Patents

Literature

72results about How to "Good warming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

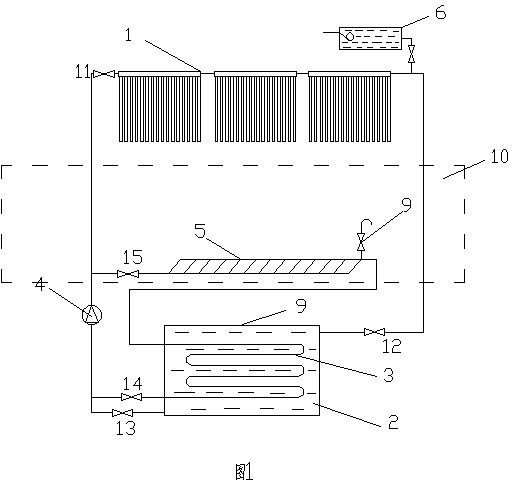

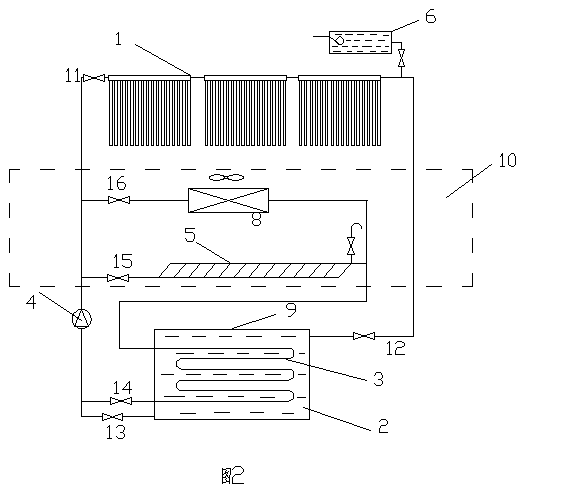

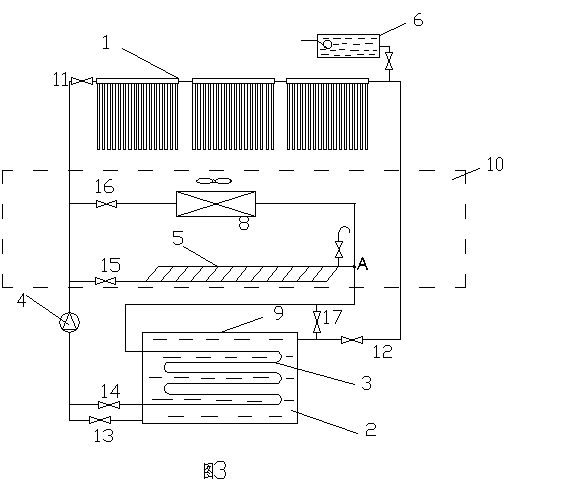

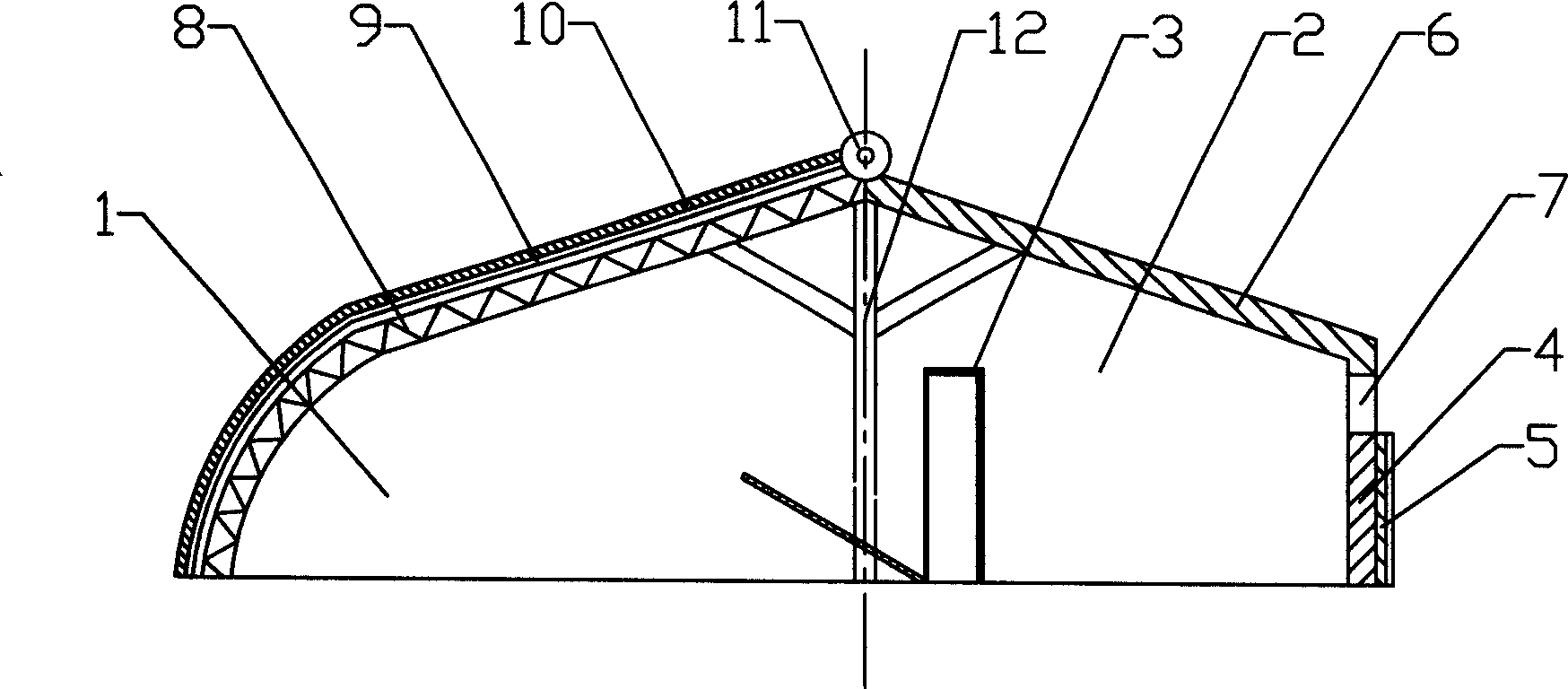

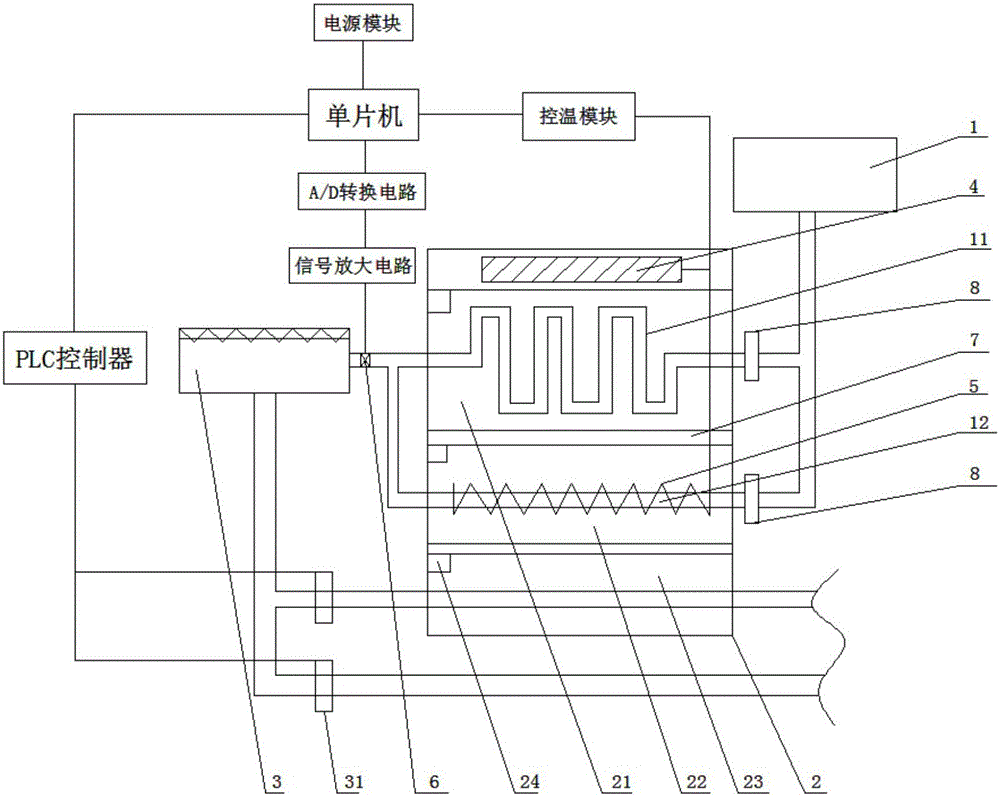

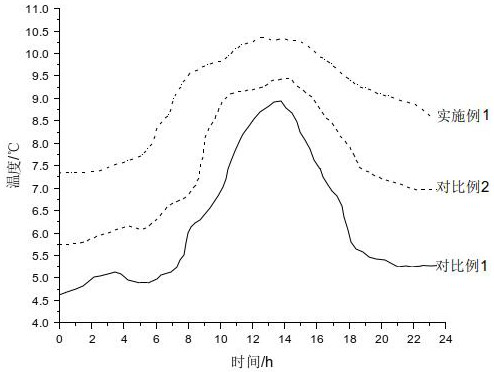

System for comprehensively utilizing energy sources in greenhouse

InactiveCN102986479ATo promote metabolismReduce consumptionClimate change adaptationRenewable energy machinesPlant rootsFluid infusion

The invention relates to a greenhouse energy source comprehensively utilizing system, in particular to a system for comprehensively utilizing energy sources in a greenhouse and belongs to the technical field of the greenhouse. The system is suitable for being used under the conditions of temperature difference between day and night, low temperature in winter and continuous overcast and rainy seasons and mainly improves various energy source utilizing efficiency of the greenhouse through various energy source utilizing technologies. The system for comprehensively utilizing energy sources in the greenhouse comprises a solar heat collecting system, an underground heat storage system, an efficient heat exchange system, a control system, an underground cooling system, a fluid infusion water tank, a circulating pump, a fan and a heat storage tank body. The system remarkably improves the greenhouse energy source utilizing rate by combining a solar energy utilizing technology, a heat exchange technology and a heat storage technology in greenhouse warming, has great technological and economic advantages, can maintain appropriate soil temperature required by plant root systems and ensure the requirement of greenhouse plants to the house temperature, can enable crops to rapidly grow and being high in yield, high in quality and benefit, improves the solar energy utilizing rate of an existing greenhouse, reduces existing energy consumption and production cost, prolongs a production period, and has high economic and social benefits.

Owner:SHAOXING INST OF TECH COLLEGE OF ENG PEKING UNIV BIOENG CENT

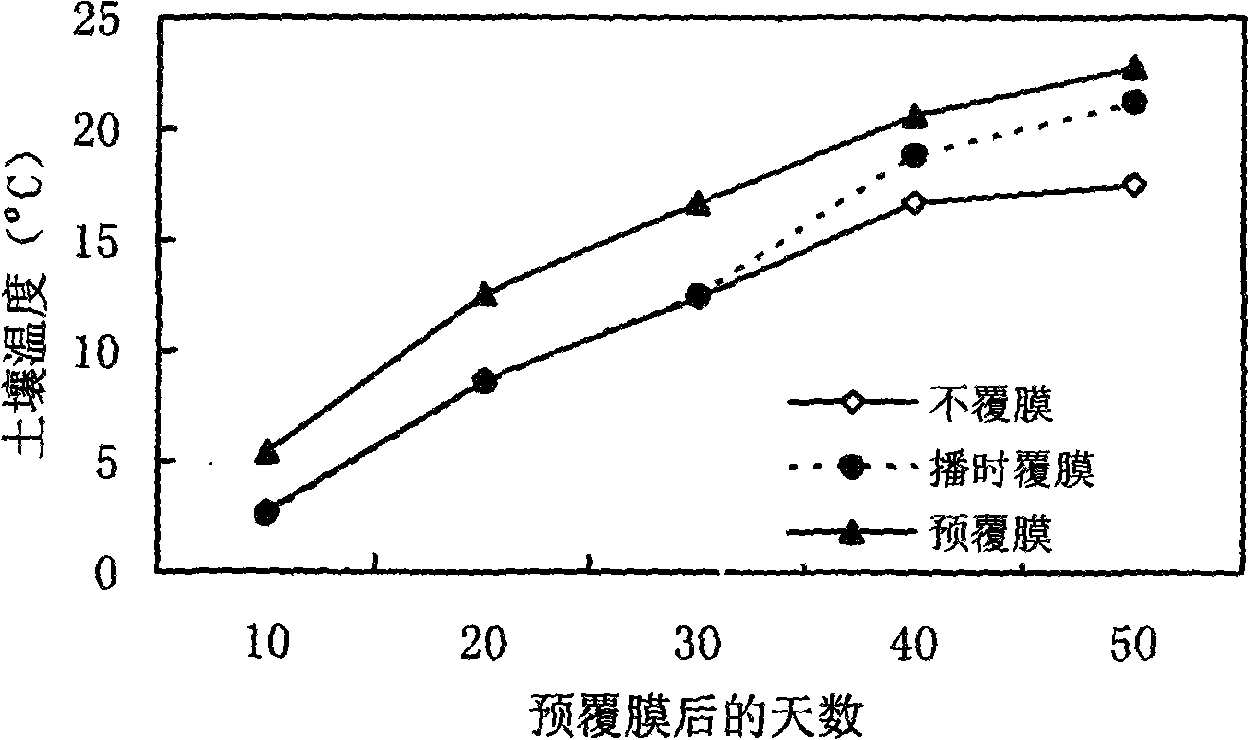

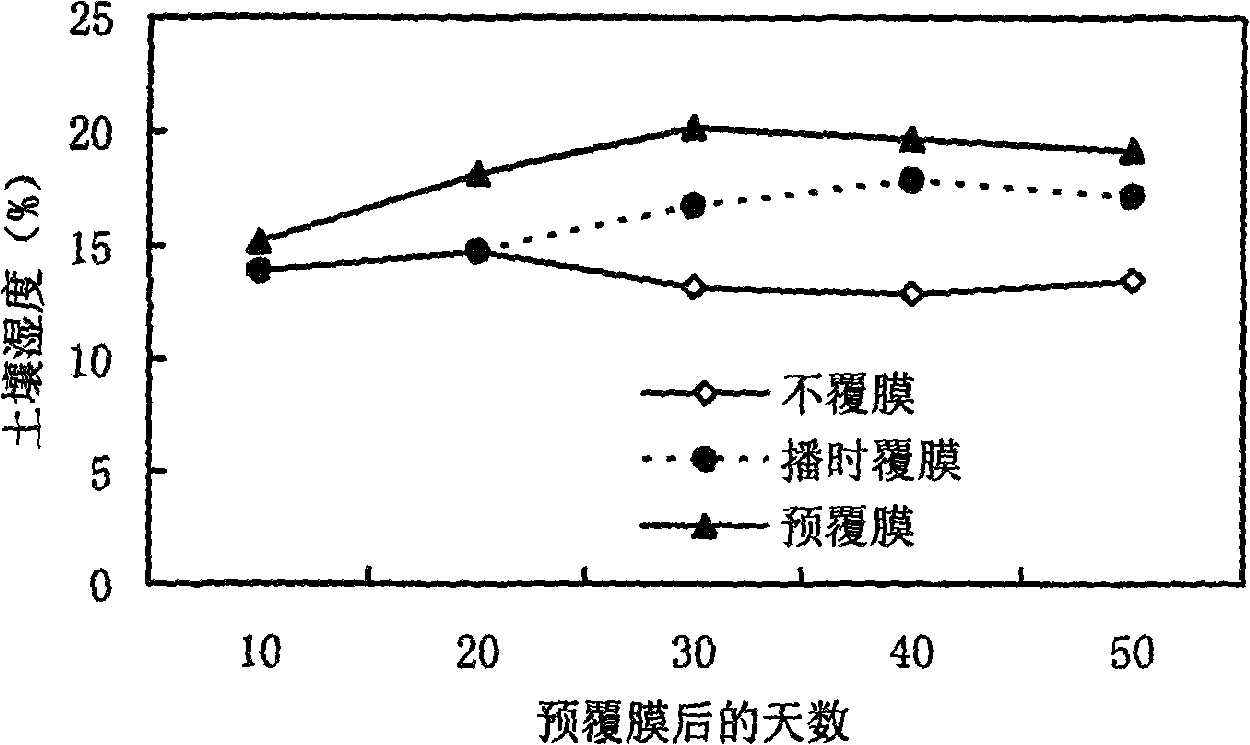

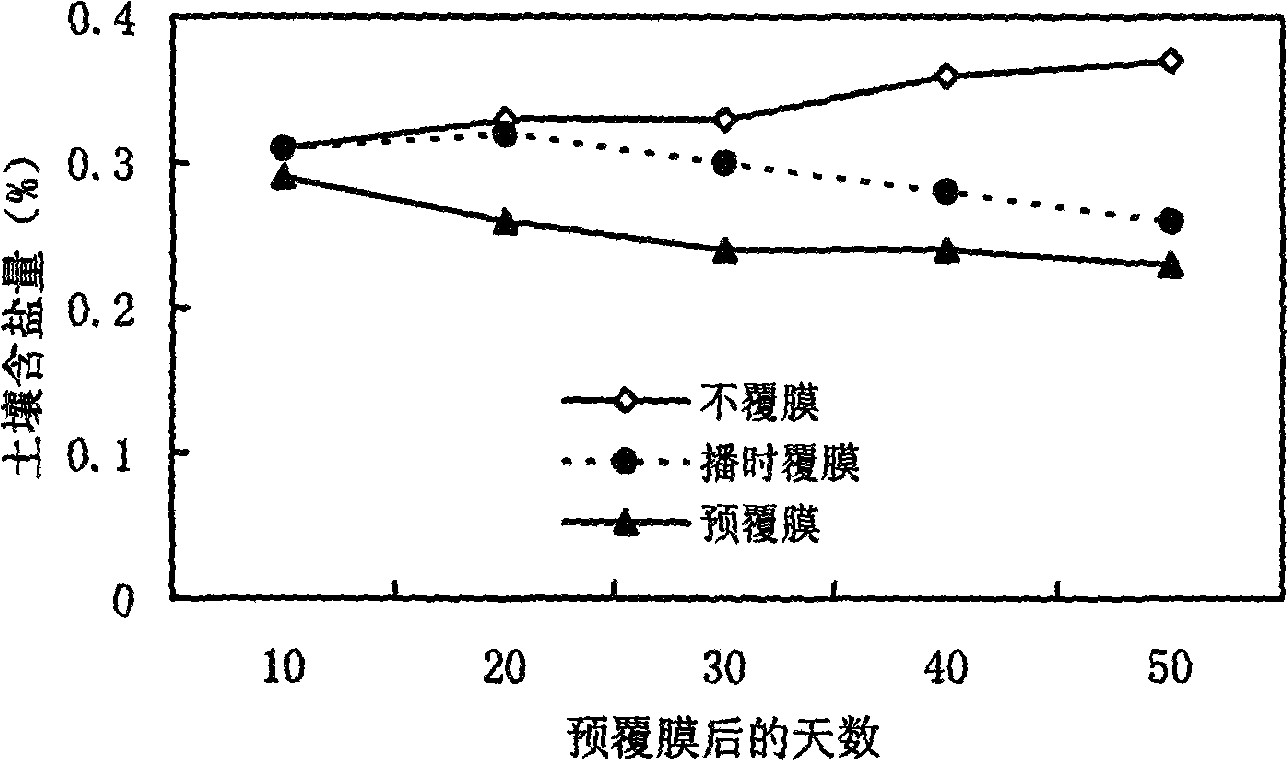

Alkaline land cotton pre-coating film seedling establishment method

InactiveCN101258809ASeedlings grow fastThe effect of increasing production is remarkablePlantingFertilising methodsComing outAlkali soil

The invention discloses a seedling formation method in alkaline lands by pre-coating film on cotton, which aims at increasing the seedling formation rate of the cotton in alkaline lands and realizing seedlings full and strong. The method of the invention is characterized in that: cotton fields having the salt content of below 0.4% and has certain accumulative rain and snow in winter are thawed in early spring, then ditches are opened in the rows of the pre-sowed cotton, and 2 tons of miscellaneous manure and 40 to 60kg of compound fertilizer which contains about 15 percent of N, about 15 percent of P2O5 and about 15 percent of K2O are fertilized, and then mulching film is used for covering the ditches immediately after the ditches are covered with soil and raked; as for an alkaline land with salt content of more than 0.4 percent, 80m<3> of fresh water is irrigated for each mu (mu: a Chinese unit of area, 1 / 15 of a hectare) at the end of winter to restrain salt content, ditches are opened and then miscellaneous manure and N-P-K compound fertilizer are fertilized in the early of middle of March, and film is covered after the land is prepared. The cotton fields which are leveled, fertilized and pre-coated with film are steadily passes earth temperature of 15 DEG C at the position of 5cm below the film, then bunch planting the ditinted and coated cotton seeds according to preset row spacing and plant spacing. The cottons are thinned out after the young seedling grow tidily, and final singling is carried out after two true leaves come out. The method of the invention achieves the functions of increasing temperature, water preserving and controlling salt by pre-coating the mulching film, promotes the seedling emergency and formation of cottons in alkaline land sand realizes synergetic salt control effect by concentrated fertilization under the film, thereby having significant yield increasing effect.

