Patents

Literature

57results about How to "Easy to heat up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

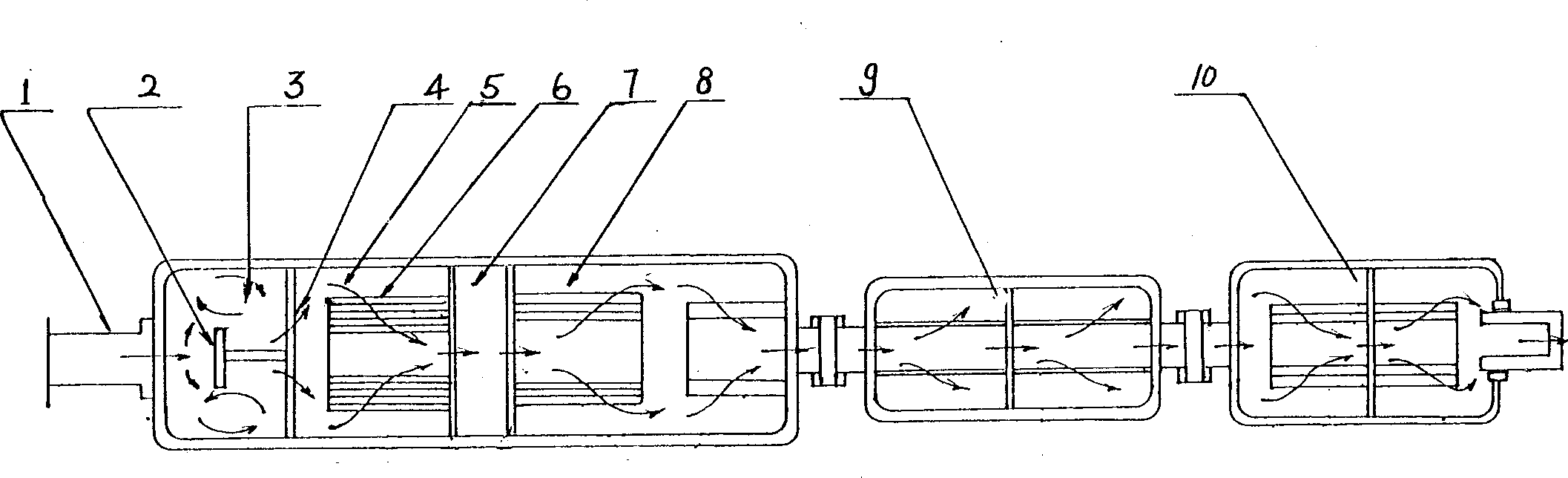

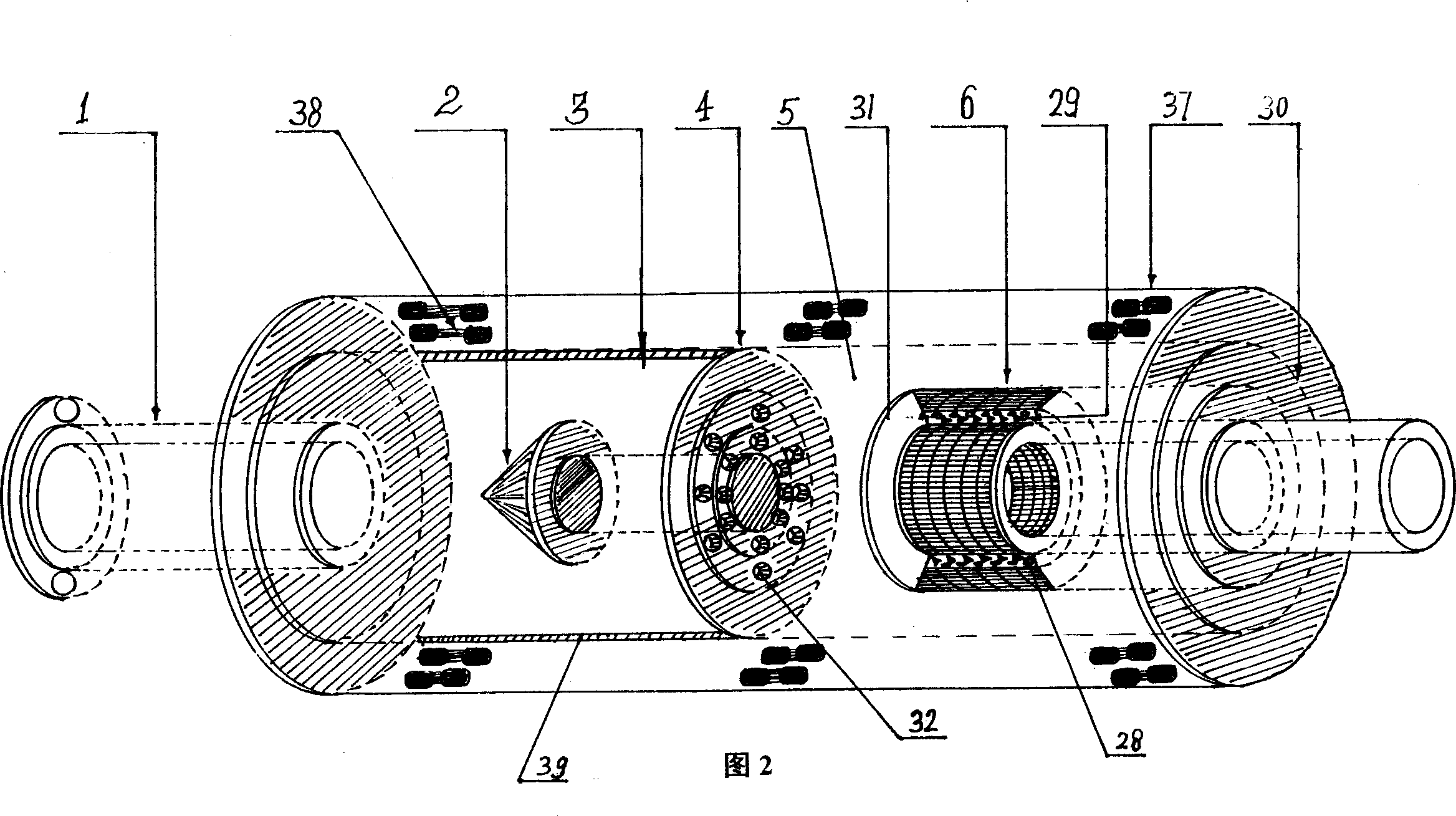

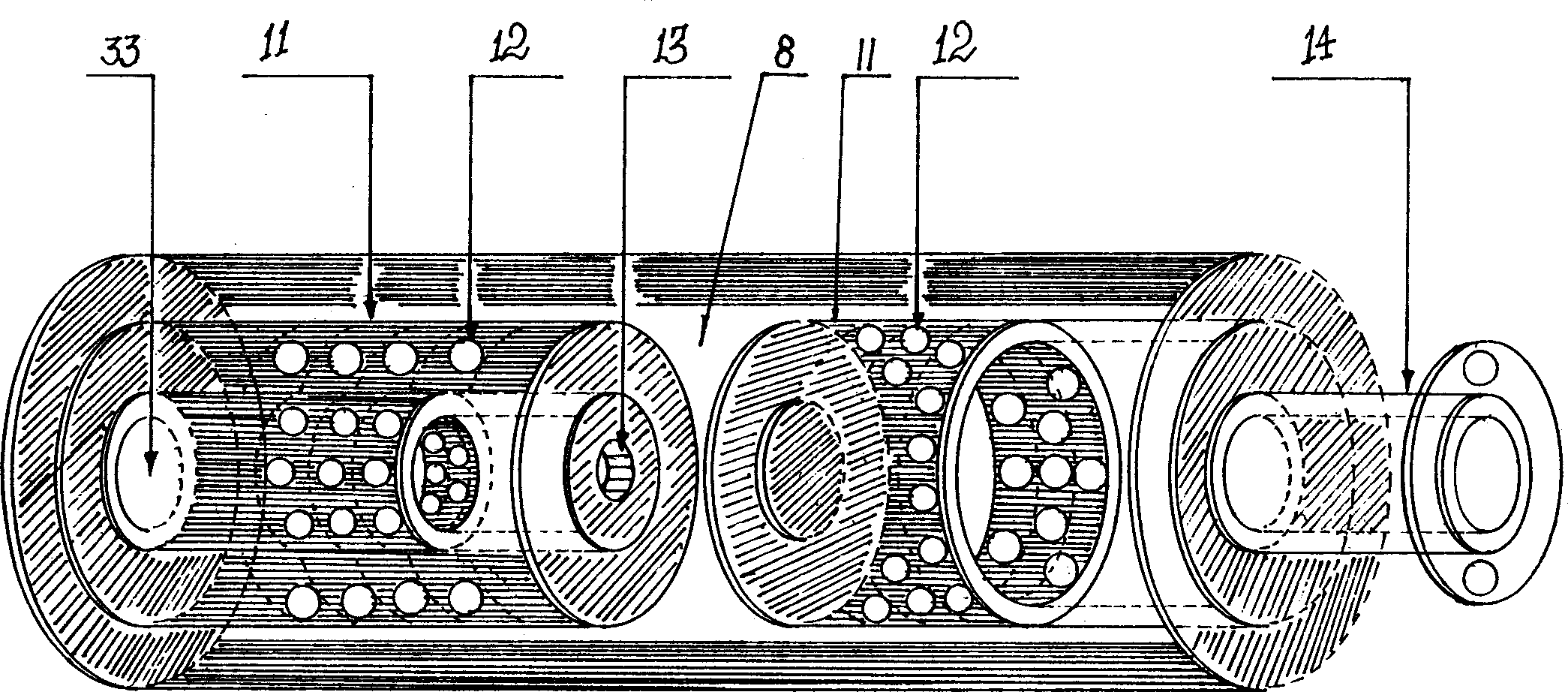

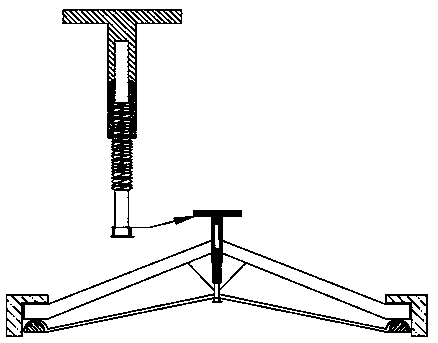

Purifying system for high power output and low-temp tail gas discharge of IC engine

InactiveCN1360139AReduce ingredient contentEasy to recycleExhaust apparatusDispersed particle separationActivated carbonLow noise

A system for higher power output and low-temp exhaust and cleaning of tail gas for IC engine is composed of temp-raising pressure-retaining swirler, filter, silencing cooler and vacuum adsorber. Saidswirler consists of swirl chamber, airflow guide cone, and flow limiting plate. Said silencing cooler comprises internal and external silencing cooling tubes with silencing holes. Said vacuum adsorber has internal and external metallic tubes with exhaust holes, activated carbon between two tubes and flow barrier. Its advantages are low cost, high output power, low noise and temp of exhausting tail gas, and tail gas cleaning function.

Owner:李树胜

Method for extracting oil from rubber seed

ActiveCN101475872AReduce sizeSpeed up dryingFatty-oils/fats productionEdible oils/fatsEngineeringHeat generation

The invention discloses novel technology for squeezing oil from fresh rubber seeds. The technology is characterized in that the fresh rubber seeds are not required to be stacked on a stock dump for a long time but directly crushed, dried, cooked, hardened, tempered and squeezed. The time from incoming of raw materials to obtaining of squeezed rubber seed oil and squeezed rubber seed oil cakes can be shortened to be within 3 hours. The technology can avoid the phenomena of heat generation, germination and mould development caused by the fact that the rubber seed raw materials are stacked on the stock dump for a long time in the prior art, can greatly improve the quality of the obtained rubber seed oil and the obtained rubber seed oil cakes, and can also improve the oil yield and the cake yield.

Owner:XISHUANGBANNA HUAKUN BIOTECH CO LTD

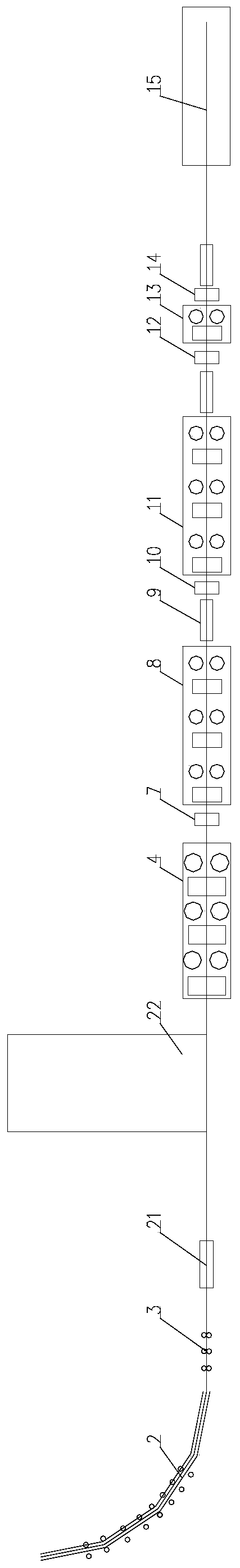

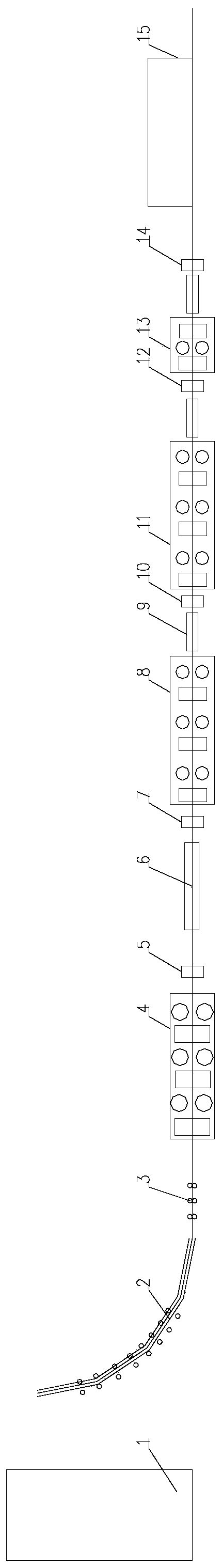

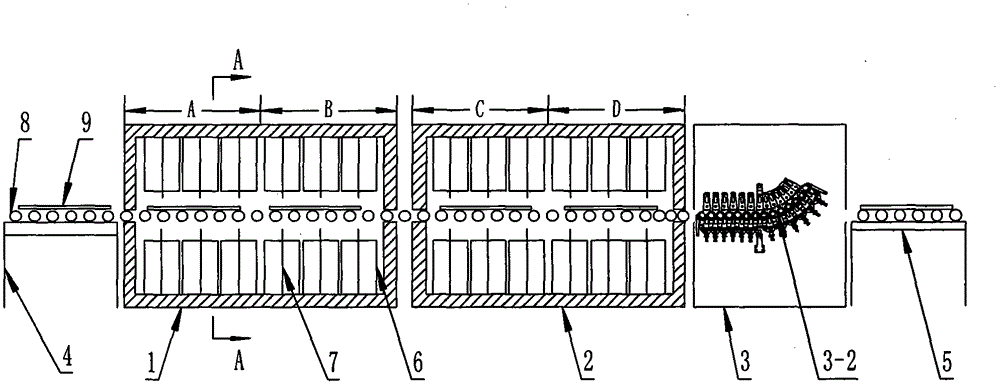

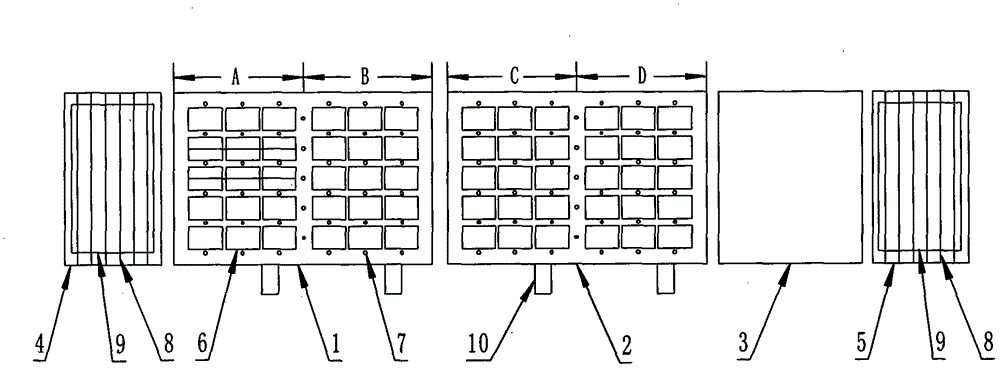

Short-process long material endless rolling production line and short-process long material endless rolling method

PendingCN110052495AGood warming effectLow powerMetal rolling arrangementsProduction lineEconomic benefits

The invention belongs to the technical field of the ferrous metallurgy industry, and relates to a short-process long material endless rolling production line and a short-process long material endlessrolling method. The short-process long material endless rolling production line comprises a steel making furnace, a continuous casting machine, a withdrawal and straightening machine, a rough rollingproduction line, an intermediate rolling production line, a finish rolling production line, a reducing and sizing mill production line and a cooling table. The steel making furnace, the continuous casting machine, the withdrawal and straightening machine, the rough rolling production line, the intermediate rolling production line, the finish rolling production line, the reducing and sizing mill production line and the cooling table are closely connected in sequence. The rough rolling production line comprises a rough rolling unit, an accident shear and cooling table, a heat preservation deviceand a pair of first end cutting flying shears in sequence. The heat preservation device supplements the heat for a casting blank which is subjected to rough rolling operation, and the separation distance between an inlet of the withdrawal and straightening machine and an inlet of the rough rolling unit ranges from 9m to 30m. The intermediate rolling production line comprises an intermediate rolling unit, a water cooling tank and a pair of second end cutting flying shears in sequence. The finish rolling production line comprises a finish rolling unit, a water cooling tank and a pair of third end cutting flying shears in sequence. The reducing and sizing mill production line comprises a reducing and sizing mill unit, a water cooling tank and a pair of fixed-length flying shears in sequence.By the adoption of the short-process long material endless rolling production line, the technological arrangement is simple, the separation distance between the continuous casting machine and the rough rolling unit is small, the rough rolling gripping operation is facilitated, the relative power consumption of the heat preservation or supplement which is conducted after the rough rolling operation is accomplished is low, the cost is low, the industrial production is easily achieved, and the short-process long material endless rolling production line has the obvious economic benefit.

Owner:CISDI ENG CO LTD +1

Production process of quick frozen istant rice and its soup

InactiveCN1887111AFully retain the color, fragrance and shapeKeep color, fragrance and shapeFood preservationVegetable proteins working-upQuick FreezePreservative

The present invention discloses one kind of quick frozen instant rice and its soup. The quick frozen instant rice has no any preservative added, no natural nutrient loss, convenient and quick eating, reasonable matching of rice, dishes and soup and scientific diet structure. The production process includes the steps of steaming rice, cooling steamed rice, forming rice, quick freezing and storing the rice product in refrigerator.

