Patents

Literature

150results about How to "Reduce operating efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

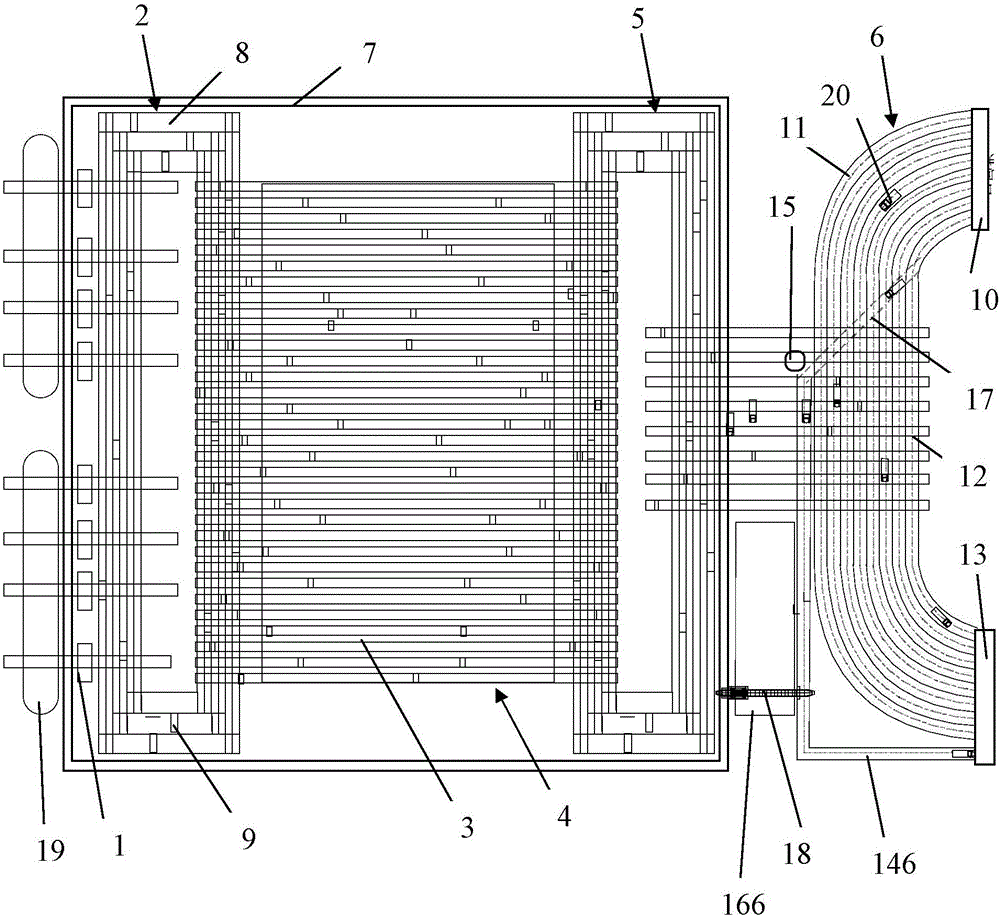

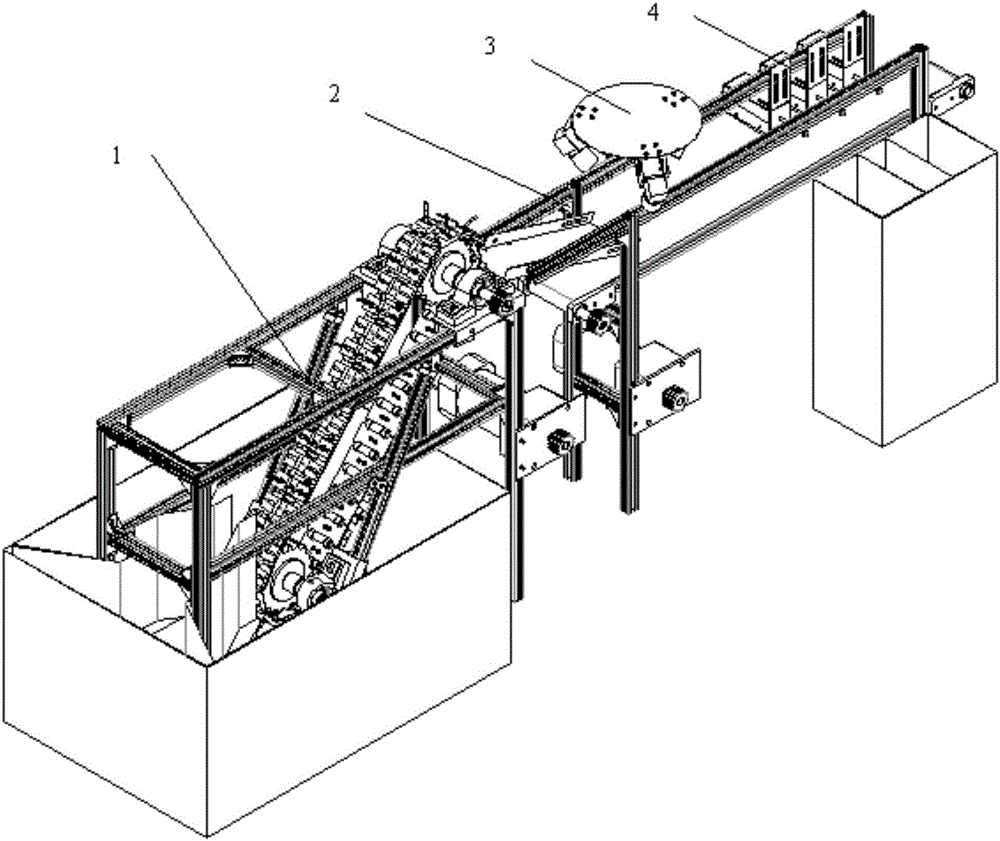

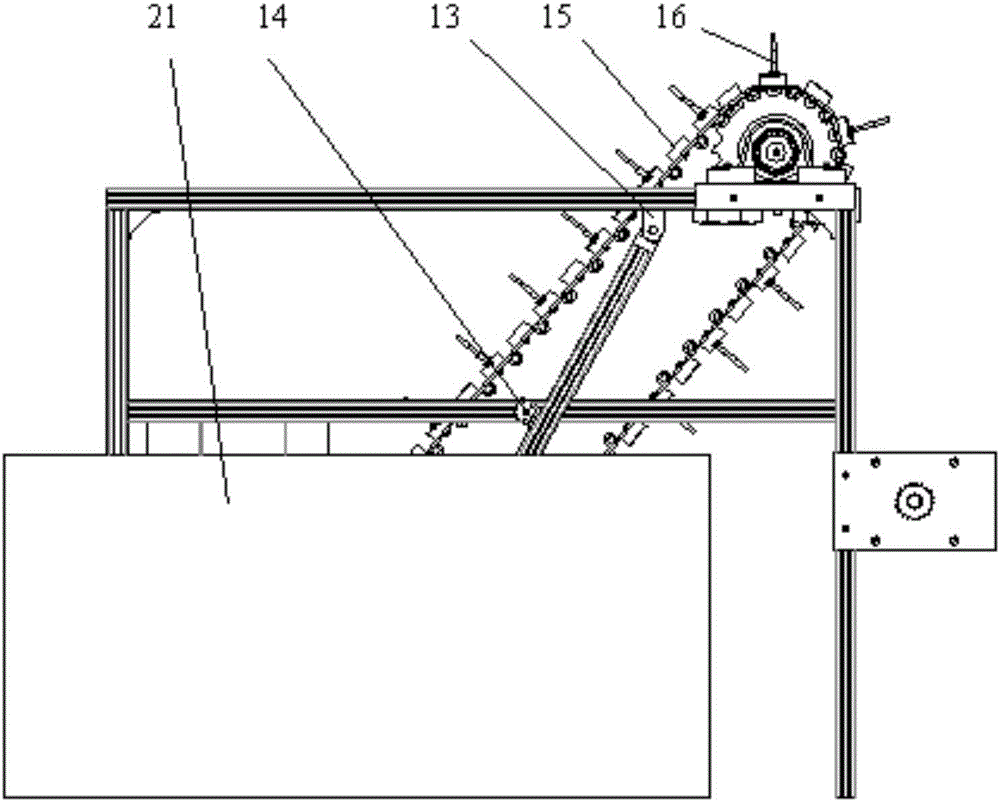

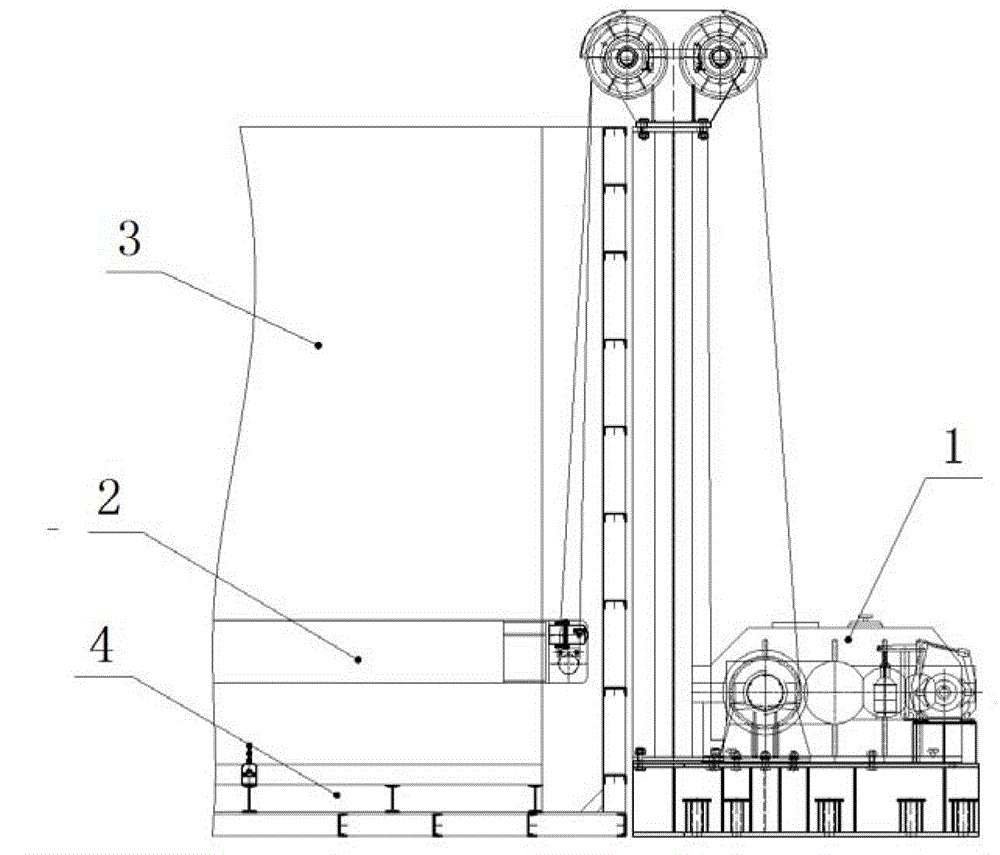

Loading and unloading system for distribution center type automated container terminal

The invention relates to a loading and unloading system for a distribution center type automated container terminal. The loading and unloading system comprises a plurality of quay cranes, a nearshore multipath rectangular-ambulatory-plane automatic transportation system, an elevated container automatic loading and unloading system, a storage yard, a container evacuating port side multipath rectangular-ambulatory-plane automatic transportation system, a container evacuating port transportation system, an annular special container channel and a control system. Compared with the scheme of an existing automated container terminal, the loading and unloading system for the distribution center type automated container terminal is advantaged in that the loading and unloading system is creative and unique, and is high in production efficiency, safety, automation degree and stability, and is simple in structure, simple to control and complete in scheme.

Owner:TIANJIN PORT CONTAINER TERMINAL

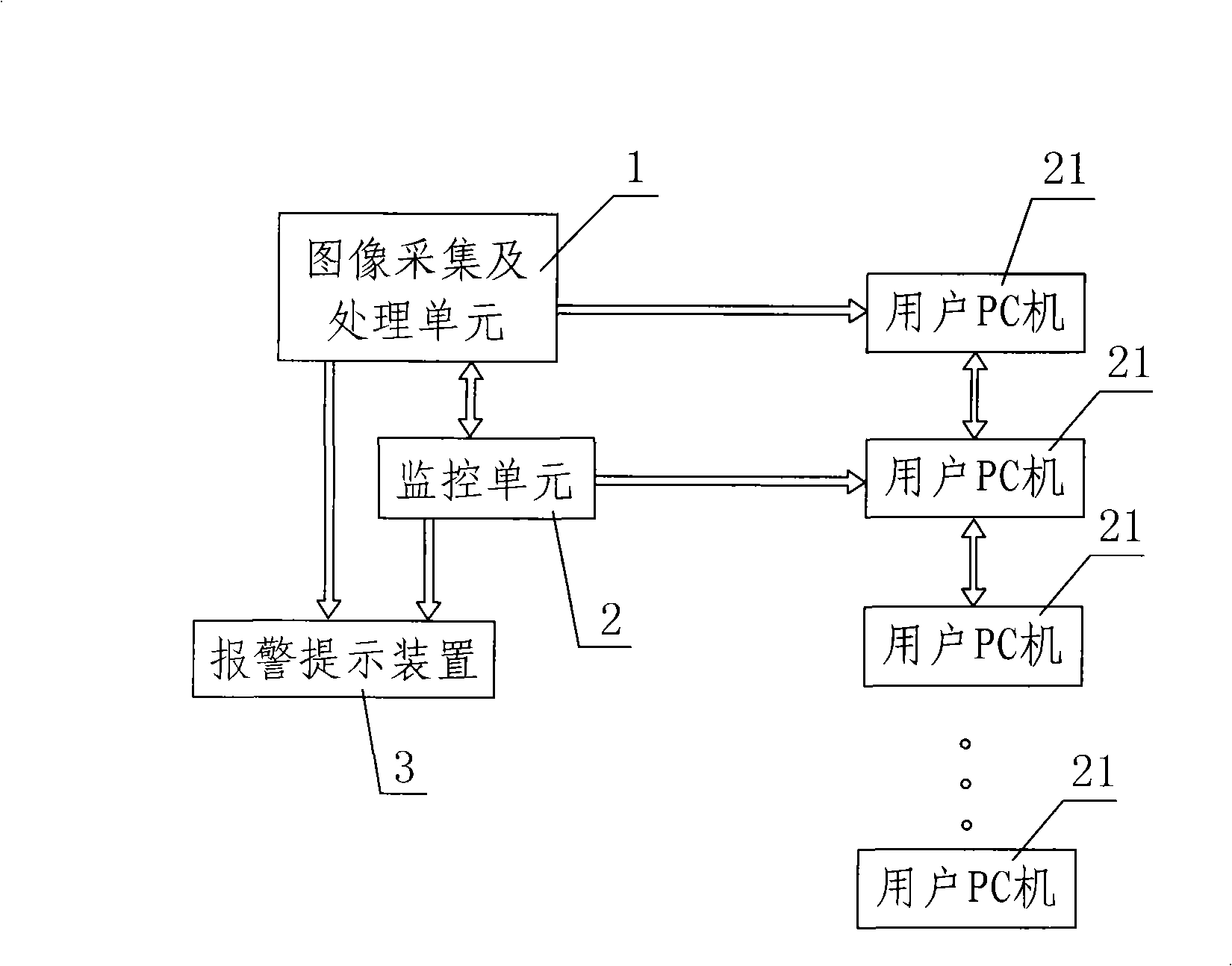

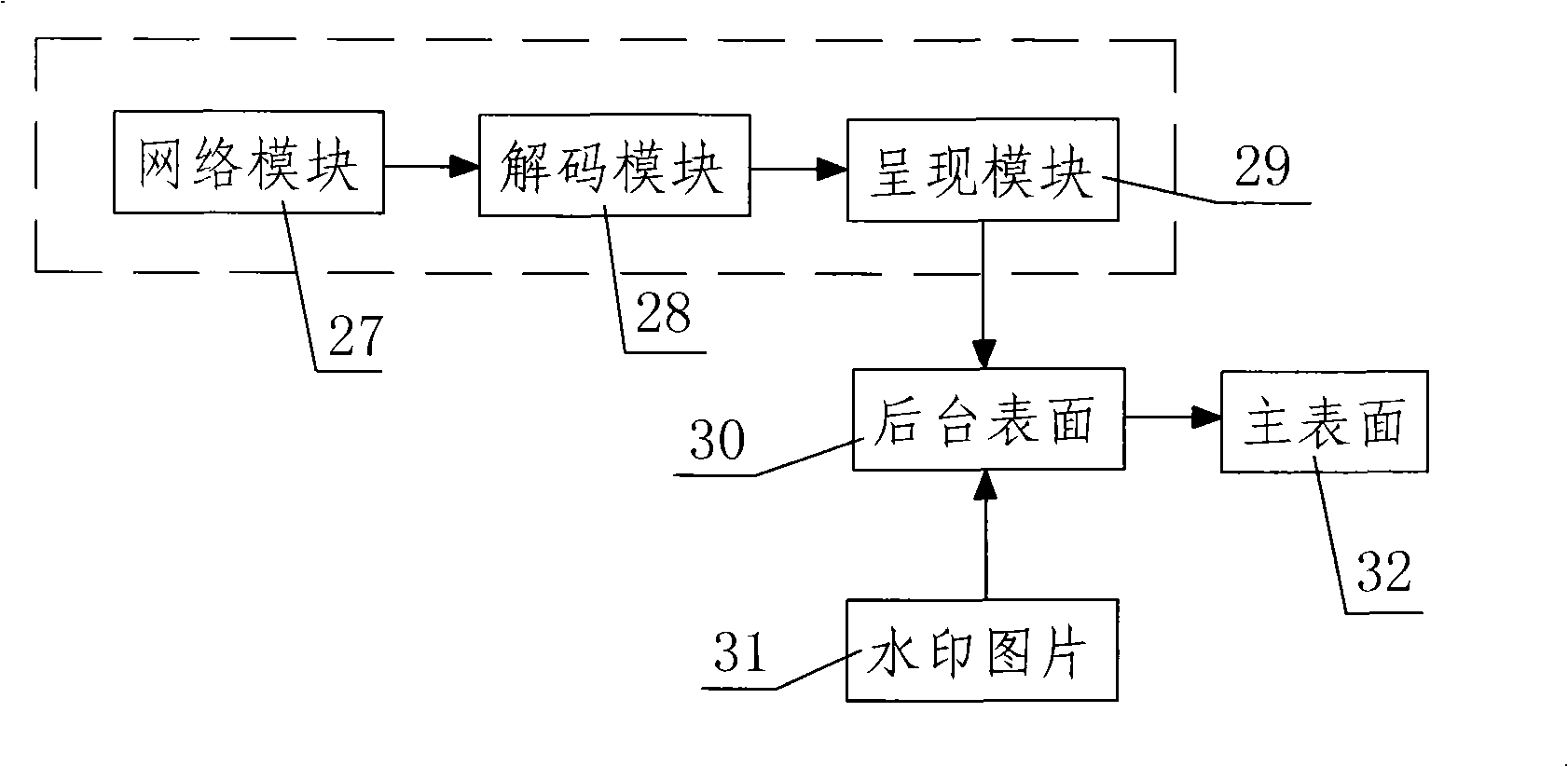

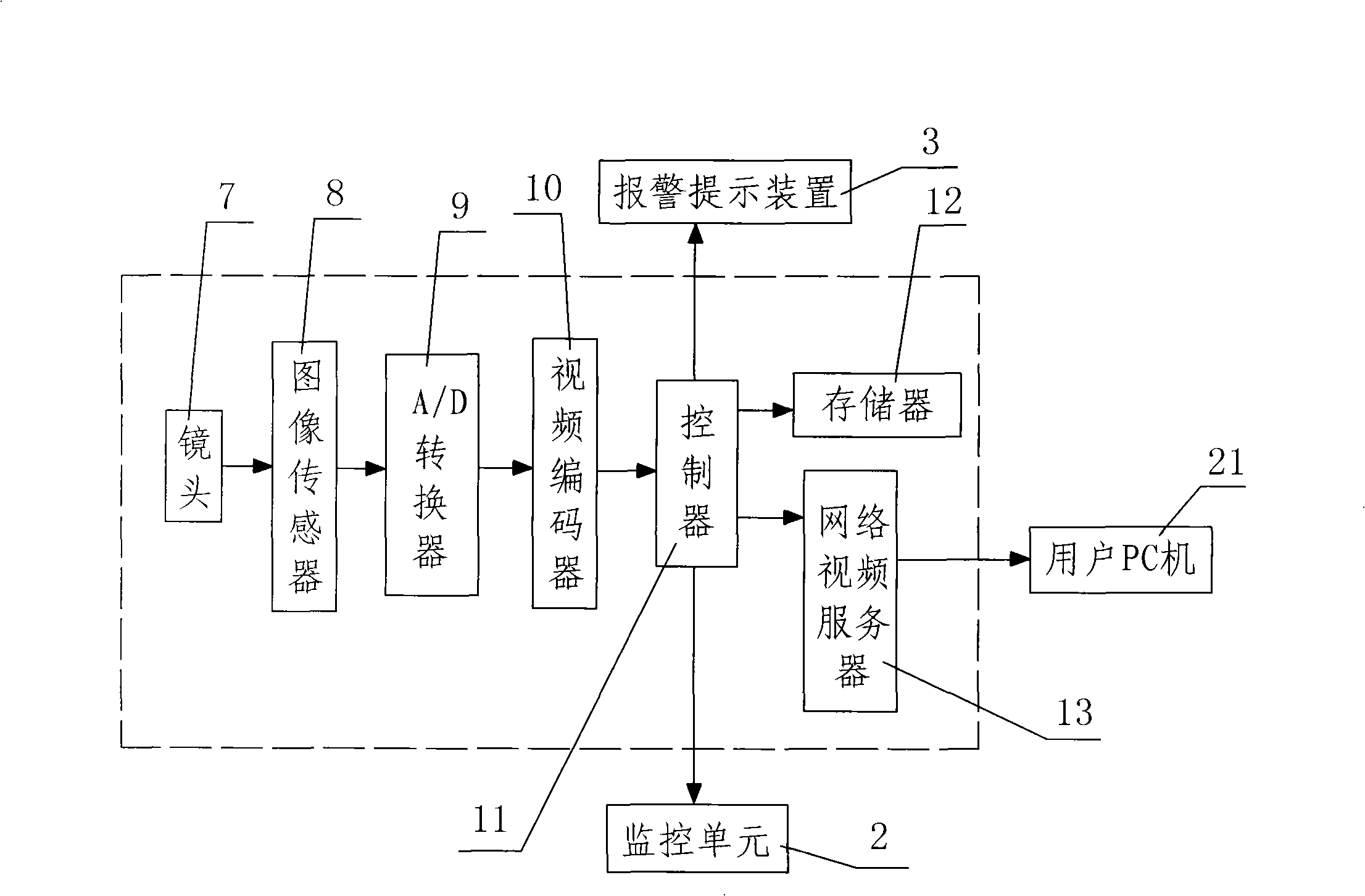

Motor train set parking contraposition video monitoring system

InactiveCN101349916AReasonable structureEasy to useData switching by path configurationClosed circuit television systemsVideo monitoringComputer module

The invention discloses a motor train set stop counterpoint video monitoring system, comprising an image acquisition and processing unit for real-timely monitoring the motion of a maintained motor train set, a monitoring unit embedded with a scale function module and an alarm prompt device controlled by the monitoring unit, wherein the image acquisition and processing system is mounted according to the maintenance position on which a maintained motor train set should stop, the image acquisition and processing system is connected with the monitoring unit connected with at least one user PC, the image acquisition and processing system and the user PC and the user PC are connected and communicated via a wireless network, the scale function module real-timely measures the motion speed of the maintained motor train set and the distance between the maintained wheel of the motor train set and the maintenance position. The invention can accurately display the distance between the maintained wheel of a maintained motor train set and the processing position, via which drivers can park accurately, realize accurate counterpoint of wheels and attain high working efficiency.

Owner:李剑 +2

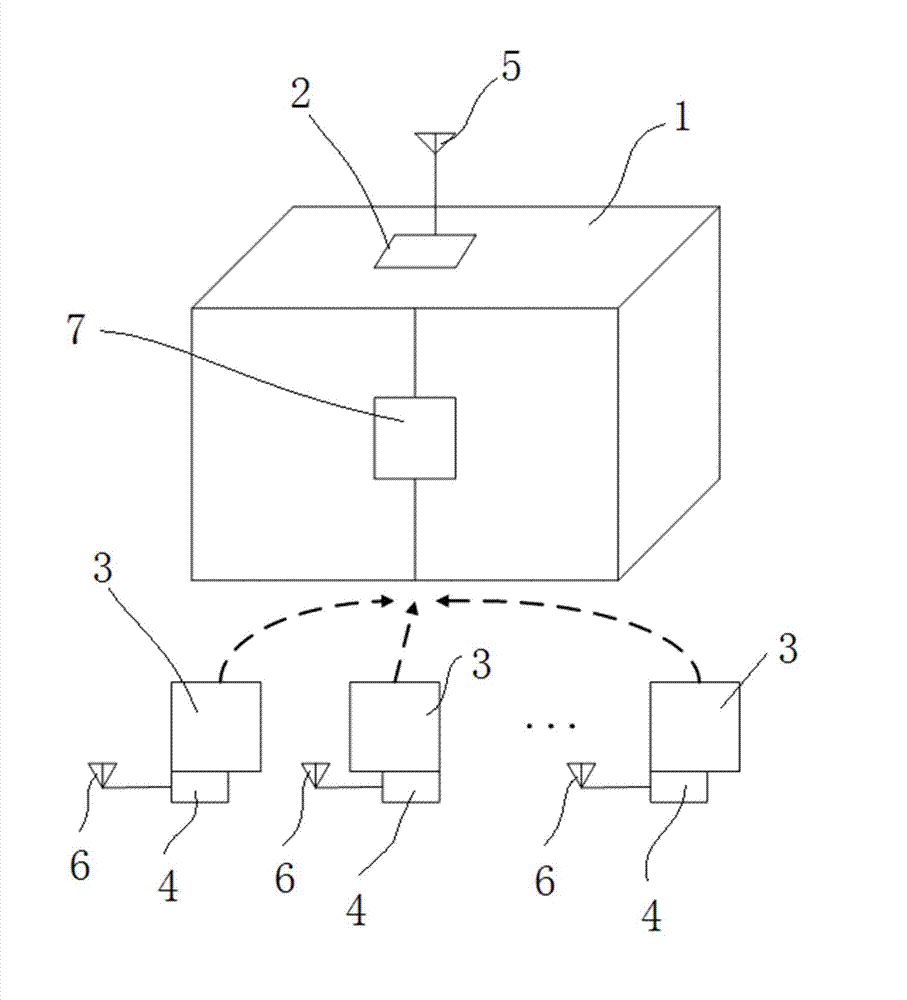

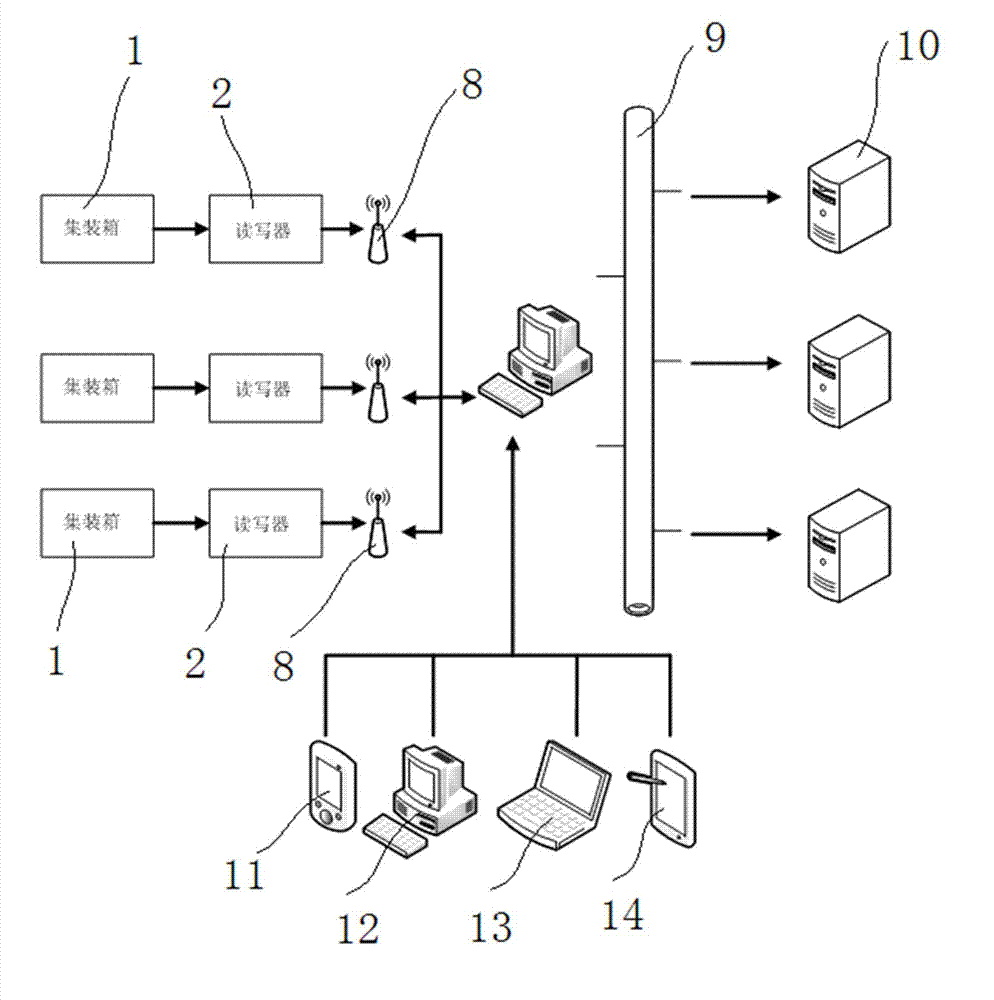

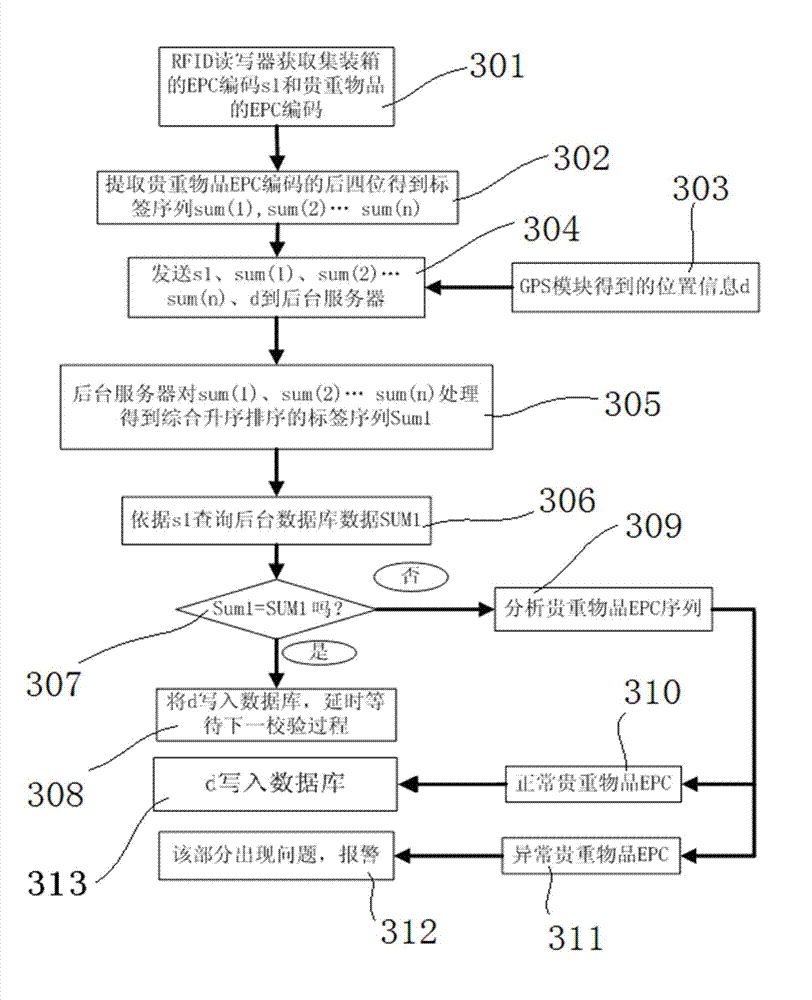

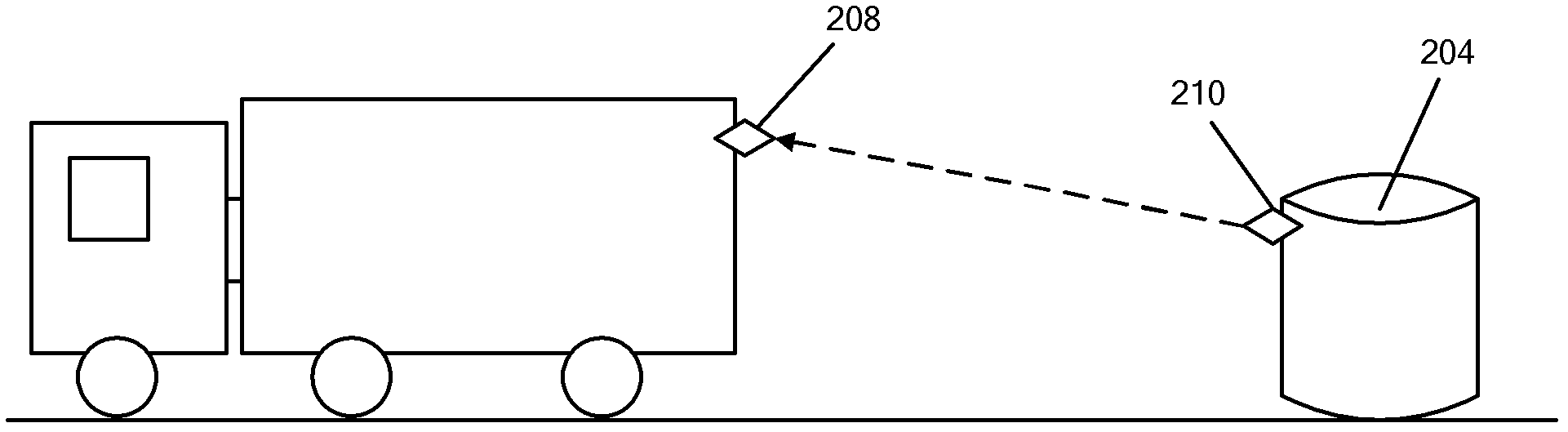

Monitoring system for transport of valuables based on radio frequency identification (RFID) and monitoring method of monitoring system

