Ultra-low temp refrigerating device

An ultra-low temperature freezing and freezer technology, which is applied to household refrigeration devices, refrigerators, refrigeration components, etc., can solve the problems of reduced freezing capacity of shielded freezers, reduced freezing capacity of JT freezers, insufficient freezing capacity of shielded freezers, etc. The effect of suppressing the fluctuation of the capability and realizing the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

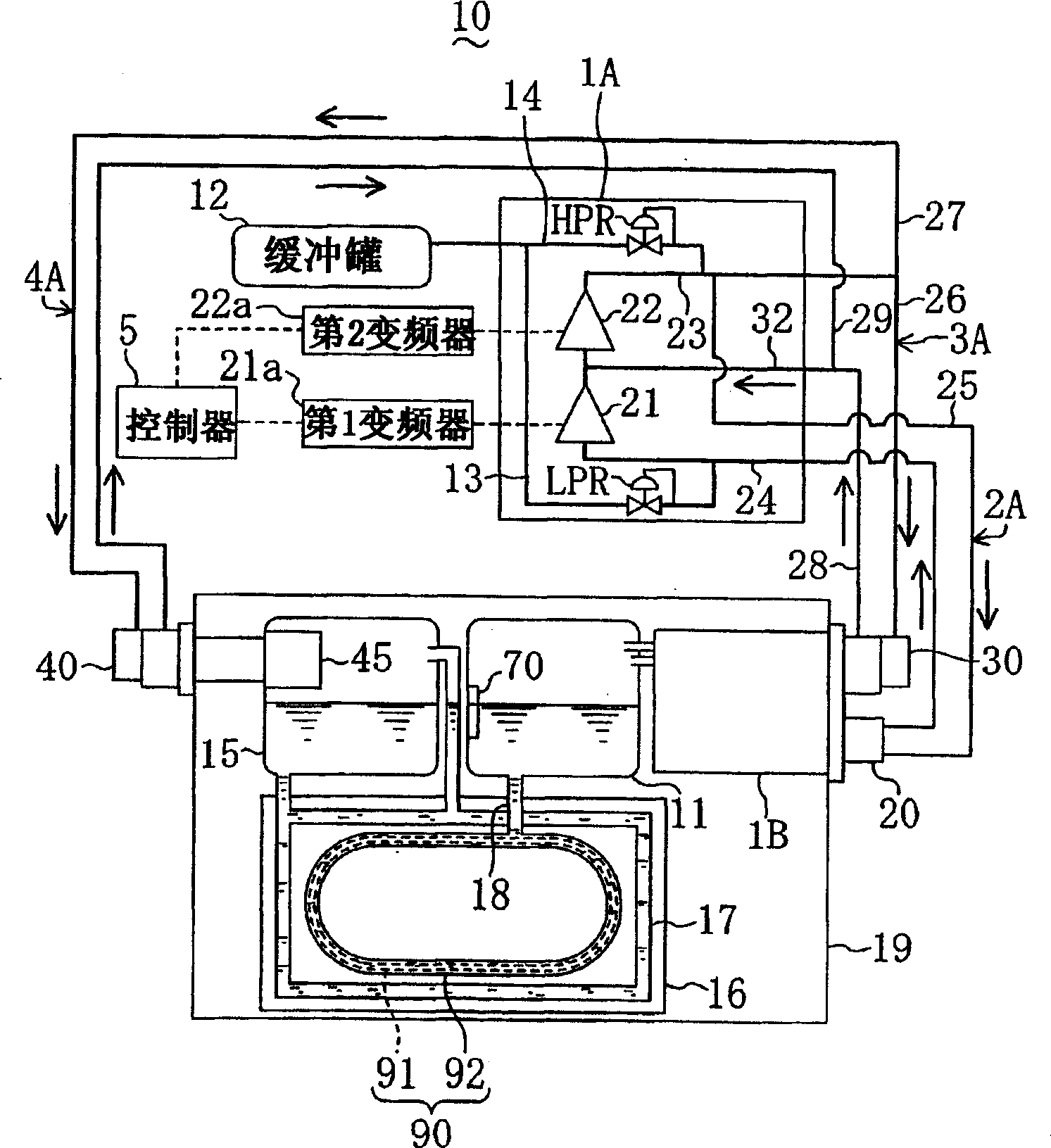

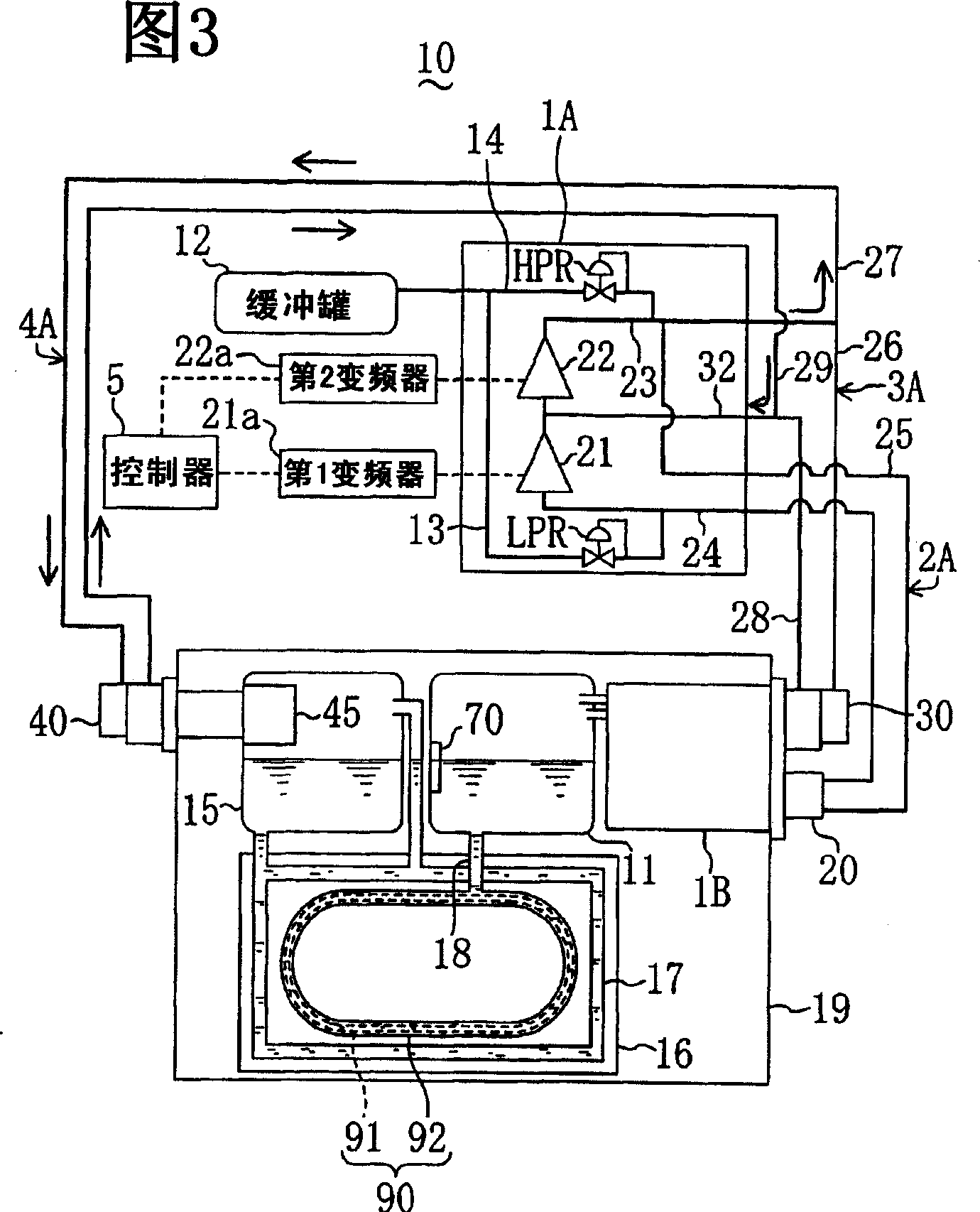

[0032] figure 1 The shown cryogenic refrigeration device 10 is a so-called vehicle-mounted refrigeration device mounted on a superconducting linear electric locomotive (not shown), and is a device for freezing the superconducting magnet 90 of the superconducting linear electric locomotive.

[0033] -Composition of ultra-low temperature freezer-

[0034] The cryogenic freezer 10 includes a helium refrigerator 20 for generating, cooling and holding liquid helium, and a nitrogen refrigerator 40 for cooling and holding liquid nitrogen. The helium refrigerator 20 has a precooling refrigerator 30 for precooling helium. These helium refrigerators 20 and nitrogen refrigerators 40 both use helium as a refrigerant.