Owner:李昭津

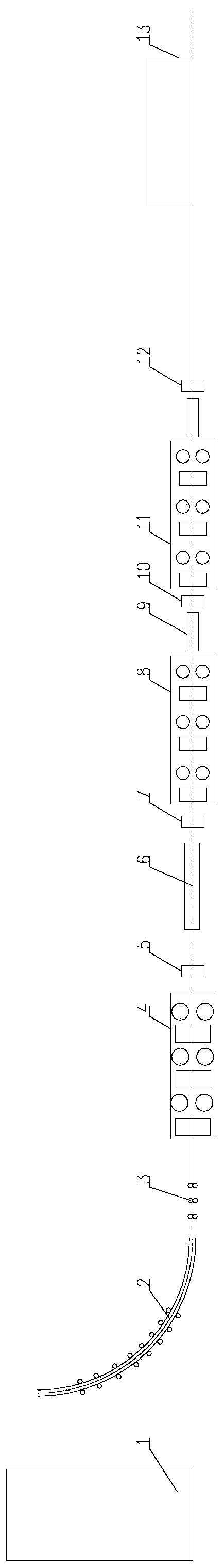

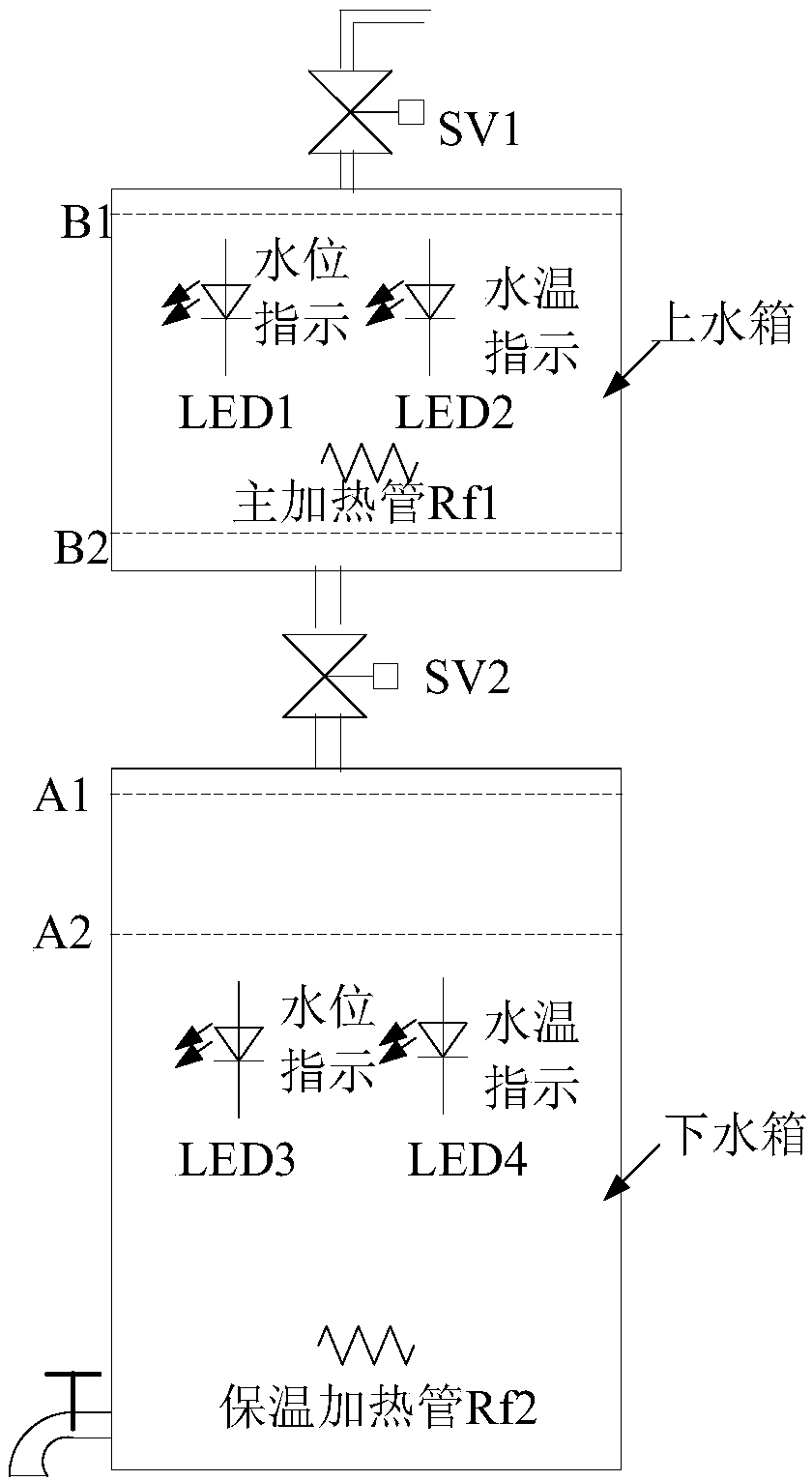

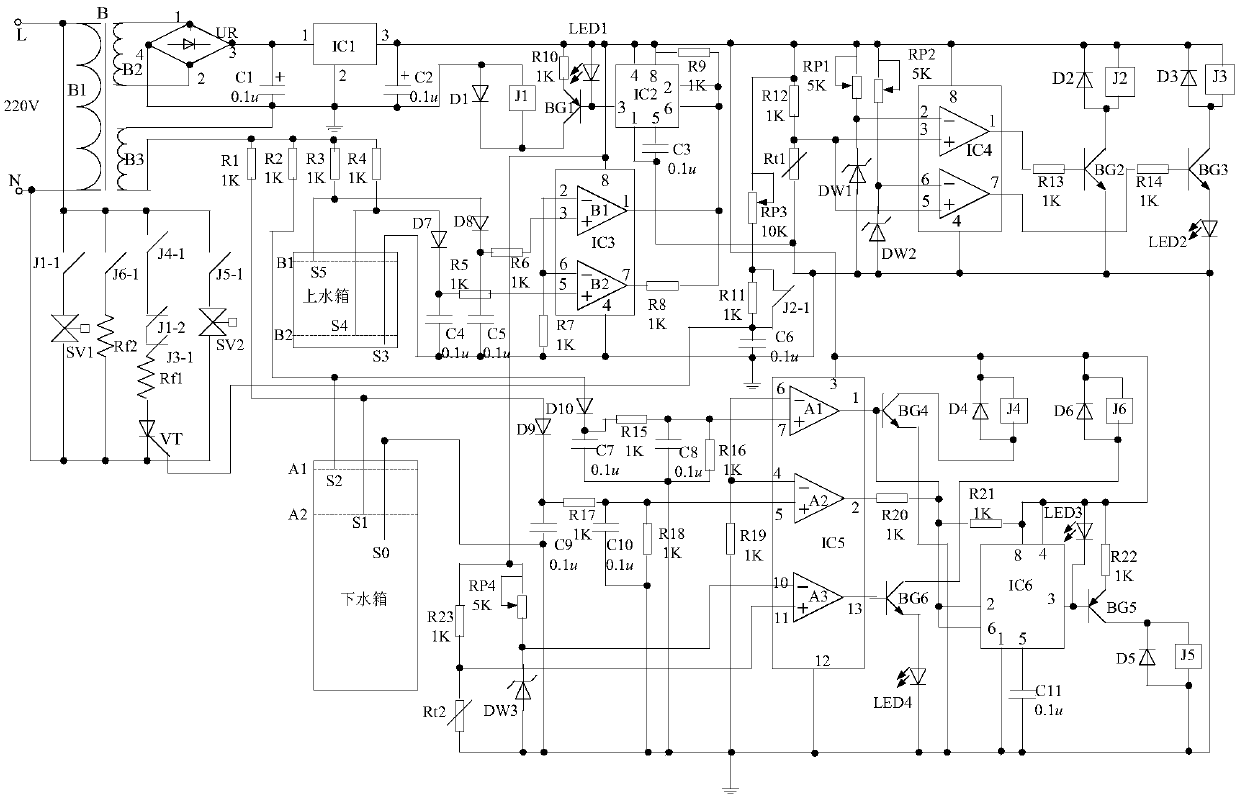

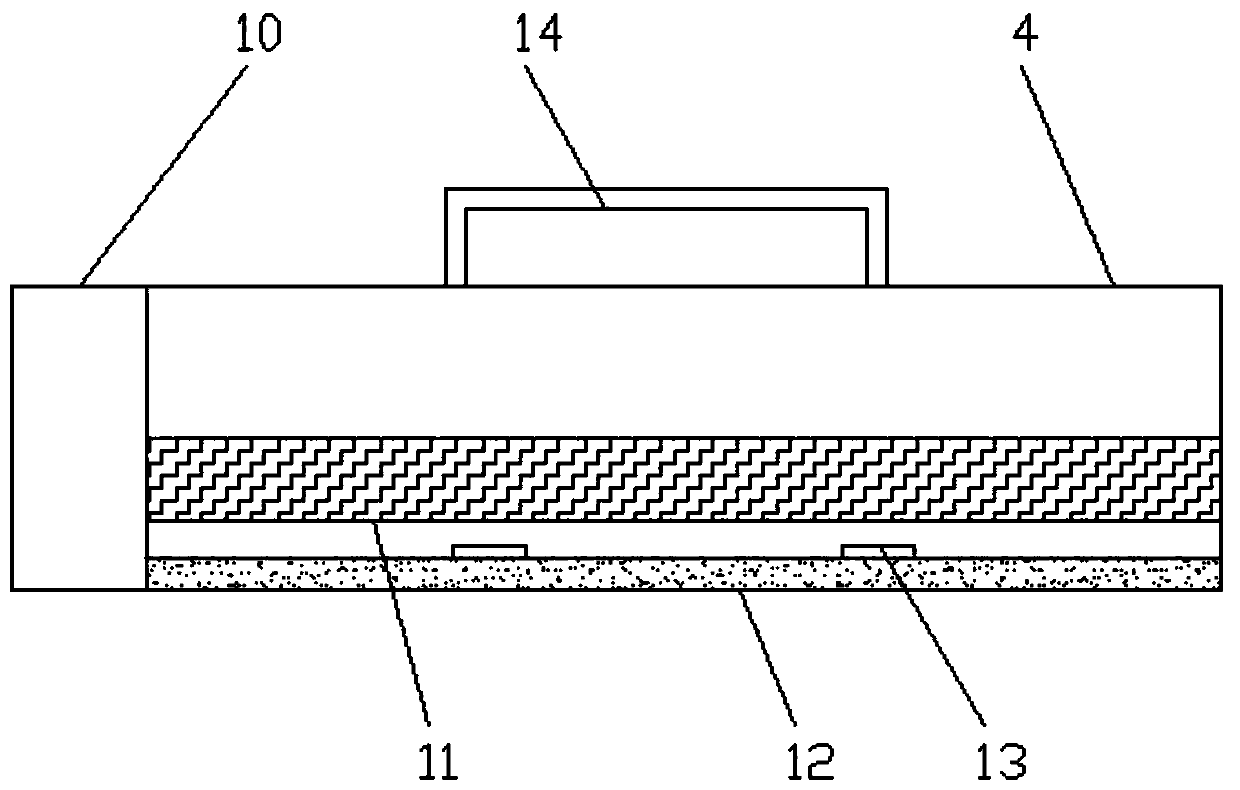

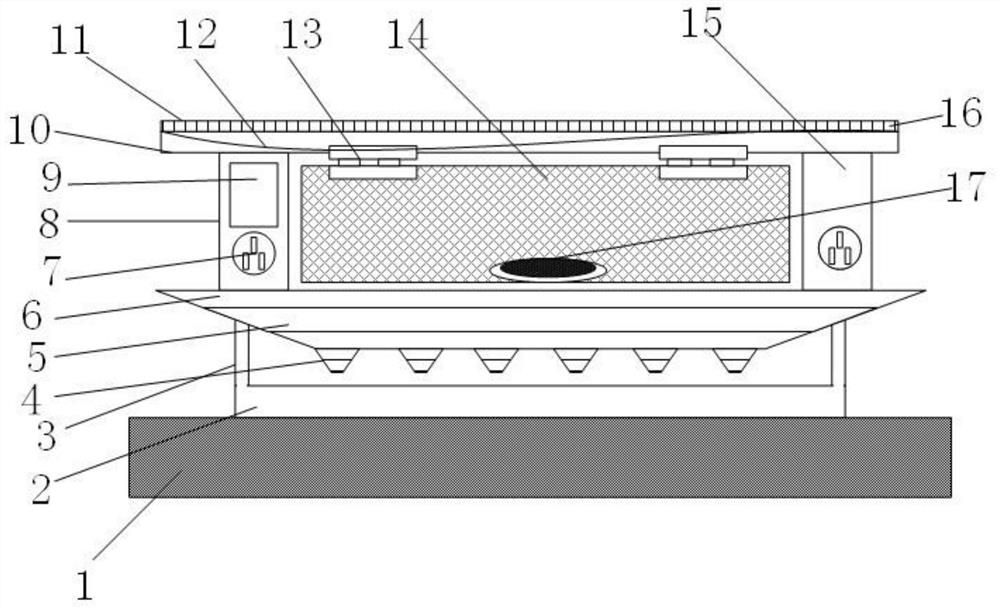

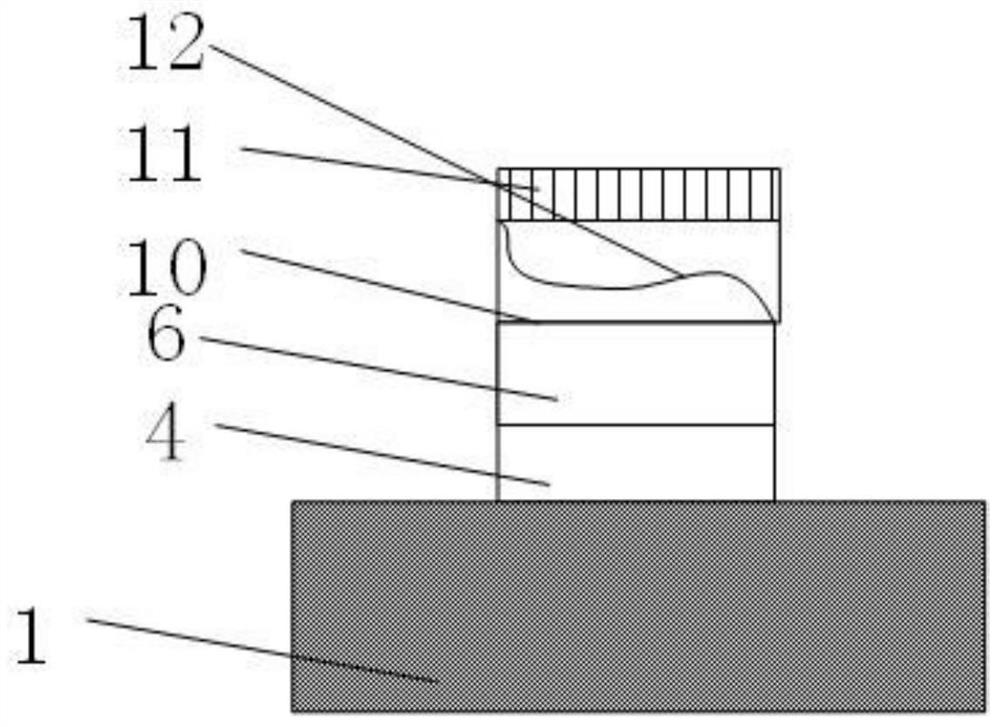

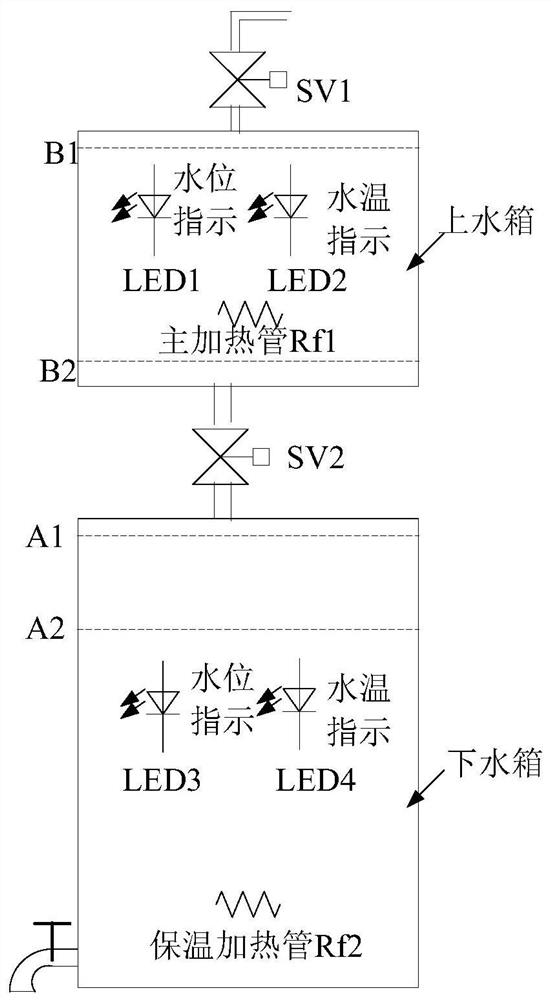

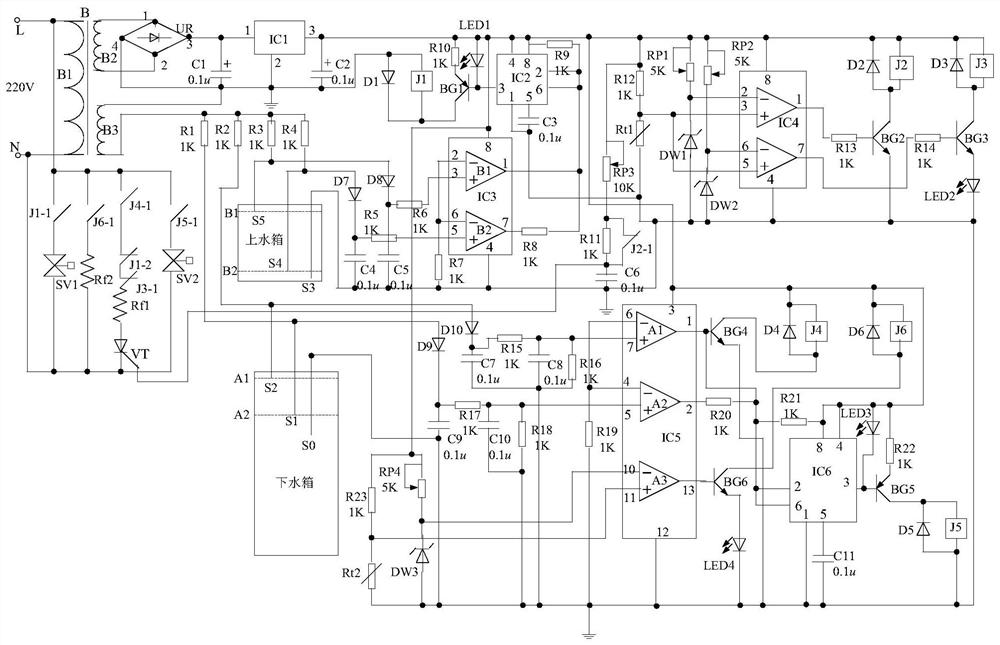

Electric water heater with double water tanks

The invention discloses the electric water heater with the double water tanks. The cold water is heated in an upper water tank and then is conveyed to a lower water tank for heat preservation and storage, a water level line arranged on the upper water tank is used for controlling the water supply amount and the injected cold water amount of the upper water tank to the lower water tank, then according to the water level line arranged in the lower water tank, when the water level in the lower water tank process is reduced to the position of the different water level lines, the cold water in theupper water tank begins to heat again, the hot water in the lower water tank is not used up, when the water level of the hot water in the lower water tank is low, the cold water in the upper water tank is heated, so that the water supplementing is carried out on the lower water tank, then the water level in the lower water tank returns to the high position again, the cold water is reinjected intothe upper water tank to facilitate the next heating and use, and the circulation is repeated. Due to the fact that the electric water heater are divided into the upper water tank and the lower water tank, the upper water tank can be used for heating cold water in the use process of the lower water tank, when the water level in the lower water tank is low, water in the upper water tank can be injected into the lower water tank, so that continuous supply of hot water in the lower water tank is guaranteed.

Owner:XUZHOU COLLEGE OF INDAL TECH

Preparation method for ceramic fiber composite crumb rubber modified asphalt

The invention discloses a preparation method for ceramic fiber composite crumb rubber modified asphalt, and belongs to the technical field of modified asphalt. According to the method, barium acetate and tetrabutyl titanate are mixed to prepare a ceramic fiber, the ceramic fiber and a waste tyre are milled to prepare mixed crumb rubber, the crumb rubber is coupled to be mixed in a high-speed shear apparatus to prepare the modified asphalt, and by the coupling effect, the asphalt is connected with the crumb rubber more closely, the strength of the asphalt is strengthened and the performance of the asphalt is improved. The preparation method has the benefits that the preparation method is simple, and in a preparation process, the ceramic fiber, the crumb rubber and the asphalt are high in compatibility and dispersibility, unlikely to be separated and easy to load, unload and transport; the modified asphalt is easy to heat, high in stability and unlikely to be influenced by low temperature and high temperature.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

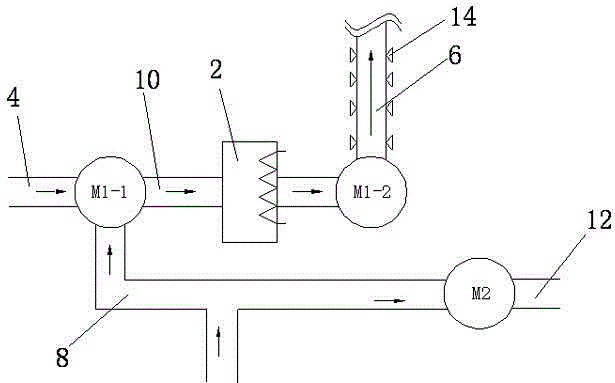

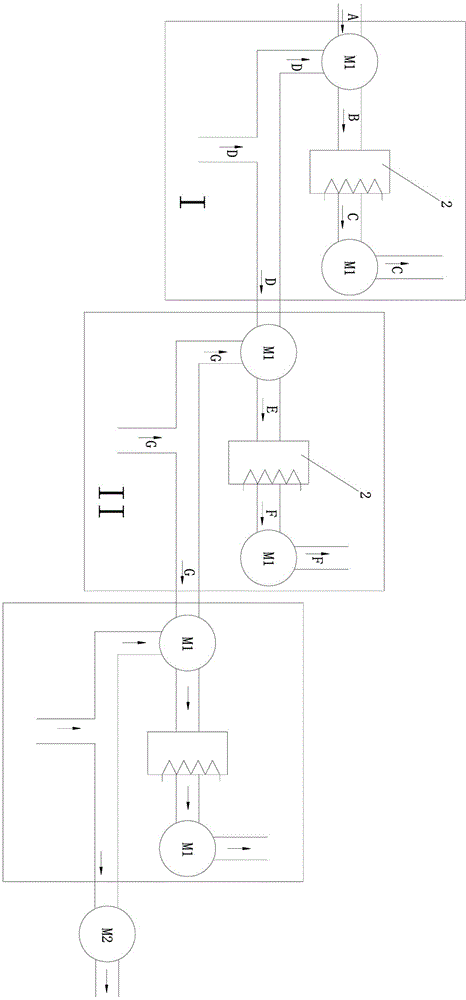

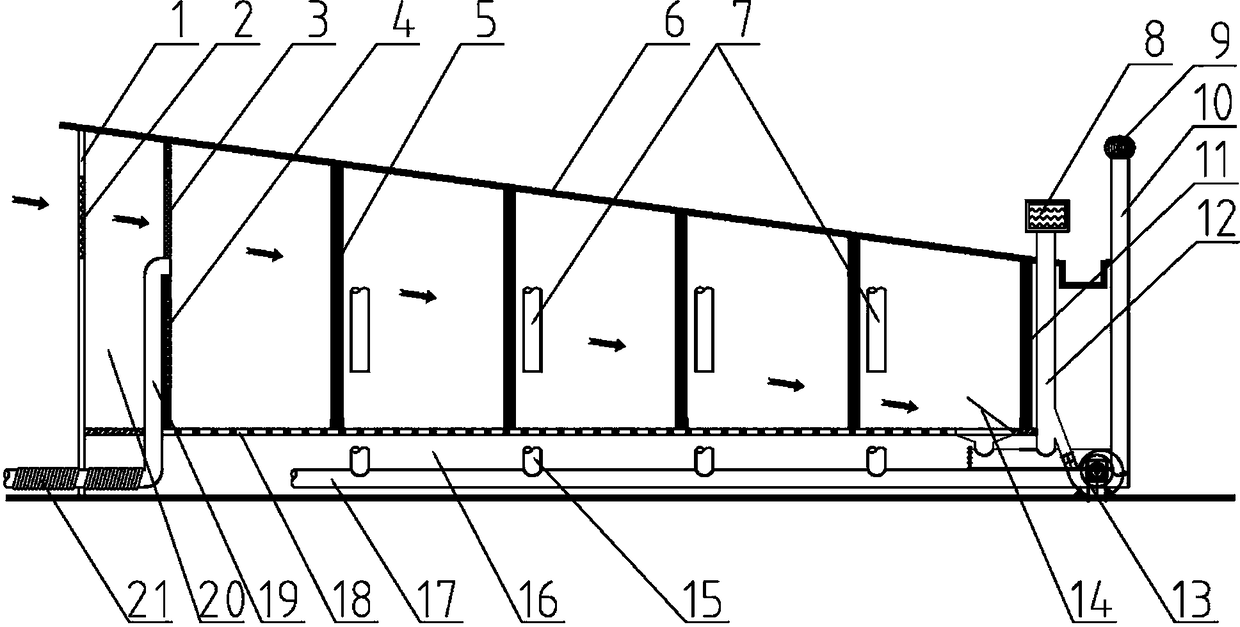

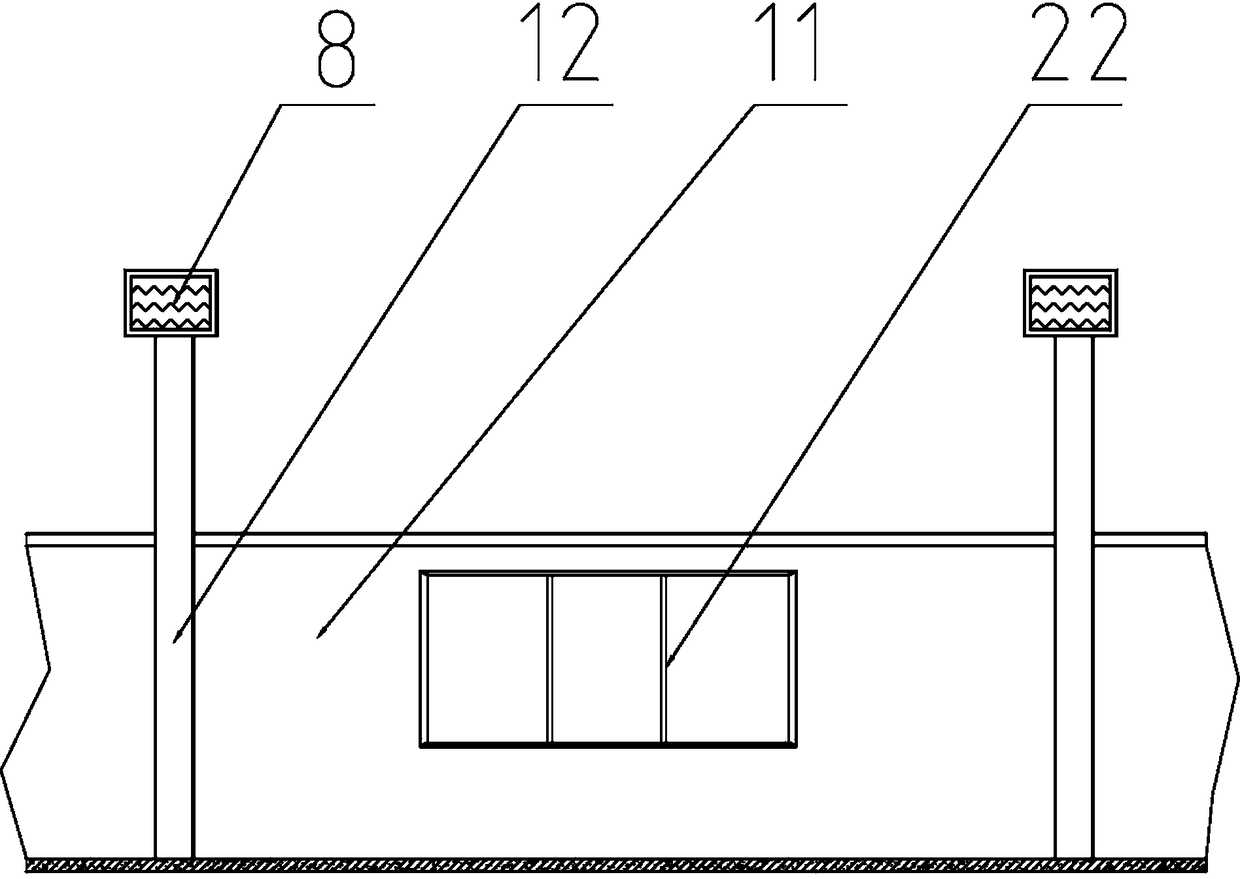

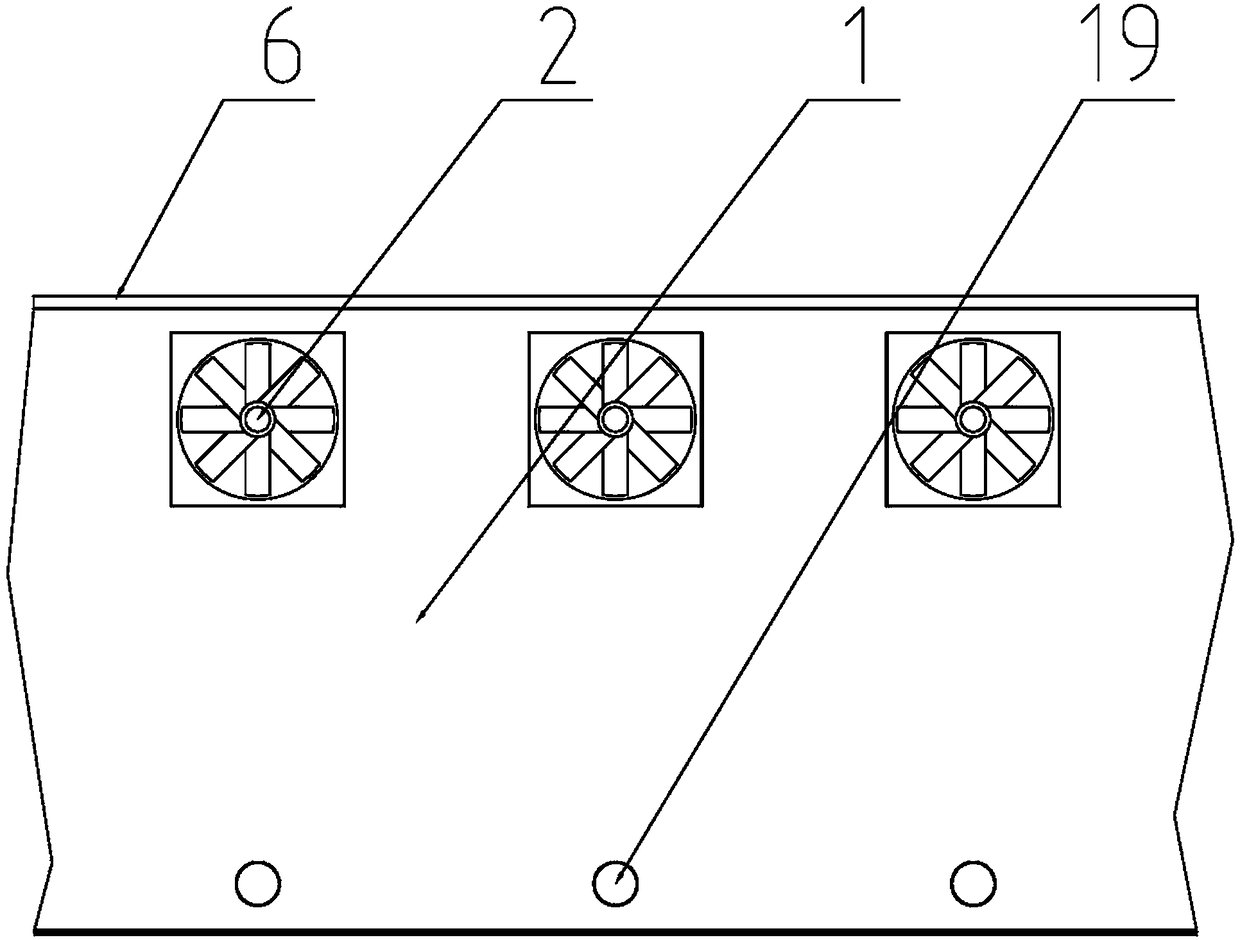

Hot air circulating system of textile drying room

InactiveCN103954114AHigh thermal efficiencyEfficient use ofDrying gas arrangementsTemperature differenceExhaust pipe

The invention provides a hot air circulating system of a textile drying room. The hot air circulating system comprises an air conveying pipe with an air inlet and an air outlet at the two ends, a circulating draught fan and air exhausting draught fans which are used for guiding air in the air conveying pipe, and a heater for heating the air in the air conveying pipe. The hot air circulating system is characterized in that the air conveying pipe comprises an air inlet chamber communicated with the air outside the drying room, an air outlet pipe and an air returning pipe which are communicated with the air in the drying room, an air guide pipe for communicating the air inlet pipe and the air outlet pipe, and an air exhausting pipe which is communicated with the indoor and outdoor parts of the drying room through the air exhausting draught fan, wherein the circulating draught fans comprise a first circulating draught fan and a second circulating draught fan which can work independently; the air inlet pipe is respectively communicated with the air returning pipe and the air guide pipe through the first circulating draught fan; the air guide pipe is sequentially communicated with the air outlet pipe through the heater and the second circulating draught fan. The hot air circulating system provided by the invention is used in the drying room so as to reduce the energy consumption and improve the heat efficiency; the temperature difference of all parts is small so as to be good for further improving the drying uniformity and the heat efficiency of textiles.

