Mounting method for flake-like truss composite structure

A technology of combined structure and installation method, which is applied in the preparation of building components on site, building structure, and processing of building materials, etc., can solve the influence of physical properties of main truss profiles, low installation efficiency of steel trusses, and reduced equipment use efficiency, etc. problems, to achieve the effect of shortening the overall construction period, improving the overall operation efficiency, and improving the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

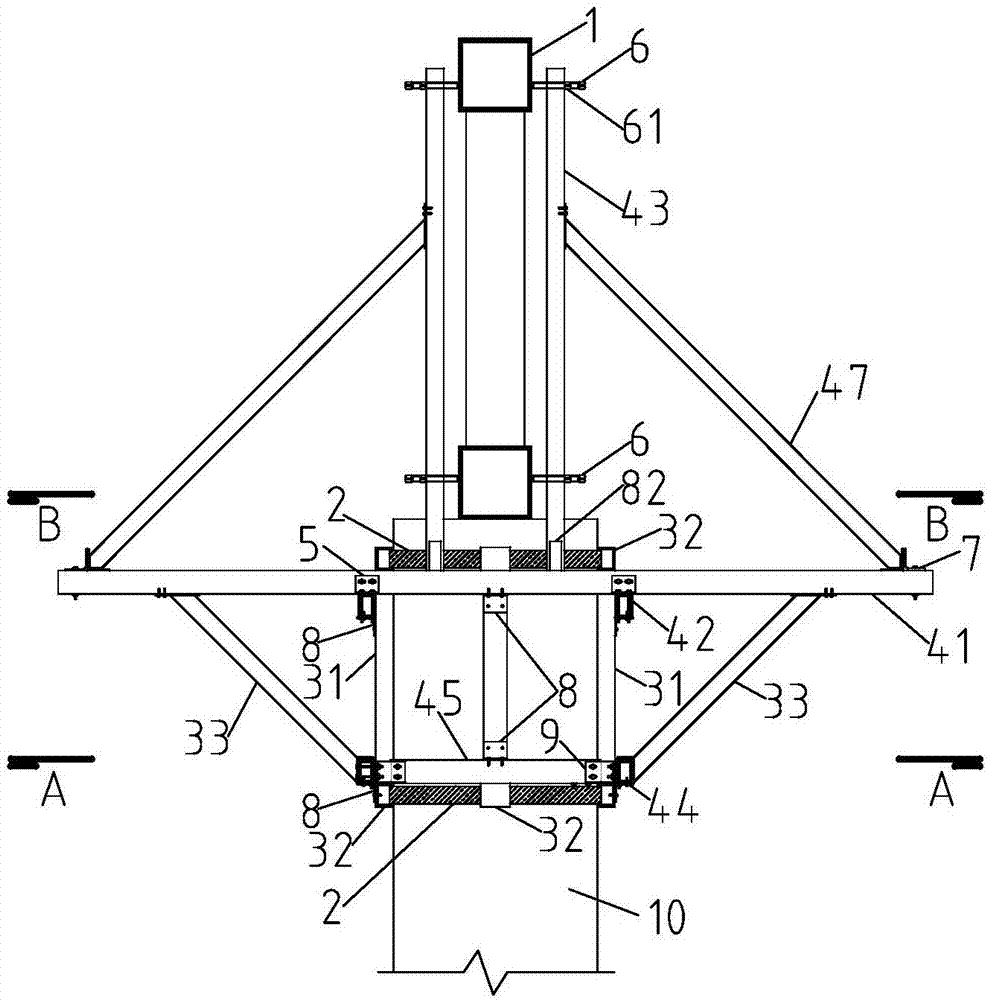

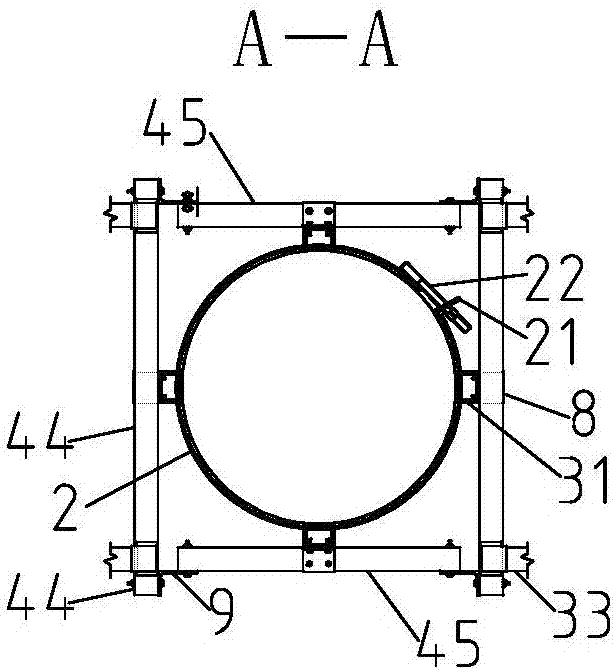

