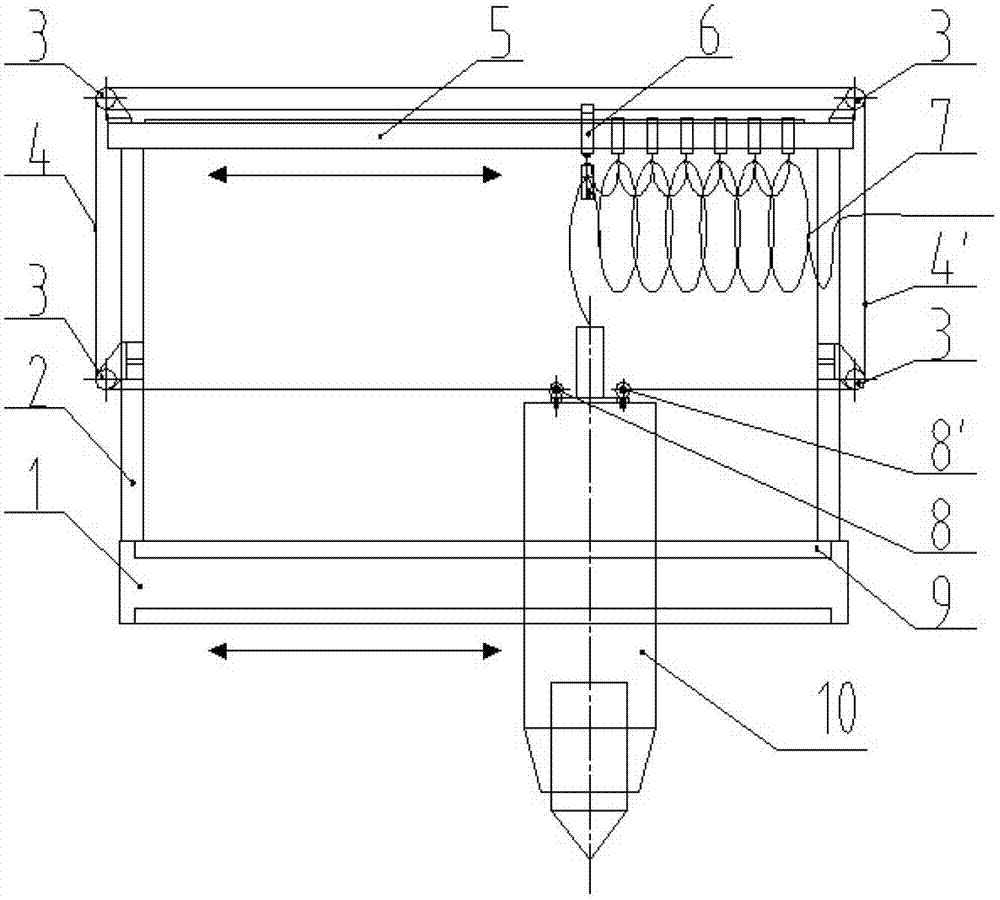

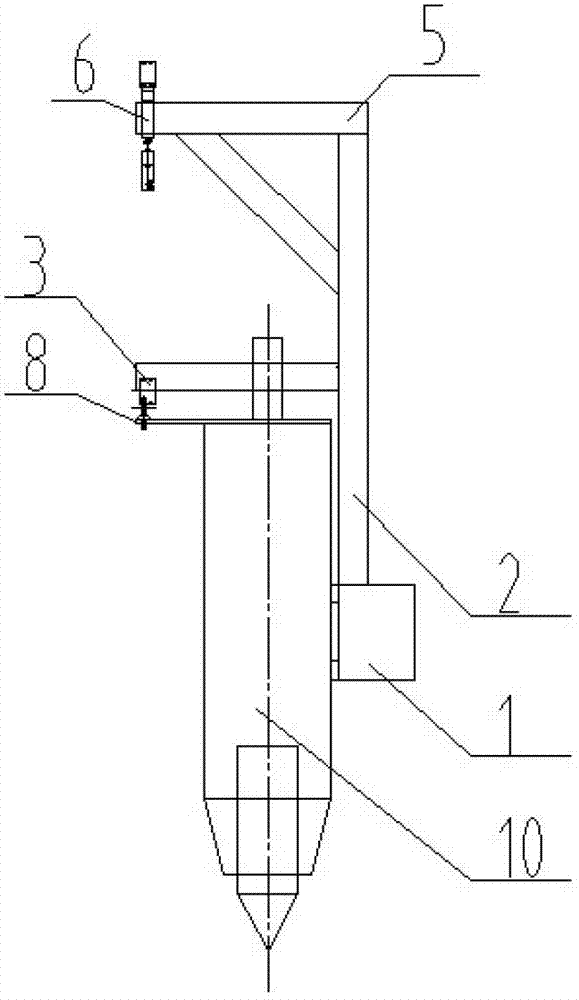

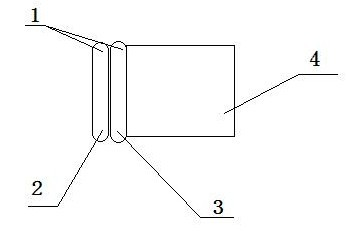

Optical fiber bearing bracket of laser processing equipment

ActiveCN102785026ARealize multi-axis motionGuaranteed reservesLaser beam welding apparatusLaser processingEngineering

The invention discloses an optical fiber bearing bracket of laser processing equipment, which adopts a framework structure, wherein the framework structure comprises a cross beam, an optical fiber bearing support, a left column and a right column; the cross beam and the optical fiber bearing support are parallel to each other; the left column and the right column span the cross beam and the optical fiber bearing support; the cross beam serves as a rail on which a laser head moves left and right; a hook component is arranged on the optical fiber bearing support, comprises a plurality of hooks which are distributed at intervals integrally, and can move left and right along the optical fiber bearing support; an optical fiber is led out of an optical fiber laser, and wound around the hooks in sequence in a ring-shaped manner; the tail end of the optical fiber is connected to the laser head; three pulleys are arranged on the optical fiber bearing support, the left column and the right column respectively; and two cables pass through the three pulleys clockwise and counterclockwise respectively, and are connected to the left and the right sides of the laser head and those of the hook component respectively, so that the laser head and the optical fiber move synchronously. According to the invention, the optical fiber can be fed stably and reliably during a laser processing process, and the fracture of the optical fiber can be avoided effectively.

Owner:HUAZHONG UNIV OF SCI & TECH

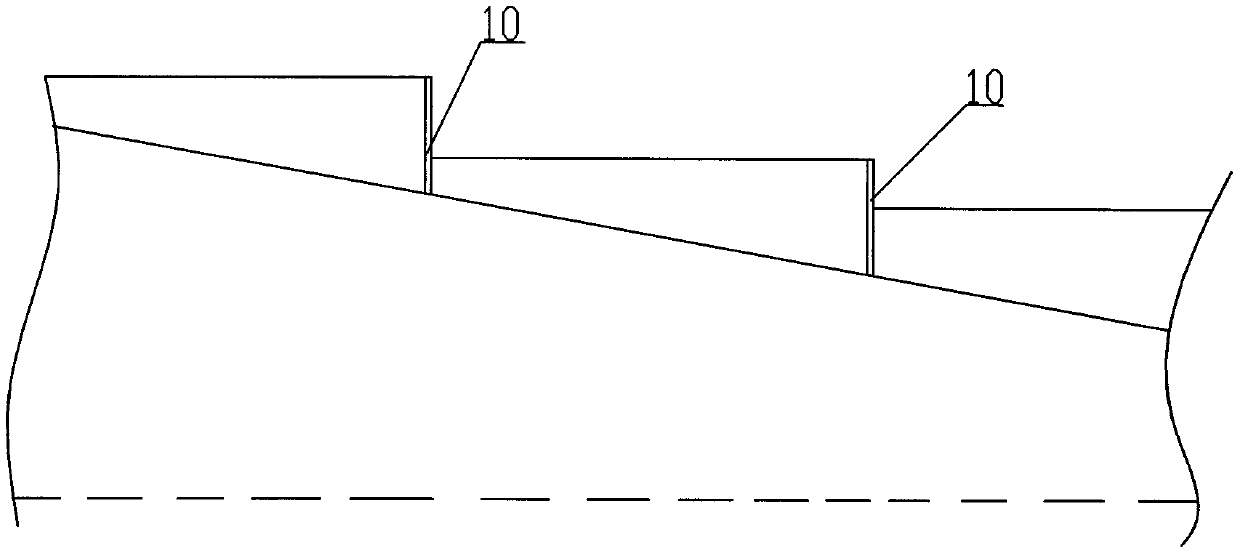

Fuel-tank of motor vehicle

PendingCN108891255AReduced risk of oil failureGuaranteed fuel supplyUnderstructuresFuel supplyShortest distanceFuel tank

A motor vehicle fuel tank It belongs to the field of fuel tank, comprises a tank body and an oil suction pipe, A partition plate is arranged inside the tank body to divide the tank body into a crude oil tank and an oil suction tank, The filling port is located in the crude oil tank, As that space length of the oil suction tank is small than the space length of the crude oil tank, the suction pipeextends into the suction tank to suck fuel, As that oil is supply by extending the oil suction pipe into the oil suction tank with small space length, The risk that the original suction pipe can not suck oil due to the excessively long original tank body can be reduced, and since the liquid level change of the suction tank with the smaller space length is far smaller than that of the original tankwith the larger space length when the whole tank is inclined, the fuel supply can be ensured when the suction pipe can face the gradient of the shorter distance.

Owner:高密市中科容器厂

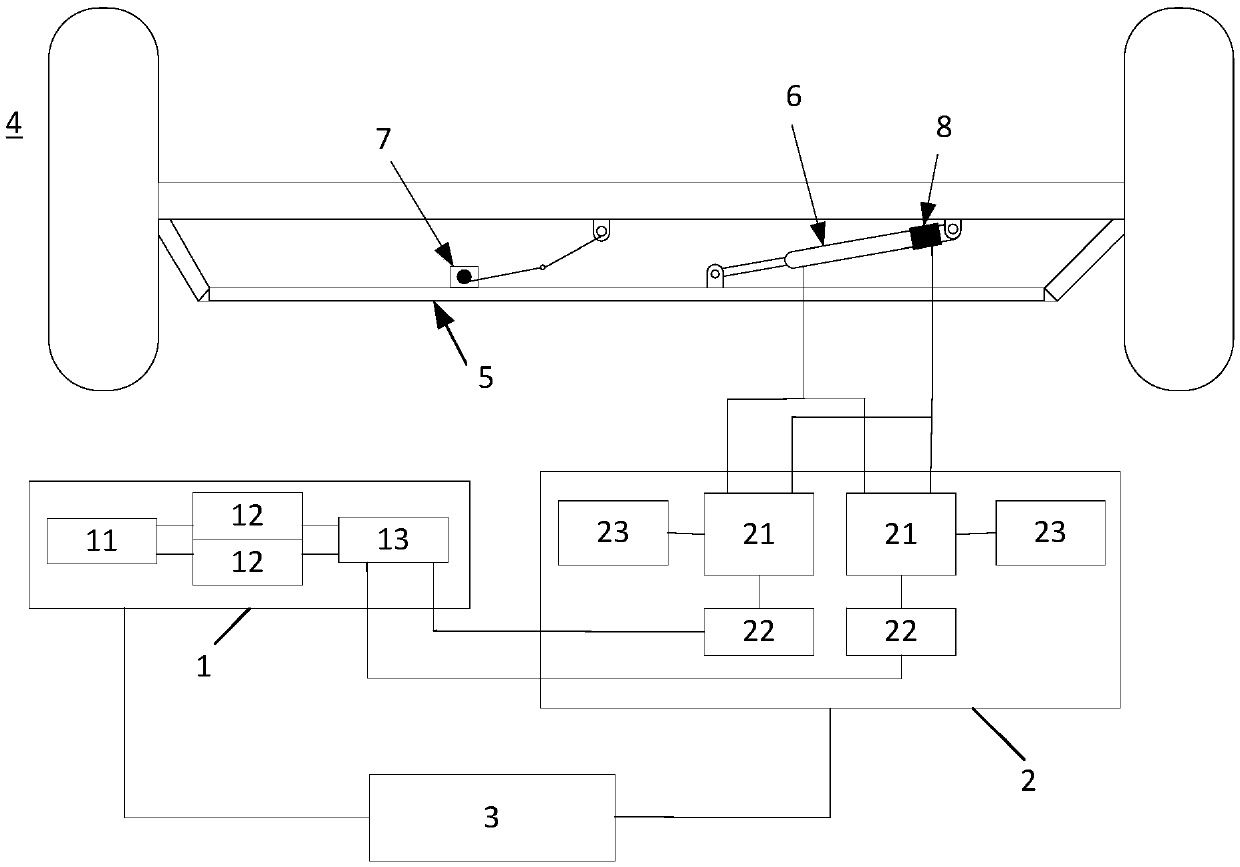

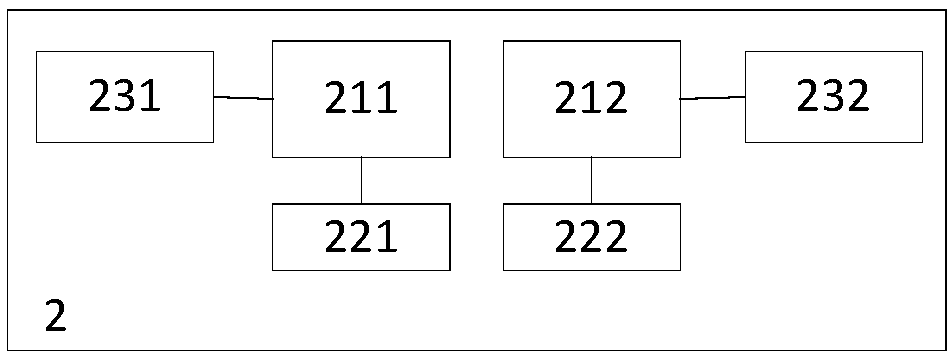

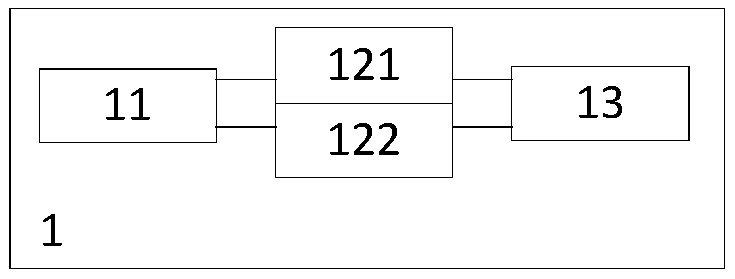

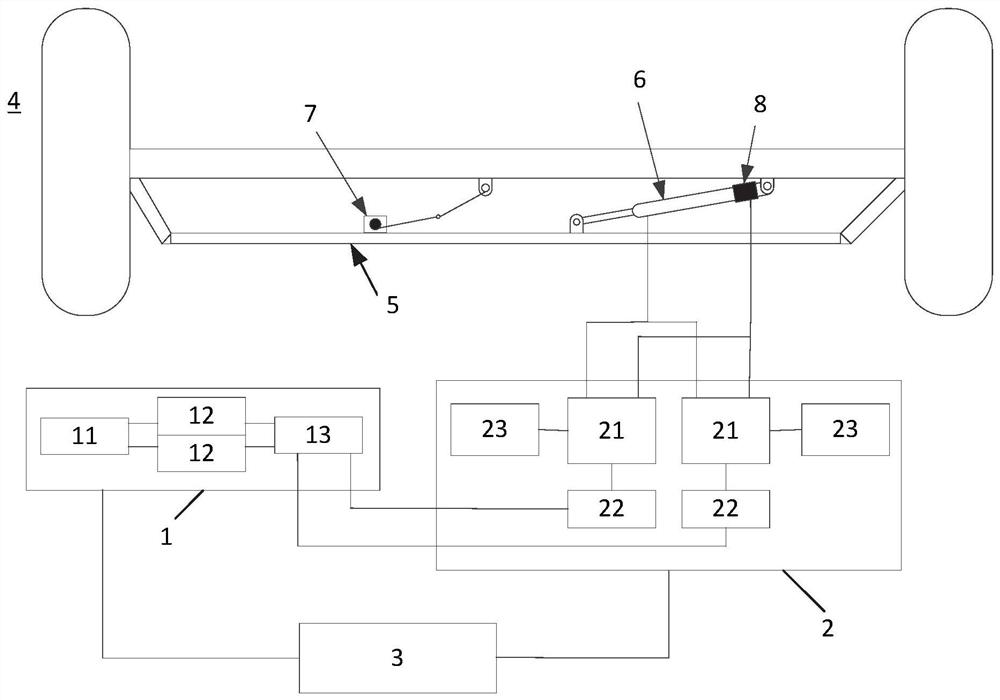

High-precision quick-response intelligent rail electric vehicle steering system

ActiveCN111098919APrecise control of oil supplyEasy to controlFluid steeringSteering for vehicles in tandemLoop controlElectric vehicle

