Short-process long material endless rolling production line and short-process long material endless rolling method

A technology of endless rolling and production line, applied in the direction of metal rolling, which can solve the problems of long waiting time for continuous casting slabs, short rolling time of a single piece, high temperature loss, etc., to facilitate temperature supplementation and temperature control, and reduce energy consumption The effect of consumption and cross-sectional temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

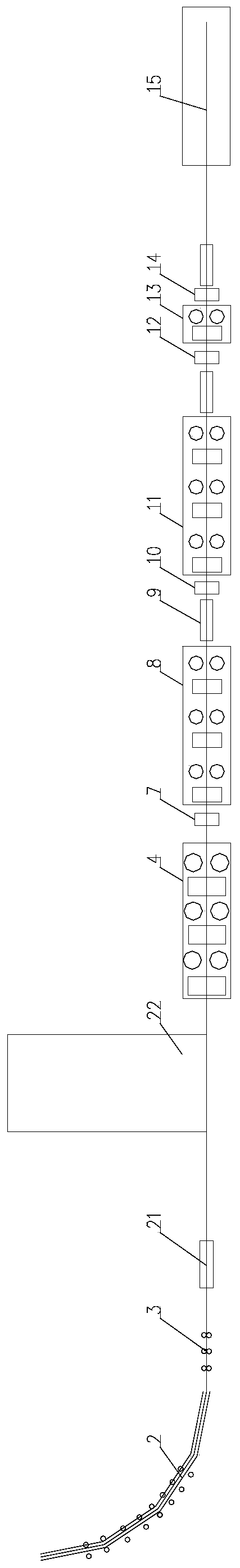

[0039] like figure 2 The short-process long product endless rolling production line shown includes steelmaking furnace 1, continuous casting machine 2, tension leveler 3, rough rolling production line, intermediate rolling production line, finishing rolling production line, and sizing 13 production lines closely connected in sequence and cooling bed 15, the rough rolling production line includes rough rolling unit 4, emergency shears and cooling bed 5, heat preservation device 6 and first cutting flying shear 7 in turn, heat preservation device 6 is the billet temperature supplement after rough rolling, tension leveler 3 The distance between the entrance and the entrance of the rough rolling unit 4 is 9-30m; the middle rolling production line includes the middle rolling unit 8, the water cooling box 9 and the second cutting flying shear 10; the finishing rolling production line includes the finishing rolling unit 11, the water cooling box 9 and the The third cutting head flyi...

Embodiment 2

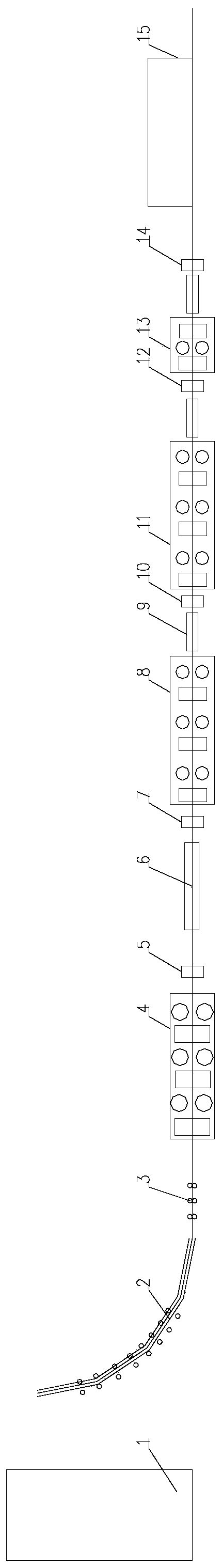

[0049] like image 3 The difference between Embodiment 2 and Embodiment 1 of the short-flow endless rolling production line for long products shown is that Embodiment 2 lacks a reducing and sizing production line.

[0050] A short process endless rolling method for long products, comprising the following steps:

[0051] A. Steelmaking: use 100-130t electric arc furnace plus external refining method for smelting;

[0052] B. Continuous casting: single-machine single-strand continuous casting machine 2 is used to produce billets or rectangular billets, and the cross-section of continuous casting billets is 150mm×150mm~180mm×180mm or equal-area rectangular billets;

[0053] C. Rough rolling unit rolling: the square billet heated in step B is rolled in 6 rough rolling units for 4 passes by means of horizontal and vertical alternate or flat roll rolling, and for rectangular billets, 5 or 7 passes The second roughing group 4 is rolled, no matter it is a rectangular billet or a squ...

Embodiment 3

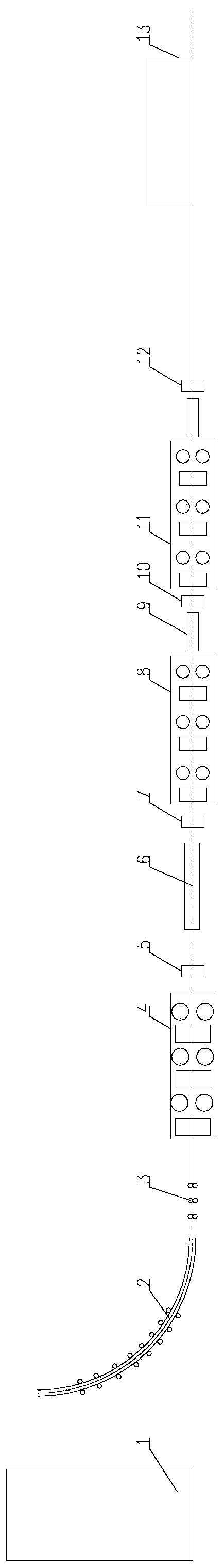

[0059] like Figure 4 In the shown short-process endless rolling production line for long products, the difference between embodiment 4 and embodiment 1 is that the finishing rolling group 11 in embodiment 4 includes a pre-finishing rolling group 16 and a fourth cutting head flying shear 17. The 13-diameter production line includes the sizing-reducing 13 unit, the water-cooled box 9 and the high-speed flying shear 18 in turn, and the sizing-reducing 13 production line includes a laying machine 19 and a lapping device 20.

[0060] A short process endless rolling method for long products, comprising the following steps:

[0061] A. Steelmaking: use 100-130t electric arc furnace plus external refining method for smelting;

[0062] B. Continuous casting: single-machine single-strand continuous casting machine 2 is used to produce billets or rectangular billets, and the cross-section of continuous casting billets is 150mm×150mm~180mm×180mm or equal-area rectangular billets;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com