Owner:WUJIANG LONGSHENG TEXTILE

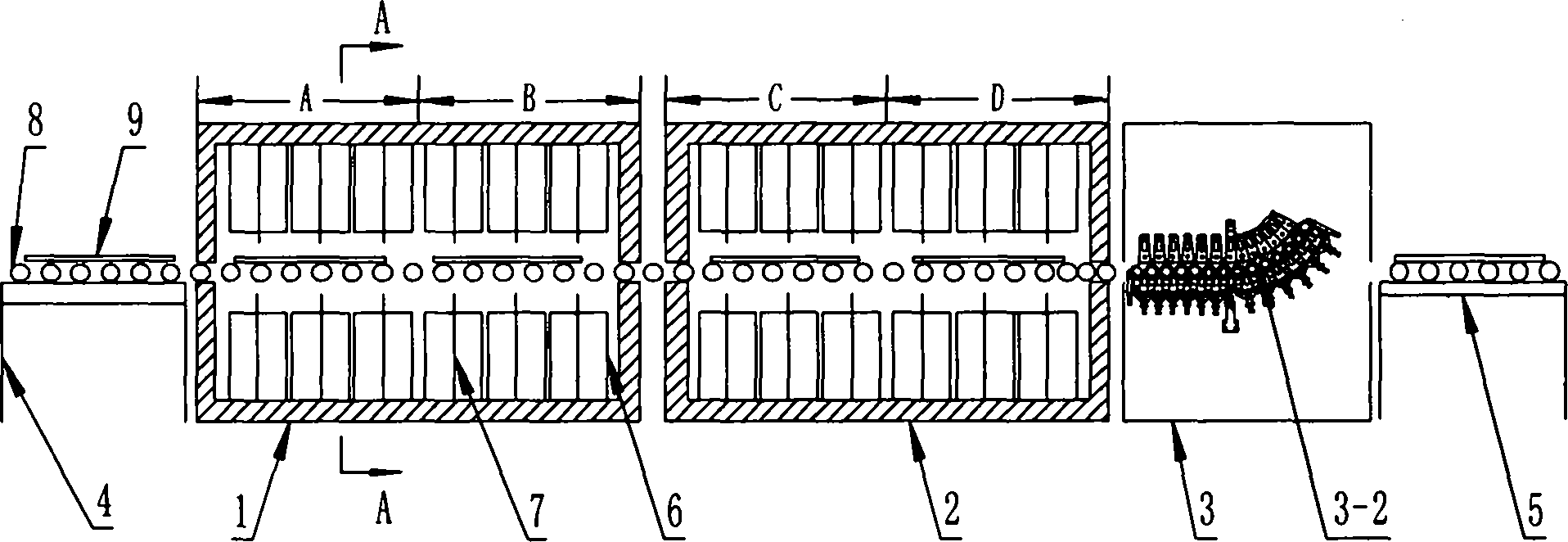

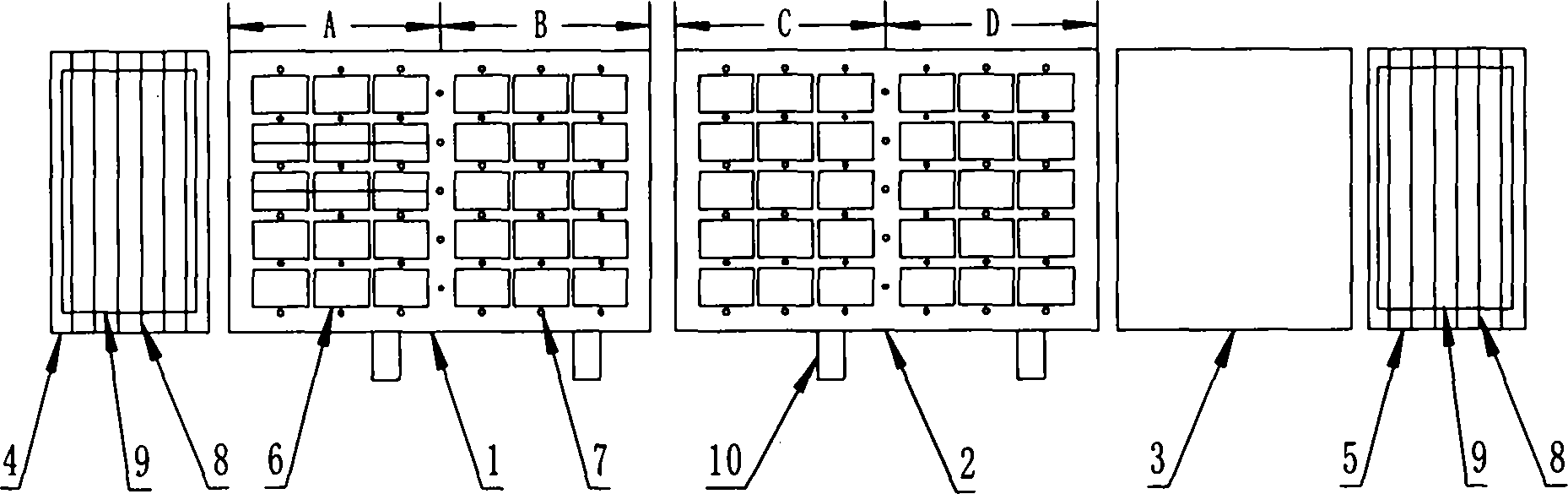

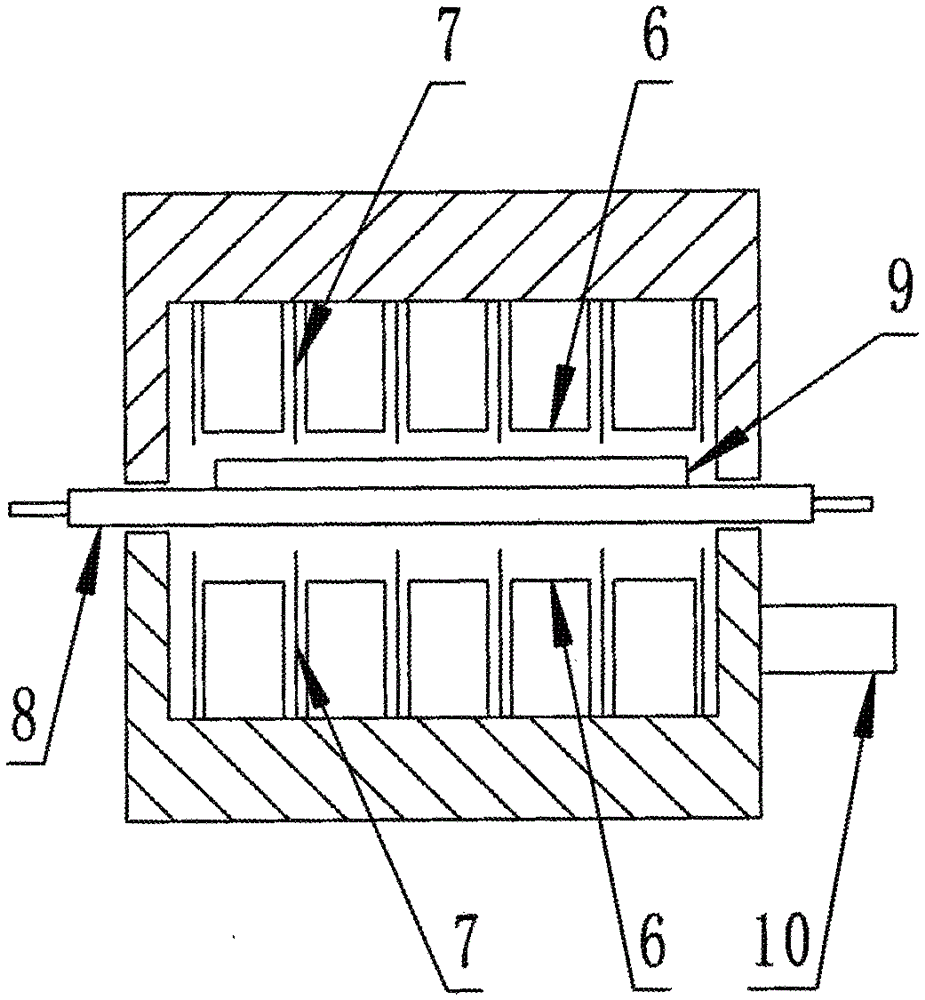

Double-chamber four-station glass bending and toughening device and control method thereof

ActiveCN104230156AShorten heating timeEasy to heat upGlass tempering apparatusGlass productionTemperature controlAutomatic control

The invention discloses a double-chamber four-station glass bending and toughening device and a control method thereof. The double-chamber four-station glass bending and toughening device consists of a preheating furnace, a first-station heating area, a second-station heating area, a heating furnace, a third-station heating area, a fourth-station heating area, a bent steel forming section, a variable arc mechanism, a die attach section, a die taking section, a matrix temperature control module, a porcelain tube, a heating furnace wire, a furnace wire lead-out rod, a thermocouple, a transfer roller, glass and a motor. The control method comprises the following steps: automatically controlling different heating temperatures and heat preservation time by a matrix fuzzy control program according to different parts of the glass, continuously heating and preserving the temperature after the temperature of the whole glass is consistent, cycling the process till the whole glass in the first-station heating area, the second-station heating area, the third-station heating area and the fourth-station heating area is heated to a set temperature, and uniformly heating the glass progressively. Therefore, the overall temperature of the glass is consistent, and a phenomenon that the glass quality is influenced due to different heating temperatures of various parts is avoided.

Owner:MOUNTAIN GLASS TECH

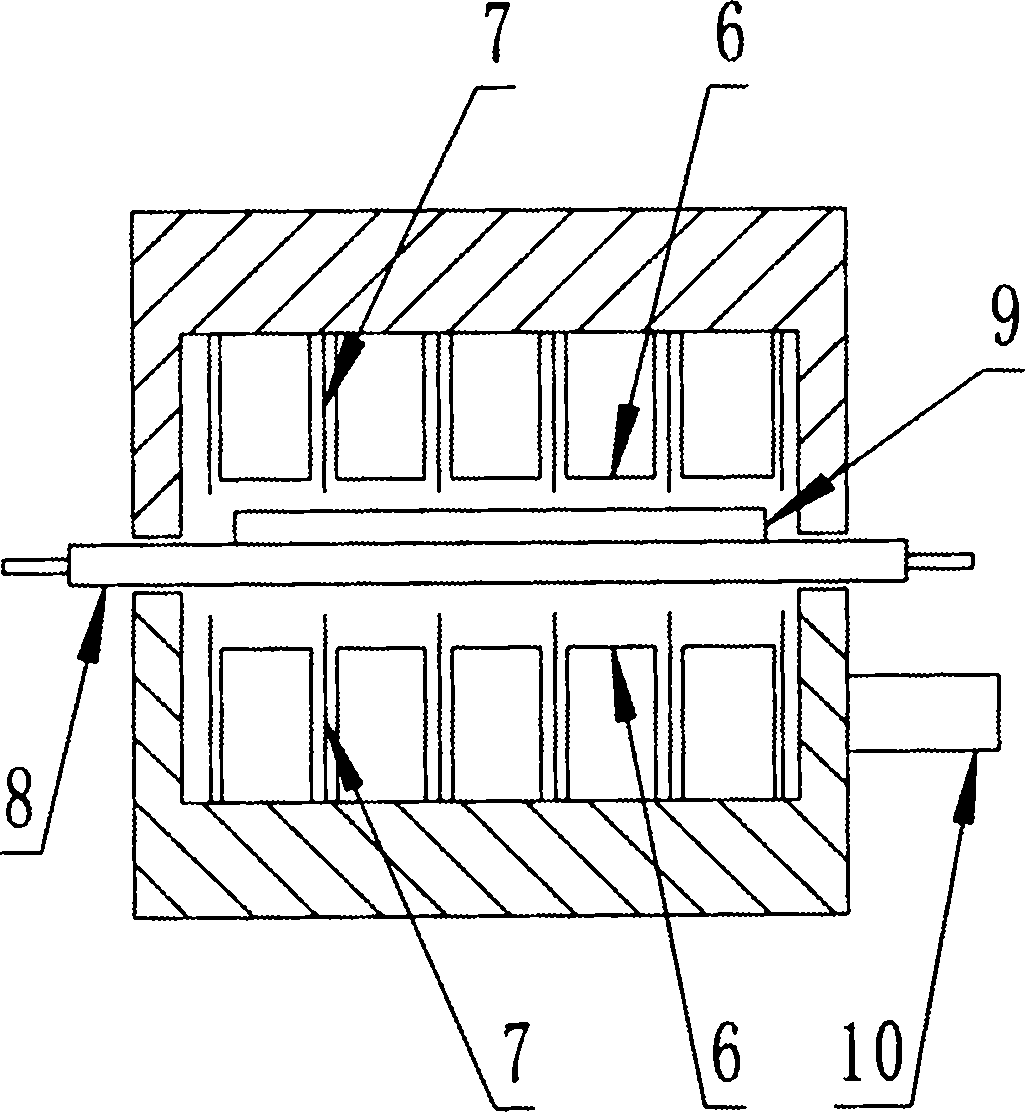

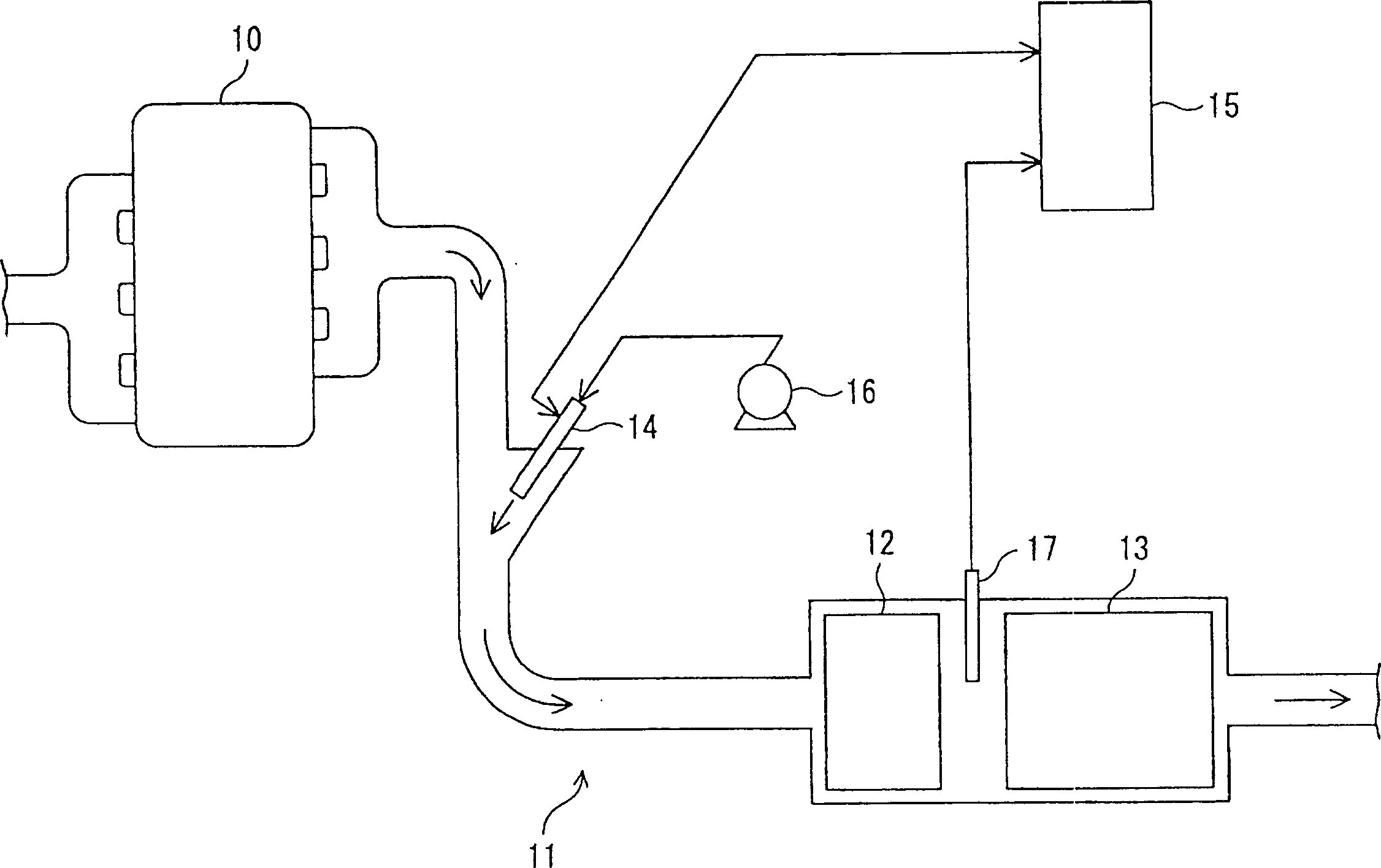

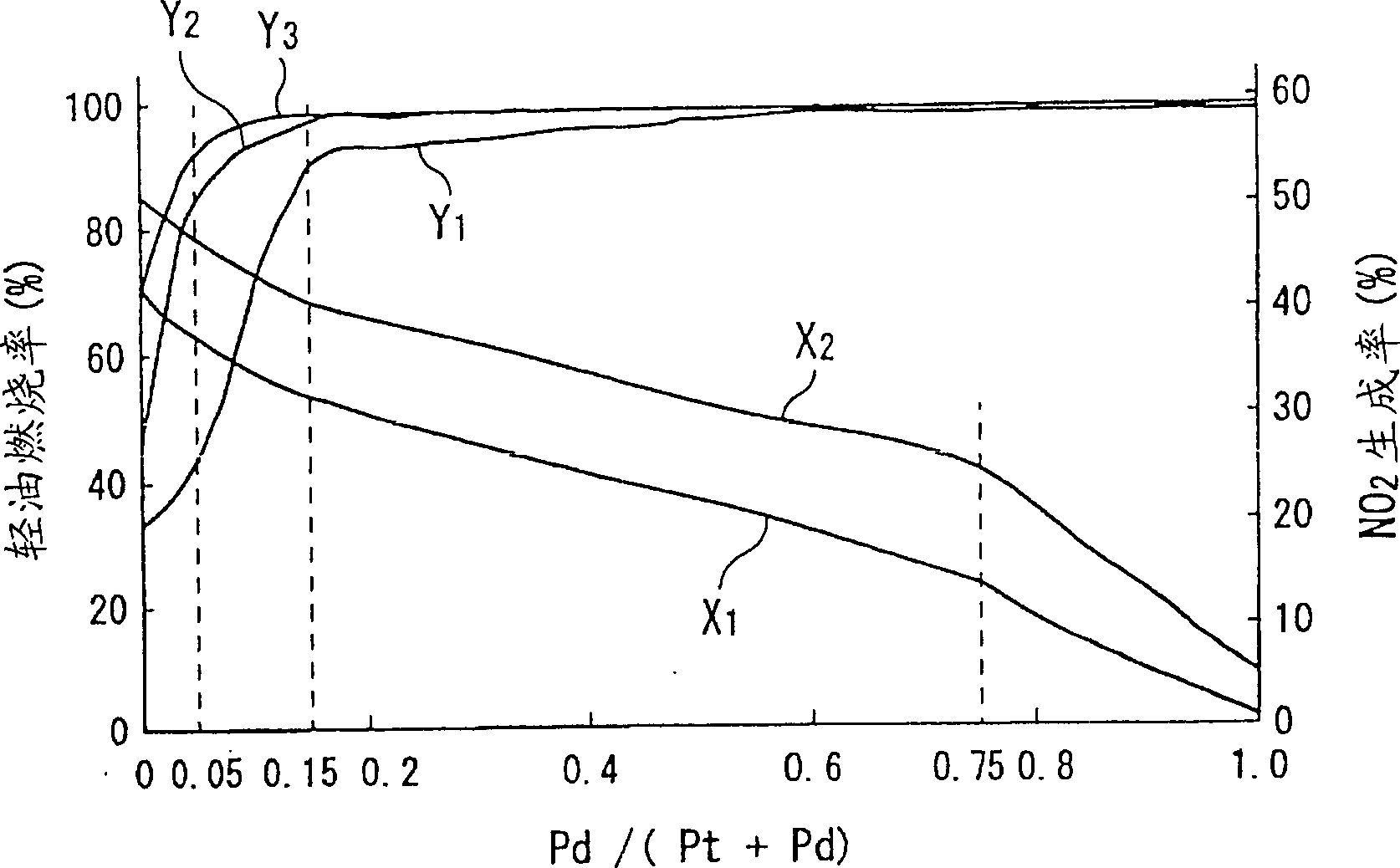

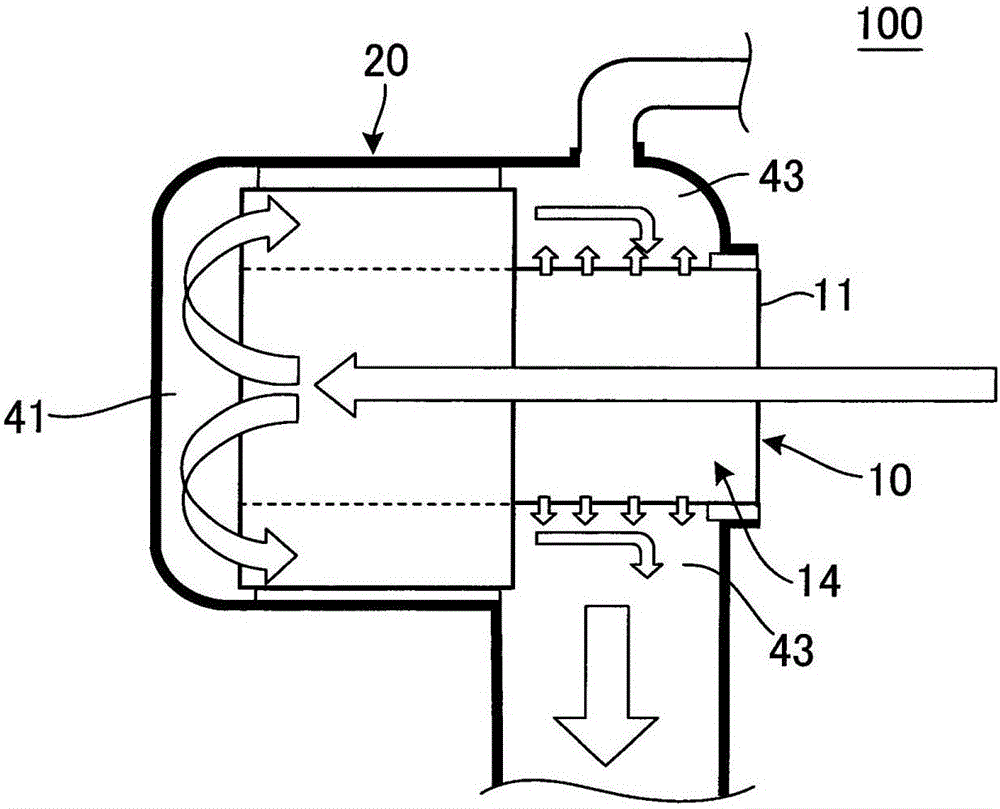

Exhaust gas purifying apparatus

InactiveCN1664322AEnsure oxidationEasy to heat upElectrical controlInternal combustion piston enginesParticulatesEnvironmental engineering