The invention provides a high-precision quick-response hydraulic steering system capable of being applied to an intelligent rail electric vehicle and the intelligent rail electric vehicle provided with the hydraulic steering system. The hydraulic steering system has characteristics of quick response, high precision and high reliability, the intelligent rail electric vehicle can achieve accurate control over left-right rotation of an axle and high-precision closed-loop control over vehicle steering, and the safe driving requirement of trackless traffic can be met.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

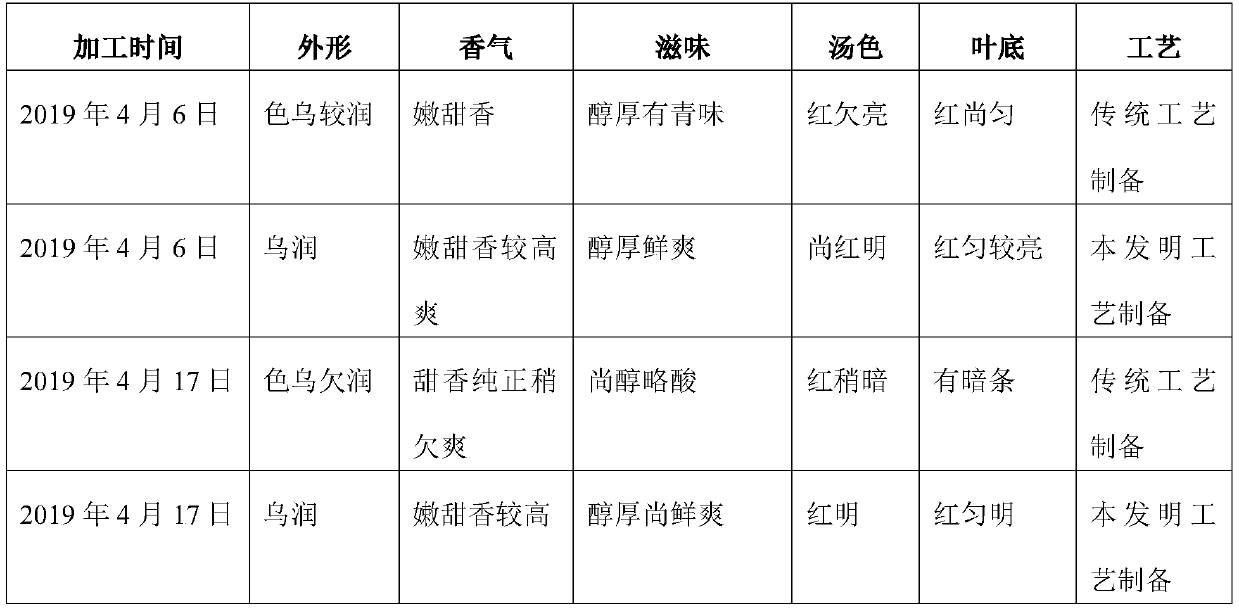

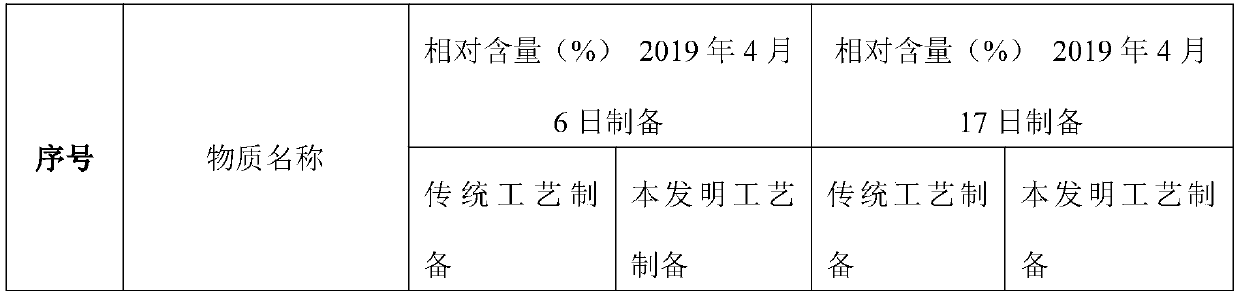

Preparation method of tender sweet-scented granular black tea

ActiveCN110800817AImprove tendernessIncrease twist forcePre-extraction tea treatmentBiotechnologyFermentation

The invention belongs to the technical field of tea processing, and particularly relates to a preparation method of tender sweet-scented granular black tea. The method comprises the following steps: performing fresh leaf treatment; performing withering, rolling, deblocking and fermentation; performing spreading to a withering room; performing primary baking; performing shaping; and performing drying and re-baking. According to the method, the granular black tea with excellent taste and flavor can be produced while the tea preparation efficiency is ensured. The black tea prepared by the methodhas tight and firm shape particles, dark and moist color, and sweet and mellow taste, and the aroma is mainly tender-sweet scent and with floral and fruity scent. The method has the characteristics that the source of raw materials is easy to obtain, and can significantly improve the utilization rate and added value of local tea resources in the current season.

Owner:TEA RES INST ANHUI ACAD OF AGRI SCI +1

Novel marble composite plate and processing method thereof

InactiveCN108019012AImprove the decorative effectGuaranteed StrengthCovering/liningsComposite plateComposite material

The invention relates to a novel marble composite plate. The novel marble composite plate comprises a marble sheet, an insulation board, marble and a base material which are sequentially composited from top to bottom. The marble sheet is composited with the insulation board through glue, the insulation board is composited with the marble through glue, and the marble is composited with the base material through glue. The marble sheet and the marble are different in color, and the glue and the marble are the same in color. The novel marble composite plate is formed by processing through the following steps of processing of the base material, material selecting, attaching, drying, cooling, edge cutting, thickness fixing and polishing, selecting and processing of the sheet, inlaying of the sheet, drying, cooling, grinding, inspection and packing into storage. The novel marble composite plate has the advantages that the novel marble composite plate processed through the processing method can be polished again after being used for a period of time by a user, the marble sheet is ground off to show another color, under the condition that the mounted marble composite plate does not need tobe replaced, the user can replace the laid marble composite plate with different colors and different patterns, and thus the decorative effect is extremely good.

Owner:江苏昶浩建材有限公司

Steel plate bin discharging device

The invention discloses a steel plate bin discharging device, and belongs to the field of steel plate bins. The steel plate bin discharging device comprises a bin shell. The interior of the bin shellis divided by a partition plate into an upper chamber and a lower chamber. Multiple discharge areas in conic funnel shapes are formed on the partition plate, a discharge opening is arranged at the bottom of each discharge area, a blocking rod is arranged in each discharge opening, and the lower ends of the blocking rods are connected with a first piston plate located in the lower chamber together.A discharging opening capable of being connected with the low side of the first piston plate is formed on the lower portion of the peripheral side of the bin shell. The upper ends of the blocking rods are connected with lifting rods, and the upper ends of the lifting rods are higher than the upper end faces of materials. Air supply cavities are formed on the inner sides of the lifting rods, air spray nozzles communicating with the corresponding air supply cavity are spirally distributed on each lifting rod in the height direction of the corresponding lifting rod at equal distance, and air supply pipes communicating with the air supply cavities and an air source are arranged in the lower portions of the lifting rods. According to the steel plate bin discharging device, discharging uniformity is good, and materials can be efficiently prevented from being caked.

Owner:鱼台县旺星粮油机械制造有限公司

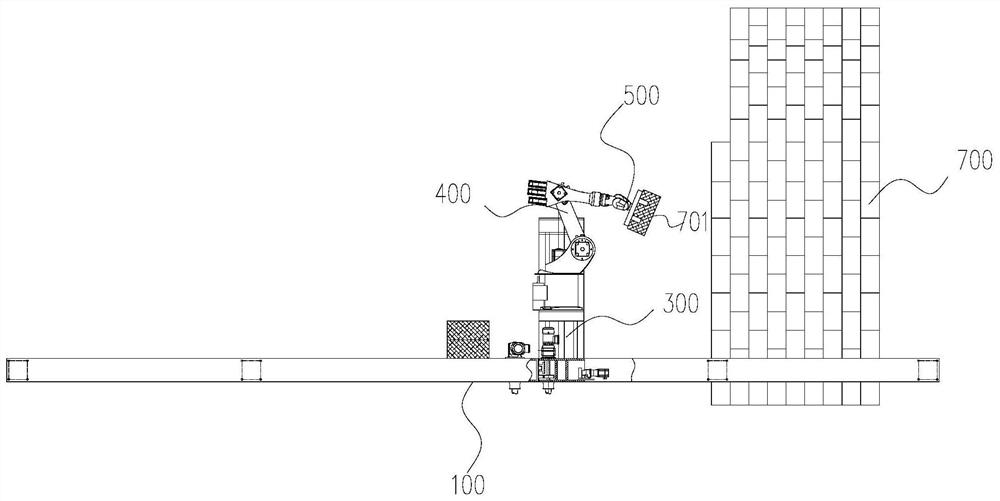

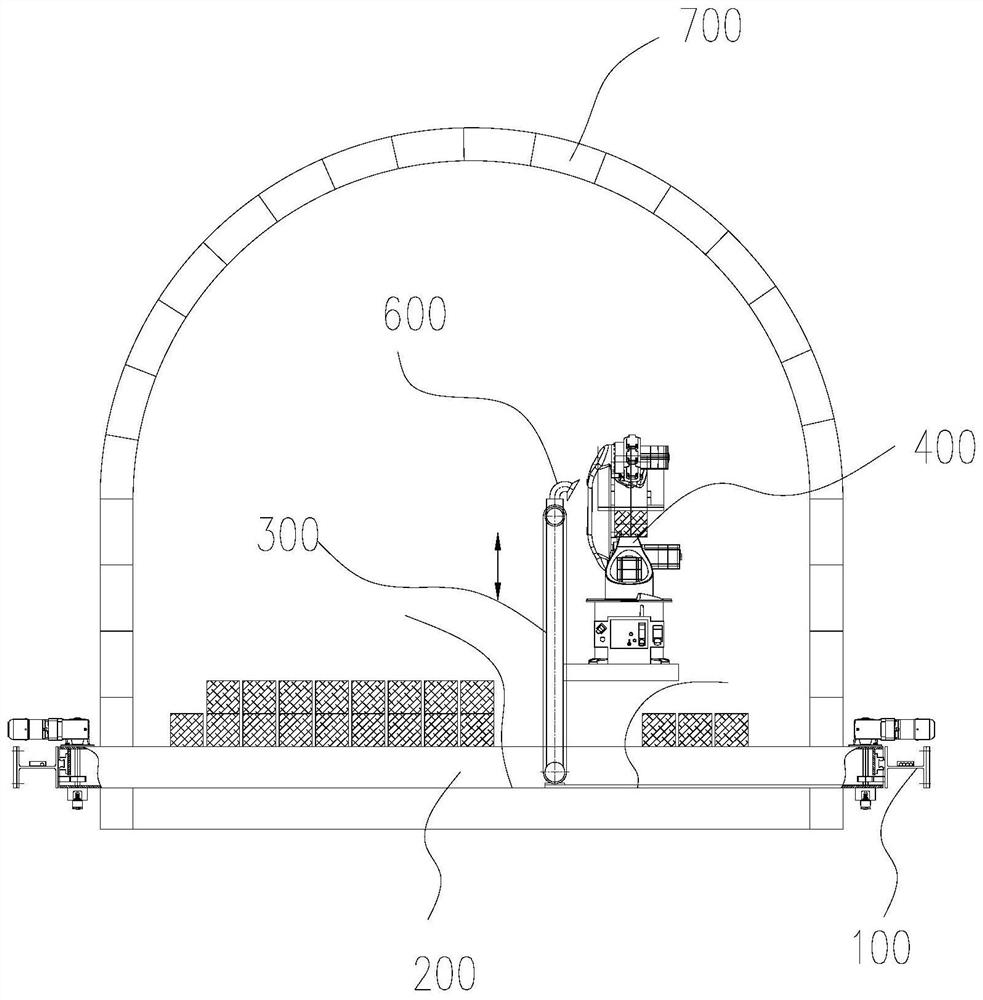

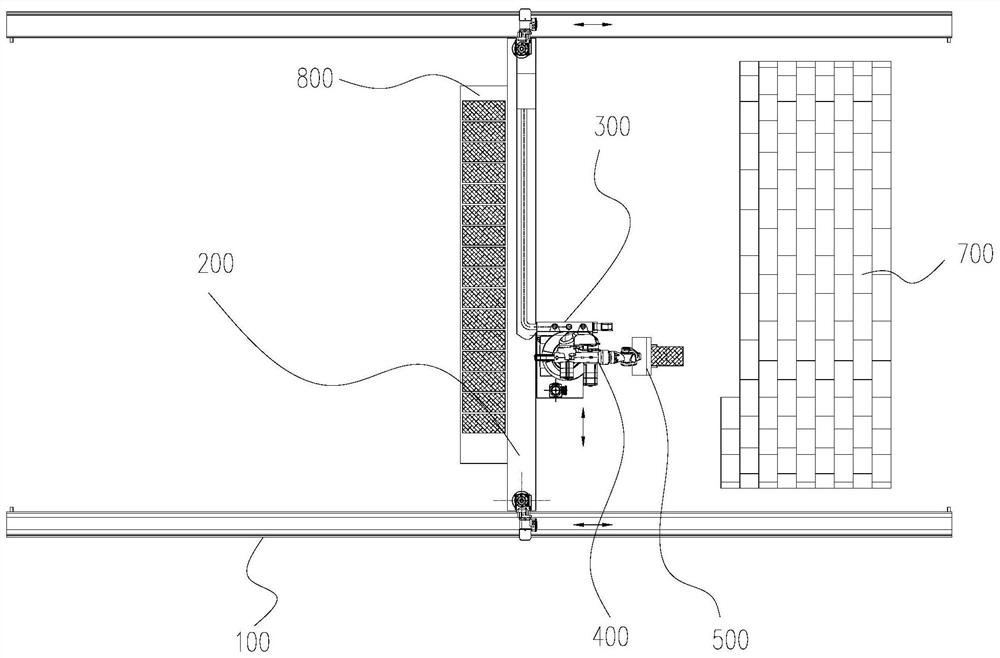

Glass melting furnace masonry robot and method

InactiveCN112727125APracticalHigh degree of automationBuilding material handlingGlass meltingSlurry pump

The invention discloses a glass melting furnace masonry robot. The glass melting furnace masonry robot comprises a first base, a second base, a lifting mechanism, a mechanical arm with six degrees of freedom, a grabbing mechanism, a slurry pumping assembly and a controller connected to all above parts; the first base is horizontally arranged on the two sides of a melting furnace, and the second base can be connected to the first base in a sliding mode; the lifting mechanism can be slidably connected to the second base, the mechanical arm can be connected to the lifting mechanism in the vertical direction in a lifting mode, and the grabbing mechanism can be rotatably connected to the tail end of the mechanical arm; a pipeline of the slurry pumping assembly is laid along the second base and the lifting mechanism; and a plastering opening of the slurry pumping assembly is located in the side face of the mechanical arm. The invention further discloses a method adopting the glass melting furnace masonry robot. The glass melting furnace masonry robot has the beneficial effects that the practicability is high, plastering and masonry can be achieved, and the automation degree is high; and traditional work by worker can be replaced for operation, so that the problem that industry workers are fewer and fewer is solved.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