InactiveCN102902992AEnsure safetyLong reading distanceCo-operative working arrangementsLogisticsLogistics managementMonitoring system

The invention relates to the application field of the radio frequency identification technology and provides a monitoring system for transport of valuables based on radio frequency identification (RFID). An RFID reader is installed on a container, RFID tags are attached to all valuables, the RFID reader sends read codes and container location information to a background server and checks the read codes and the container location information with the data inside a database, when the exam of the information of valuables is passed, the container location information is read to the database, and when the exam of the information of valuables fails, the system alarms. The invention also provides a monitoring method of the system. The data exam is conducted through statistical process control (SPC) data sequences, and valuables are monitored. By the aid of the system and the method, for logistics corporations, the cost is saved, the efficiency is improved and the hazard is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH +1

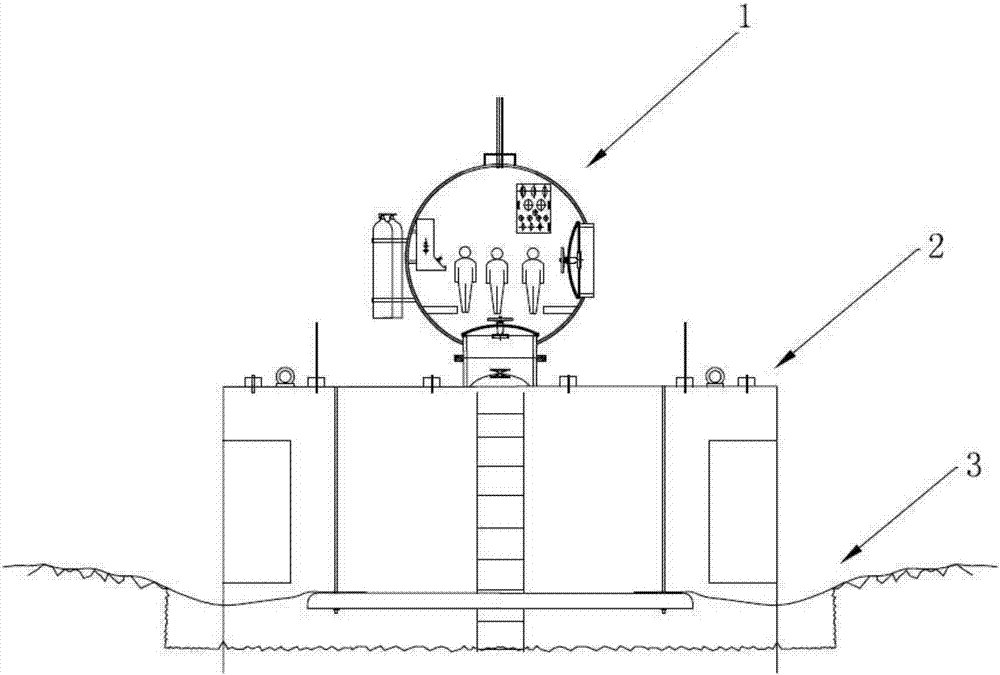

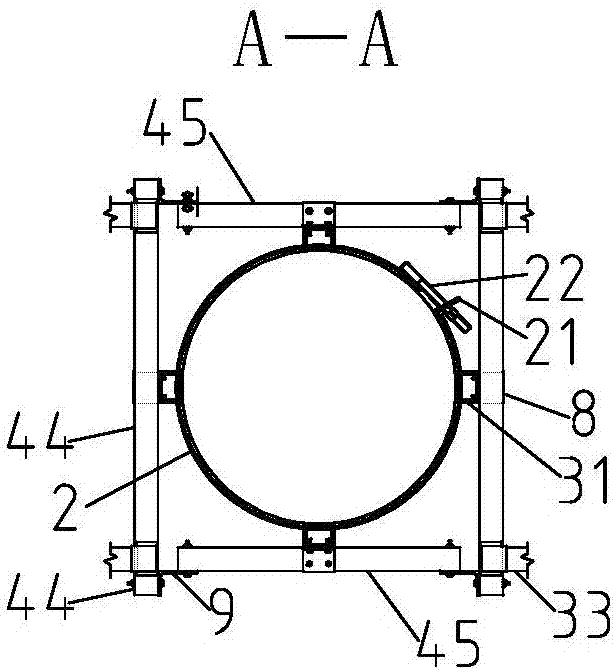

Deep-sea high-pressure dry type maintenance device

The invention relates to a deep-sea high-pressure dry type maintenance device. The deep-sea high-pressure dry type maintenance device comprises a diving bell, and one end of the diving bell is in butt joint with a high-pressure dry type maintenance chamber in an airtight or watertight mode. The deep-sea high-pressure dry type maintenance device is reasonable in design and convenient to use; and by adoption of the modular structural design, the diving bell and the high-pressure dry type maintenance chamber can be connected and separated rapidly on a deck, and therefore the deep-sea high-pressure dry type maintenance device has the advantages of being easy to assemble and reliable in connection. By adoption of the deep-sea high-pressure dry type maintenance device, the integral hanging and recycling of the diving bell and the maintenance chamber is achieved, so that maintenance workers can keep staying in a high-pressure and dry environment in the whole maintenance process, a wet working environment is avoided, and the range of working objects is expanded; and meanwhile, the maintenance workers are provided with a safe and comfortable working space. By adoption of the deep-sea high-pressure dry type maintenance device, the requirement for saturation diving can be met, working time can be effective prolonged for the maintenance workers by providing high pressure gas in the diving bell and the maintenance chamber, so that long-time underwater working is achieved, working efficiency is improved, and the whole working period is shortened.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

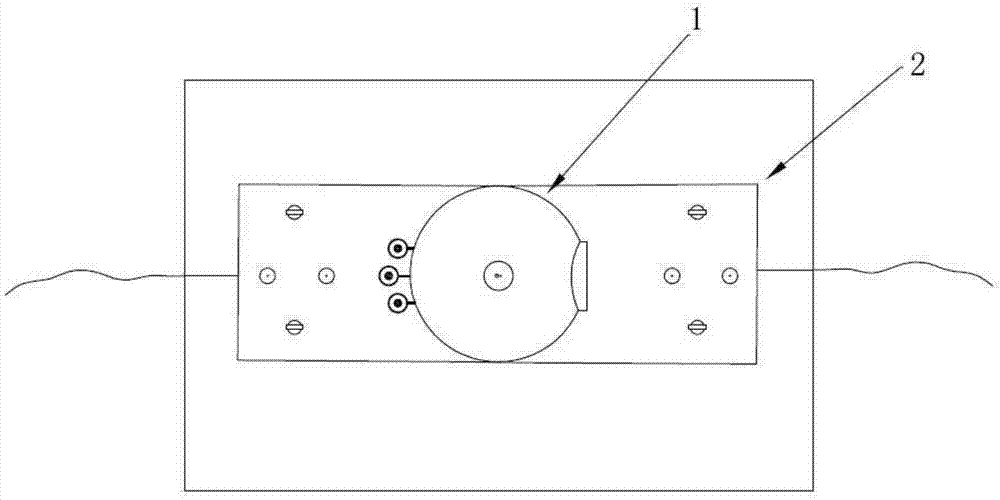

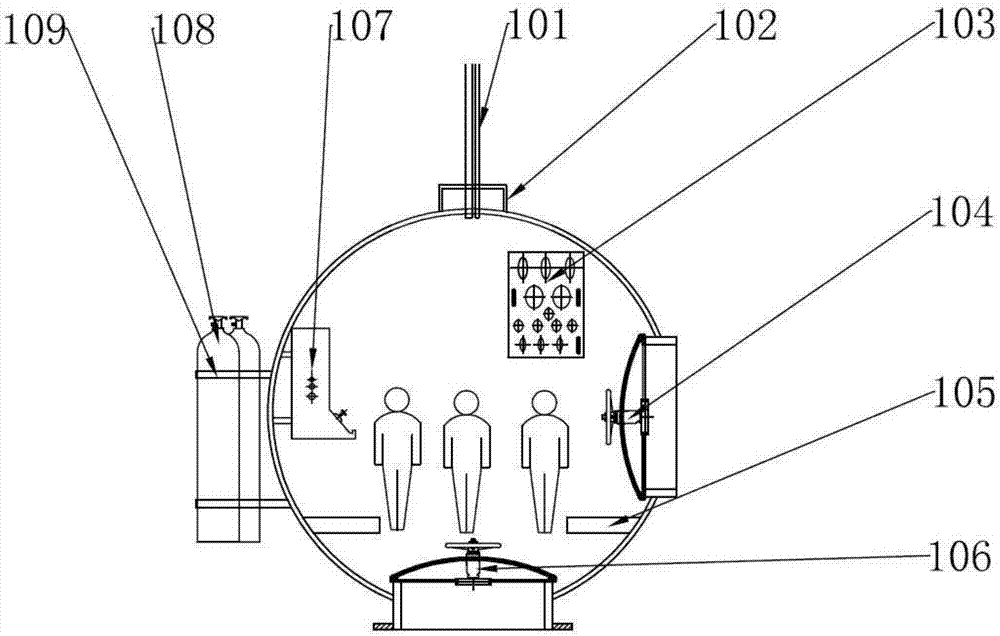

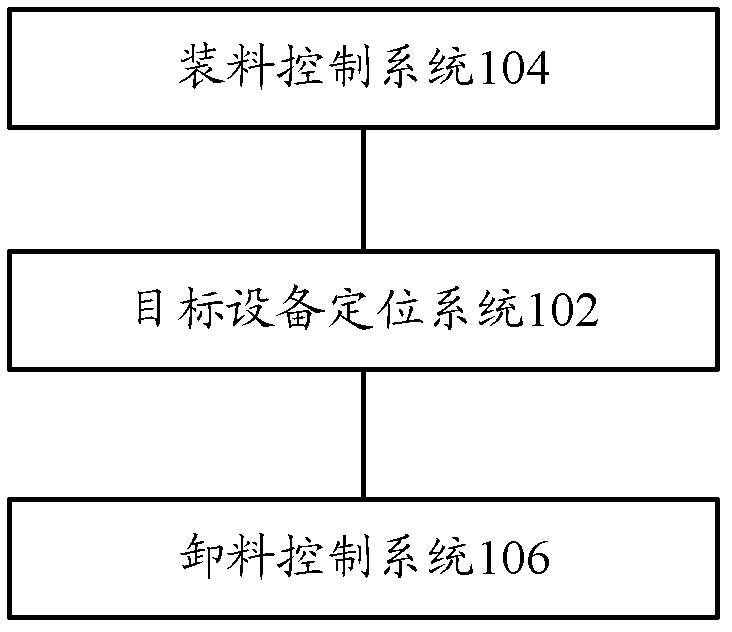

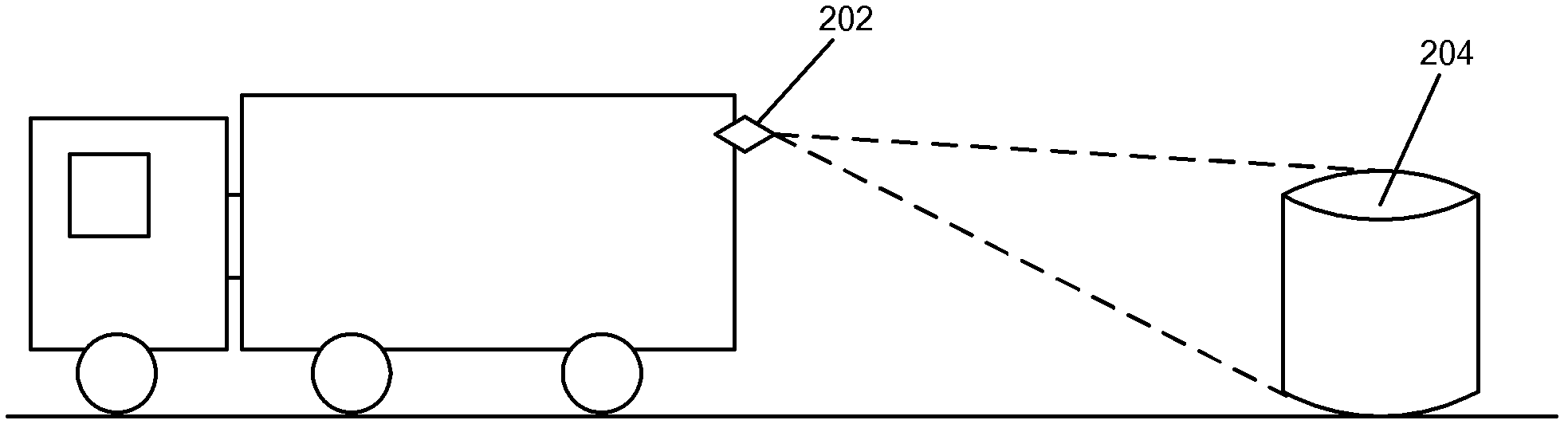

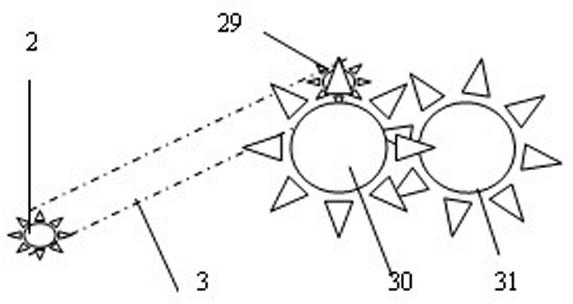

Concrete transporting equipment, loading system, unloading system and automatic loading and unloading method

InactiveCN102602318AReduce operating efficiencyConcrete transportationLoading/unloading vehicle arrangmentControl signalControl system

The invention provides concrete transporting equipment, which comprises a target equipment positioning system, a loading control system and an unloading control system, wherein the target equipment positioning system is used for determining a position and a type of target equipment which refers to concrete mixing equipment or a concrete pump; the loading control system is used for sending out a loading control signal to the concrete mixing equipment when the concrete transporting equipment arrives at the loading position of the concrete mixing equipment, so as to control the concrete mixing equipment to load the concrete transporting equipment; and the unloading control system is used for controlling the concrete transporting equipment to unload to the concrete pump when the concrete transporting equipment arrives at the unloading position of the concrete pump. Correspondingly, the invention further provides a loading system, an unloading system and an automatic loading and unloading method. By the aid of the technical scheme of the concrete transporting equipment, during loading and unloading of concrete, automatic loading / unloading is performed when the concrete transporting equipment arrives at the target positions, so that the number of construction staff is decreased, and work efficiency is improved.

Owner:SANY HEAVY IND CO LTD (CN)

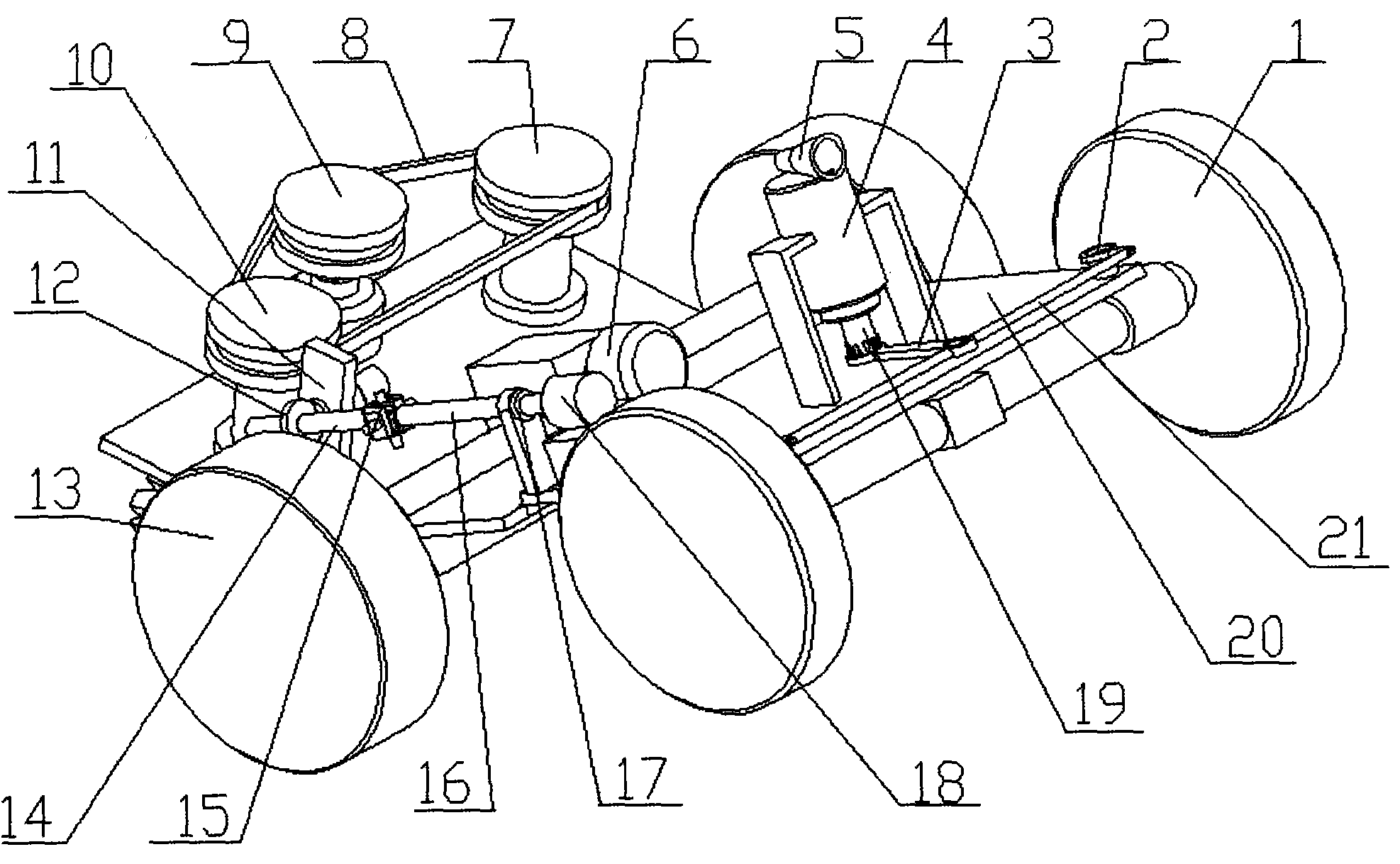

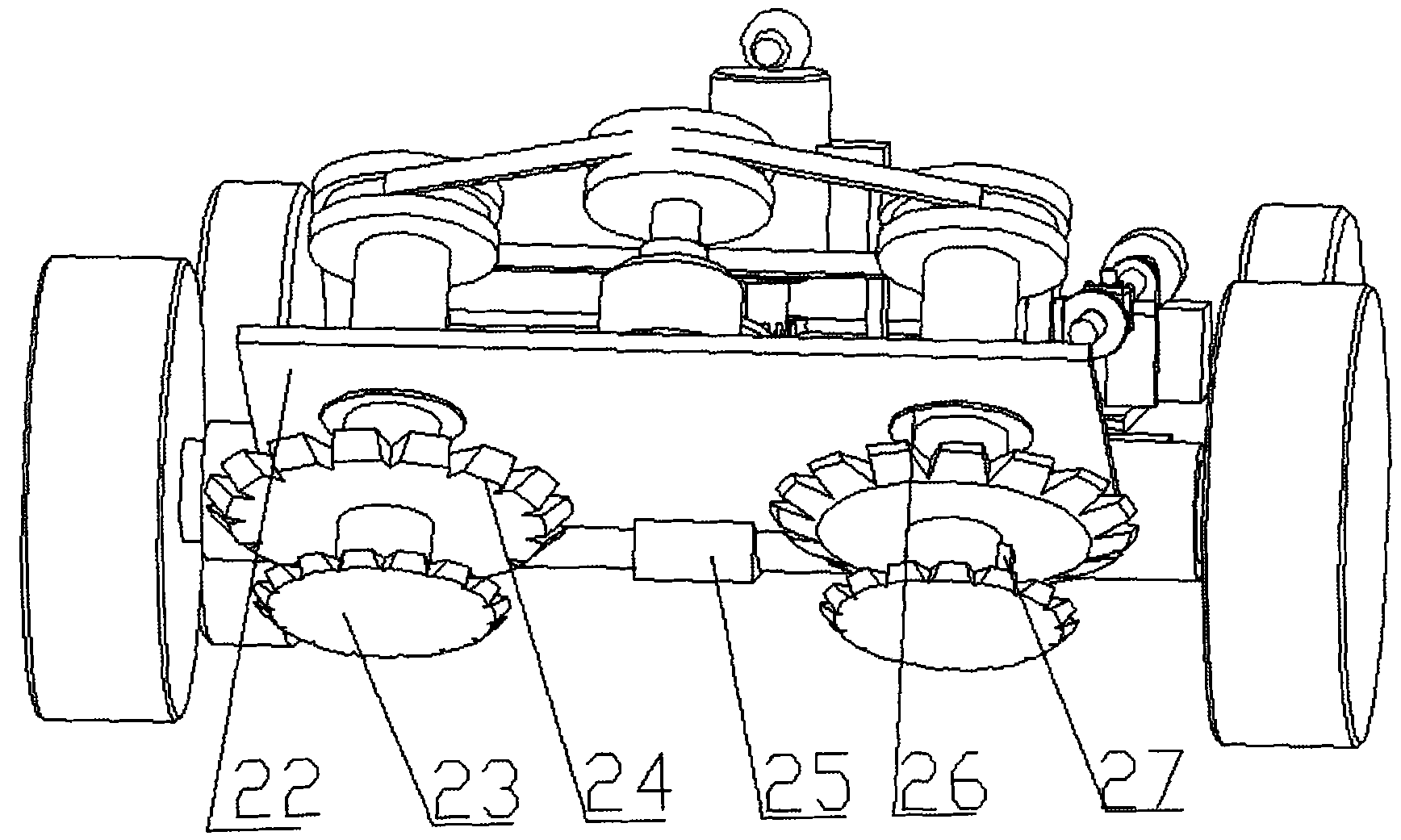

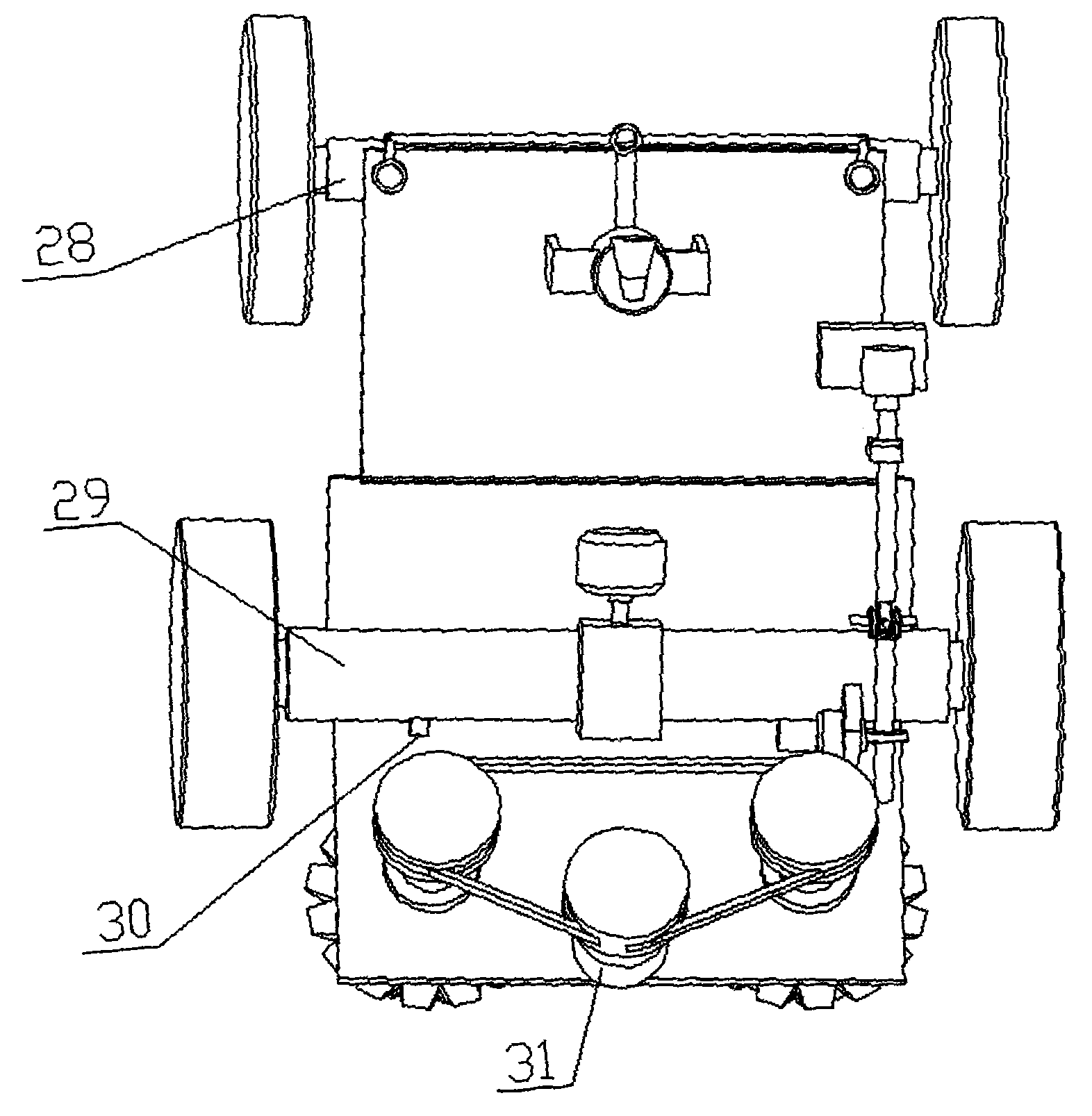

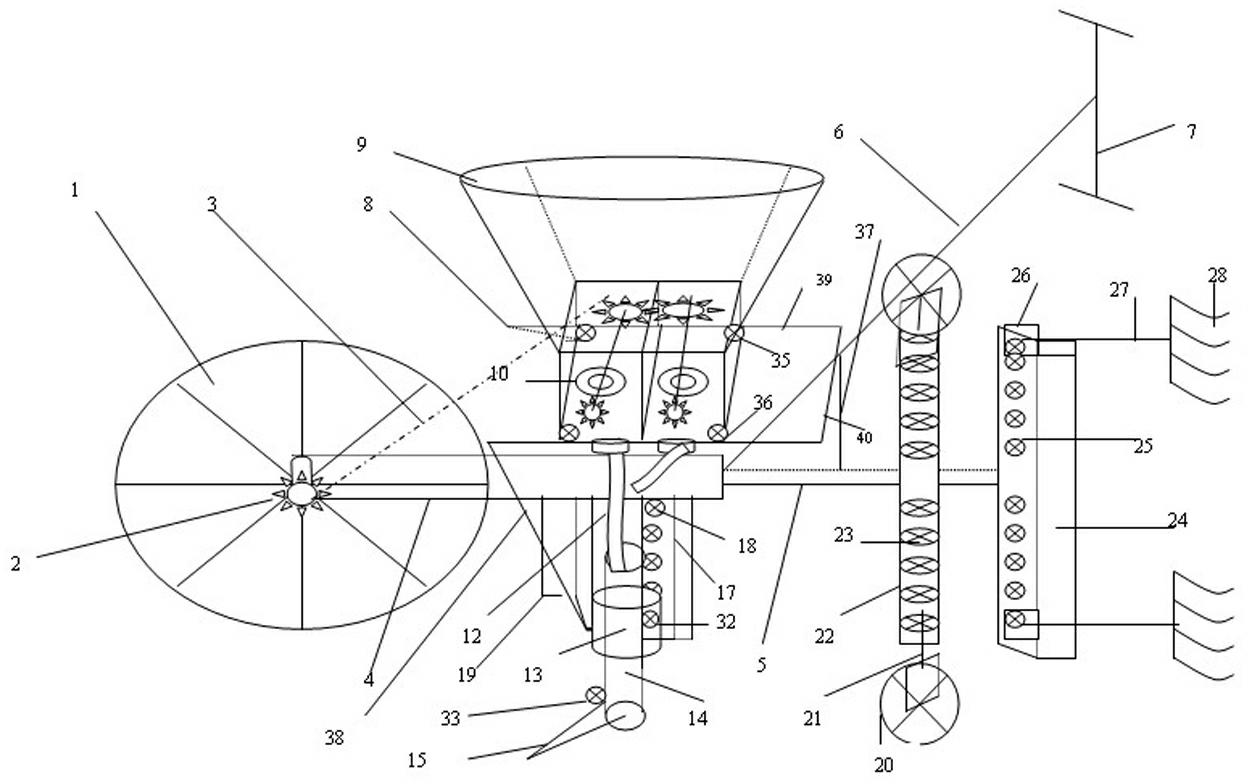

Depth self-adjusting type corn inter-row weeding machine

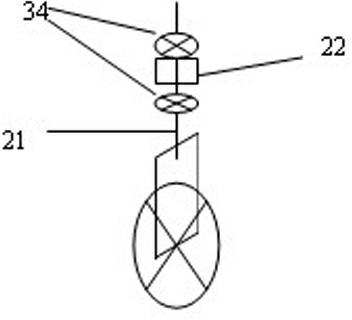

InactiveCN103718679AAvoid negative effectsReduce work intensitySoil-working equipmentsWeed killersPulp and paper industryDrive motor

The invention discloses a depth self-adjusting type corn inter-row weeding machine. The depth self-adjusting type corn inter-row weeding machine is composed of a steering part, a driving part, a depth adjusting part, a working part and the like, wherein the steering part is composed of a steering lever, a shifting fork, a steering motor, a vision sensor, a driving motor and the like; the driving part is composed of a driving motor, a rear shaft differential mechanism and the like; the depth adjusting part is composed of a depth adjusting motor, a shaft coupler, a driving screw rod, a working screw rod, a screw rod nut and the like; the working part is composed of a working motor, a driving belt wheel, a left driven belt wheel, a right driven belt wheel, a grass crushing blade, a weeding blade and the like; the steering part is mounted at the front end of a rack; the driving part is mounted in the middle of the rack and is close to a rear shaft part; the depth adjusting part is mounted at the right end of the rack and the working part is mounted at the rear end of the rack. The weeding machine disclosed by the invention gas has good adaptability and corn inter-row management work can be carried out conveniently.

