Washing machine

A technology for washing machines and washing tanks, which is applied in the field of washing machines, and can solve the problems of reduced operating efficiency of heat pumps, difficulties in heating up the condenser, and heating up of tap water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

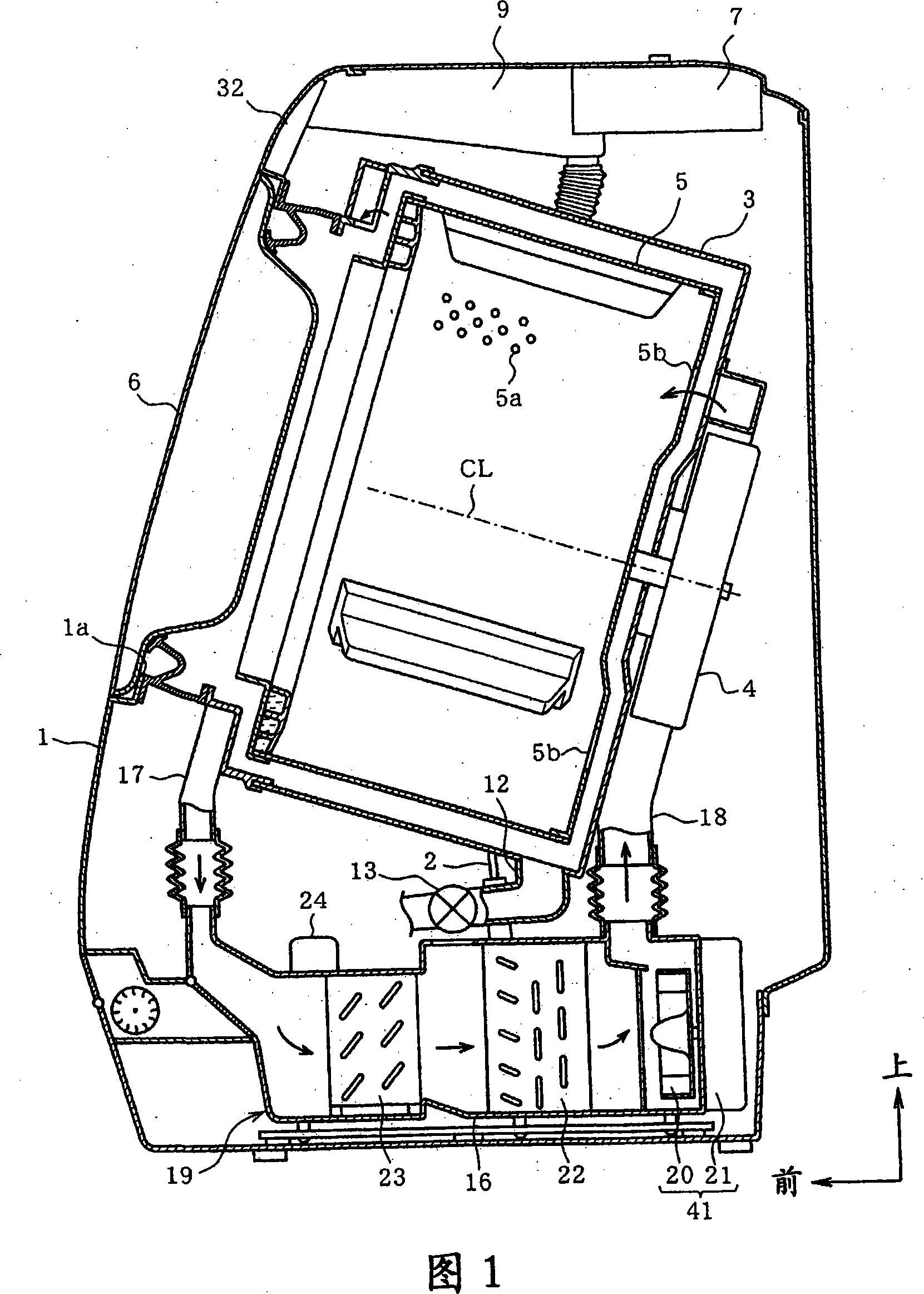

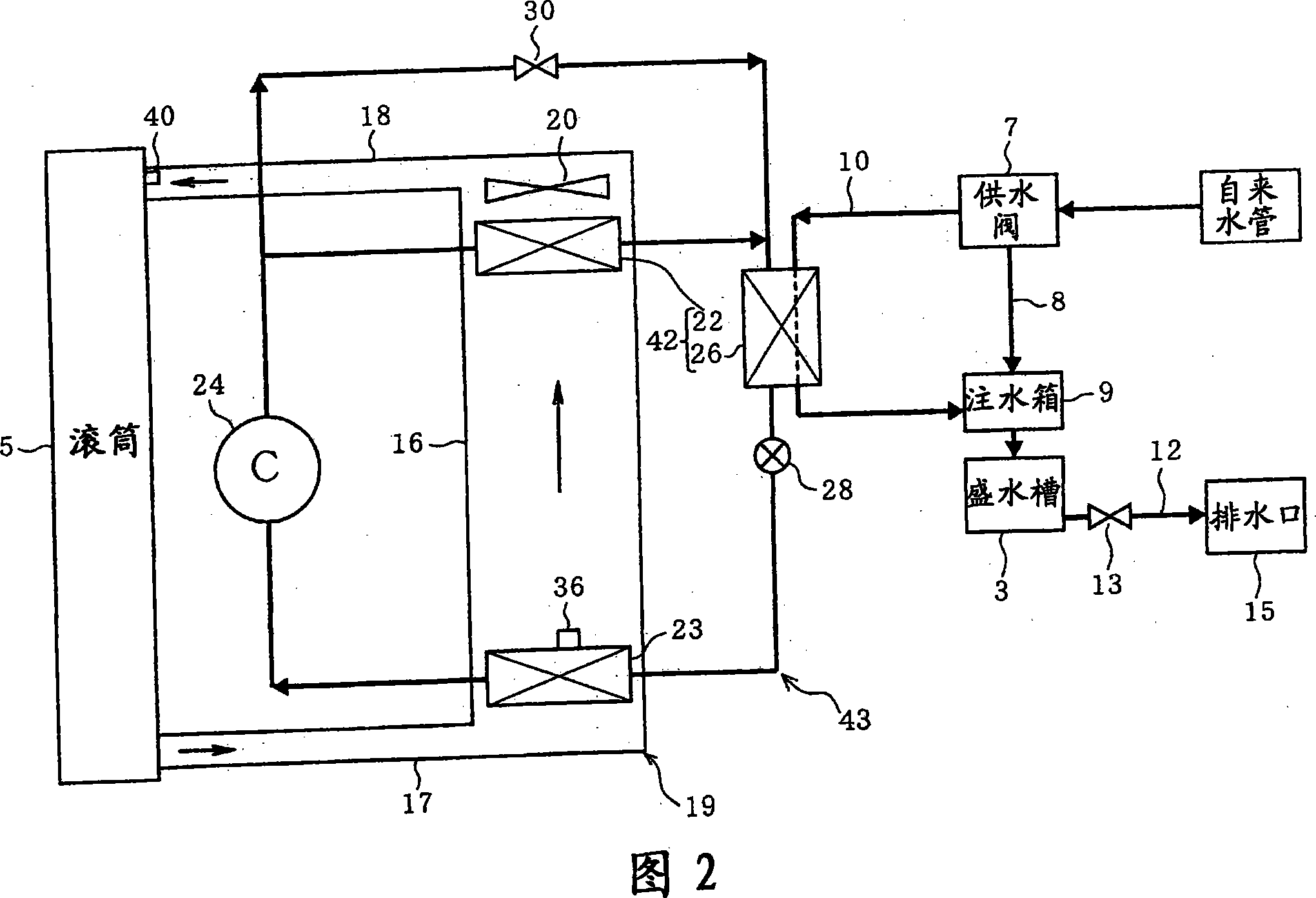

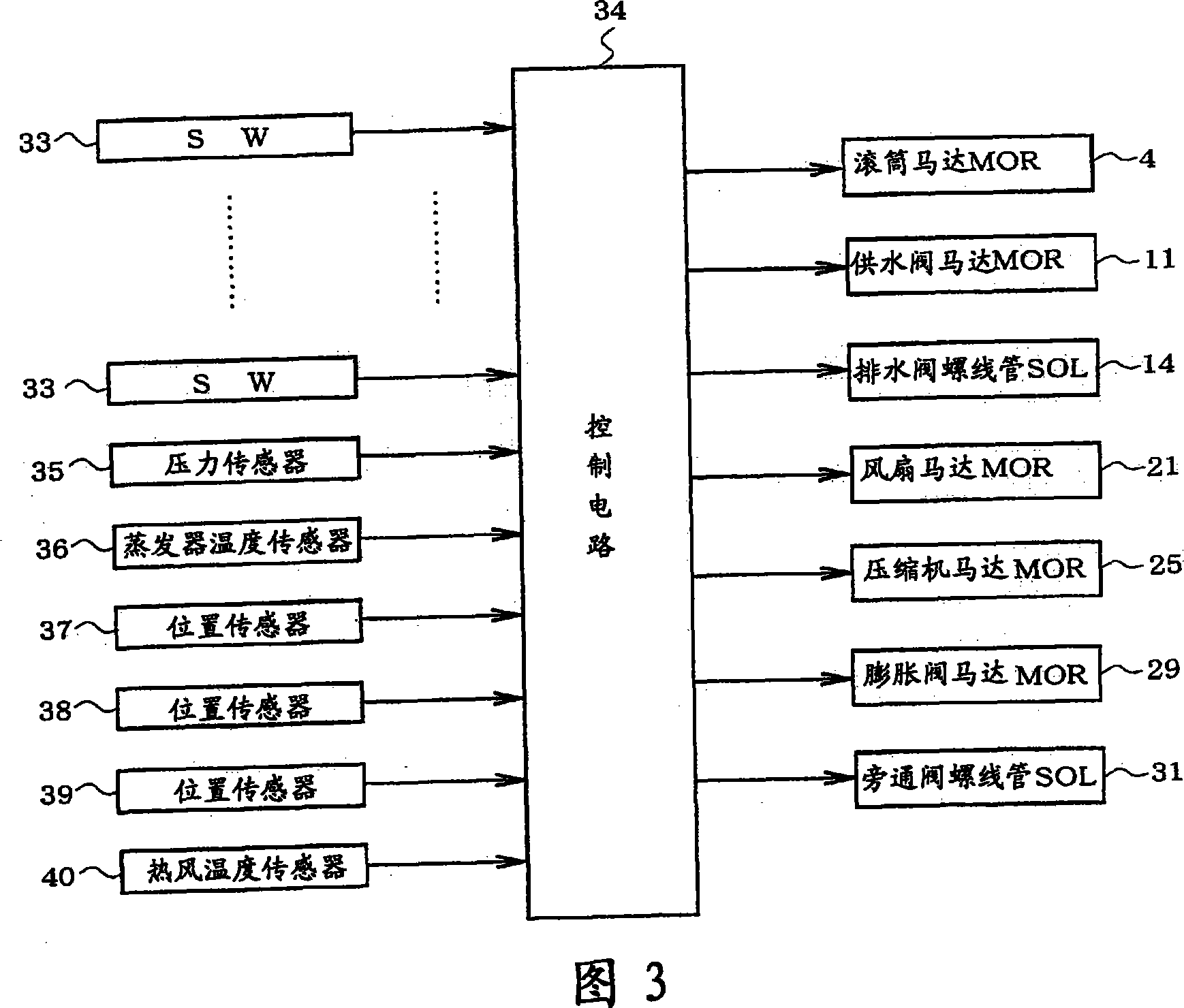

[0033] Inside the outer case 1 , as shown in FIG. 1 , a plurality of dampers 2 are accommodated. A water tank 3 is fixed to rods of the plurality of dampers 2 , and the water tank 3 is accommodated inside the outer case 1 in a damped state and a buffered state via the plurality of dampers 2 . The water tank 3 is in the shape of a bottomed cylinder with the rear closed, and is arranged in an inclined state with the axis line CL being high at the front and low at the rear. On the rear plate of the water tank 3 , a stator of a drum motor 4 is fixed outside the water tank 3 . The drum motor 4 includes an outer rotor type DC brushless motor in which a rotor is disposed on the outer periphery of a stator, and the rotating shaft of the drum motor 4 protrudes into the water tank 3 .