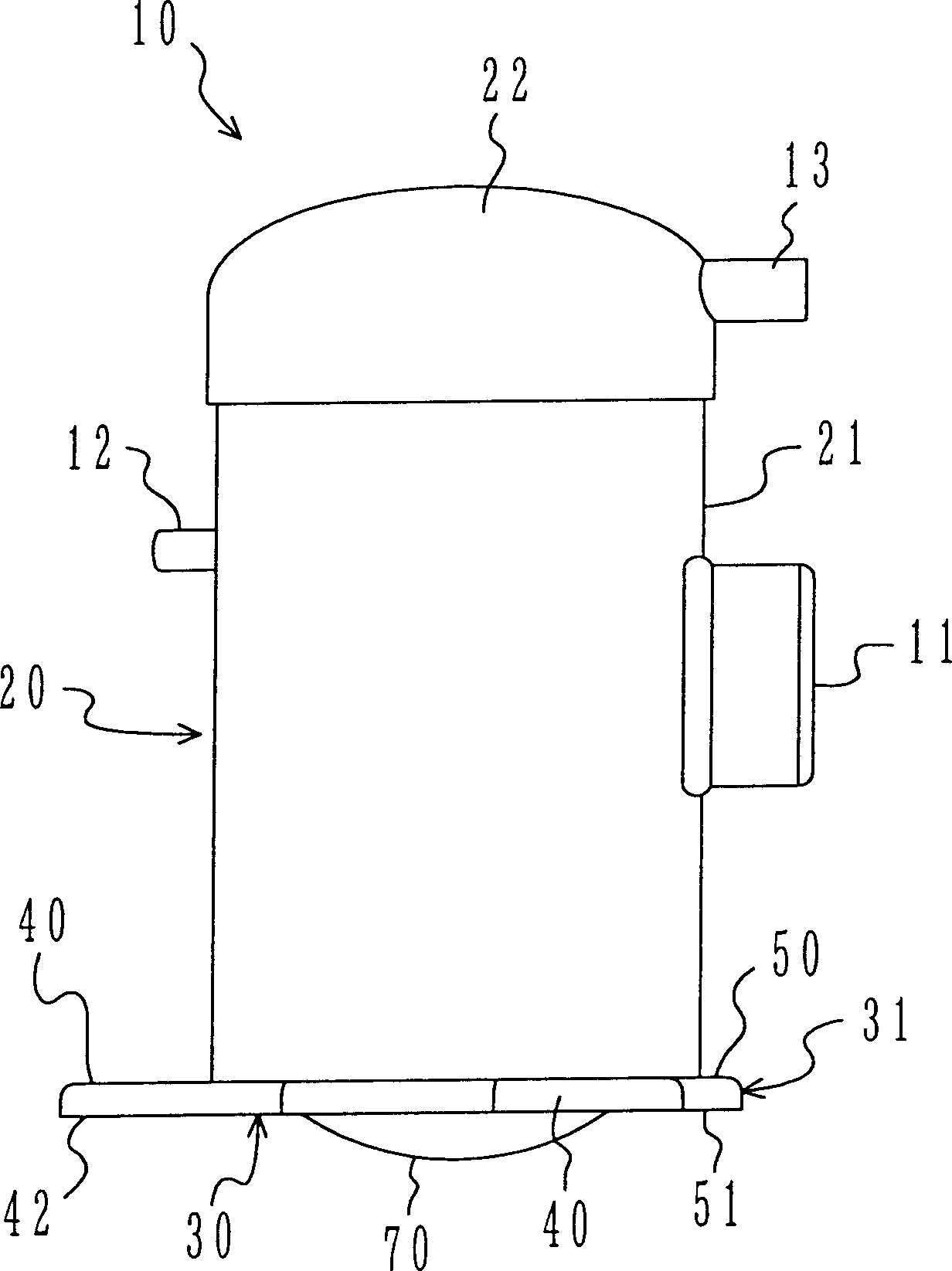

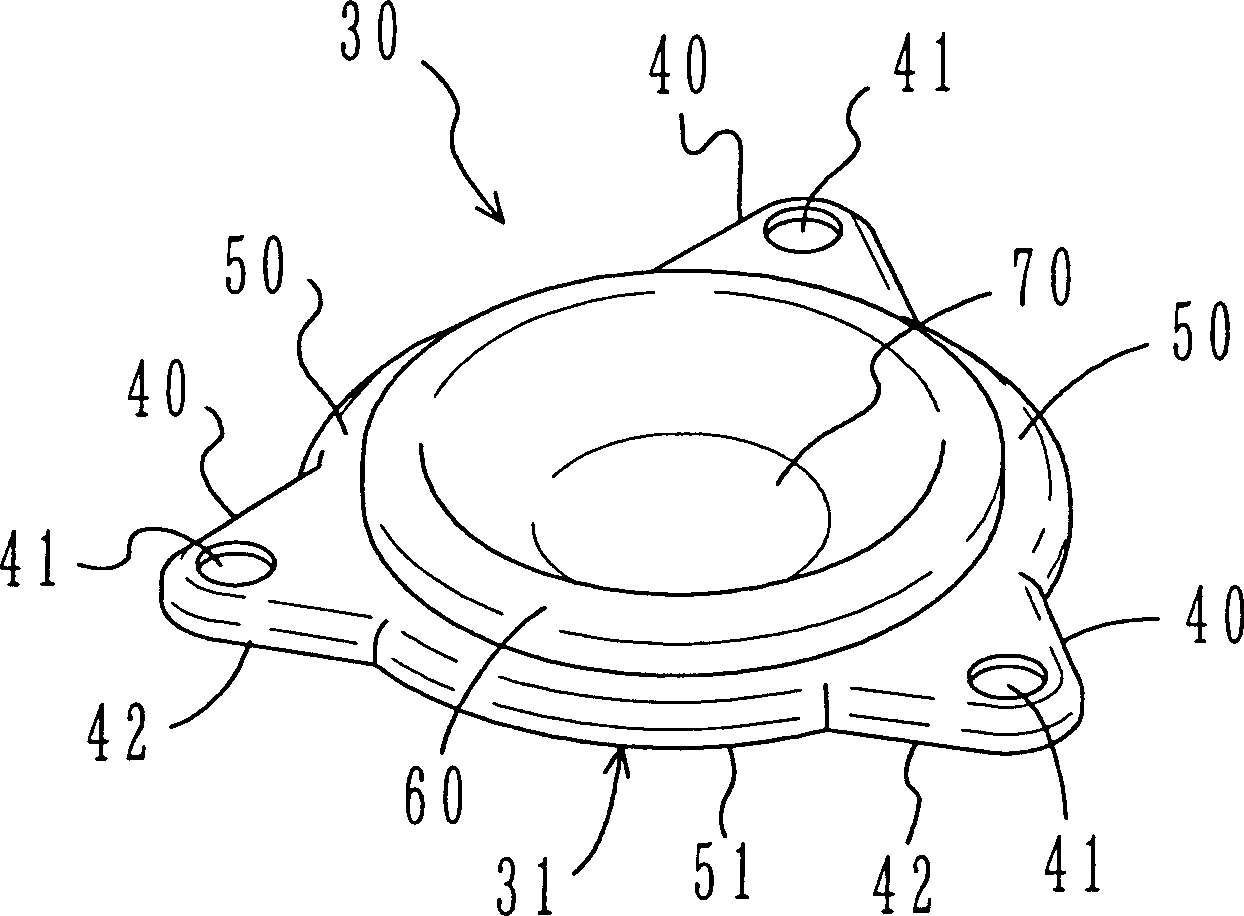

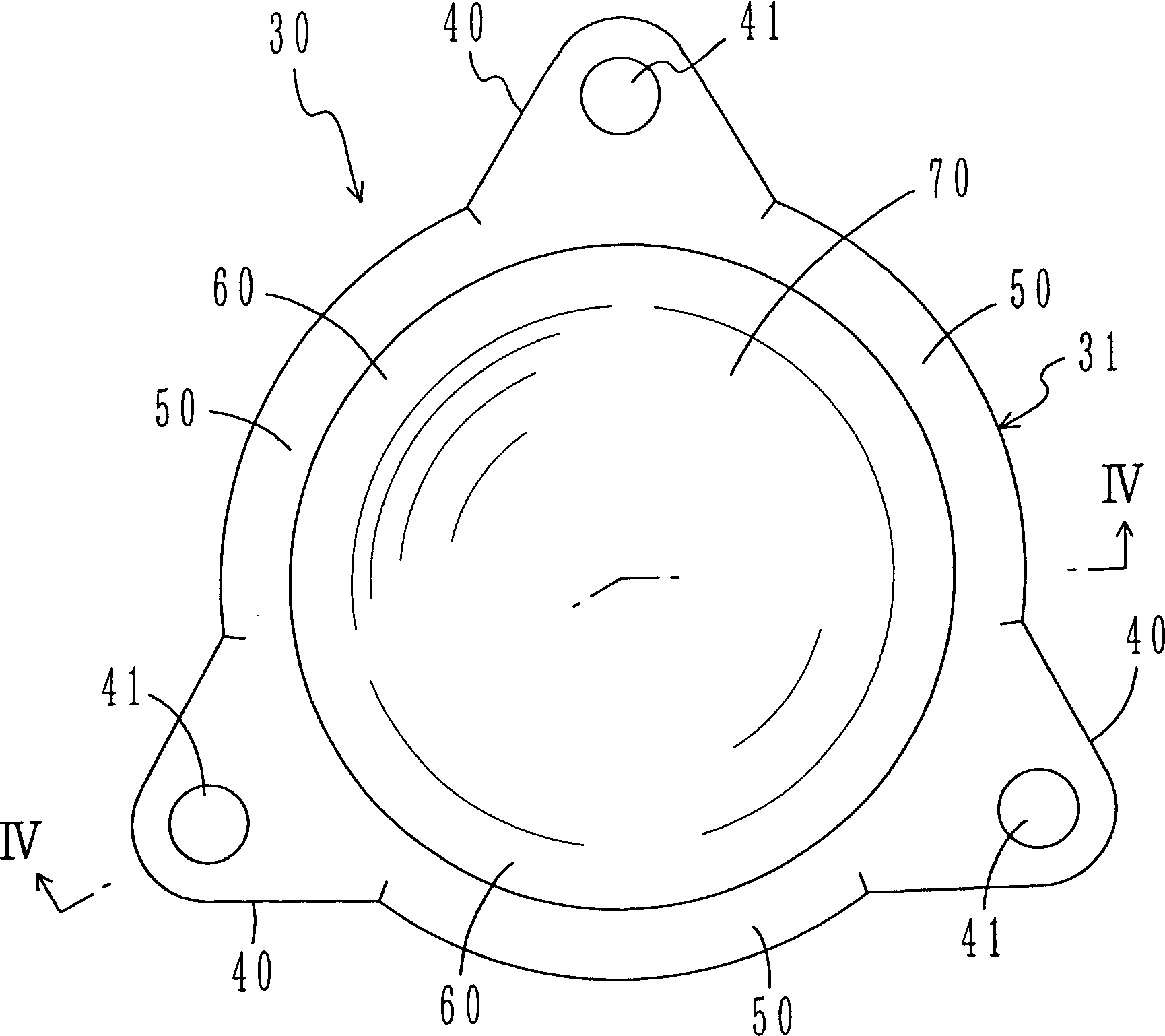

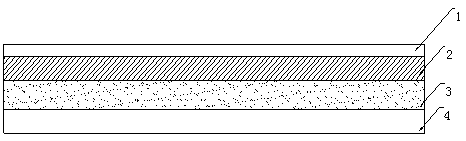

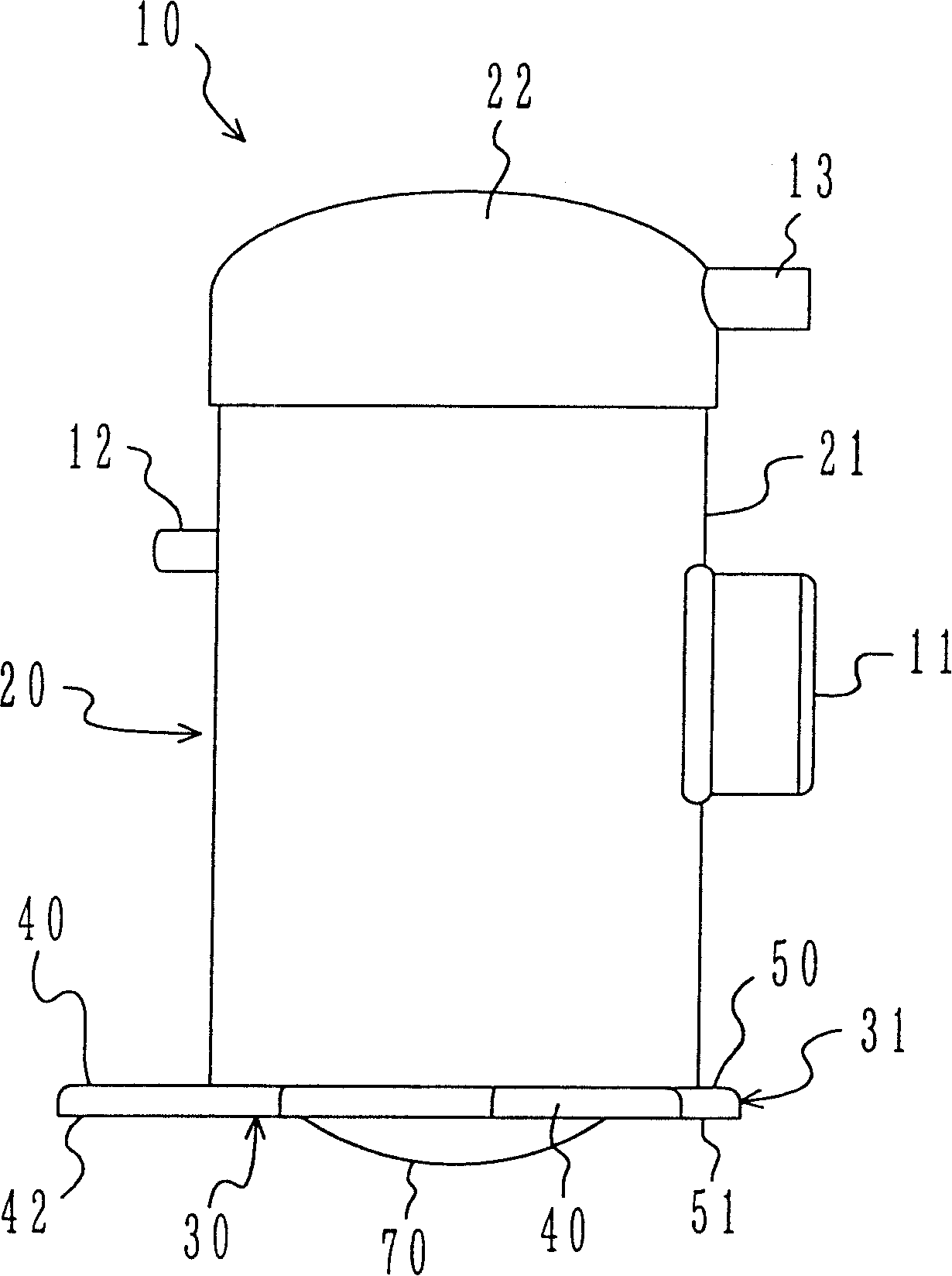

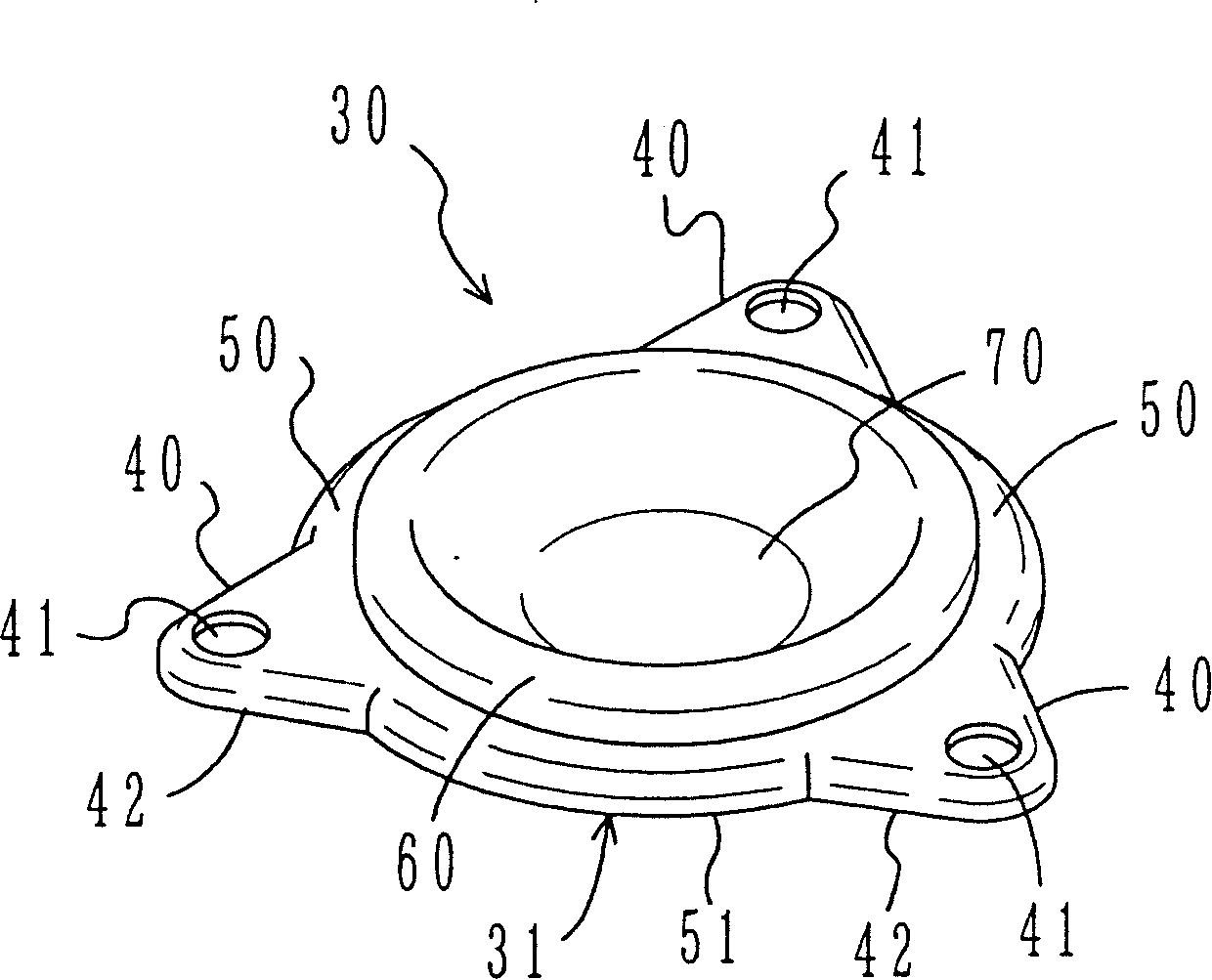

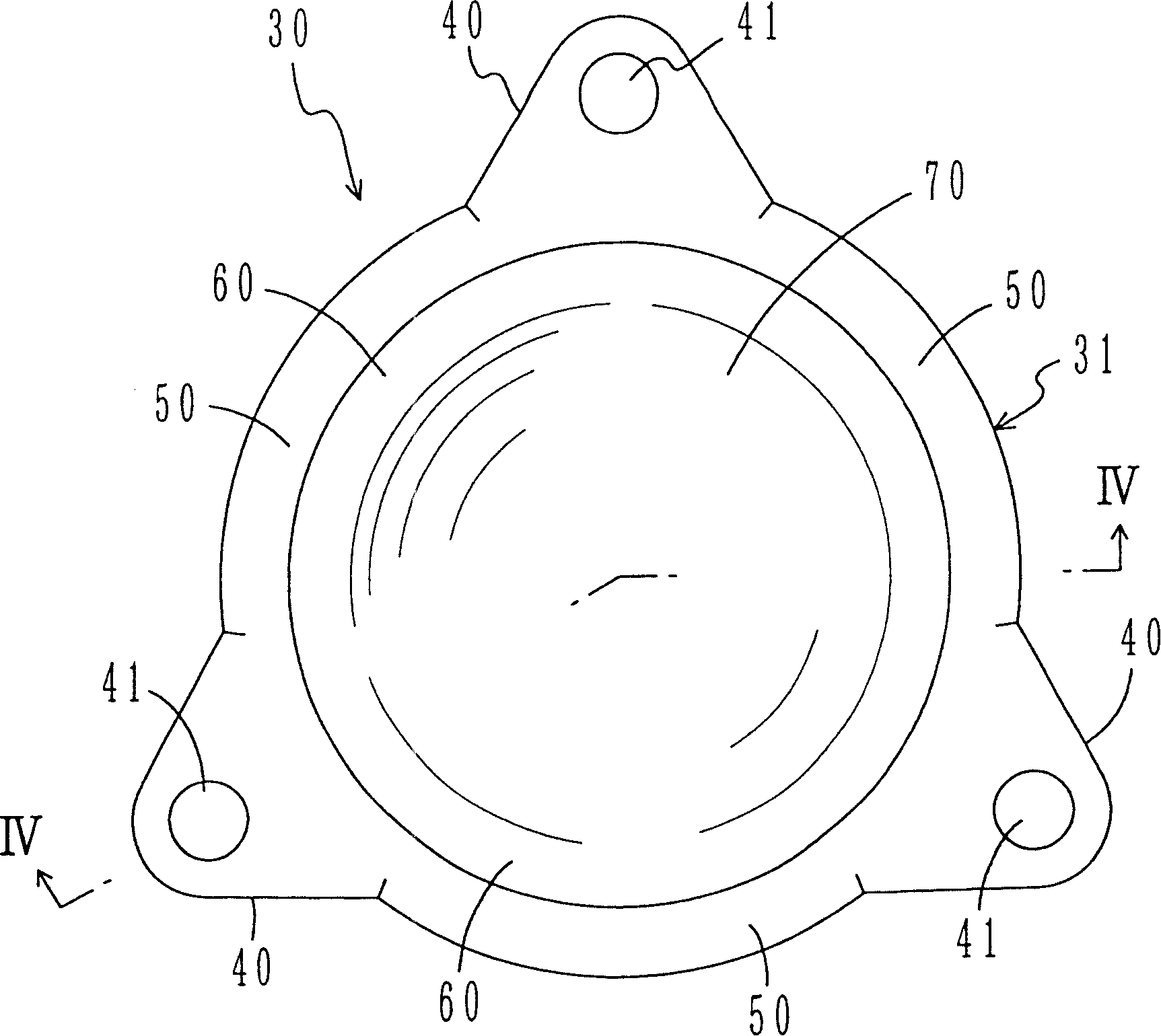

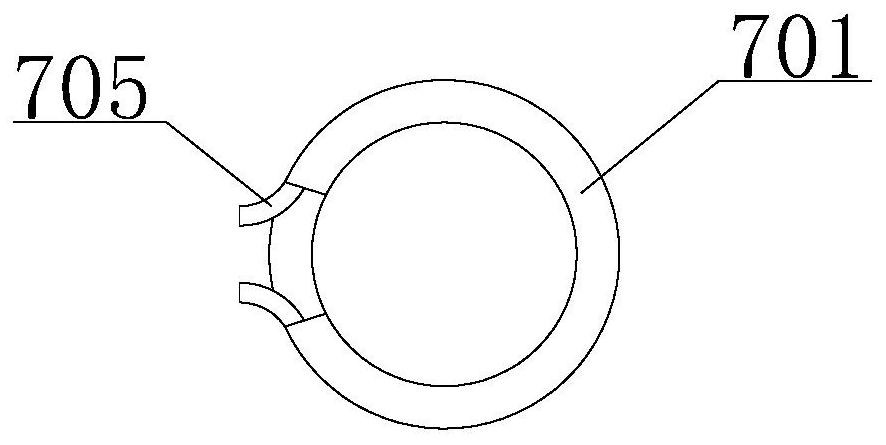

Compressor

InactiveCN1512070AStress reliefBending moment controlRotary/oscillating piston pump componentsLiquid fuel engine componentsStructural engineeringEngineering

The compressor barrel bottom includes one flat outer edge part welded and fixed to the lower part of the barrel bottom, and one annular raised continuous cup-like turned-U part inside the outer edge part. The annular raised cup-like part includes one outer vertical wall, one inner vertical wall and one transitional top wall between the top of the outer vertical wall and the top of the inner vertical wall. The inner vertical wall has arced cross section inclined towards the center of the compressor from top to bottom. The annular raised part has formed concave semi-spherical bottom part in the inner side, and the barrel bottom has installing feet formed integrally with the outer edge part.

Owner:DAIKIN IND LTD

Novel marble composite board

InactiveCN107605113AImprove the decorative effectQuality improvementCovering/liningsLayered productsWood veneerEngineering

Owner:江苏昶浩建材有限公司

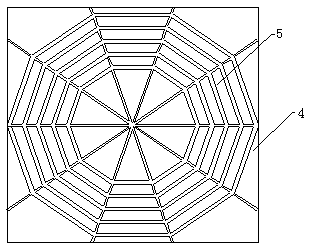

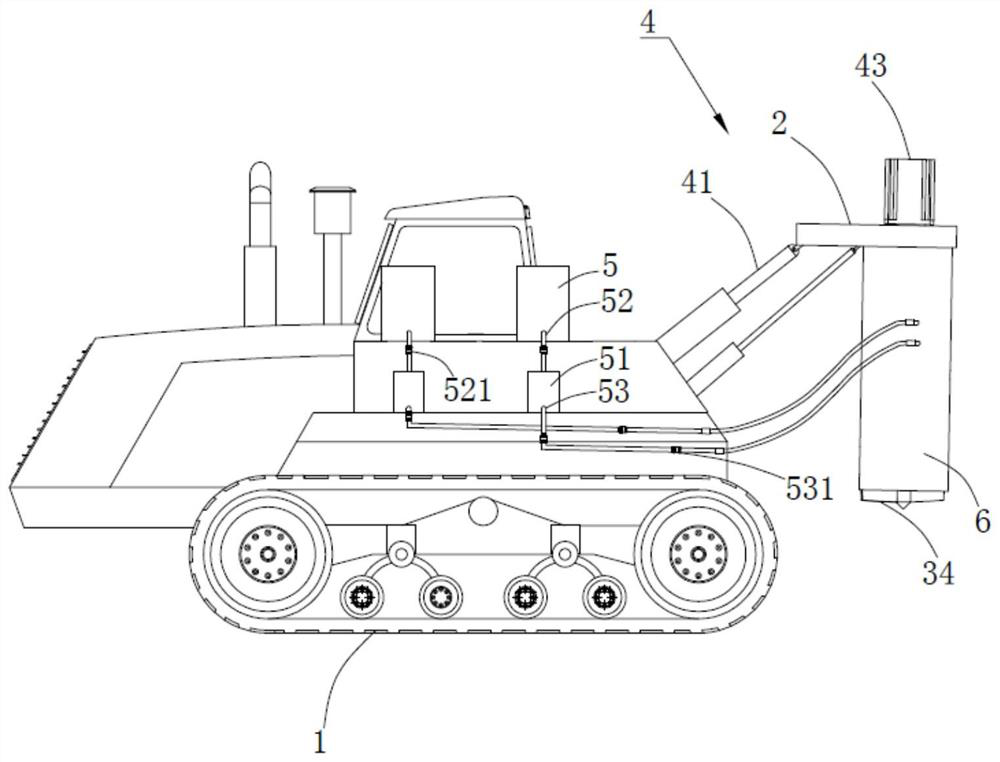

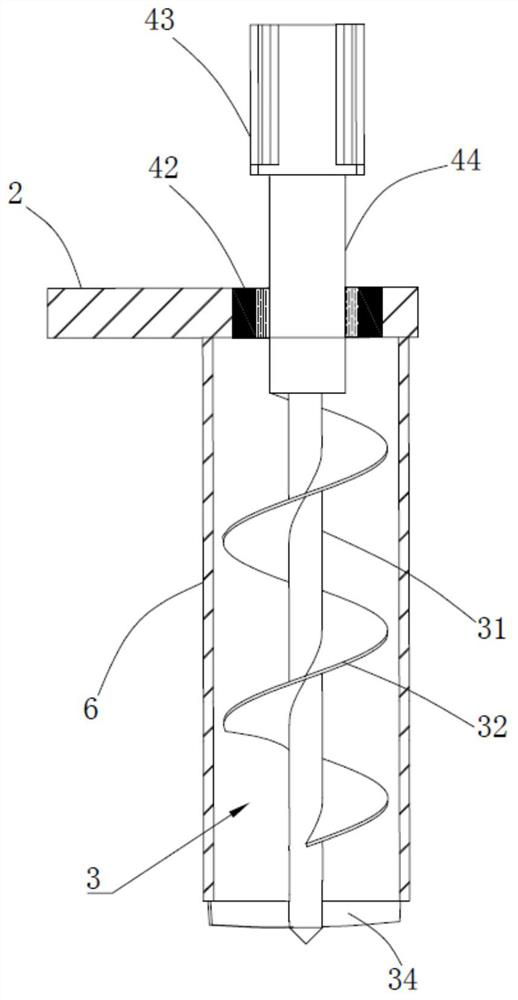