Owner:NORTHWEST A & F UNIV

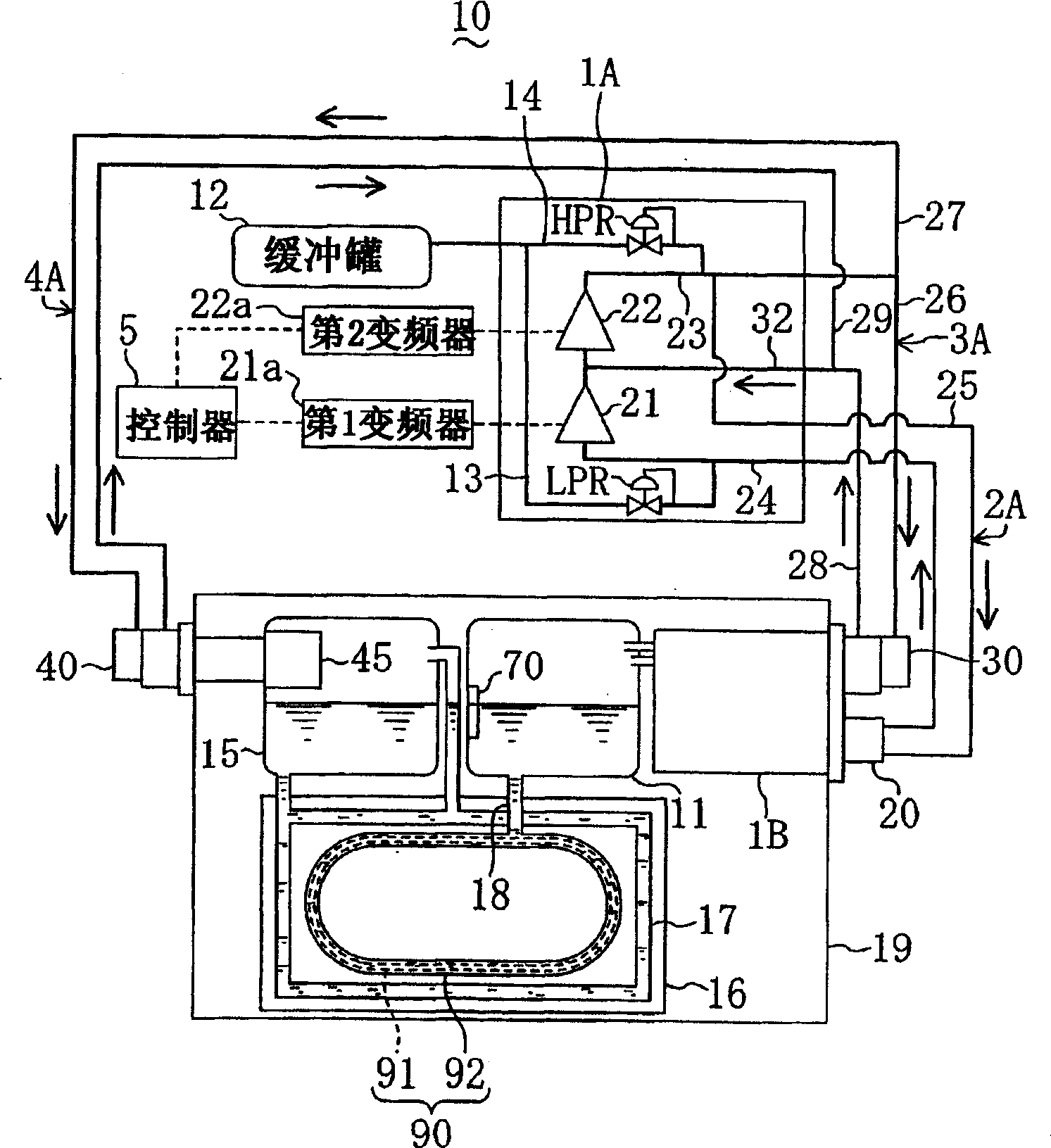

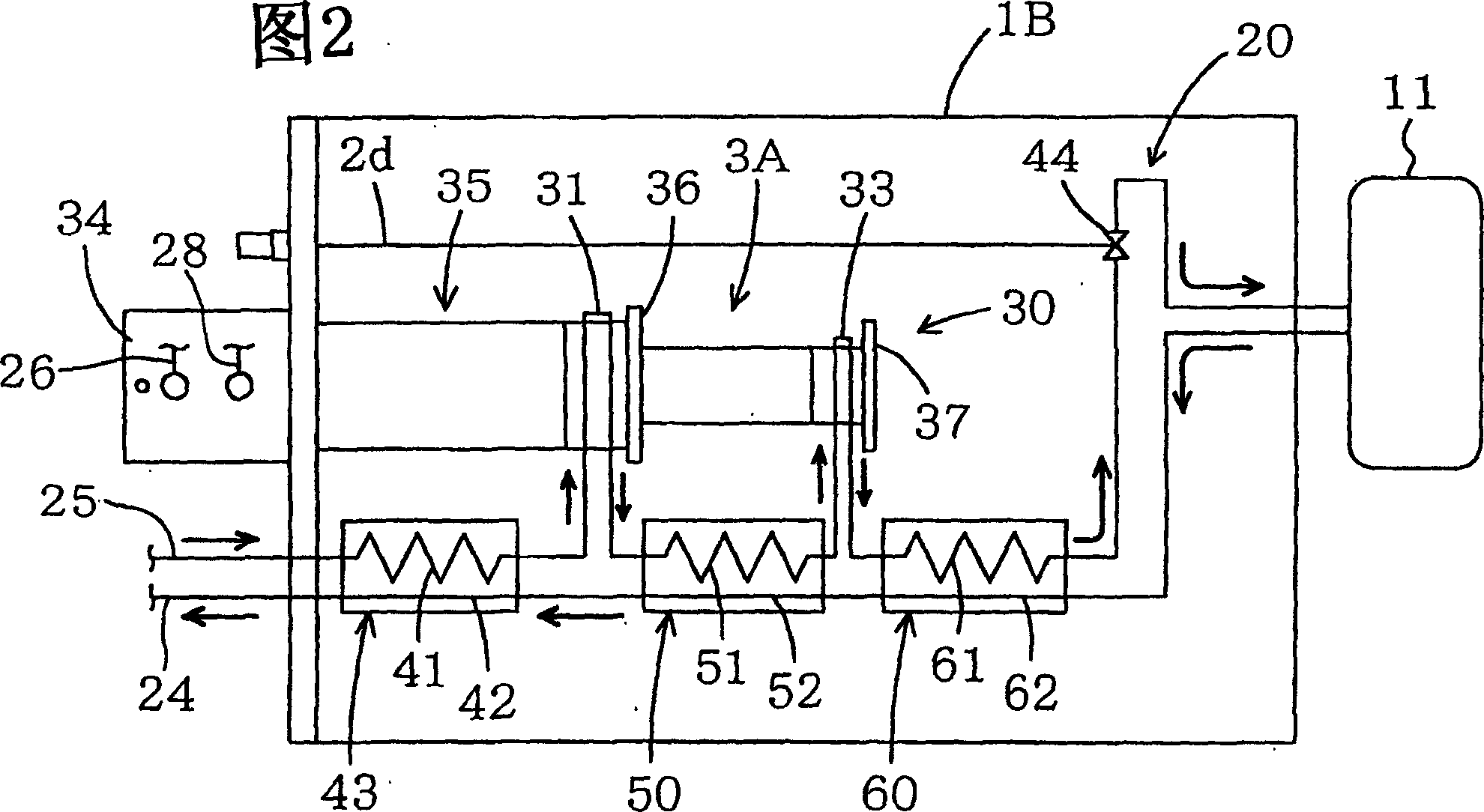

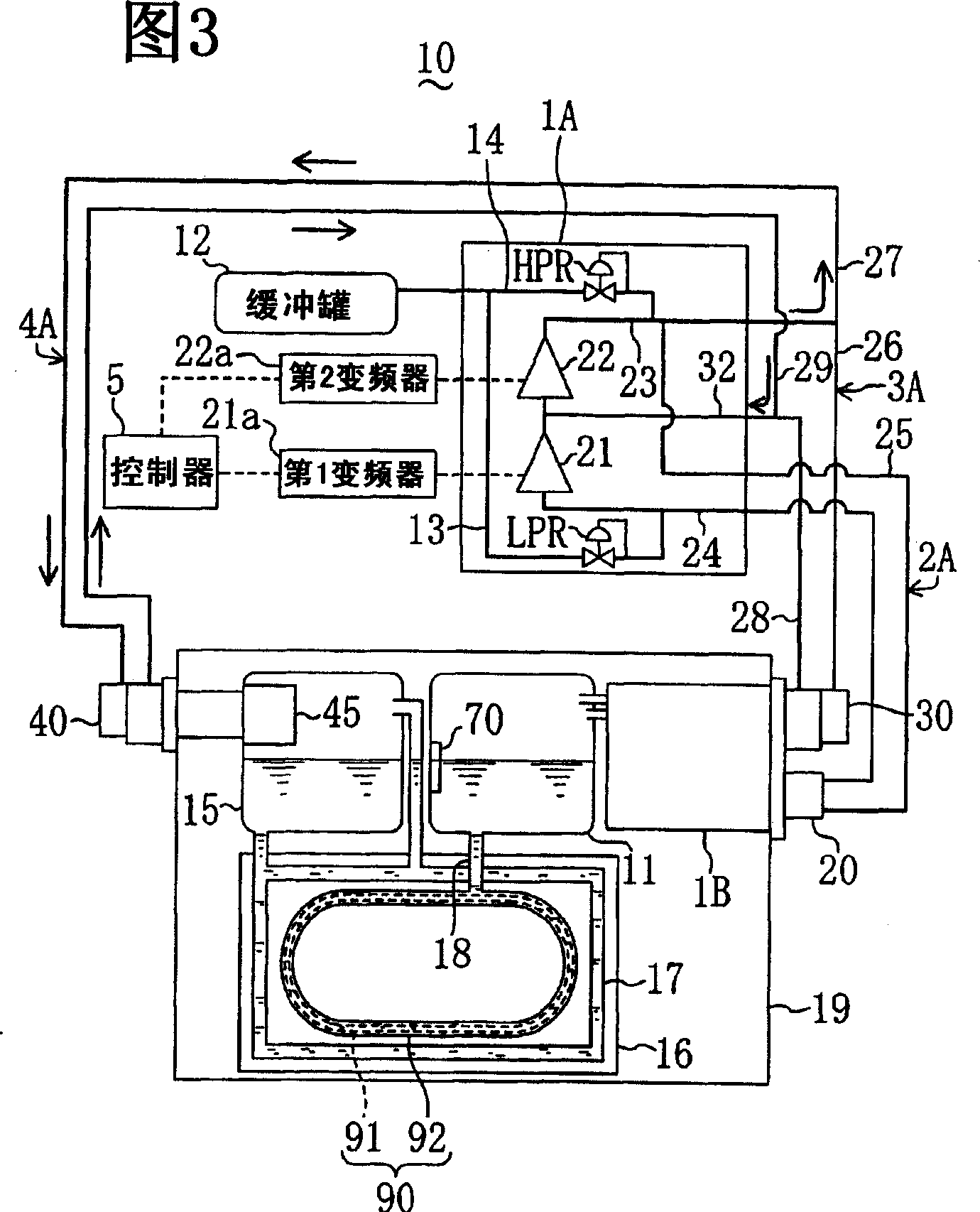

Ultra-low temp refrigerating device

InactiveCN1459606AImprove operational efficiencyReduce electricity consumptionDomestic cooling apparatusCompression machines with non-reversible cycleSuperconducting CoilsNitrogen

The cryogenic refrigeration system of the present invention includes: a shield plate for preventing a radiant heat from entering a superconducting magnet; a helium refrigerator for generating a liquid helium, the helium refrigerator including a pre-cooling refrigerator for pre-cooling a helium gas; and a nitrogen refrigerator for cooling nitrogen in a nitrogen tank; and a controller, whereby when a vehicle is running, a low pressure side compressor and a high pressure side compressor are operated, and the helium refrigerator and the nitrogen refrigerator are operated, whereas when the vehicle is not running, the operation of the pre-cooling refrigerator of the helium refrigerator is stopped while the operation of the nitrogen refrigerator is continued.

Owner:CENTRAL JAPAN RAILWAY COMPANY +1

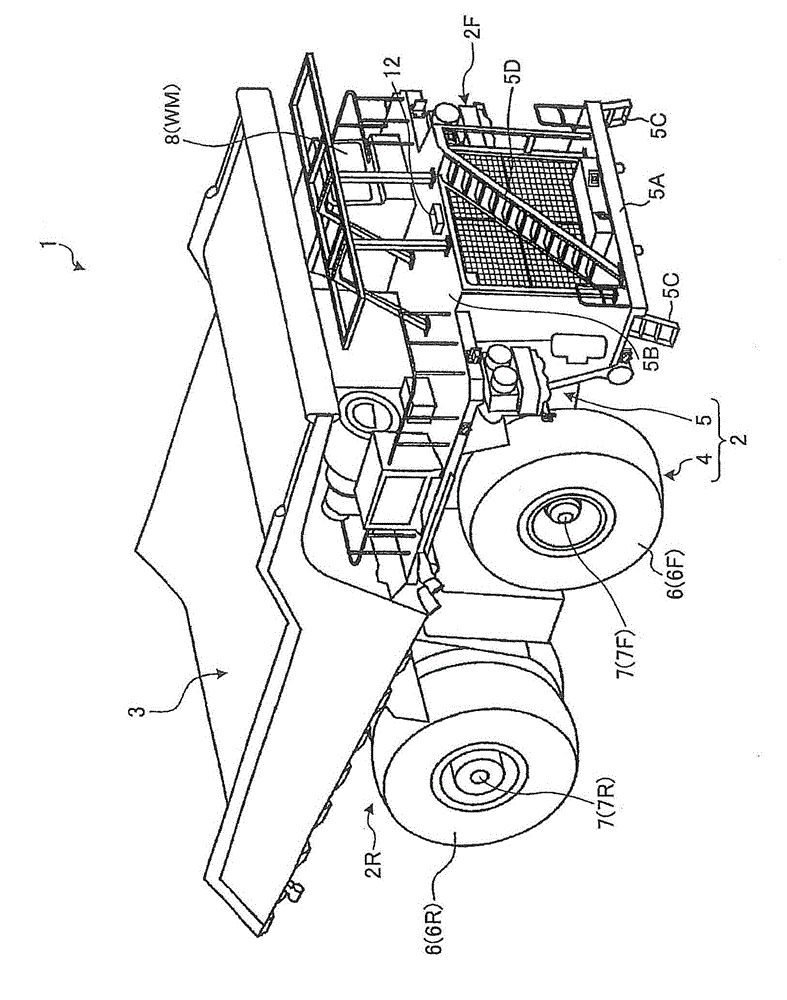

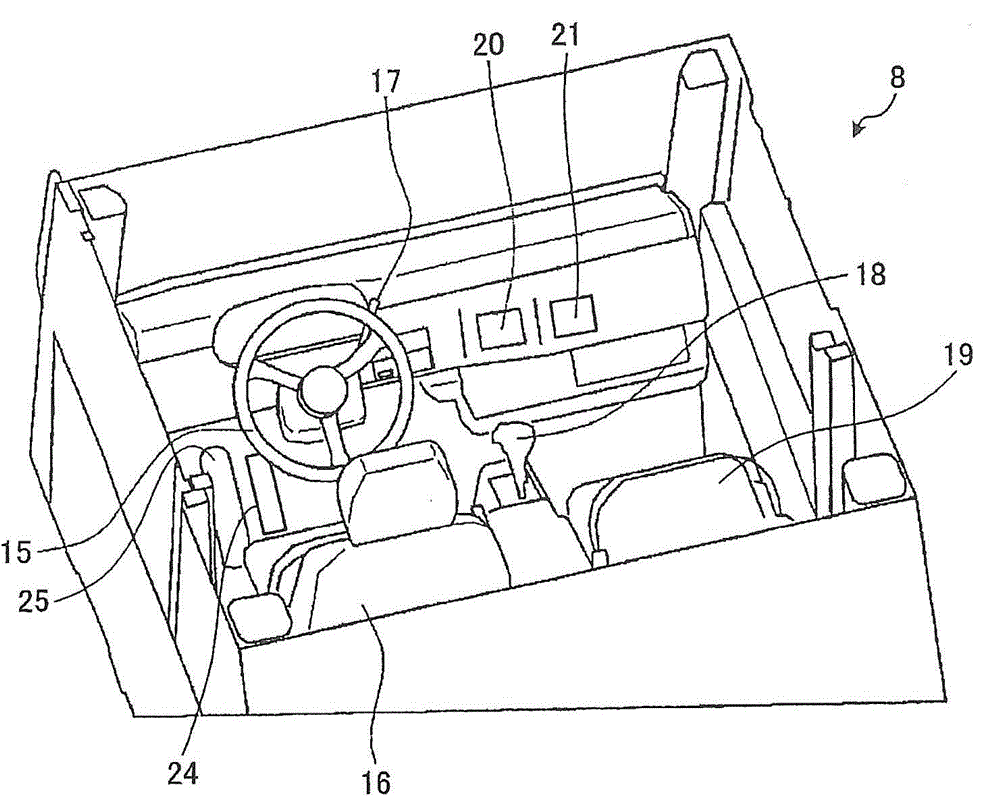

Transport vehicle and control method for transport vehicle

ActiveCN105611981AReduce damageSuppresses the decline in work efficiencyEntertainmentRoad vehicles traffic controlCartAutomotive engineering

Owner:KOMATSU LTD

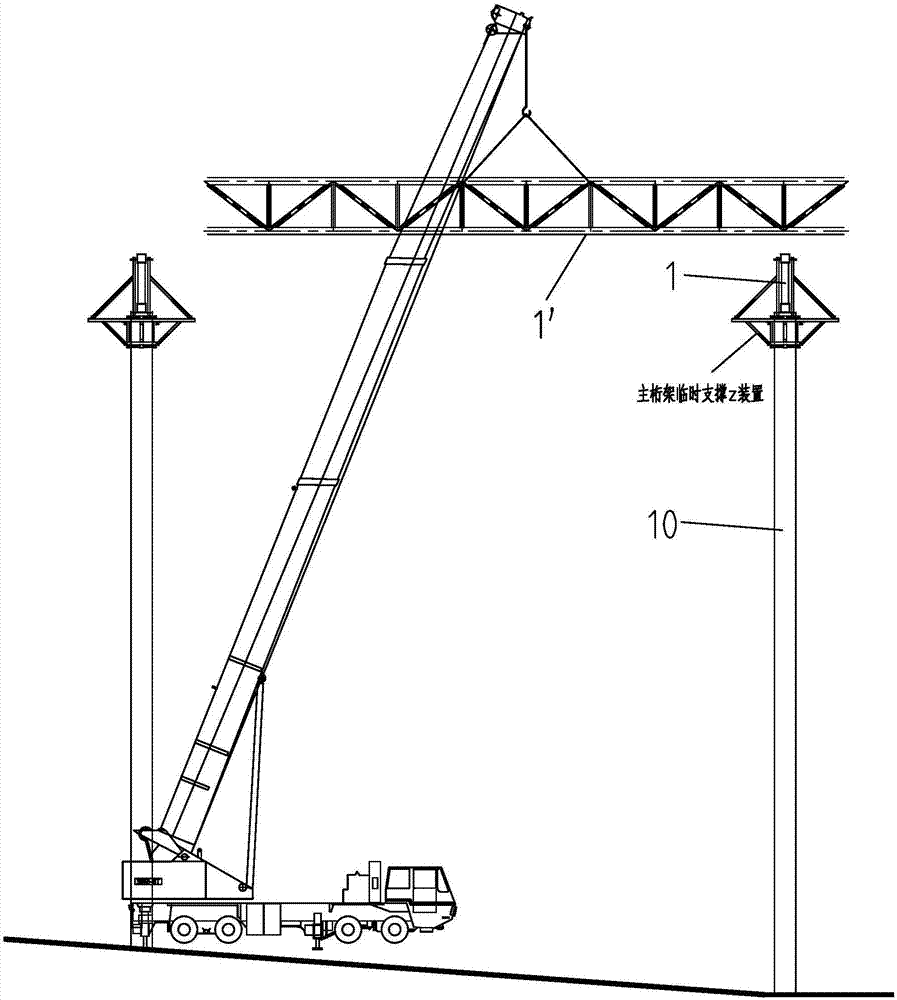

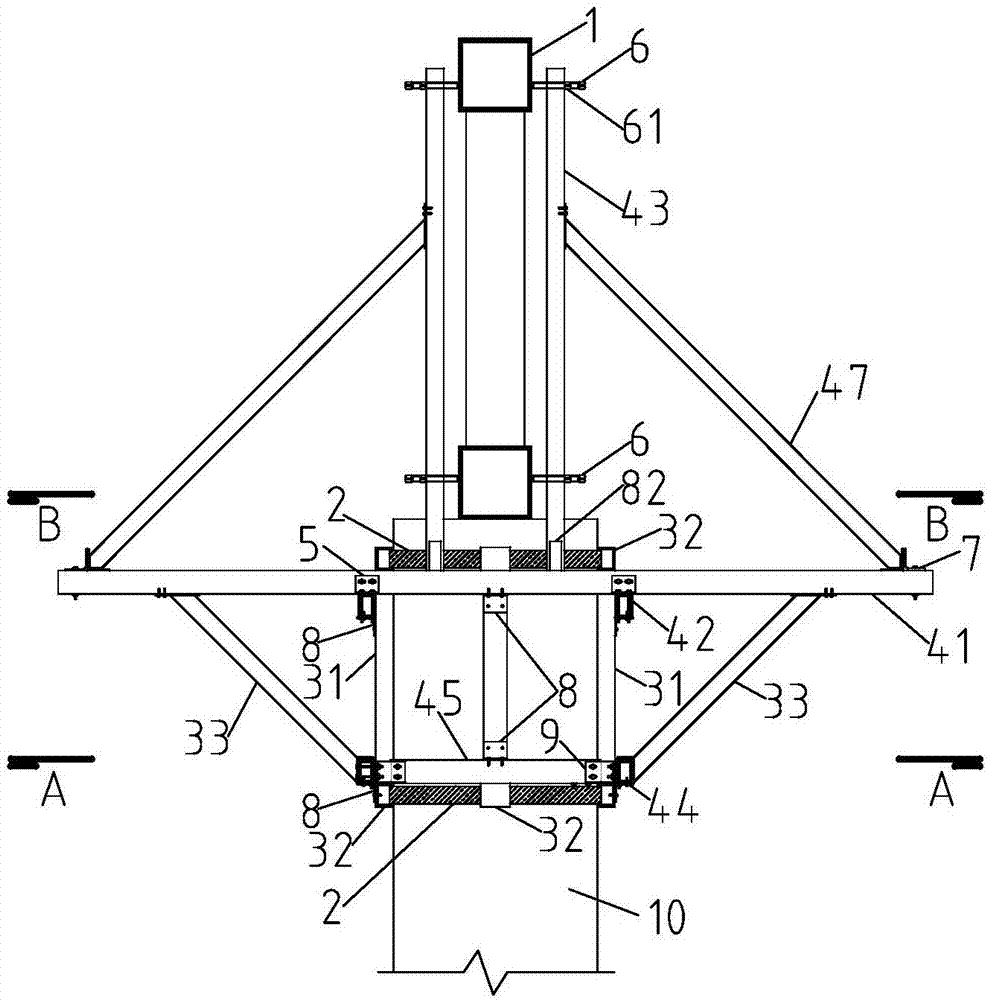

Mounting method for flake-like truss composite structure

ActiveCN106988537AReduce the time required for installationImprove efficiencyBuilding material handlingShoresComposite structureSteel structures

The invention relates to a mounting method for a flake-like truss composite structure and belongs to the technical field of aloft steel structure mounting. The mounting method is achieved by means of a primary truss temporary supporting device and a secondary truss temporary supporting device. By adoption of the mounting method, in-place stability and speed adjustment of the in-place position of one single steel truss can be effectively achieved, in-place stability of the steel truss not connected with a transverse rod is improved, the occupied time of a hoisting machine is shortened, mounting work efficiency of the steel truss is improved, the mounting period of the steel truss is shortened, and the in-place precision of the steel truss is improved.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