Owner:SHANDONG COTTON RES CENT

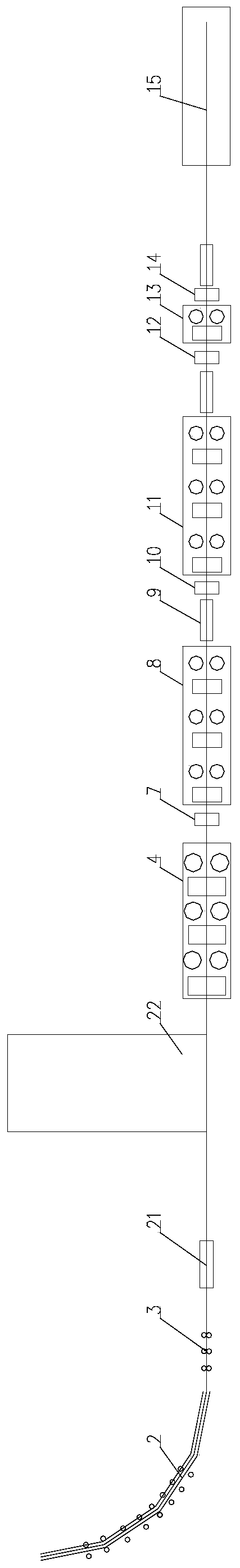

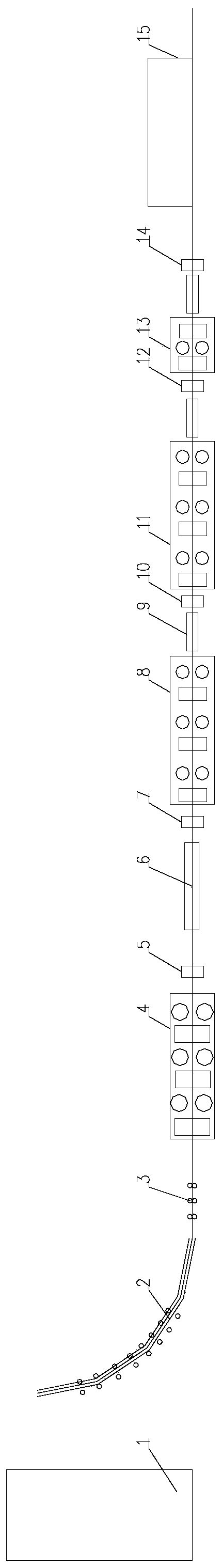

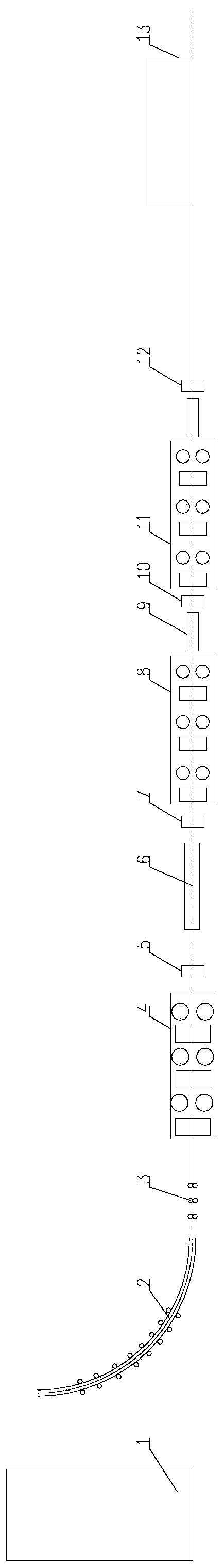

Short-process long material endless rolling production line and short-process long material endless rolling method

PendingCN110052495AGood warming effectLow powerMetal rolling arrangementsProduction lineEconomic benefits

The invention belongs to the technical field of the ferrous metallurgy industry, and relates to a short-process long material endless rolling production line and a short-process long material endlessrolling method. The short-process long material endless rolling production line comprises a steel making furnace, a continuous casting machine, a withdrawal and straightening machine, a rough rollingproduction line, an intermediate rolling production line, a finish rolling production line, a reducing and sizing mill production line and a cooling table. The steel making furnace, the continuous casting machine, the withdrawal and straightening machine, the rough rolling production line, the intermediate rolling production line, the finish rolling production line, the reducing and sizing mill production line and the cooling table are closely connected in sequence. The rough rolling production line comprises a rough rolling unit, an accident shear and cooling table, a heat preservation deviceand a pair of first end cutting flying shears in sequence. The heat preservation device supplements the heat for a casting blank which is subjected to rough rolling operation, and the separation distance between an inlet of the withdrawal and straightening machine and an inlet of the rough rolling unit ranges from 9m to 30m. The intermediate rolling production line comprises an intermediate rolling unit, a water cooling tank and a pair of second end cutting flying shears in sequence. The finish rolling production line comprises a finish rolling unit, a water cooling tank and a pair of third end cutting flying shears in sequence. The reducing and sizing mill production line comprises a reducing and sizing mill unit, a water cooling tank and a pair of fixed-length flying shears in sequence.By the adoption of the short-process long material endless rolling production line, the technological arrangement is simple, the separation distance between the continuous casting machine and the rough rolling unit is small, the rough rolling gripping operation is facilitated, the relative power consumption of the heat preservation or supplement which is conducted after the rough rolling operation is accomplished is low, the cost is low, the industrial production is easily achieved, and the short-process long material endless rolling production line has the obvious economic benefit.

Owner:CISDI ENG CO LTD +1

Virus-free basic potato seed production technology

InactiveCN102017888ANot easy to weather and thinEasy to useCultivating equipmentsSoilless cultivationGramPlanting seed

The invention provides a virus-free basic potato seed production technology comprising the following three steps of seedbed treatment, cutting and management. The technology is characterized in that washed river sand is employed as the seedbed base, the management is carried out according to a certain method, and the formula of used nutrient solution is that 0.24 grams of N, 0.2 grams of P2O5 and0.48 grams of K2O are added in each liter of water and 0.6 grams of N, 0.6 grams of P2O5 and 0.6 grams of K2O are added in each liter of water. By adopting this technology, the yield of virus-free basic potato seeds per unit area is high, and the virus-free basic potato seeds are large in size, with 68% greater than 3 grams. As a technology for planting seeds for production, the technology of theinvention is low in requirement and high in survival rate.

Owner:昆明市农业科学研究院

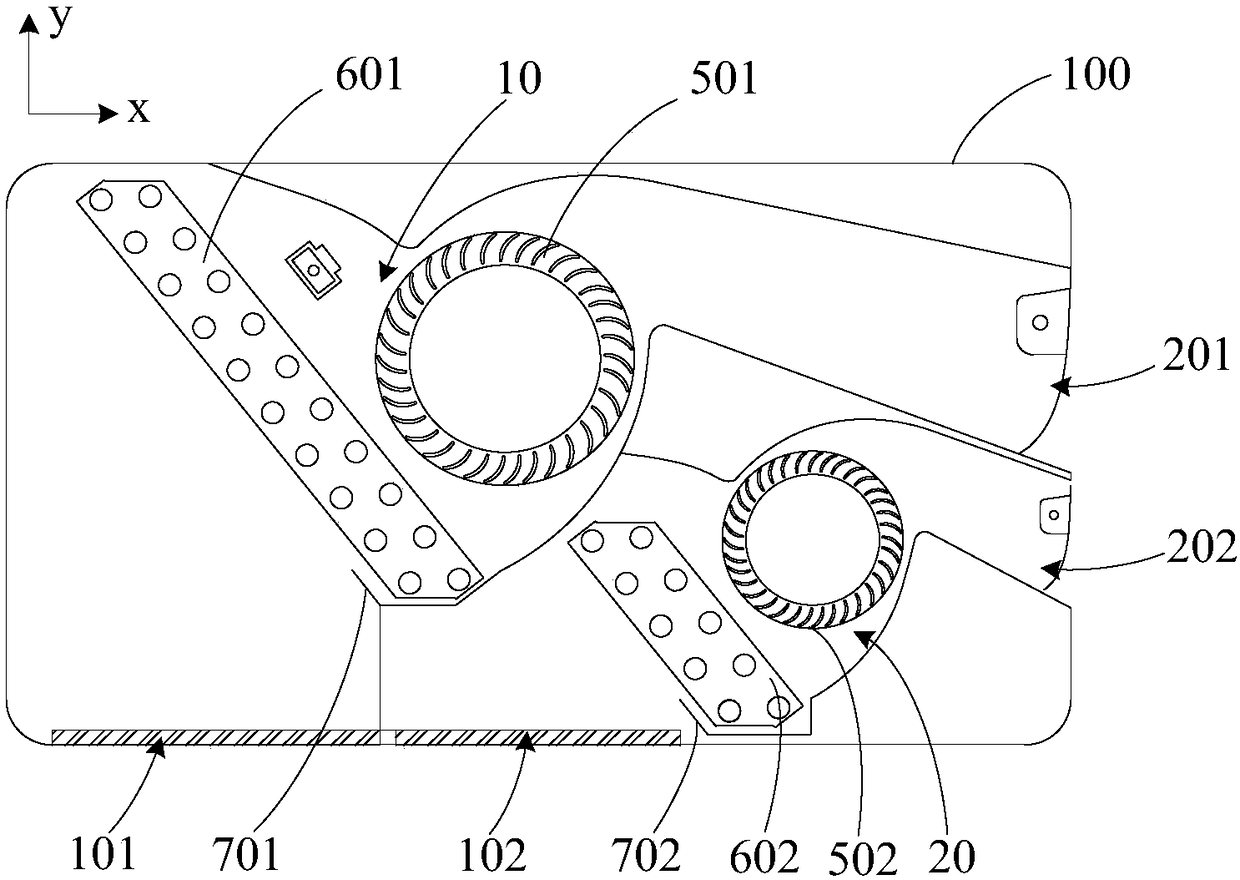

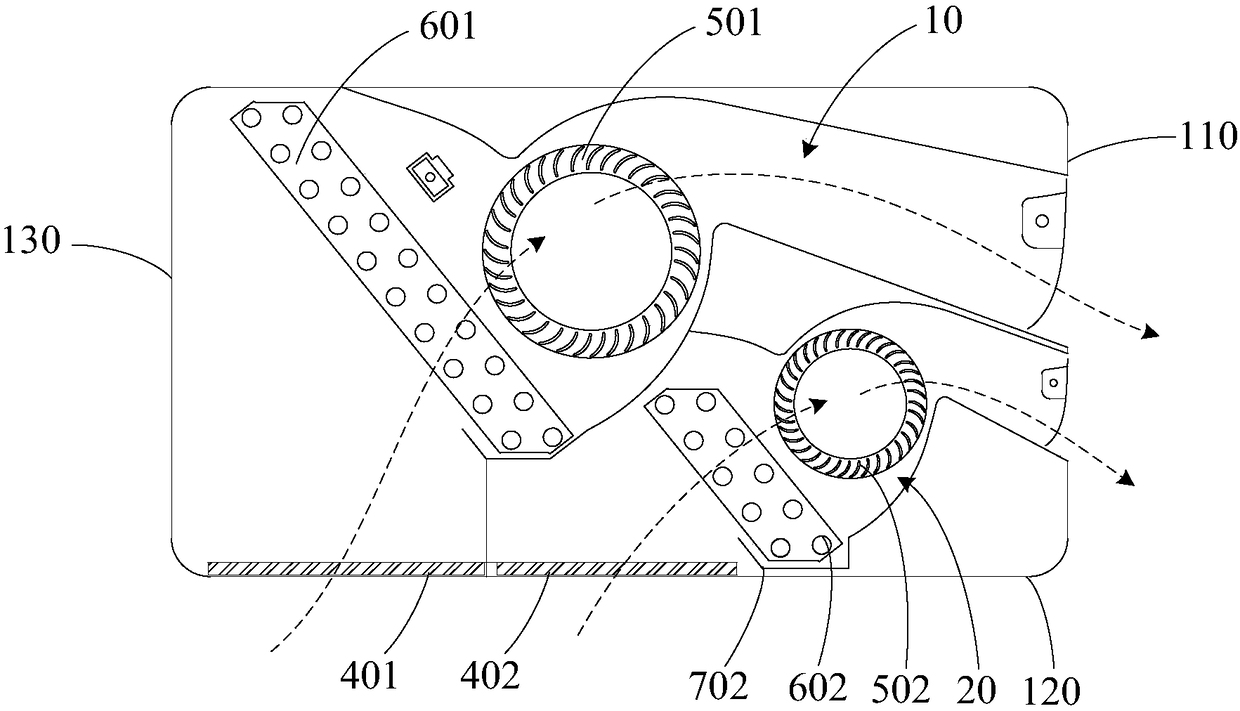

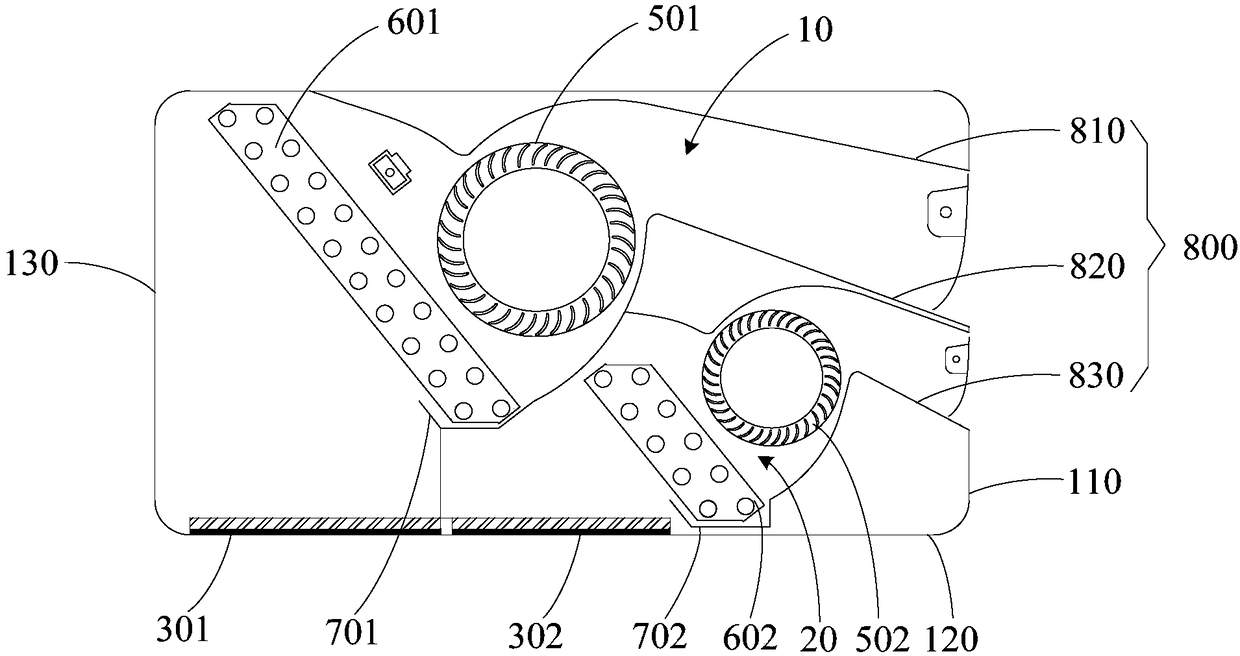

Indoor unit of air conditioner and air conditioner

PendingCN108278683AImprove comfortAvoid blowing toCondensate preventionLighting and heating apparatusEngineeringFlue

The invention discloses an indoor unit of an air conditioner and the air conditioner. The indoor unit of the air conditioner comprises a housing, a first wind wheel, a second wind wheel, a first heatexchanger, a second heat exchanger and a controller, wherein a first air outlet and a second air outlet in the lower side of the first air outlet are formed in a panel of the housing; a first air inlet and a second air inlet are formed in positions, different from a top plate and the panel of the housing, of the housing; a first flue which communicates with the first air inlet and the first air outlet and a second flue which communicates with the second air inlet and the second air outlet are formed inside the housing; the first wind wheel is mounted in the first flue; the second wind wheel ismounted in the second flue; the first heat exchanger is mounted in the first flue and is close to the first wind wheel; the second heat exchanger is mounted in the second air flue and is close to thesecond wind wheel; and the controller is connected with the first wind wheel and the second wind wheel. The indoor unit of the air conditioner disclosed by the invention can solve the problem that comfort under a heating mode of the indoor unit of a conventional air conditioner is poor.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

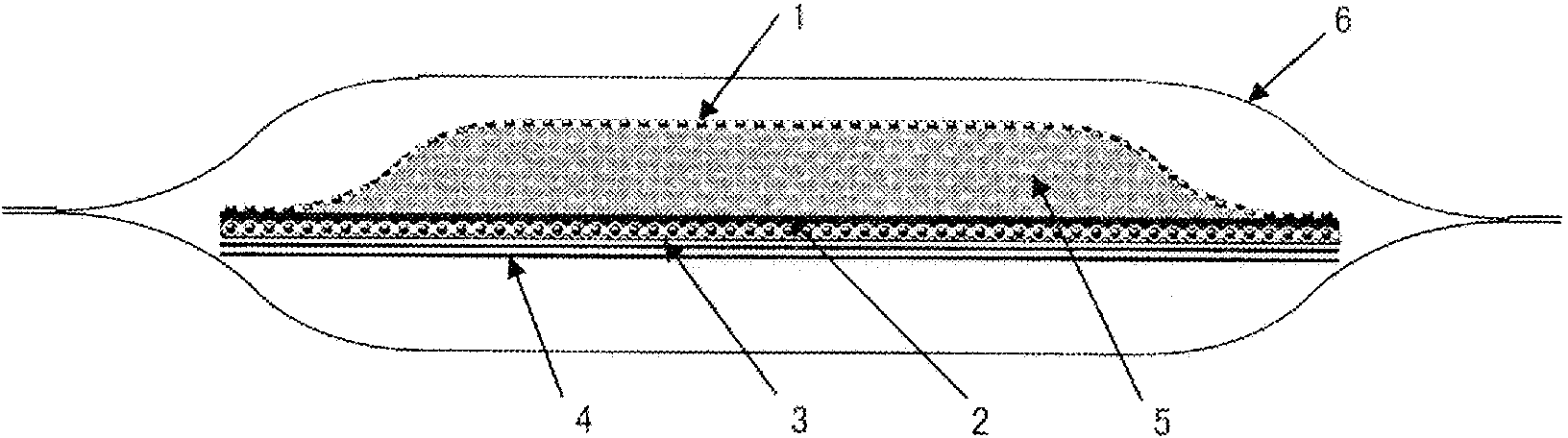

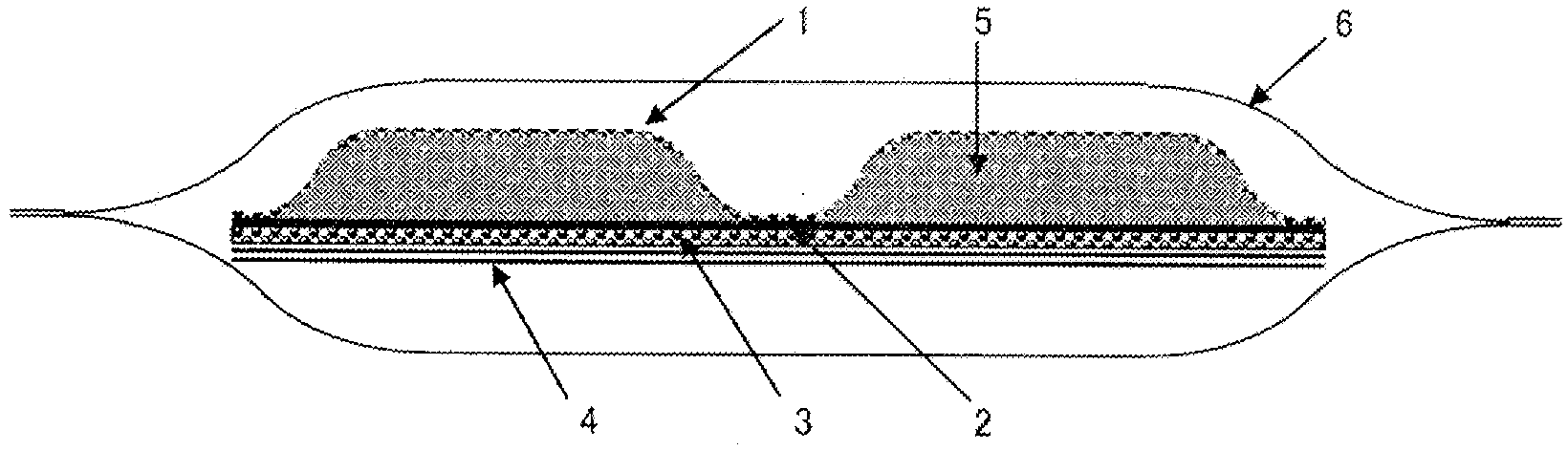

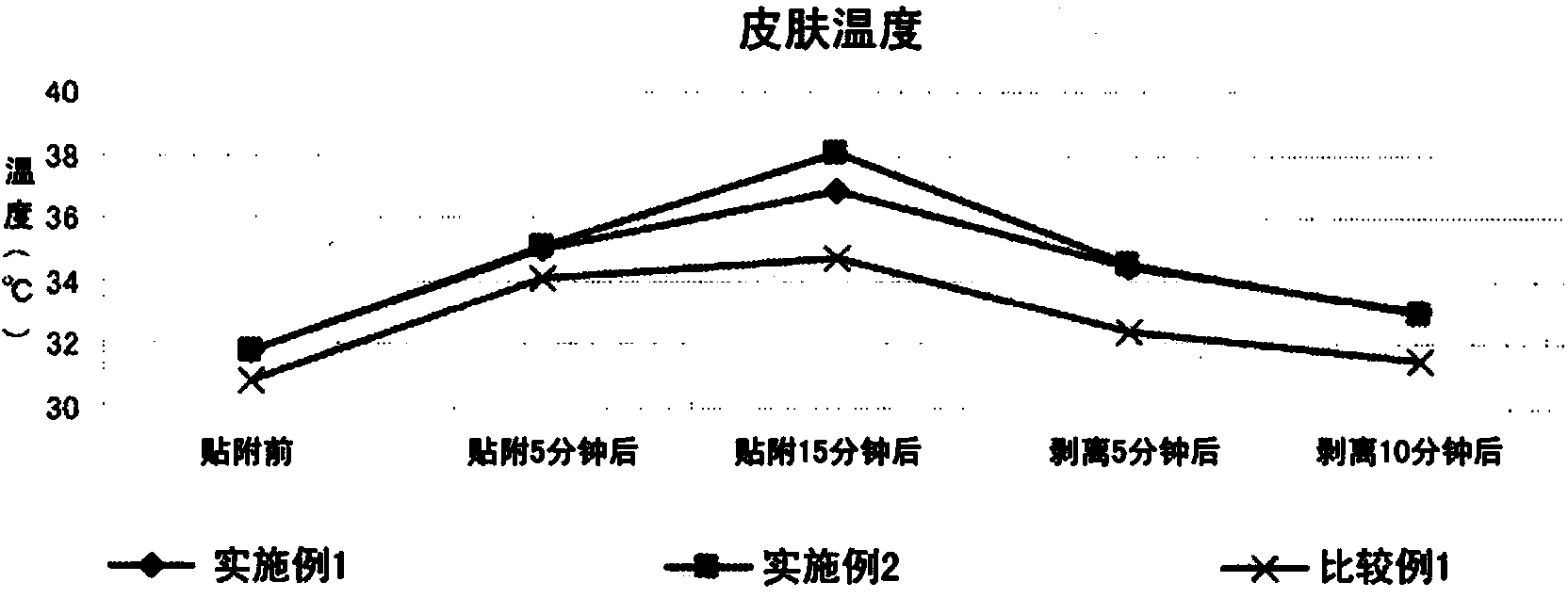

Heat generation tool

InactiveCN104394814ASoothe the coldEffectively warmTherapeutic coolingTherapeutic heatingBoiling pointHeating effect

Provided is a heat generation tool which is capable of easing sensation of coldness when applying to the skin and warming the skin efficiently, supplies oil effectively to the skin, and eases sensation of coldness after peeling from the skin so as to provide a high heating effect even after use. This heat generation tool comprises an adhesive layer, the specific heat at 20°C of the adhesive layer being less than 3 J / g.K. The adhesive layer contains a base and an oil with a specific heat at 20°C of less than 3 J / g.K and a boiling point at 1 atmosphere of 100°C or more, the oil content in the adhesive layer being 30 to 90 weight%.