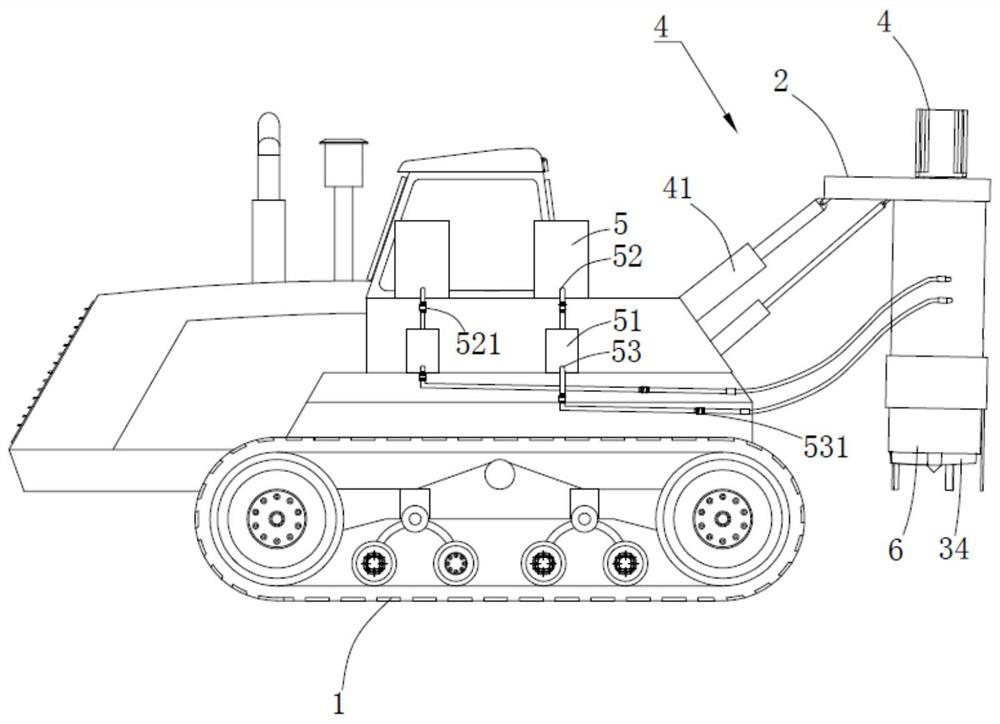

Automatic pit digging and soil making machine

The invention discloses an automatic pit digging and soil making machine. The machine comprises a machine body, a knife rest, a pit digging knife arranged on the knife rest and a driving mechanism fordriving the pit digging knife to drill holes, the pit digging knife is covered with a protective cover which is fixedly connected with the knife rest and used for preventing stone chips from splashing, and the machine body is provided with a plurality of material boxes. The material boxes communicate with the interior of the protective cover through feeding pipes, and the feeding pipes are provided with feeding valves. As the pit digging knife is covered with the protective cover, the stone chips generated by rapid rotation of the pit digging knife are blocked by the protective cover, and splashing of the stone chips is prevented; meanwhile, after pit digging is completed, the feeding valves are opened, so that added materials in the material boxes enter the protective cover through the feeding pipes, the stone chips in the protective cover and the added materials are mixed to form soil for planting trees under the action of rotation of the pit digging knife, and therefore the steps of pit digging in a soil layer with large stone blocks and large soil making amount are completed; and the processes of manual hole digging and soil conveying are omitted, and the manual investment ofhole digging operation is reduced.