[0038] The sheet truss composite structure is composed of parallel main trusses and secondary trusses welded between the main beams. The installation method of the sheet truss composite structure in this embodiment, the installation method uses a method such as figure 2 , image 3 , Figure 4 Temporary supports for the main truss shown and as Figure 5 , Figure 6 The secondary truss temporary support device shown is realized.

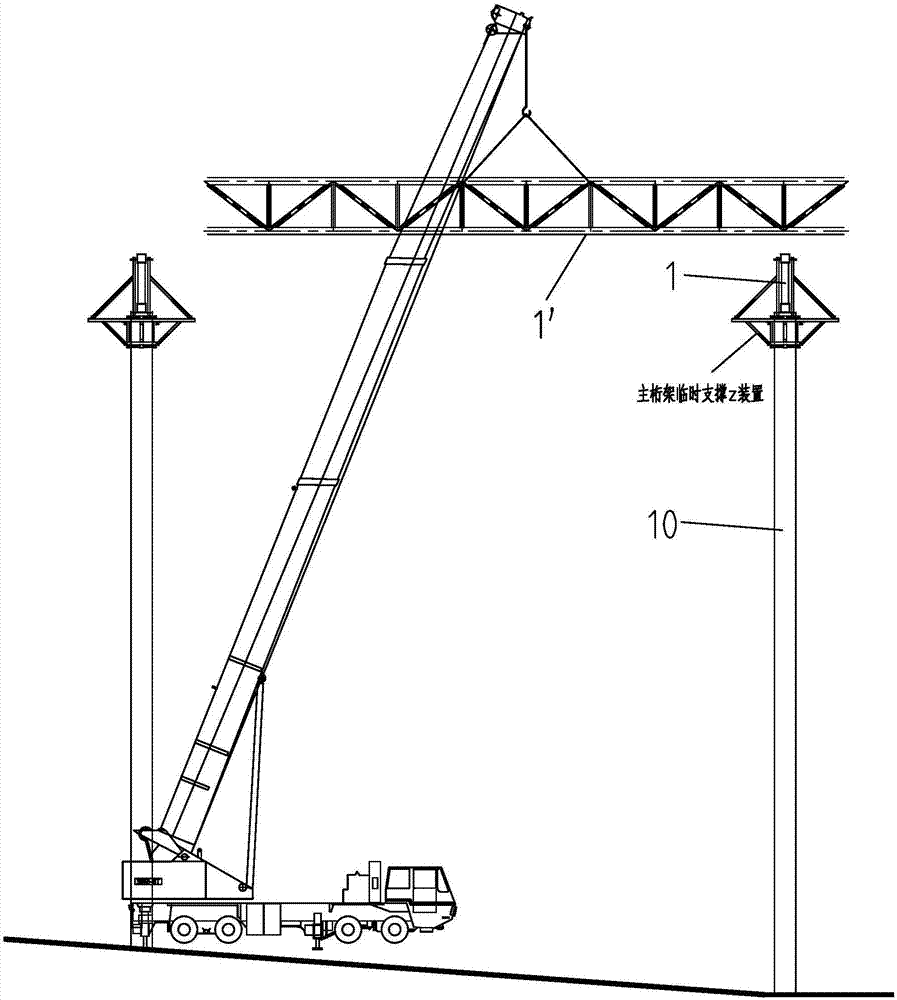

[0039] Such as figure 1 Shown is a schematic diagram of the hoisting of the sheet truss composite structure. It can be seen from the figure that the main truss 1 has been fixed above the steel pipe column 10 through the main truss temporary support device, and the secondary truss 1' is being hoisted.

[0040] The installation method of the sheet truss composite structure in this embodiment includes the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com