Owner:KOBAYASHI PHARMA CO LTD

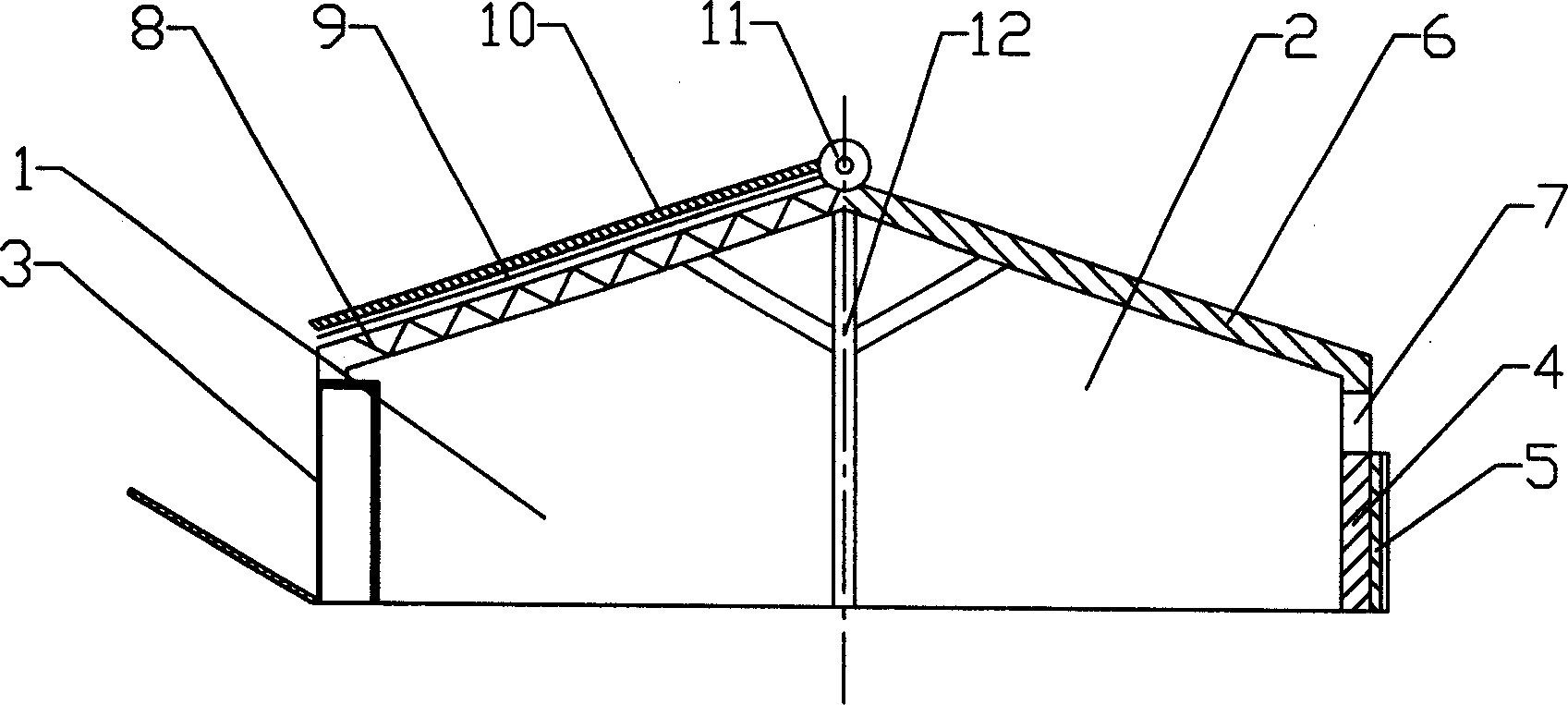

Multi purpose solar energy house

InactiveCN1914987ANot restricted by external environmental conditionsVersatileClimate change adaptationRenewable energy machinesThermal energyFruit tree

A multi-purpose solar house for planting vegetables, fruit tree, or melon and culturing animals or fowls in it is composed of a solar great shed, several heat-accumulating temp regulating rooms, and solar temp regulating cabinet in it. The solar heat energy can be accumulated in the day and then released at night.

Owner:王成增

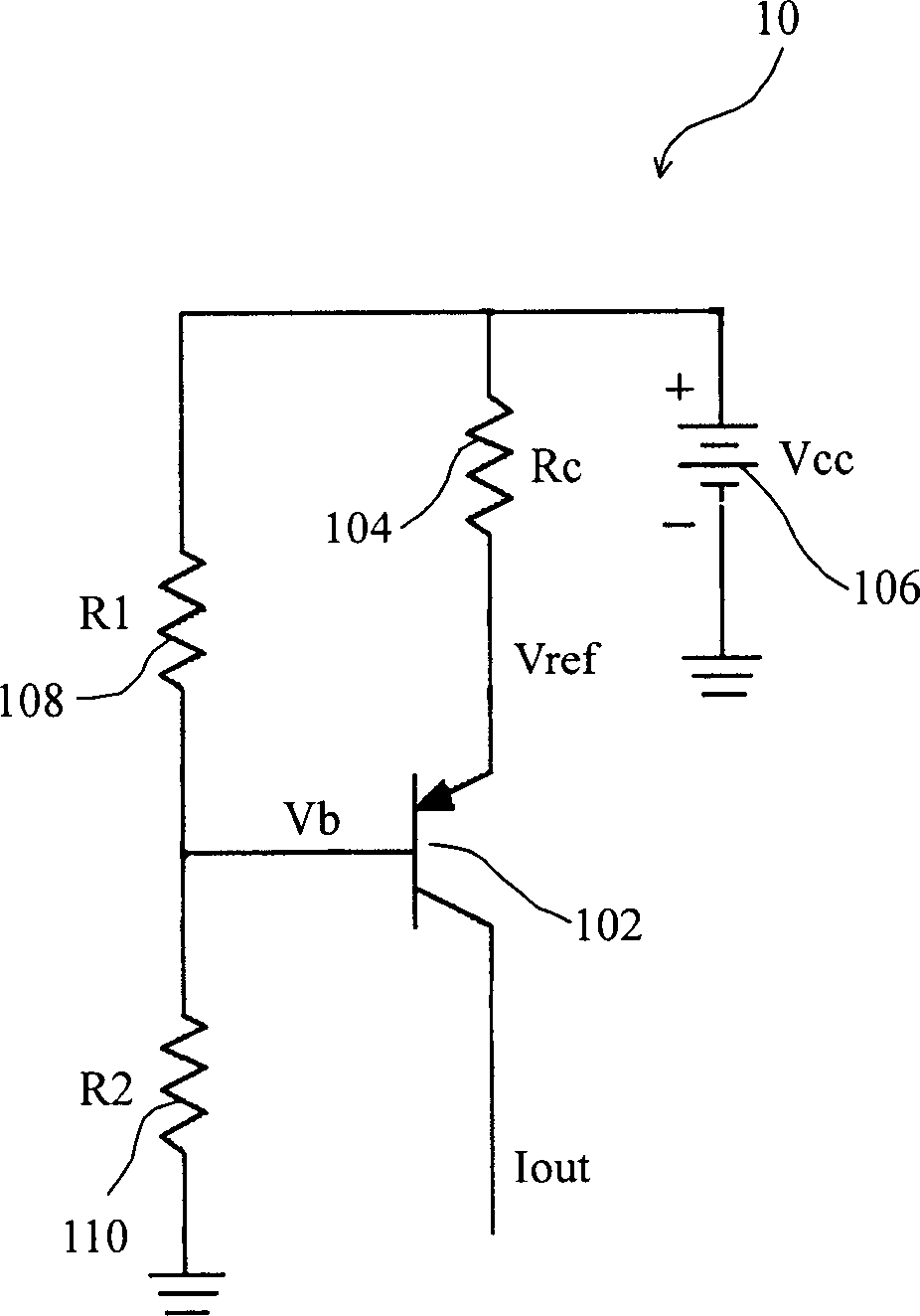

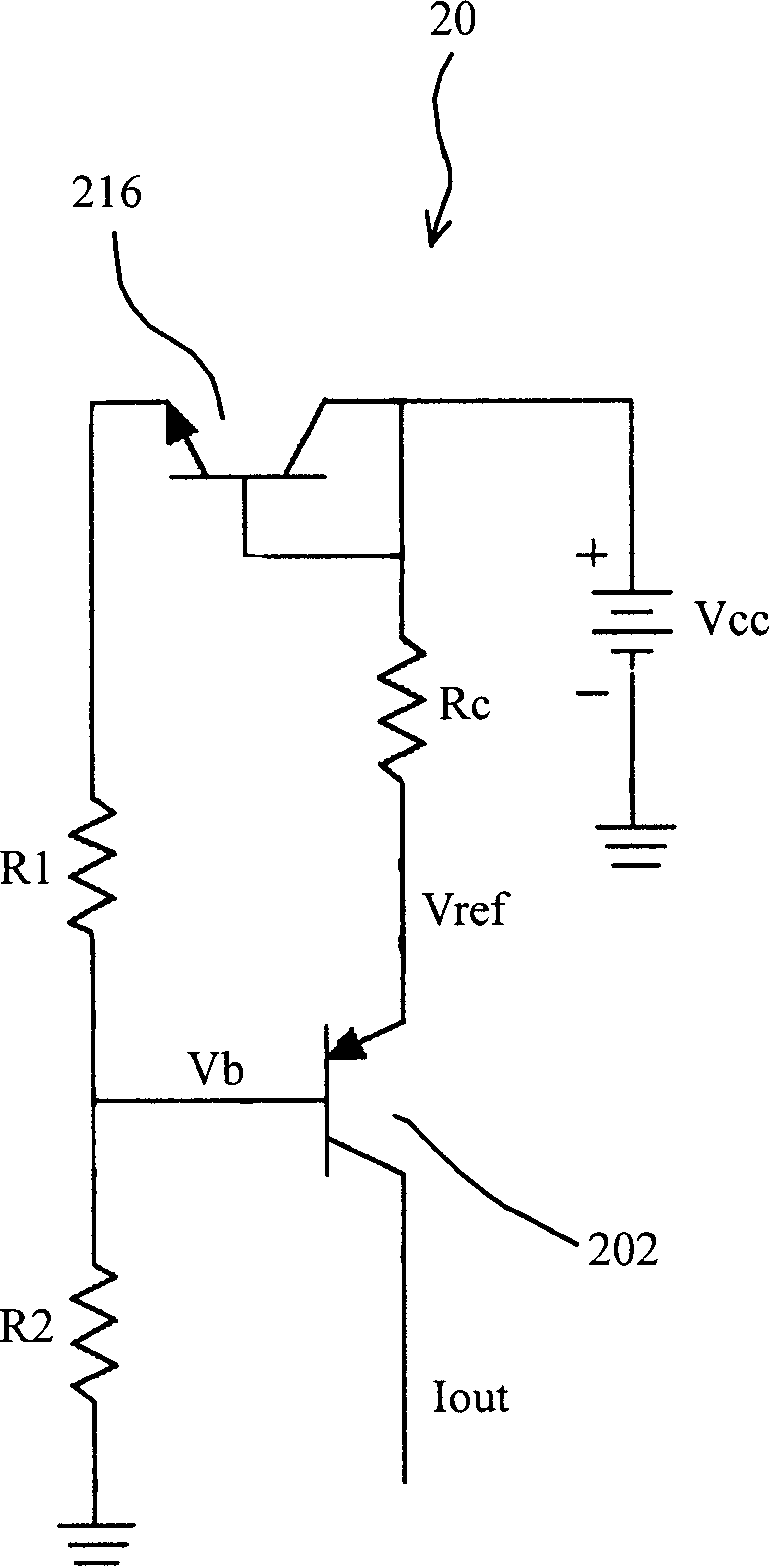

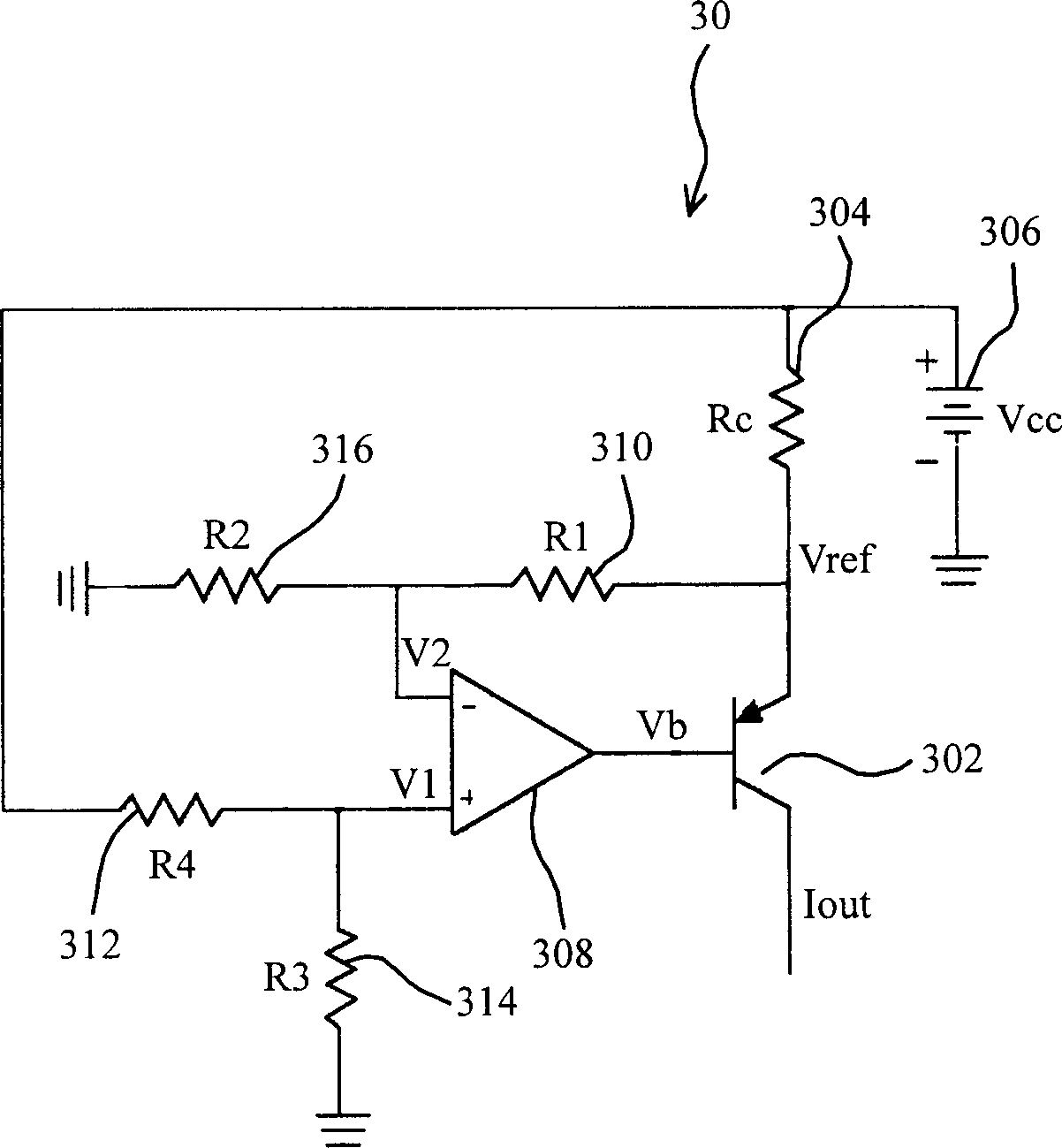

Circuit of constant current source

InactiveCN1797260AInsensitive to parameter dispersionGood output consistencyElectric variable regulationCompensation effectDc voltage

The invention provides a constant current source, comprising: a power supply for supplying a DC voltage; a first transistor, having three ends, where the third end of the first transistor is connected to that of a second transistor; and a second transistor, where its type is identical with that of the first one, and its first end is connected to the first end of the power supply, its second end is connected to the second end of the power supply and its third end is connected with its first or second end; as the third and second ends of the second transistor are interconnected, the first end of the first transistor is connected with that of the second transistor and the second end of the first transistor is used to output a first-direction current; as the third and first ends of the second transistor are interconnected, the first end of the first transistor is used to output a second-direction current and the second end of the first transistor is connected with that of the second transistor. The invention is insensitive to parameter discreteness of a constant current transistor, and has good output consistency and good temperature compensation effect.

Owner:HUAWEI TECH CO LTD

Peat humic acid degradable liquid mulching film containing rare-earth micro-element fertilizers and anti-freezing agents

InactiveCN103858718AGood warming effectPromote growth and developmentPlant protective coveringsFertilizer mixturesAnti freezingPeat

The invention discloses a preparing method and application of a peat humic acid degradable liquid mulching film containing rare-earth micro-element fertilizers and anti-freezing agents. The preparing method includes the technological steps that after fine selection and sundry removal are carried out on peat humic acid, the peat humic acid is smashed into powder ranging from 80 meshes to 400 meshes, raw materials are evenly stirred according to the weight ratio that the peat humic acid: mulching film-forming agents: cross-linking agents: the anti-freezing agents: rare earth: annexing agents: water = 3-10:1-5:0.2-1:0.5-1:0.1-1:0.2-0.5:30-60, the raw materials are reacted for 0.5 hours-2 hours at 20 DEG C-90 DEG C, and the peat humic acid degradable liquid mulching film containing the rare-earth micro-element fertilizers and the anti-freezing agents is generated. The peat humic acid degradable liquid mulching film has the good warming performance and the good low-temperature-resistant performance; when hot water cannot be provided due to condition limitation, cold water can be directly used to be evenly stirred with the raw materials to be sprayed to form the mulching film, and complete degradation can be achieved after the peat humic acid degradable liquid mulching film is used for 2-3 months.