[0034] A drum (drum) 5 is fixed to the rotation shaft of the drum motor 4 . The drum 5 corresponds to a washing tank. By operating the drum motor 4 , it rotates integrally with the rotating shaft of t...

Embodiment 2

[0079] A three-way valve 45 is connected to the discharge port of the compressor 24 as shown in FIG. 8 . The three-way valve 45 is driven by a valve solenoid including an electromagnetic solenoid. The three-way valve 45 can make the refrigerant discharged from the compressor 24 flow into the separate condenser 26 and the separate condenser 22 respectively, and prevent the refrigerant discharged from the compressor 24 from flowing into the separate condenser 26. Flow into the split condenser 22 switches between dry states.

[0080] FIG. 9 shows the control content of the control circuit 34 when the hot water washing course is set. The CPU of the control circuit 34 switches the water supply valve 7 from the cold water injection state to the water injection stop state in step S7 when there is normal temperature tap water at the water injection interruption level in the water tank 3 . Then, in step S8, the three-way valve 45 is switched to the water injection state, in step S9, ...

Embodiment 3

[0084] Inside the main duct 16 , as shown in FIG. 10 , a corrugated finned condenser 50 is housed. The condenser 50 is configured such that a plurality of fins are interposed between linear portions of one refrigerant pipe in a serpentine shape, and the plurality of fins are respectively joined to the linear portions of the refrigerant pipe. FIG. 11( a ) shows the piping state of the condenser 50 . The refrigerant tubes 51 of the condenser 50 are arranged in four rows in the left-right direction. One water pipe 52 in a serpentine shape is joined to a plurality of fins of the condenser 50 . The water pipes 52 are arranged in two rows in the left-right direction. The inner surface of the water pipe 52 is formed of a smooth surface as shown in FIG. 11( b ). Each row of the water pipes 52 is interposed between the rows of the refrigerant pipes 51 as shown in FIG. This water pipe 52, as shown in Figure 10, is connected on the heating outlet of water supply valve 7 via water pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com