Owner:TIANJIN UNIV

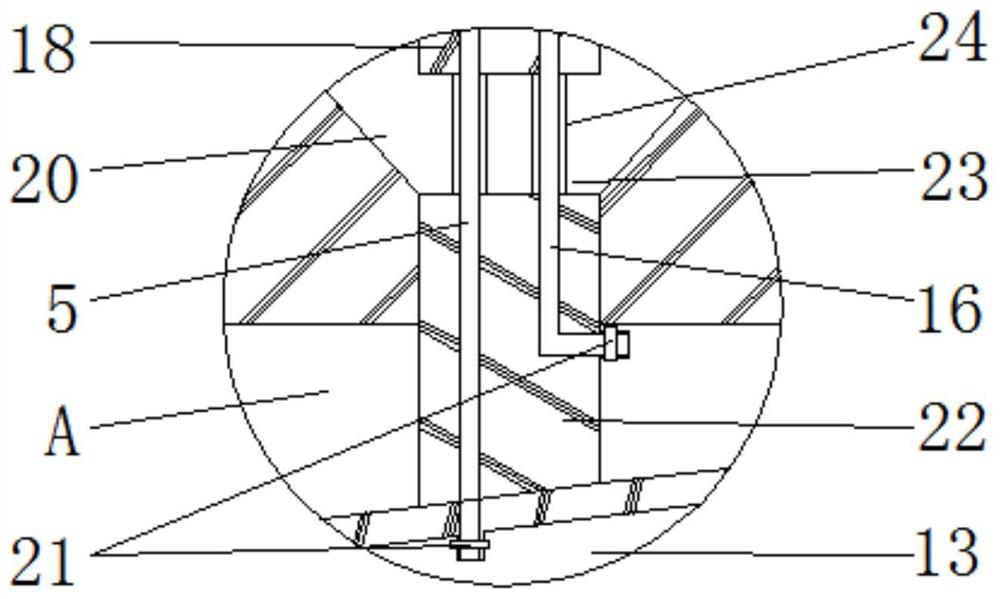

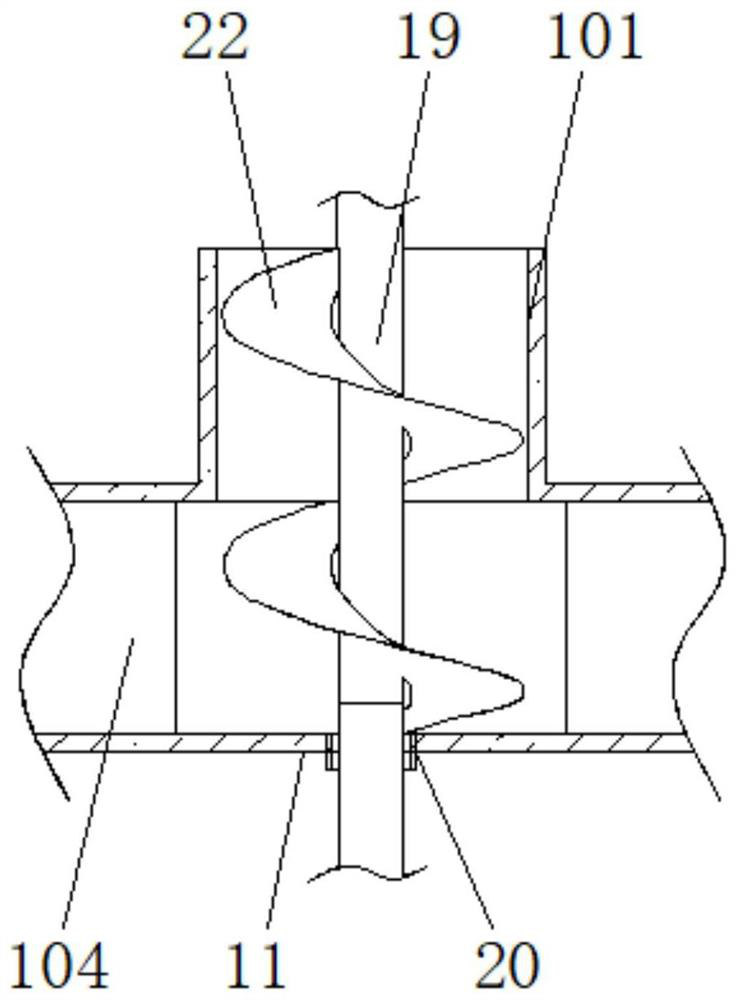

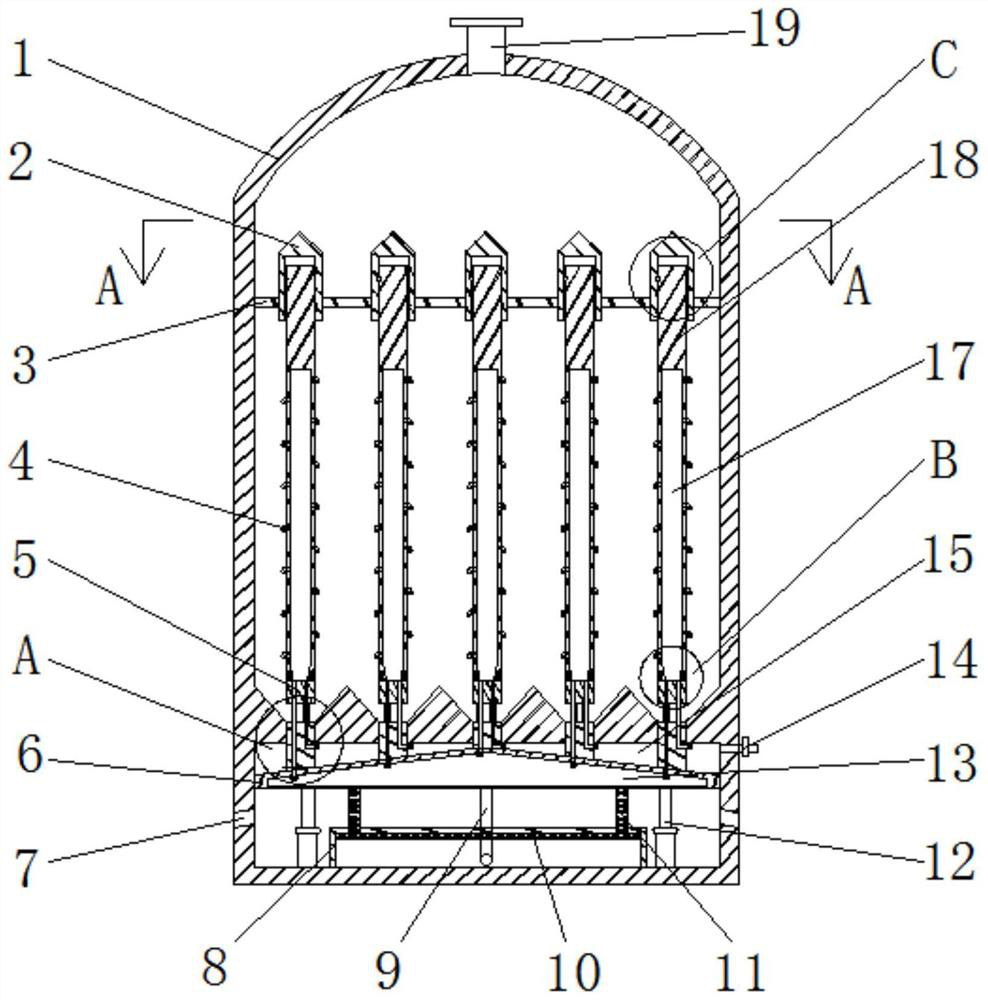

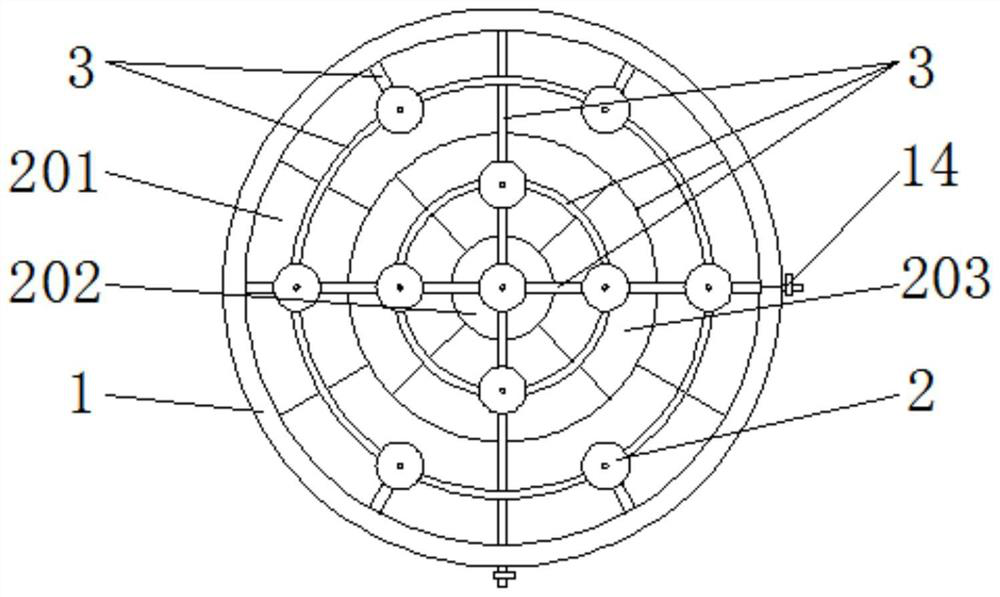

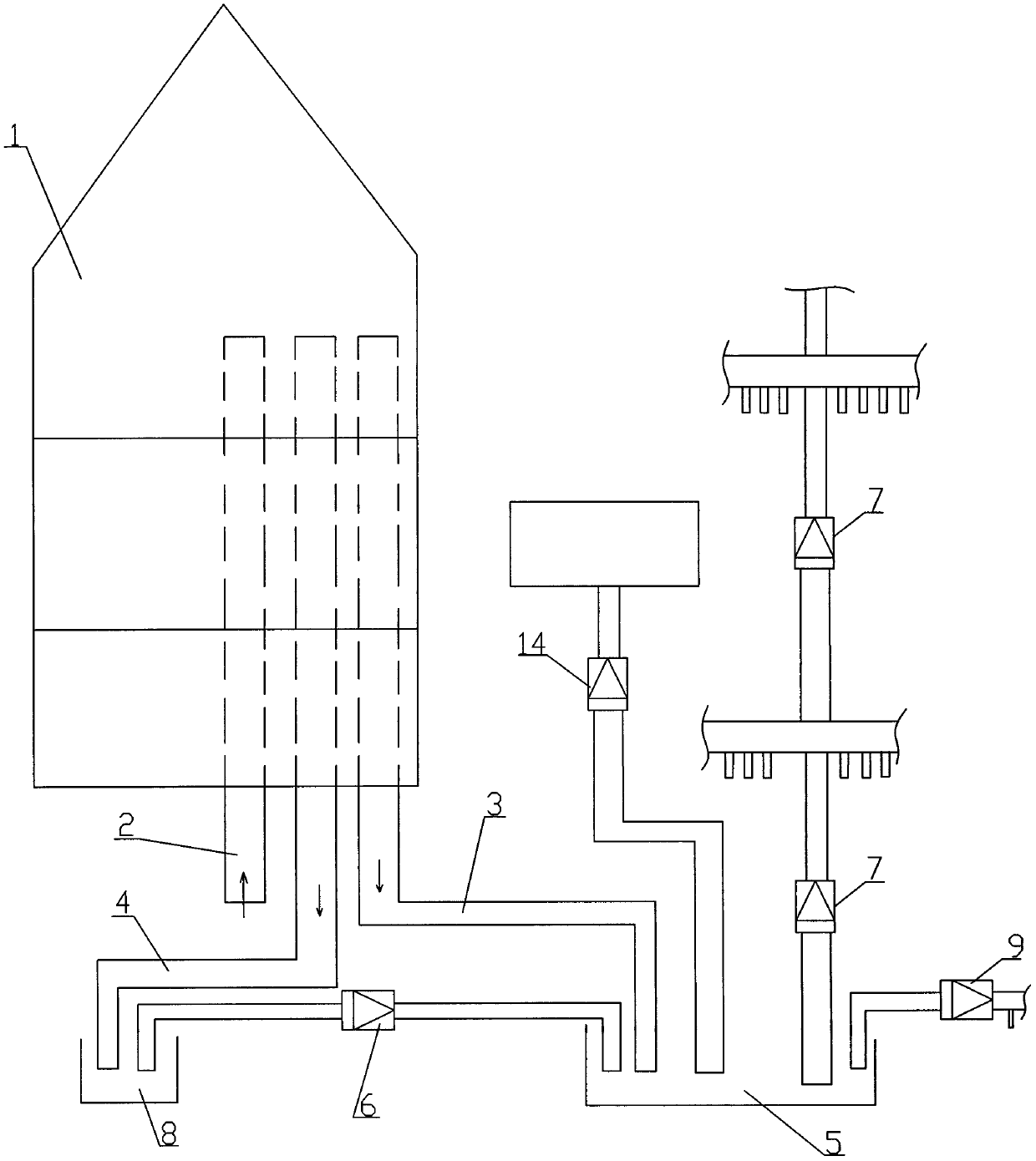

A layered boiler water exchange tank structure based on water vapor heat energy exchange

The invention discloses a layered boiler heat exchange water tank structure based on water-steam-heat energy exchange. The structure comprises a boiler body and a water tank shell, wherein the water tank shell is arranged above the boiler body; a normal-temperature water storage tank, a mixed warm water tank and a high-temperature water tank are sequentially arranged in the water tank shell from top to bottom; a smoke heat exchange layer and a steam heat exchange layer are correspondingly arranged on the upper side and the lower side of the mixed warm water tank; a steam interlayer is arrangedon the top of the high-temperature water tank; a movable shaft penetrates through the middle of the mixed warm water tank; a stirring paddle is integrally arranged in the middle of the movable shaft;and driving blades are arranged at the upper end and the lower end of the movable shaft. According to the structure, a multi-layer water tank structure formed by the normal-temperature water tank, the mixed warm water tank and the high-temperature water tank meets the continuous hot water supply and the multiple spot heating water supply of longer time, and the stirring paddle driven by synchronous water is matched to keep uniform temperature of inside water.

Owner:连云港市瑞成机械有限公司

Compressor

InactiveCN100379995CReduce weightStress reliefRotary/oscillating piston pump componentsLiquid fuel engine componentsStructural engineeringEngineering

The compressor barrel bottom includes one flat outer edge part welded and fixed to the lower part of the barrel bottom, and one annular raised continuous cup-like turned-U part inside the outer edge part. The annular raised cup-like part includes one outer vertical wall, one inner vertical wall and one transitional top wall between the top of the outer vertical wall and the top of the inner vertical wall. The inner vertical wall has arced cross section inclined towards the center of the compressor from top to bottom. The annular raised part has formed concave semi-spherical bottom part in the inner side, and the barrel bottom has installing feet formed integrally with the outer edge part.

Owner:DAIKIN IND LTD

A steel silo unloading device

ActiveCN111824611BPrevent compactionReduce compactionLarge containersEngineeringStructural engineering

The invention discloses a steel silo unloading device, belonging to the field of steel silo. The bottom of each feeding area is provided with a feeding port, each feeding port is provided with a blocking rod, and the lower end of the blocking rod is jointly connected with a first block located in the lower chamber. The piston plate, the lower part of the peripheral side of the silo shell is provided with a discharge port that can be connected with the lower side of the first piston plate; the upper end of the blocking rod is connected with a lifting rod, and the upper end face of the lifting rod is higher than the upper end face of the material; The inner side of the rod is provided with an air supply cavity, and the lifting rod is spirally distributed with air nozzles connected to the air supply cavity at equal intervals along the height direction. . The discharging uniformity of the invention is good, and the material can be effectively prevented from being hardened.

Owner:鱼台县旺星粮油机械制造有限公司

A kind of seed production method of tobacco male sterile hybrid first generation seeds

InactiveCN103348909BAvoid catastrophic lossReduce line spacingPlant genotype modificationNicotiana tabacumHybrid seed

The invention provides an economical and efficient production method of a tobacco male sterile first generation hybrid seed. The method includes: at an altitude of less than 700 meters, under the climate conditions meeting the requirements of early vegetative growth and later reproductive growth of tobacco plants, conducting seedling culture on a maternal tobacco plant and a paternal tobacco plant separately, then employing isolation planting, performing topping on the maternal tobacco plant, then collecting paternal pollen and preparing pollination, during pollination, adding starch and blending them, adopting an artificial pollination pen or pollination gun to perform pollination, carrying out deblossoming on the maternal tobacco plant both before and after pollination, and when the capsule pericarp browning reaches more than 80%, conducting single fruit harvesting in batches and performing drying, then conducting threshing processing to obtain the male sterile first generation hybrid seed. The method provided in the invention has the advantages of reasonable design, low production investment, and high seed yield. On the basis of ensuring a variety purity (99%) and a seed germination rate (95%), maximization of a high-quality germplasm propagation coefficient is realized, the seed yield is greatly improved, and the seed production cost is decreased significantly.