An oxidation catalyst apparatus and a particulate collecting filter are provided sequentially from an upstream side in an exhaust gas passage of a diesel engine. A ratio of the weight of Pd to a sum of the weights of Pt and Pd carried on the oxidation catalyst apparatus is satisfactory with the following inequality: 0.05<=Pd / (Pt+Pd)<=0.75. When the rise of the temperature of the particulate collecting filter is needed, fuel is supplied into the oxidation catalyst apparatus.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

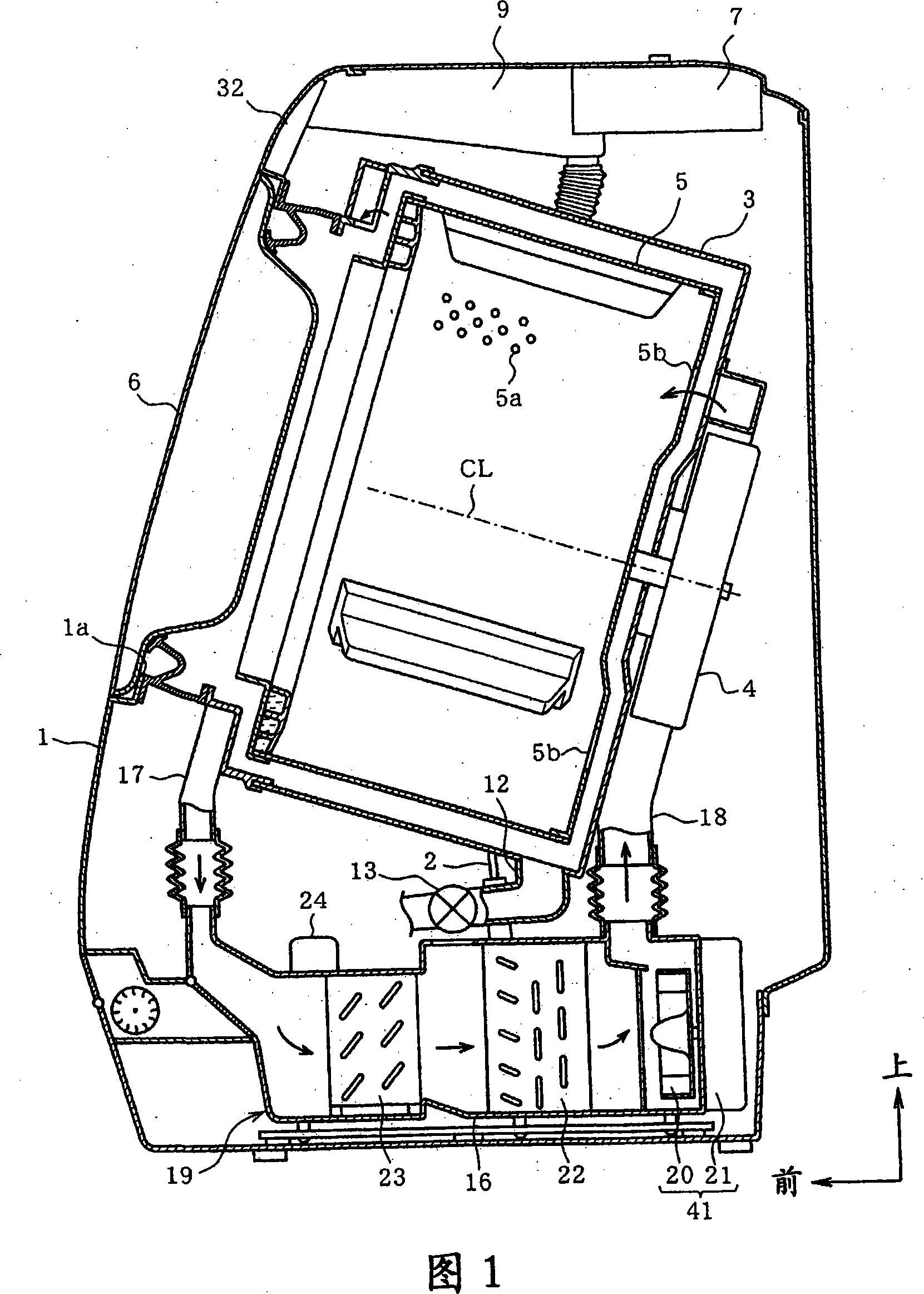

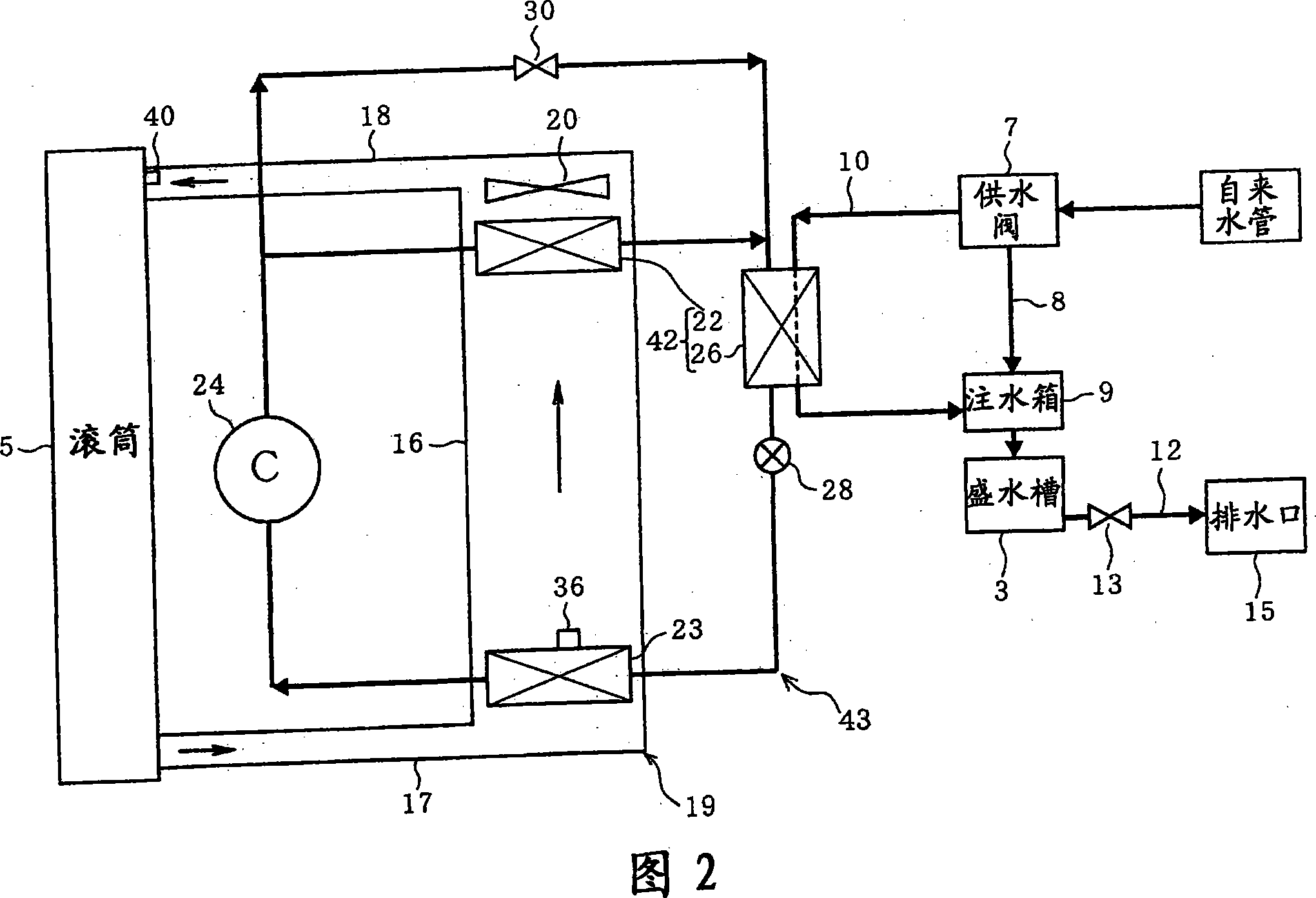

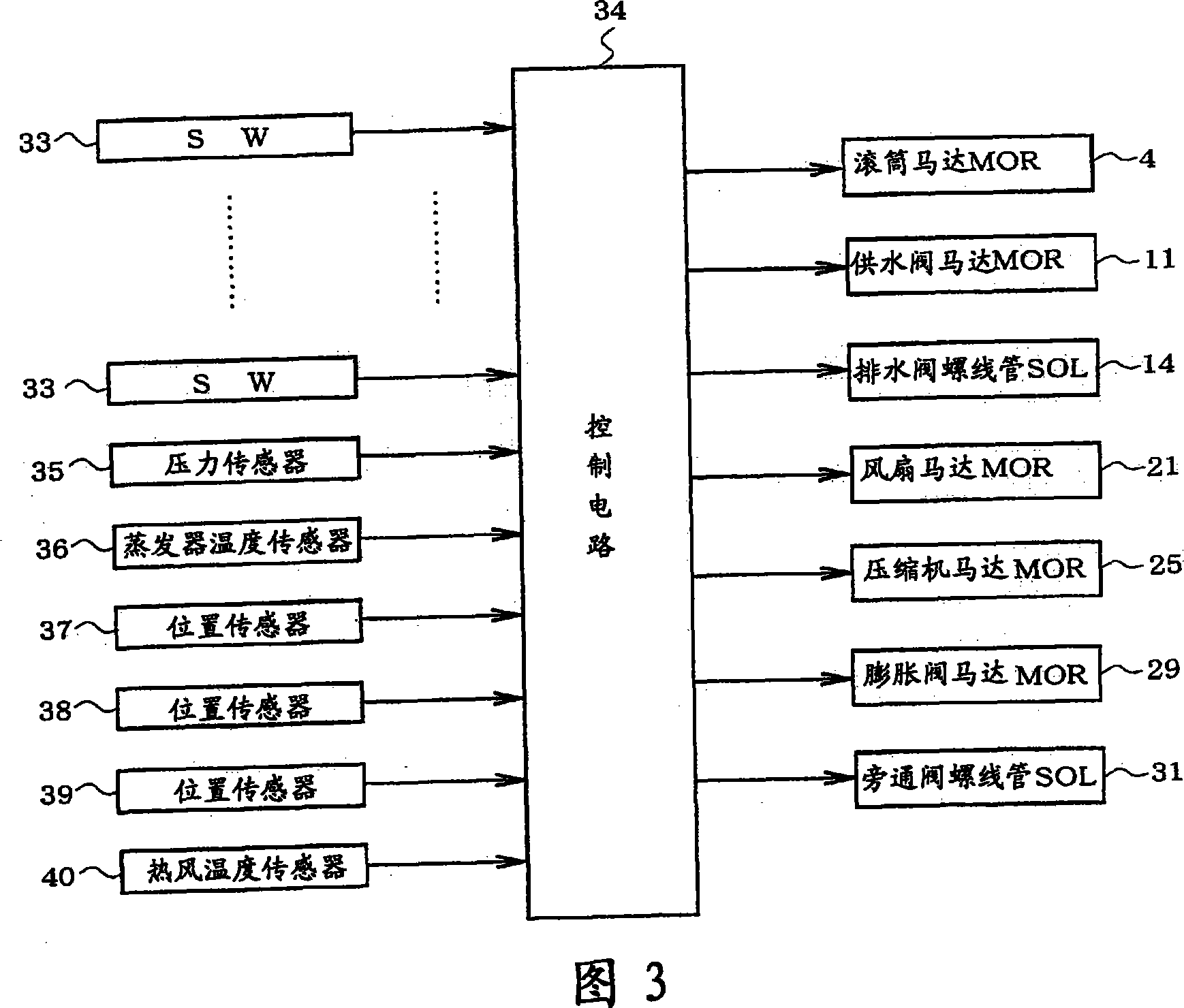

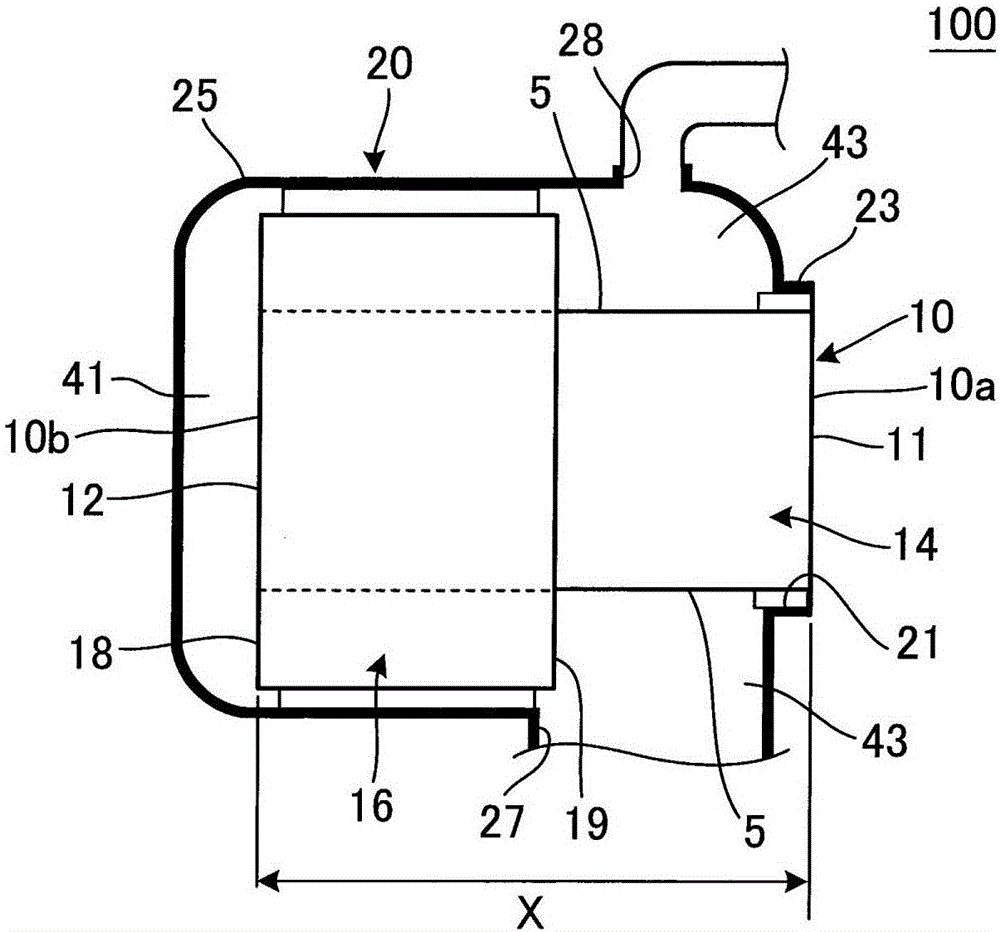

Washing machine

InactiveCN101096808AEasy to heat upReduce operating efficiencyOther washing machinesWashing machine with receptaclesTap waterWater storage tank

The objective of the invention is to raise the water temperature to the temperature which is suitable for washing. Injecting the tap water with ordinary temperature to the water storage tank by the water pipe (8), heating the tap water in the water storage tank (2) by operating the heat pump (43) to inject the hot wind to the water storage tank. The temperature of the condenser (26) has become enough high comparing with the beginning of hot wind injection treatment after a preset time from injecting hot wind for treating, injecting the tap water to the water storage tank through the water pipe (10) when the temperature of the condenser (26) has reached a high enough temperature. Therefore, the tap water in the water pipe (10) is warmed on a large scale as the water has absorbed the thermal capacity of the condenser (26) itself thereby raising the water temperature to the temperature which is suitable for washing.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

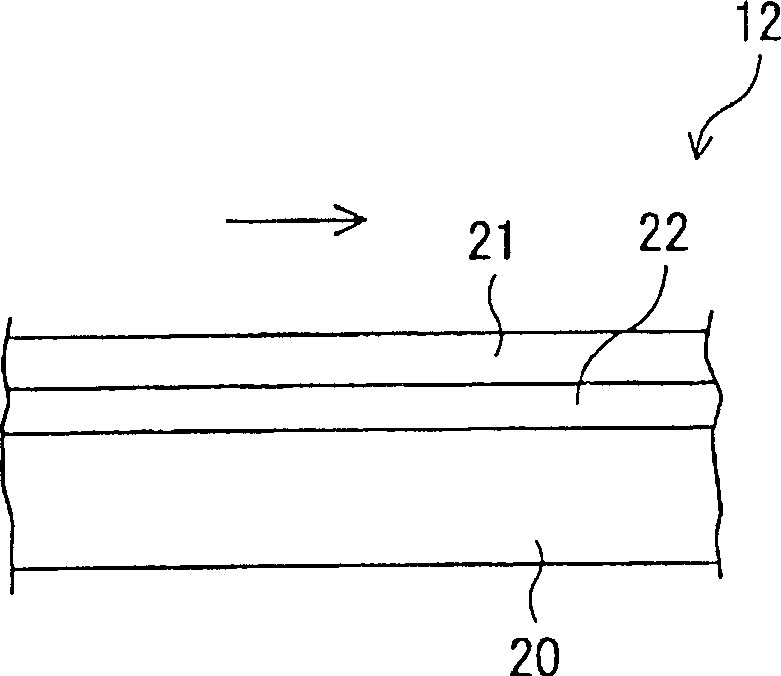

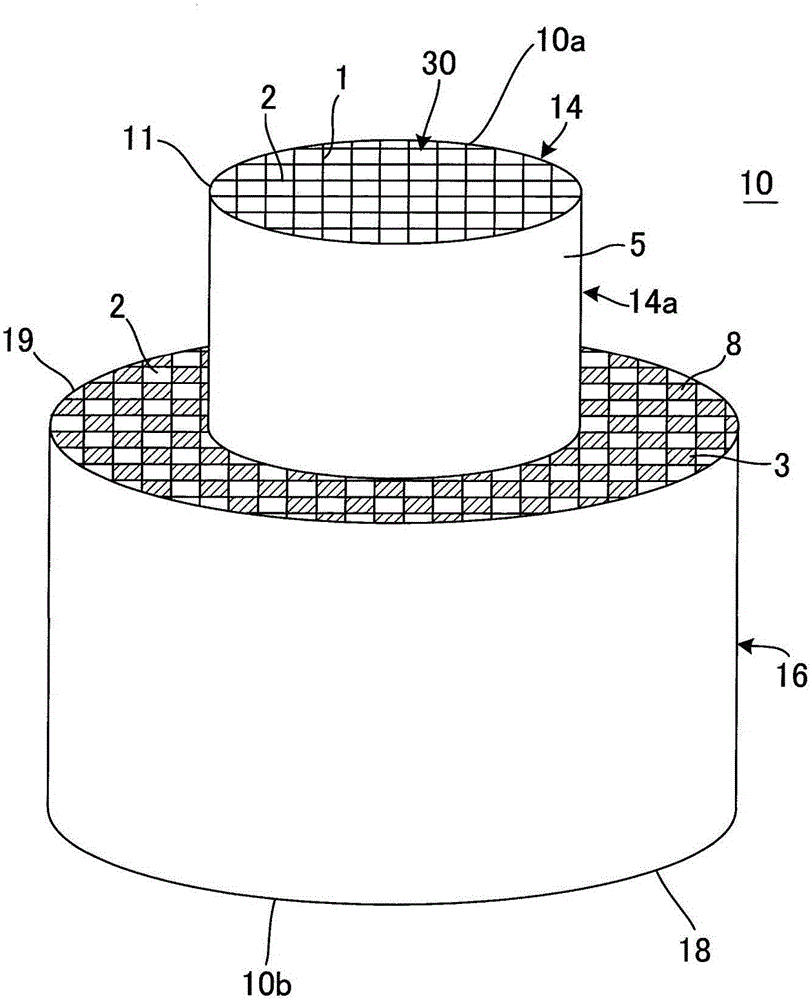

Exhaust gas treating device and manufacturing method of honeycomb structure

ActiveCN106499470AEasy to heat upReduce sizeInternal combustion piston enginesDispersed particle filtrationMechanical engineeringHoneycomb structure