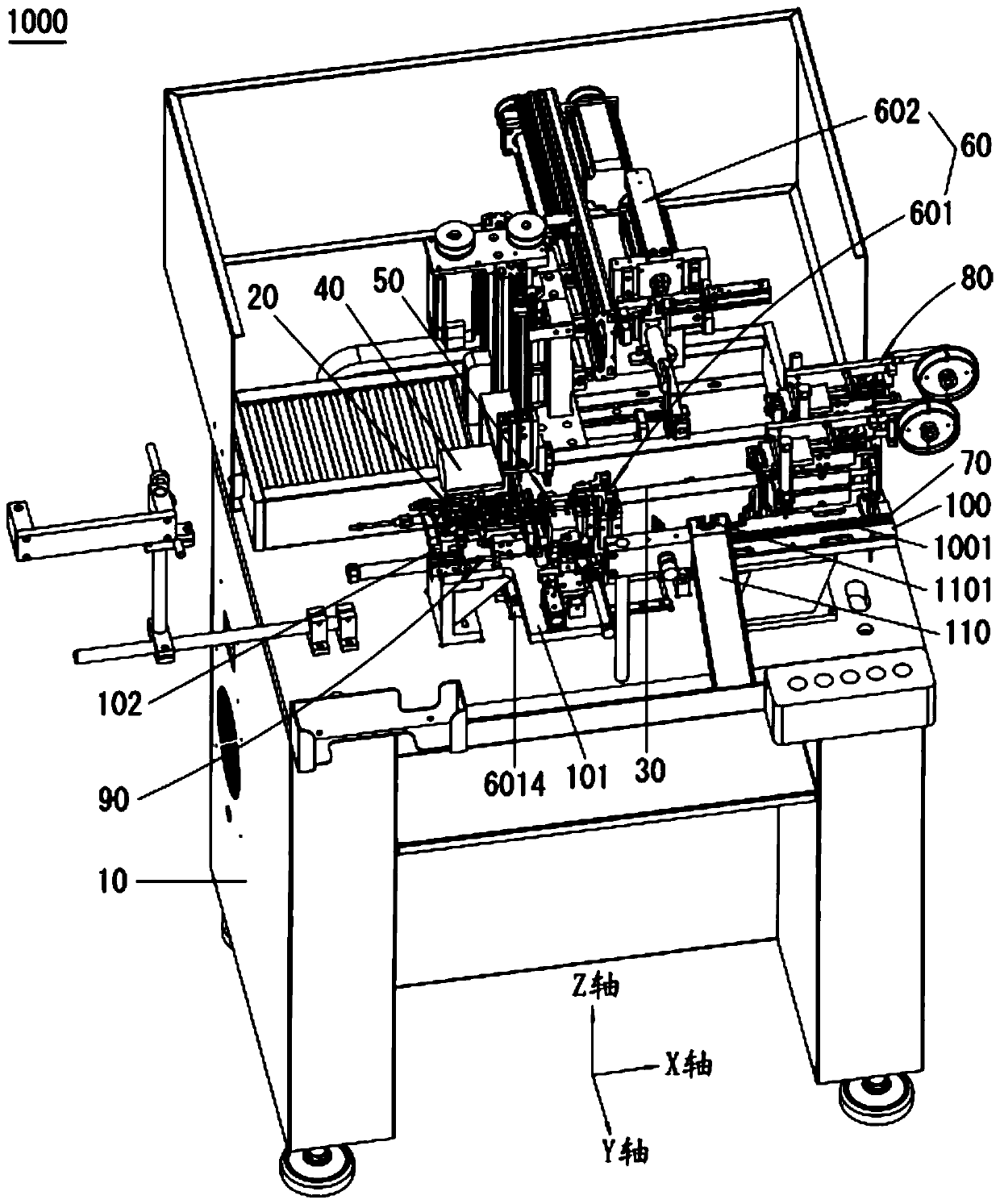

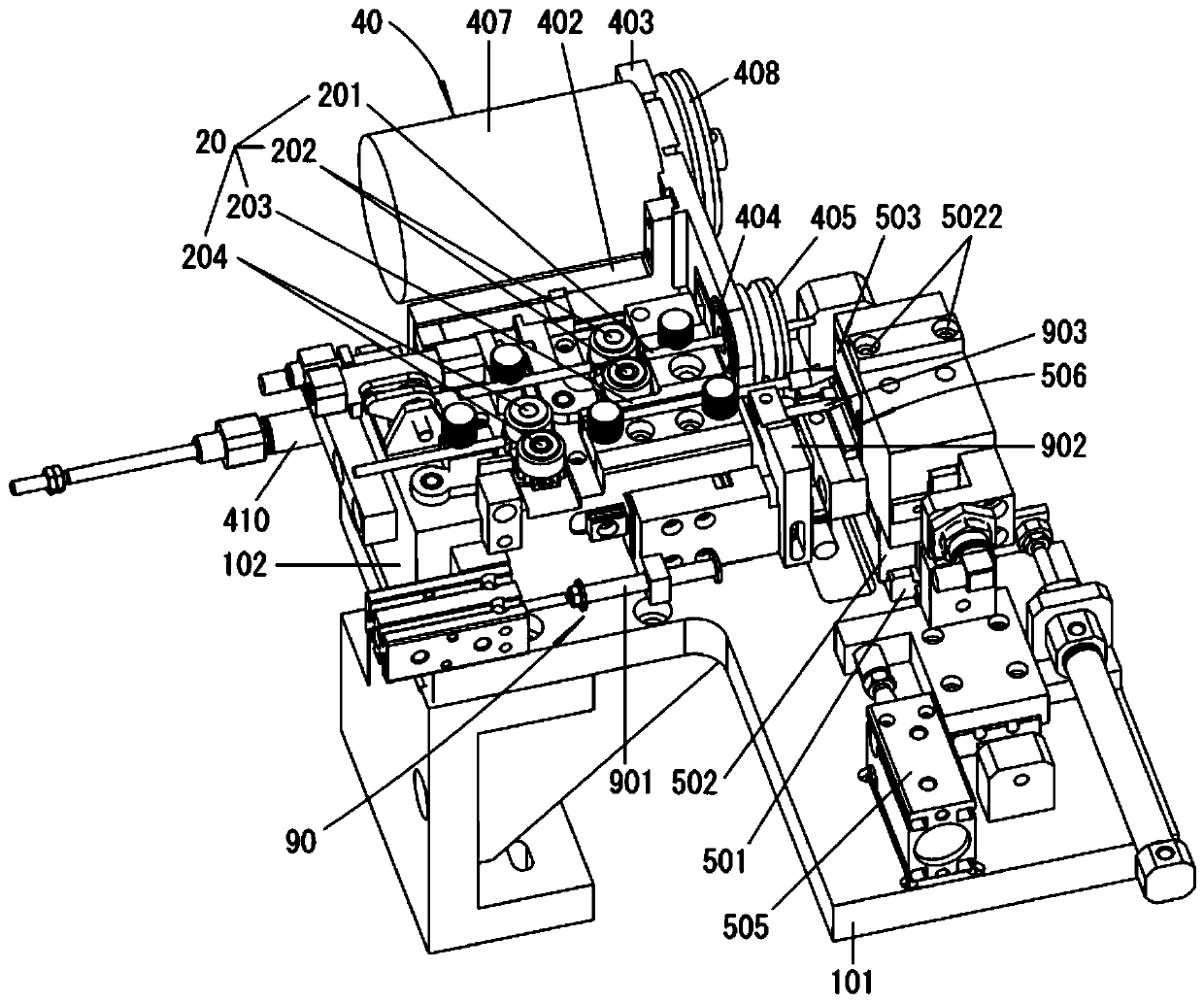

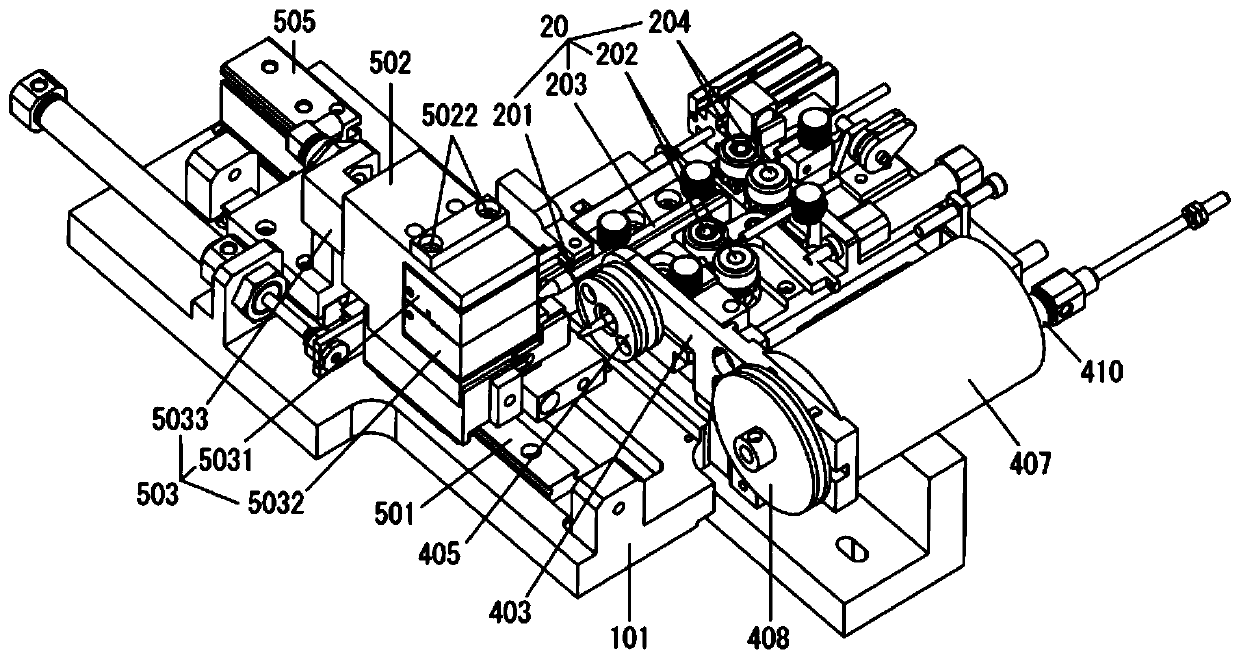

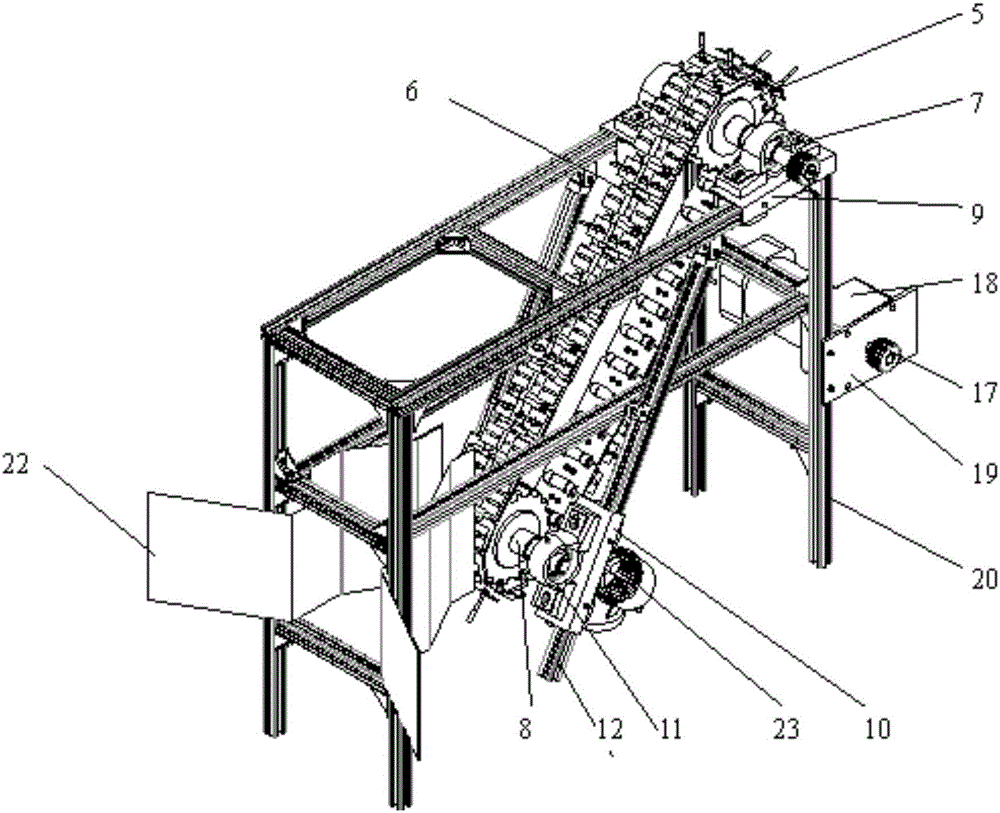

Stranded wire penetrating sleeve winding and rubber coating machine

PendingCN111477454AImprove work efficiencyReduce operating efficiencyCoils manufactureWire rodEngineering

The invention discloses a stranded wire penetrating sleeve winding and rubber coating machine. The stranded wire penetrating sleeve winding and rubber coating machine comprises a rack, a main controller, a wire feeding and pipe feeding mechanism, a wire stranding mechanism, a sleeve penetrating mechanism, a wire winding and sleeve winding and fixing mechanism, a rubber coating mechanism and a sleeve opening expanding mechanism. The stranded wire penetrating sleeve winding and rubber coating machine is advantageous in that automatic wire feeding and pipe feeding can be realized, a plurality ofwires which are wound together are automatically stranded so as not to be bifurcated, a sleeve is automatically arranged outside the wire rod which is stranded and twisted into a whole in a penetrating manner, winding, sleeve winding and fixing and automatic rubber coating are automatically carried out on the coil framework, the whole line production is coherent and good in continuity, the coil framework assembling production period can be greatly shortened, the sleeve opening expanding mechanism is used for expanding a sleeve opening in the rear end of a sleeve, and a wire rod can more conveniently penetrate into the sleeve opening expanding mechanism, so the stranded wire penetrating sleeve winding and rubber coating machine is high in practicability, good in using effect and capable ofbeing widely popularized and effectively popularized.

Owner:深圳市鹏达金电子设备有限公司

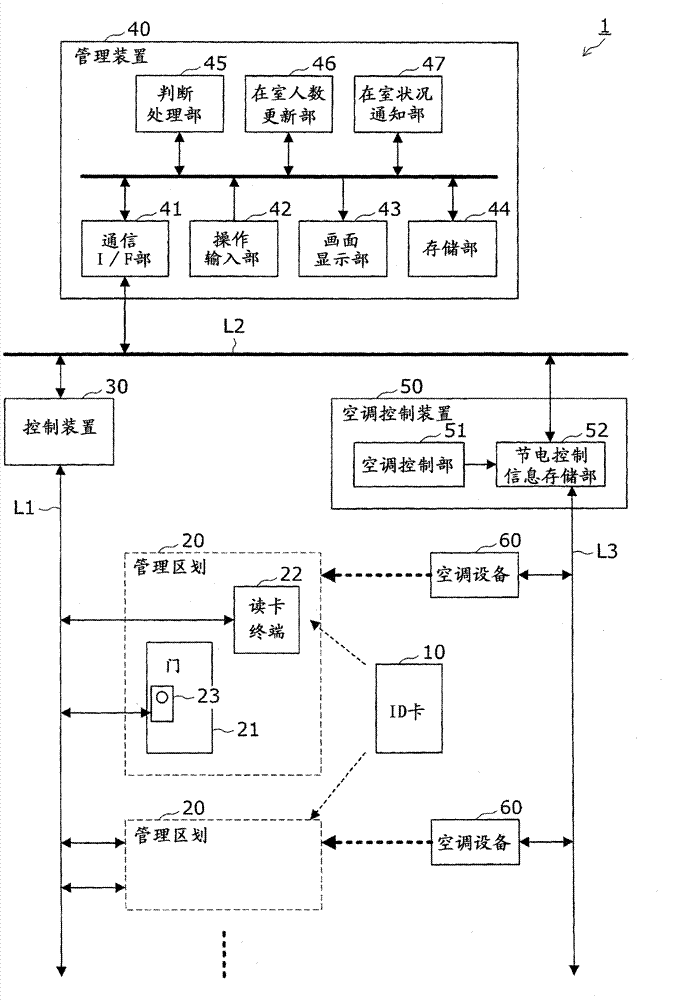

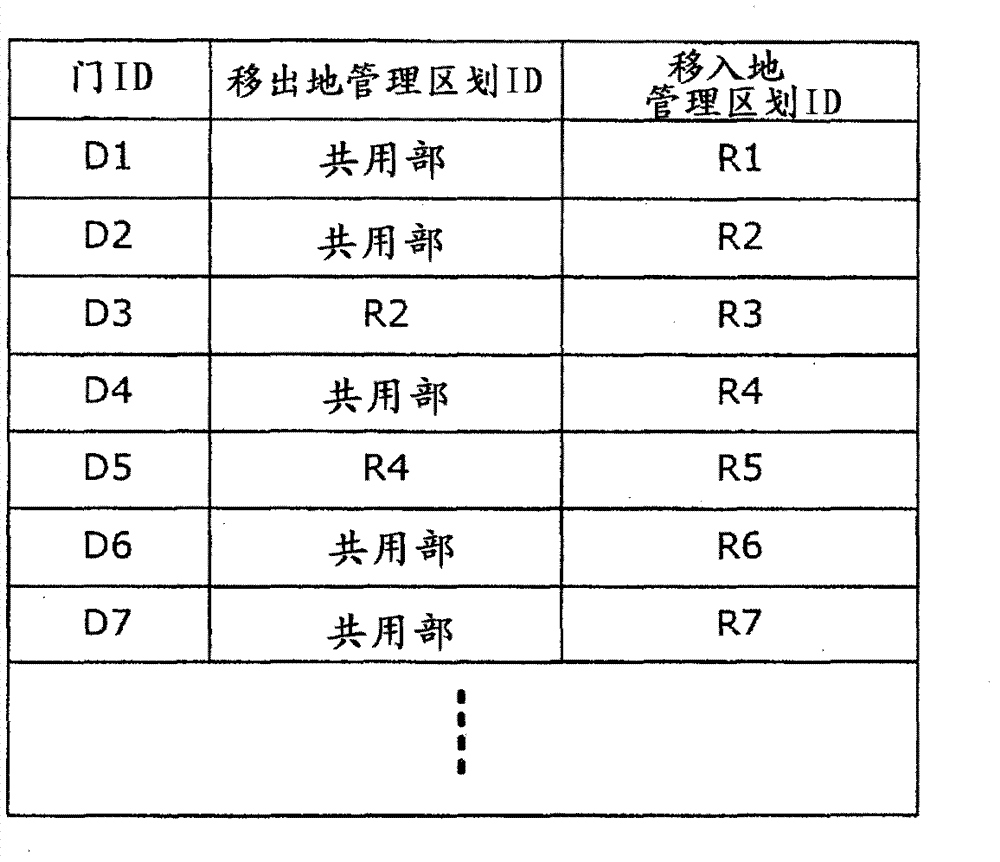

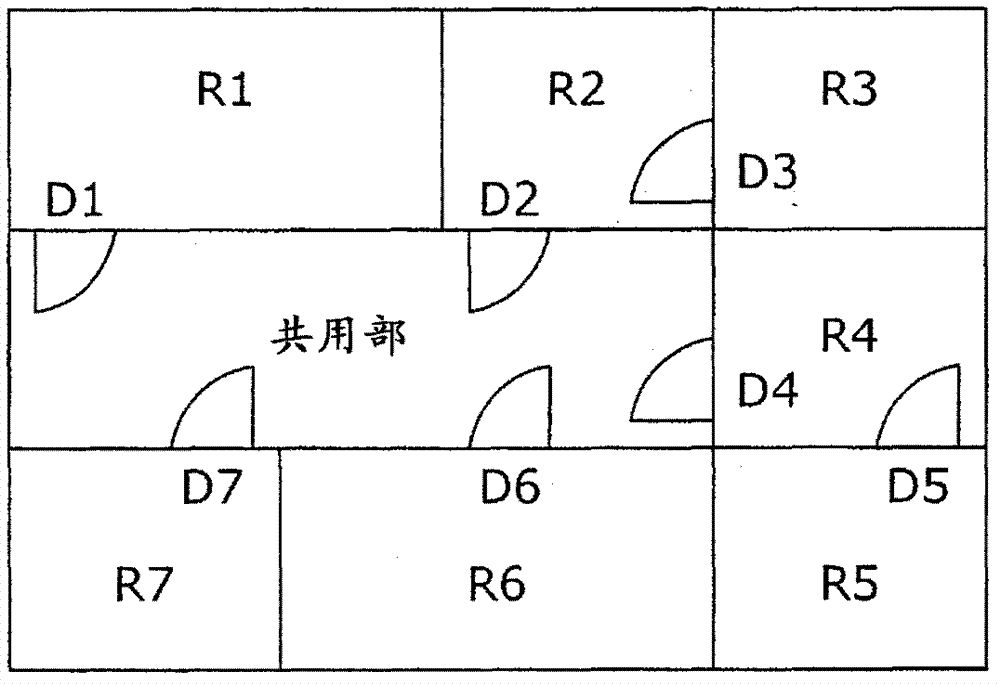

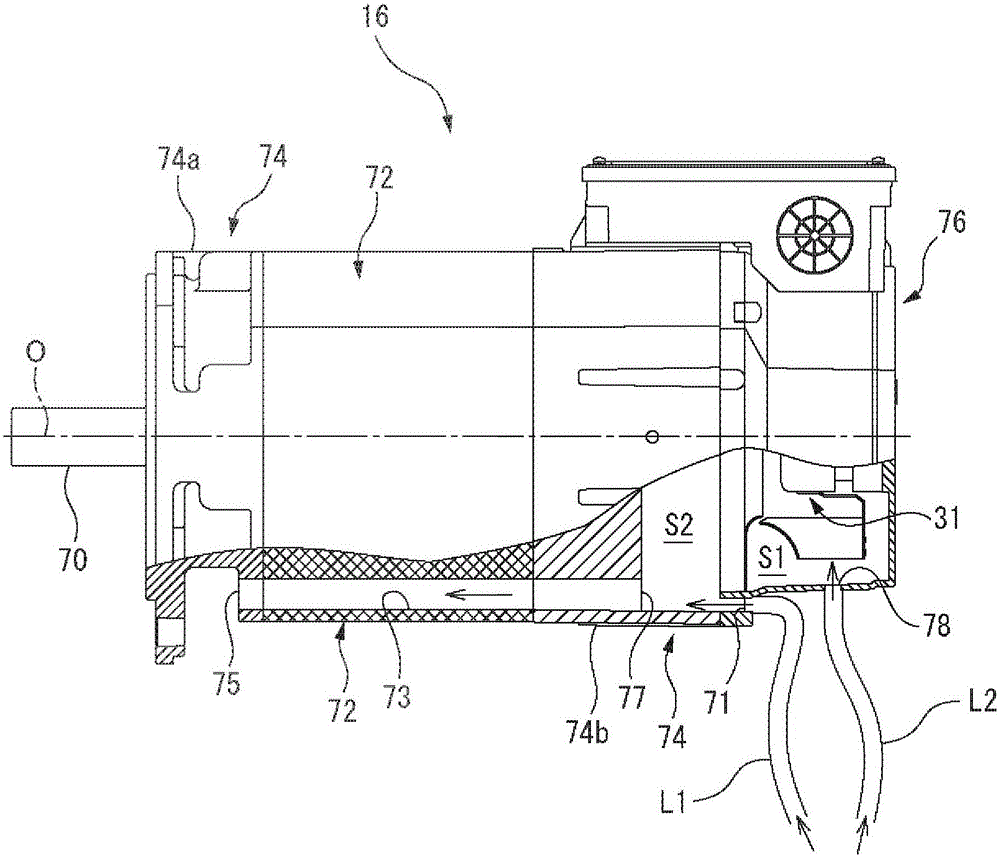

Facility controlling system and method

InactiveCN102737420AReduced operating efficiencyControl power-saving operationMechanical apparatusSpace heating and ventilation safety systemsControl parametersElectricity

The invention relates to a facility controlling system and a method, which carry out optimal electricity-saving operation according to the occupant counts in regions. When, in an administering device (40), there has been an evaluation that a user is authorized to enter into any given controlled region, the occupant counts of a movement origin controlled region and of a movement destination controlled region are updated by an occupant count updating portion and stored in a storing portion, in a status noticing portion (47) the occupancy statuses specified by the individual occupant counts in the storing portion are reported to an air-conditioning controlling device (50). In the air-conditioning controlling device (50), electricity-saving control parameters corresponding to the applicable occupancy statuses are obtained from an electricity-saving control information storing portion (52) by an air-conditioning controlling portion (51) in response to occupancy statuses reported by the administering device (40), to cause air-conditioning equipment, corresponding to the applicable region, to perform electricity-saving operation based on the electricity-saving control parameters.

Owner:YAMATAKE HONEYWELL CO LTD

Portable furrowing, topdressing, pressing and soil covering integral machine for cornfield

InactiveCN102326477AMake up for the vacancySolve the poor effect of covering soilFertiliser distributersAgricultural engineeringSoil cover

The invention relates to a portable furrowing, topdressing, pressing and soil covering integral machine for cornfield, which aims at completing the work procedures of furrowing, topdressing, pressing and soil covering in one step. The operation efficiency is high. The portable furrowing, topdressing, pressing and soil covering integral machine for the cornfield comprises a topdressing device, a pressing device, a soil covering device, a transmission device, a machine frame and an earth wheel, wherein the machine frame comprises a front fork, a front fork handle, an inclined vertical rod, a pull rod and an armrest, the armrest is in a shape similar to an I shape, the topdressing device comprises a fertilizer box, a fertilizer box support frame, two sets of fertilizer discharge components and two sets of fertilizer conveying components, the fertilizer discharge components comprise fertilizer discharge shafts, regulating valves, blocking wheels, fertilizer cleaning brushes, fertilizer pulling wheels and compression springs, the fertilizer box support frame comprises four cross beams, two vertical beams, two inclined vertical arms and one front beam, the pressing device comprises a regulation plate B, pressing wheels and a pressing wheel handle, the middle point of the regulating plate B is welded on the front fork handle of the machine frame, one pressing wheel is respectively arranged at the left side and the right side of the regulating plate B, the soil covering device comprises a regulating plate C and a rake, and the rake consists of a rake handle and rake teeth.