Owner:江西双佳科技股份有限公司 +1

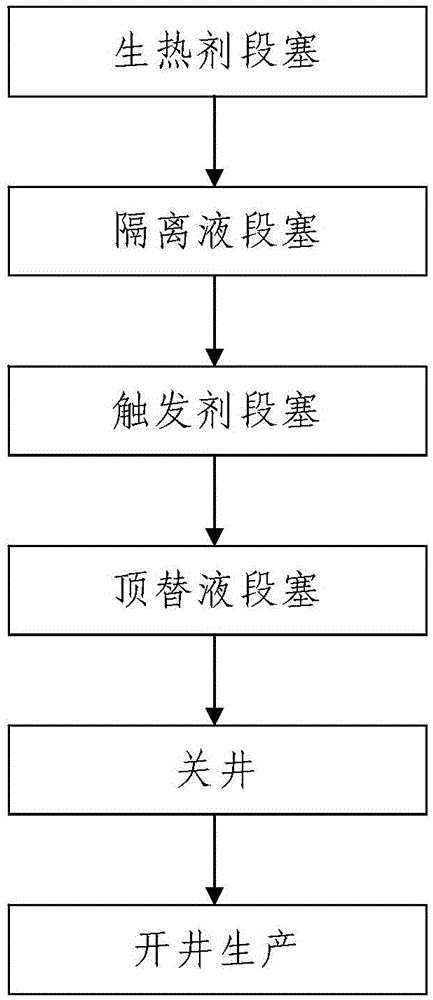

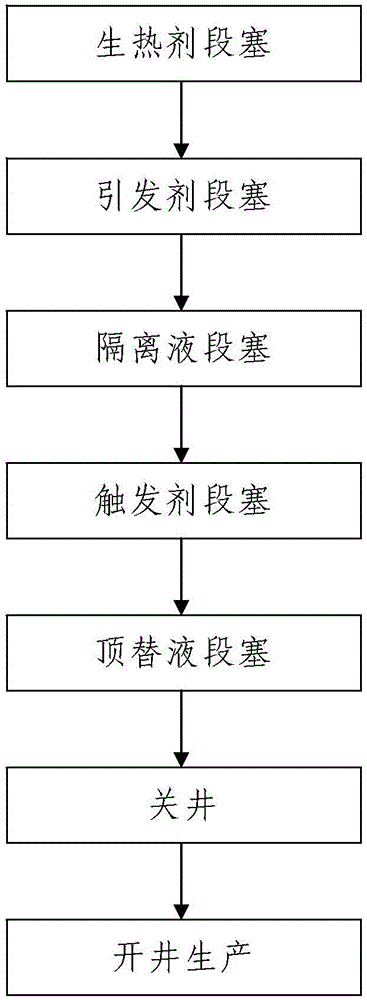

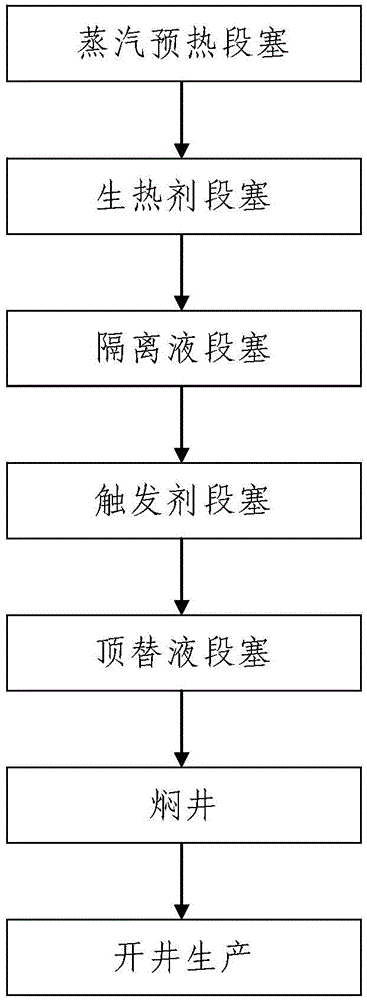

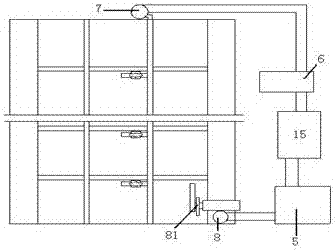

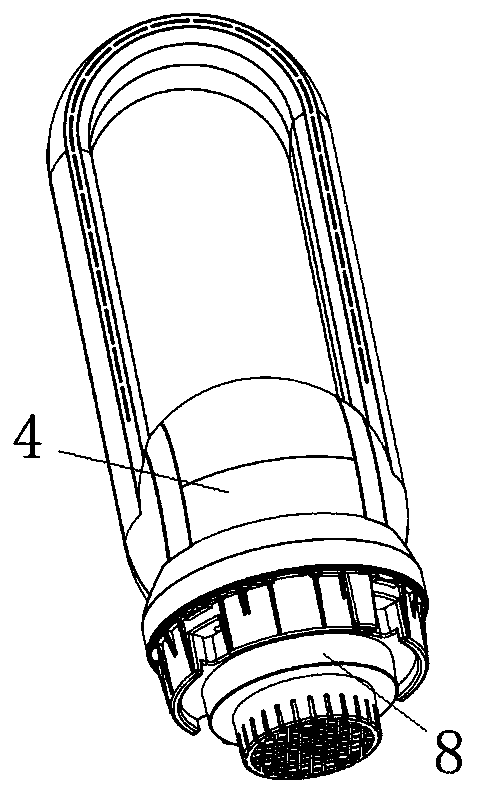

Injection process and injection equipment of chemical heat generating system in thick oil storage layer

ActiveCN105089592AThe injection process steps are simpleReasonable designFluid removalDrilling compositionInjection equipmentPlunger pump

The invention discloses an injection process of a chemical heat generating system in a thick oil storage layer; a cold production mode is used for injecting as follows: heat generating agent slug injection, separation liquid slug injection, trigger agent slug injection, replacement liquid slug injection, well closing and well opening production; a steam injection heat production mode is used for injecting as follows: steam preheating slug injection, heat generating agent slug injection, separation liquid slug injection, trigger agent slug injection, replacement liquid slug injection, well braising and well opening production; the process is simple in steps, reasonable in design, convenient to operate, safe and reliable in injection process and excellent in use effect, and can simply finish the injection process of the chemical heat generating system in the thick oil storage layer; moreover, the invention further discloses injection equipment of the chemical heat generating system in the thick oil storage layer; the equipment comprises four liquid mixing devices and one liquid injection pipe connected with a shaft of a target well; a plunger pump, a pressure detecting unit and a fifth one-way valve are mounted on the liquid injection pipe; and the equipment is simple in structure, reasonable in design, convenient for pipeline connection, simple in use and operation and excellent in use effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

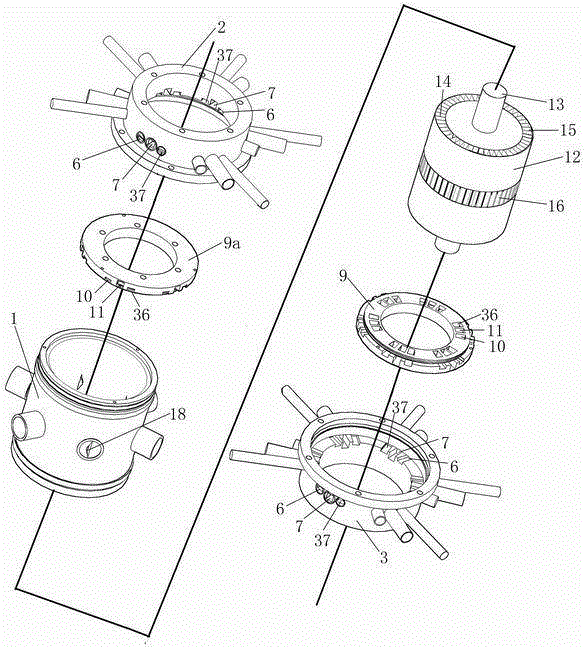

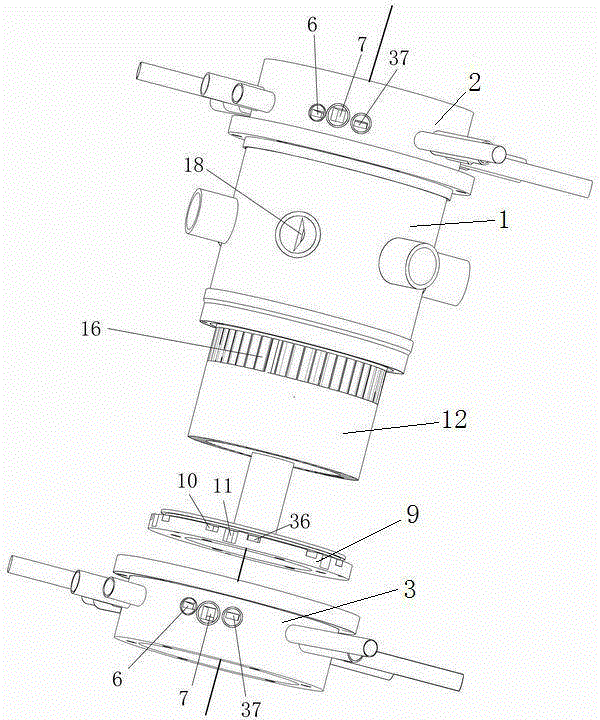

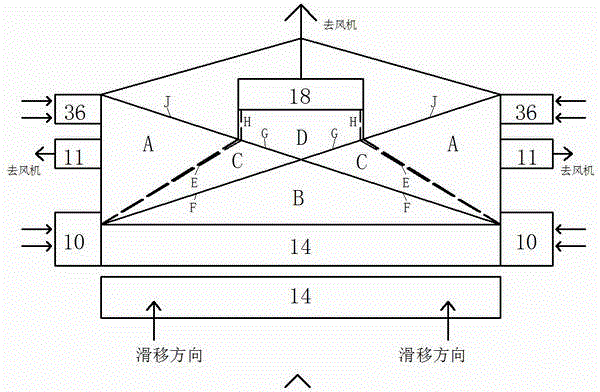

Shock wave collision dual-supercharging-type wave pressure supercharger

ActiveCN104533851AIncrease boost effectFast thermal separationFluid-pressure convertersShock waveRefrigeration

The invention discloses a shock wave collision dual-supercharging-type wave pressure supercharger, and belongs to the technical field of refrigeration and evaporation. According to the wave pressure supercharger, a shock wave and transmission shock wave dual-supercharging mechanism is utilized, and the high-pressure ratio of compressed gas is increased. A main machine body, an upper machine body and a lower machine body are connected through dual-end loose flanges. The main machine body comprises a main machine body shell and a rotary drum, the middle symmetric position of the main machine body shell is provided with supercharging gas outlets distributed evenly and circumferentially, shock wave collision tubes are evenly distributed on the rotary drum circumferentially, and the middle symmetric position of the rotary drum is provided with a square hole outwards. The upper machine body and the lower machine body are symmetrically arranged relative to the main machine body and are each provided with a detachable nozzle distribution disc, wherein high-pressure driving fluid nozzles and low-pressure expansion fluid nozzle outlets are distributed on the nozzle distribution disc periodically and circumferentially. According to the wave pressure supercharger, by the adoption of the shock wave collision principle, the gas supercharging effect is greatly improved due to a middle isosceles trapezoid supercharging fluid outlet, the temperature increasing effect is remarkable, the pressure reduction and temperature decrease effects are obvious due to two-side low-pressure expansion fluid outlet gas, the gas hot separation speed is high, the effect is good, the machine body size is small, and the wave pressure supercharger is portable and easy to maintain.

Owner:DALIAN UNIV OF TECH

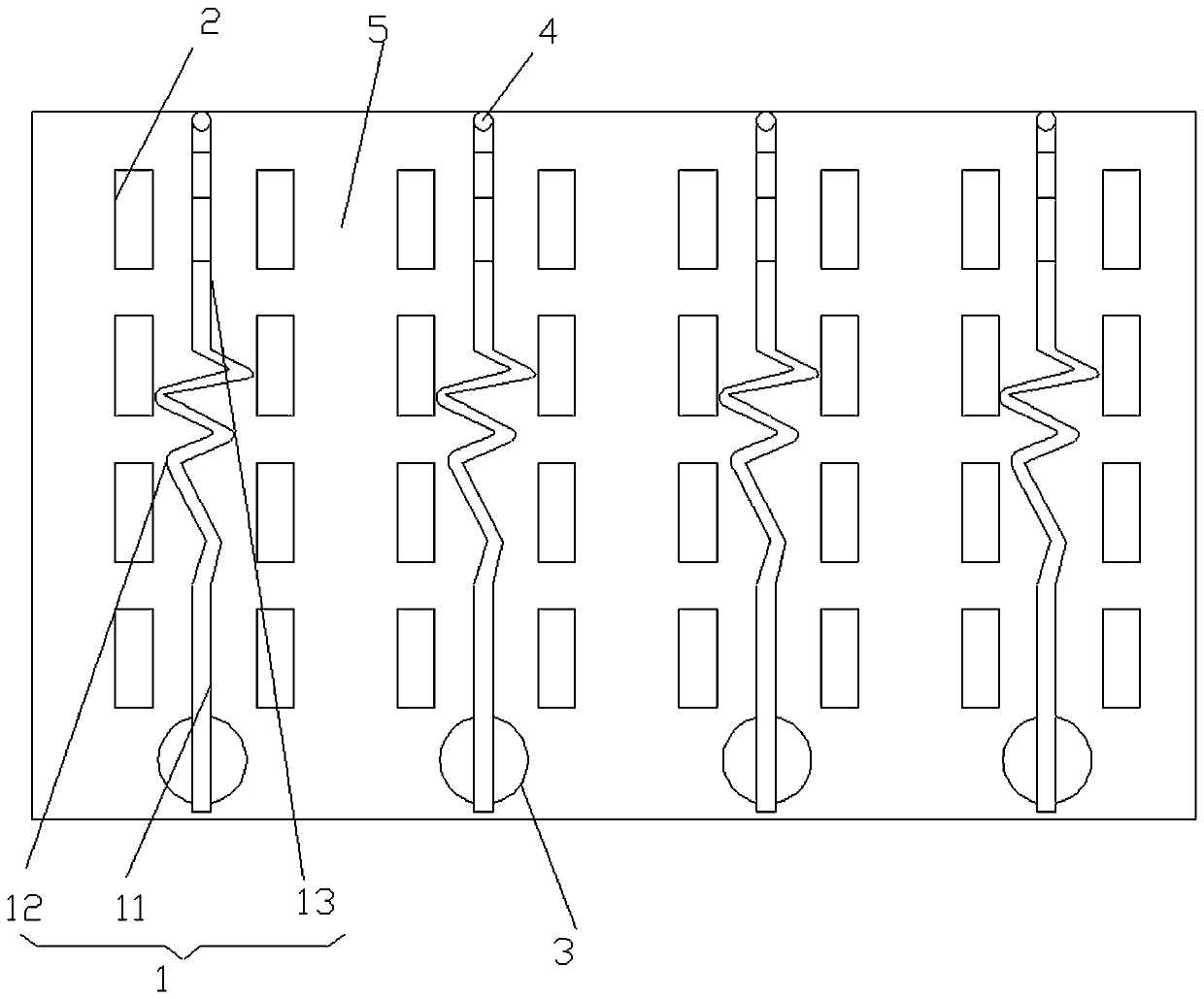

Energy-saving, stereo, multi-layer and intelligent plant factory

ActiveCN107197714AUniform temperature up and downReduce running timeDispersed particle filtrationClimate change adaptationPlant factoryPlant cell

The invention discloses an energy-saving, stereo, multi-layer and intelligent plant factory which comprises a workshop, a planting bed and a temperature rising, sterilization, disinfection and automatic lifting light supplementing device. Four layers of solar panels are used at the top of the workshop, a heat preservation curtain is laid on the solar panels, the solar panel thickness is 10 mm, the temperature rising curtain is black and absorbs light, a temperature rising chamber is formed between the solar panels and the temperature rising curtain, holes are formed in the temperature rising curtain, and the temperature rising curtain corresponds to a circulation fan in size and position. Multiple layers of planting grooves and an automatic nutrient solution circulating system are arranged on a planting bed main frame, galvanized steel pipes are arranged below each layer of planting grooves, upper and lower layers of parallel galvanized steel pipes are connected through one longitudinal water feeding pipe and one longitudinal water return pipe, and vertical indoor-temperature balance is achieved through same-way circulation. Planting cell plates are arranged above easy layer, automatic light supplementing lamp adjusting and lifting frames are installed on the planting cell plates, and light supplementing lamp tubes are installed at the bottoms of the lifting frames. The plant factory is small in earlier stage investment, low in operation cost and low in energy consumption.

Owner:南宫市新创现代农业开发有限公司

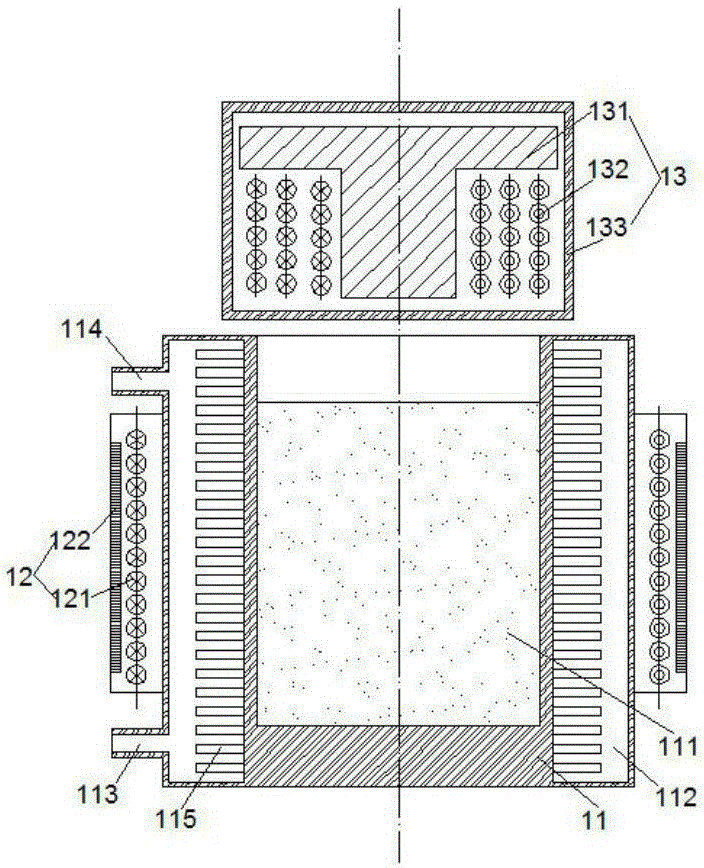

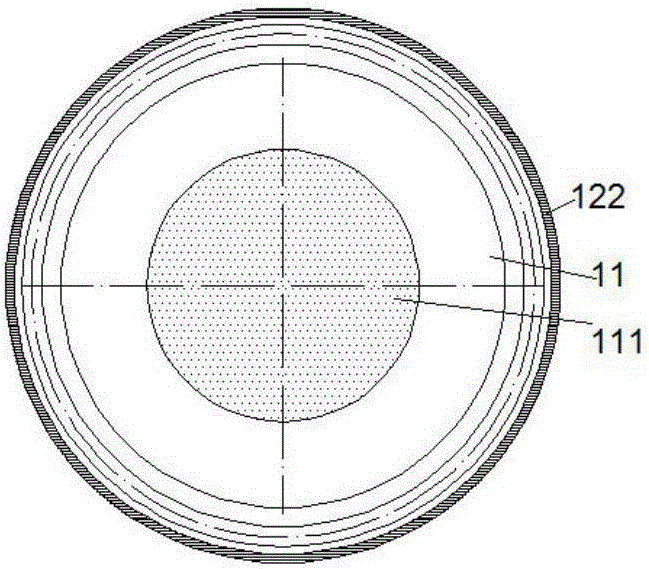

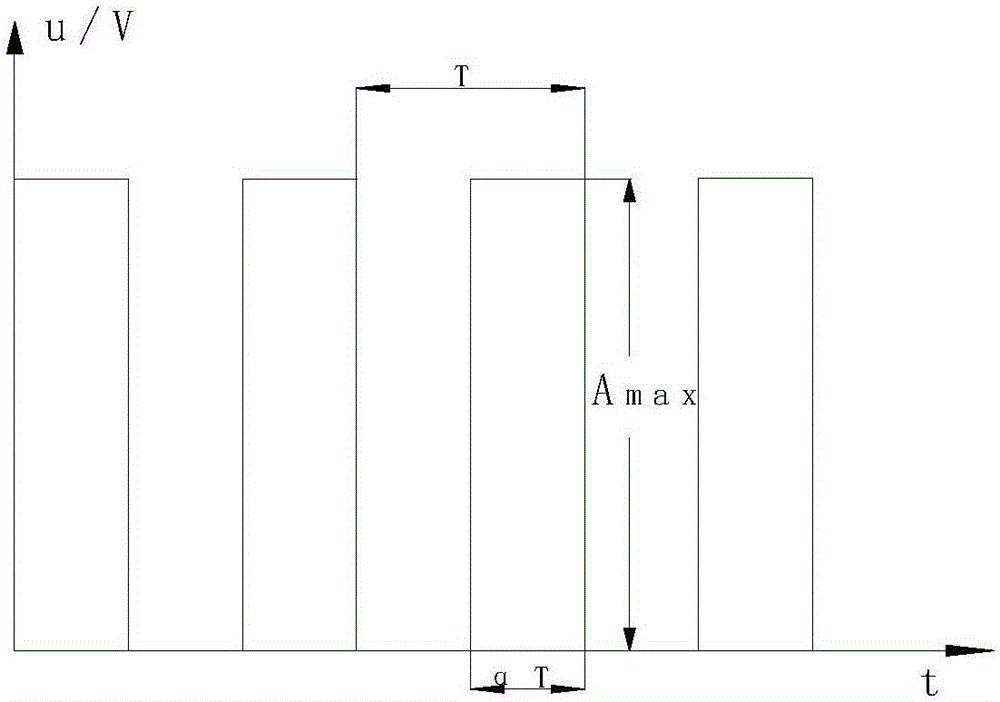

Composite electromagnetic pulse solidification structure treatment device and method for casting of ultralumin

ActiveCN106424567AReduce warm-up costsWarm up evenlyFoundry mouldsFoundry coresElectromagnetic pulseWater cooling

The invention discloses a composite electromagnetic pulse solidification structure treatment device and method for casting of ultralumin. The treatment device comprises a metal mold, a side electromagnetic pulse device and a top electromagnetic pulse device, wherein an inner chamber of the metal mold is used for storing a melt; the sidewall of the metal mold comprises an outer layer and an inner layer; a water cooling cavity is formed between the outer layer and the inner layer; a cooling water inlet is formed in the bottom part of the water cooling cavity, and a cooling water outlet is formed in the top part of the water cooling cavity; the side electromagnetic pulse device is arranged at the outer wall of the metal mold; the top electromagnetic pulse device is positioned right above the inner chamber of the metal mold. According to the composite electromagnetic pulse solidification structure treatment device for casting of the ultralumin, electromagnetic energy can enter the melt to the maximum, so that the metal mold can be uniformly preheated, and the core structure of an ultra-thick casting can be uniformly thinned through the electromagnetic energy while the solidification supercooling degree of a casting blank is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Frost prevention method for wild pepper and special aerosol

The invention provides a frost prevention method for wild pepper and a special aerosol so as to meet the frost prevention need in production of the wild pepper and further improve yield. The frost prevention method for the wild pepper comprises the steps of applying the aerosol in a field before frost approaches for frost prevention during the growth period of the wild pepper and simultaneously spraying an anti-freezing agent during the bud swelling period. The special aerosol is characterized by being prepared from the following components: 10 plus or minus 2% of waste diesel oil, 50 plus or minus 10% of sawdust, 30 plus or minus 5% of nitramine and 10 plus or 2% of fine coal powder. The frost prevention method disclosed by the invention combines plant physiological research with research and development of the aerosol and the anti-freezing agent against the early spring freezing damage problem of the wild pepper, researches a frost observation and prediction technology by taking critical frost temperature of the wild pepper as reference, researches and develops the aerosol by taking long smoking time, good temperature-increasing effect and convenience in use as targets, develops an anti-freezing medicament for the wild pepper by taking a plant inhibitor and hormonal substances as materials, seeks for a frost prevention technology matched with the wild pepper by taking the frost prediction and the comprehensive application of the aerosol and the anti-freezing agent as a starting point and further has important significance for promoting great development of the wild pepper industry in China and upgrading a high yield technology.