Owner:NGK INSULATORS LTD

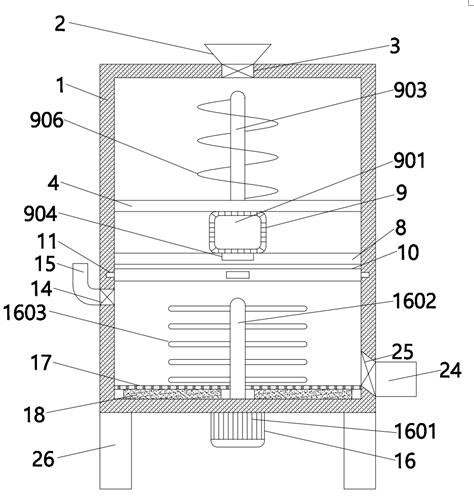

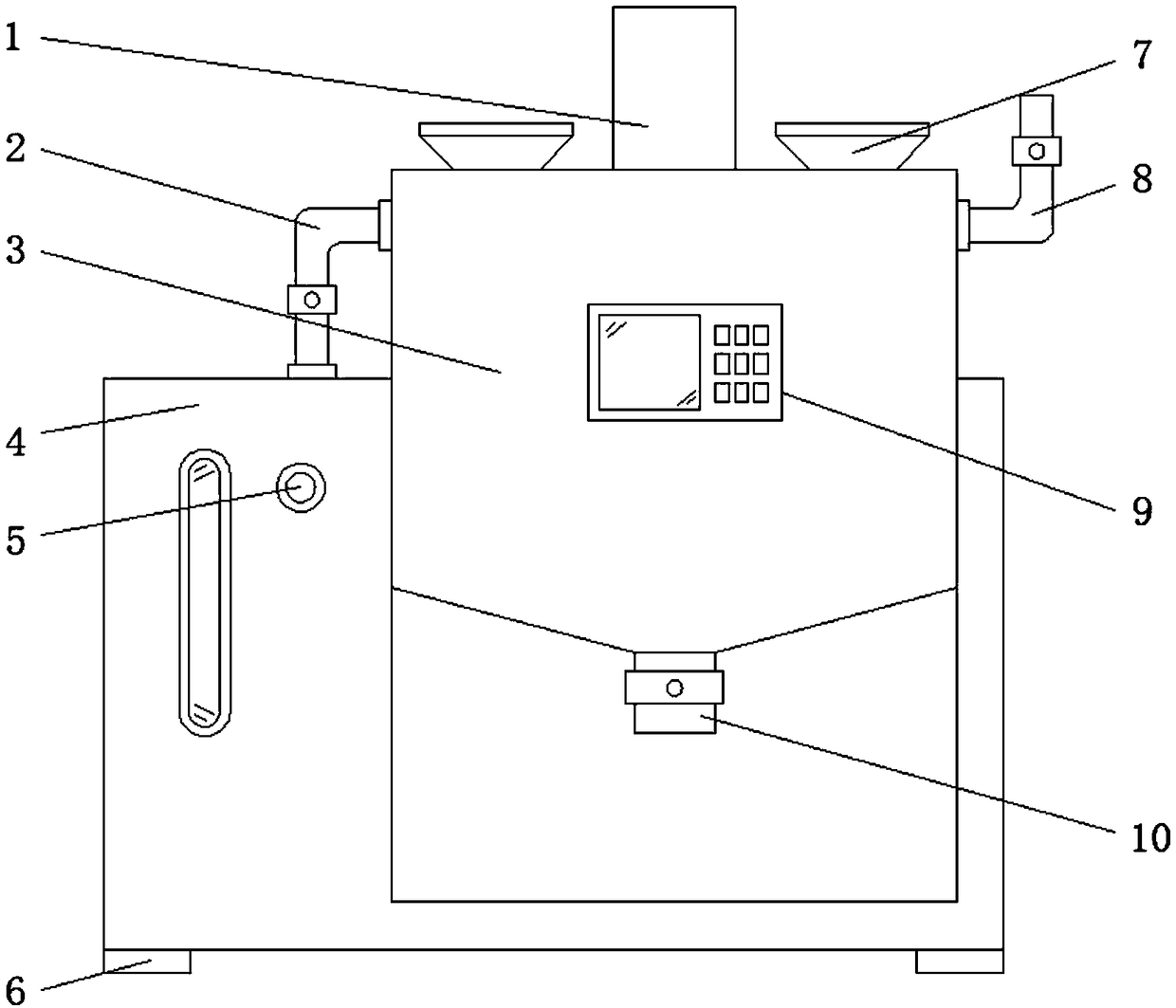

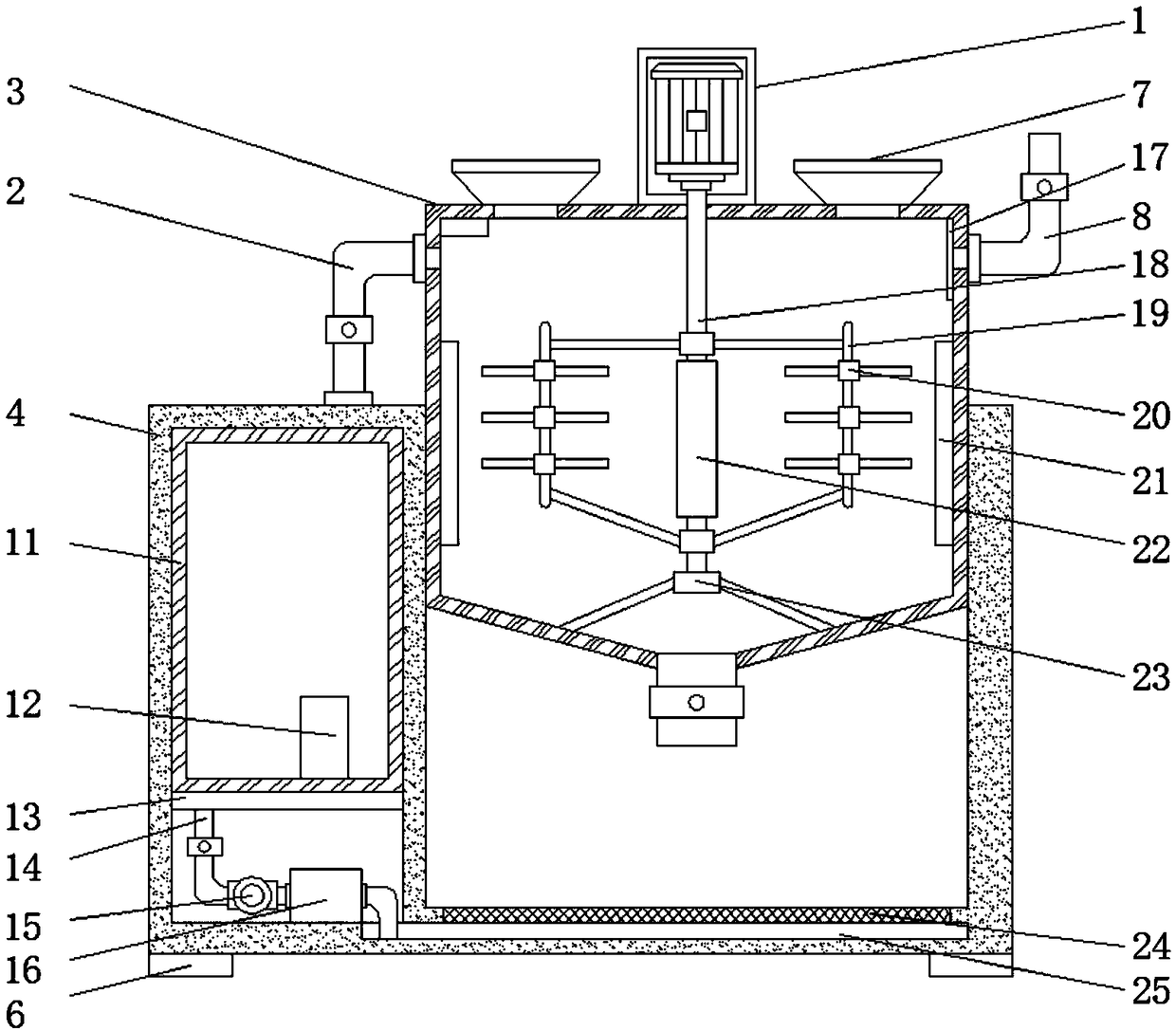

Biological feed fermentation equipment

InactiveCN112574875APrevent uneven fermentationPromote absorptionBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyNutrition

The invention discloses biological feed fermentation equipment, which comprises a fermentation box, a feeding funnel is fixedly connected to the top of the fermentation box, a first valve assembly isarranged at the joint of the feeding funnel and the fermentation box, and feed is added into the fermentation box through a feeding pipe. The first stirring mechanism is controlled by the control processor to preliminarily stir and uniformly mix feed, the feed falls to the bottom of the fermentation box after uniform stirring, then the sealing mechanism is sealed at the top of the feed, the heating device is controlled by the control processor to heat the feed, and the second stirring mechanism is started to slowly stir the feed, so that the feed is heated uniformly; meanwhile, required culture strains are added into the fermentation box through the medicine inlet pipe, so that the heating device is conveniently controlled through the control processor, and the feed which is stirred twiceand mixed with the culture strains not only facilitates nutrient absorption of livestock, but also can prevent the situation that the feed is non-uniformly fermented.

Owner:甘书学

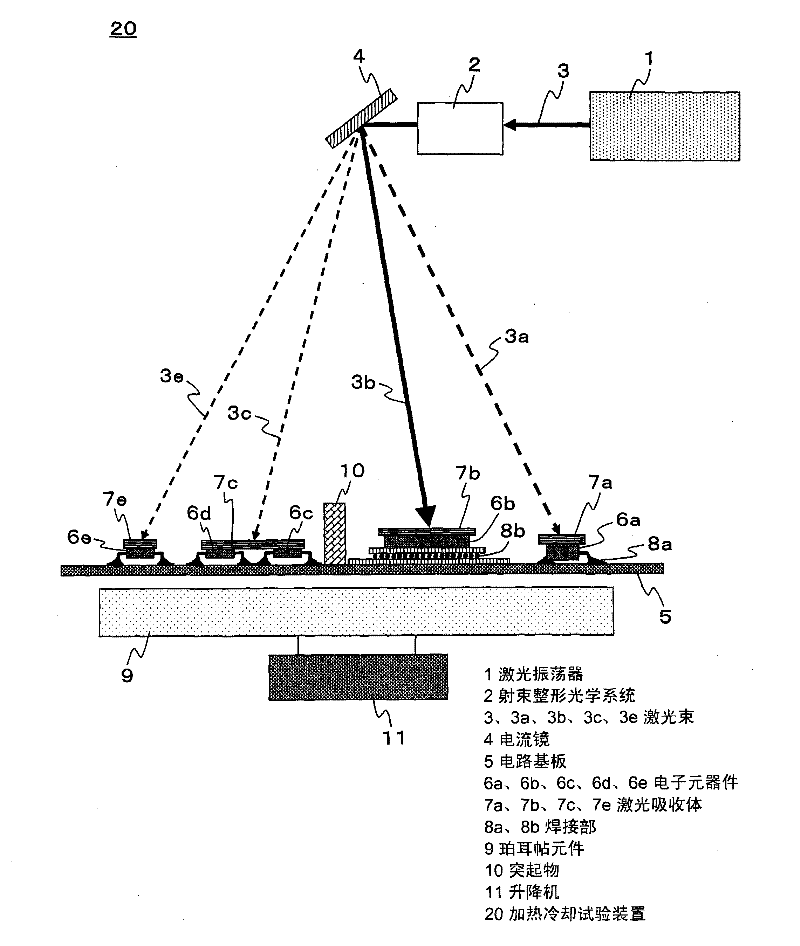

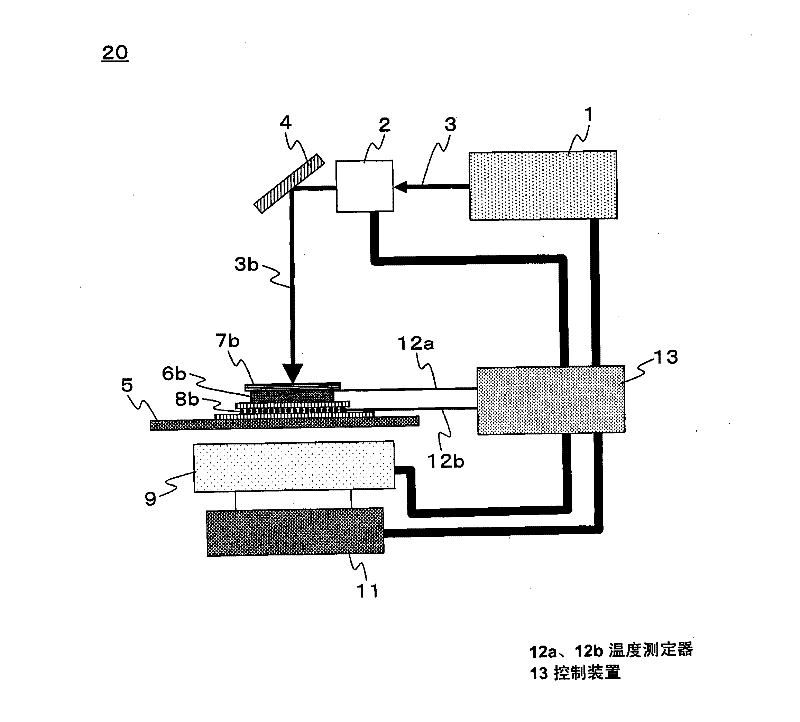

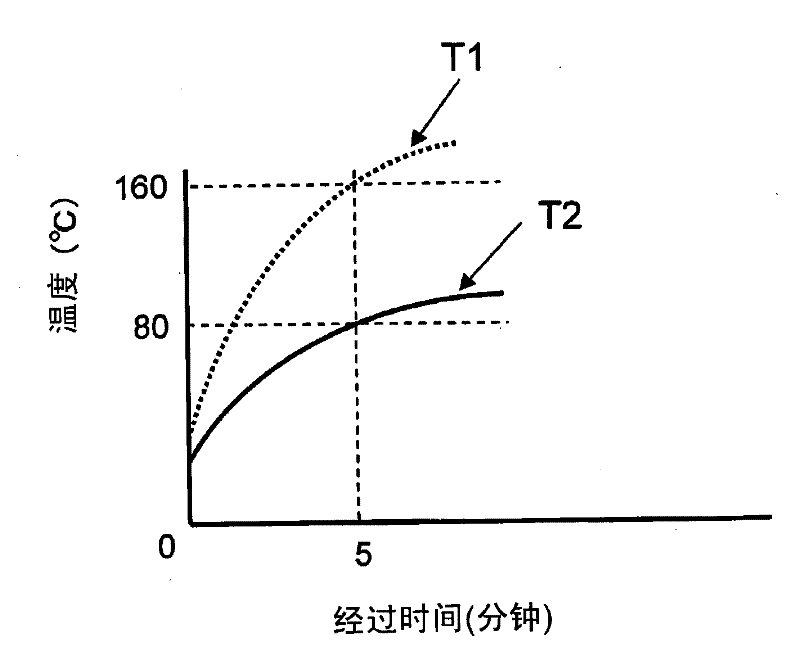

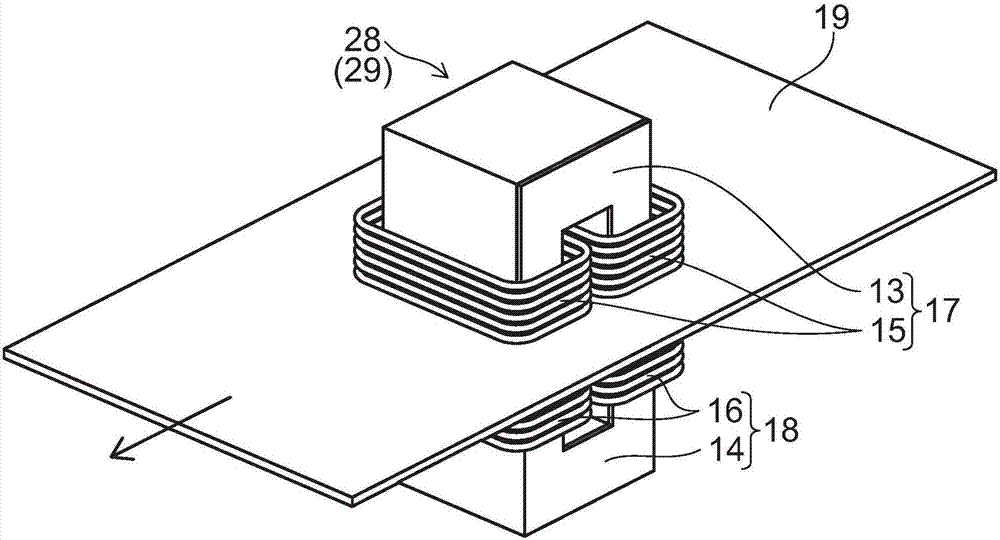

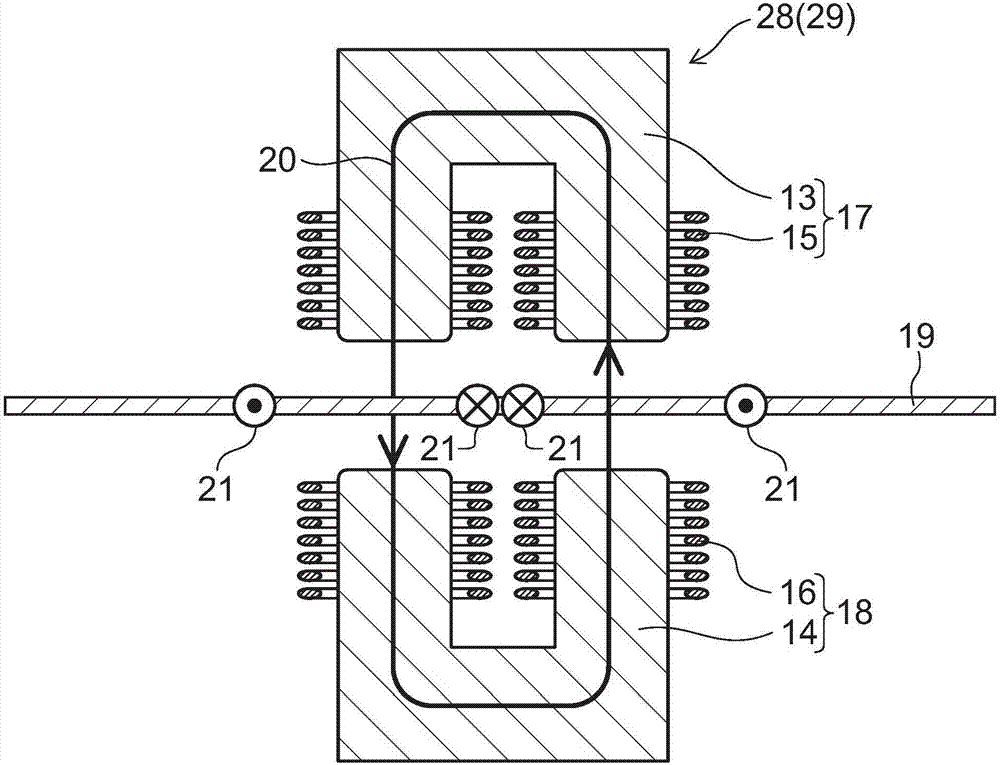

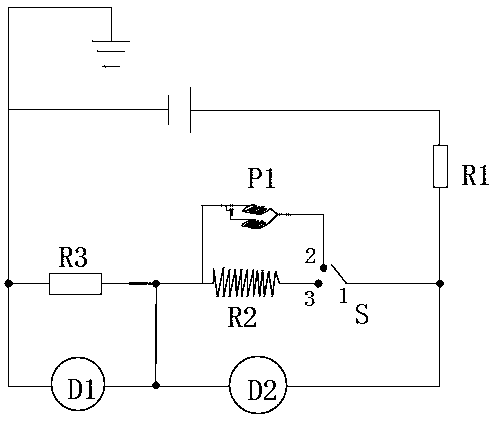

Heating cooling test method and heating cooling test device

InactiveCN102680345ASimple heatingEasy to heat upElectrical testingMaterial thermal analysisHeating coolingEngineering

The invention provides a heating cooling test method and a heating cooling test device which can simply heat in a heating up process without Peltier 's elements. The heating cooling test method is used for evaluating circuit board which is equipped with electronic components (6a-6e) and comprises the steps of heating up the electronic components, cooling the electronic components and alternatively heating up and cooling the electronic components, wherein in the step of heating, laser absorbers (7a,7b,7c,7e) equipped on the electronic components irradiate laser beams (3a,3b,3c,3e) for heating to heat the electronic components.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Ventilating method and device of animal colony house

PendingCN108566891AUniform oxygen contentEasy to operate and controlAnimal housingAcute angleFresh air

The invention discloses a ventilating method which makes a ventilation effect good, is suitable for dry and cold boreal climate conditions and is used for an animal colony house. The ventilating method is characterized in that the colony house comprises a roof installed on a high-side wall, supporting columns and a low-side wall, the roof is a slope surface, the included angle formed by the slopesurface and a horizontal plane is an acute angle of 5-15 degrees, outdoor fresh air enters the colony house through an air inlet mechanism arranged at the upper portion of one side of the high-side wall and flows towards the lower portion on one side of the low-side wall in the colony house from gradually from top to bottom, and waste air in the colony house is collected and centralizedly treatedby a pipeline-type air outlet mechanism arranged at the lower portion of one side of the low-side wall and then is discharged. Air in the colony house undergoes heating treatment through pipeline airinflow in winter, control is quick and convenient, the cost is low, operation control of workers is simple and easy, and the pipeline-type air outlet mechanism also facilitate centralized treatment and discharge of waste air in the colony house. In addition, air is guided to flow downward through air guiding pipe arranged on the supporting columns, so that fresh air in the colony house contains uniform oxygen, and temperatures at the front end and the rear end in the colony house are uniform.

Owner:阿克苏兴疆牧歌食品股份有限公司

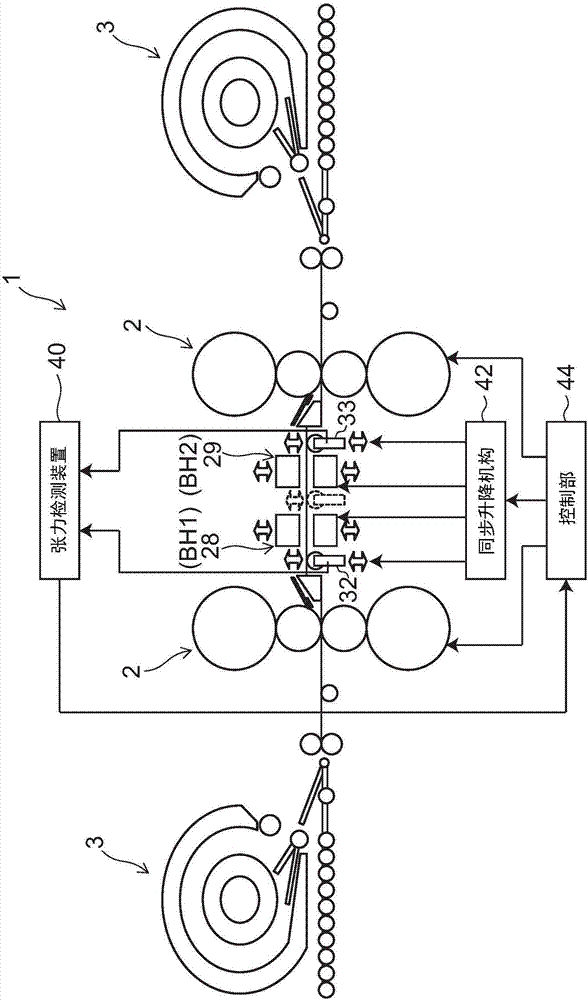

Rolling facility

ActiveCN107405658AImprove temperature distributionStable controlTemperature control deviceMeasuring devicesSheet steelEngineering

Provided is a rolling facility equipped with: two coiler furnaces; multiple mill stands provided between the two coiler furnaces for the purpose of performing reverse rolling; and induction heating devices provided between the multiple mill stands for increasing the temperature in the lengthwise direction and the width direction of a steel sheet during a prescribed reverse rolling operation or each reverse rolling operation. Thus, it is possible to improve the temperature distribution of the steel sheet.

Owner:TOSHIBA MITSUBISHI ELECTRIC IND SYST CORP

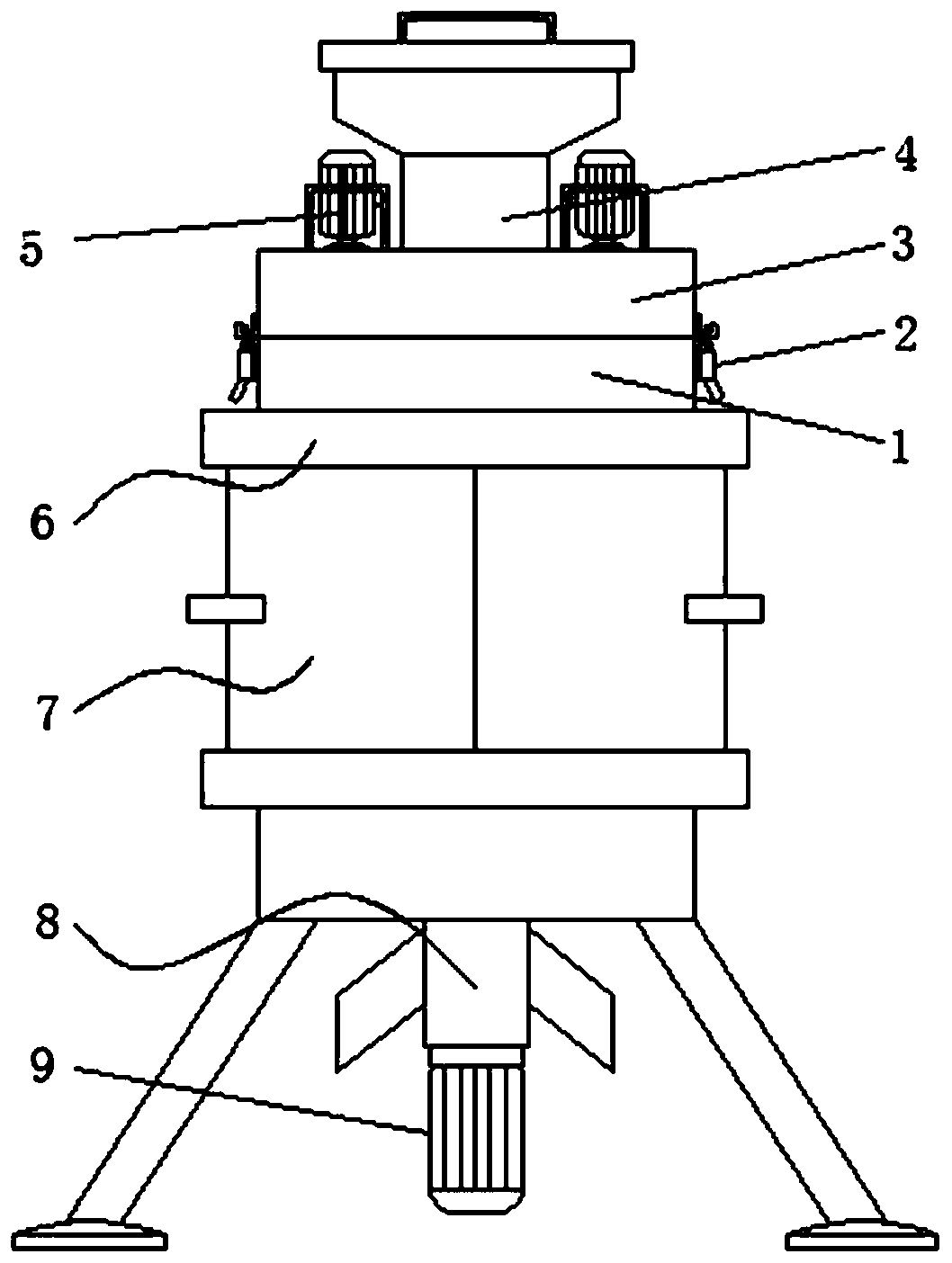

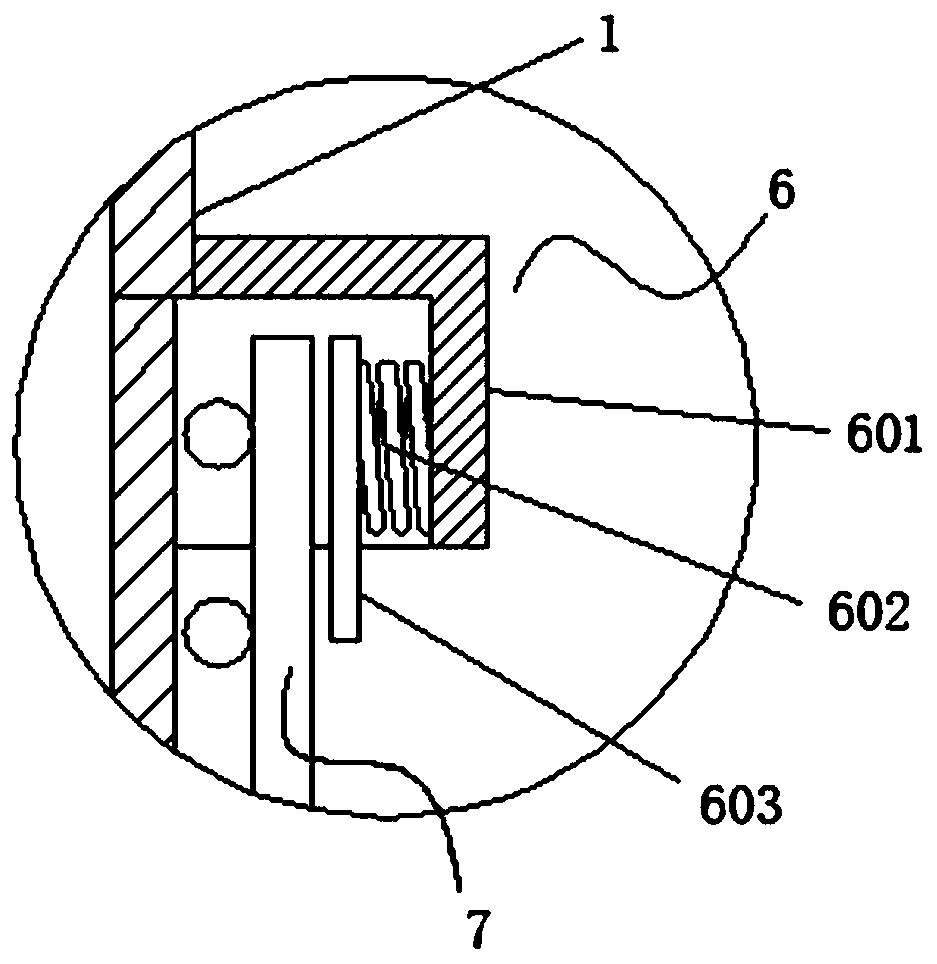

Processing and mixing device for pharmaceutical engineering

InactiveCN108654476AEasy to stir and mixEasy to reuseTransportation and packagingRotary stirring mixersImpellerArchitectural engineering

The invention discloses a processing and mixing device for pharmaceutical engineering. The processing and mixing device comprises a motor, a mixing tank and a machine body, wherein supporting legs areuniformly installed on the bottom of the machine body, a mixing tank is installed on the center of one end of the machine body, the bottom end of the mixing tank is provided with a discharging pipe,two ends of the top of the mixing tank are respectively provided with a feeding hopper, the motor is installed on the center of the top of the mixing tank between the feeding hoppers, the output end of the motor extends into the mixing tank and is provided with a rotating shaft, two ends of a stirring paddle are respectively and uniformly provided with a stirring impeller, and one end of the mixing tank is provided with an air outlet pipe. The processing and mixing device is provided with the motor, the mixing tank and the machine body, the motor is installed on the top center of the mixing tank, the rotating shaft of the output end of the motor is provided with the stirring paddle, two ends of the stirring paddle are uniformly provided with the stirring impeller, so that drugs inside thedevice can be stirred and mixed by virtue of the stirring paddle and the stirring impeller, and the drug can be sufficiently mixed.