Owner:TOBACCO RES INST OF HUBEI PROVINCE

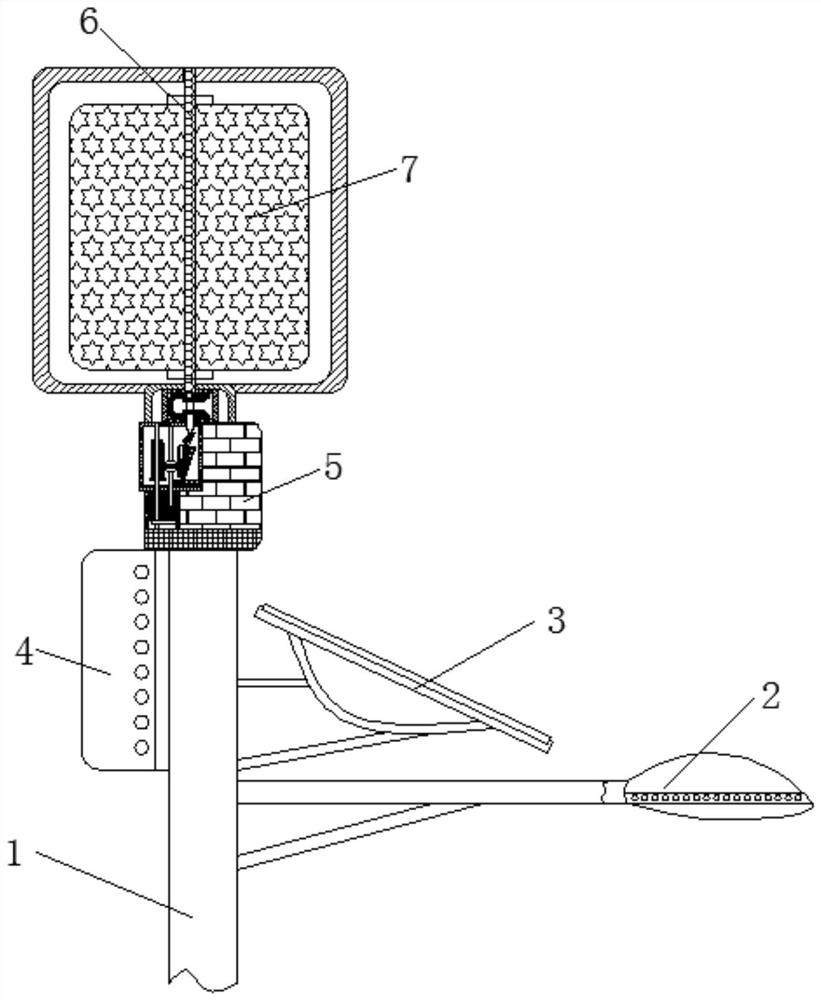

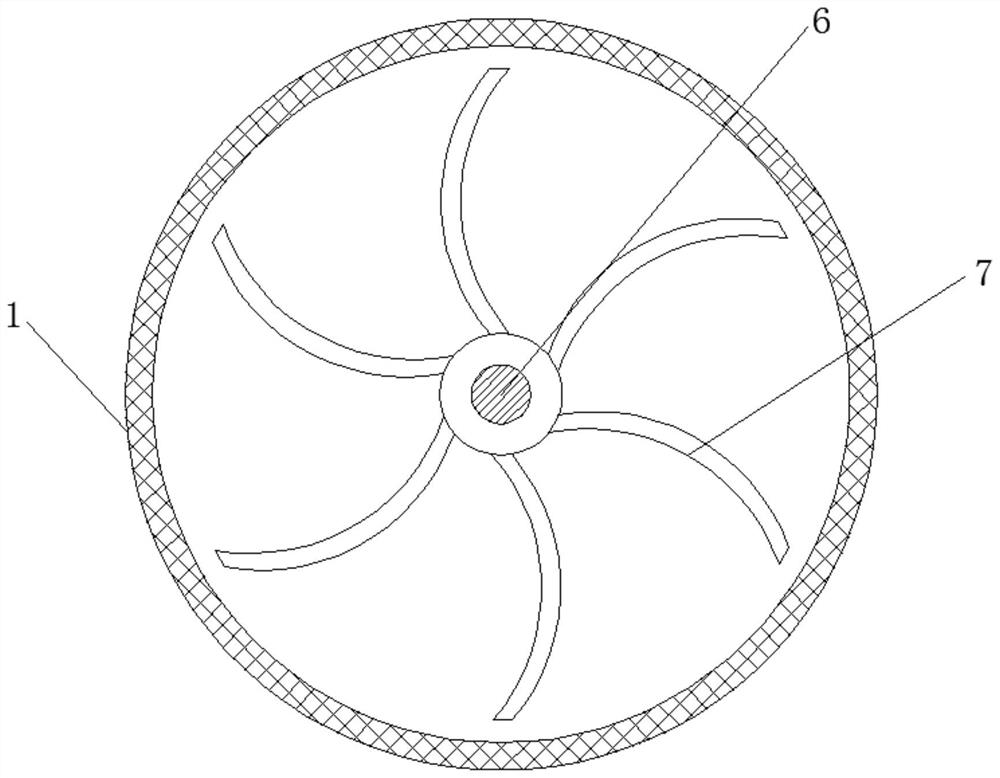

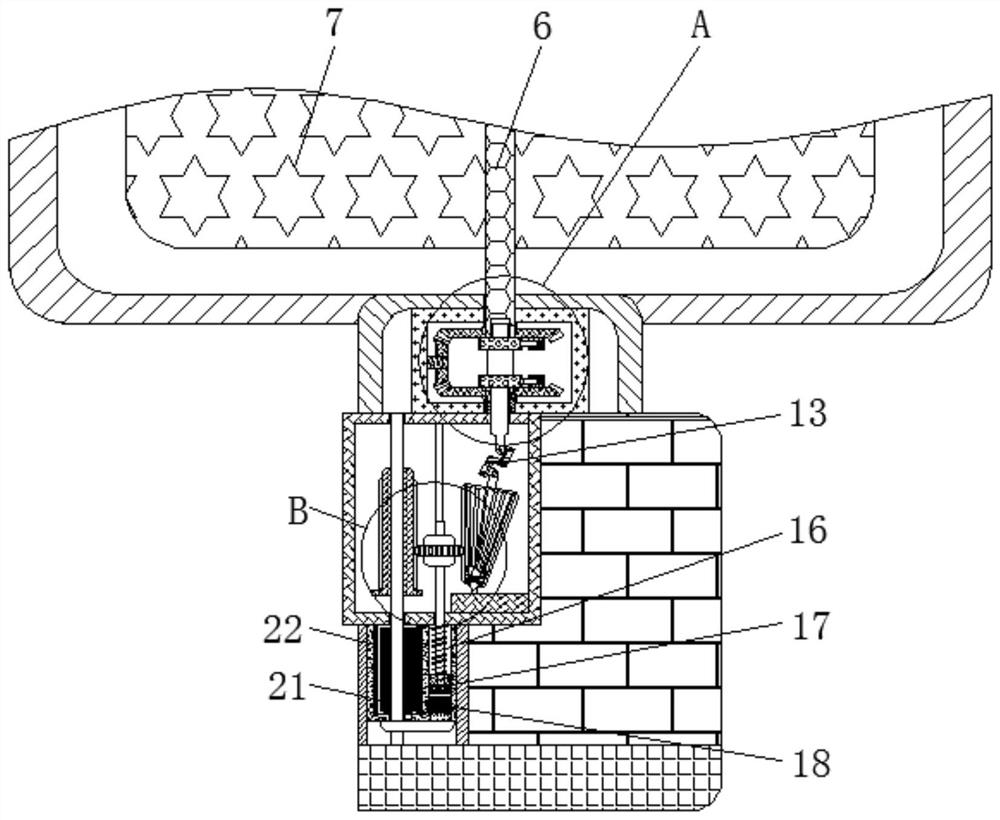

A new energy smart street light device that extends 5g signal

ActiveCN111678079BEasy to controlReduce separate constructionMechanical apparatusElectric circuit arrangementsNew energyFan blade

The present invention relates to the technical field of 5G signals, and discloses a new energy smart street light device that expands 5G signals, including a support column, and the exterior of the support column is fixedly connected with a lamp body, a photovoltaic panel and a signal device. A power storage device is fixedly connected inside, a positioning shaft is movably connected to the top of the support column, fan blades are fixedly connected to the outside of the positioning shaft, and a transmission bevel gear is fixedly connected to the bottom of the positioning shaft. Through the coordinated use of the flywheel, sliding gear, telescopic rod, movable magnetic block, electromagnet, gear column, output shaft, coil and magnetic strip, the stability of the rotation speed of the output shaft is guaranteed, and the wind power generation effect is effectively reduced. The fluctuation of the rotation speed of the output shaft ensures the stability of the wind power generation current, effectively reduces the waste of wind power generation energy, thereby achieving energy saving, effectively ensuring the reserve of electric energy, and thus improving the use effect of this setting.

Owner:百家亮(厦门)智慧科技有限公司

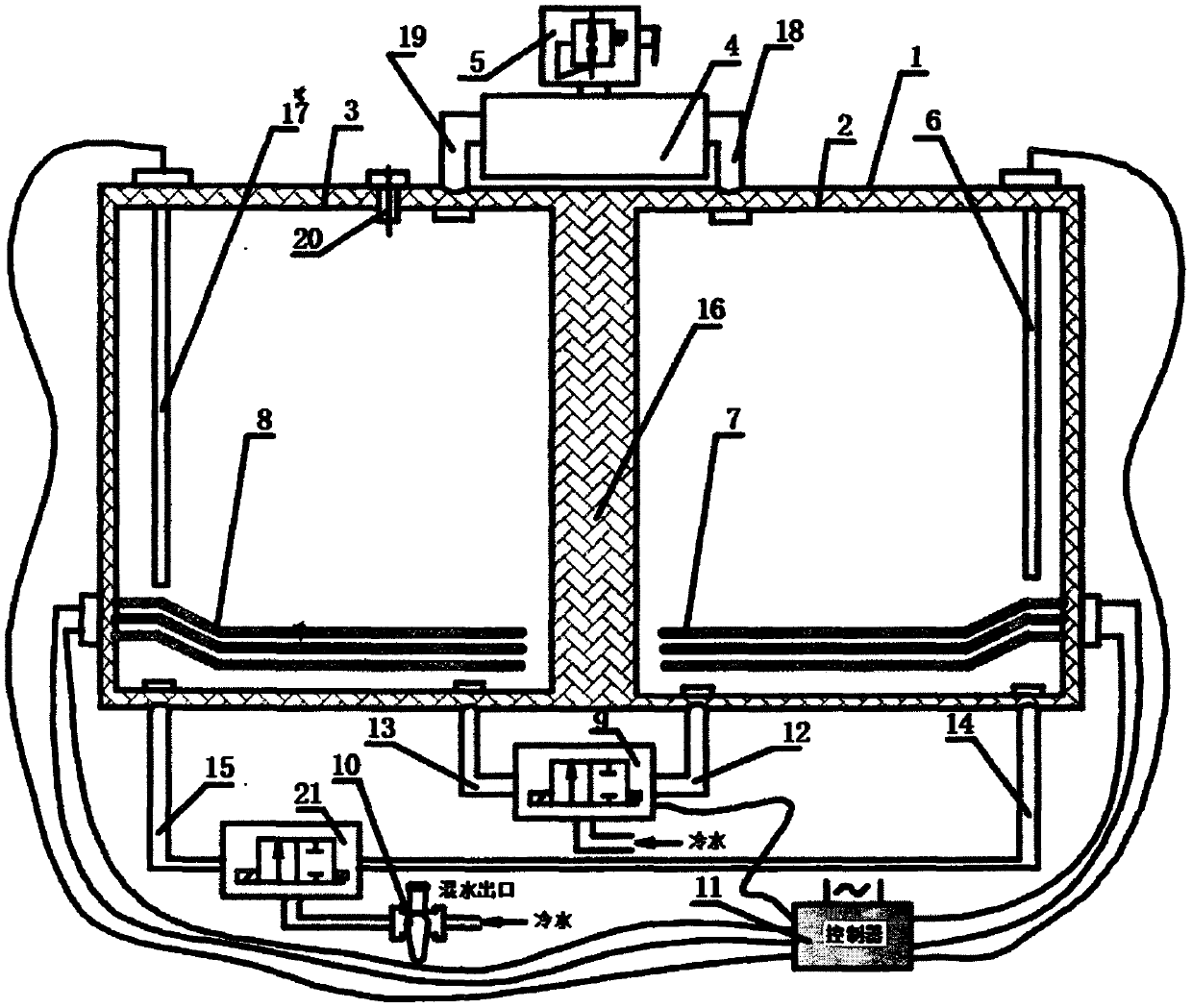

Electric water heater for separating cold and hot water

PendingCN111503884ASmall fluctuations in outlet water temperatureReduce the risk of electric leakageMechanical apparatusWater heatersSeparation technologyEngineering

The invention discloses an electric water heater for separating cold water and hot water. The electric water heater for separating cold water and hot water is characterized by comprising an external cylinder, an internal cylinder I and an internal cylinder body II, a a pressure storage chamber and an electromagnetic valve I, wherein the internal cylinder I and the internal cylinder body II are mounted in the external cylinder body; the pressure storage chamber is arranged above the external cylinder body; the electromagnetic valve I is arranged under the external cylinder body; the electromagnetic valve I is respectively connected with the internal cylinder I and the internal cylinder body II through a water feeding pipe I and a water feeding pipe II; the internal cylinder I and the internal cylinder body II are correspondingly connected with two-position two-way electromagnetic valves II used for controlling hot water to be drained through a water outlet pipe I and a water outlet pipeII; and water outlets of the electromagnetic valves II are connected with a water mixing valve. The electric water heater for separating cold water and hot water has the advantages that the structureis simple; by using a cold and hot water separating technology, the water temperature is constant during using; the hot water is drained under a condition of absolute power failure; the use is safer;and by using a physical dry burning preventing scheme, dry burning of a heating tube is effectively avoided.

Owner:JINGGANGSHAN UNIVERSITY

A garment open-end zipper sewing template and its sewing method

ActiveCN105256474BHigh precisionImprove sewing qualityWork-feeding meansMechanical engineeringIndustrial engineering

Owner:JIAXING UNIV

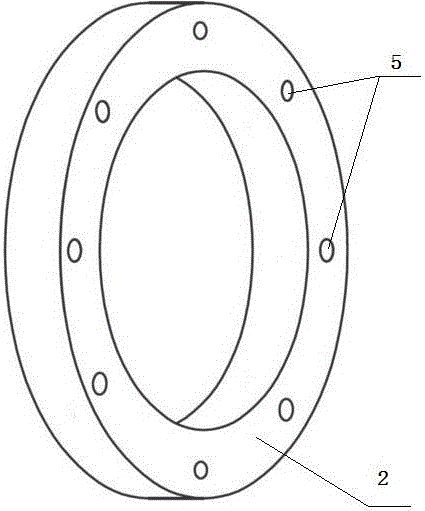

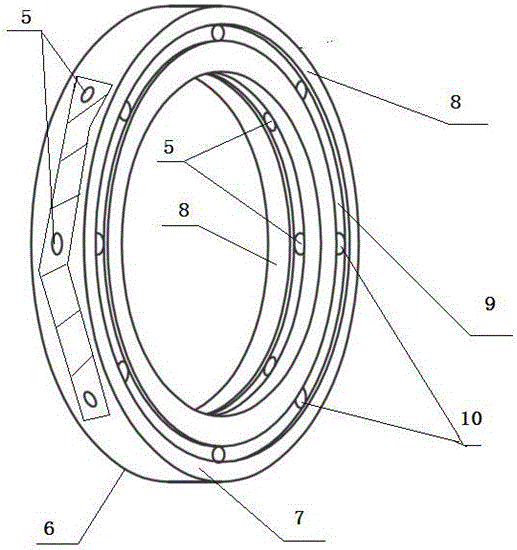

Design method for composite solid lubrication sprocket shaft group

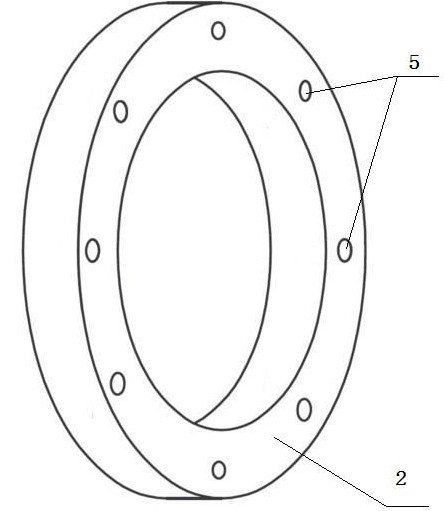

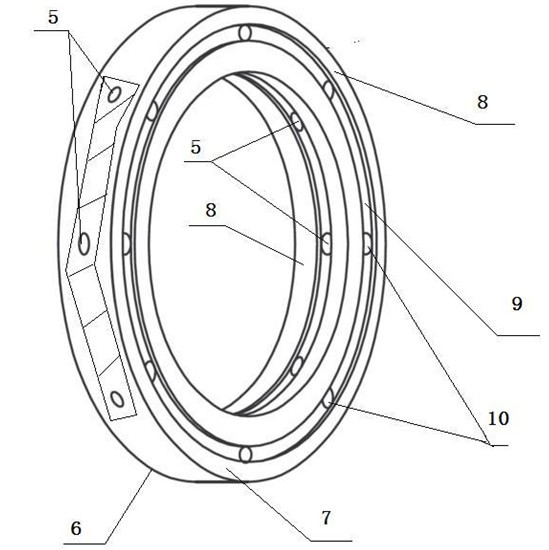

ActiveCN102606741AExtend your lifeFull compensationEngine sealsBearing componentsSprocketLubrication

The invention belongs to the field of work machinery and relates to a design method for a sprocket shaft group, in particular to a design method for a composite solid lubrication sprocket shaft group. The designed sprocket shaft group at least comprises a floating seal ring and a seal flange, wherein the floating seal ring comprises two geometrically identical metal rings, the floating ring is fixedly connected with the seal flange, and the static ring adheres to the floating ring and moves relatively to the floating ring. The design method is characterized in that the adhering surface of the floating ring or static ring is in an annular submerged pit structure, and solid lubricant is filled in the submerged pit. The designed sprocket shaft group further comprises a bearing composed of an inner ring, an outer ring, a retainer and a rolling body, and is characterized in that the contact surface between the retainer and the inner surface and the contact surface between the retainer and the outer ring are in the submerged pit structures, and the solid lubricant is filled in the submerged pit. Due to the design method for the composite solid lubrication sprocket shaft group, the phenomena such as oil leakage, unreliability of lubrication, too fast abrasion of the floating seal ring, excessive abrasion of a bearing inner sleeve, damages on a bearing retainer, excessive abrasion of a spline, damages on a gear coupler, etc. existing in the sprocket shaft group are avoided.