Owner:FENGXIAN PEPPER IND DEV BUREAU

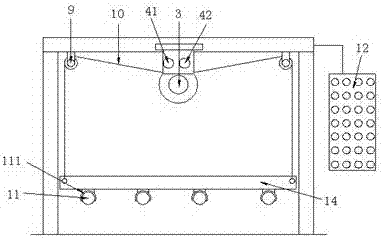

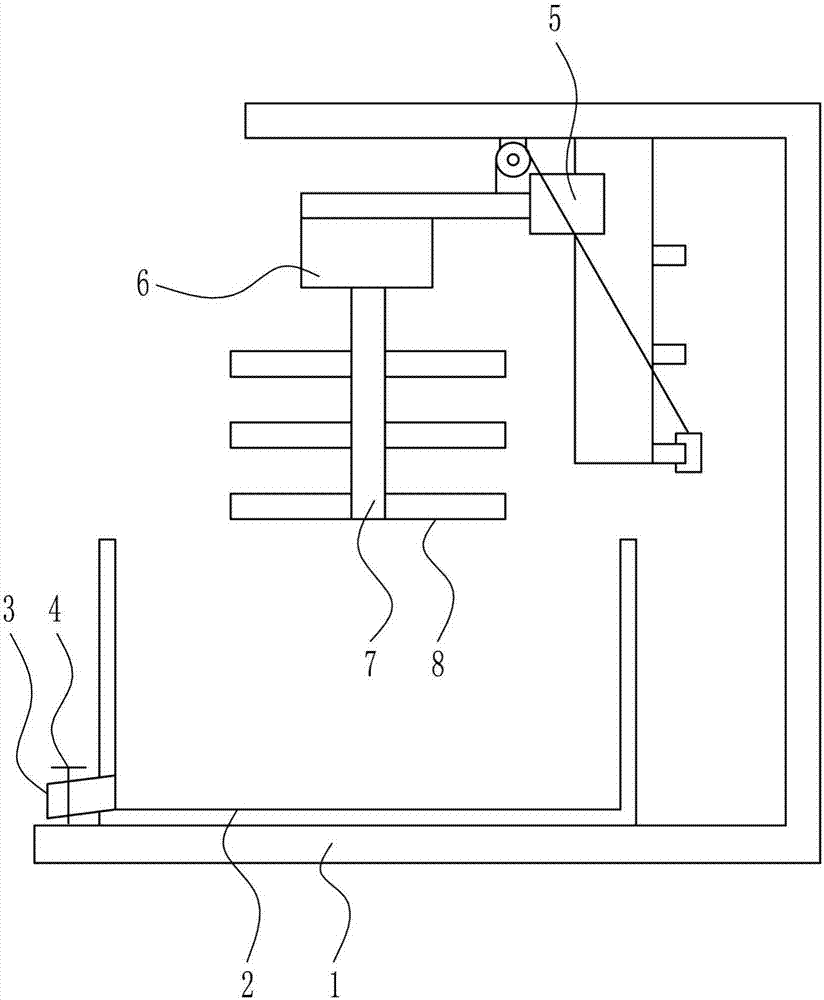

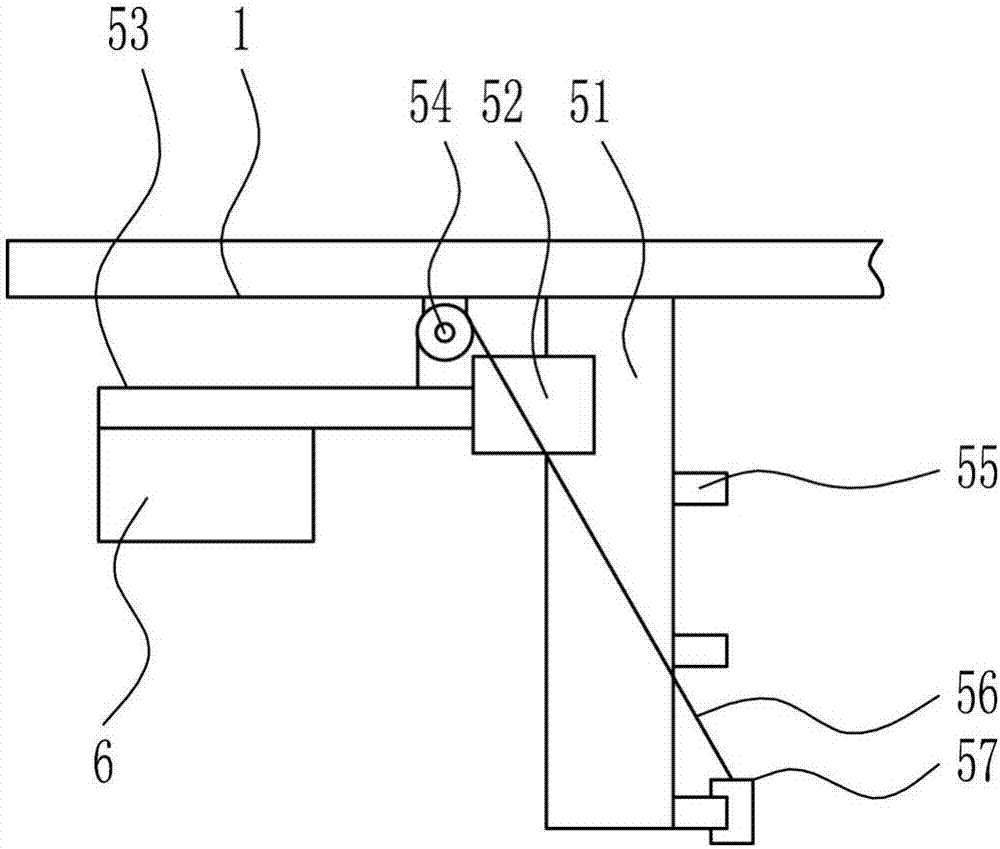

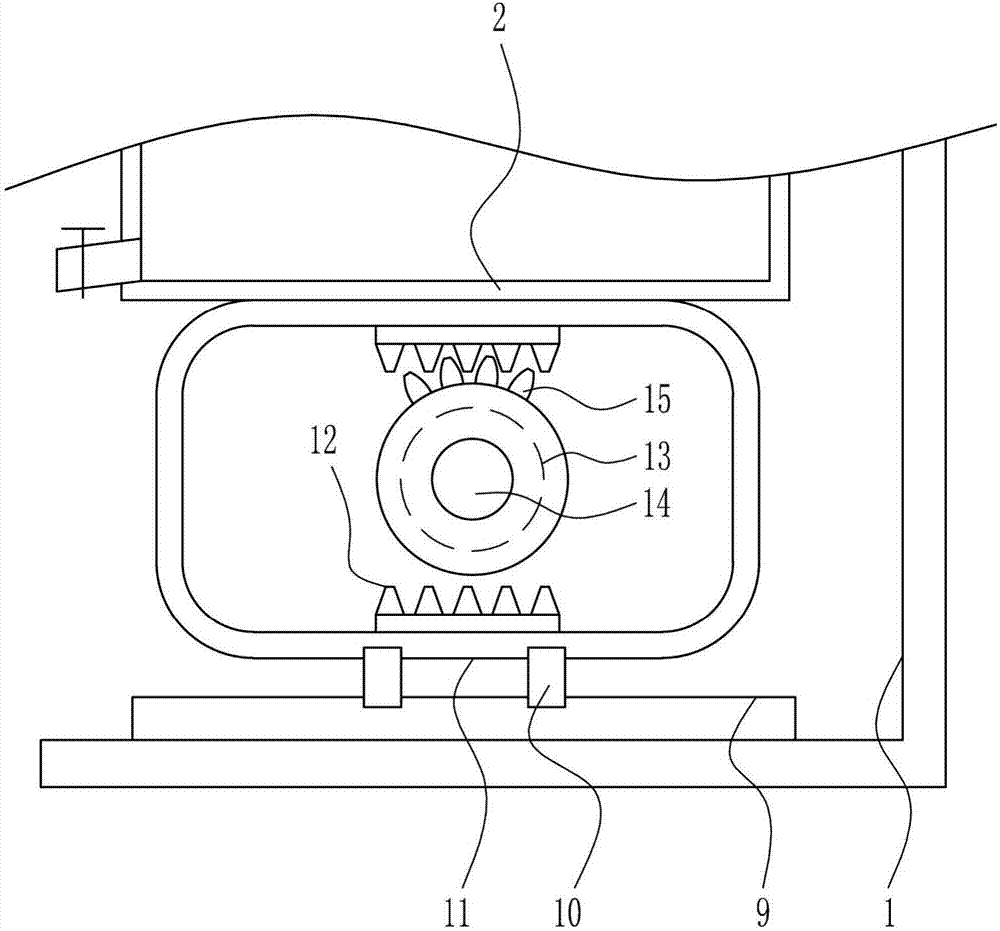

Solder paste temperature returning apparatus used for lamp bar production

InactiveCN107008185AEasy to operateGood warming effectShaking/oscillating/vibrating mixersTransportation and packagingEngineeringSolder paste

The invention relates to a solder paste temperature returning apparatus, and especially relates to a solder paste temperature returning apparatus used for lamp bar production. A technical problem to be solved in the invention is to provide the solder paste temperature returning apparatus used for lamp bar production, with ideal temperature returning. The solder paste temperature returning apparatus used for lamp bar production comprises a mounting rack, a frame body, a discharging tube, a valve, a height adjusting device and a first motor; and the bottom in the mounting rack is provided with the frame body, the discharging tube is arranged at the lower portion of the left wall of the frame body, the valve is arranged on the discharging tube, the top in the mounting rack is provided with the height adjusting device, the height adjusting device is provided with the first motor, a stirring shaft is arranged at the center of the bottom of the first motor, stirring rods are arranged at the lower portion of the stirring shaft, and the stirring rods are arranged above the frame body. A concave block is loosened and pulled to adjust the height of the stirring rods in order to adapt to different demands, and the operation is very simple and fast; and a second motor is controlled to clockwise rotate in order to drive the frame body to move to the left and right.

Owner:宁波伍兹光电有限公司

Intelligent glass system with efficient one-way light and heat transfer function

PendingCN109403808AGood heat insulationLow thermal conductivityClimate change adaptationWindows/door improvementChemistrySmart glass

The invention discloses an intelligent glass system with an efficient one-way light and heat transfer function. The intelligent glass system comprises a sunlight efficient absorption functional layer,a blackbody radiation high-reflection functional layer arranged on one side of the sunlight efficient absorption functional layer, and one or more sunlight transmission layers arranged on the side, opposite to the sunlight efficient absorption functional layer, of the blackbody radiation high reflection functional layer.The area between the blackbody radiation high reflection functional layer andthesunlight transmission layers as well as the area between two adjacent sunlight transmission layers when the sunlight transmission layers are multiple areairtight hollow or vacuum heat convection suppression layers.

Owner:ANHUI IANUS INTELLIGENT SCI & TECH CO LTD

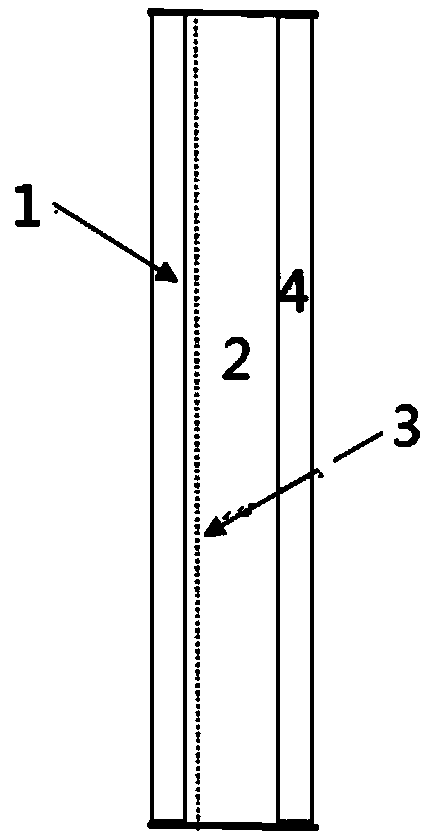

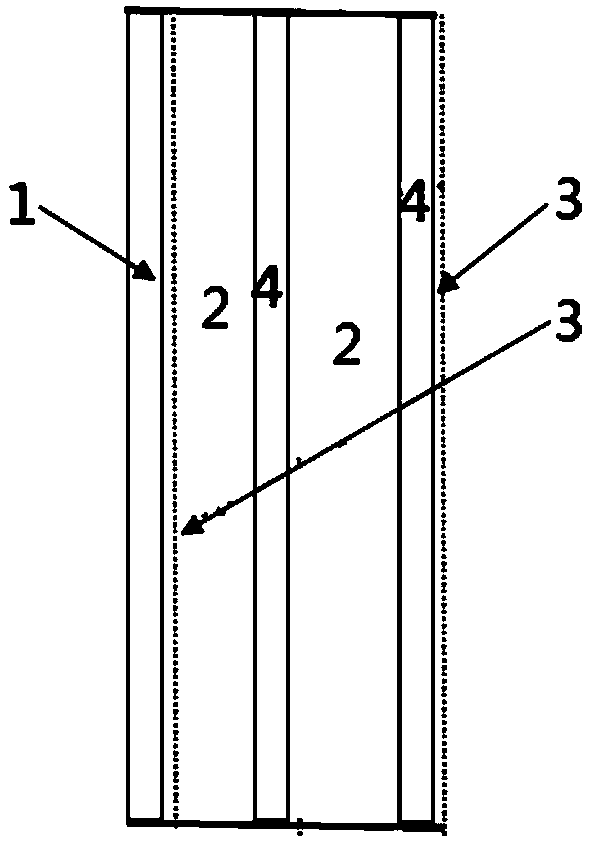

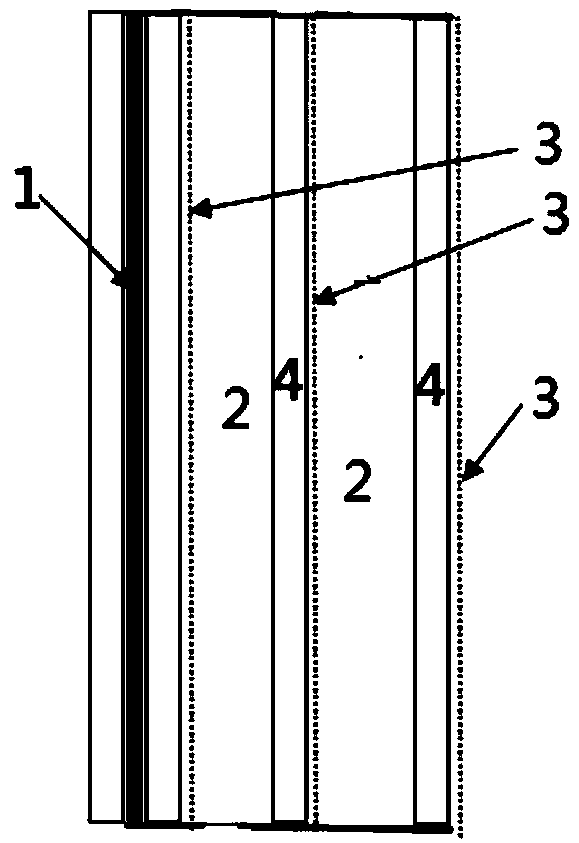

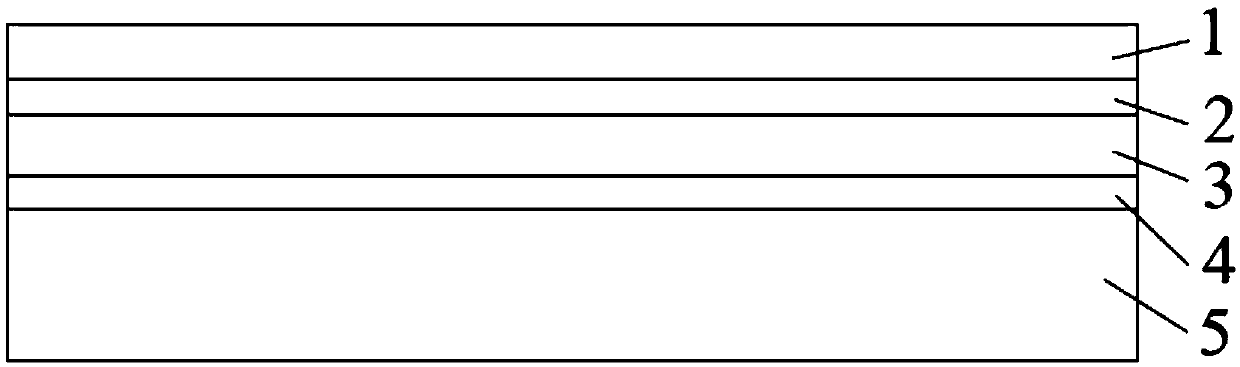

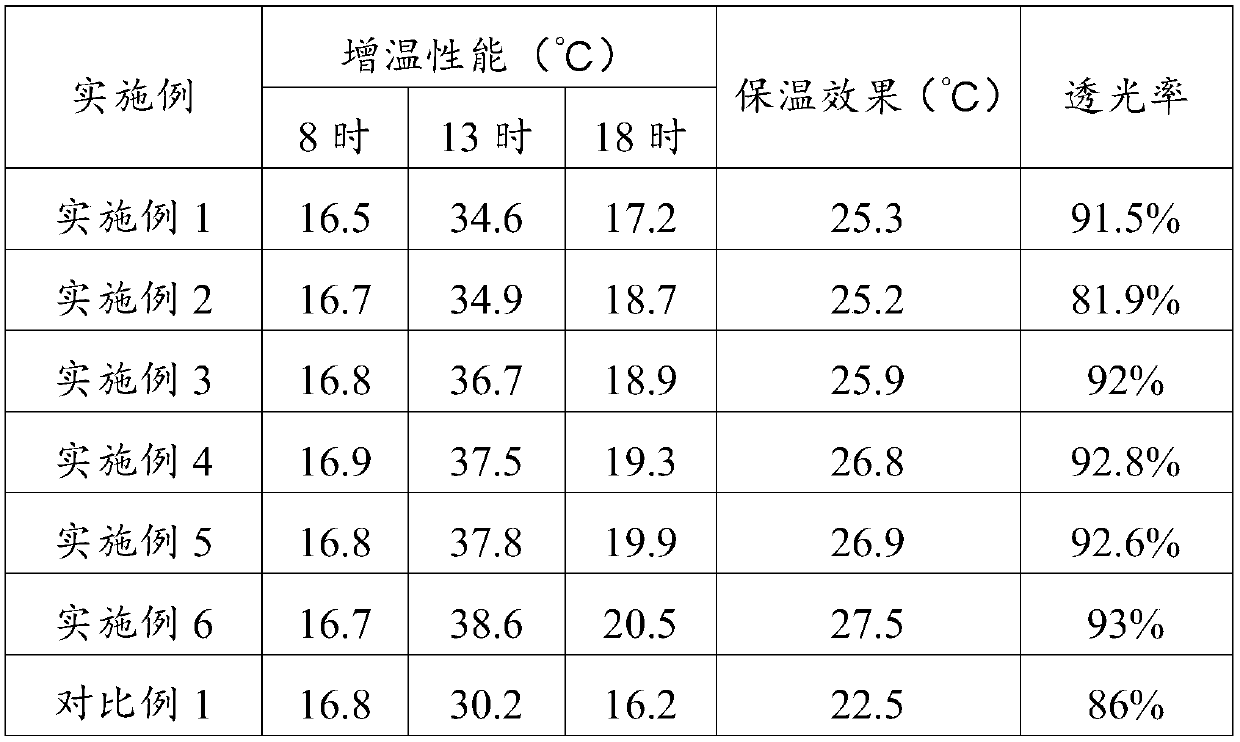

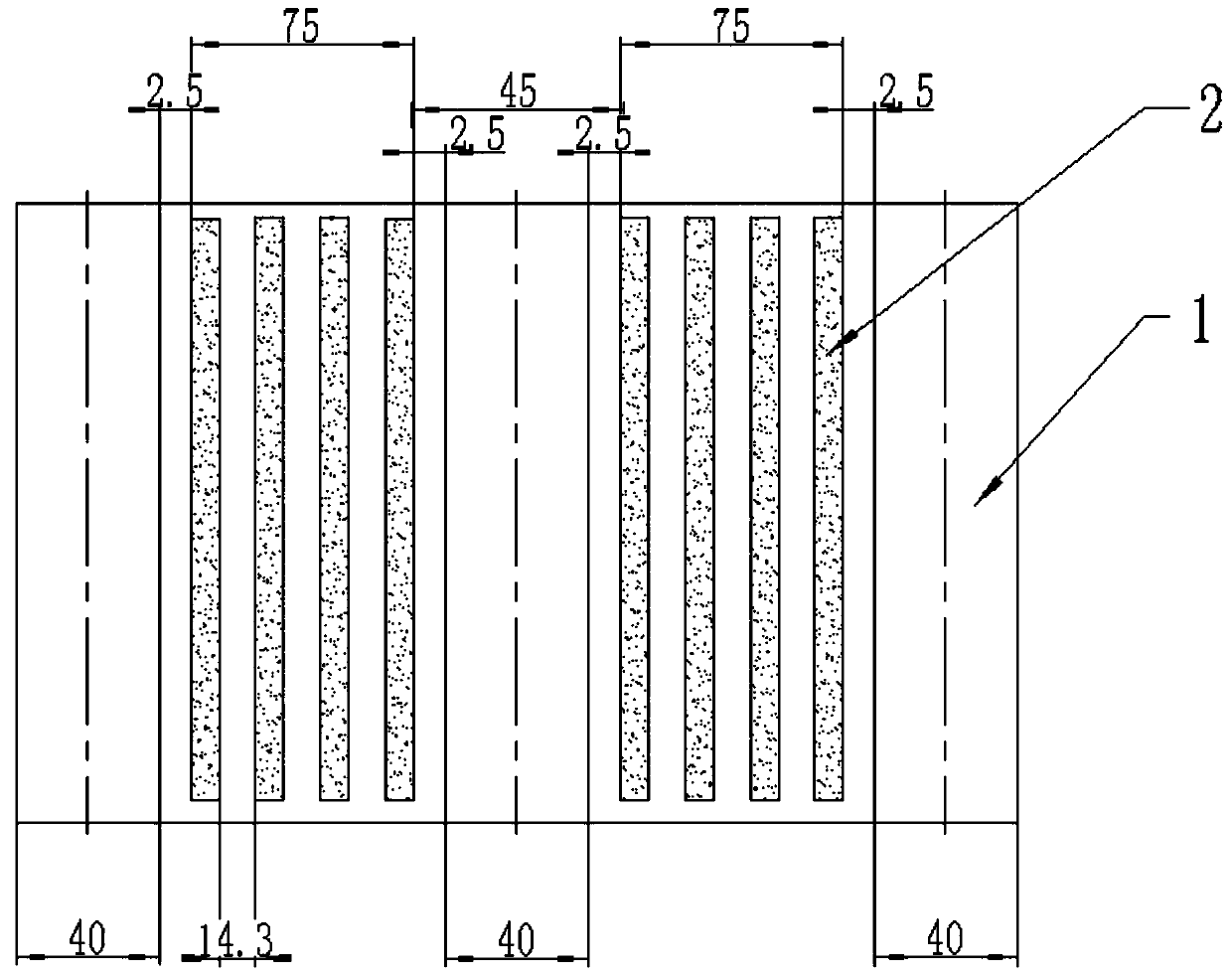

PE mulching film

ActiveCN109677070AHigh light transmittanceEasy to stretchAgricultural articlesSynthetic resin layered productsAntistatic agentTransmittance