Owner:许兰兰

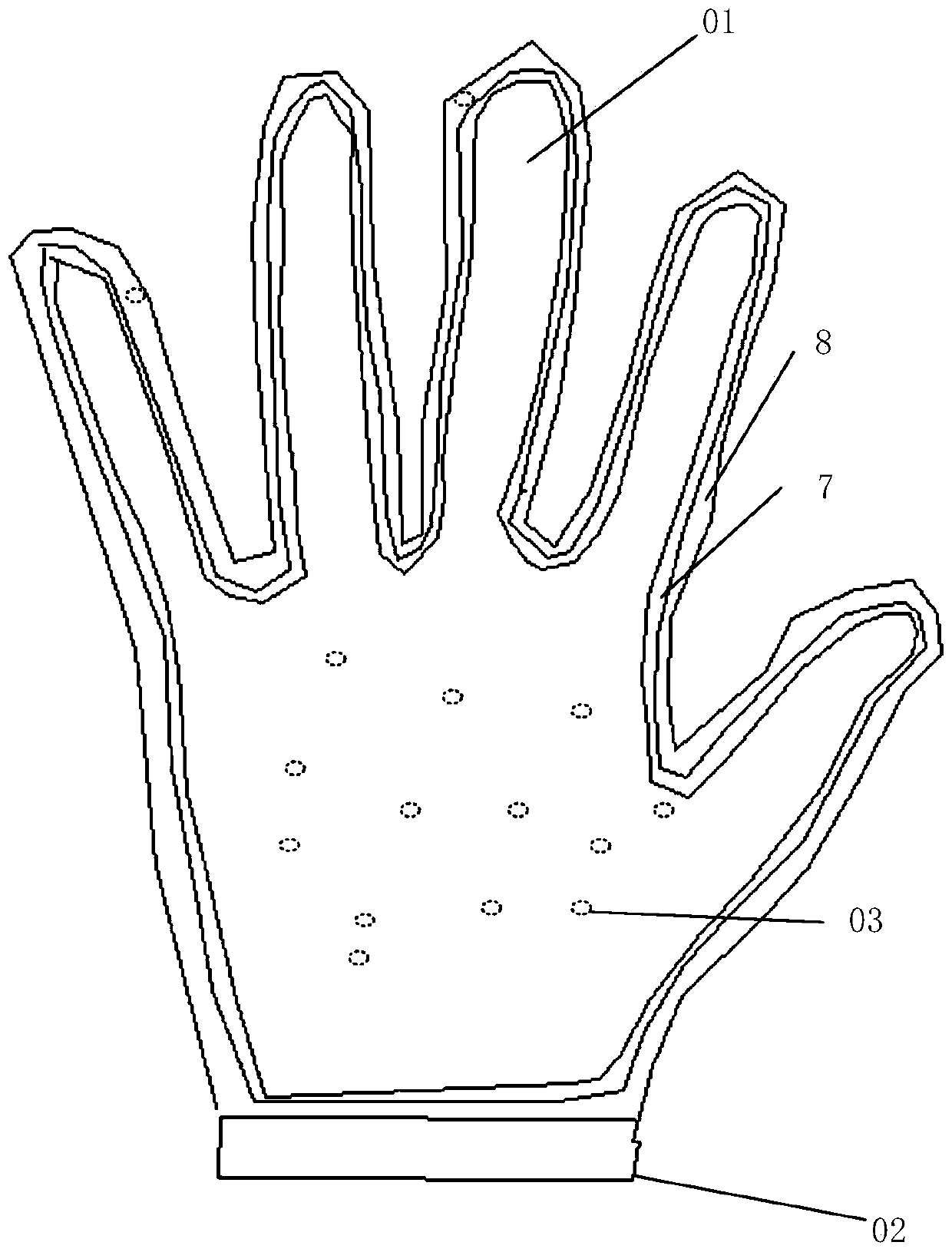

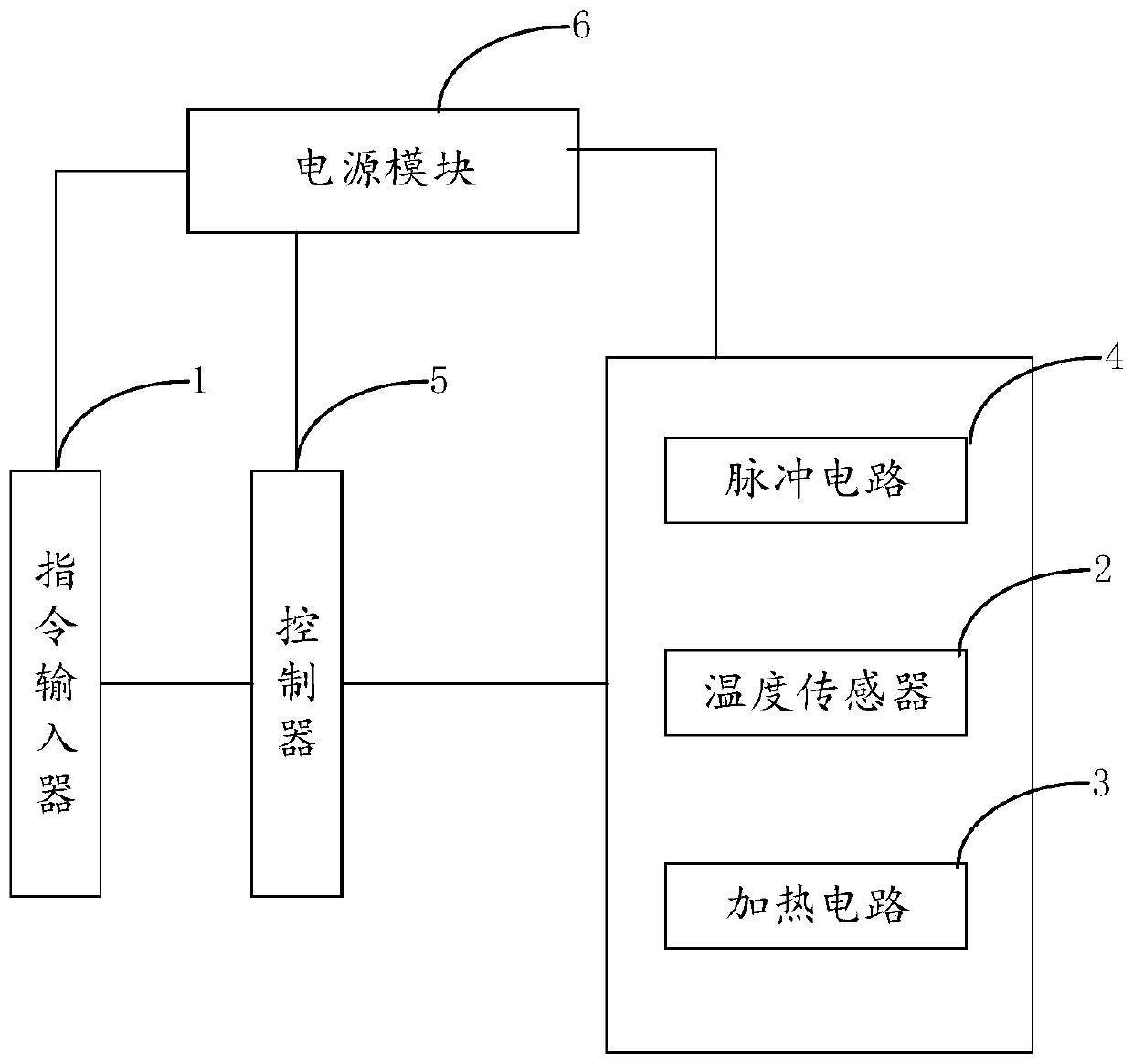

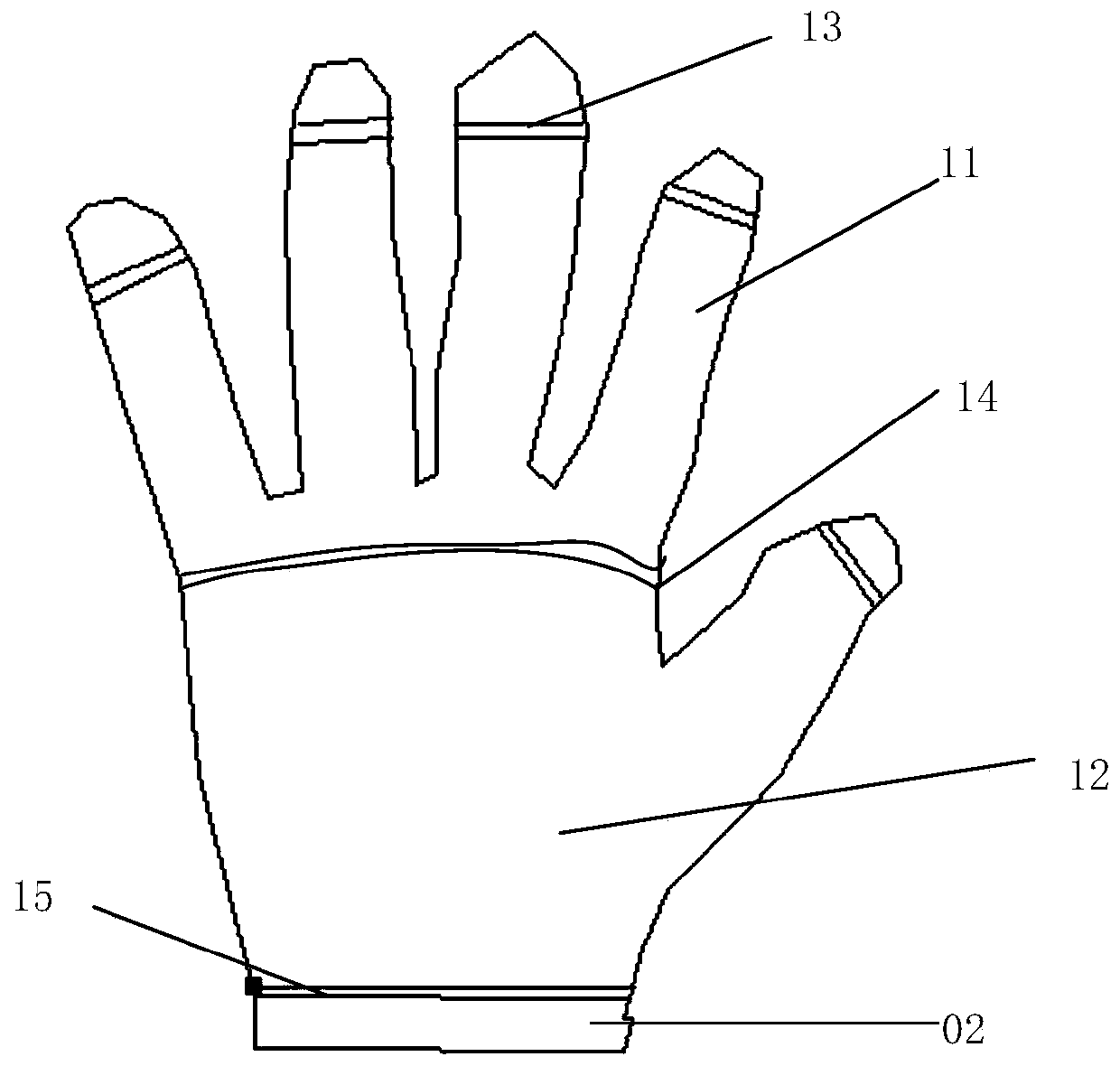

EMS physiotherapy glove

The invention provides an EMS physiotherapy glove. The glove comprises a glove body, and also comprises a command input device, a temperature sensor, a heating circuit, a pulse circuit, a controller and a power supply module. The glove body consists of a first sleeve layer, a second sleeve layer and a third sleeve layer; the third sleeve layer wraps the first sleeve layer and the second sleeve layer so as to form a placing cavity; the command input device, the temperature sensor, the pulse circuit and the controller are arranged in the placing cavity, and the command input device, the temperature sensor, the heating circuit and the pulse circuit are respectively connected with the controller; the front end of the glove body is provided with a wrist sleeve which is fixedly connected to theglove body, one side of the wrist sleeve is provided with an accommodating cavity for accommodating the power supply module, and the power supply module is connected to the command input device, the temperature sensor, the heating circuit, the controller and the pulse circuit; and a plurality of electrode bulges are also arranged in the placing cavity, and one end of each electrode bulge is connected with the pulse circuit in the placing cavity, so that the glove is convenient to heating and using by a user.

Owner:北京小汤山医院

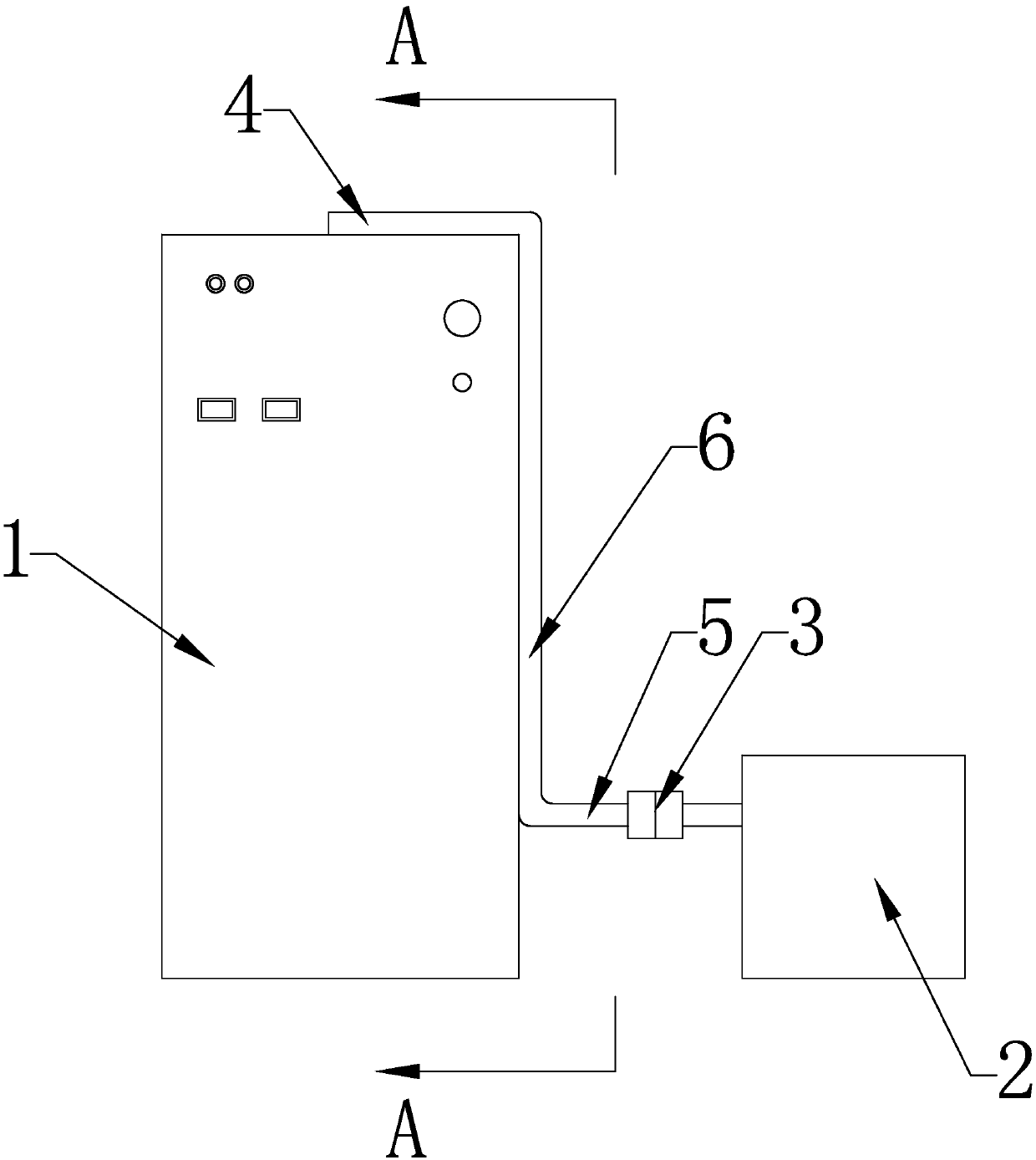

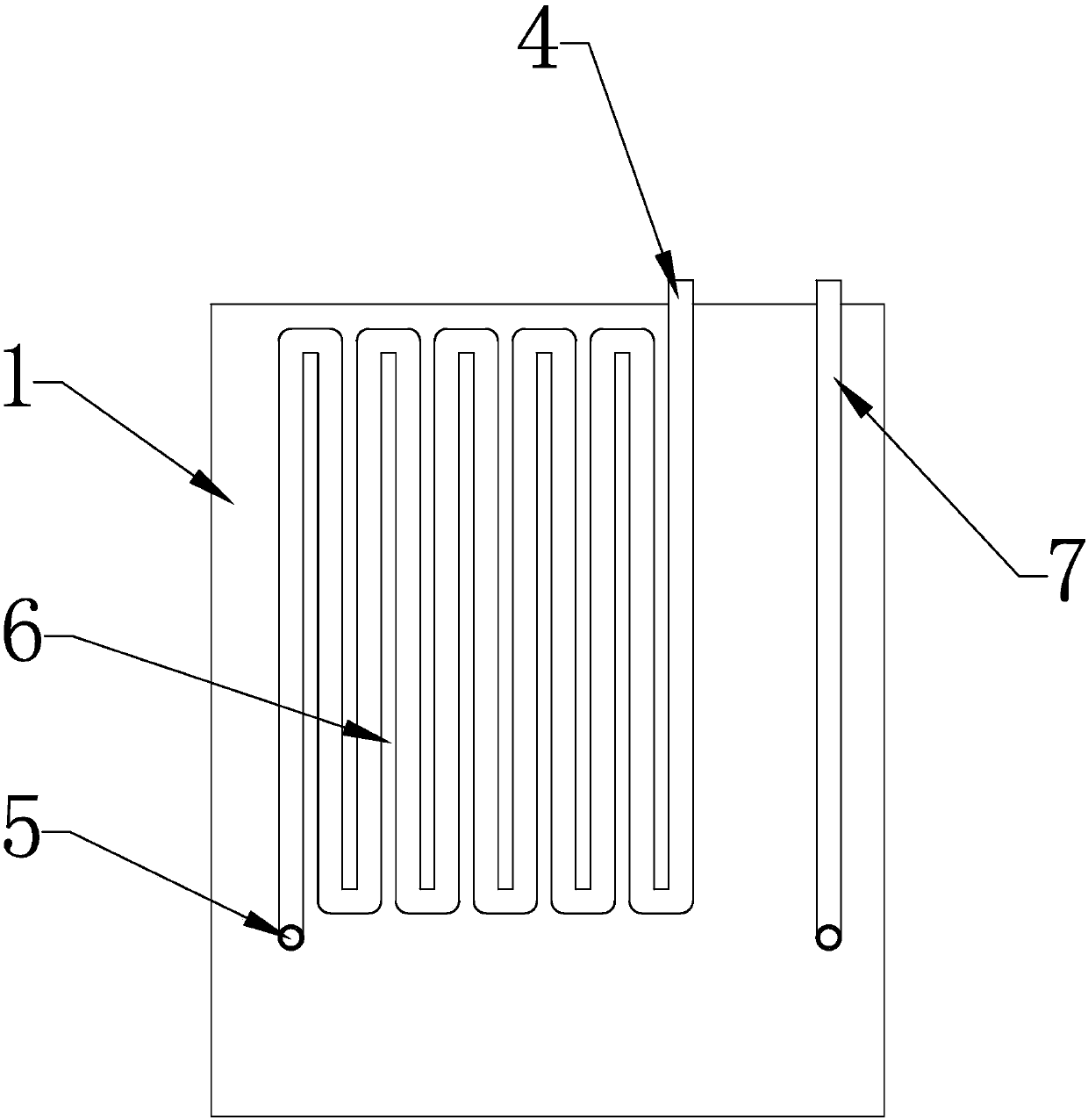

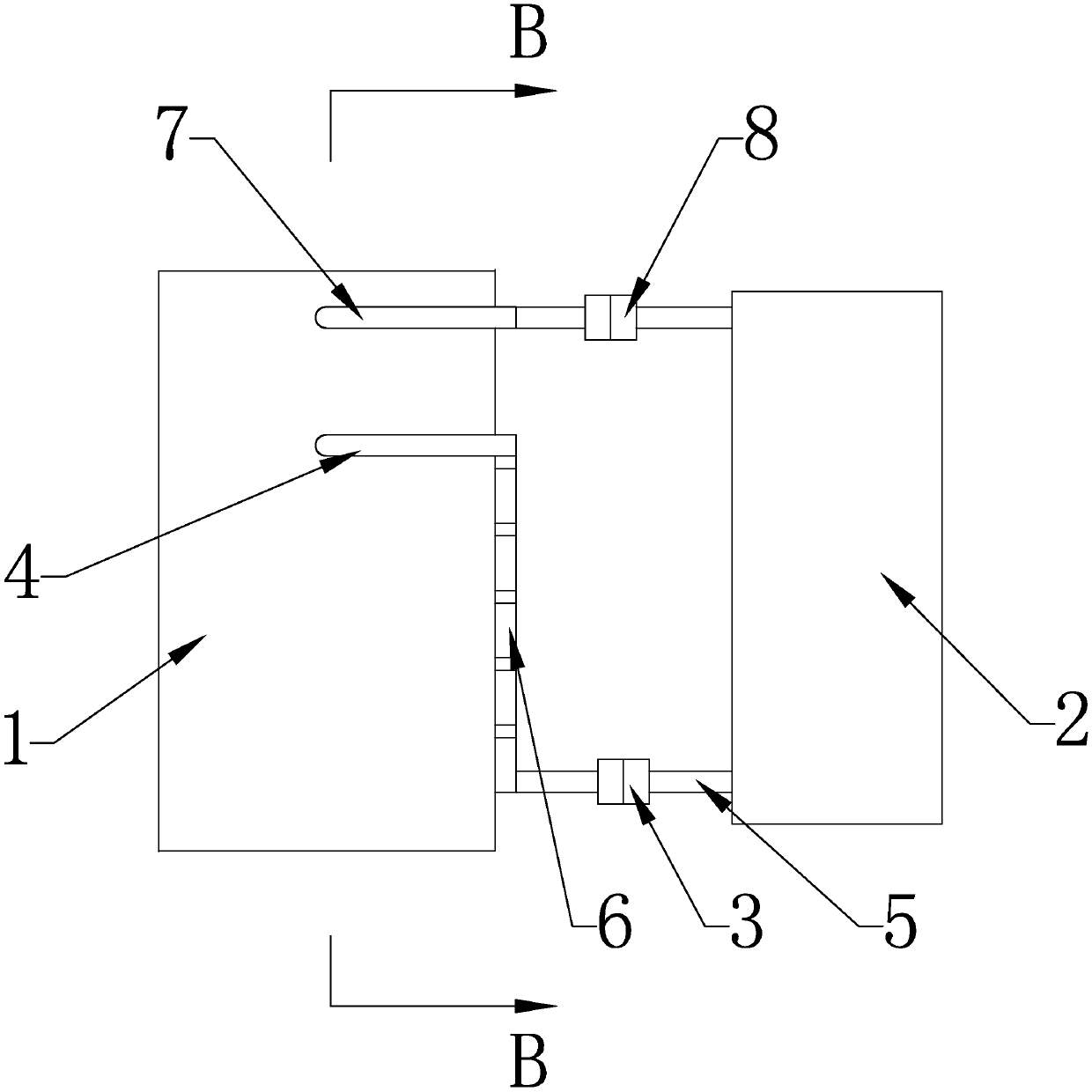

CPU radiator of mini host computer

PendingCN111045496AMultiple design spacesEasy maintenanceDigital data processing detailsEngineeringVALVE PORT

The invention discloses a mini-host computer CPU radiator. The mini-host computer CPU radiator comprises a mini-computer host case and a compressor. A water-cooling heat dissipation device is arrangedat the CPU, and a water inlet pipe and a first water outlet pipe are connected to the water-cooling heat dissipation device; the water inlet pipe penetrates through the mini computer host case to beconnected with the compressor, and an expansion valve is arranged on the water inlet pipe; a heat dissipation coil is arranged on the outer side of the mini computer host case, one end of the heat dissipation coil is connected with the first water outlet pipe, and the other end of the heat dissipation coil is connected with the compressor through a second water outlet pipe; a first separable valvegroup and a second separable valve group are respectively arranged on the second water outlet pipe and the water inlet pipe; the separable valve set comprises a first valve and a second valve, a first flange is arranged on the right side of the first valve, a second flange is arranged on the left side of the second valve, and the first valve and the second valve are hermetically connected throughflanges; cooling media are arranged in the compressor and the water pipes. The LED lamp has the advantages of being small in size and good in heat dissipation performance.