Owner:鄂尔多斯市云新技术研究有限公司 +1

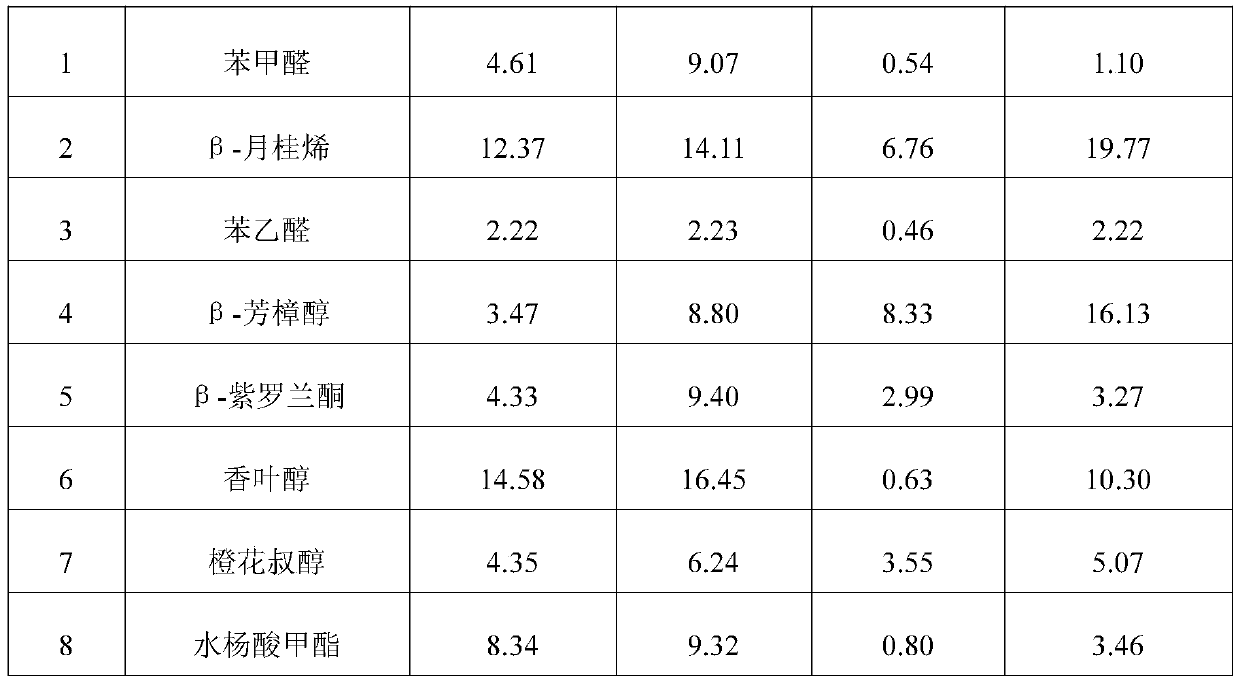

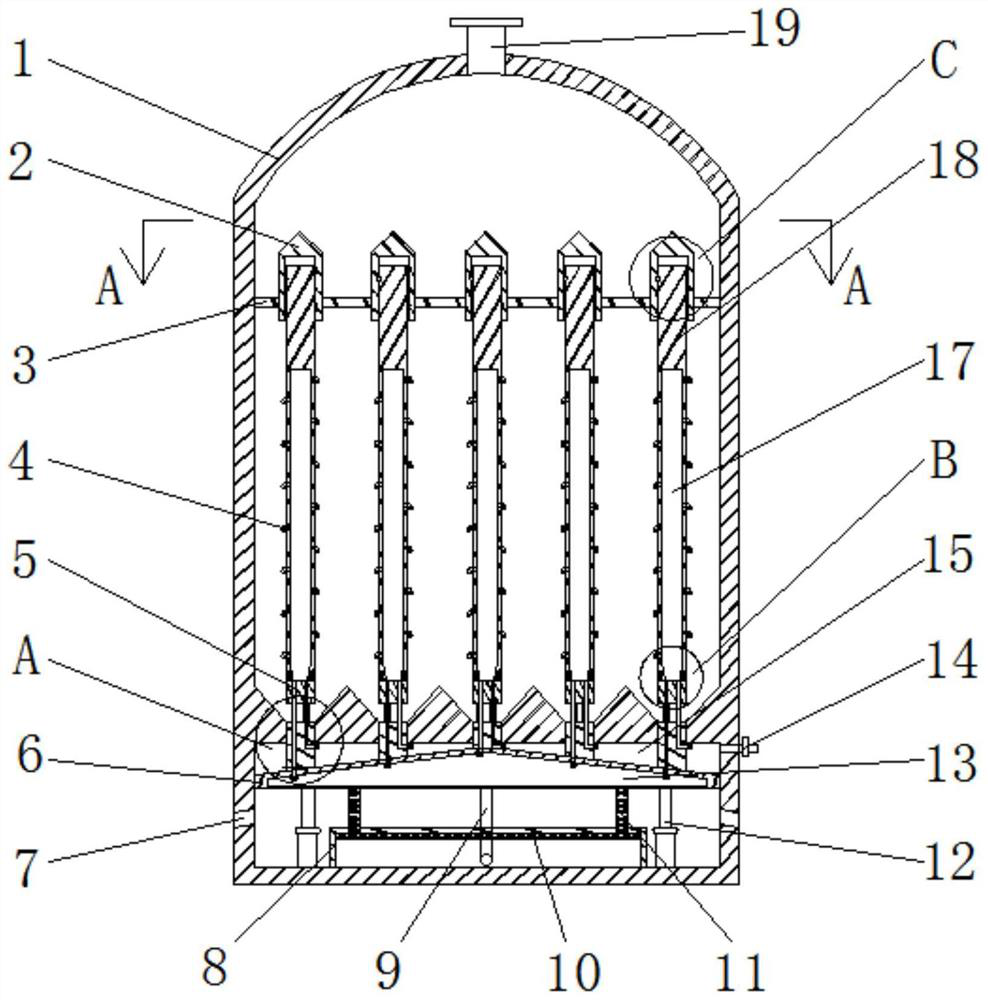

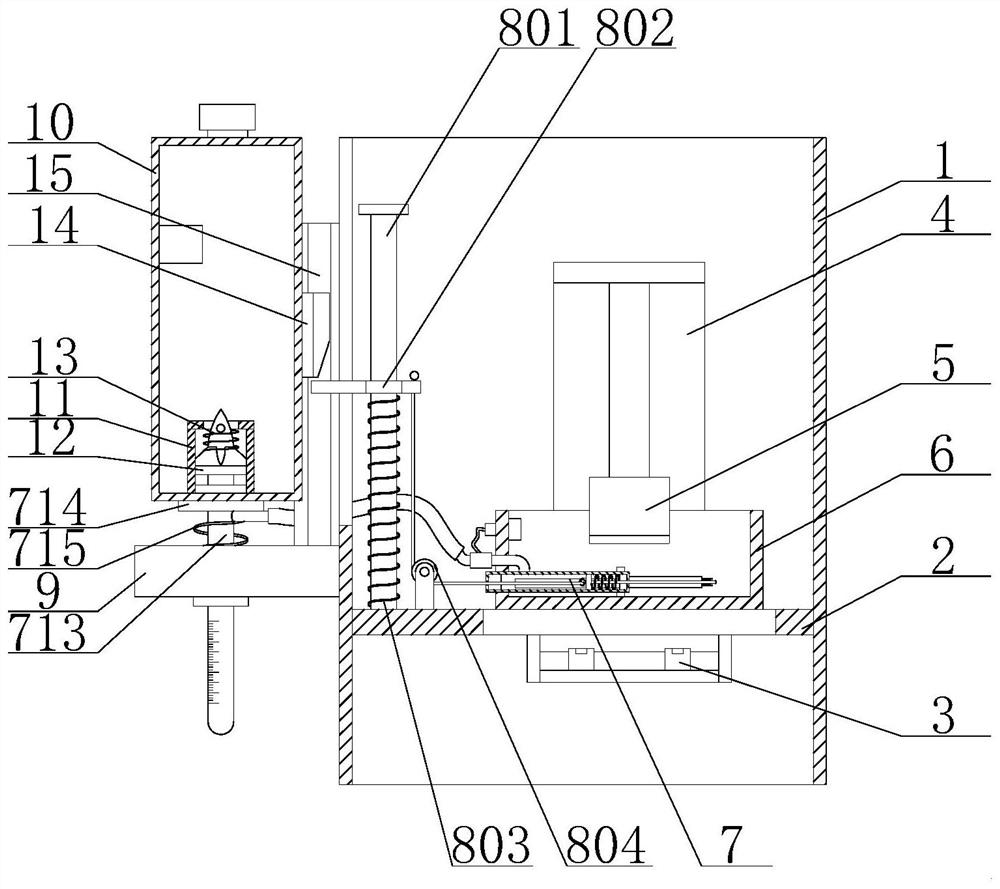

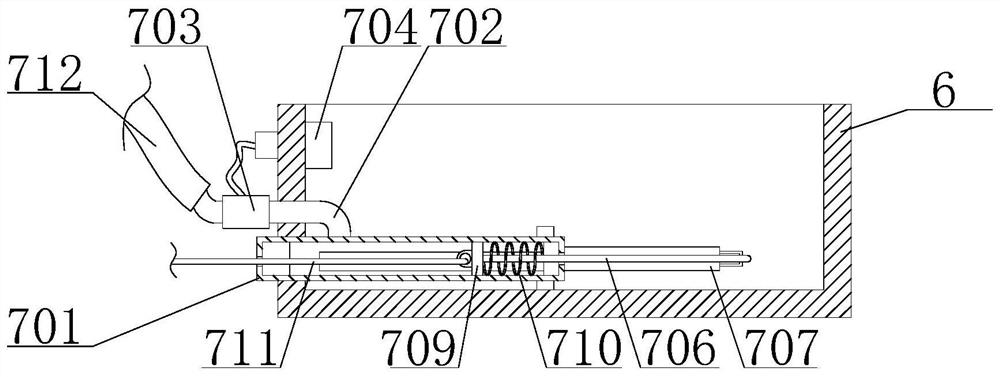

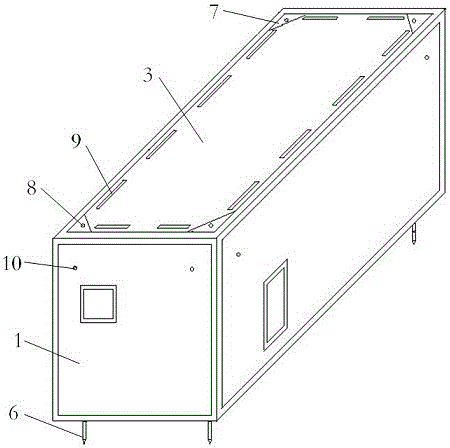

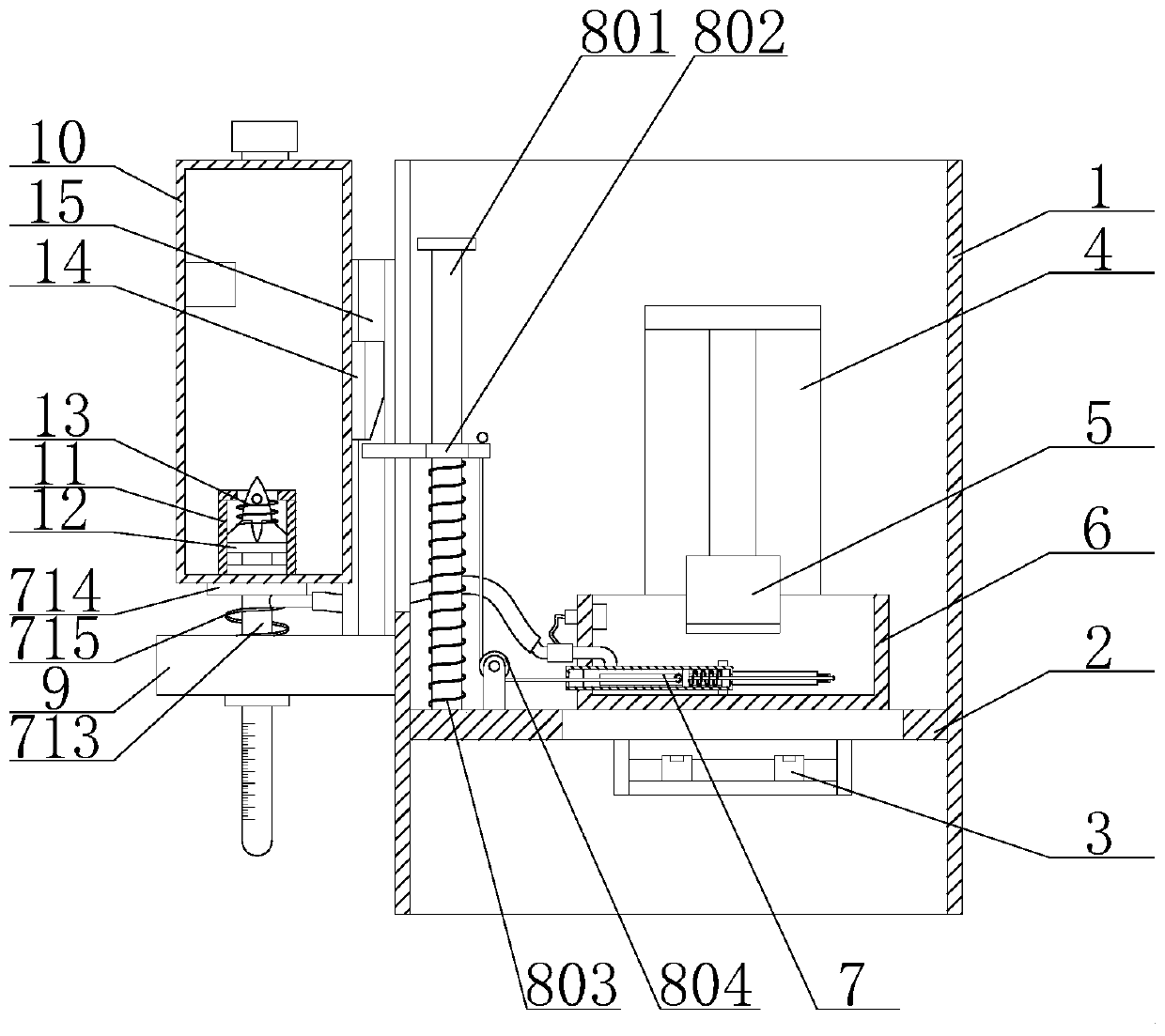

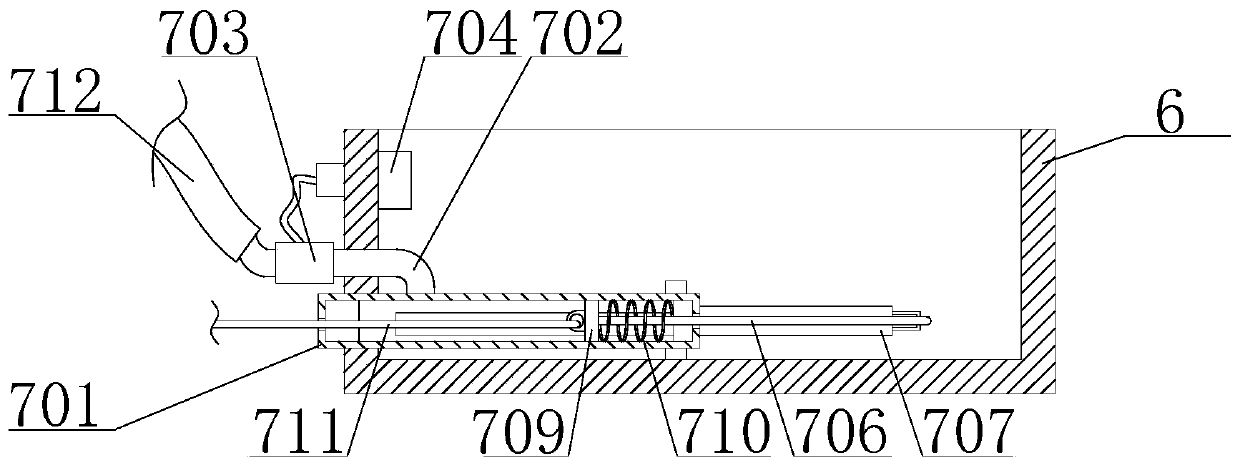

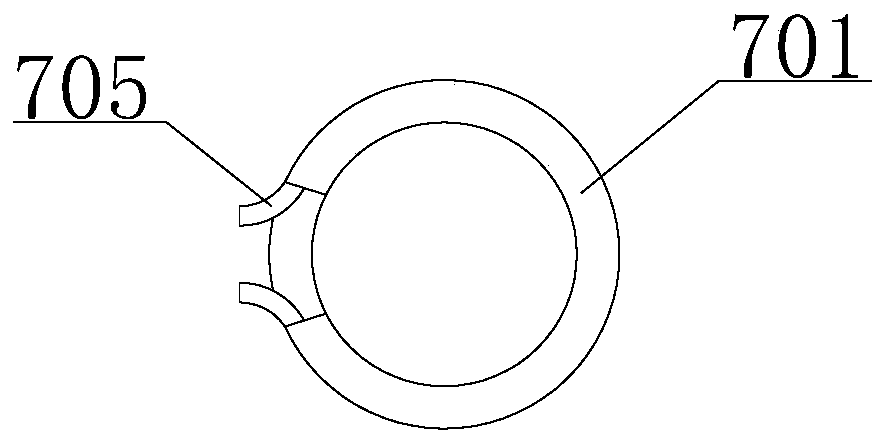

A multi-laser automatic rehydration sla3d printer

ActiveCN111391311BGuaranteed reservesQuality assuranceManufacturing enclosures3D object support structuresThermodynamicsStraight tube

The invention discloses a multi-laser automatic rehydration sla3D printer, which comprises a casing, the inner side of the casing is fixedly connected with a bearing plate, the bottom surface of the bearing plate is movably connected with a laser head, and the top surface of the bearing plate is fixedly connected There are guide rails, and the front side of the guide rails is movably connected with a sliding connection and a lifting plate. The invention relates to the field of 3D printing equipment. The multi-laser automatic rehydration sla3D printer can judge the photosensitive resin reserve inside the rehydration tank through the support plate and straight tube and other devices, and through the scale at the bottom of the straight tube, which ensures the quality of the photosensitive resin and delays its deterioration. The pressure plate realizes the smooth supply of photosensitive resin in the process of liquid replenishment, which improves the product quality. The scraping of the scraper and scraper avoids the condensation and blockage of the photosensitive resin on the surface of the rubber pressure plate, reducing equipment failure. This solves the problem that the storage of photosensitive resin in the printer is unclear, ripples are easily generated during liquid replenishment, which affects product quality, and the liquid replenishment port is easily blocked.