The invention provides a PE mulching film. The PE mulching film comprises an outermost layer, a secondary outer layer, a middle layer, a secondary inner layer and an innermost layer which are sequentially arranged, and is characterized in that the innermost layer contains an anti-dripping agent; among the outermost layer, the secondary outer layer, the middle layer, the secondary inner layer and the innermost layer, at least the outermost layer contains an antistatic agent. According to the PE mulching film provided by the invention, the outermost layer can prevent the surface of the PE mulching film from adsorbing soil so as to increase the light transmittance of the mulching film, the innermost layer can prevent one surface, close to the ground surface, of the PE mulching film from condensing to form water droplets so as to increase the overall light transmittance of the PE mulching film, and through arrangement of the secondary outer layer, the middle layer and the secondary innerlayer, the PE mulching film can maintain relatively good tensile and toughness properties. The PE mulching film provided by the invention has high light transmittance and a good warming effect, and isbeneficial to increase in the yields and the values of plants.

Owner:ZHENGXIN PACKAGING CO LTD DONGGUAN

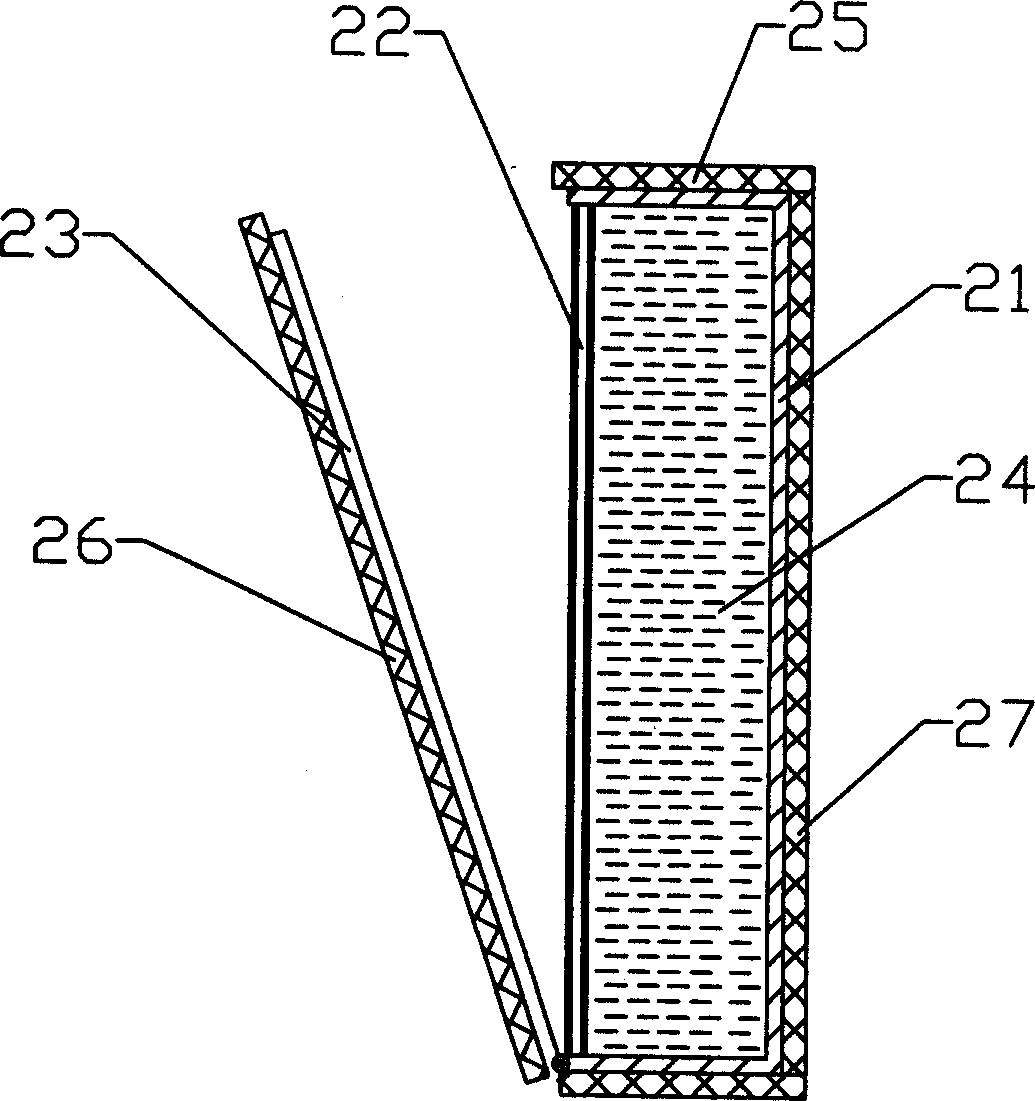

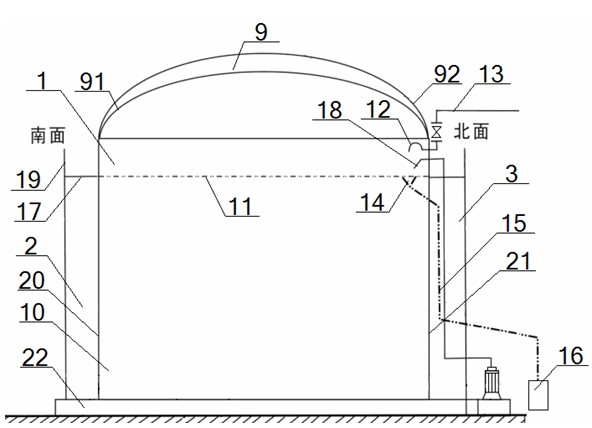

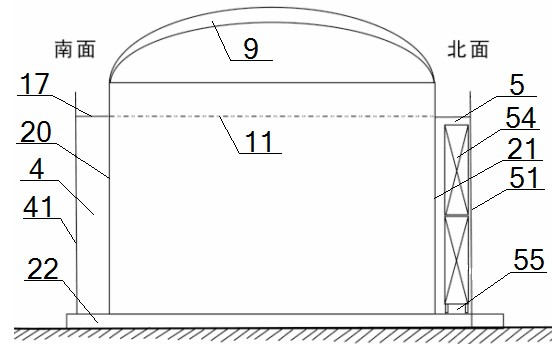

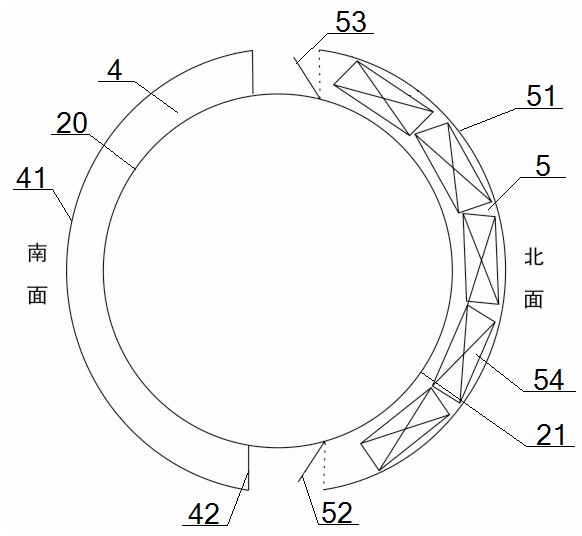

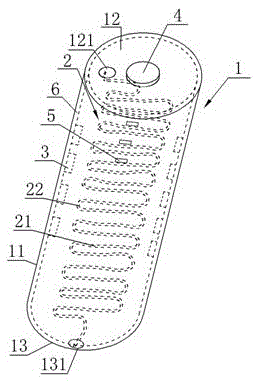

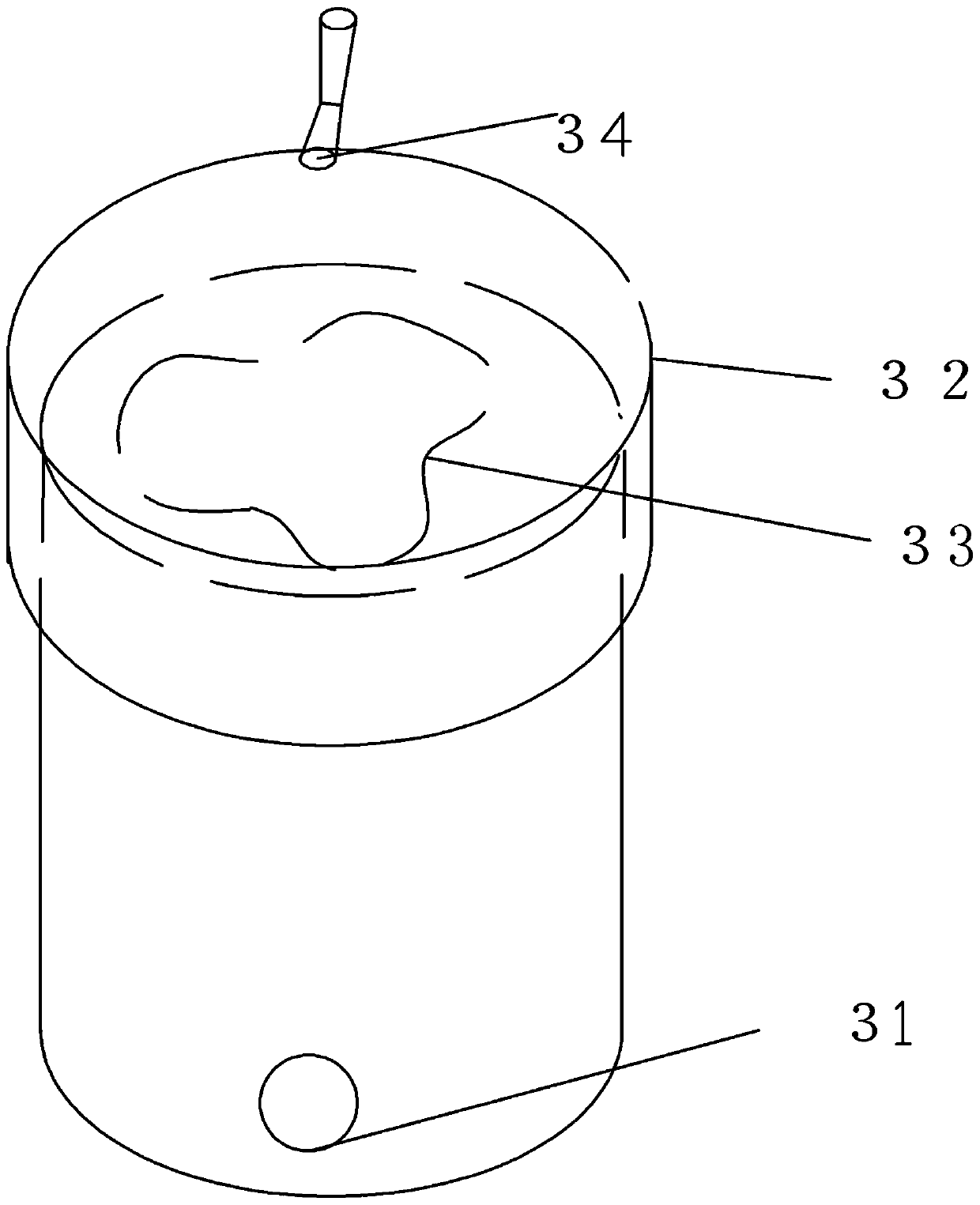

Double-heat-energy warming fermentation tank

ActiveCN102586087AGood warming effectWill not interfere with normal useBioreactor/fermenter combinationsGas production bioreactorsThermal energyEngineering

The invention provides a double-heat-energy warming fermentation tank. The double-heat-energy warming fermentation tank comprises a fermentation tank, a solar warming device and an auxiliary heat energy warming device, wherein the solar warming device is arranged around the south side wall of the tank body; the auxiliary heat energy warming device is arranged around the north side wall of the tank body; platforms are arranged at the tops of both the auxiliary heat energy warming device and the solar warming device; the solar warming device, the auxiliary heat energy warming device, the platforms, the ground and the black tank body side walls mutually form a sealed structure; the auxiliary heat energy warming device is a biological energy warming room or a full-sealed boiler directly-heated type warming room; straw fermentation warming is adopted for the biological energy warming room; and the full-sealed safety and energy-saving biogas boiler near-fermentation warming is adopted for the full-sealed boiler directly-heated type warming room. The double-heat-energy warming fermentation tank provided by the invention has the advantages of good warming effect, stronger energy conservation, low cost, strong environment friendliness and suitability for large-sized biogas projects.

Owner:方朝阳

High-purity gas pipeline constant temperature system for experiment

InactiveCN105092359AIncrease the itineraryPlay the role of heat preservation and constant temperatureTemperatue controlPreparing sample for investigationEngineeringINCREASED EFFECT

The invention discloses a high-purity gas pipeline constant temperature system for experiment. The high-purity gas pipeline constant temperature system comprises a gas pipeline, and further comprises a gas extracting and supplying device, a constant temperature box, a reactor, a heating block, a heating wire and a temperature sensor, wherein the constant temperature box is divided into a first box body, a second box body and a third box body through two layers of division plates; the gas pipeline of the gas extracting and supplying device is divided into two branch pipes; the first branch pipe penetrates through the first box body of the constant box body, and the second branch pipe penetrates through the second box body of the constant box body; the two branch pipes are connected with the reactor after being gathered. The heating block and the heating wire are arranged in the constant temperature box, so that gas flowing through the constant temperature box reaches the experiment temperature meeting the requirement, and the effects of preserving and stabilizing the temperature are achieved; furthermore, the gas pipeline is divided into the two branch pipes respectively adopting a snake-shaped structure and a linear structure; the first branch pipe with the snake-shaped structure can enhance the gas travel under the condition that the size of the box body is the same, and the temperature increase effect is better.

Owner:南京润屹电子科技有限公司

Preparation method and application method of soil warming organic fertilizer

InactiveCN111777450AGood warming effectImprove water storage capacityBio-organic fraction processingExcrement fertilisersMicroorganismLivestock manure

The invention provides a preparation method and an application method of a soil warming organic fertilizer. The preparation method comprises the following steps: pretreating livestock manure, adding zymophyte, fermenting to obtain a fermented organic fertilizer, mixing the fermented organic fertilizer with protein powder, granulating, spraying a water-retaining material to form a film so as to obtain a water-retaining organic fertilizer, adding biochar, spraying an adhesive to form a second layer of film, and ventilating and drying in the shade, thereby obtaining the organic fertilizer. The application method comprises the following steps: adding organic fertilizer particles into a nitrogen-phosphorus-potassium fertilizer solution for soaking, filtering, taking out the organic fertilizer particles, and directly applying the organic fertilizer particles to soil. The organic fertilizer provided by the invention can be adjusted according to local conditions; missing elements are supplemented to the soil in time; meanwhile, the proper temperature is kept in the soaking process to meet the growth of microorganisms, the activity of the microorganisms before entering the soil is improved,the soil temperature is increased by utilizing carbon dioxide generated by microbial activity after the microorganisms enter the soil, good microbial activity can be kept after the carbon dioxide isapplied to the soil, and an excellent soil warming effect is achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Nutritive health-care appetite-promoting spicy sauce suitable for middle-aged and aged people

InactiveCN107647374APromote digestion and absorptionNutritious and balancedVitamin food ingredientsFood preservationDiseaseBiotechnology

The invention discloses a nutritive health-care appetite-promoting spicy sauce suitable for middle-aged and aged people. The spicy sauce comprises the following raw materials: chili, oatmeal, sunflower seeds, almonds, beef, raw ginger, garlic, sesame seeds, walnuts, laver, hawthorn fruits, lentinus edodes, lotus root starch, compound vitamins, a Chinese herb extractant, egg yolk lecithin, vegetable oil, salt, a sweetener, and a preservative. The nutritive health-care appetite-promoting spicy sauce suitable for middle-aged and aged people has a reasonable formula and rich and balanced nutrients, and is suitable for digestion and absorption of the middle-aged and aged people. The spicy sauce has a moderate spicy taste and a delicious taste with a lasting time, and has the efficacy of delaying aging, beautifying skins, improving cell activity, promoting tissue regeneration, enhancing organism immunity, nourishing blood and tonifying the body, and simultaneously has the effects of loweringblood sugar, blood lipid and cholesterol and preventing diseases such as atherosclerosis and cirrhosis. Long-term consumption of the sauce can prolong life span.