Owner:王旭宁

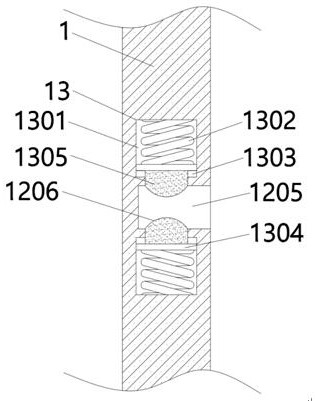

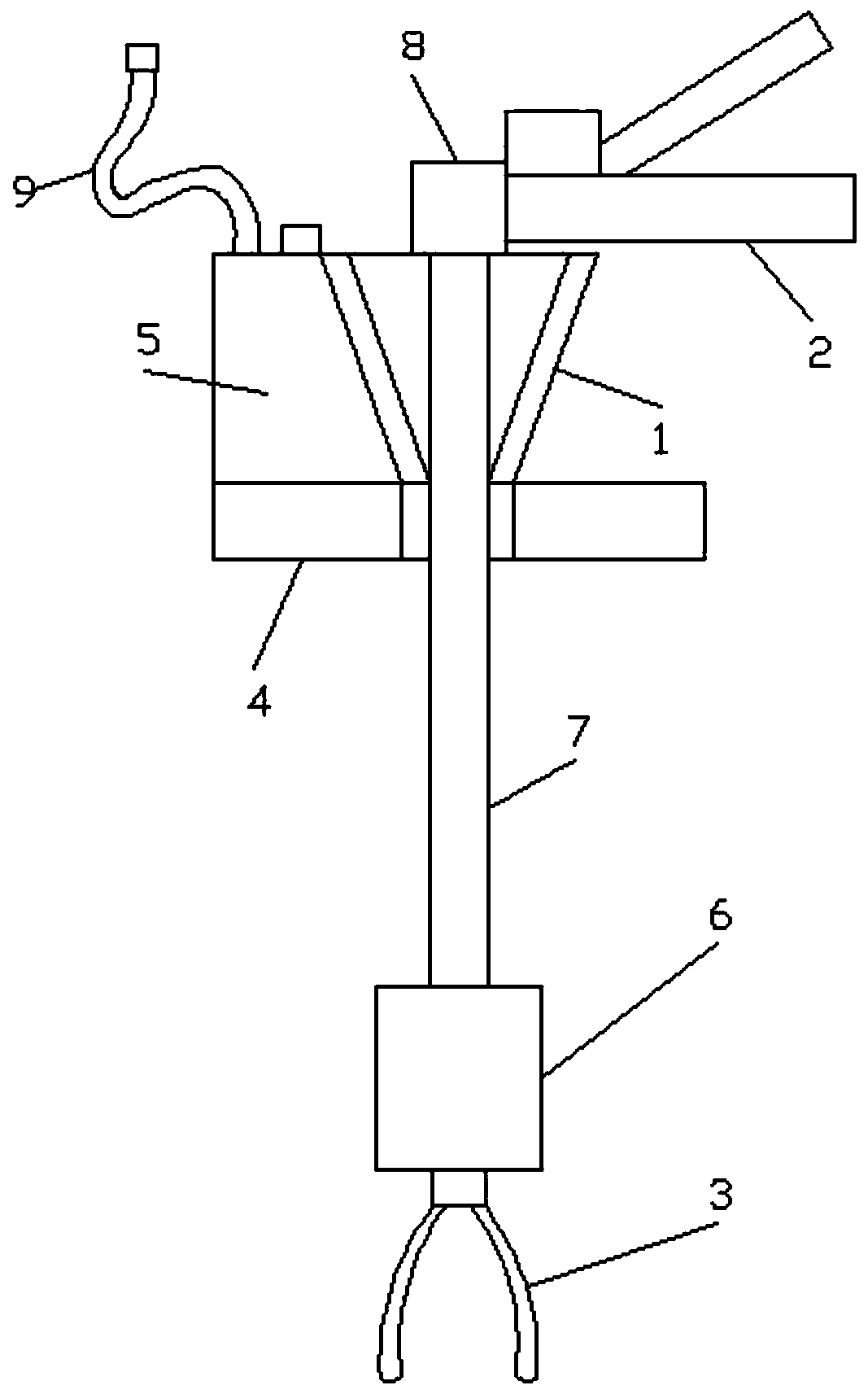

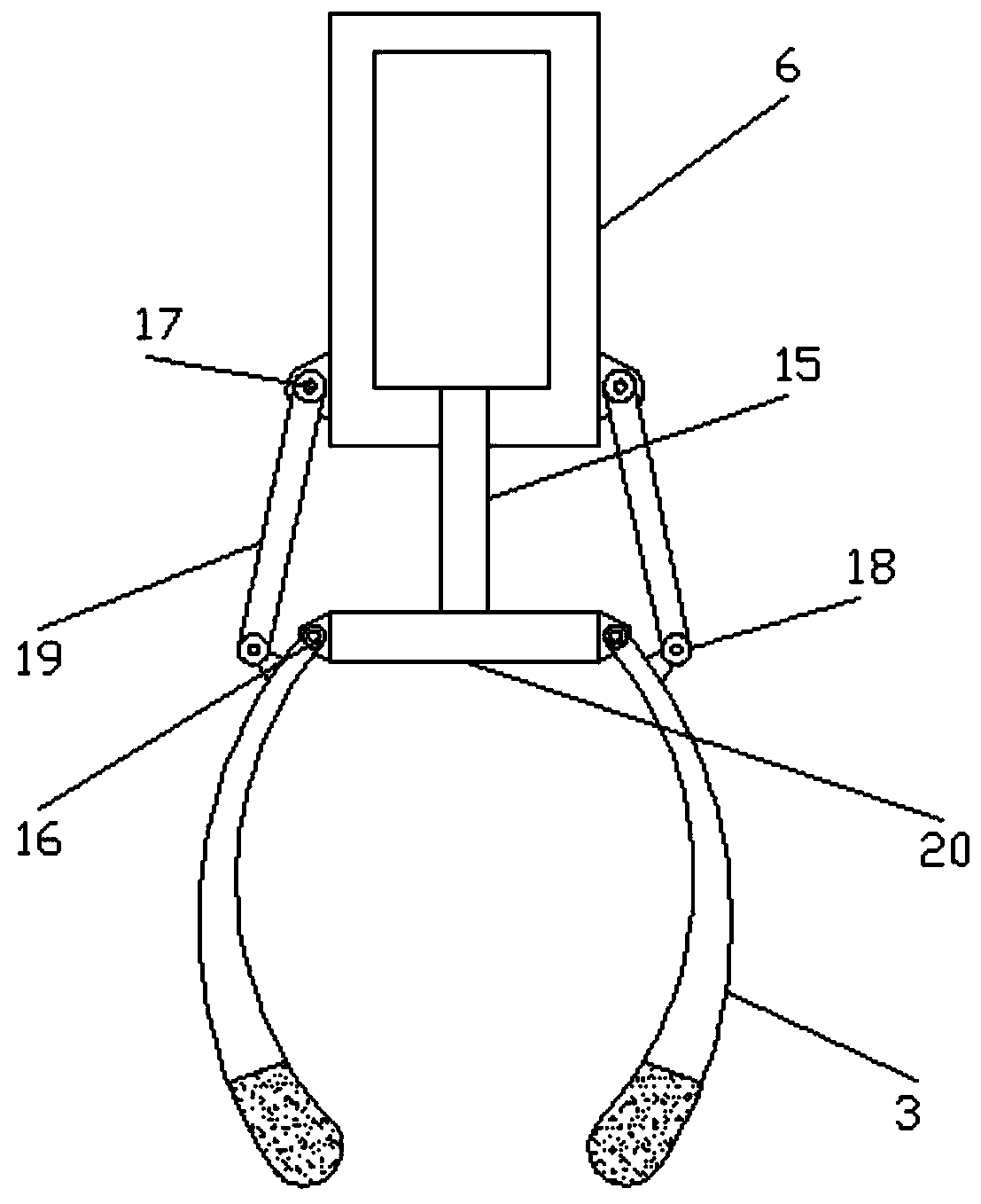

Tissue fixing device in laparoscopy

PendingCN110236701AAvoid coldEfficient and stable fixed placementInstruments for stereotaxic surgeryElectrical resistance and conductanceLaparoscopy

The invention discloses a tissue fixing device in laparoscopy. The tissue fixing device comprises a device body, a holding handle, a tissue fixing claw, fixing and supporting pressing plates, a lithium battery pack and a cylinder. The holding handle is connected with the top of the device body. The fixing and supporting pressing plates are arranged on the two sides of the middle of the device body. The tops of the fixing and supporting pressing plates are electrically connected with the lithium battery pack. The inner side end of each fixing and supporting pressing plate is electrically connected with an installing shaft. A heating resistance wire is electrically connected into each fixing and supporting pressing plate. A rubber cushion is attached to the bottom of each fixing and supporting pressing plate. NTC temperature sensors are distributed at the inner side bottom of each fixing and supporting pressing plate. A connecting shaft is arranged in the middle of the device body. The outer end of the supporting rod is connected with the tissue fixing claw through a first rotating shaft gear. The tissue fixing device in laparoscopy has the function of grabbing, fixing or blocking a certain part of tissue, has the main function of fixing in-vivo tissue organs, and is beneficial for exposing the view in the operation process and reducing accidental injuries.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

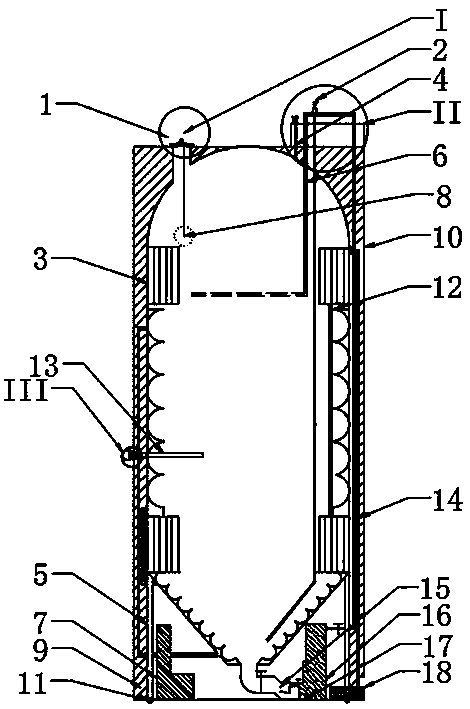

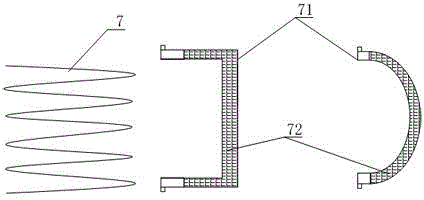

Novel beer brewing machine

ActiveCN109280585AAir pressure changeAvoid the environment that affects the fermentationHops treatmentProduct gasAtmospheric pressure

The invention belongs to the field of beer brewing, and in particular discloses a novel beer brewing machine. The beer brewing machine comprises a tank, a feeding hole and a beer outlet system, wherein the inside of the tank is provided with a fermenting cavity used for producing beer, the feeding hole is arranged in the tank and is used for feeding materials to the inside of the fermenting cavity, the beer outlet system is arranged in the fermenting cavity and is used for taking out beer, air bags in the compressed state are arranged in the fermenting cavity, and the air bags communicate witha pressurization system used for realizing pressurization on the inside of the air bags. The novel beer brewing machine has the beneficial effects that the pressurization system is used for controlling the air pressure in the air bags, then the sizes of the air bags can be adjusted, thus the air pressure inside the fermenting cavity is changed, meanwhile, by utilizing the air bags, the contact between air providing pressure and the beer can be isolated, and thus the influences on the fermenting environment due to the introduction of the impurities are avoided.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Multifunctional medicine packaging towel

InactiveCN103239566AGuaranteed efficacyNot easy to burnAntipyreticAnalgesicsTraditional medicineDrug effect

The invention discloses a multifunctional medicine packaging towel, comprising a medicine packaging towel body, wherein the multifunctional medicine packaging towel is characterized in that a particle filler is composed of: 20% by weight of pine needle, 20% by weight of green tea, 15% by weight of tarragon, 5% by weight of perilla leaf, 5% by weight of dahurian angelica root, 10 % by weight of common fennel fruit, 25% by weight of salt; and the medicine packaging towel uses a microwave heating mode or a direct charging heating mode. The medicine packaging towel has health care effects of invigorating the circulation of blood, dispelling wind, dehumidifying, dispelling cold, relieving pain, insulating, etc. The multifunctional medicine packaging towel is agile and convenient for use, and can be wrapped on a foot, or is wrapped around important parts of a human body like a shoulder, a neck, a waist or a knee. The multifunctional medicine packaging towel can also be placed in a blanket in winter for warming and health caring, and is not easy deterioration when continuously used, and the drug effect lasts long.

Owner:余新邦

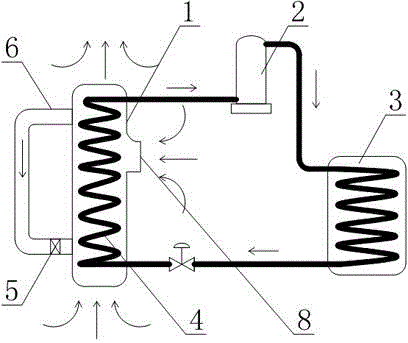

Biological energy absorption method and air energy heat pump system based on same

InactiveCN104792005AHigh power outputIncrease temperatureFluid heatersHeat pumpsThermal energyEnergy absorption

The invention provides a biological energy absorption method and an air energy heat pump system based on the same. The method is used for solving the problems that in the prior art, warming is conducted on a livestock farm commonly through an air conditioner or other heating devices in the fresh air inputting process, the air conditioner or other heating devices commonly operate at a larger load under this condition, and the influence on the culturing cost of energy expenditure is larger. The problems are solved on the dependence of leading biological waste heat into a specific portion of a hat pump heat absorption segment, so that a heat pump can absorb biological energy about to be discharged effectively, the biological heat energy is converted for other purposes, and power output of the heat pump is improved. The air energy heat pump system is simple in structure, wide in purpose, convenient to popularize and capable of utilizing the biological energy waste heat effectively, meanwhile, the waste heat absorption efficiency is high, reduction of energy consumption in production and life is facilitated, and power output of the heat pump is improved.

Owner:南京市安略能源设备有限公司

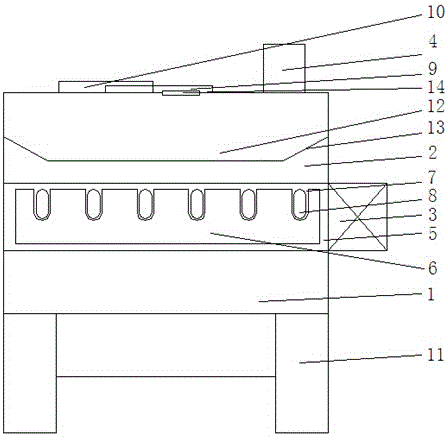

Improved flattening oven

The invention relates to an improved flattening oven. The improved flattening oven comprises a base and an oven body; the oven body is fixed to the base, a temperature control box is arranged on the side wall of the oven body, an air outlet is formed in the upper top face of the oven body, a combustion groove is formed between the base and the oven body, an oven plate is arranged in the combustion groove, a U-shaped groove is formed in the oven plate, a heating pipe is arranged in the U-shaped groove, an observation window is formed in the upper top face of the oven body, and a sliding way allowing the observation window to slide is arranged on the upper top face of the oven body. The improved flattening oven has the beneficial effects that the temperature control box can carry out heating control over the heating pipe, the heating pipe is placed in the oven plate, the oven plate and the oven body are movably connected, the damaged heating pipe can be conveniently replaced, and due to the observation window in the oven body, the copper powder heating degree in the oven body can be conveniently observed.

Owner:JIANGSU TEHO METAL IND

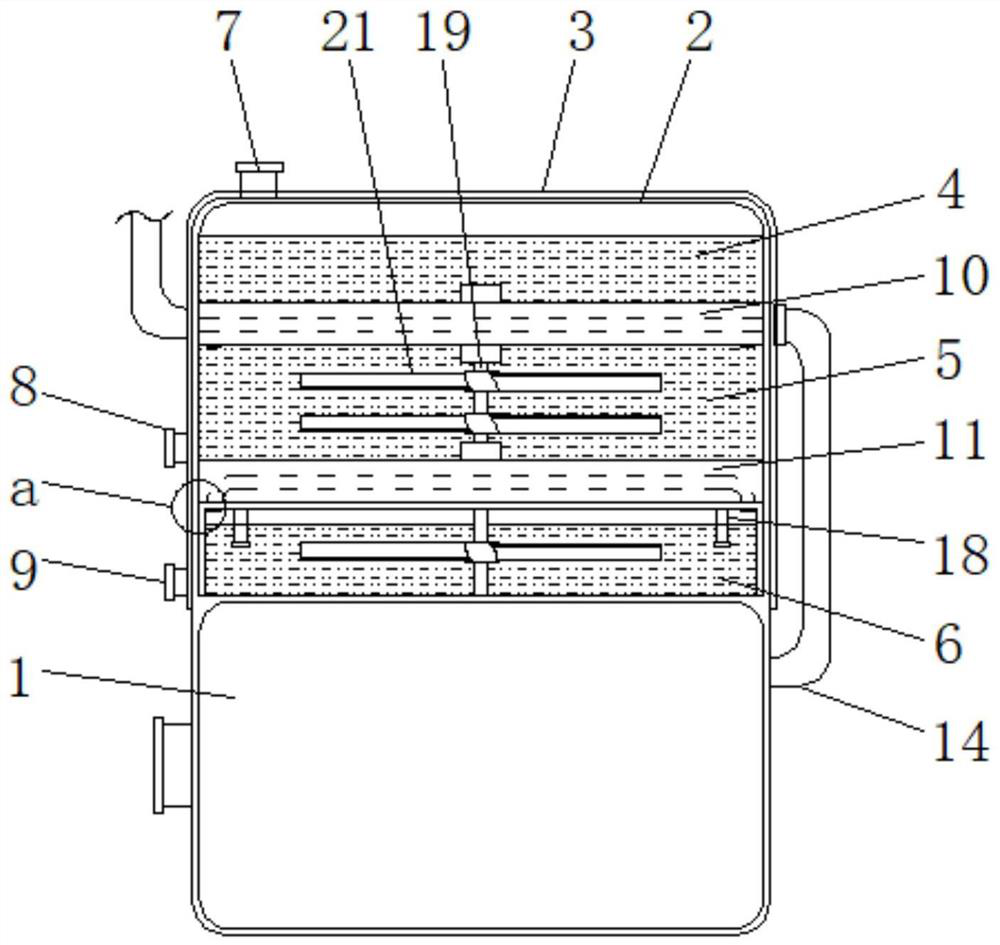

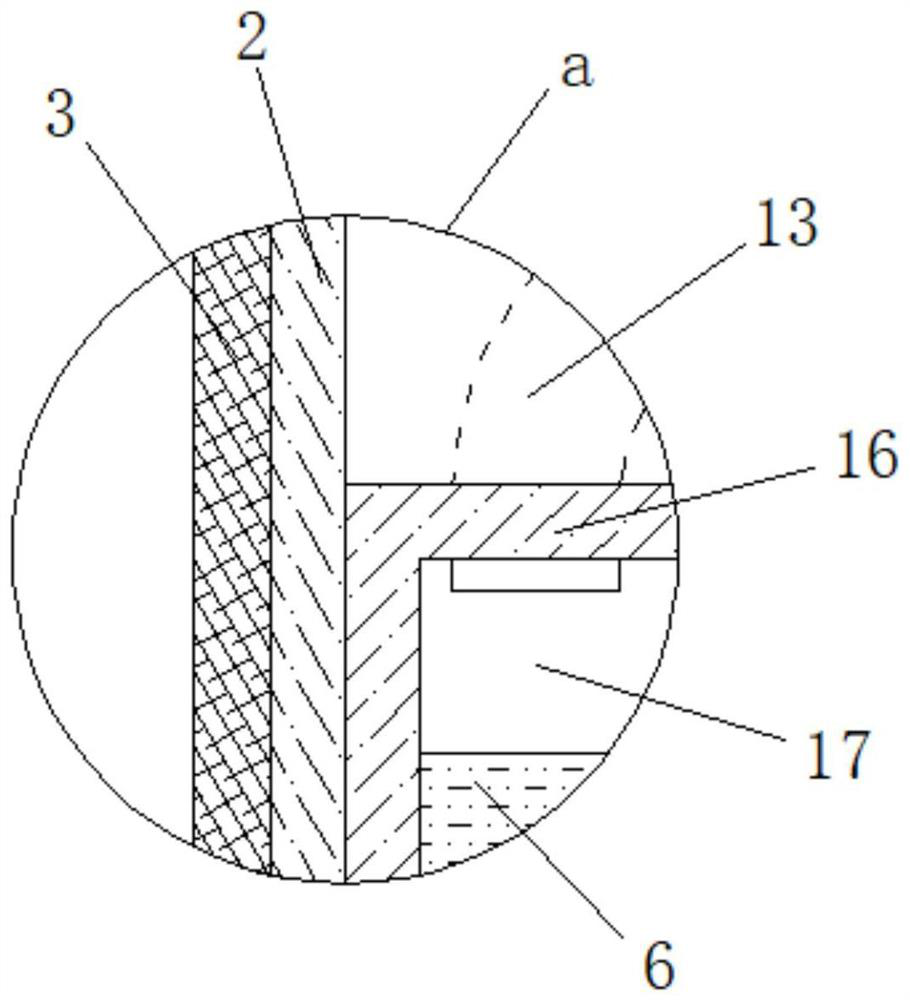

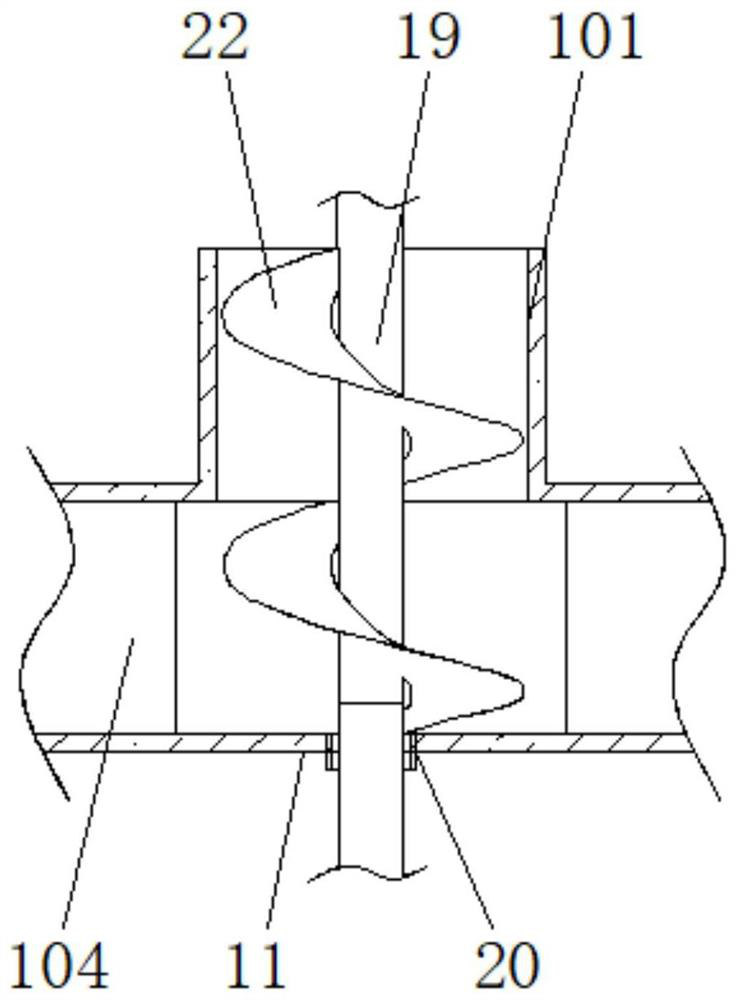

A layered boiler water exchange tank structure based on water vapor heat energy exchange

The invention discloses a layered boiler heat exchange water tank structure based on water-steam-heat energy exchange. The structure comprises a boiler body and a water tank shell, wherein the water tank shell is arranged above the boiler body; a normal-temperature water storage tank, a mixed warm water tank and a high-temperature water tank are sequentially arranged in the water tank shell from top to bottom; a smoke heat exchange layer and a steam heat exchange layer are correspondingly arranged on the upper side and the lower side of the mixed warm water tank; a steam interlayer is arrangedon the top of the high-temperature water tank; a movable shaft penetrates through the middle of the mixed warm water tank; a stirring paddle is integrally arranged in the middle of the movable shaft;and driving blades are arranged at the upper end and the lower end of the movable shaft. According to the structure, a multi-layer water tank structure formed by the normal-temperature water tank, the mixed warm water tank and the high-temperature water tank meets the continuous hot water supply and the multiple spot heating water supply of longer time, and the stirring paddle driven by synchronous water is matched to keep uniform temperature of inside water.