Owner:WHEAT RES INST OF AGRI SCI

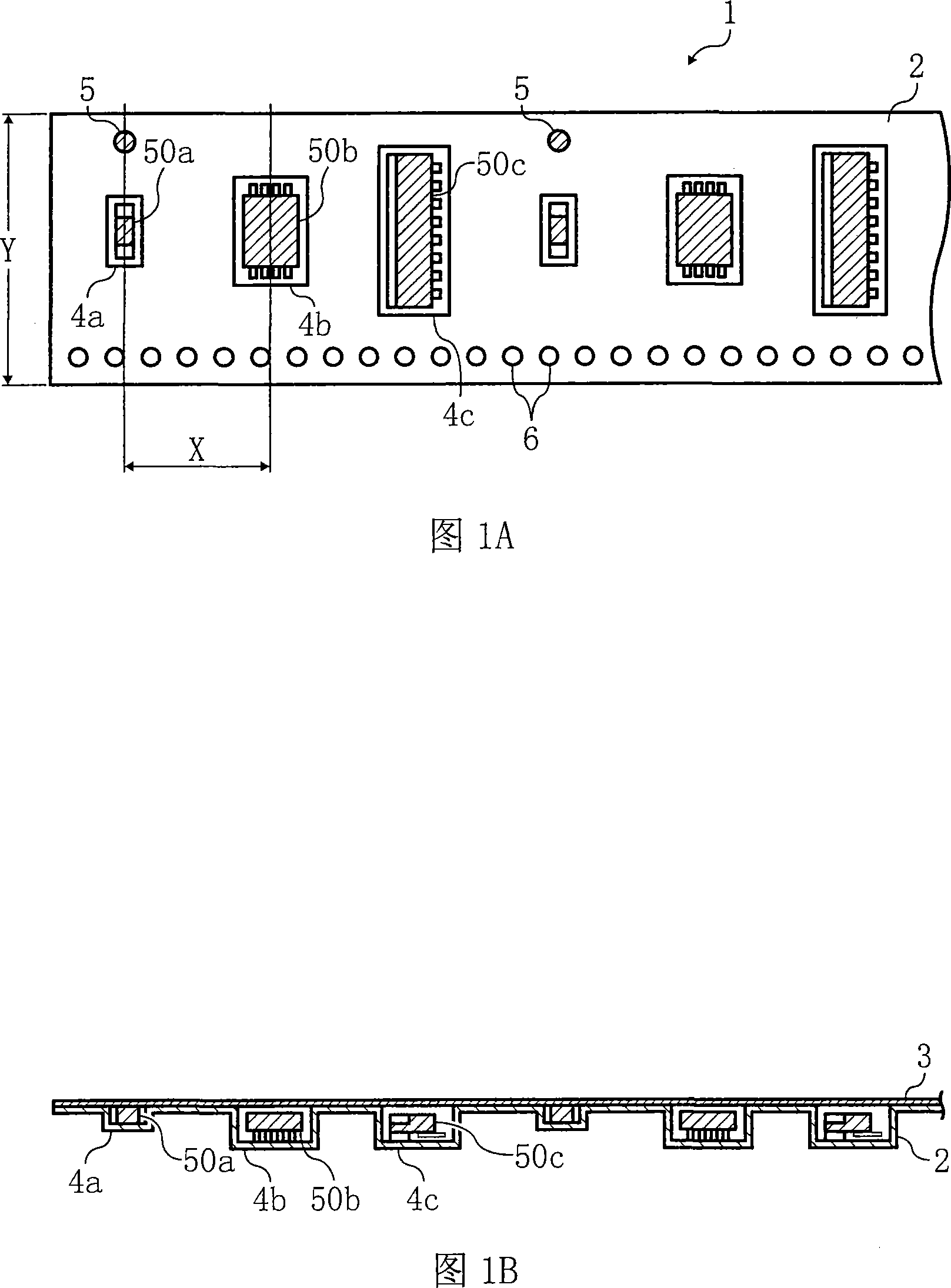

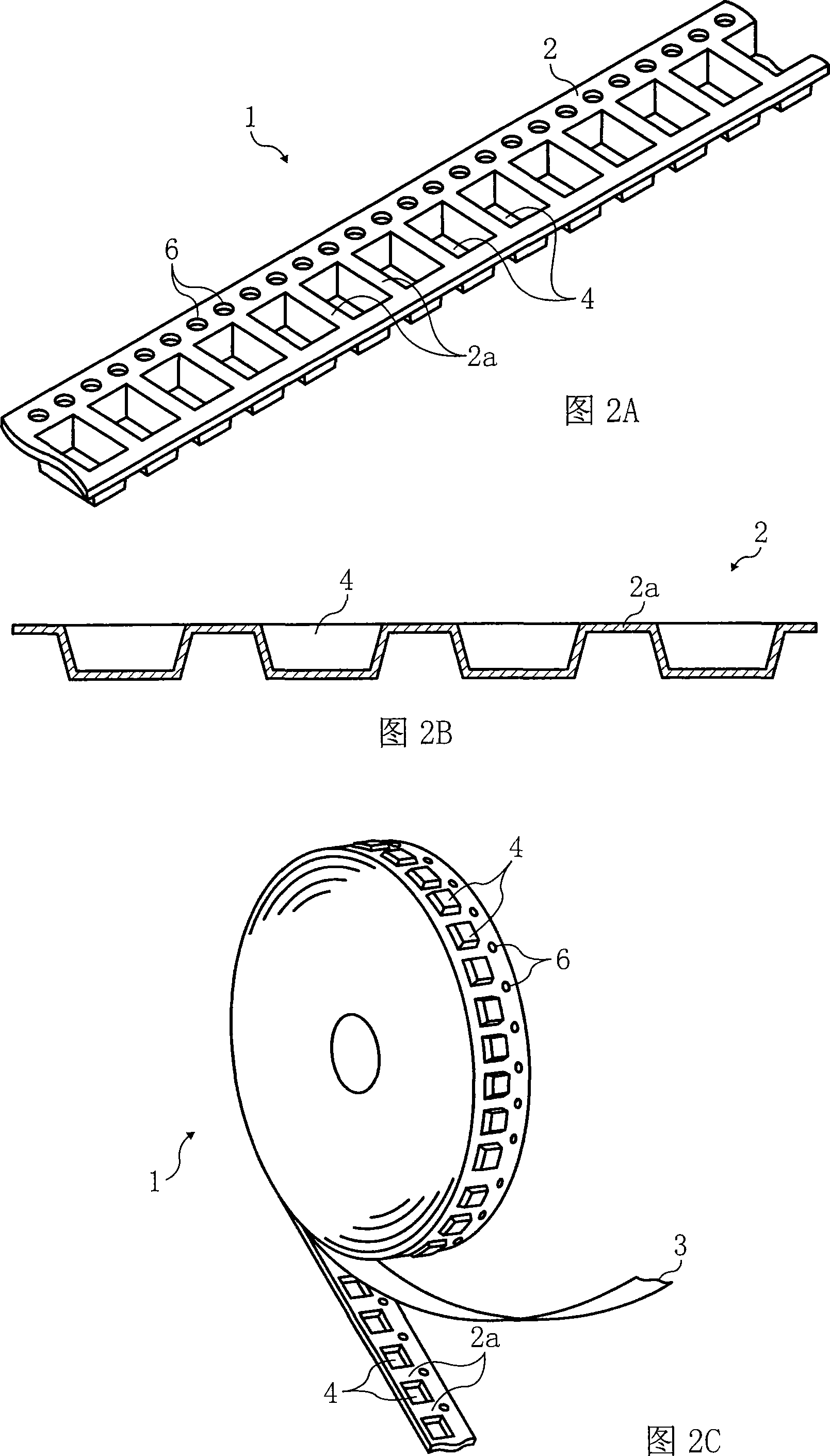

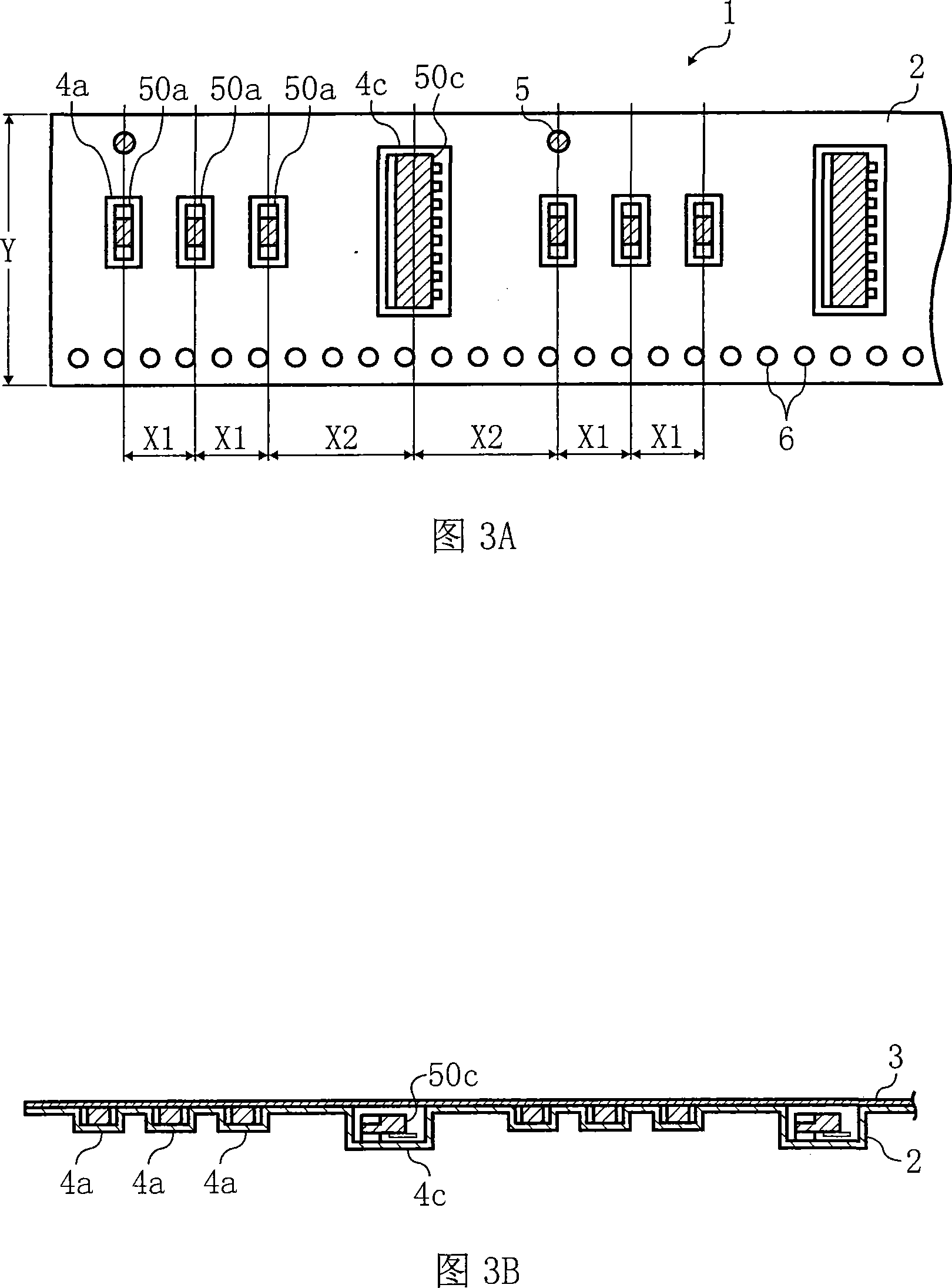

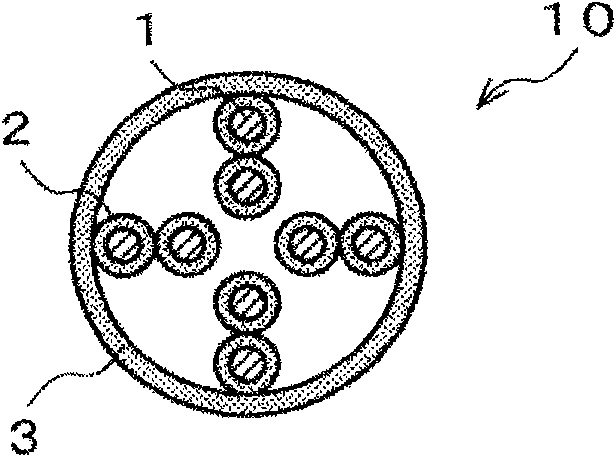

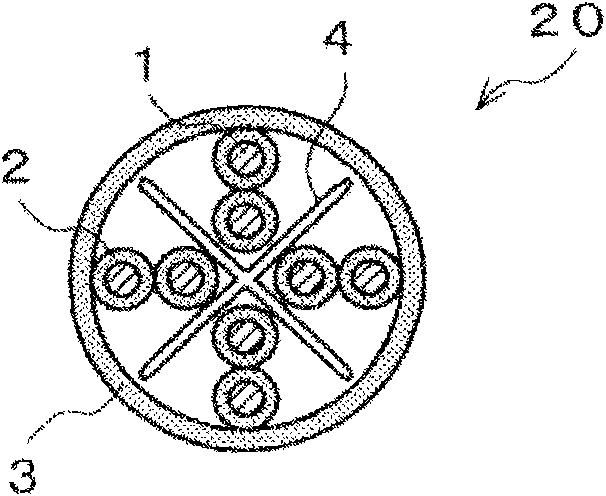

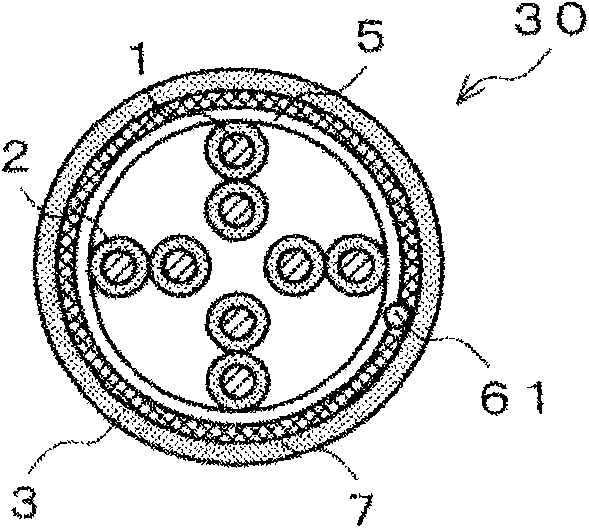

Conveying belt part, method for making belt data for conveying belt part and method for making conveying belt part

InactiveCN101094585AReduce the numberIncrease varietyPackagingElectrical componentsEngineeringElectronic component

Conveyer belt component capable of high effectively mounting electronic element on the printed circuit board are provided. The conveyer belt component 1 are composed of carrier belt 2 and covering belt 3 covering on the carrier belt 2. On the carrier belt 2, forming storing portions 4a, 4b and 4c for storing separately a plurality of kinds electronic elements 50a, 50b and 50c to be mounted no the printed circuit board. The storing portion 4a, 4b or 4c are relative to each electronic element 50a, 50b and 50c will be stored, their shapes are different. In addition, the conveyer belt component 1 can be coiled as measuring tape.

Owner:RICOH KK

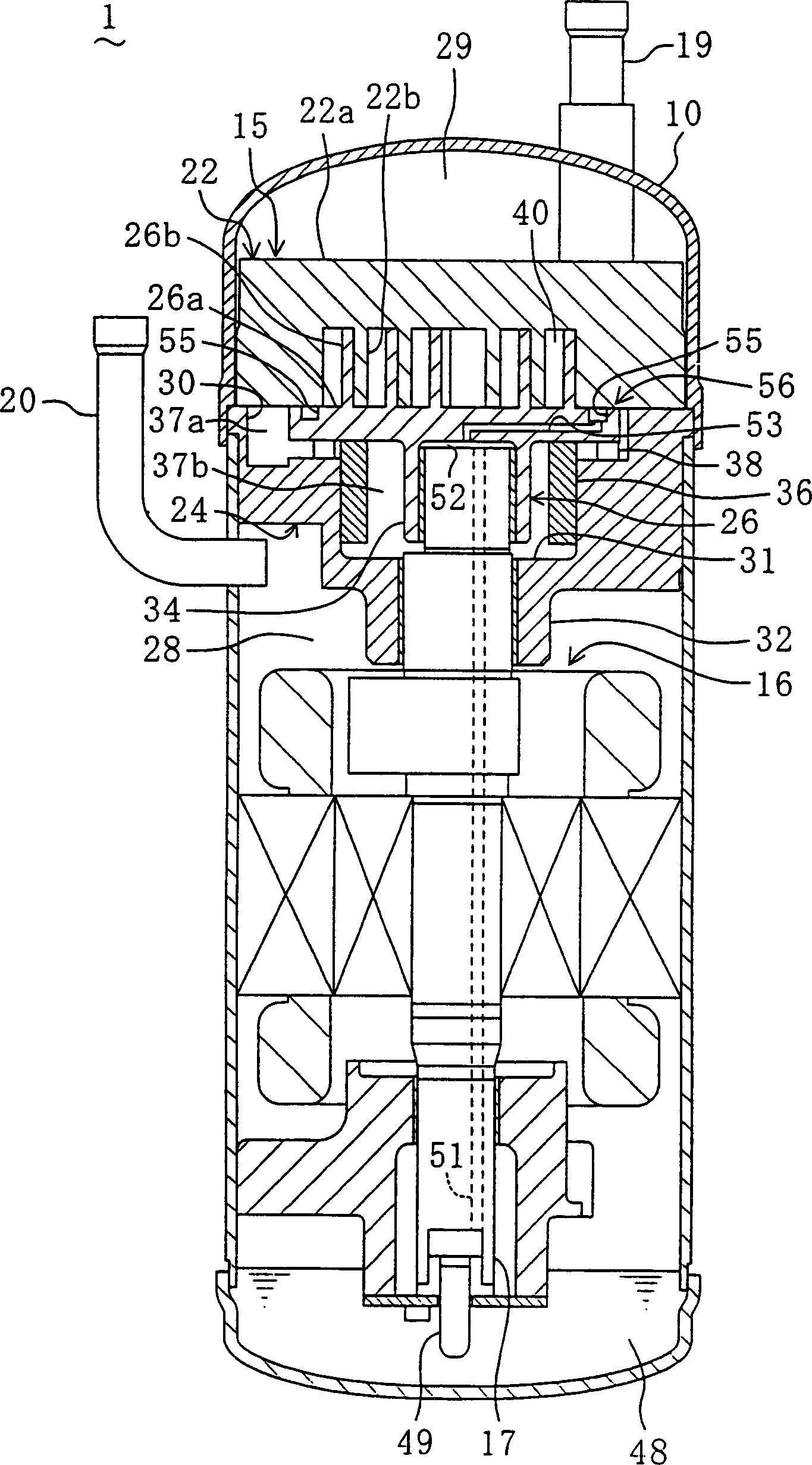

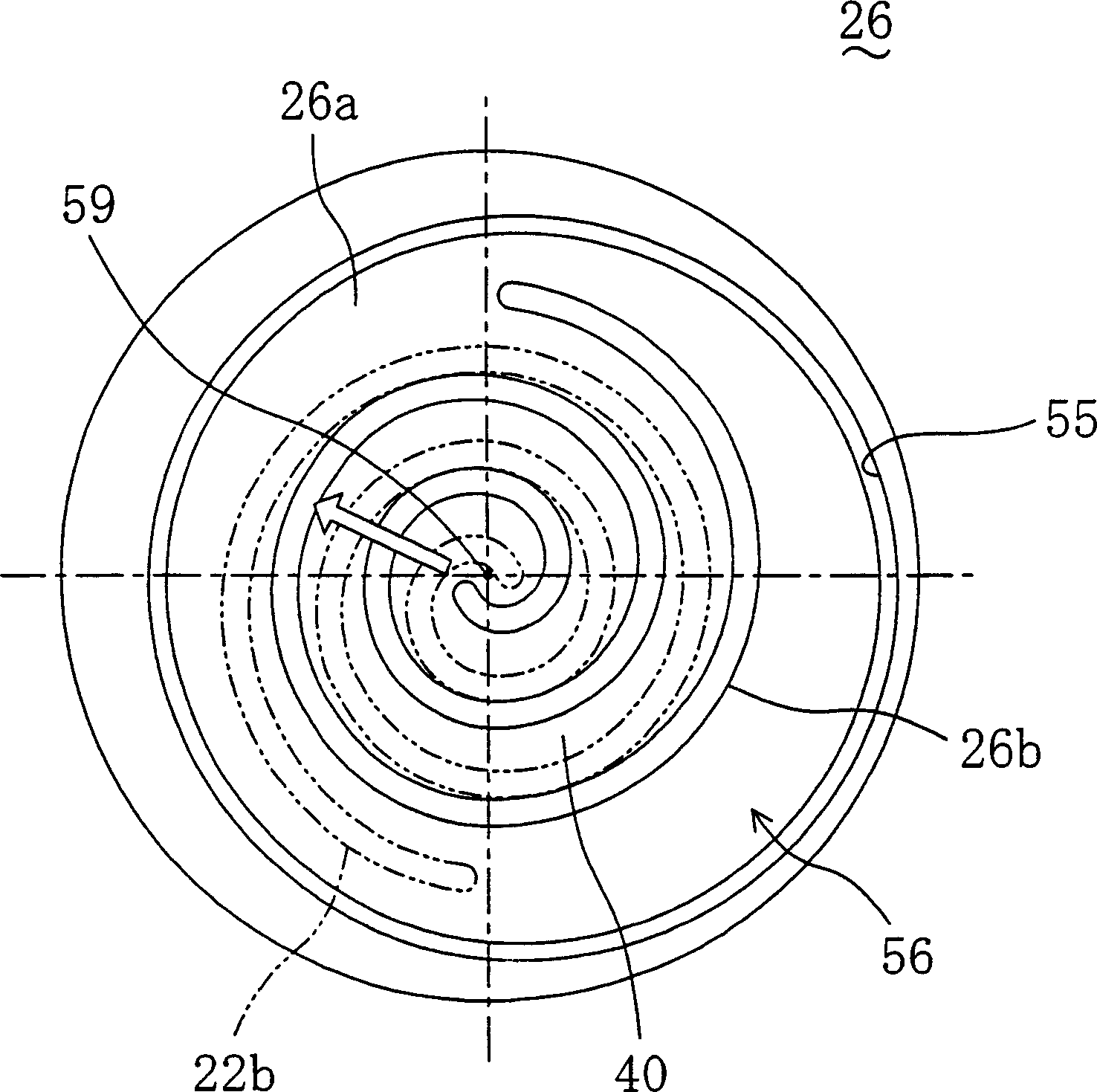

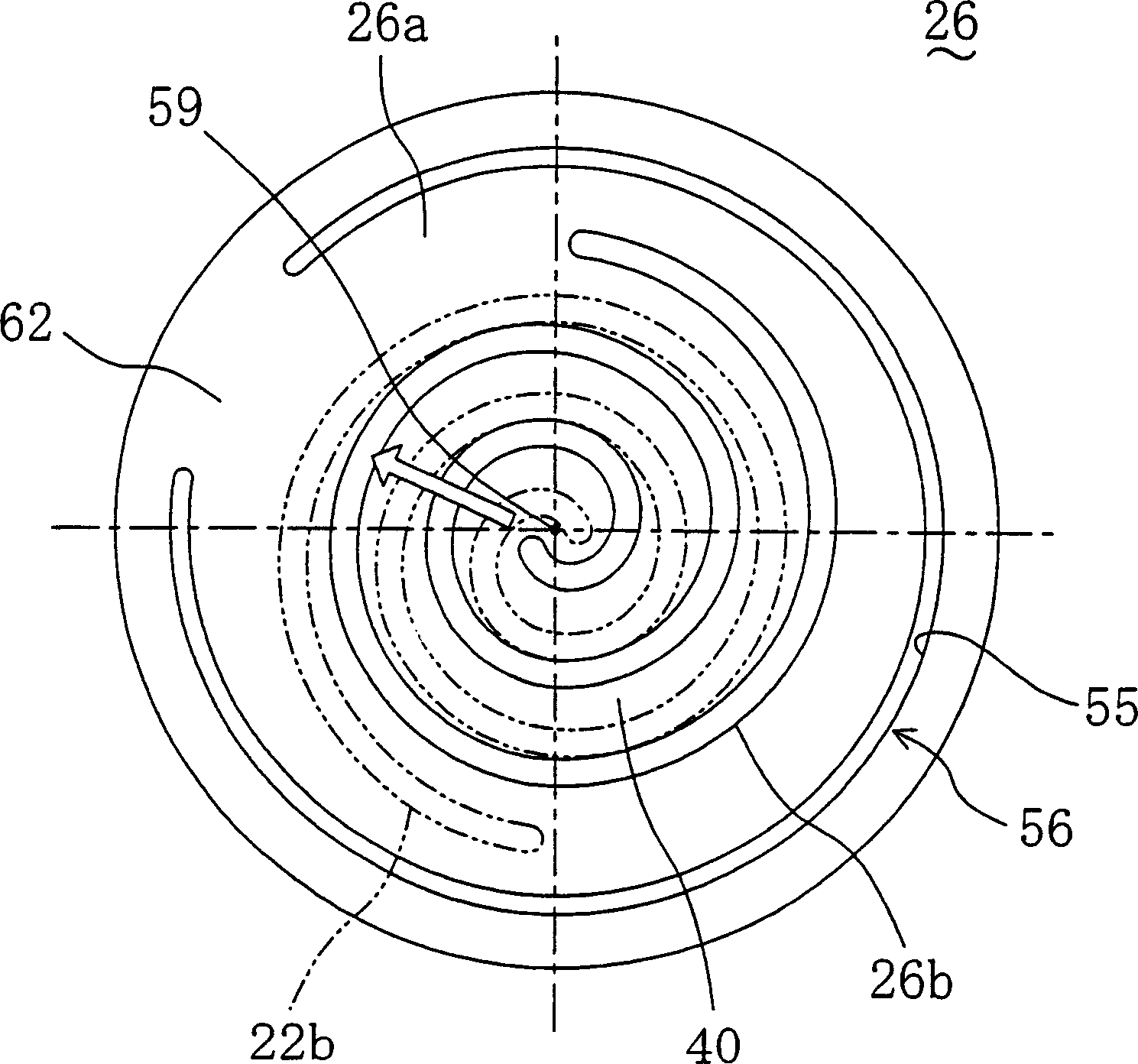

Scroll-type compressor

InactiveCN1592820APrevent leakagePrevent reduction in operating efficiencySealing arrangement for pumpsRotary piston pumpsMechanical engineeringEngineering

Owner:DAIKIN IND LTD

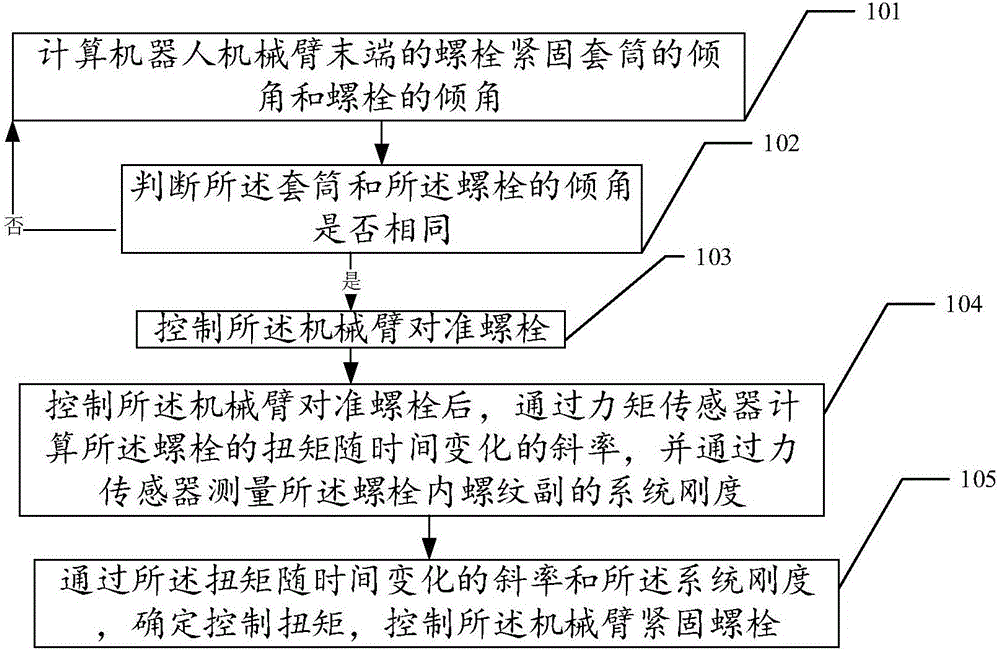

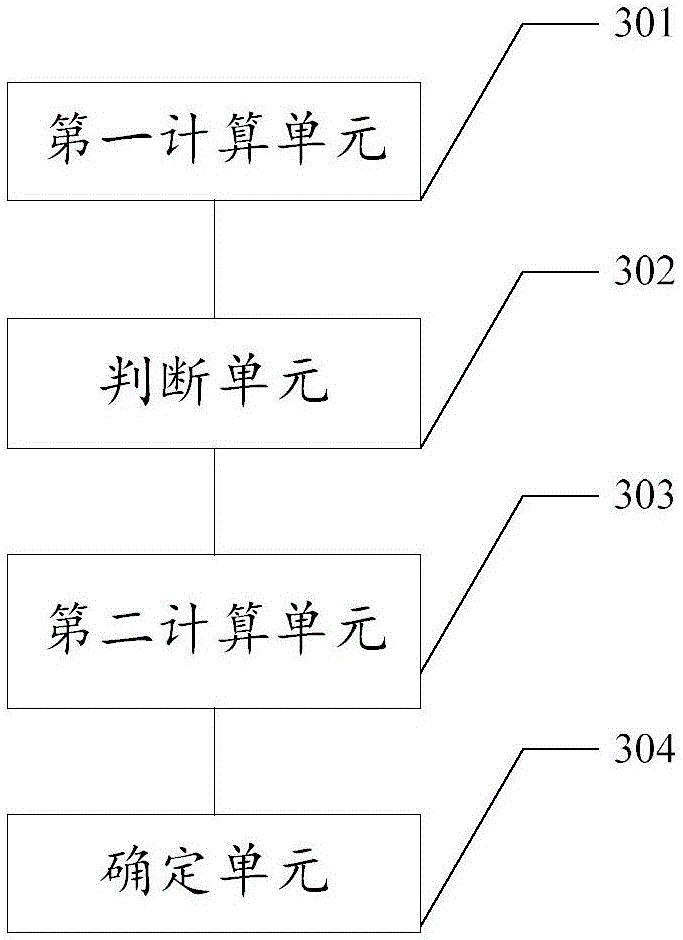

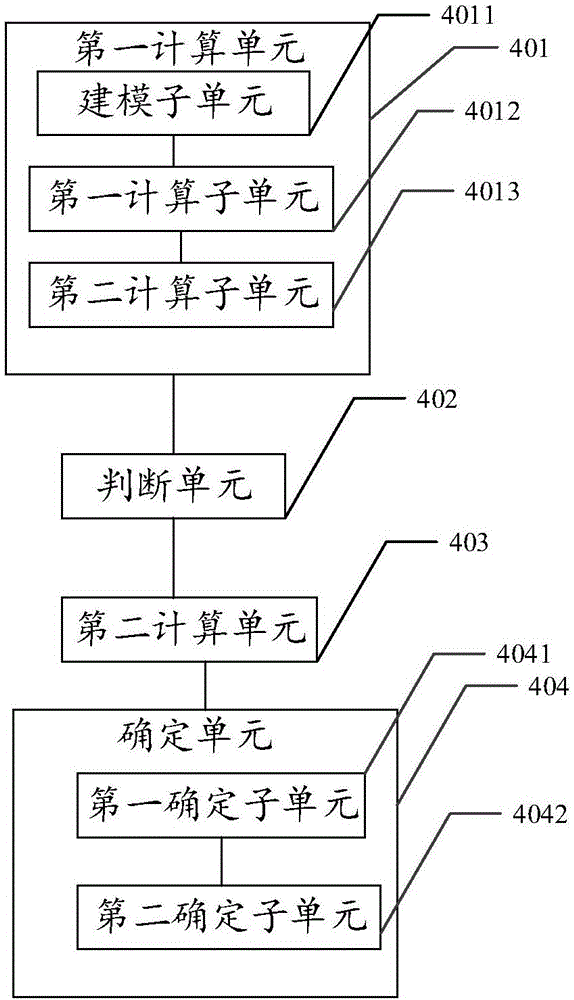

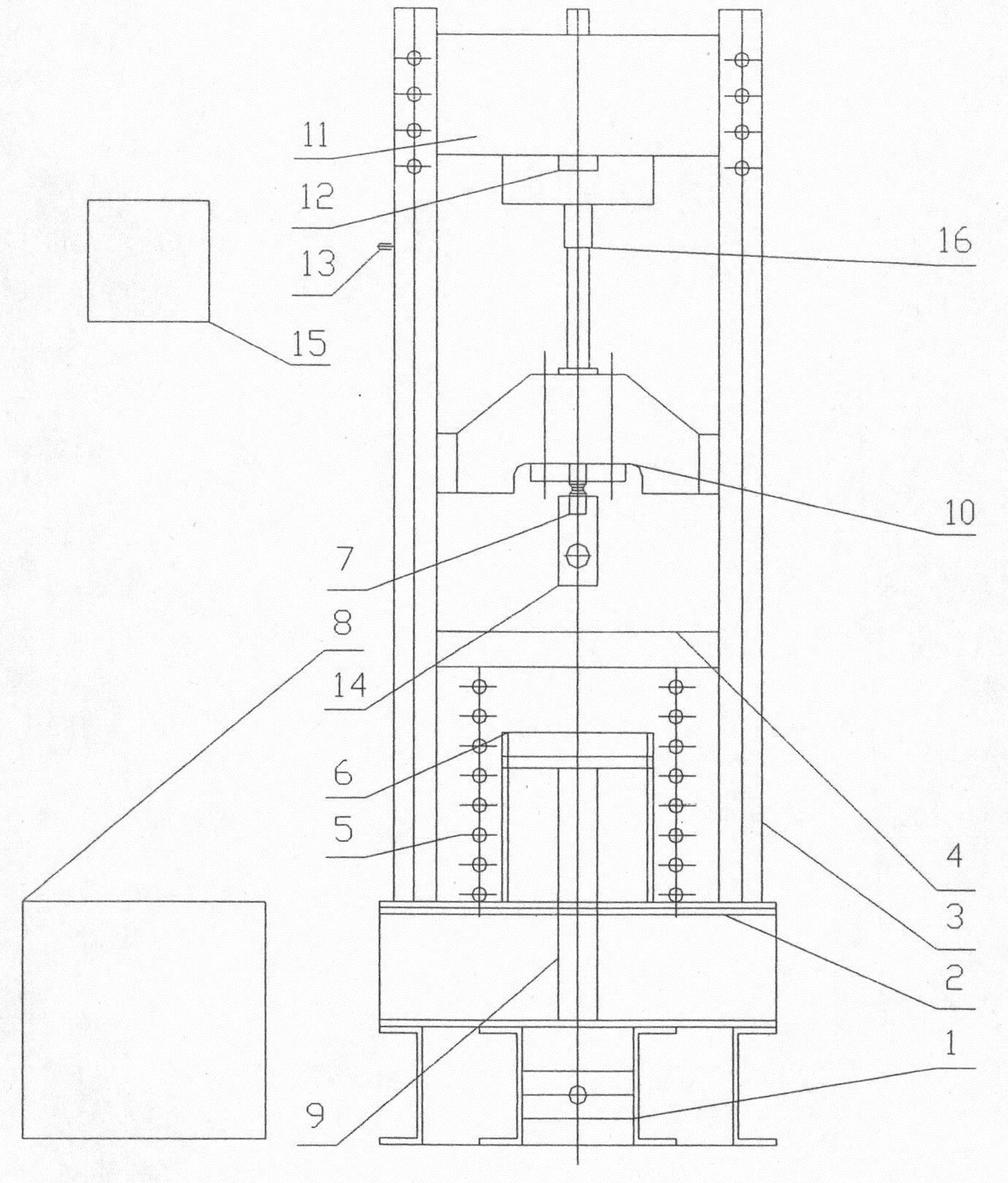

Control method of transmission line bolt fastening robot and controller

ActiveCN106329399AReduce operating efficiencyMetal working apparatusApparatus for overhead lines/cablesRobot controlTransmission line

The embodiment of the invention discloses a control method of transmission line bolt fastening robot and a controller, for solving lack of high efficiency and precision in existing technology as well as control algorithm of transmission line bolt fastening robot. Most electrified robots cannot finish automatic centering and fastening of bolts on transmission line. Sing of bolts and robots in pneumatic condition is not considered, remote control of centering of electrified robots through video has low working efficiency, which hinders development of automation in electrified operation field. Besides, the internal stress of bolts changes under influence of the environment, therefore, to screw bolts by constant torque only according to experience will generate great damage to service life of bolts, thus influence technical problem of power supply reliability.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Test device for missile metal brake cone buffer

ActiveCN109104907BSolve efficiency problemsFix security issuesAmmunition testingShock testingEngineeringActuator

A test device for a missile metal brake cone buffer, comprising; a body including a base on which two pairs of four guide rails are installed; impact blocks are installed between the guide rails; the center of the base has a guide protective sleeve, and There is a hydraulically controlled actuator connected to the hydraulic loading system; the guide protective sleeve is covered with energy storage springs; the buffer beams and the brake cone installation bases are installed on the guide rails on both sides, and there are load cells inside; A speed sensor is installed; a high-strength steel block is installed at the bottom of the impact block, and a shear bolt is installed in the center of the steel block, and the shear bolt is installed between the impact block and the actuator. The invention solves problems such as the determination of the dynamic mechanical properties of the brake cone in the development process of the missile metal brake cone, achieves rapid verification of the mechanical properties of the metal brake cone, shortens the development cycle, reduces test risks, improves test safety and test accuracy, etc. Beneficial effect.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