Owner:无为黄老头风味食品有限公司

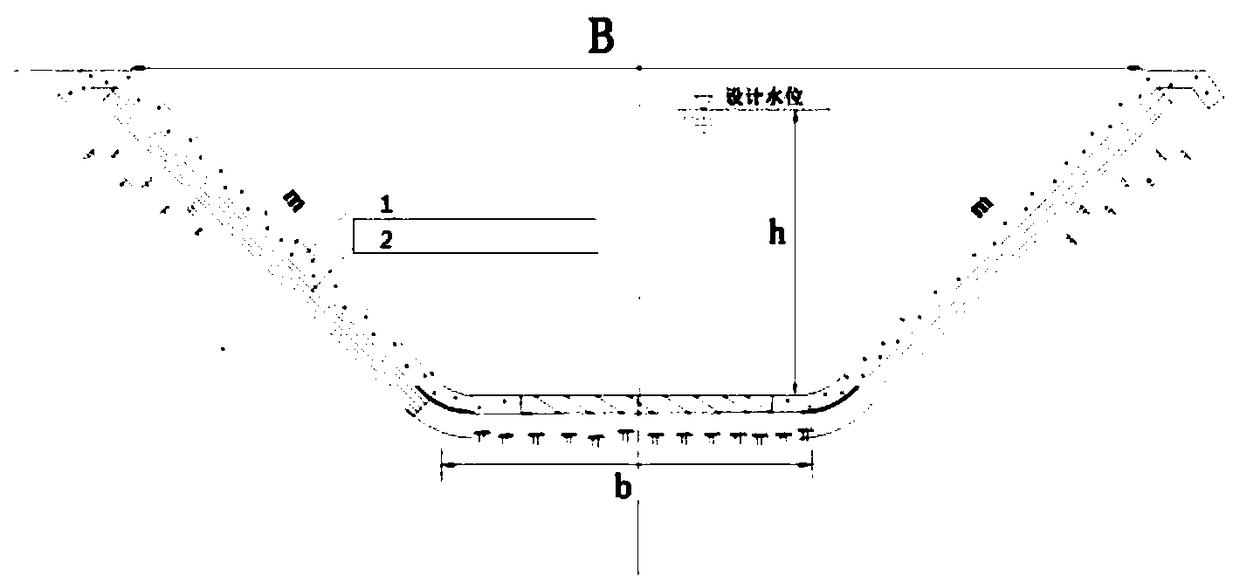

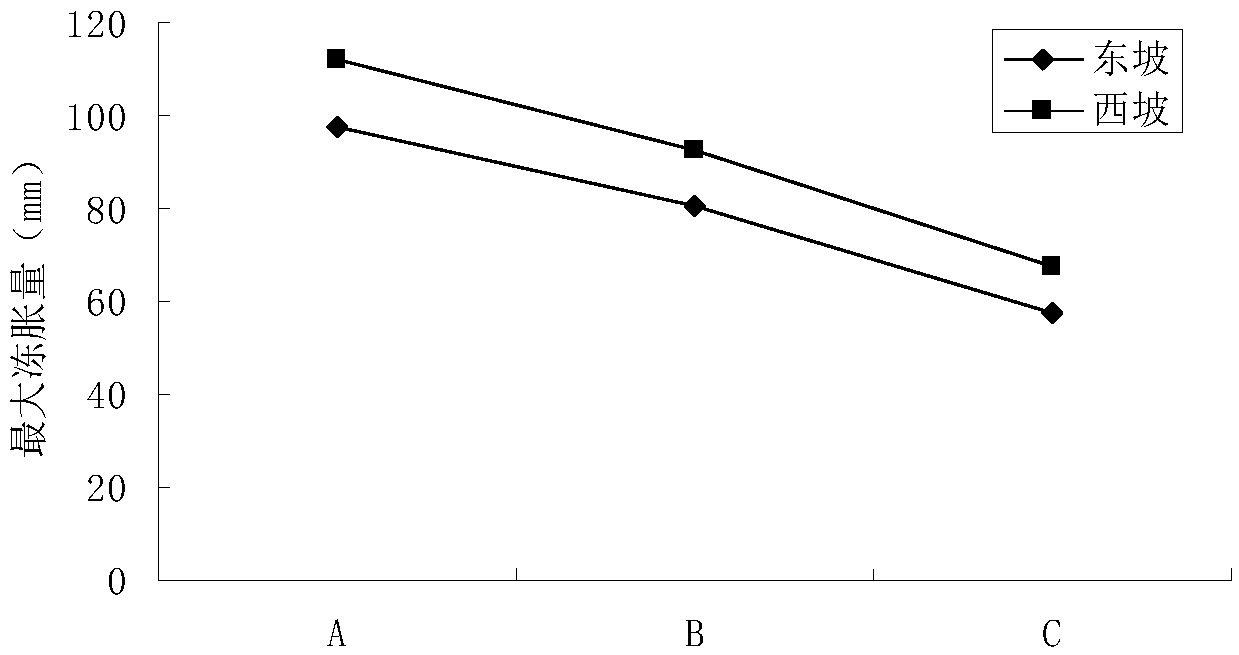

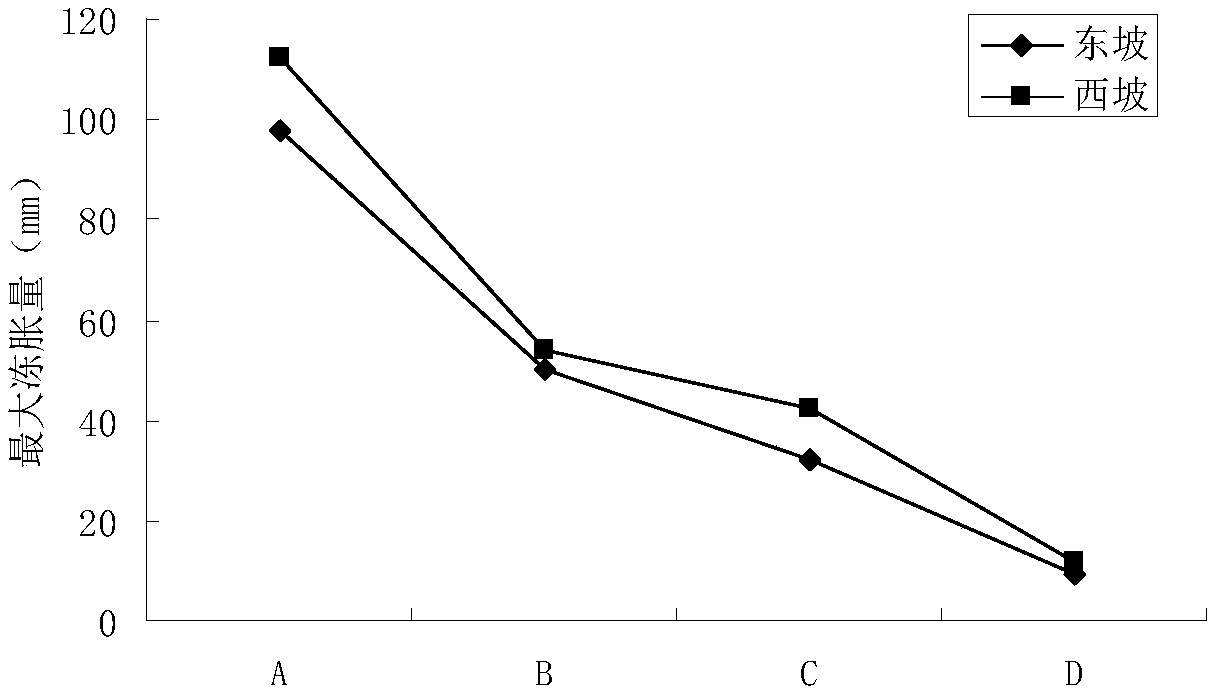

Anti-frostbite swelling method for mold bag concrete channel through polystyrene board

InactiveCN108643129AReduced frost heaveIncreasing the thicknessArtificial water canalsEngineeringPolystyrene

The invention discloses an anti-frostbite swelling method for a mold bag concrete channel through a polystyrene board and belongs to the technical field of channel projects. The anti-frostbite swelling method for the mold bag concrete channel through the polystyrene board comprises the following steps that channel bed foundation soil a mold bag to be laid is compacted, and a channel slope is flattened; after the channel slope is flattened, the polystyrene board is laid on the channel slope face, and the thickness of the polystyrene board is 4 cm-12 cm; and the mold bag is laid on an insulationboard, before filling of concrete, the mold bag is soaked with water, and the thickness of the mold bag concrete is controlled to be 8 cm-15 cm. By laying the polystyrene board in a mold bag concretechannel lining, the frostbite swelling deformation of the channel foundation soil can be reduced, the frostbite swelling damage is restrained, the service life of a channel can also be prolonged, andthe maintaining cost of the channel is reduced.

Owner:INST OF WATER CONSERVANCY SCI RES OF INNER MONGOLIA AUTONOMOUS REGION

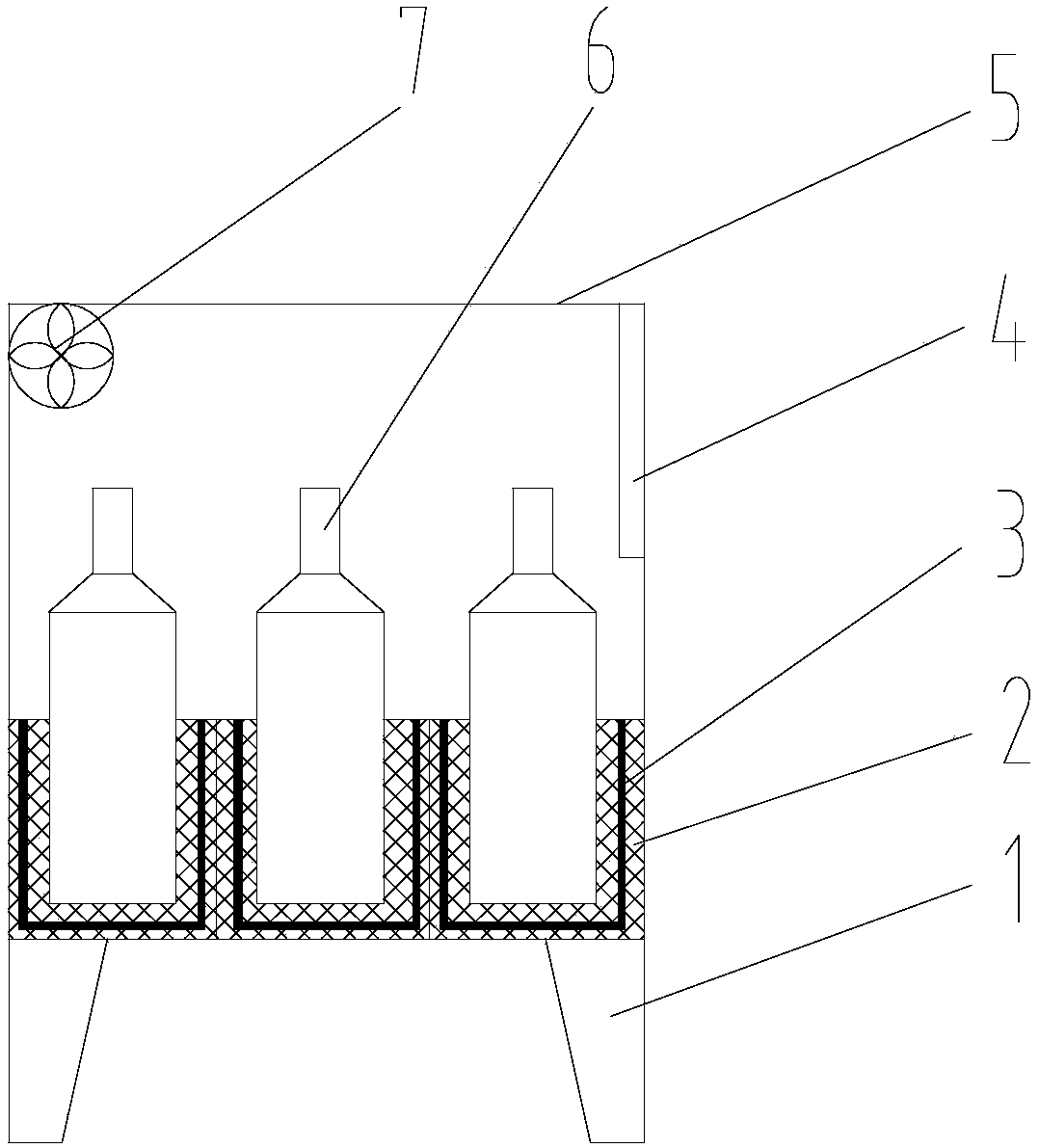

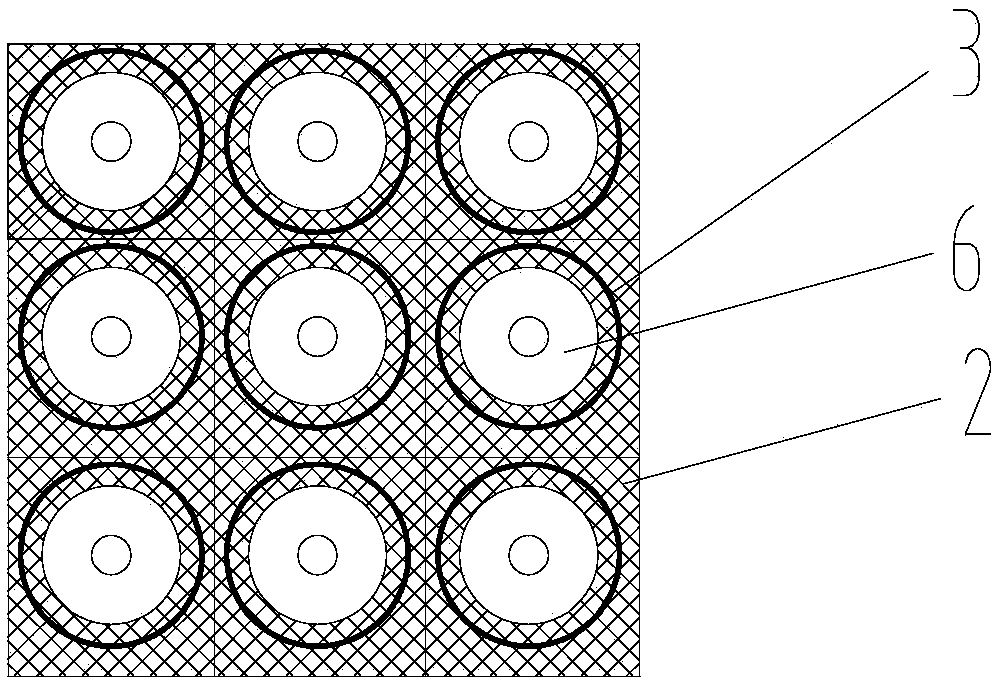

Wine heating cabinet

InactiveCN107692582AGood warming effectFast heatingShow cabinetsCocktail cabinetsElectricityEngineering

The invention discloses a wine heating cabinet and belongs to the technical field of wine cabinets. A cover is hinged to the top of the wine heating cabinet, and multiples supporting bases are arranged on the bottom of the wine heating cabinet; the bottom in the wine heating cabinet is divided into multiple rectangular vertical containing chambers through partition plates, the containing chambersare filled with heat preservation cotton, and cylindrical cavities are excavated vertically in the heat preservation cotton; electric heating wires are arranged in the heat preservation cotton, and aflame-retardant material covers the outer walls of the electric heating wires; a draught fan is arranged on the top in the wine heating cabinet, and an ultraviolet lamp is arranged on one side of theinner wall of the wine heating cabinet. The wine heating cabinet has the functions of wine heating and sterilization, and is high in practicability and convenient to move and use.

Owner:成都科创诺商贸有限公司

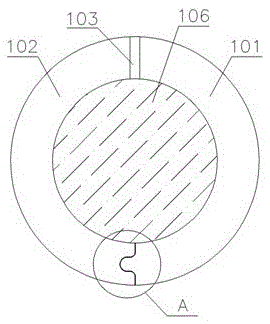

Warming device for end of direct drinking water outlet pipe

A warming device for the end of a direct drinking water outlet pipe comprises the water outlet pipe, and the warming device is arranged at the end of the water outlet pipe. The warming device comprises a water conveying pipe, an outer sleeve pipe wrapping the outer wall of the water conveying pipe, infrared heaters, a power supply unit and a switch, wherein the outer sleeve pipe comprises a first outer sleeve pipe body and a second outer sleeve pipe body; the cross section of the first outer sleeve pipe body and the cross section of the second outer sleeve pipe body are in matched semi-ring shapes, a sealing protrusion is arranged at the other end of the first outer sleeve pipe body, a sealing groove matched with the sealing protrusion for sealing is formed in the other end of the second outer sleeve pipe body, and the first outer sleeve pipe body and the second outer sleeve pipe body are locked by the sealing protrusion and the sealing groove to form a ring shape; the sealing protrusion is provided with a clamping portion, the sealing groove is provided with a clamping fit portion, and the sealing protrusion and the sealing groove are clamped and locked through the clamping portion and the clamping fit portion. The warming device is simple in structure, convenient to use, good in stability, high in reliability, low in manufacturing cost, high in practicability and capable of slightly warming the end of the direct drinking water outlet pipe so as to improve the drinking comfort level.

Owner:靖江市华信科技创业园有限公司

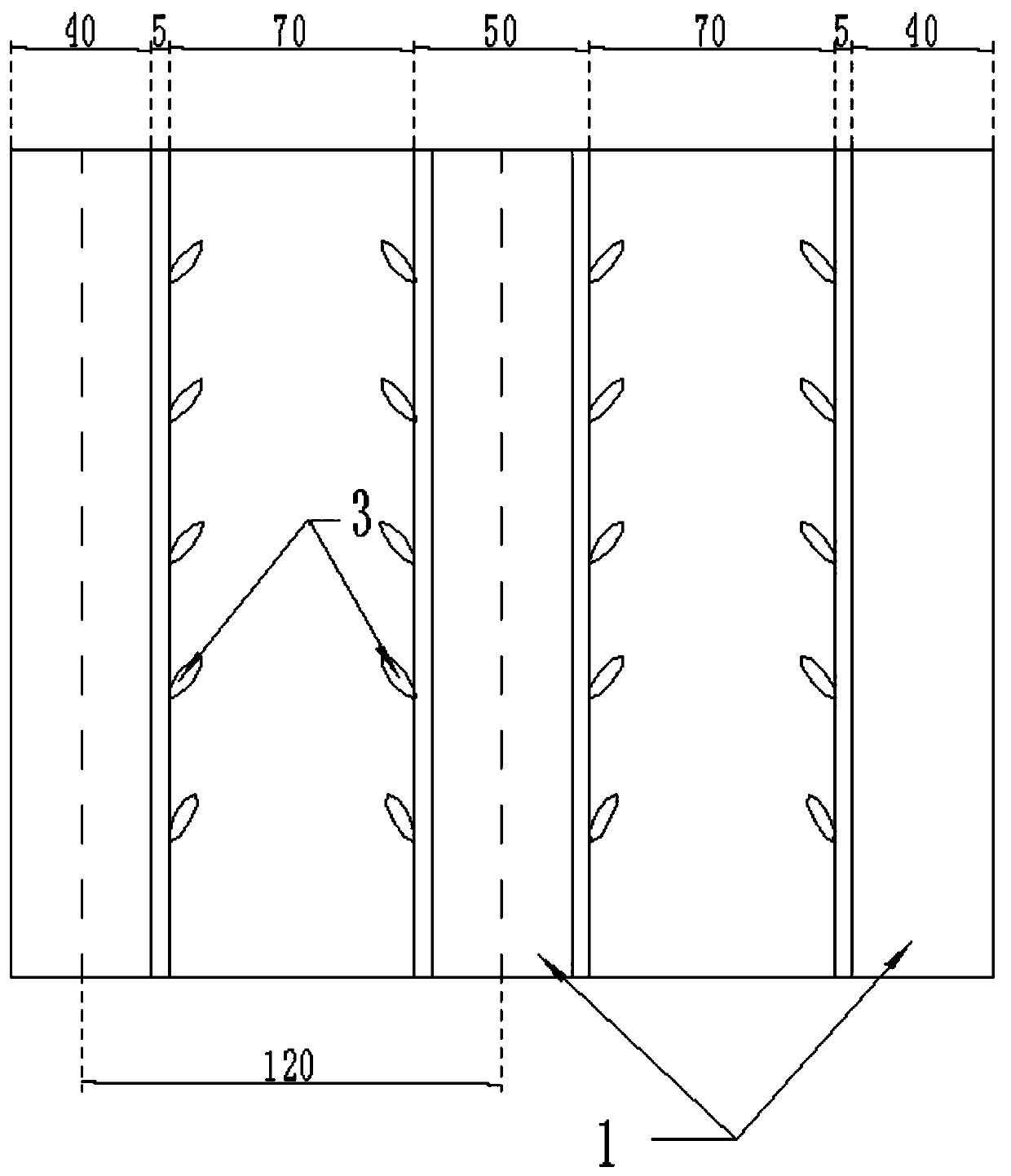

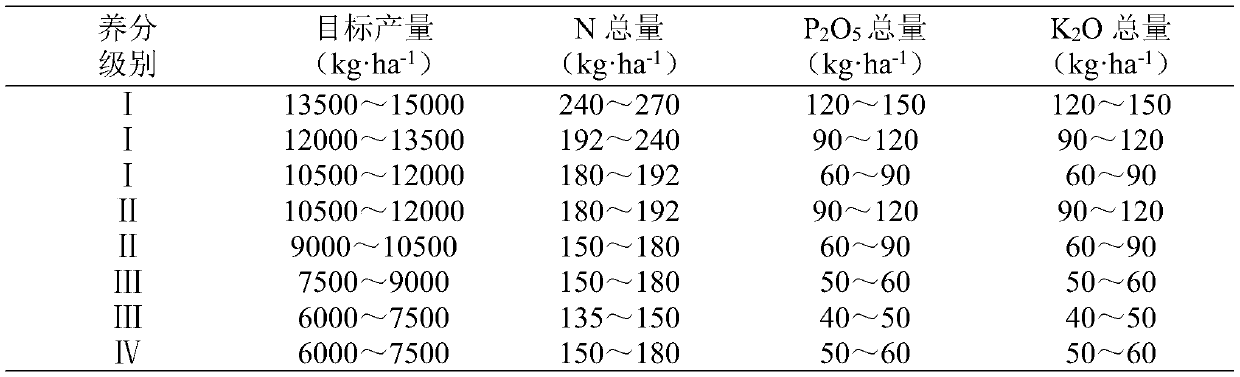

Winter wheat and summer corn scarifying, ridging, laminating and micro-irrigation water and fertilizer integrated cultivation method

PendingCN110786213AImprove lighting conditionsIncrease photosynthetic rateFertilising methodsCereal cultivationSoil scienceTillage

The invention discloses a winter wheat and summer corn scarifying, ridging, laminating and micro-irrigation water and fertilizer integrated cultivation method which includes the steps: performing water-saving tillage operation on soil before winter wheat sowing, sequentially performing water-saving sowing operation and water and fertilizer management during growth of winter wheat, and crushing andreturning straws after winter wheat harvesting; sowing a line of corns on each of two sides of each ridge, performing deep furrow application of base fertilizers; performing corn season water management by a demand-based supplemental irrigation method; crushing and returning straws after corn harvesting. Fertilizer application rate is determined according to soil texture, the major nutrient content of an arable layer and target corn yield. Tillage water saving, coverage water saving, facility water saving and agronomic water saving are integrated, the advantage of integrated innovation is highlighted, the cultivation target of drought resistance, water saving, simplifying and high efficiency is achieved, economic, social and ecological benefits are remarkable, and the method has a wide popularization and application prospect.