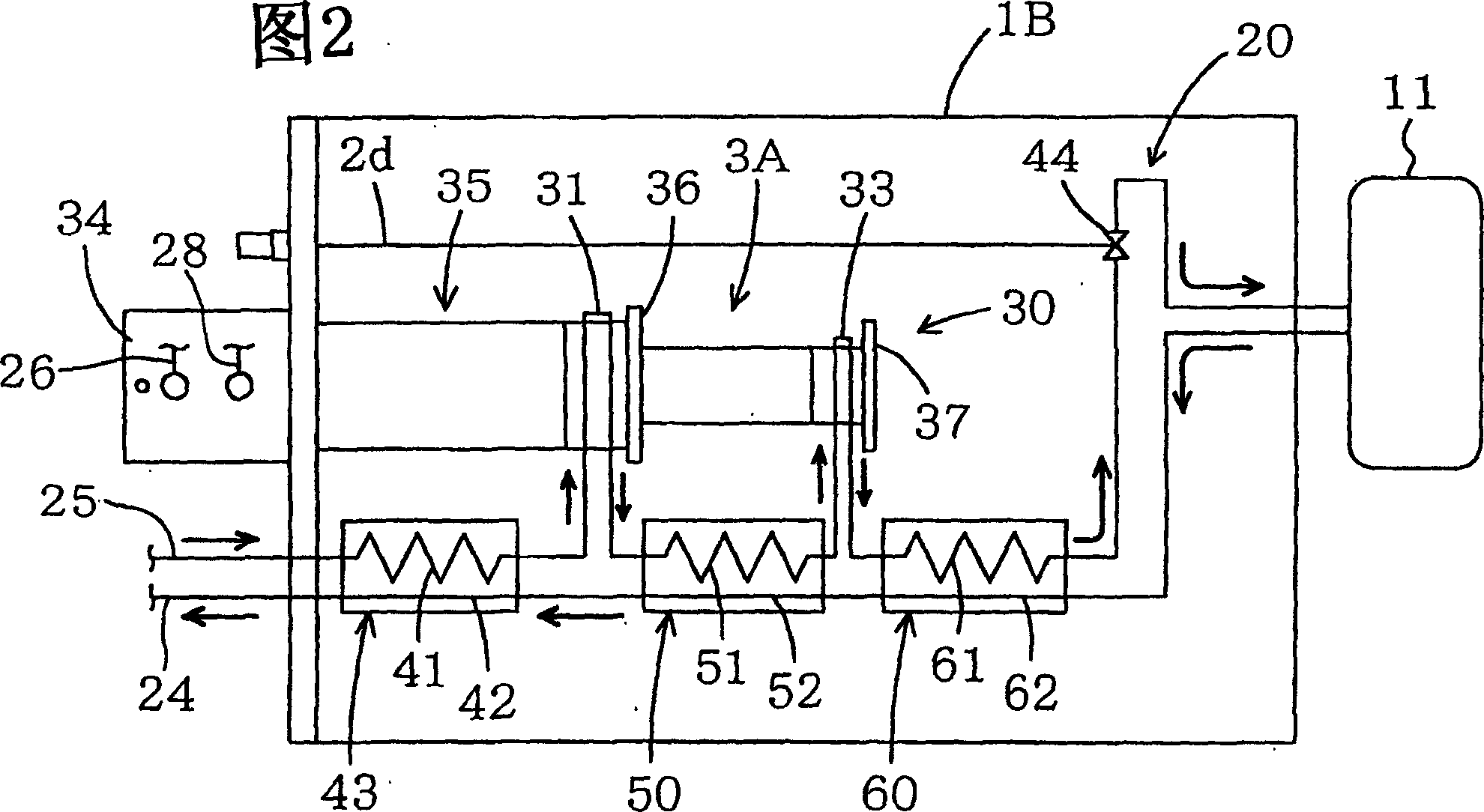

[0035] The cryogenic refrigerator 10 is equipped with a helium refrigerator 20 having a first circuit 2A as a JT circuit and a precooling circuit 3A as a refrigeration circuit of a precooling refrigerator 30, and a second refrigerant circuit as a nitrogen refrigerator 40....

Embodiment 2

[0073] As shown in FIG. 4 , instead of the liquid level sensor 70 , a pressure sensor 71 for detecting the internal pressure of the buffer tank 12 may be provided as means for detecting the amount of liquid helium in the helium tank 11 .

[0074] As mentioned above, the buffer tank 12 for supplying and recovering helium gas is installed on the ultra-low temperature freezer 10, and the pressure of each circuit 2A, 3A, and 4A circulating helium is maintained at a predetermined pressure. A certain correlation was found between the amount of liquid helium in 11 and the internal pressure of the buffer tank 12. That is, when the evaporation amount of liquid helium in the helium tank 11 is large, the amount of liquid helium decreases and the internal pressure of the buffer tank 12 increases. Contrary to this, when the evaporated amount of liquid helium of the helium tank 11 decreases, the amount of liquid helium increases and the internal pressure of the buffer tank 12 decreases.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com