Owner:运城黑麦科技有限公司

Vanadium nano electrothermal material

PendingCN111304590AImprove securityGuaranteed reservesMaterial nanotechnologyVacuum evaporation coatingSputteringVanadium atom

The invention provides a vanadium nano electrothermal material, belongs to the technical field of branch nanomaterials of new material large classes, and particularly provides a vanadium nano electrothermal material body mainly formed by vanadium. The nanomaterial is formed in the manner that vanadium, nickel, tungsten and chromium at the mass percent of 40%-80%-10%-30%-5%-16%-0%-15% are embed-plated on base materials with different sizes and shapes such as the pipe shape, the plate shape, the piece shape, the strip shape and the round shape made of quartz glass, ceramic and other materials with specially-treated surfaces through sputtering. The thickness of a film is 5,000-20,000 nanometers, the material has the properties that the electrothermal conversion rate is high, heating is extremely rapid, the heating surface temperature is high, the durability is long, the material is resistant to scratching and does not disengage, the power is not attenuated, and the magnetic radiation is low, and power can be supplied through 10 V-220 V alternating and direct currents. The material is prepared into various heating assemblies and designed into various novel electric appliances and equipment, the beneficial effects that instant heating is achieved, the cost performance is high, energy is saved, and environmental friendliness is achieved are achieved, use is easy, and the applicationrange is wide. The vanadium nano electrothermal material fills up the blank of the world in the field of electrothermal heating application and has extremely high use value and broad application prospects.

Owner:彭文婷

Composite solid lubrication sprocket shaft group

ActiveCN102606741BGuaranteed uninterrupted compensationGuaranteed reservesEngine sealsBearing componentsSprocketEngineering

The invention belongs to the field of operating machinery, and relates to a chain wheel shaft group, in particular to a composite solid lubricated chain wheel shaft group. It includes at least a floating sealing ring and a sealing flange. The floating sealing ring is two geometrically identical metal rings. The floating ring is fixedly connected to the sealing flange. The stationary ring fits the floating ring and the two move relative to each other. Its characteristics are: floating The bonding surface of the ring or the stationary ring is an annular latent pit structure, and there is a solid lubricant in the latent pit. It also includes a bearing, which is composed of an inner ring, an outer ring, a cage and a rolling element, and is characterized in that: the contact surface of the cage, the inner ring and the outer ring is a latent pit structure, and there is a solid lubricant in the latent pit. The design method of the composite solid lubricated sprocket shaft group solves the problems of oil leakage, unreliable lubrication, excessive wear of the floating seal ring, abnormal wear of the inner sleeve of the bearing, damage of the bearing retainer, excessive wear of the spline, and gear coupling in the sprocket shaft group. device damage, etc.

Owner:鄂尔多斯市云新技术研究有限公司 +1

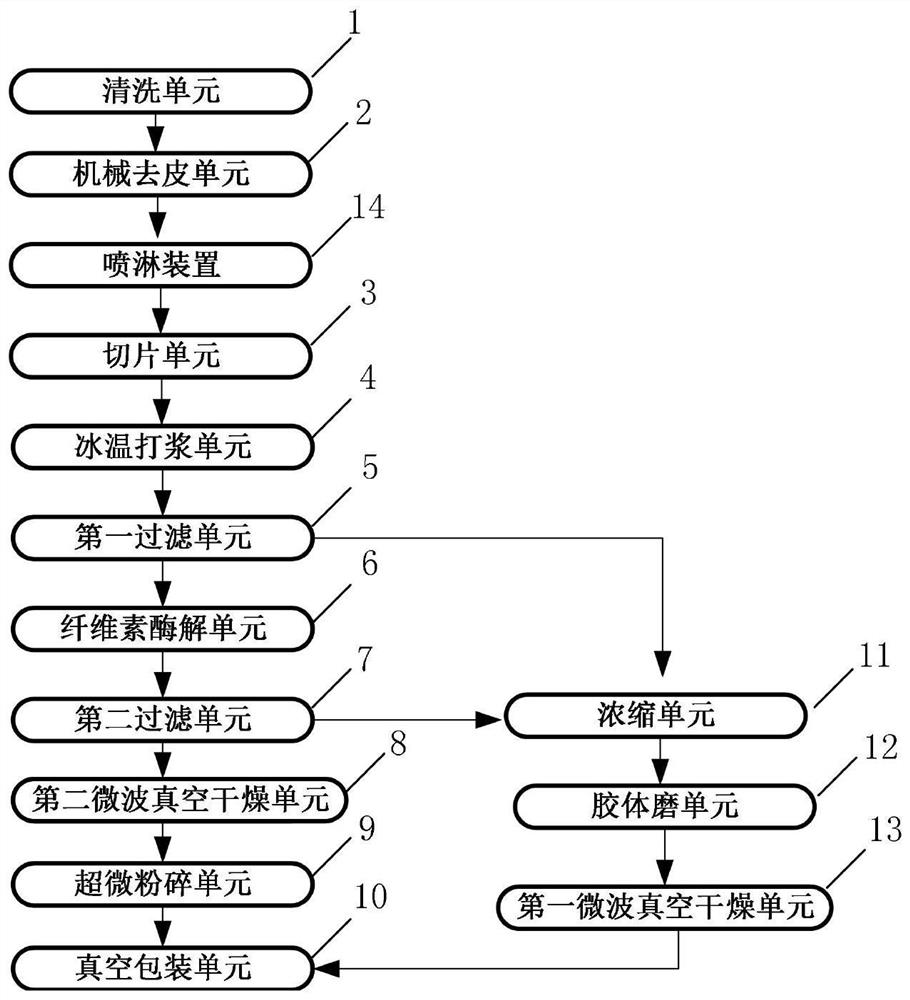

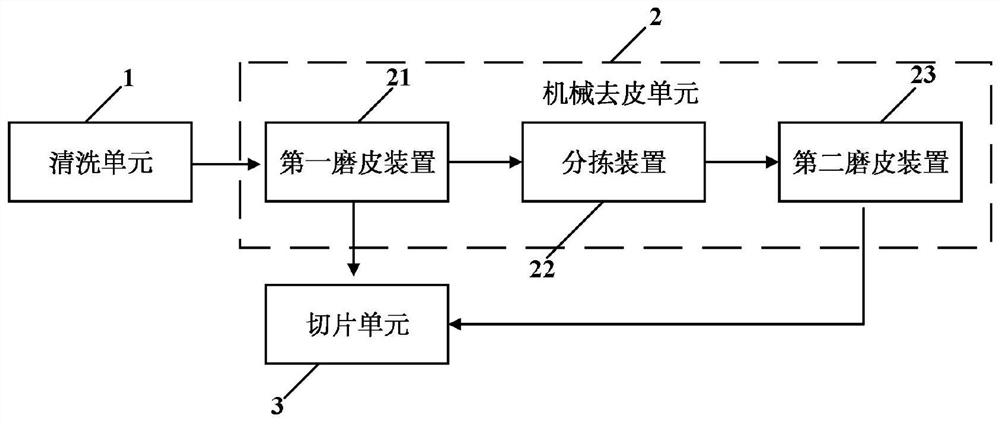

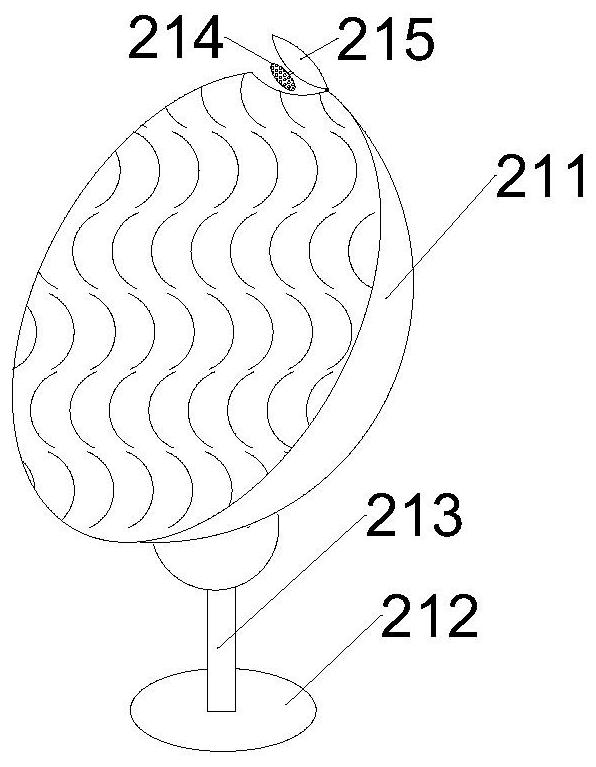

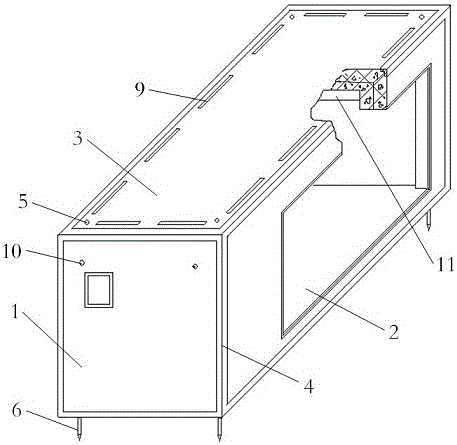

Sweet potato raw whole flour, production method and production system thereof and mechanical peeling unit

PendingCN112189836AImprove finenessIncrease dosageDrying solid materials with heatVegetable peelingIce waterProcess engineering

The invention relates to a sweet potato raw whole flour, a production method and a production system thereof and a mechanical peeling unit. The production method comprises the following steps: firstly, mechanically peeling sweet potatoes, slicing the peeled sweet potatoes, pulping the slices in ice water at 0-4 DEG C, and filtering to obtain a first filtrate and a first filter residue; mashing thefirst filter residue, adding cellulase for enzymolysis, and then extruding and filtering to obtain a second filtrate and a second filter residue; mixing the second filtrate and the first filtrate, treating by a colloid mill, and performing microwave vacuum drying at 40-60 DEG C to obtain the first sweet potato raw whole flour; and performing microwave vacuum drying of the second filter residue, and carrying out superfine grinding to obtain the second sweet potato raw whole flour. High temperature is avoided in the whole process, so that gelatinization of the sweet potato raw whole flour in the production process is avoided; adding the cellulase into the filter residue for enzymolysis, carrying out superfine grinding after microwave vacuum drying, filtrate is treated by a colloid mill, andthe fineness of the sweet potato raw whole flour is improved.

Owner:HUBEI UNIV OF CHINESE MEDICINE

Simplified house

InactiveCN106368311AImprove structural performanceImprove seismic performanceBuilding constructionsStructure propertyEngineering

The invention discloses a simplified house and relates to the technical field of engineering construction. An integrated steel bar angle steel frame is embedded in the simplified house and plays a firm supporting role on the simplified house. The edges of the integrated steel bar angle steel frame are exposed out of the outer surface of the simplified house. If combined installation of multiple simplified houses is needed, the simplified houses are welded in a welding mode to form a firm whole house, and the simplified house has the advantages of good integral structure property. Due to existence of guiding holes and guiding rods, the simplified house can be rapidly installed and can be also firm and solid, and a large amount of installation time is saved. The simplified house is firm in structure, simple in assembly, short in construction period and worthy of popularization and usage.

Owner:广西东创智能科技有限公司

Multi-laser automatic liquid supplementing sla3D printer

ActiveCN111391311AGuaranteed reservesQuality assuranceManufacturing enclosures3D object support structuresComputer printingStraight tube

The invention discloses a multi-laser automatic liquid supplementing sla3D printer. The multi-laser automatic liquid supplementing sla3D printer comprises a machine shell, wherein a bearing plate is fixedly connected to the inner side of the machine shell, a laser head is movably connected to the bottom surface of the bearing plate, a guide rail is fixedly connected to the top surface of the bearing plate, and a lifting plate is movably and slidably connected to the front surface of the guide rail. The invention relates to the field of 3D printing equipment. According to the multi-laser automatic liquid supplementing sla3D printer, through devices such as the bearing plate and a straight pipe, the storage amount of photosensitive resin inside a liquid supplementing box can be judged through scales at the bottom end of the straight pipe, the quality of the photosensitive resin is guaranteed, and the deterioration of the photosensitive resin is delayed; the smooth supply of the photosensitive resin in the liquid supplementing process is achieved through a sleeve and a rubber pressing plate, and the production quality is improved; the condensation and the blockage of the photosensitive resin on the surface of the rubber pressing plate are avoided through scraping and sweeping of scraper blades and a scraper, and equipment failures are reduced; and the problem that the storage amount of the photosensitive resin of the printer is not clear, and ripples are prone to generate during liquid supplementing, so that the product quality is influenced, and a liquid supplementing openingis prone to block is solved.

Owner:运城黑麦科技有限公司

Biological ecological purification method for surface water

InactiveCN111434624AEasy to manageMaximize room to growWater/sewage treatment by irradiationSpecific water treatment objectivesWater storageWater flow

The invention relates to a biological ecological purification method for surface water. The technical key points are as follows: the method comprises a resident sewage treatment system and a rain sewage treatment system; the residential sewage treatment system comprises a house main body; a water inlet pipe, a first drain pipe and a second drain pipe are arranged in the house body; discharged sewage is discharged into a high-pressure pump pumping and spraying pool through the first drain pipe, the discharged sewage is discharged into a septic tank through the second drain pipe, septic tank water is pumped into the high-pressure pump pumping and spraying pool through a first water pump to be blended into Baume degree mixed liquid, and then the Baume degree mixed liquid is pumped and sprayedto the ground through a high-pressure pump; according to the rainwater and sewage treatment system, after rainwater flows toward a ditch and a river branch, the ditch and the river branch are dividedinto a plurality of water storage areas, a water storage dam is arranged between every two adjacent water storage areas, the water surface of each water storage area is divided into an aquatic vegetation growth area and a water flow area in the width direction, and a sewage blocking floating mat net is arranged between each aquatic vegetation growth area and the corresponding water flow area. A pollution source is thoroughly cut off, and rainwater and sewage are subjected to split-flow purification treatment.

Owner:梁流辉 +2

A high-precision and fast-response smart rail car steering system

ActiveCN111098919BPrecise control of oil supplyEasy to controlFluid steeringSteering for vehicles in tandemLoop controlControl engineering

The invention provides a high-precision and fast-response hydraulic steering system applicable to smart rail cars and a smart rail car equipped with such a hydraulic steering system. The hydraulic steering system has the characteristics of fast response, high precision and high reliability. The intelligent rail car can realize the precise control of the left and right rotation of the axle and the high-precision closed-loop control of the vehicle steering, which can meet the safe driving requirements of the trackless traffic.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com