Owner:NORTHWEST A & F UNIV +1

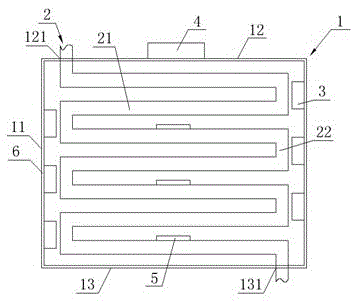

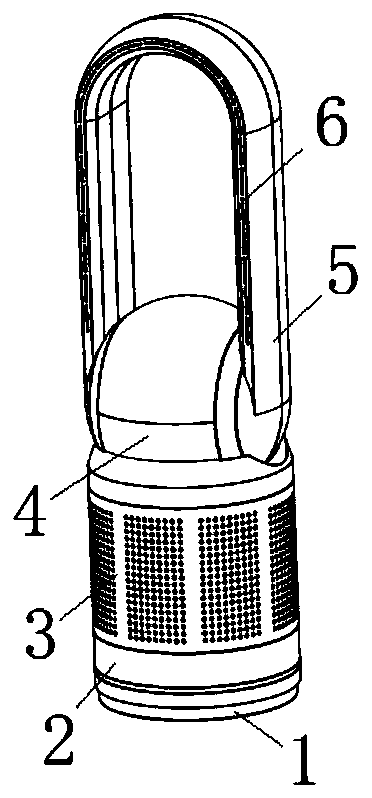

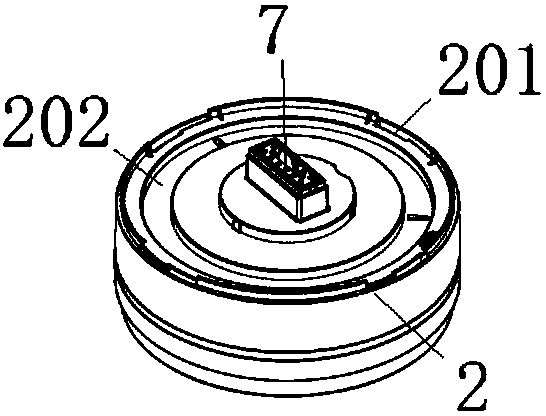

Fan air-outlet structure and bladeless fan with same

PendingCN110469549AReasonable structural designGood warming effectPump componentsAir heatersEngineeringAir heating

The invention discloses a fan air-outlet structure. The fan air-outlet structure includes an air outlet chamber, and the air outlet chamber is provided with an inlet used for introducing air from a draught fan into the air outlet chamber and an air outlet used for blowing air flow out from the air outlet chamber. The structure further includes a heater for heating the air flow in the air outlet chamber, the heater is arranged in the air outlet chamber and is of a strip-shaped structure, and the strip-shaped heater is arranged along an air duct inside the air outlet chamber. The bladeless fan includes a base, a shell and the draught fan and further includes the fan air-outlet structure, and the air outlet of the fan is communicated with the inlet of the air outlet chamber. The structure iscompact, arrangement and installation are facilitated, and the air heating effect is good. Moreover, stop of heating does not affect the ventilation effect of natural wind.

Owner:리성

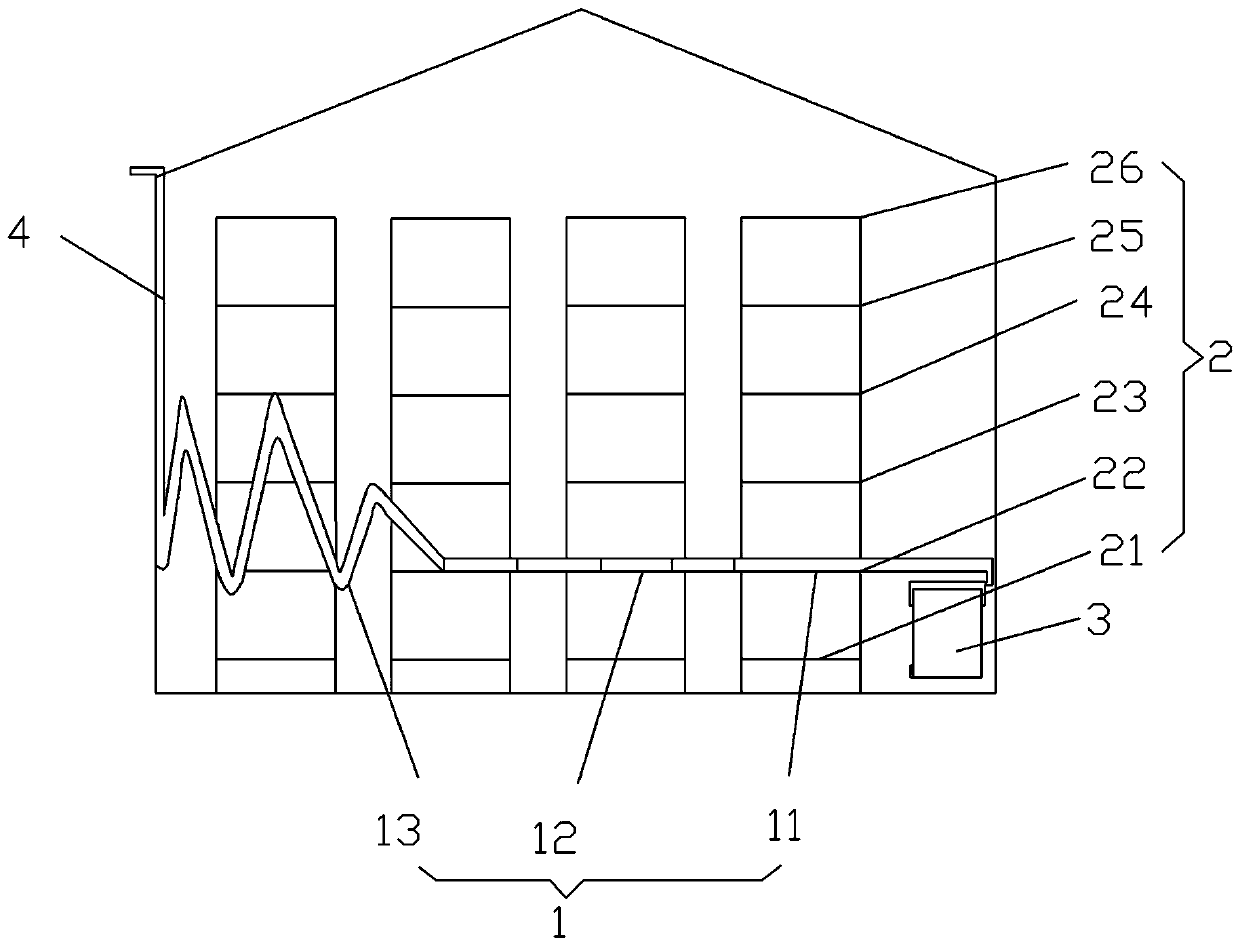

Synchronous temperature-increasing mushroom house device and its synchronous temperature-increasing cultivation method specially used for Agaricus blazei

ActiveCN106613311BEvenly dispersedMushroom shape is goodCultivating equipmentsMushroom cultivationAgaricus blazeiEngineering

The invention discloses a synchronous temperature-increasing mushroom house device special for agaricus blazei murill and a synchronous temperature-increasing cultivation method thereof. The synchronous temperature-increasing mushroom house device is characterized in that a heat dissipation pipeline consists of a heat dissipation pipeline front portion connected through a smoke outlet of a coal stove, a heat dissipation pipeline rear portion connected with a smoke discharging chimney and a heat dissipation pipeline middle connected between the front portion and the rear portion, wherein the heat dissipation pipeline front portion is a horizontal straight pipe located among 2-4 layers of mushroom beds, the heat dissipation pipeline middle is a horizontal transverse coiled pipe located among 2-4 layers of mushroom beds, and the heat dissipation pipeline rear portion is a vertically bent vertical coiled pipe located among 1-4 layers of mushroom beds. The synchronous temperature-increasing mushroom house device has the advantages that environment temperature can be conveniently and effectively controlled, a synchronous temperature-increasing effect is good, orderly original agaricus blazei murill bases are promoted, mushroom shapes are good, further the increased unit yield of the agaricus blazei murill can be up to 7.2-9.3 kg / m<2>, the yield obtained after temperature increase can be increased by 44-55% compared with the yield obtained without temperature increase, the sporocarp quality is good, and a yield-increasing effect is remarkable.

Owner:莆田市荔城区农业局

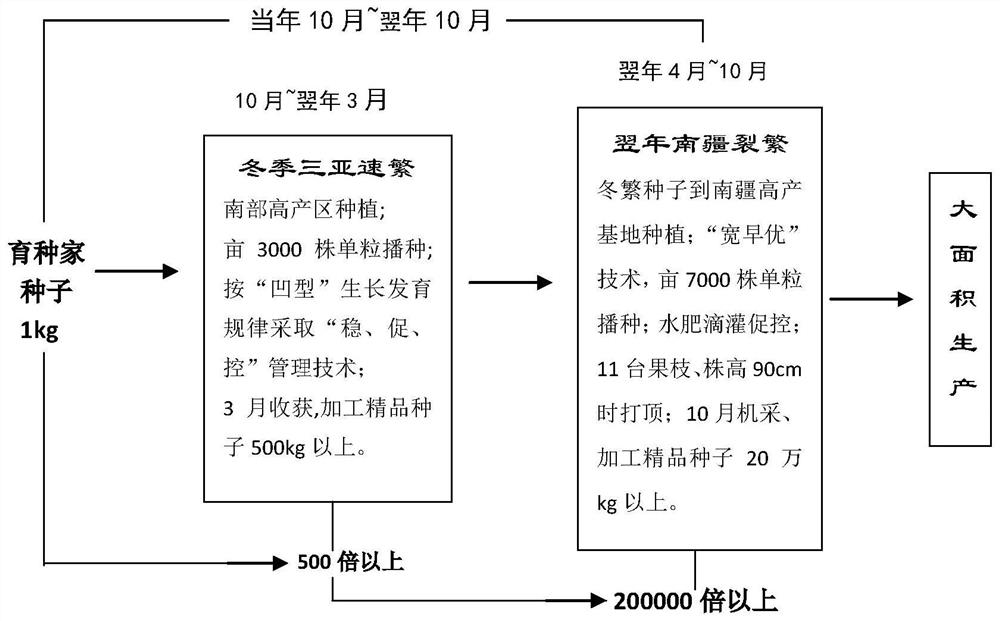

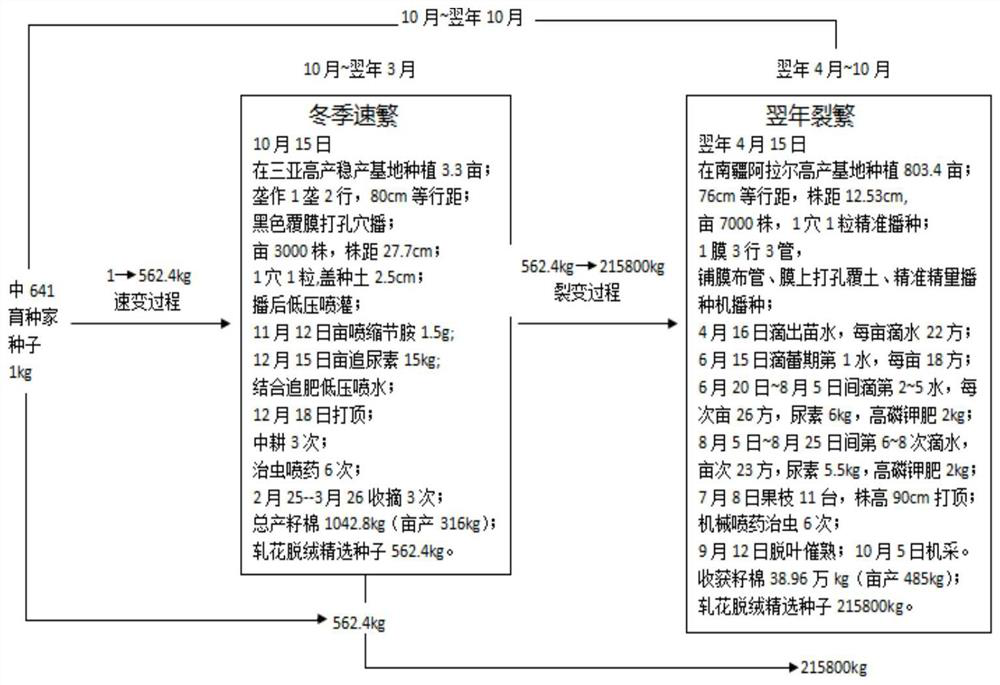

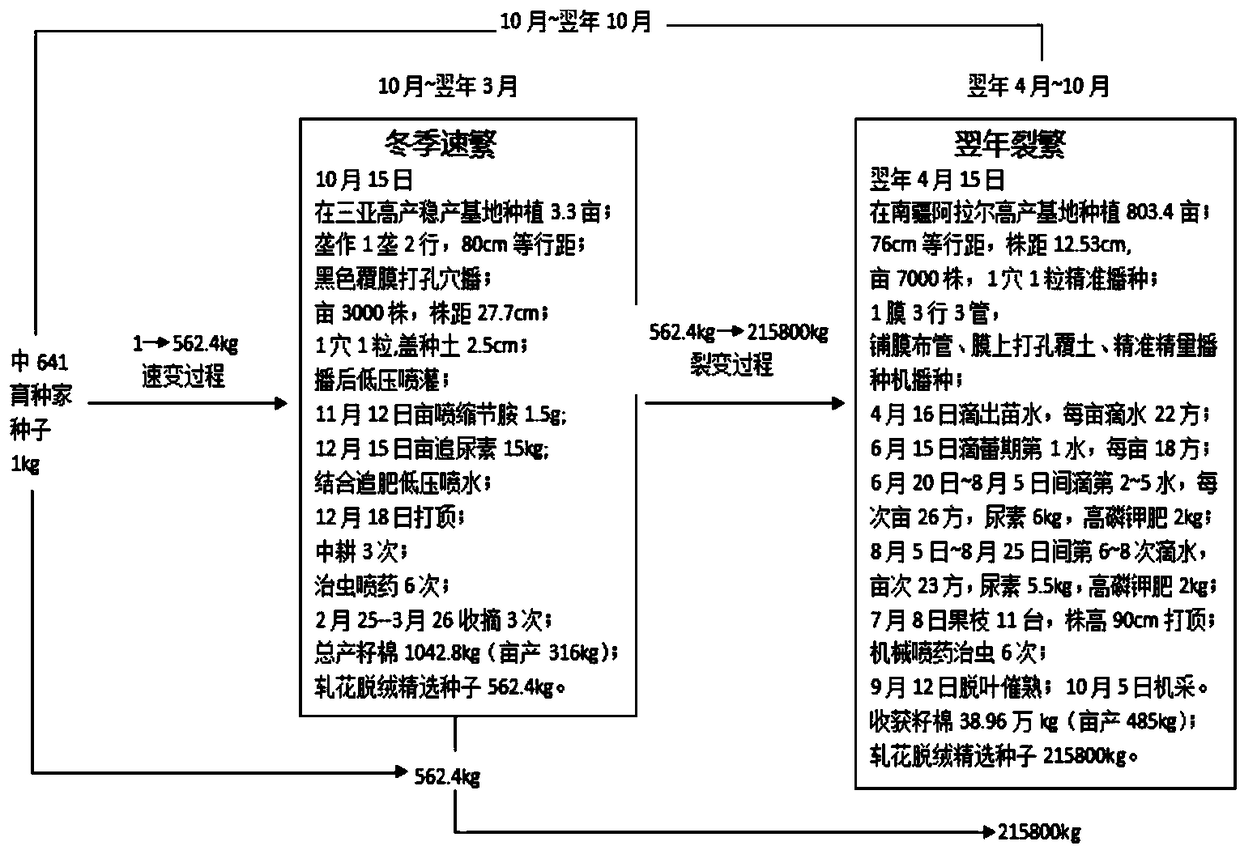

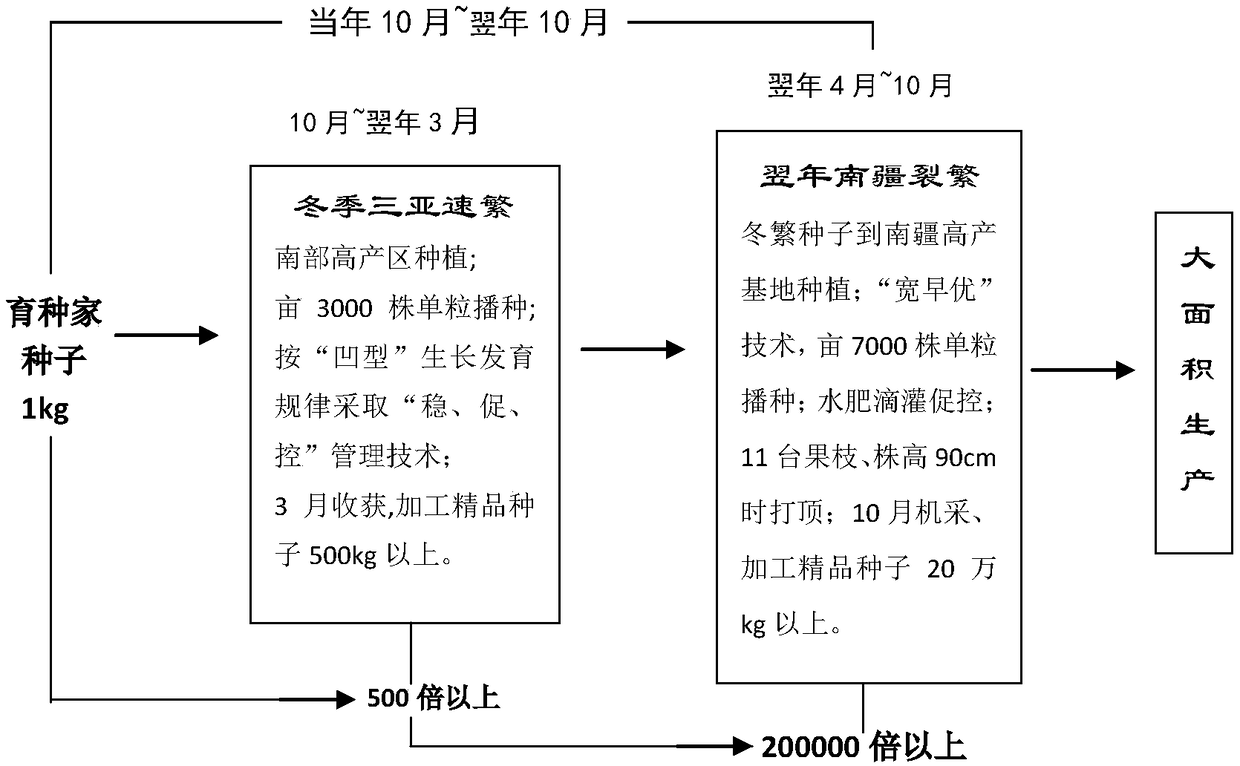

A method for cotton seed production with annual 200,000 times

ActiveCN109006313BIncrease opportunities for multiplicationPromote high yield and high qualityCotton cultivationHorticultureBotany

The invention discloses a method for cotton seed production with an annual rate of 200,000 times. The steps are: 1. selection of varieties; Ridge cultivation with black plastic film covering; 4. According to the concave growth pattern of cotton in winter in the south, adopt the management method of stability, promotion, and control: 5. In the mid-term bud flower and boll stage and the low temperature stage in Hainan in the next year, reapply flower boll fertilizer and water flower boll water; 6. As the temperature rises in the later period, the cotton begins to open bolls, and watering is controlled under the development of cotton bolls; 7. The cotton is harvested after the cotton bolls are opened and matured in March of the following year; 8. The seeds are transported to the high-yield and stable-yield breeding area in southern Xinjiang for sowing in April 9. Green prevention and control of diseases, insect pests and weeds; 10. Defoliation and ripening in September, and mechanized harvesting in October. The method is easy to operate and easy to operate. Within one year, 200,000 kg of seeds can be produced from 1 kg of seeds, and 200 kg of breeder seeds can be obtained. The seeds produced within one year can be used to plant more than 80% of the cotton fields in the country.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Yearly 200,000-time cotton seed production method

ActiveCN109006313AIncrease opportunities for multiplicationPromote high yield and high qualityCotton cultivationBudInsect pest

The invention discloses a Yearly 200,000-time cotton seed production method comprising the following steps: 1, variety selection; 2, sowing period: selecting a land in the Hainan Sanya region, whereinthe land is fertile, easy in irrigation and pathogen infection-free; 3, using a ridge culture black mulch film to cover the land; 4, employing a front-stable middle-promotion post-control method to manage according to a cotton winter off-season multiplication concave growing law; 5, heavily dressing a flower boll fertilizer and fully watering a flower boll water in a middle stage cotton flower bud and boll stage and a next year Hainan low temperature stage; 6, controlling watering under the cotton boll growth conditions when the temperature rises in the late state and cottons start to open bolls; 7, harvesting the cottons in March the next year when the cottons open bolls and get ripe; 8, transporting seeds to a south Xinjiang high and stable yield seed production region in Xinjiang, andsowing in April; 9, carrying out green prevention and control for insect pests and weeds; 10, defoliating and ripening in September, and mechanically harvesting in October. The method is feasible, simple in operation, and one kg of seeds can produce 200,000 kg within one full year, thus obtaining 200kg of breeder seeds; by using the seeds prepared in one year, the method can plant 80% of the cotton fields in the whole country.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

A peat humic acid degradable liquid mulch film containing rare earth micro-fertilizer and antifreeze

InactiveCN103858718BGood warming effectPromote growth and developmentPlant protective coveringsFertilizer mixturesAnti freezingPeat

The invention discloses a preparing method and application of a peat humic acid degradable liquid mulching film containing rare-earth micro-element fertilizers and anti-freezing agents. The preparing method includes the technological steps that after fine selection and sundry removal are carried out on peat humic acid, the peat humic acid is smashed into powder ranging from 80 meshes to 400 meshes, raw materials are evenly stirred according to the weight ratio that the peat humic acid: mulching film-forming agents: cross-linking agents: the anti-freezing agents: rare earth: annexing agents: water = 3-10:1-5:0.2-1:0.5-1:0.1-1:0.2-0.5:30-60, the raw materials are reacted for 0.5 hours-2 hours at 20 DEG C-90 DEG C, and the peat humic acid degradable liquid mulching film containing the rare-earth micro-element fertilizers and the anti-freezing agents is generated. The peat humic acid degradable liquid mulching film has the good warming performance and the good low-temperature-resistant performance; when hot water cannot be provided due to condition limitation, cold water can be directly used to be evenly stirred with the raw materials to be sprayed to form the mulching film, and complete degradation can be achieved after the peat humic acid degradable liquid mulching film is used for 2-3 months.

Owner:江西双佳科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com