Quenching equipment for large rings

A quenching equipment and ring technology, applied in the field of heat treatment and quenching, can solve the problems that the crane cannot perform other operations, affect the heating efficiency of the workpiece, and occupy a large space for the crane, so as to improve the utilization rate of the crane, improve the operation efficiency, reduce the Effect of quenching processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

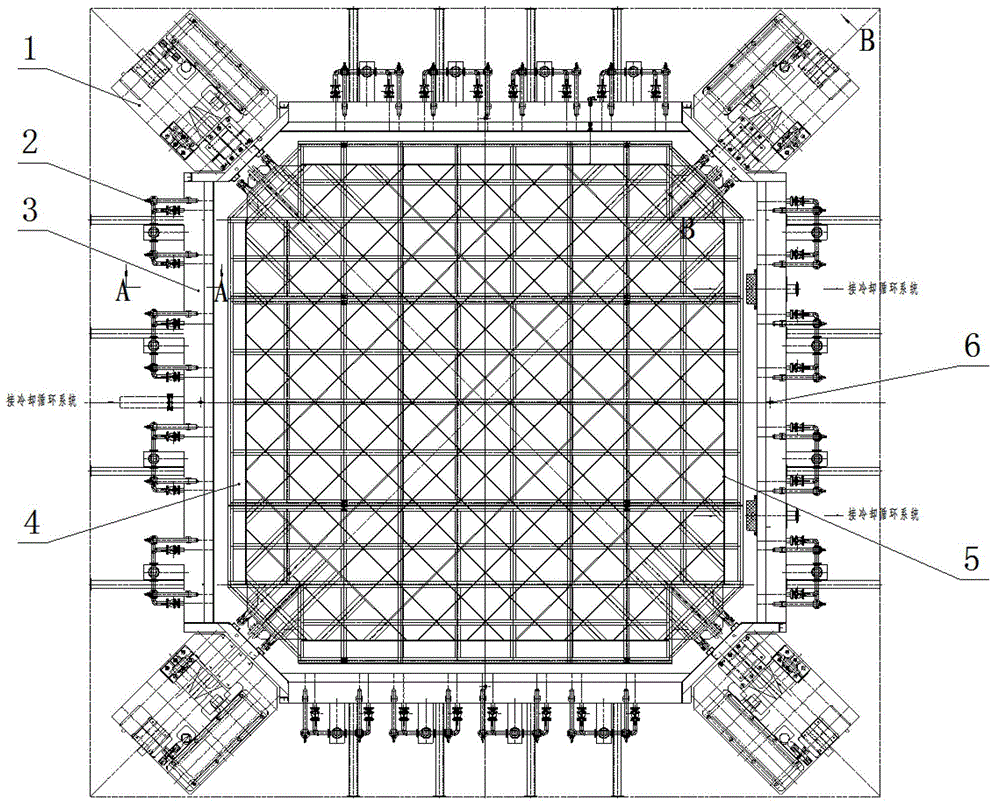

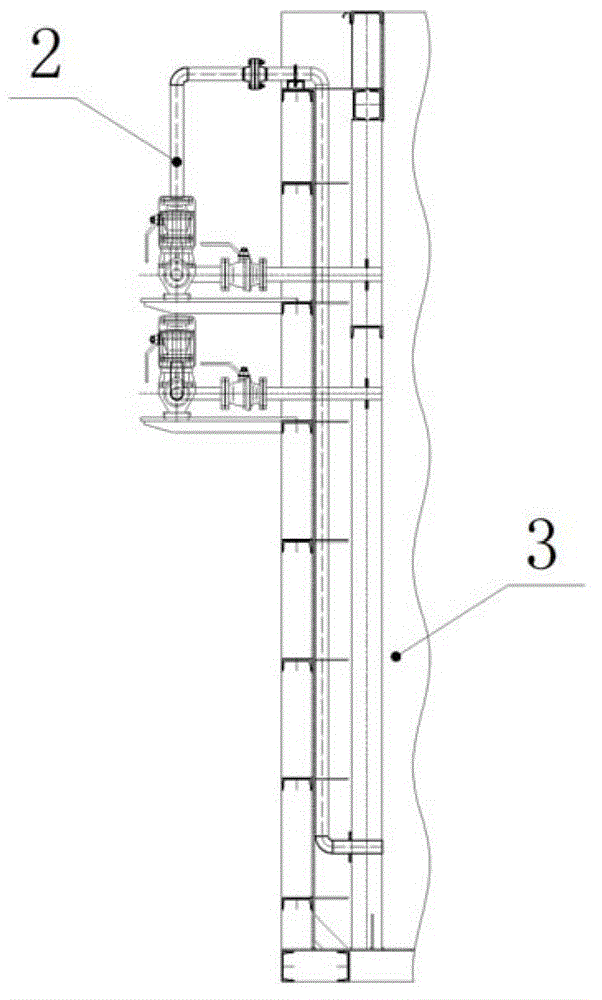

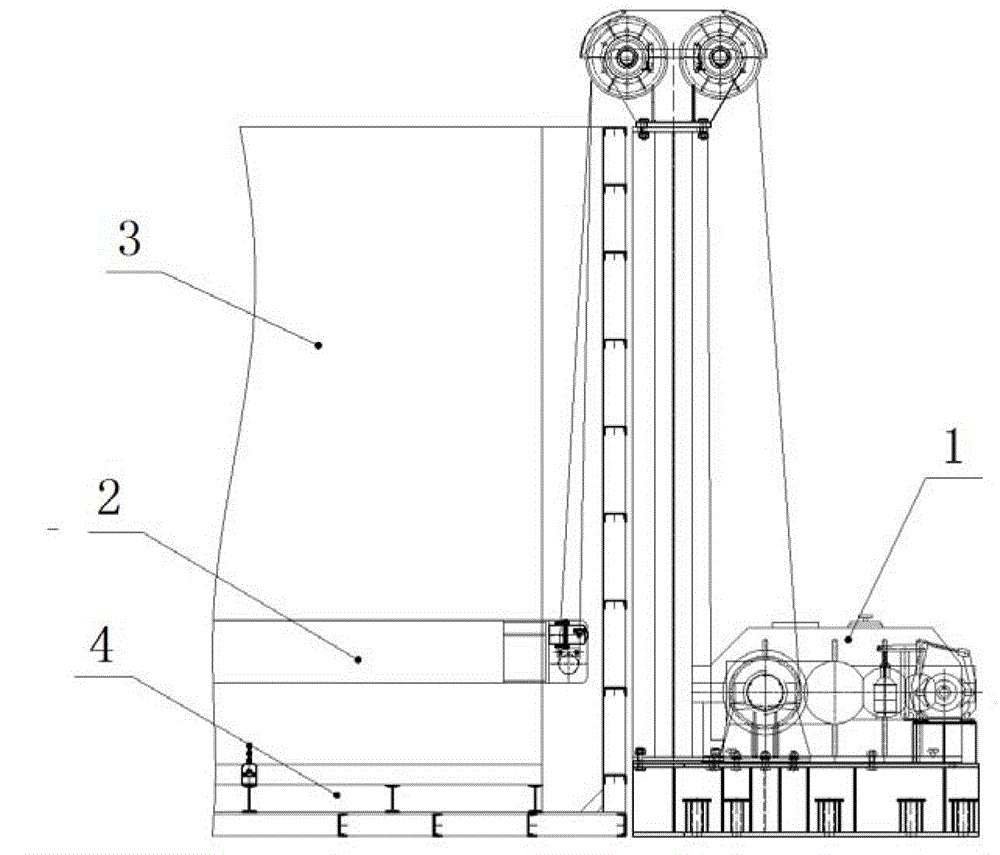

[0026] see Figure 1-Figure 7 , a large-scale ring quenching equipment, including a quenching tank 3, a stirring device 2, a temperature detector 6, a slag collecting device 4 arranged at the bottom of the quenching tank, and a cooling circulation system (not shown in the figure). The body of the quenching tank is provided with a quenching platform 5 that can be lifted up and down. In this embodiment, the quenching tank adopts a square welded structure, and the quenching platform adopts a square disc structure that matches the shape of the quenching tank. A lifting mechanism 1 for lifting and lowering the quenching platform is installed on the outer sides of the four corners of the quenching tank, and the lifting mechanism is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com