Stranded wire penetrating sleeve winding and rubber coating machine

A technology of casing and rubber wrapping machine, which is applied in the manufacture of coils, electrical components, inductors/transformers/magnets, etc. It can solve the problems of increased labor costs and time costs, burrs on the nozzles, and inability to connect together. Achieve the effect of reducing labor cost and time cost, shortening assembly production cycle, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to understand the essence of the present invention more clearly and intuitively.

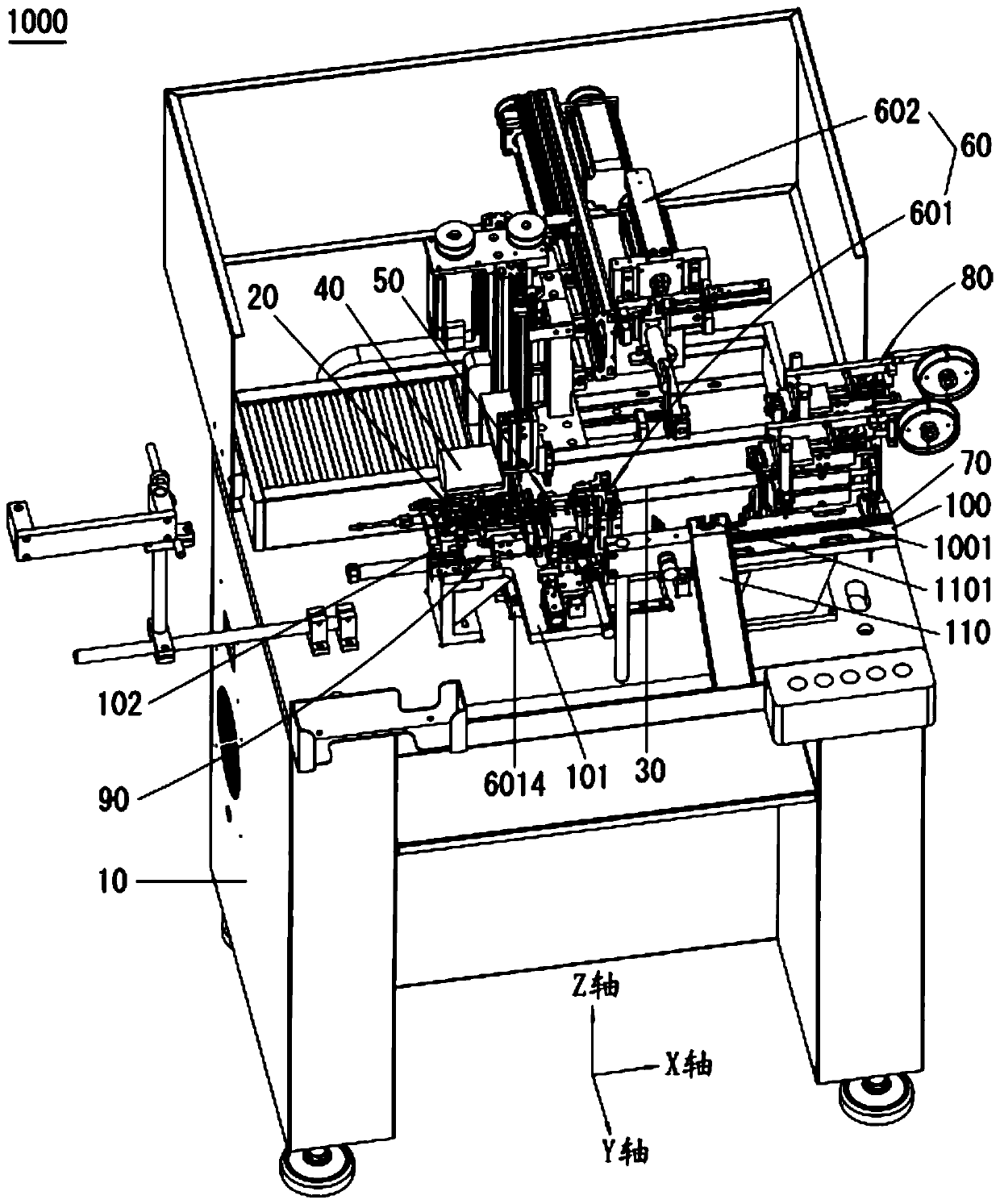

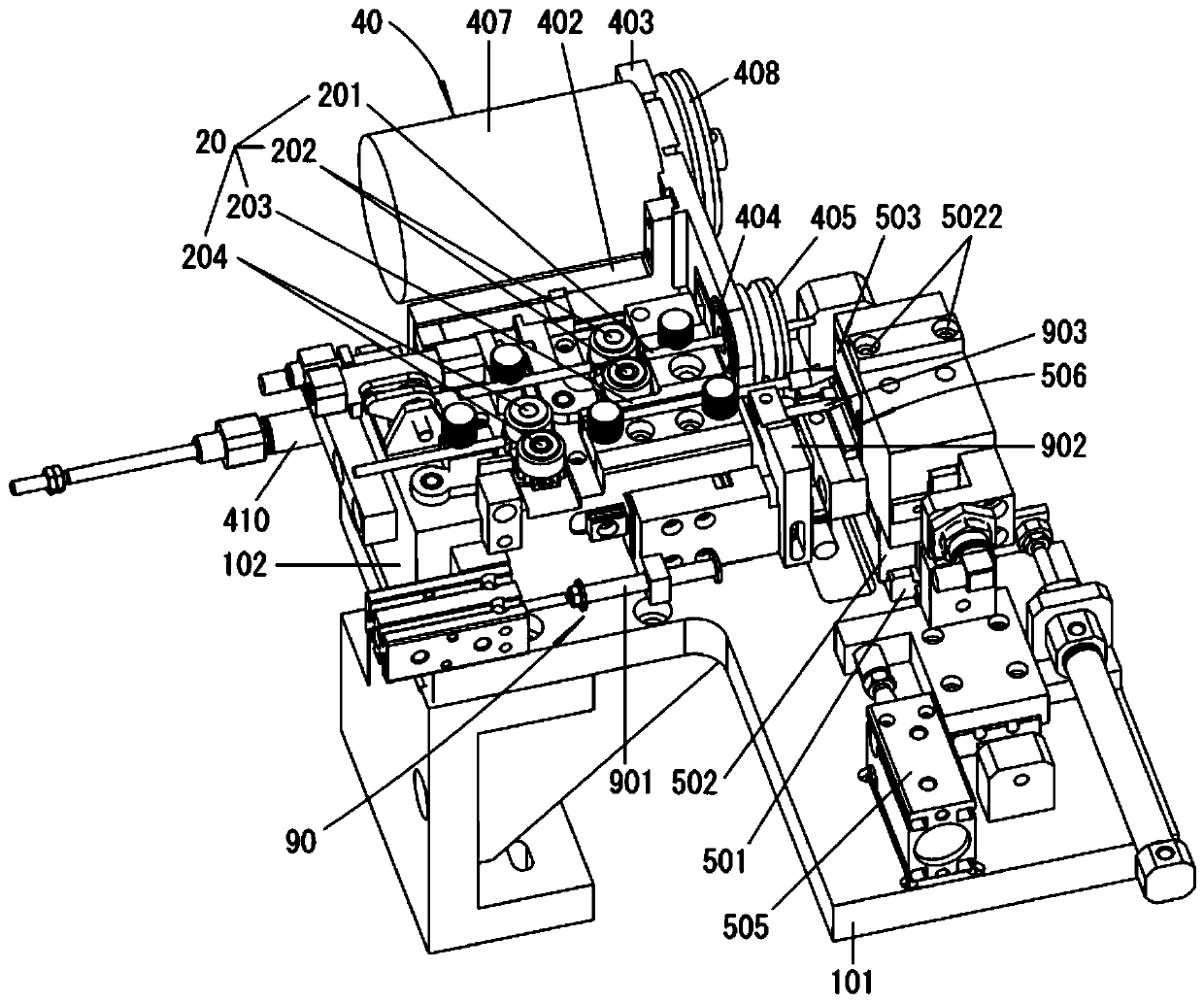

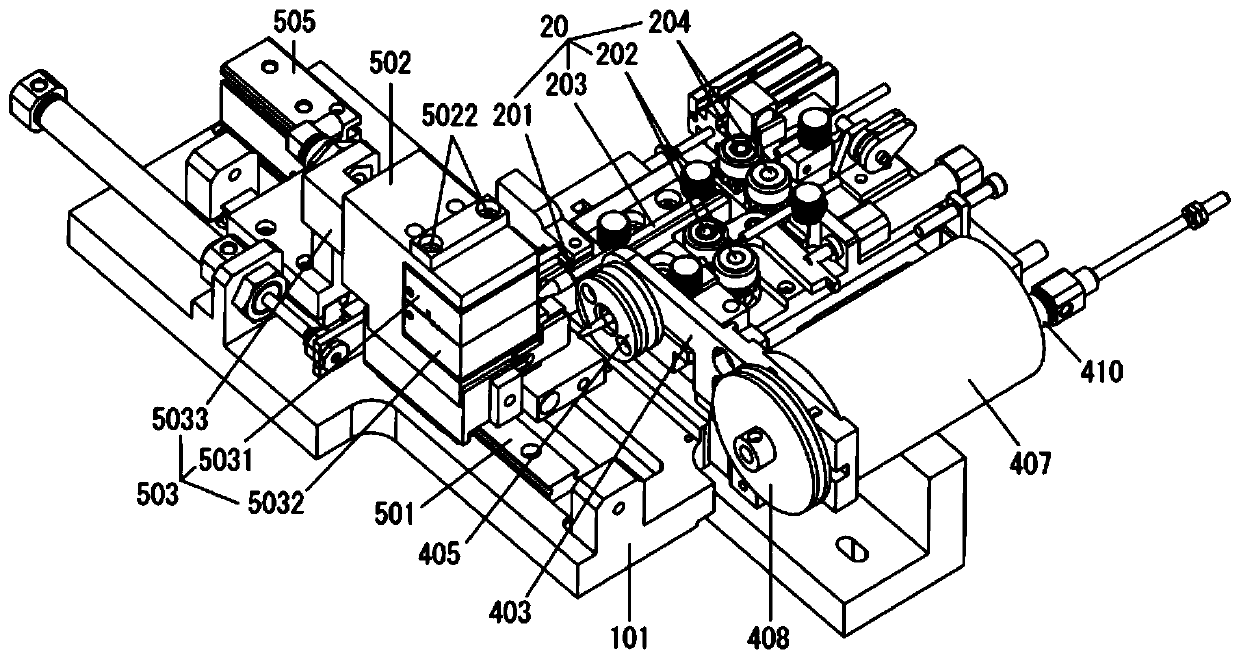

[0091] combine Figure 1-Figure 14 shown;

[0092] A twisted wire threading sleeve winding wrapping machine 1000 provided by the present invention includes a frame 10 and a main controller located on the frame 10, and also includes:

[0093] Wire feeding and tube feeding mechanism 20; the wire feeding and tube feeding mechanism 20 is connected to the main controller for forward feeding wire 30 and pipe;

[0094] Wire twisting mechanism 40; the wire twisting mechanism 40 is connected to the main controller, and is arranged on the front side of the wire feeding and pipe feeding mechanism 20, and is used for conveying the wire and pipe feeding mechanism 20 forward. A plurality of twisted wires 30 are stranded, so that a plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com