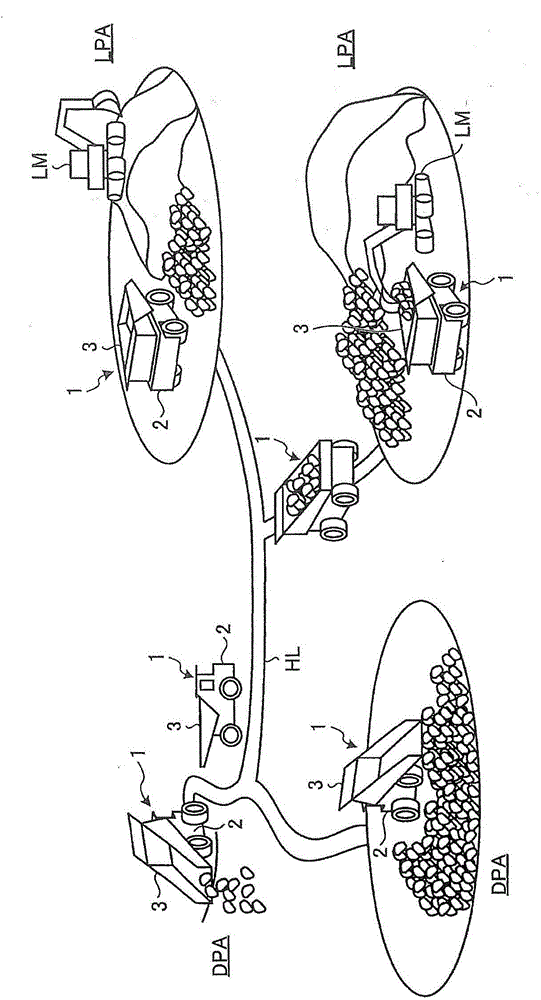

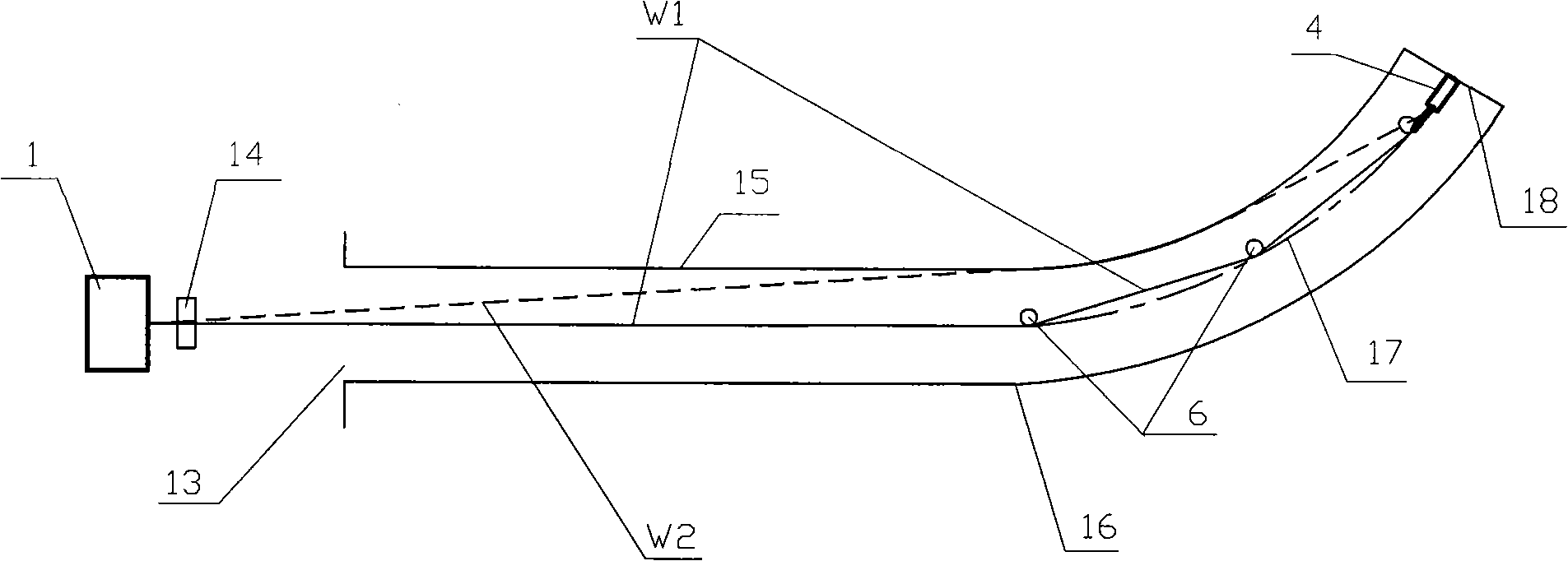

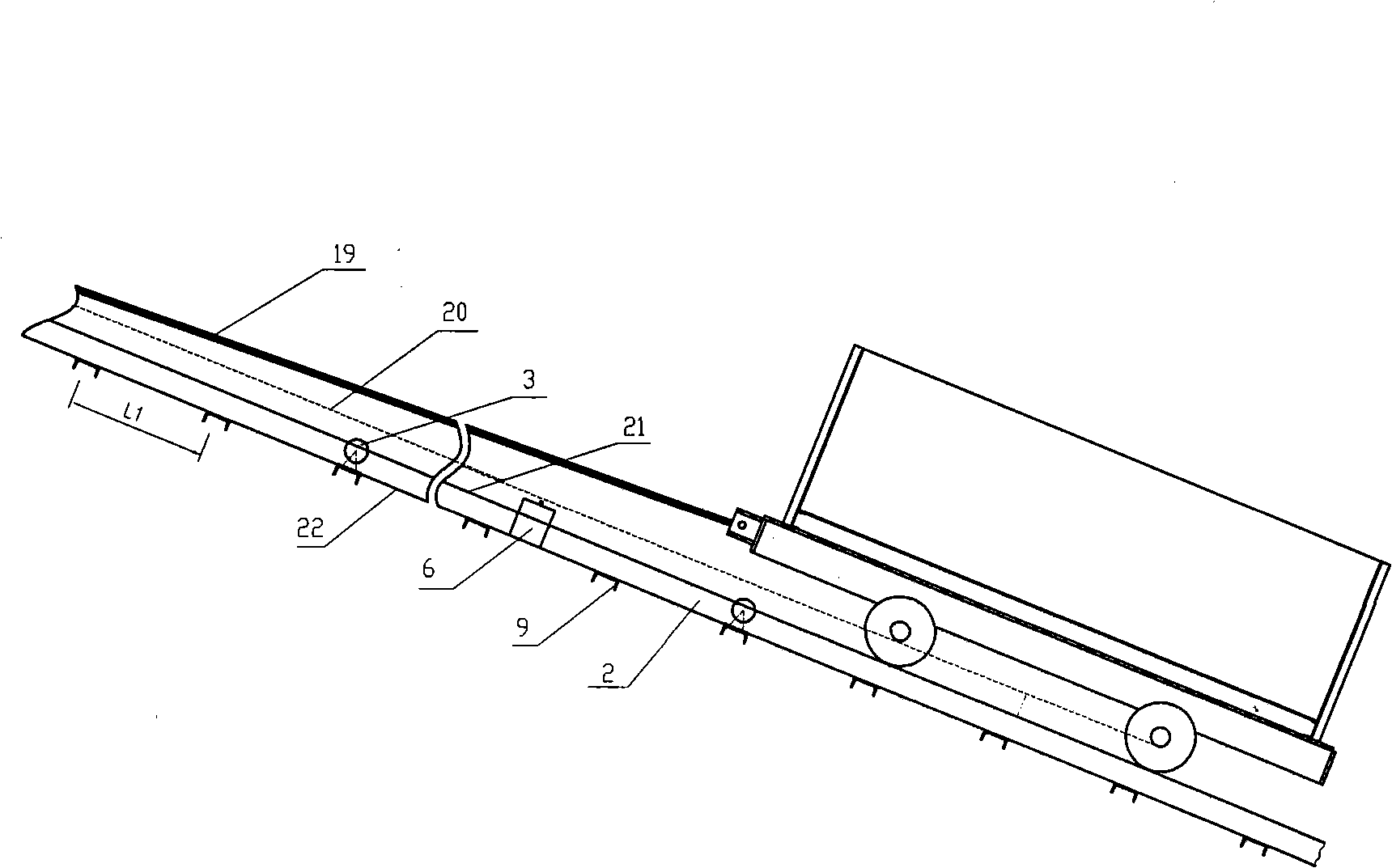

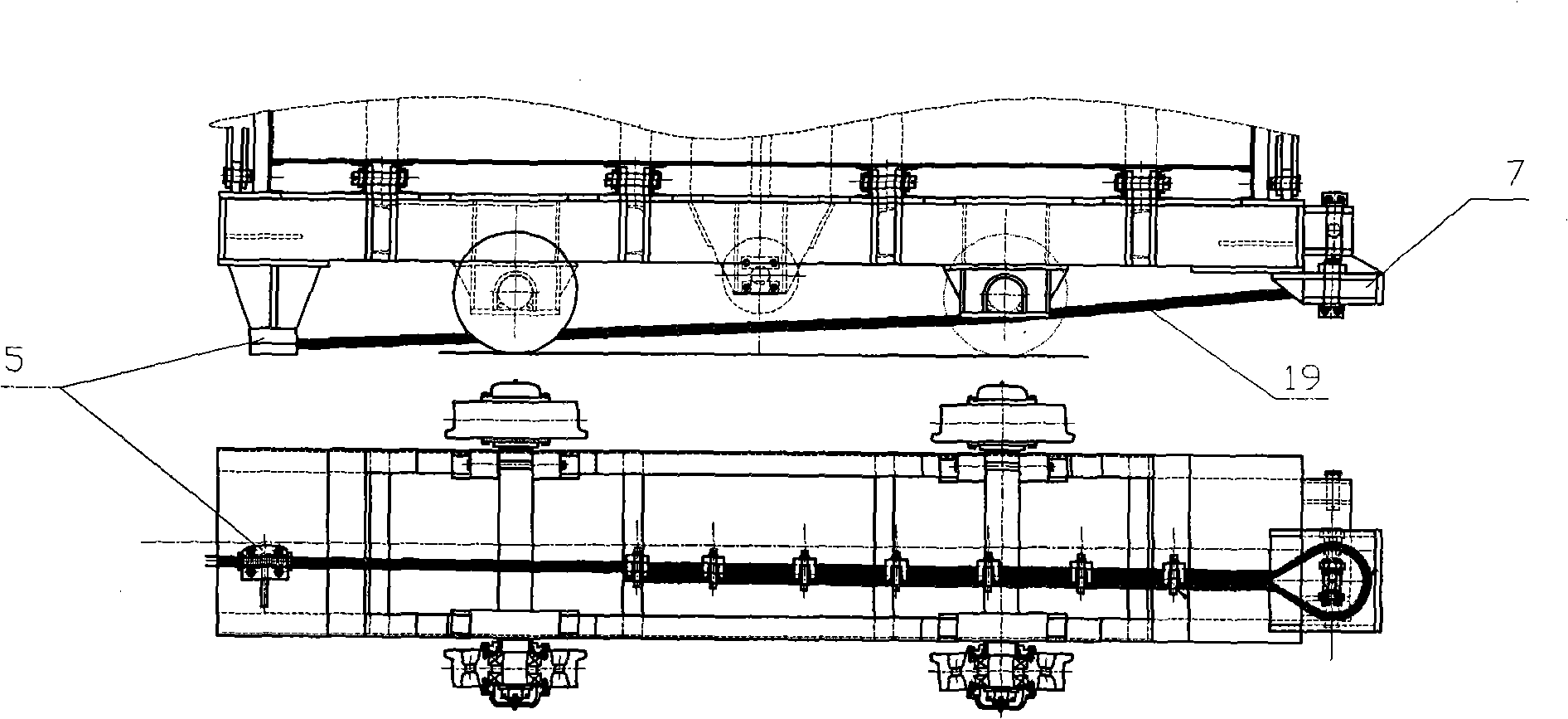

Rail hoisting transportation method for small radius curve incline shaft

The invention discloses a rail elevating transportation method for small-radius curve slope mines, which includes mounting an elevating device (1), paving rails (2), mounting a signal system, and mounting ground rolls (3), and is characterized in that a rail transportation system combined with an elevator (1), the rails (2) and a mine car (4) is adopted inside a small-radius curve slope mine, steering vertical rolls (6) are installed inside curve segment rails, the mine car (4) is refitted, a rope grip machine (5) is installed on the mine car (4), and a mine car security alarm system is installed. The method realizes the purpose of safe and high-efficient material transportation in small-radius curve slope mines. The method has the advantages of simple device technology, easy operation, quick speed, good security, obvious benefit, and the like. The method can fully utilize the existing devices and additionally just needs certain accessories, thereby saving the investment, and simultaneously improving the transportation efficiency and saving the transportation cost.

Owner:中铁隧道集团一处有限公司

Halogen-free and flame-retarded resin composition and cable using the same

InactiveCN102167878AReduce environmental loadGood flexibilityInsulated cablesInsulated conductorsPliabilityChemistry

The invention discloses a halogen-free and flame-retarded resin composition and a cable using the same. The halogen-free and flame-retarded resin composition is small in environmental load, good in pliability and low in friction. The halogen-free and flame-retarded resin composition comprises ethylene-vinyl acetate copolymer (A) which has over 30 mass % of vinyl acetate, crystallized polyolefin resin (B), resin composition (C) having metallic hydroxides in a substrate polymer crosslinked by the ethylene-vinyl acetate copolymer, an acrylic acid series processing auxiliary agent (D) added in the resin composition, and a fatty acidamide lubricant (E).

Owner:HITACHI METALS LTD +1

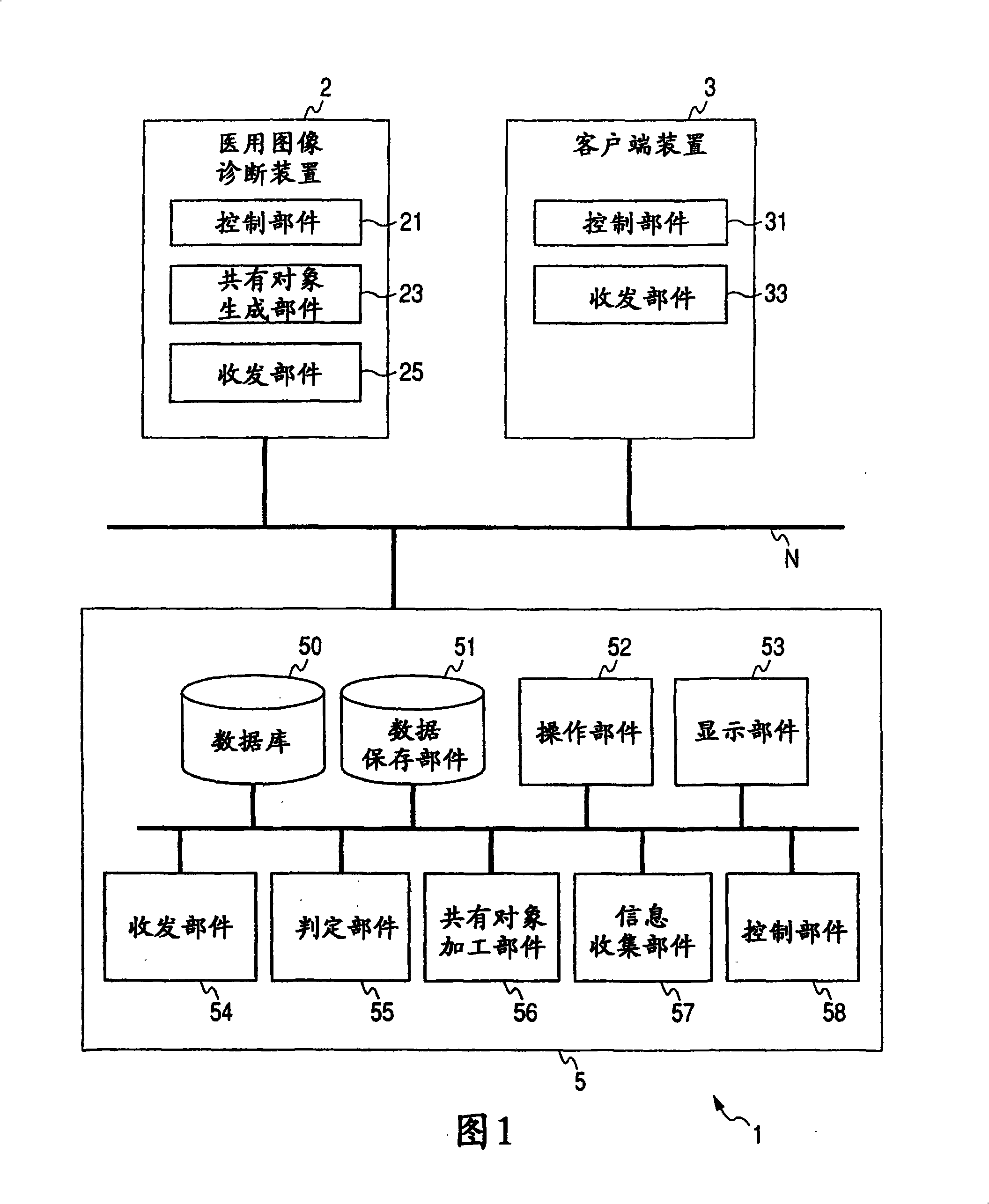

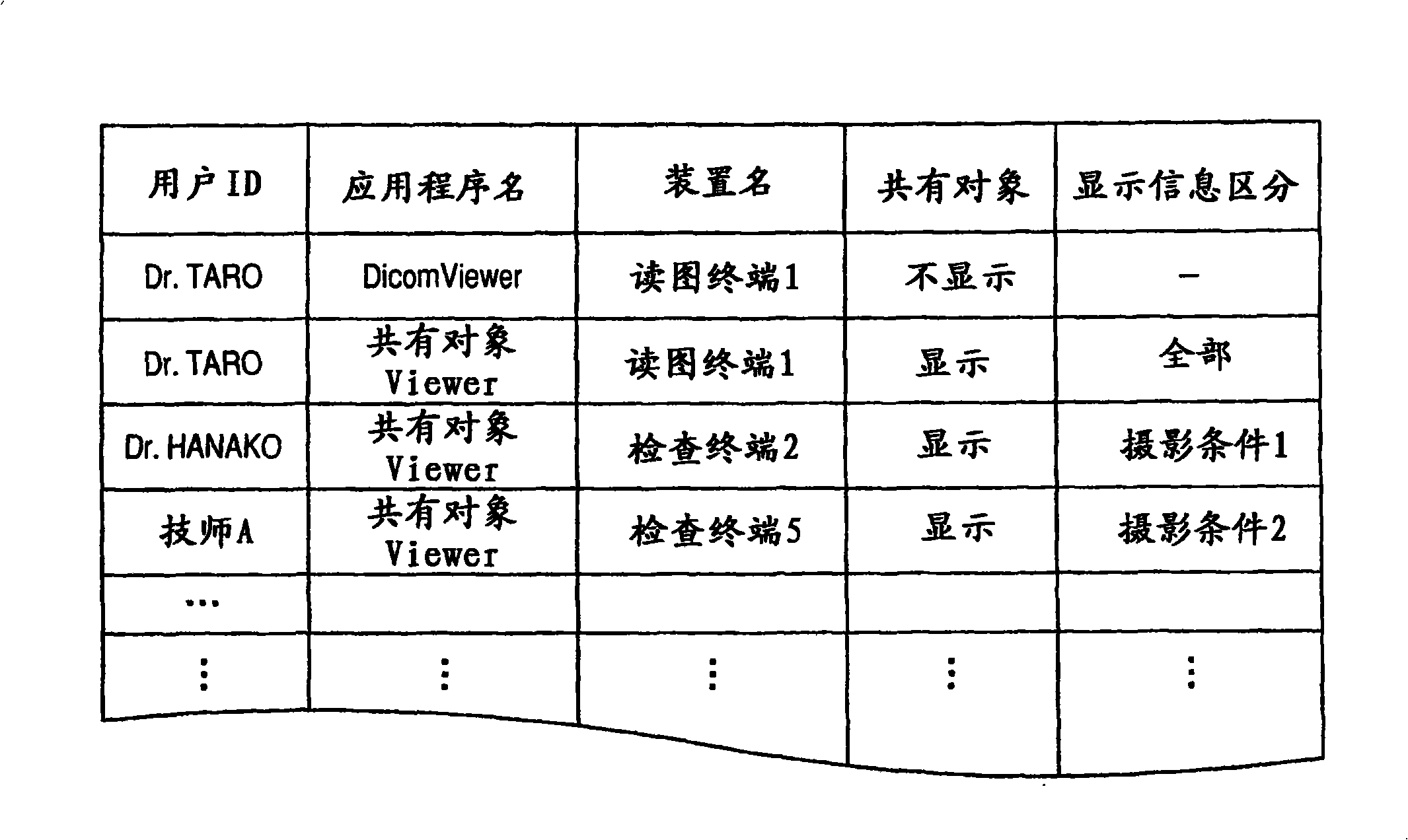

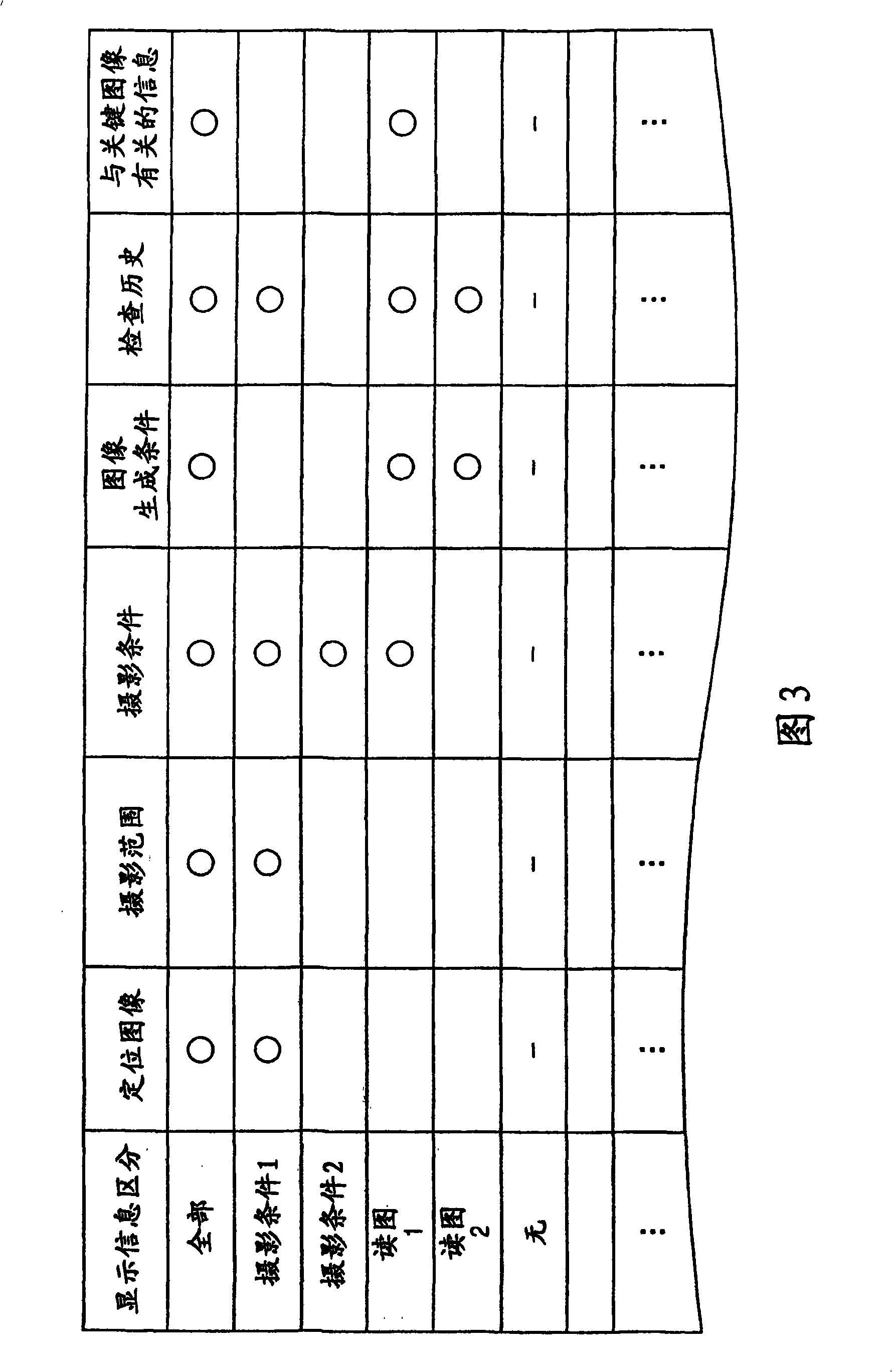

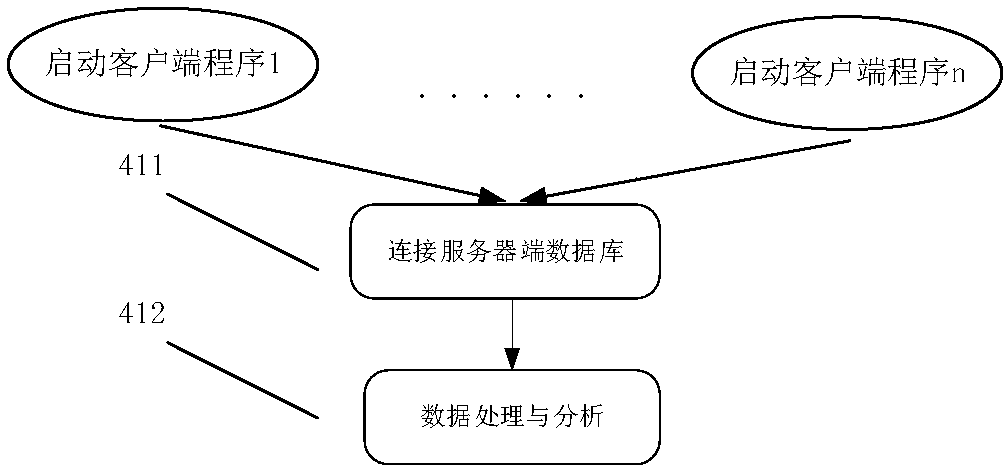

Imaging diagnosis supporting system and diagnosis supporting method

ActiveCN101283930ACommunication efficiency does not occurReduced communication efficiencySurgeryMedical automated diagnosisSupporting systemImage diagnosis

In a server apparatus, an information classification is determined by a user and a utilization situation, and provision information is determined on the basis of the determined information classification. A common object is processed to include only the determined provision information, and then provided to a client apparatus. To the client apparatus, a common object including requisite minimum information is provided.

Owner:TOSHIBA MEDICAL SYST CORP

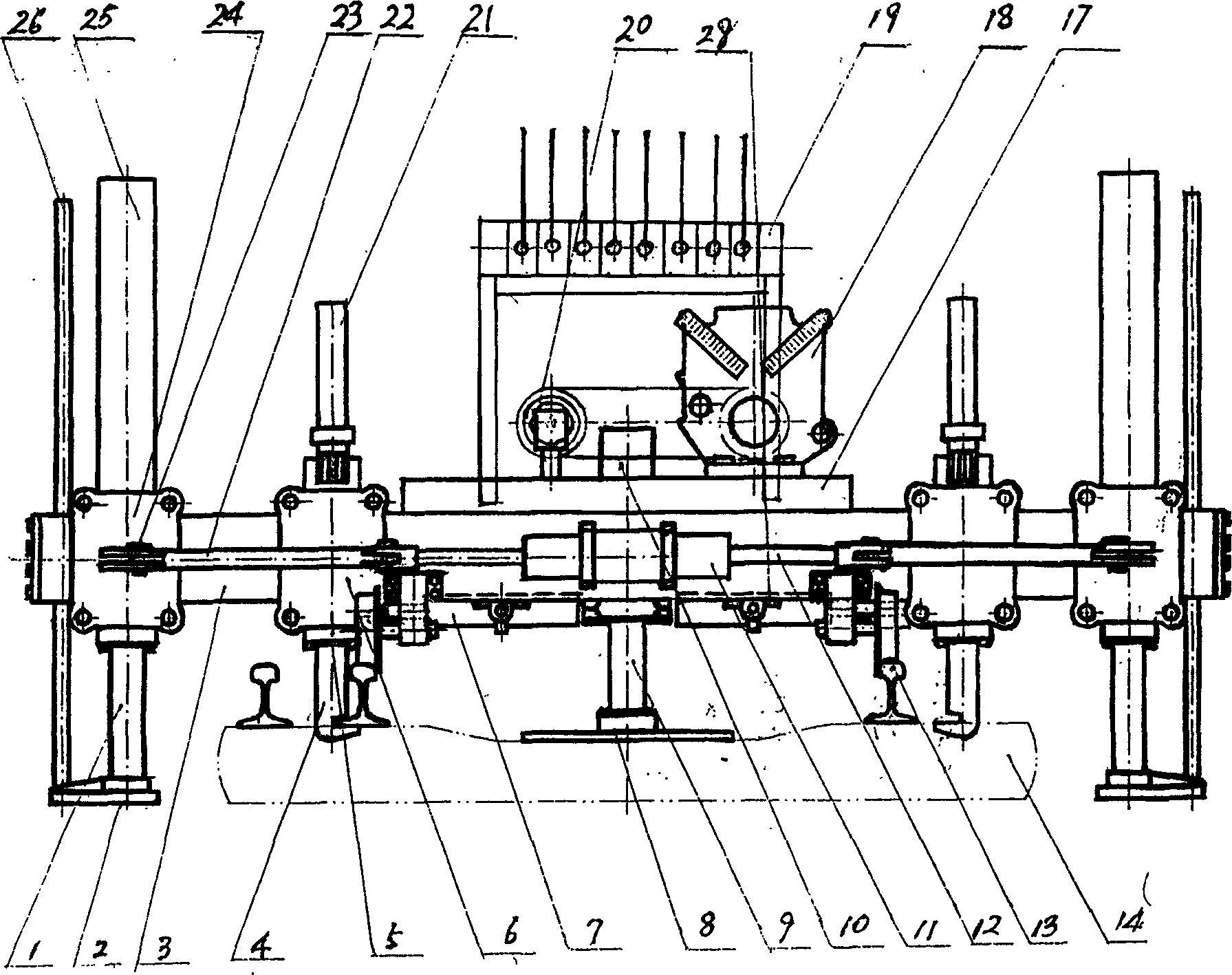

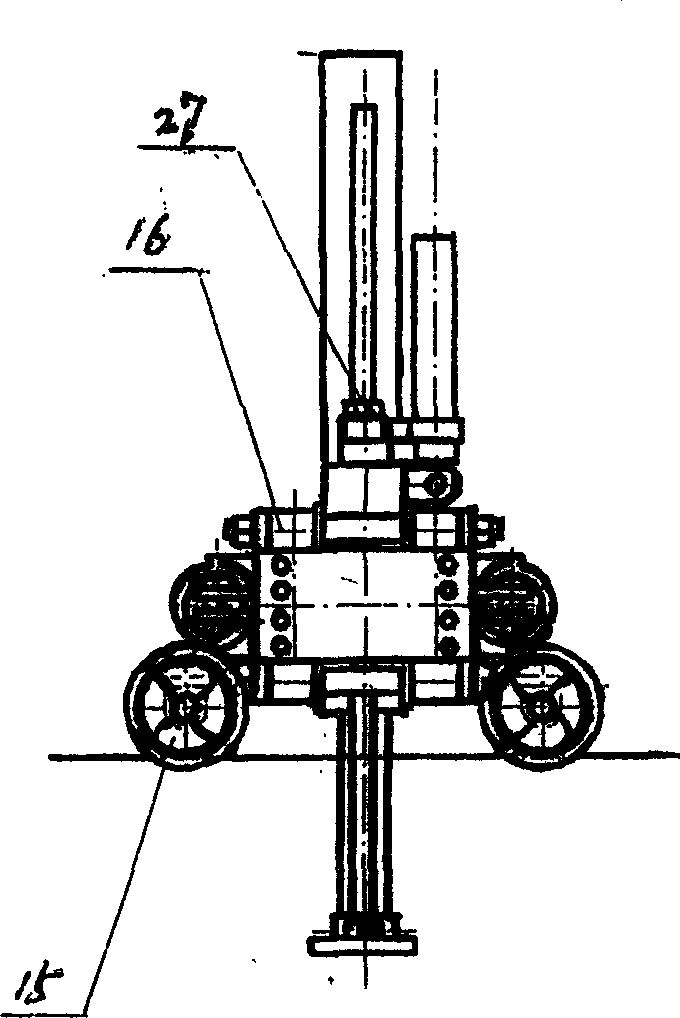

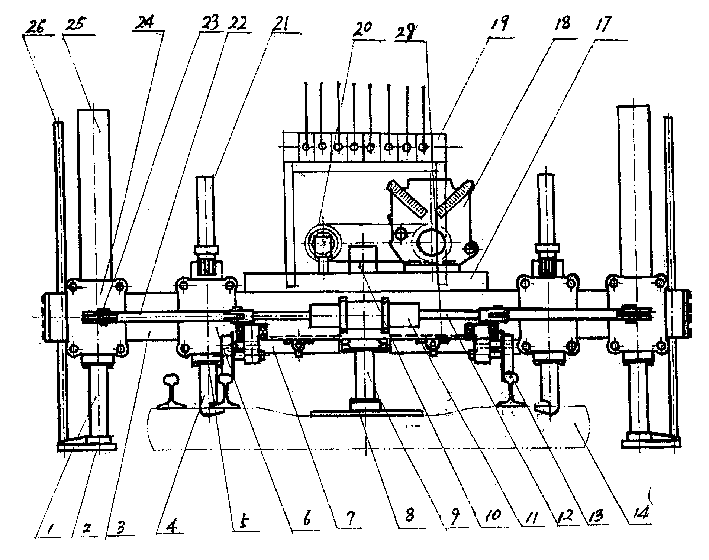

Hydraulic switches track-lifting and shifting machine

InactiveCN1465814ASatisfies the requirements of the operation of the speed-up turnoutPowerfulRailway track constructionFuel tankHooking

The present invention relates to a hydraulic rail-lifting track-shifting machine, consisting of machine unit, track-hooking device, rail-lifting device, track-shifting device, main machine rotating device and power system, etc. in which the main unit is formed from cross-beam and oil tank, the sleeve of the track-hooking device is cover-mounted on the track hook, the track hook is connected with lifting oil cylinder by means of nut, the track-hooking rolling frame is connected with horizontal track-hooking oil cylinder, two large offset oil cylinders of the rail-lifting device are respectively fixed on two rail-lifting rolling frames, and the horizontal track-shifting oil cylinder is fixed on the cross-beam of machine body and connected with pulling rod.

