Rail hoisting transportation method for small radius curve incline shaft

A technology of small radius curve and transportation method, applied in the direction of transportation of passenger cars, transportation and packaging, lifting equipment in mines, etc., can solve the problems of low safety and efficiency, difficult to use, etc. good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

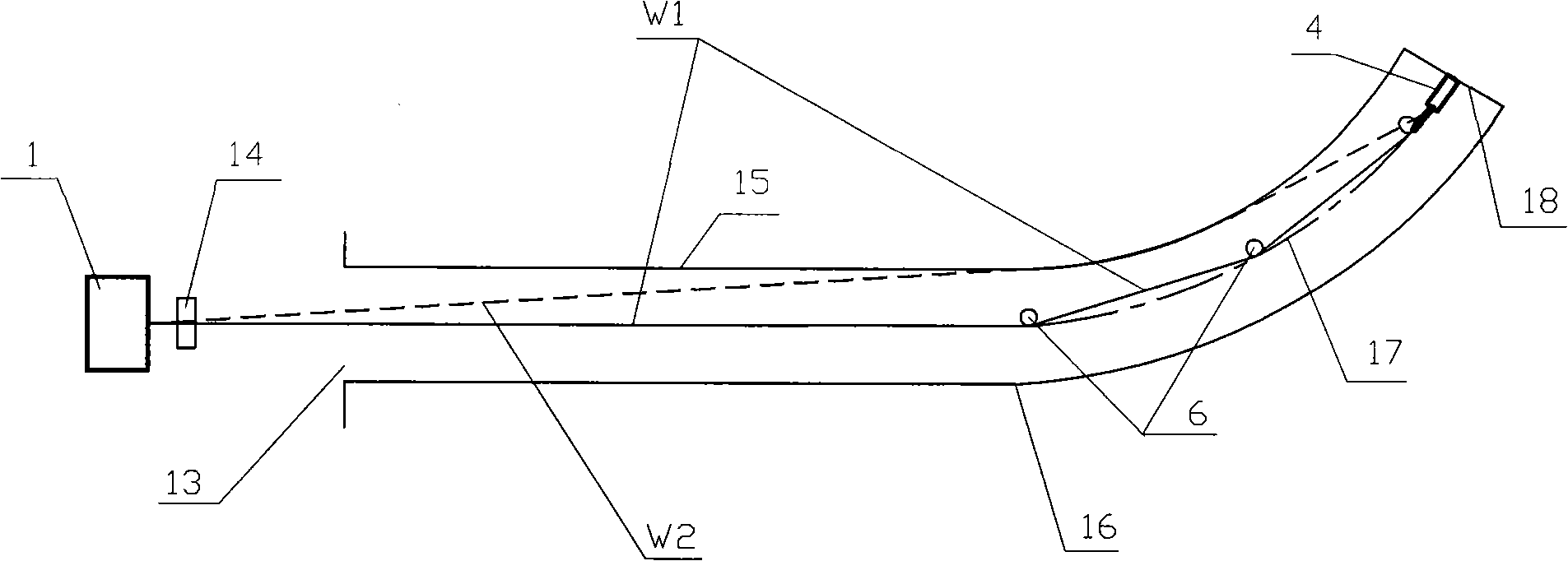

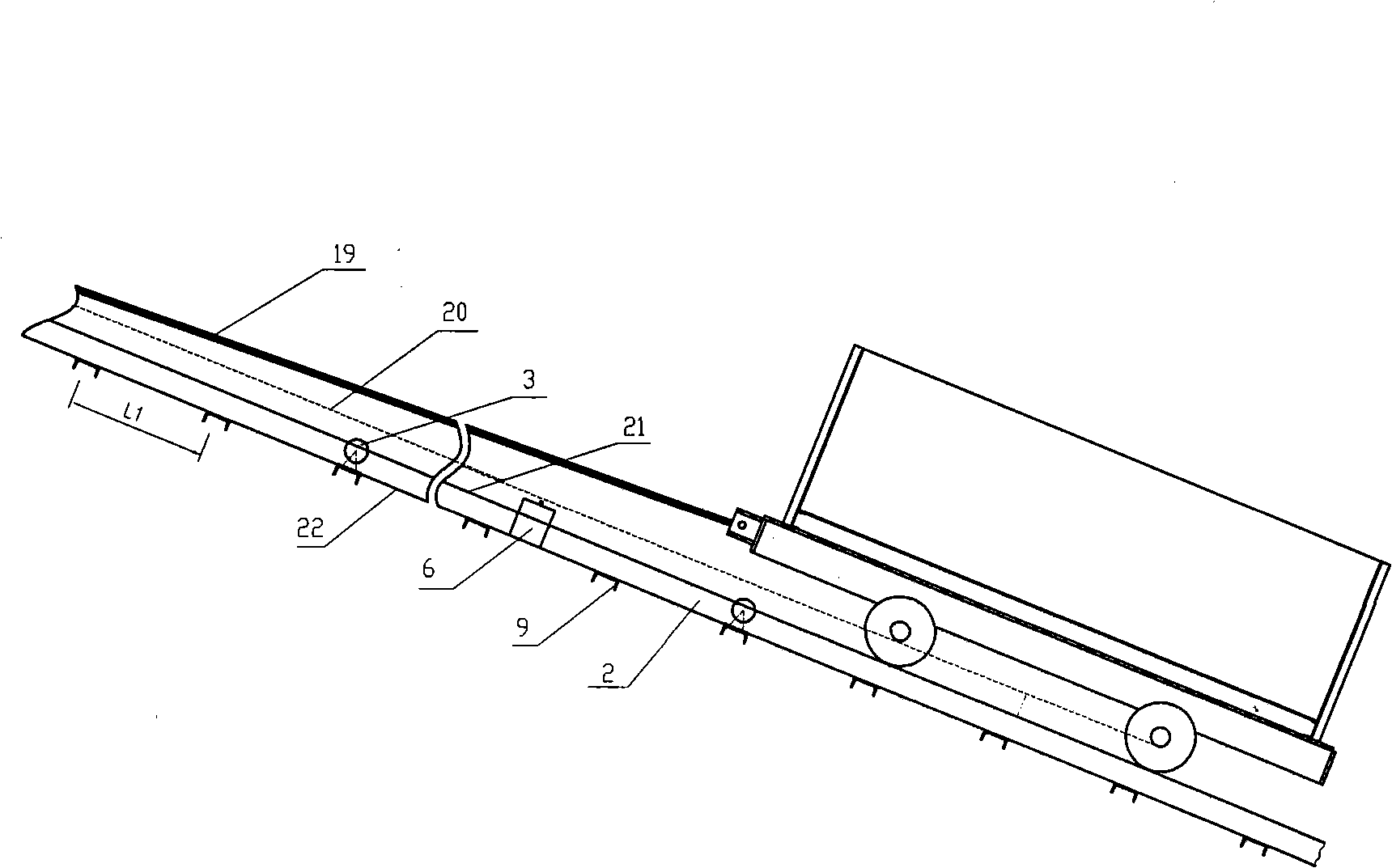

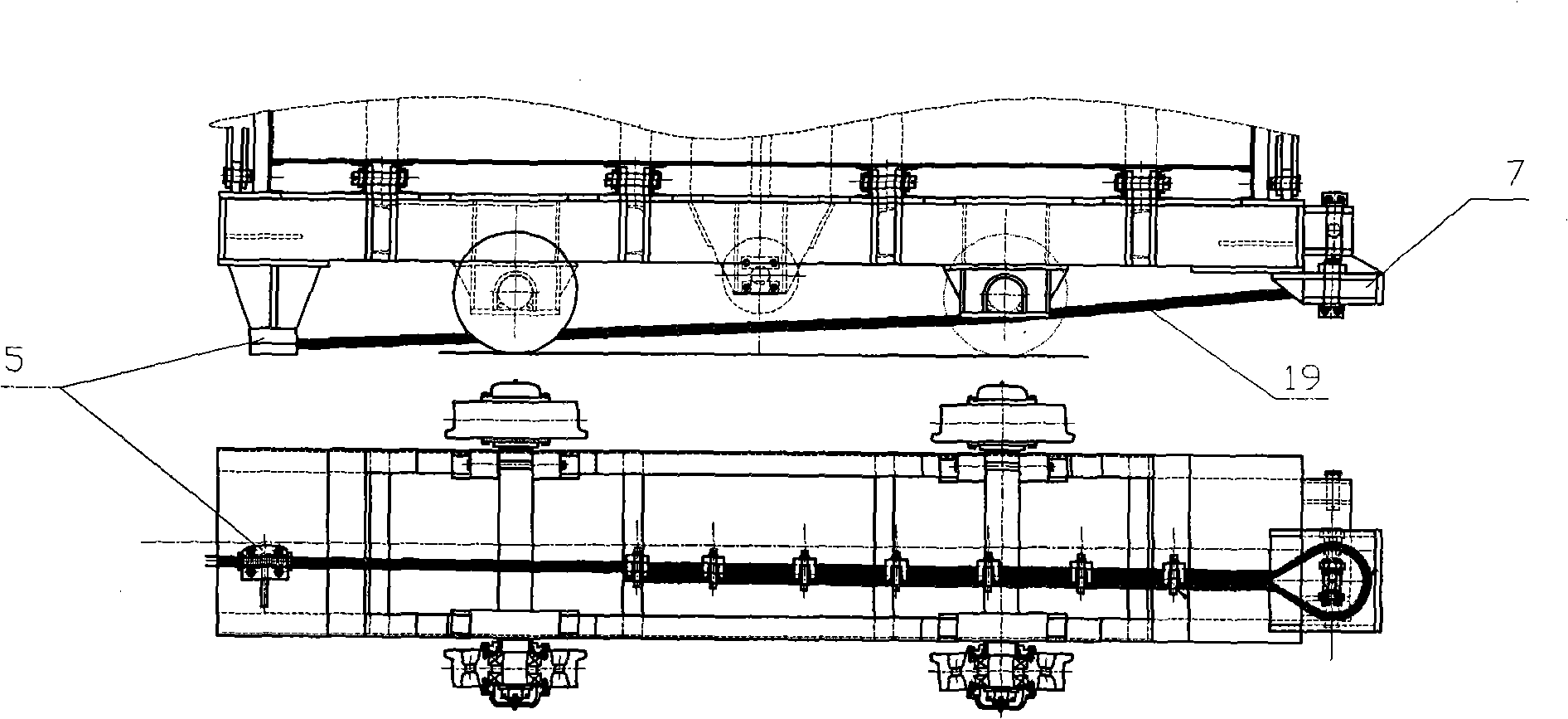

[0037] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention includes the following specific implementation steps:

[0038] (1) Install lifting equipment 1

[0039] General inclined shaft hoisting equipment 1 such as hoist is installed at hole design position. The installation technical requirements are the same as those of the ordinary inclined shaft transportation system.

[0040] (2) laying track 2

[0041] The straight section adopts two-lane four-lane transportation, and the laying of track 2 has the same technical requirements as the track laying of ordinary inclined shaft transportation system. The transportation in the curved section adopts single-track double-track, and the type and gauge of the rails are the same as those in the straight section.

[0042] (3) Install the signaling system

[0043] The signal communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com