Portable furrowing, topdressing, pressing and soil covering integral machine for cornfield

An all-in-one machine and soil-covering technology, applied in fertilization devices, fertilizer distributors, applications, etc., can solve the problems of low nitrogen fertilizer utilization rate, high operating cost and economic benefits, and poor nitrogen fertilizer covering effect, so as to improve the efficiency of top-dressing operations and reduce The cost of top dressing operation and the effect of solving the poor soil covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

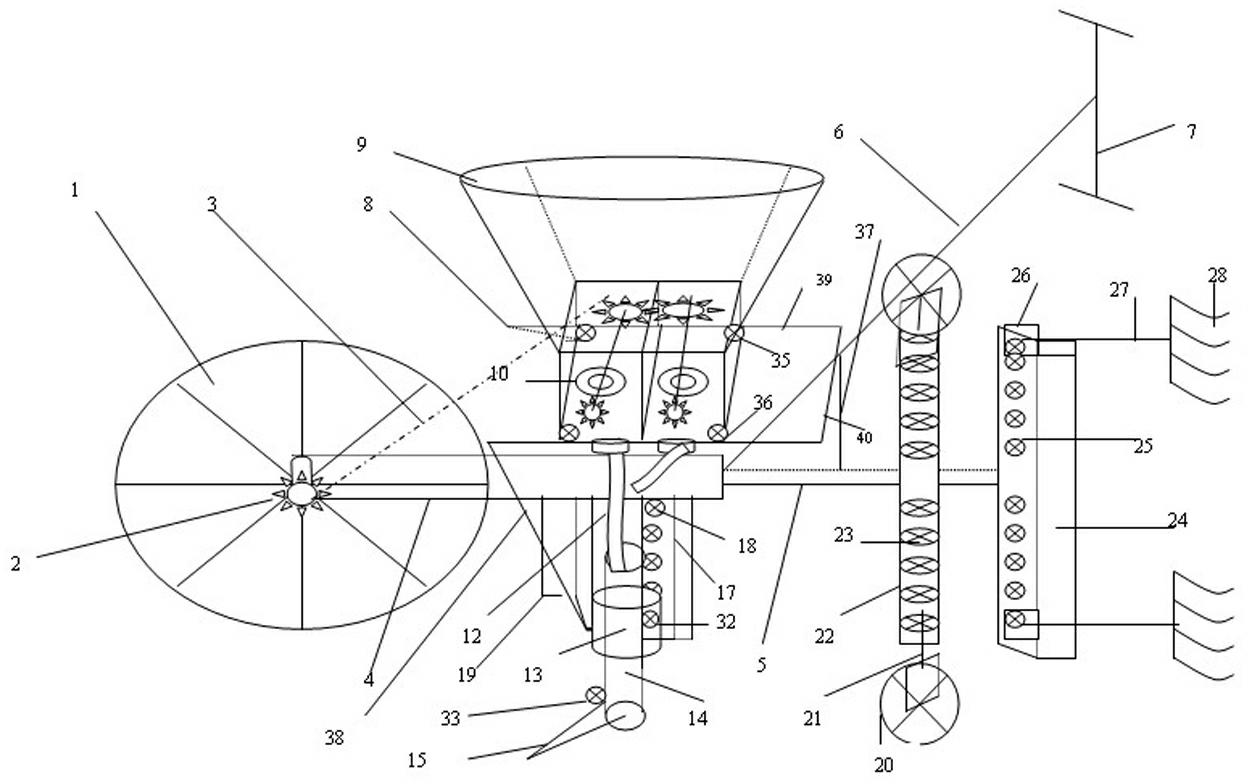

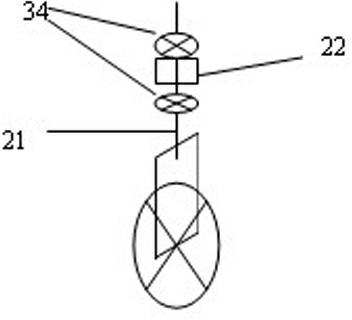

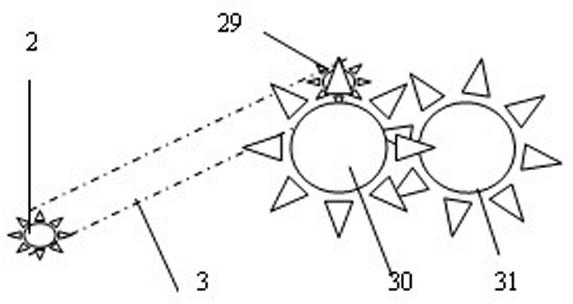

[0016] Frame comprises front fork 4, front fork handle 5, oblique upright rod 6, pull rod 37 and the handrail 7 of shape I-shaped; The front end of the front fork 4; the topdressing device is installed at the end of the front fork 4 and directly above it, and the front fork handle 5 is respectively equipped with a suppressing device and a soil covering device from front to back, and the middle point of the adjustment plate B 22 is welded on the front of the front fork handle 5. The left and right sides of the adjustment plate B22 are respectively equipped with a suppression wheel; the middle point of the adjustment plate C24 is welded to the rear portion of the front fork handle 5, and the left and right sides of the adjustment plate C24 are each equipped with a rake; the topdressing device includes fertilizer boxes 9, 8 fertilizer box brackets, 2 sets of fertilizer discharge components, and 2 sets of fertilizer transport components. The fertilizer discharge components (each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com