Owner:SHENYANG PERMANENT WAY APP PLANT SHENYANG RAILWAY SUB BUREAU

Strawberry external quality lossless grading device based on machine vision and implementation method thereof

The invention discloses a strawberry external quality lossless grading device based on machine vision. The strawberry external quality lossless grading device comprises a lifting mechanism, a conveying mechanism, a visual discrimination mechanism, a screening mechanism and a control mechanism. The lifting mechanism is arranged at the leftmost end. The conveying mechanism is installed at the right end of the lifting mechanism. The visual discrimination mechanism and the screening mechanism are fixedly installed above the conveying mechanism left and right. The control mechanism is in electric signal connection with the lifting mechanism, the conveying mechanism, the visual discrimination mechanism and the screening mechanism. According to the strawberry external quality lossless grading device based on machine vision, on the premise that the requirement for convenient use is met, the effects of being simple in structure and convenient to operate are achieved, lossless grading can be conducted on the size, the shape, the appearance and other external qualities of strawberries, the safe using performance is good, and the practical using requirement is met.

Owner:CHUZHOU UNIV

Method for producing light automobile acoustic carpet

InactiveCN104192041AReduce weightLow costVehicle arrangementsLaminationEnvironmental resistanceSurface layer

The invention relates to a method for producing a light automobile acoustic carpet, and belongs to the technical field of automobile part production. The light automobile acoustic carpet is obtained through paving, adsorption forming and water jet cutter cutting of an acoustic shock pad surface layer below the carpet, paving, temperature drying and pressing forming of an acoustic shock pad base material below the carpet, and paving, temperature drying, attaching forming and water jet cutter cutting of a surface carpet and a semi-finished acoustic shock pad below the carpet. The light automobile acoustic carpet produced through the method meets the index requirements of performance such as shock absorption, environmental friendliness and lightness; the weight of the automobile acoustic carpet is greatly reduced, and the requirement for the whole automobile light design is met.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

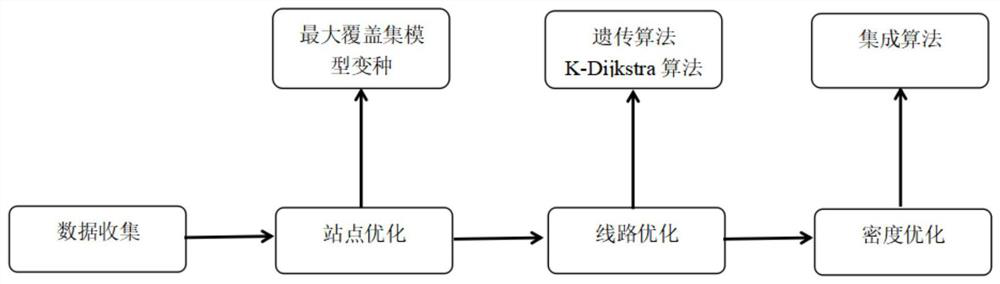

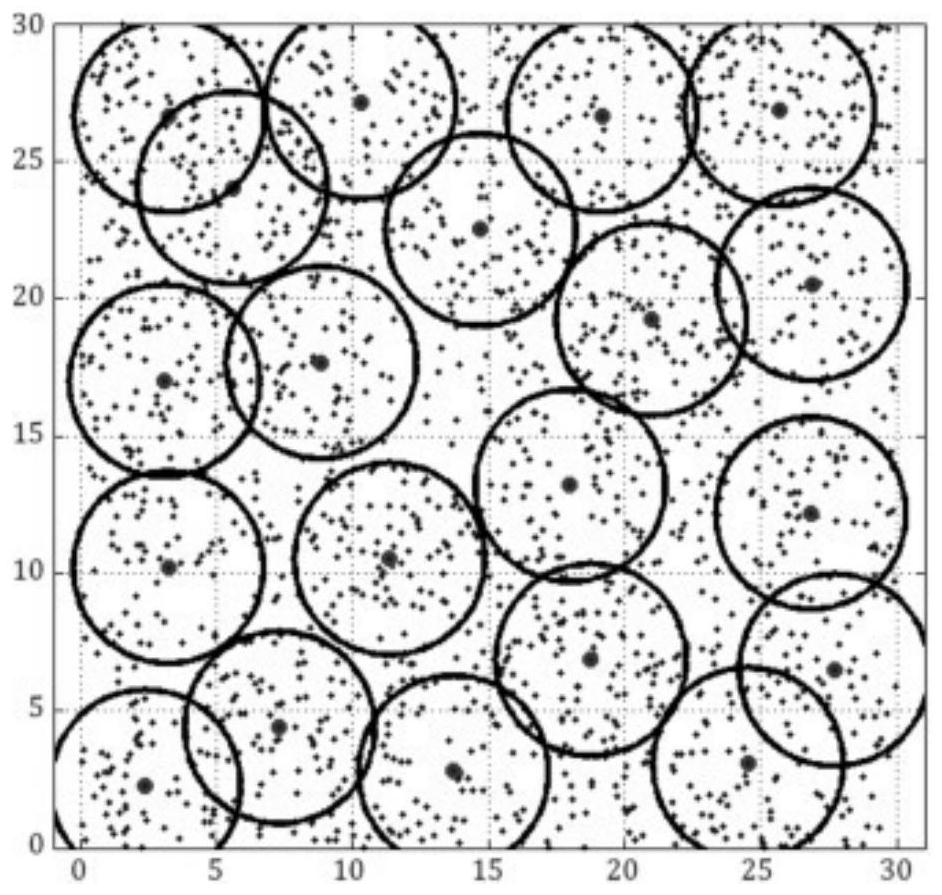

Urban bus network optimization method

ActiveCN112347596AReasonable distributionAdjust departure densityGeometric CADForecastingUrban busTransit bus

The invention discloses an urban bus network optimization method, which provides a bus optimization solution comprehensively, end-to-end and systematically from the three stages of bus station distribution, bus route planning and departure density adjustment, is clear in structure and clear in logic, comprehensively improves the operation efficiency of a bus system, optimizes the riding experienceof passengers, Meanwhile, the coupling between the schemes is weak, each city can adjust module input and select module according to own needs to finally generate own characteristic schemes, and theoptimization method can solve the problems of uneven station distribution, repeated station construction, low system coverage rate, high line repetition rate, unreasonable line setting, and fixed departure time of an existing public transportation system .

Owner:浙江非线数联科技股份有限公司

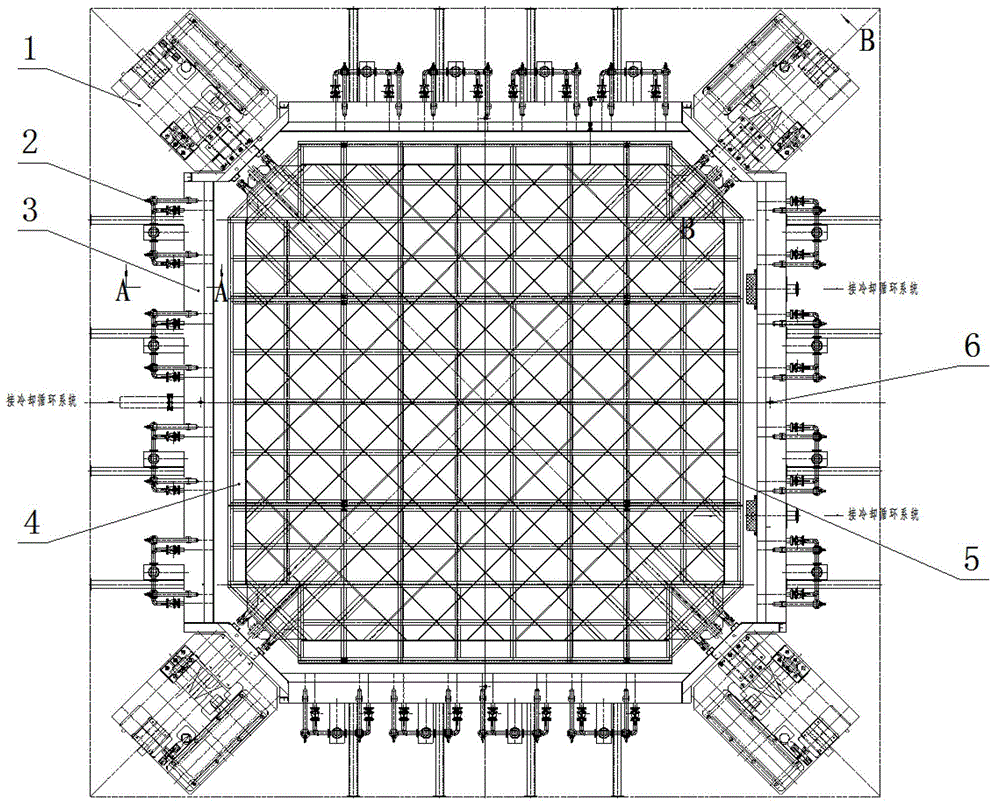

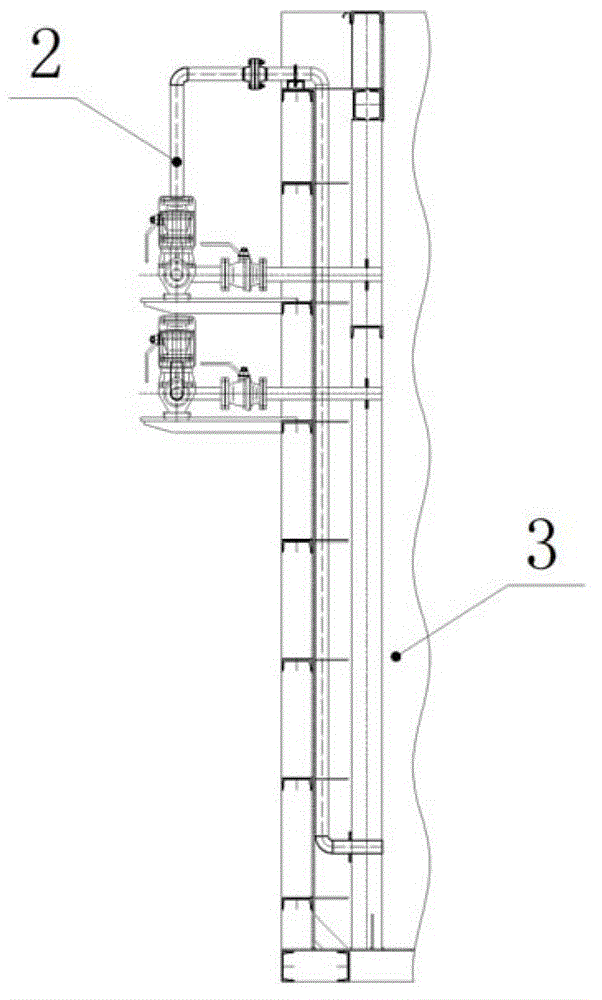

Quenching equipment for large rings

InactiveCN102719633AReduce operating efficiencyImprove mix qualityFurnace typesHeat treatment furnacesSlagHeating furnace

The invention relates to quenching equipment for large rings. The quenching equipment comprises a quenching tank, a mixer, a temperature monitor, a slag collector and a cooling circulating system and is characterized in that a lifting quenching platform is arranged in the quenching tank body, lifting mechanisms used for lifting the quenching platform are arranged at the outer sides of four corners of the quenching tank body, the lifting mechanisms are connected with the quenching platform via connecting pieces, and a plurality of pump-type circulating mixers are arranged at the outer sides of the peripheral tops of the quenching tank body. The quenching equipment has the advantages of saving energy, greatly reducing the quenching processing cost, and improving the mixing quality of quenching liquid; and the lifting quenching platform arranged in the quenching tank body is utilized to replace a traveling hoist to operate, the heated workpieces can be placed on the quenching platform for quenching treatment. Therefore, the utilization ratio of the travelling hoist and the operation efficiency of a heating furnace can be improved, great amount of energy can be saved, the time for operation of the traveling hoist can be shortened, and other operations are not affected by the traveling hoist.

Owner:TIANJIN SERI MACHINERY EQUIP

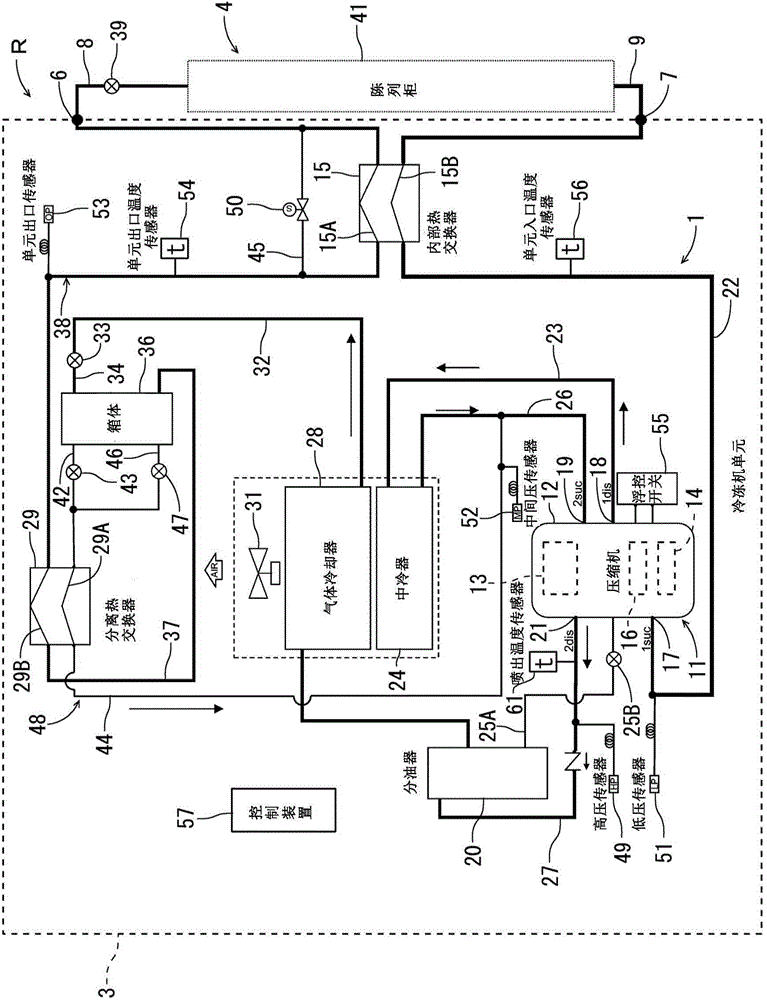

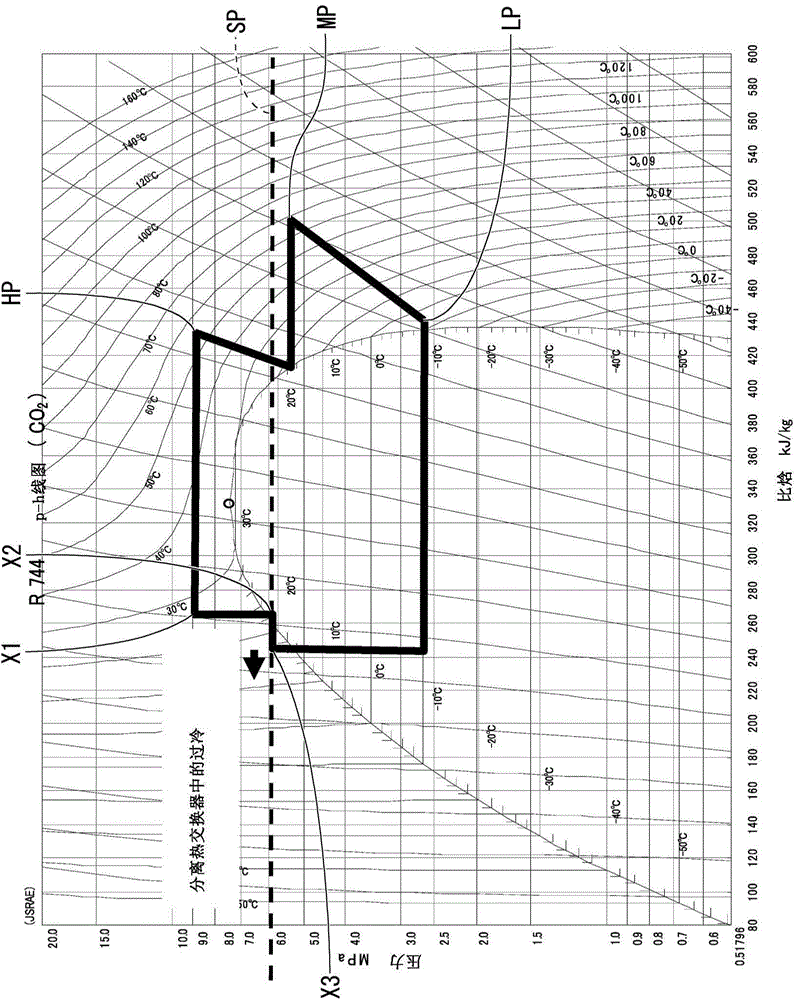

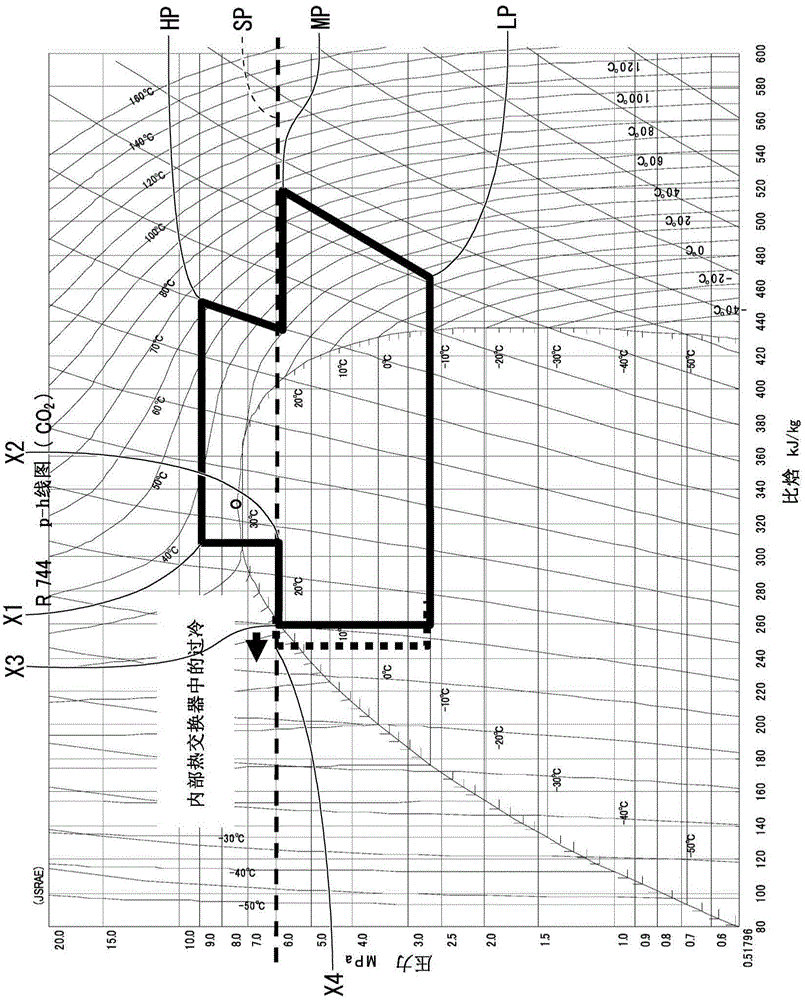

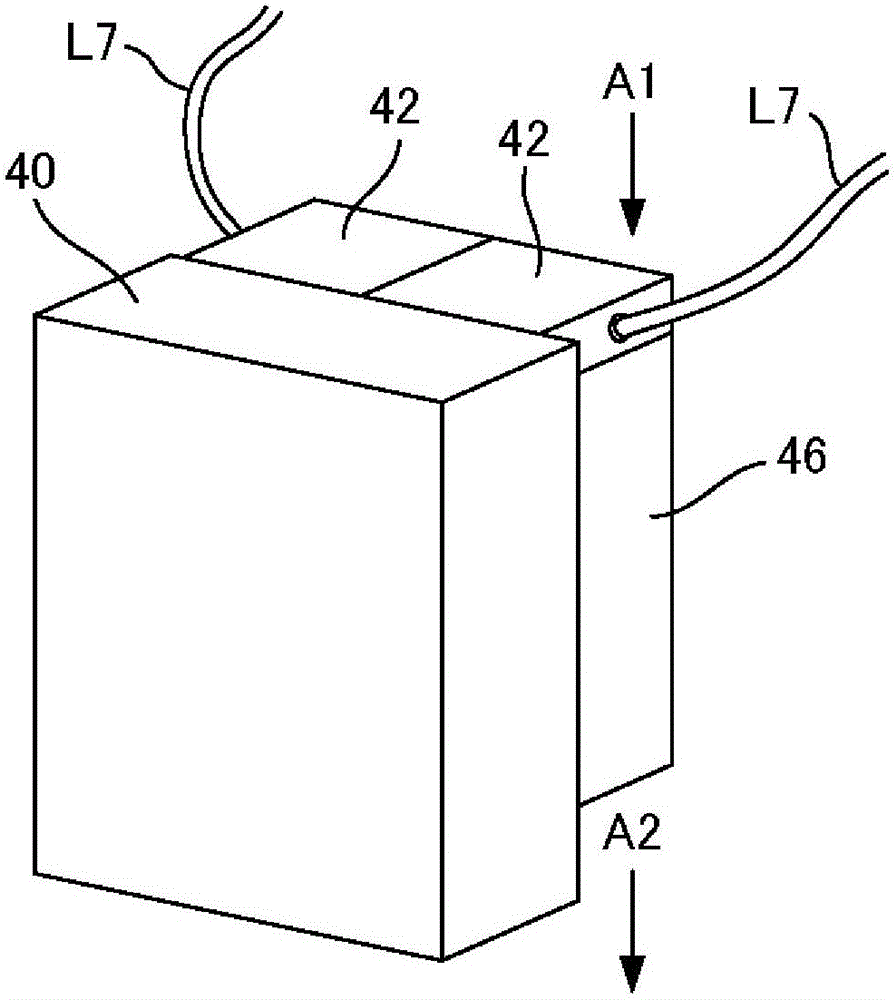

Freezing apparatus

ActiveCN104833124AReduce specific enthalpyImprove freezing effectMechanical apparatusCompression machines with non-reversible cycleGas coolerHigh pressure

The invention provides a freezing apparatus. When the high pressure side is up to a critical pressure, a compression mechanism can be prevented from being influenced by the high pressure, and the freezing capacity of the freezing apparatus can be prevented from being influenced by outside air temperature. The freezing apparatus comprises an electric expansion valve (33) that is connected to the downstream side of an air cooler (28) and the upstream side of an electric expansion valve (39); a casing (36) that is connected to the downstream side of the freezing apparatus and the upstream side of an electric expansion valve (39); a separating heat exchanger (29) that is set at the downstream side of the freezing apparatus and the upstream side of an electric expansion valve (39); an auxiliary circuit (48) that helps a refrigerant in the casing flows from electric expansion valves (43,47) into the separating heat exchanger, and then into the middle compression part of a compressor (11); and a main circuit (38) that helps the refrigerant flows from the lower part of the casing into the separating heat exchanger , and flows into the electric expansion valve (39) after heat exchange with the refrigerant flows in the first path; and a control apparatus (57) adjusts the pressure in the high pressure side of the refrigerant loop at the upstream side through the electric expansion valve (33).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

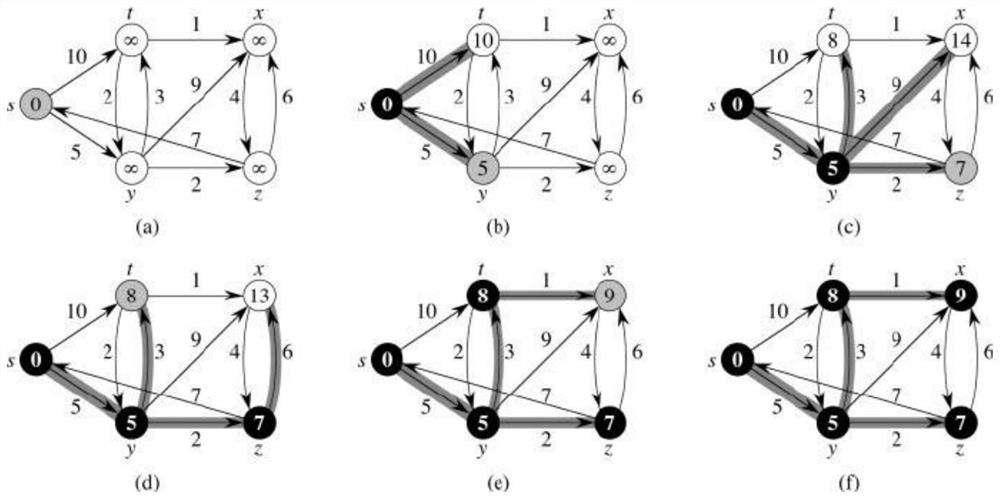

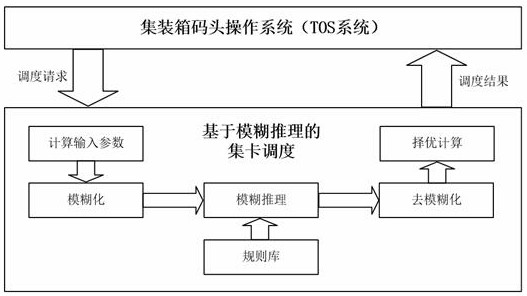

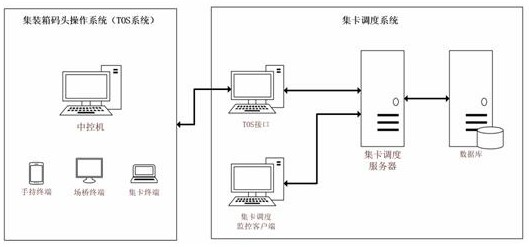

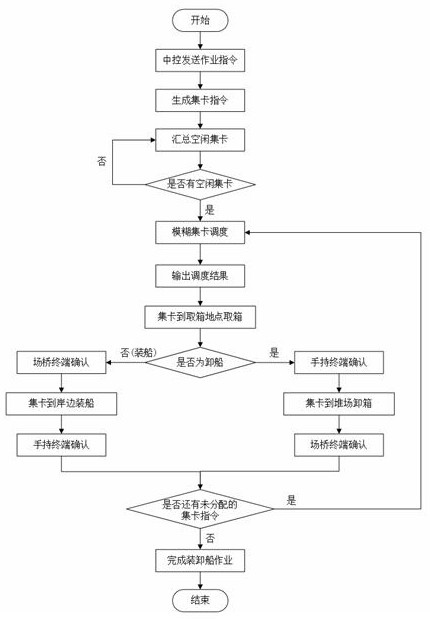

Container truck dispatching method based on fuzzy reasoning

ActiveCN112070296AReduce travel timeShorten driving distanceForecastingResourcesFuzzy ruleFuzzy reasoning

The invention discloses a container truck dispatching method based on fuzzy reasoning, and the method is characterized in that the method comprises the following steps: deploying an operation system,setting an optimal path of an operation region, defining an input parameter, setting a fuzzy rule, requesting container truck dispatching by a container wharf operation system, carrying out the container truck dispatching calculation, and executing a container truck dispatching result by the container wharf operation system. According to the method, a fuzzy mathematics method is adopted to realizethe operation dispatching of the container trucks, the ship loading and unloading efficiency is improved, the ship period is shortened, the operation efficiency of the container trucks is greatly improved, the number of the container trucks is controlled, the production cost is reduced, the wharf traffic flow is reduced, and the safety coefficient is improved.