Owner:连云港市瑞成机械有限公司

A double-chamber four-station glass bending tempering device and control method

ActiveCN104230156BShorten heating timeEasy to heat upGlass tempering apparatusGlass productionWire rodTemperature control

A dual-chamber four-station glass bending tempering device and control method, comprising: a preheating furnace, a heating zone at one station, a heating zone at two stations, a heating furnace, a heating zone at three stations, a heating zone at four stations, a bending Steel forming section, arc changing mechanism, upper segment, segment extraction, matrix temperature control module, porcelain tube, heating furnace wire, furnace wire lead-out rod, thermocouple, conveying roller, glass, motor; according to different parts of the glass, the matrix is fuzzy The control program automatically controls different heating temperatures and holding times. After the temperature of the whole piece of glass is consistent, it continues to heat up and keep warm. The temperature can be fixed to make the glass evenly heated step by step, to ensure the overall temperature of the glass is consistent, and to avoid the different heating temperatures of various parts from affecting the quality of the glass.

Owner:MOUNTAIN GLASS TECH

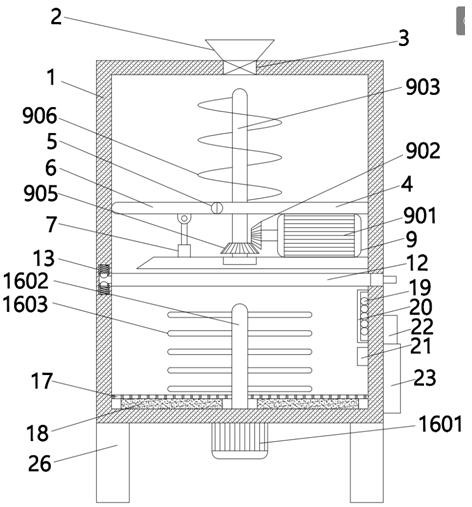

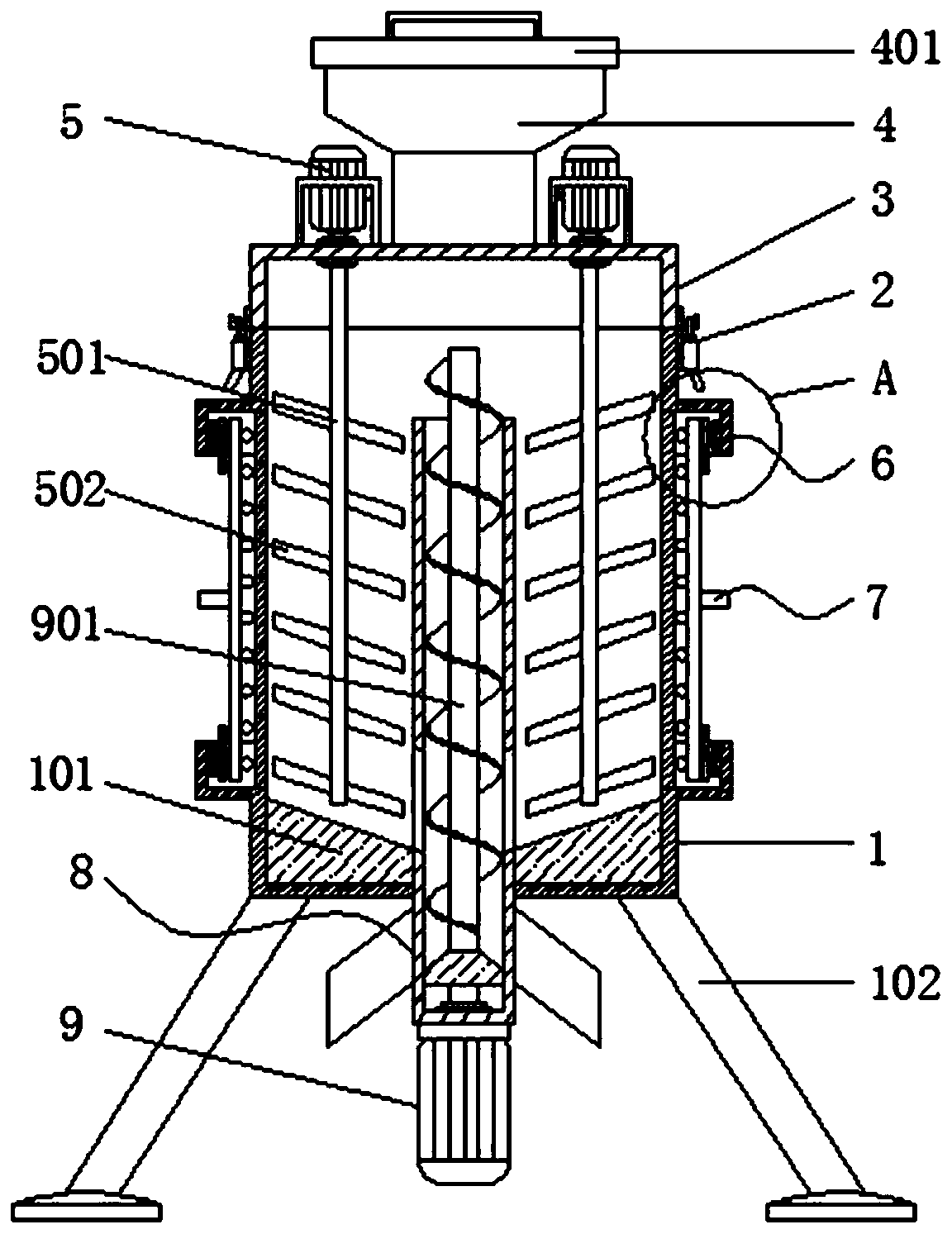

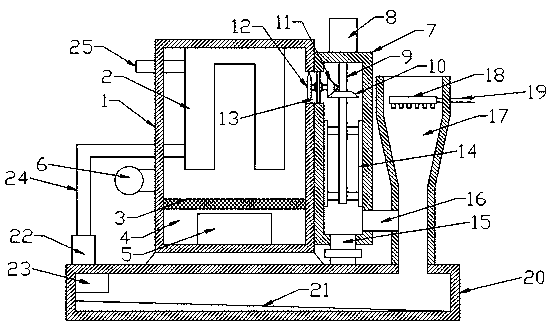

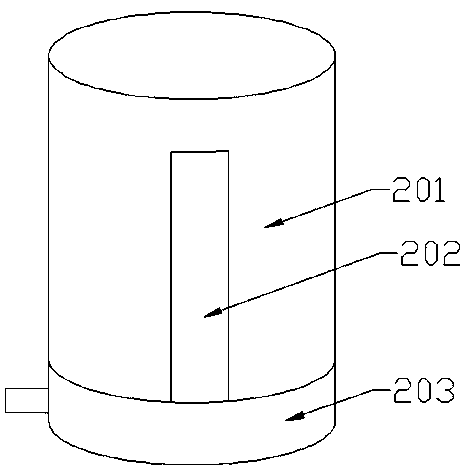

Fermentation device for biological preparation and processing method

InactiveCN111423261ASmooth entryEasy to upgradeBio-organic fraction processingOrganic fertiliser apparatusBiotechnologyElectric machinery

The invention discloses a fermentation device for biological preparation. The fermentation device comprises a fermentation outer cylinder, jacking assemblies are fixedly arranged on the outer side surfaces of a top cylinder body and a bottom cylinder body of the fermentation outer cylinder, a plurality of groups of fermentation cylinder heating assemblies are arranged between the two groups of jacking assemblies in a jacking manner, a material lifting assembly is fixedly arranged in the fermentation outer cylinder, a bidirectional material lifting motor is fixedly arranged at the bottom of thematerial lifting assembly, the stirring motor drives a stirring rod and an inclined stirring blade to rotate so that various fermentation raw materials in the fermentation outer barrel are uniformlystirred, the inner part of the fermentation outer cylinder is heated through a plurality of groups of fermentation cylinder heating assemblies, the bidirectional material lifting motor drives a material lifting screw rod to rotate in two directions, discharging and lifting of biological fermentation materials are achieved, through rotation of the inclined stirring blades, when the fermentation rawmaterials are located on an inverted-cone-shaped material guiding base, a downward sliding pushing force exists, and therefore it is guaranteed that the fermentation raw materials can smoothly enterthe material lifting barrel through the inclined feeding port.

Owner:绍兴市高砚智生物科技有限公司

A high-efficiency, energy-saving and environment-friendly boiler

ActiveCN107543311BIncrease the heating areaIncrease profitWater heatersSolid removalDrive shaftFlue gas

Owner:YANGZHOUSR BOILER

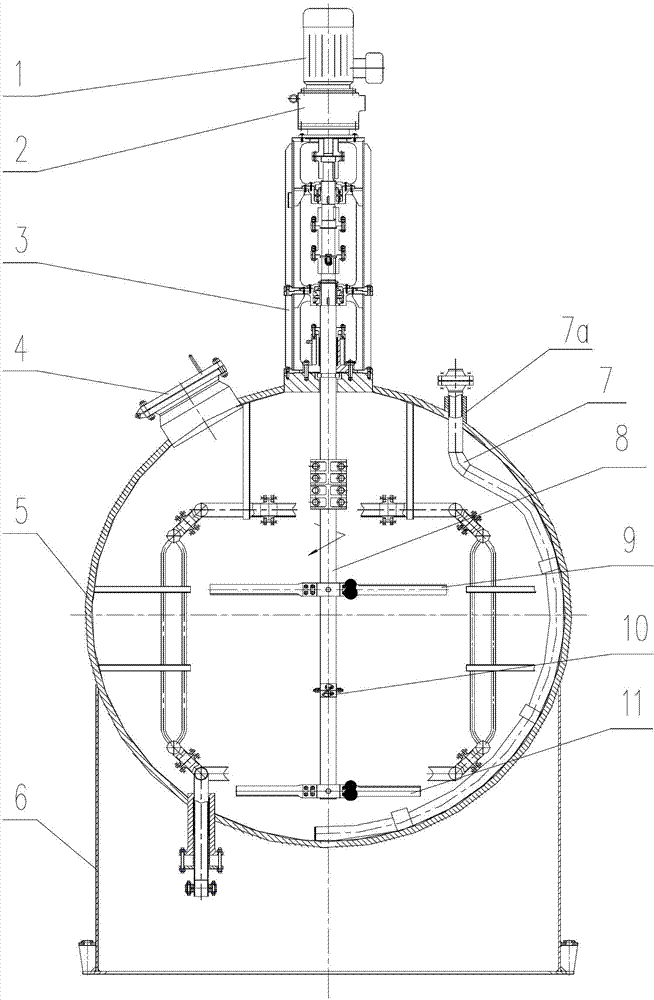

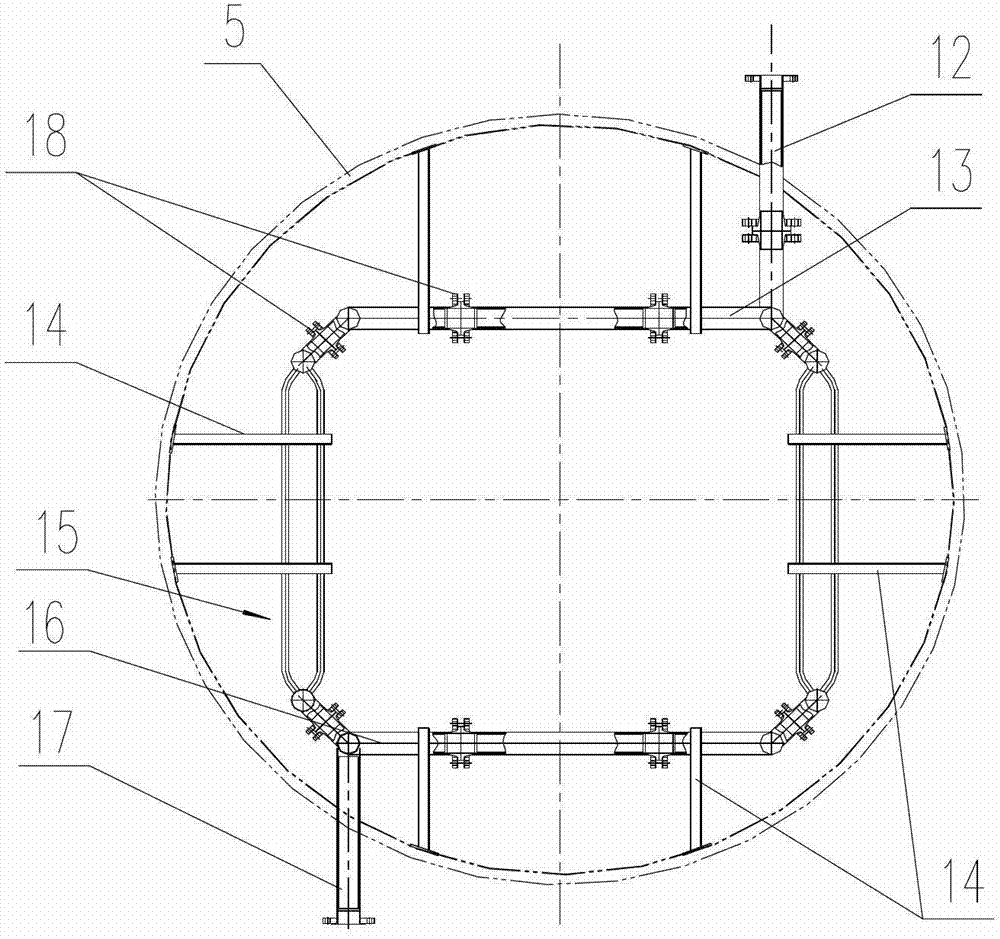

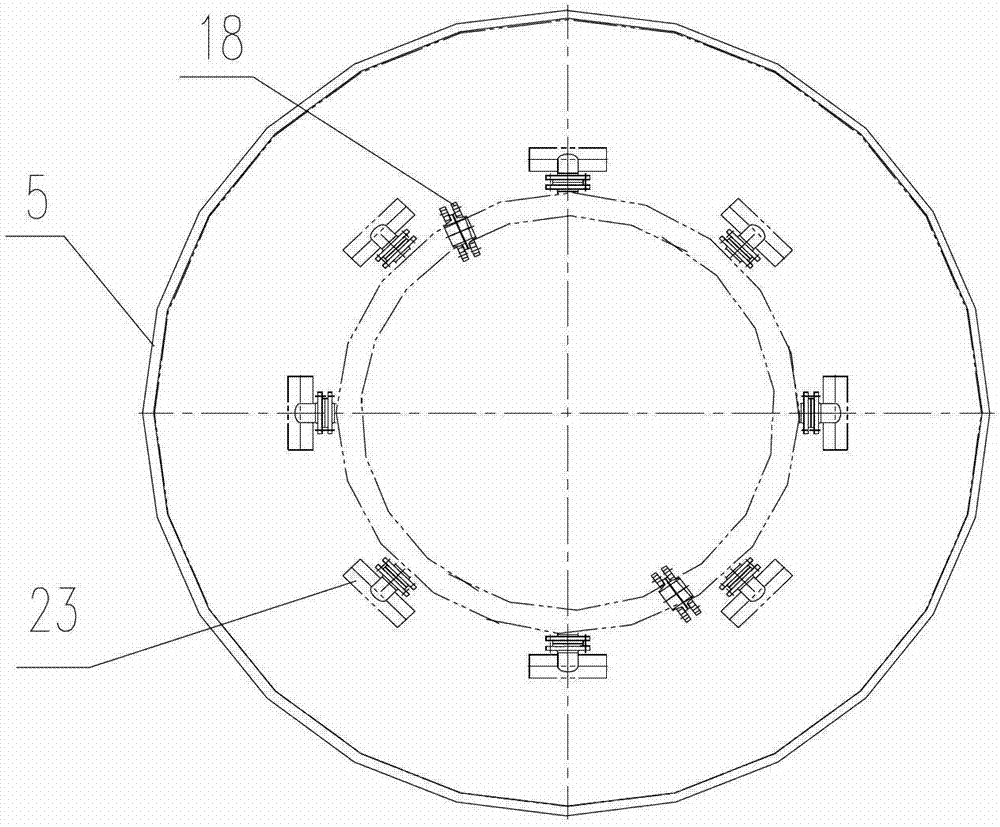

Large ammonification high pressure spherical stirring reaction kettle

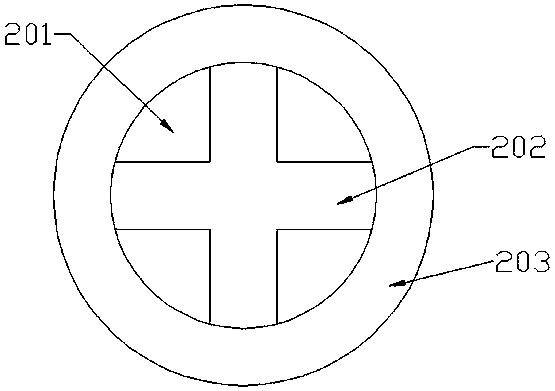

ActiveCN102989372BUniform force distributionImprove the forceChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processReducerSpherical shaped

The invention relates to a large ammonification high pressure spherical stirring reaction kettle. A kettle body is welded by two spherical shaped kettles, the upper portion of the kettle body is provided with a feeding port, a discharging port, a safety relief device and an instrument control device, and the lower portion of the kettle body is provide with a skirt support. A stirring device is arranged at the upper end of the kettle body and matched with the kettle body in sealed mode, a motor, a reducer and the stirring device and sequentially connected, the lower portion of a stirring shaft penetrates into the kettle body, and a stirring device is fixed on the stirring shaft. A discharge pipe extends the a center position of the lower portion of the kettle body along the inner wall of the kettle body, a heat exchange device is arranged in the kettle body, the kettle body is made of an explosion double-layer composite plate material, an inner layer is made of stainless steel, an outer layer is made of carbon steel, the stirring shaft and the stirring device which are arranged in the kettle are made of stainless steel, and the heat exchange device is made of titaniumtim. The large ammonification high pressure spherical stirring reaction kettle has the advantages of guaranteeing energy conservation and consumption reduction, heat-transfer capability, homogeneity capability, antiseptic property and product quality of ammonification high pressure spherical stirring reaction kettle along with the enlargement of volume of the reaction kettle.

Owner:ANHUI BAYI CHEM IND

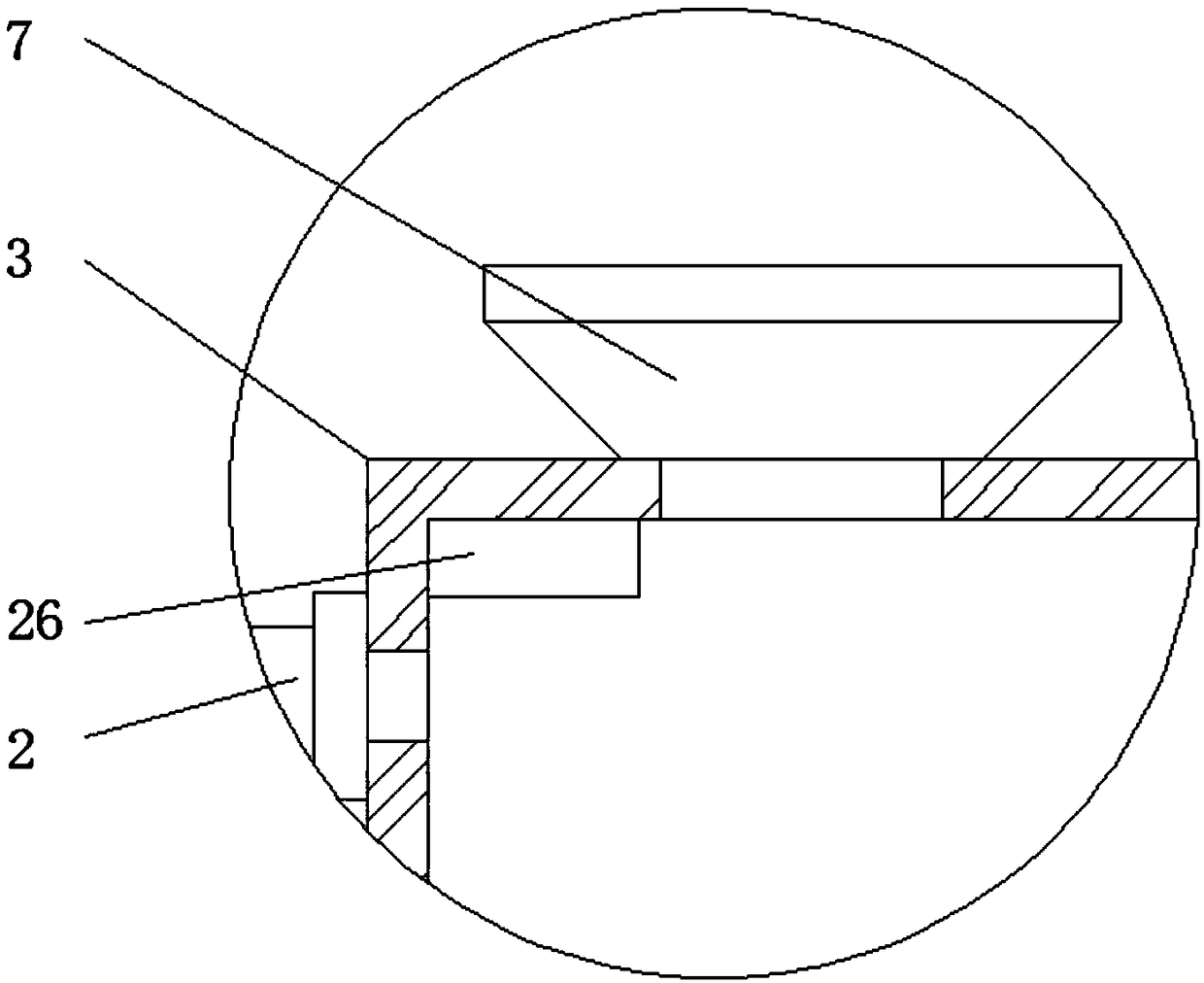

Heating tool for lubricating oil production

InactiveCN112442418AEasy to adjust temperatureEasy to heat upLubricant compositionHeat sinkOil production

The invention discloses a heating tool for lubricating oil production. The tool comprises an underframe block, a U-shaped oil plate, an oil plate support frame, an oil leakage funnel, a lower table plate, a trapezoidal oil plate, a charging three-phase head, a heat conduction column, an overhaul partition plate, a heat conduction plate, a cooling fin plate, an annular thermal resistance wire, a tapping hinge, an outer thermal baffle, a right heat conduction column, a cooling lattice and a plate opening handle, the upper end of the underframe block is fixedly connected with the U-shaped oil plate, the oil plate support frame is fixedly arranged on the U-shaped oil plate, the oil leakage funnel is fixedly arranged above the oil plate support frame, charging three-phase heads are fixedly arranged at the upper ends of the left side and the right side of the trapezoidal oil plate, and the overhaul partition plate is fixedly arranged at the upper end of the heat conduction column. Accordingto the invention, through internal heating of the heat conduction column and the right heat conduction column, the heating tool is conductedto the heat conduction plate for heating, the rapid heatingeffect is achieved, temperature adjustment is facilitated, heating operation for different lubricating oil production is more convenient, and efficiency is improved.

Owner:江苏察克润滑科技有限公司

An electric water heater with double water tanks

ActiveCN109556283BEasy to useGuaranteed continuous supplyWater heatersHeat conservationThermal water

Owner:XUZHOU COLLEGE OF INDAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com