Owner:广州南沙联合集装箱码头有限公司

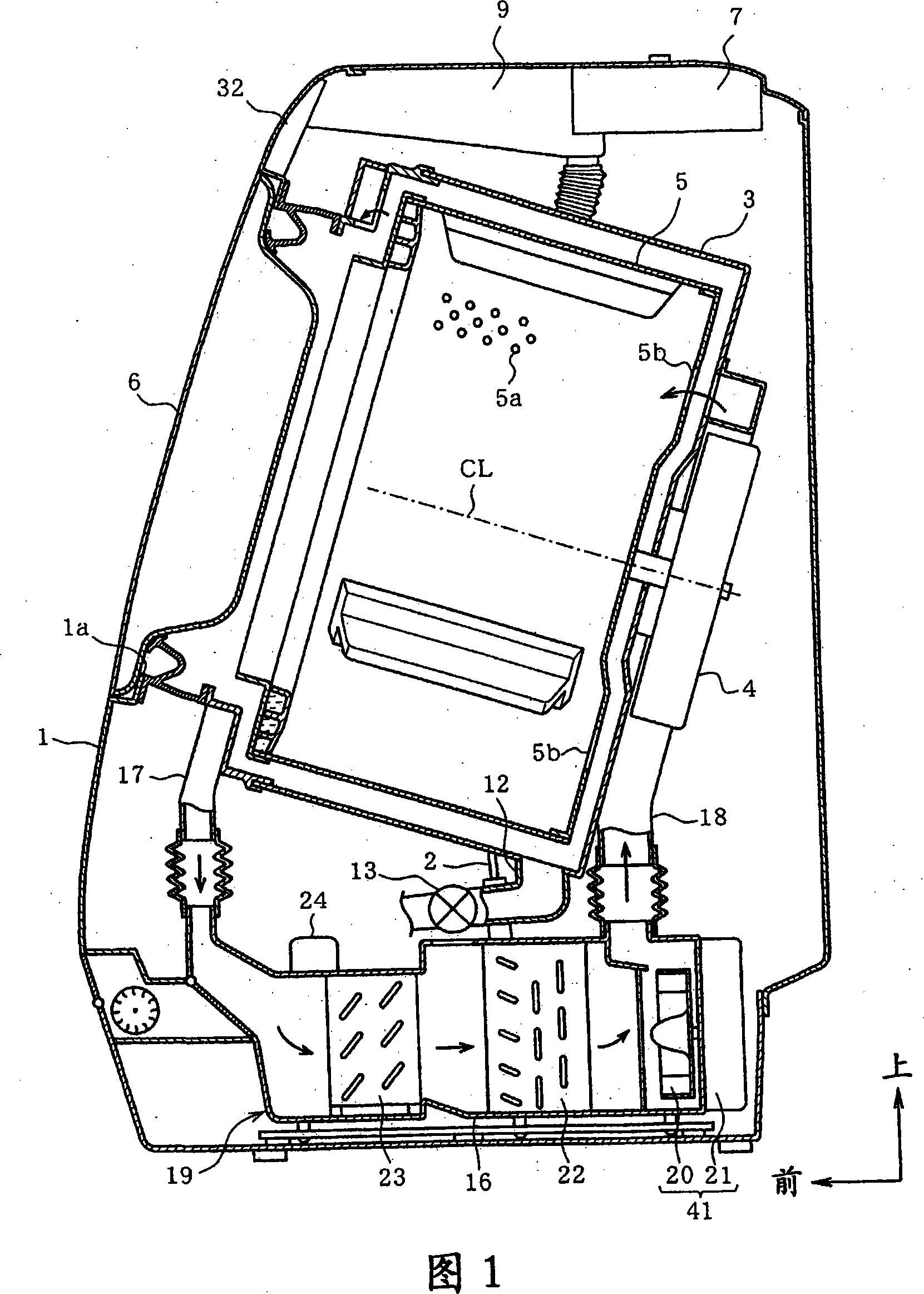

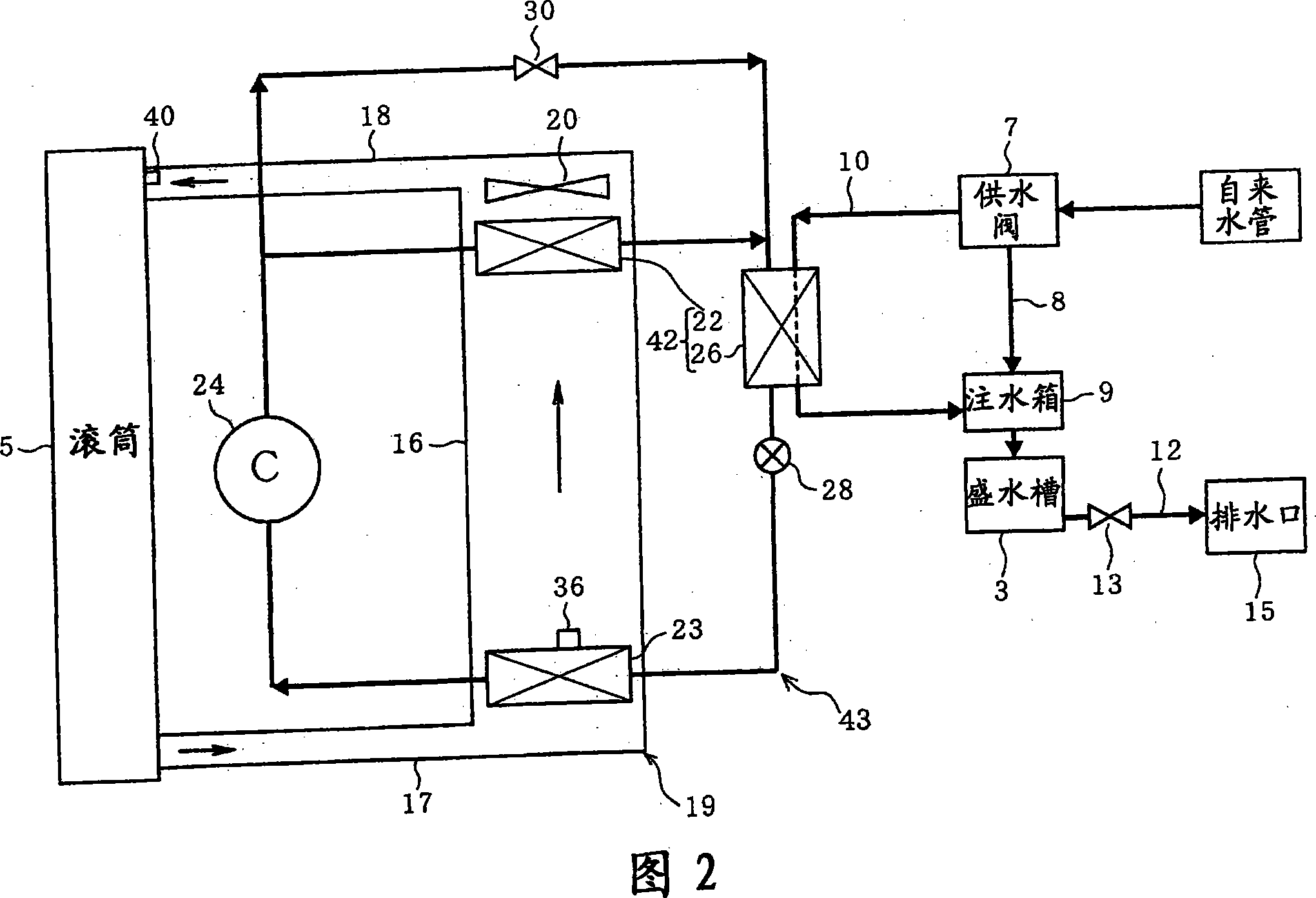

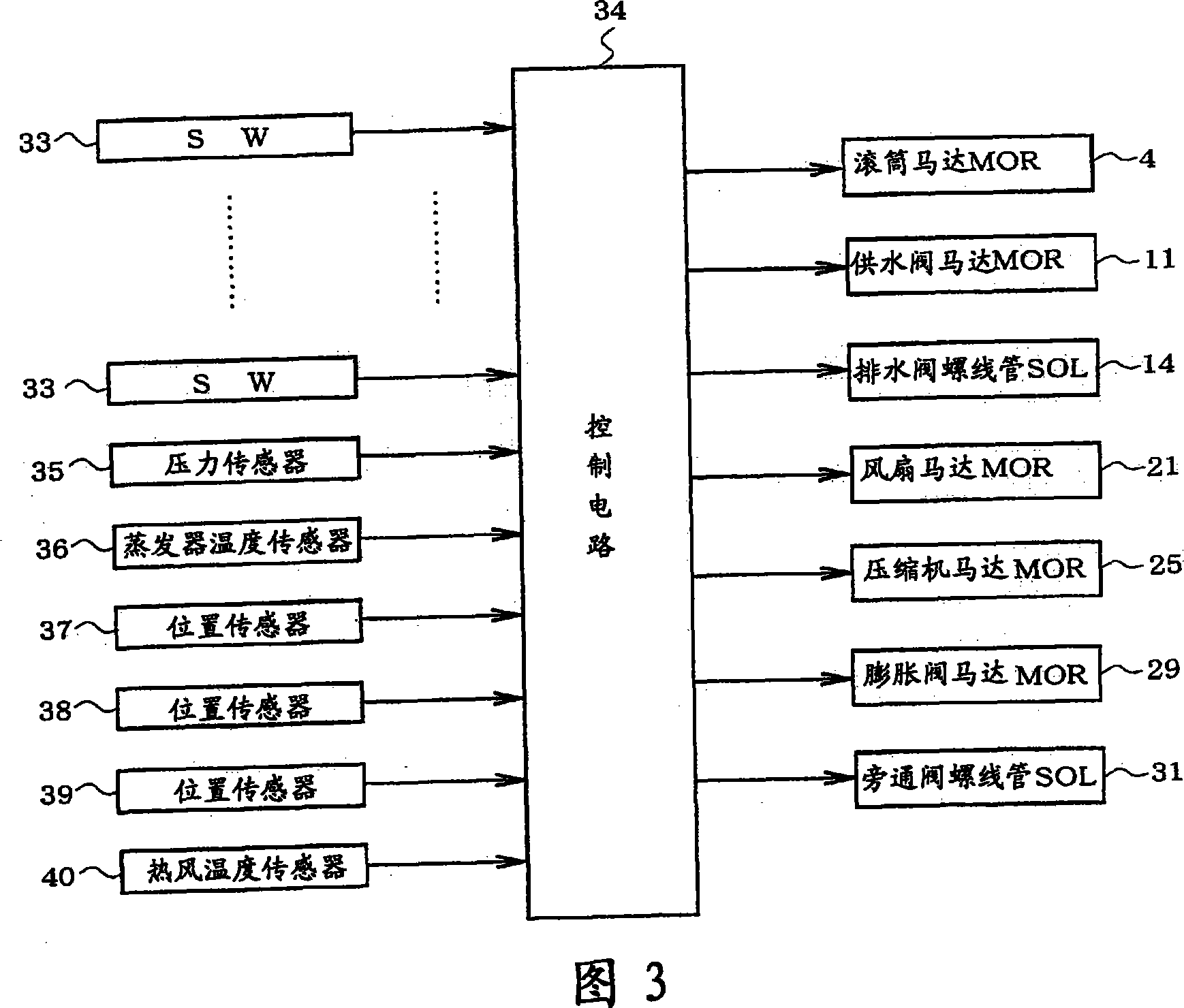

Washing machine

InactiveCN101096808AEasy to heat upReduce operating efficiencyOther washing machinesWashing machine with receptaclesTap waterWater storage tank

The objective of the invention is to raise the water temperature to the temperature which is suitable for washing. Injecting the tap water with ordinary temperature to the water storage tank by the water pipe (8), heating the tap water in the water storage tank (2) by operating the heat pump (43) to inject the hot wind to the water storage tank. The temperature of the condenser (26) has become enough high comparing with the beginning of hot wind injection treatment after a preset time from injecting hot wind for treating, injecting the tap water to the water storage tank through the water pipe (10) when the temperature of the condenser (26) has reached a high enough temperature. Therefore, the tap water in the water pipe (10) is warmed on a large scale as the water has absorbed the thermal capacity of the condenser (26) itself thereby raising the water temperature to the temperature which is suitable for washing.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

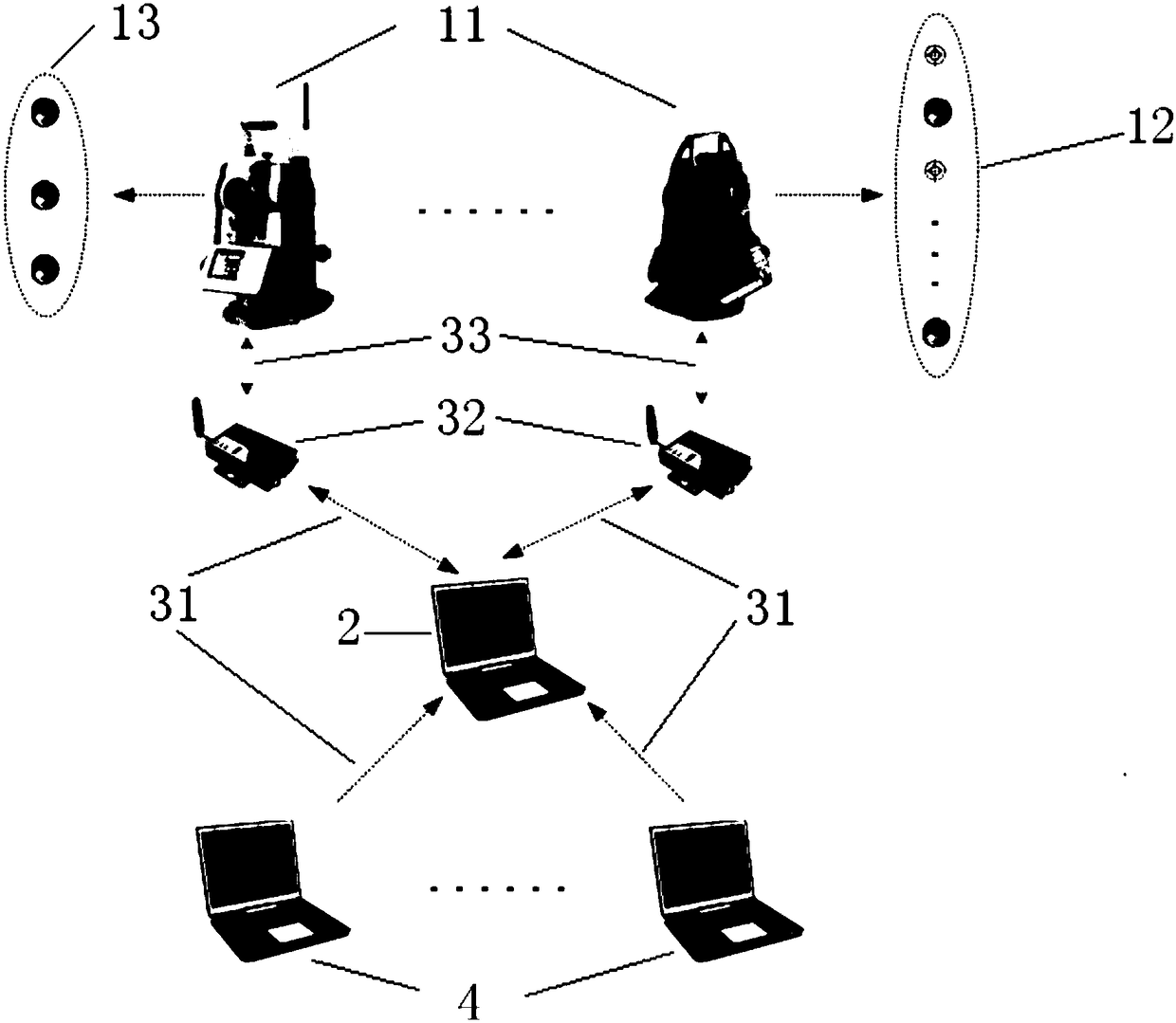

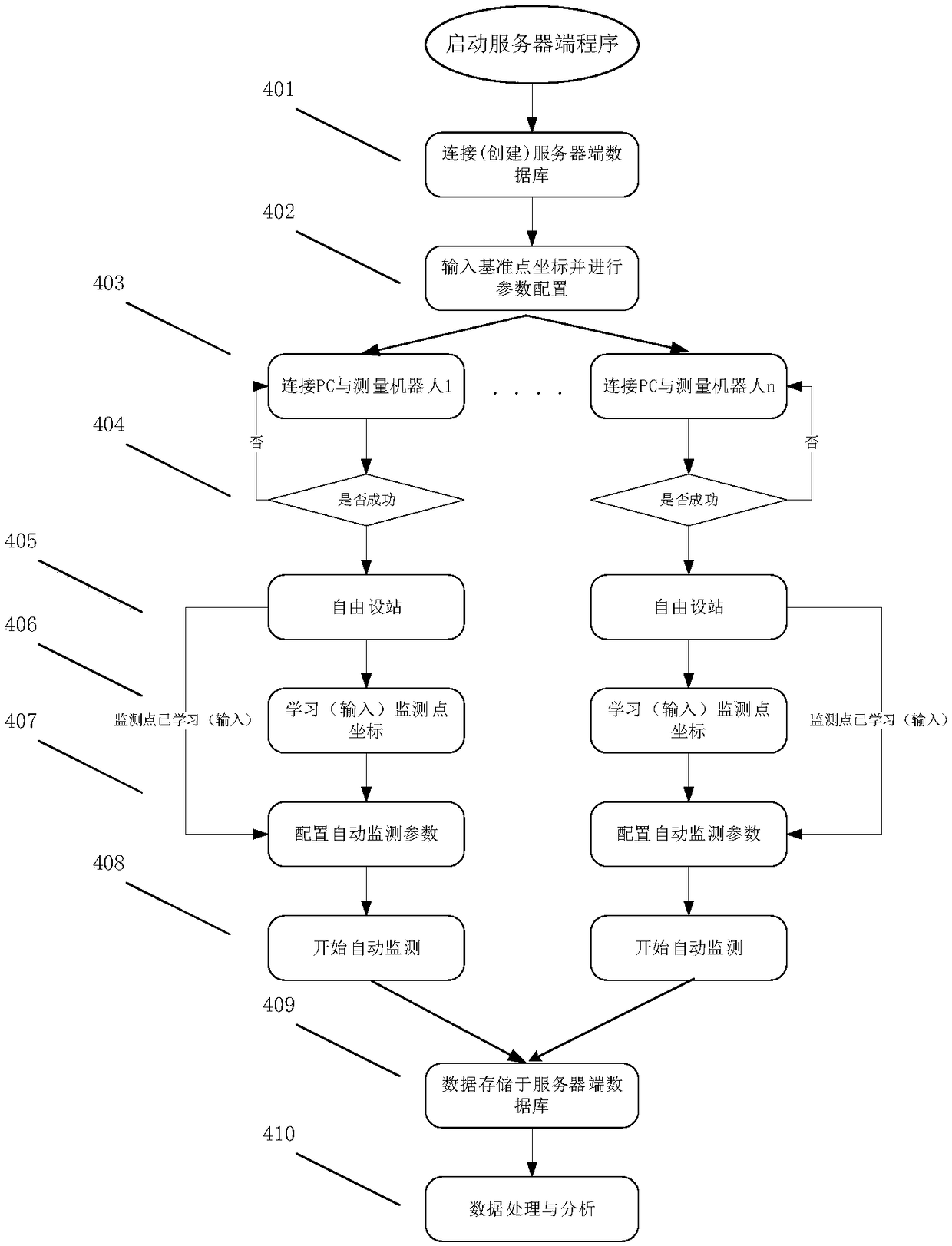

Automatic deformation monitoring system and method for free station establishment of various kinds of measuring robots

ActiveCN108362215ADoes not affect normal monitoring workImprove rationalityUsing optical meansAutomatic Deformation Monitoring SystemData acquisition

The invention relates to an automatic deformation monitoring system and method for free station establishment of various kinds of measuring robots. The system comprises a data acquisition module, a core control module and a data communication module. The data acquisition module is used for acquiring the three-dimensional coordinate of a monitoring point. The core control module is a server-side computer and is used for real-time control of the data acquisition module. The data communication module is used to realize two-way communication between the data acquisition module and the core controlmodule. The data acquisition module comprises various different brands of measuring robots and any number of target prisms or reflectors. Any number of target prisms or reflectors are fixed on monitoring points. Compared with the prior art, the system and method have the advantages of multiple-station observation, free station establishment, remote control, network query and the like.

Owner:TONGJI UNIV

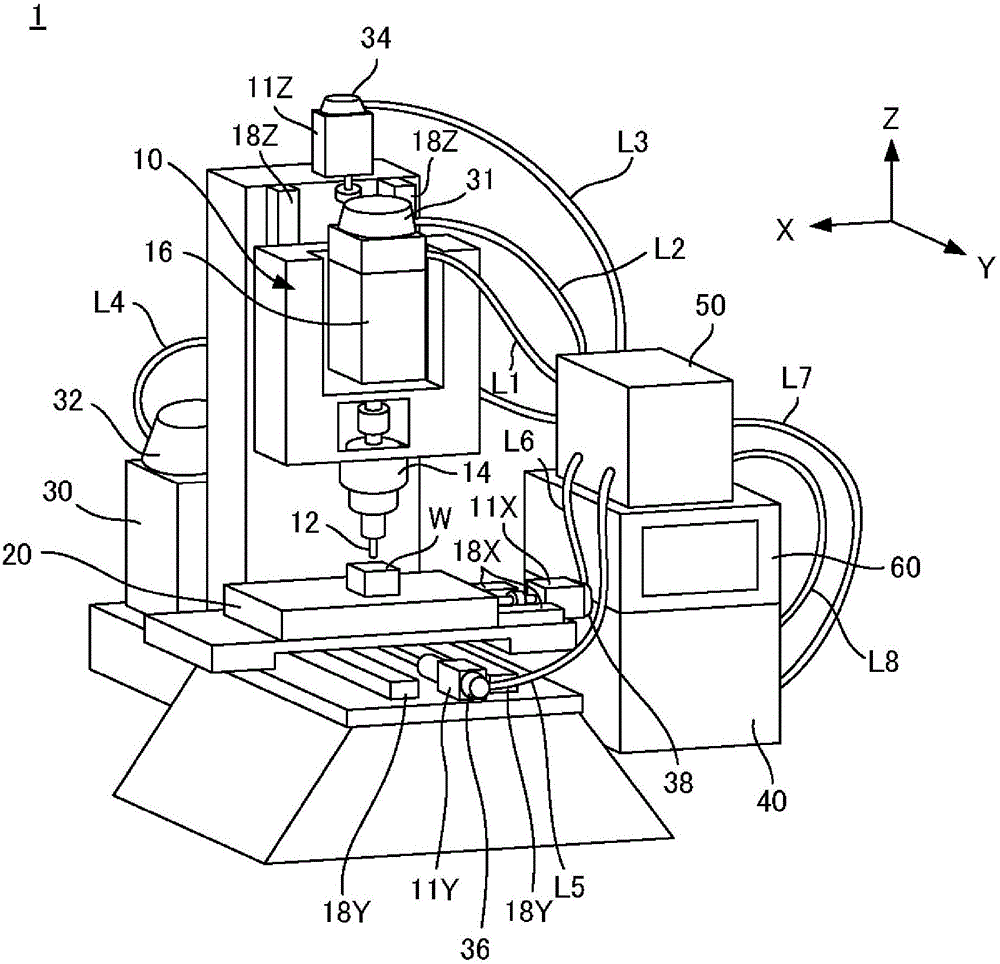

Machine tool

InactiveCN106166689AReduce cooling effectReduce failureManipulatorMaintainance and safety accessoriesForeign matterForeign object

A machine tool is disclosed in the invention and includes a cooling fluid supplying part, e.g., a fan or a flow path, for supplying a cooling fluid which dissipates heat generated from the machine tool during operation. The cooling fluid supplying part is operable to supply the cooling fluid independently of a cooling action of a machining point of the machine tool. The machine tool also includes a cleaning part for cleaning the cooling fluid supplying part. The cooling fluid supplying part may be a fan or a flow path of the cooling fluid. Accordingly, the cooling effect for cooling the machine tool can be prevented from being decreased due to the foreign objects attached to the cooling fluid supplying part; the machine tool can be prevented from being damaged due to excessive heat, and the operation efficiency can be prevented from being decreased.

Owner:FANUC LTD

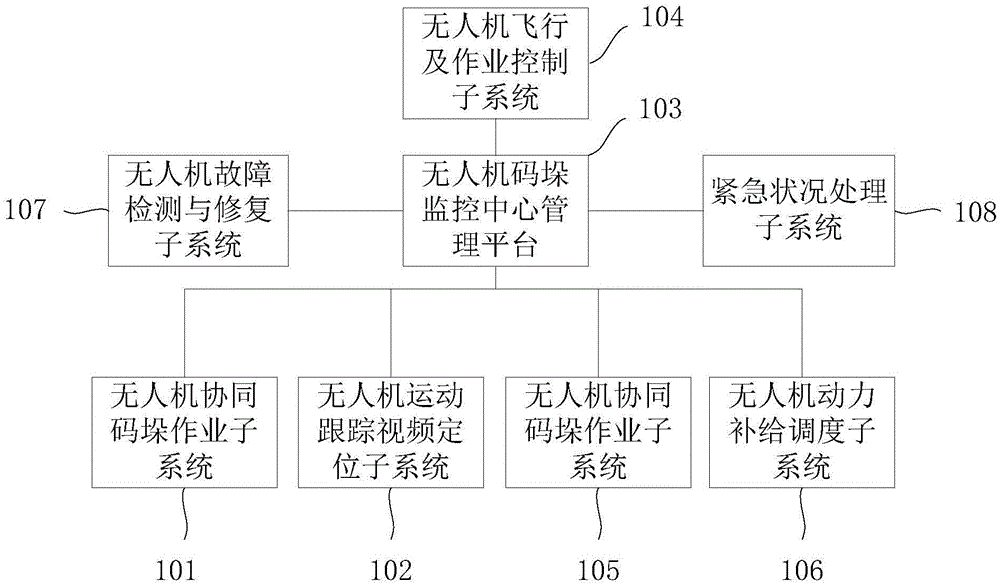

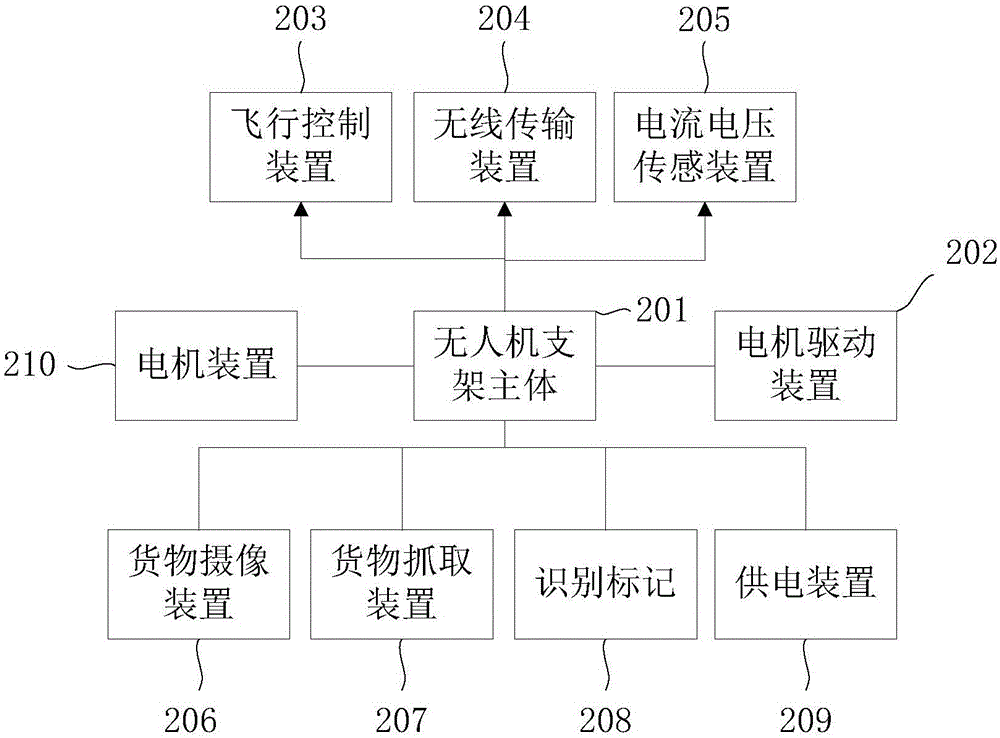

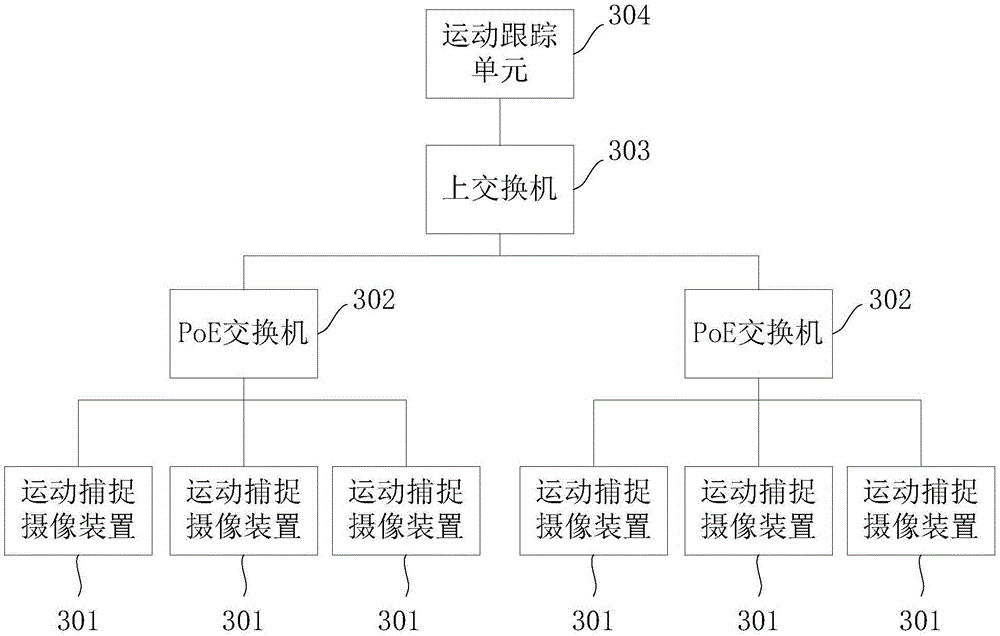

Unmanned plane piling operating system

InactiveCN105068559AImprove flexibilityImprove work efficiencyStacking articlesTarget-seeking controlUncrewed vehicleNo production

The embodiment of the invention provides an unmanned plane piling operating system comprising an unmanned plane cooperative piling operating subsystem, an unmanned plane motion tracking video positioning subsystem, an unmanned plane piling monitoring center management platform, an unmanned plane flight and operating control subsystem, an unmanned plane piling capturing recognition subsystem, an unmanned plane power supply scheduling subsystem, and an unmanned plane fault detection and recovery subsystem and emergency processing subsystem. The unmanned plane piling operating system has the following beneficial effects: the operating flow can be changed again at any time under the circumstance that no production equipment needs to be adjusted and only the flight control system of the unmanned plane needs to be changed according to specific demands; the working efficiency can be improved or reduced by turning on or off unmanned planes; multiple package assembling line can be dealt with by one unmanned plane; with the system, flexibility of the piling work can be improved; and compared with the traditional piling work, lots of manpower and material costs can be saved and the piling efficiency can be improved.

Owner:北京中物智联科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com