Intelligent glass system with efficient one-way light and heat transfer function

A smart glass and high-efficiency technology, applied in the direction of parallel glass structure, window/door improvement, building components, etc., can solve the problem of no one-way transmission of light and heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

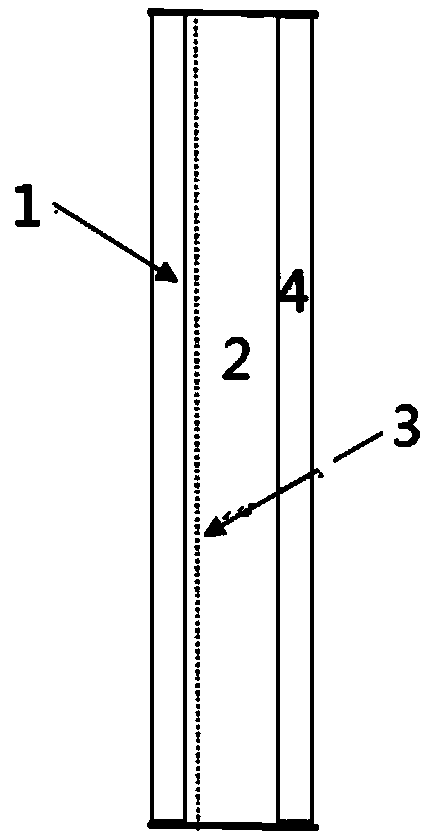

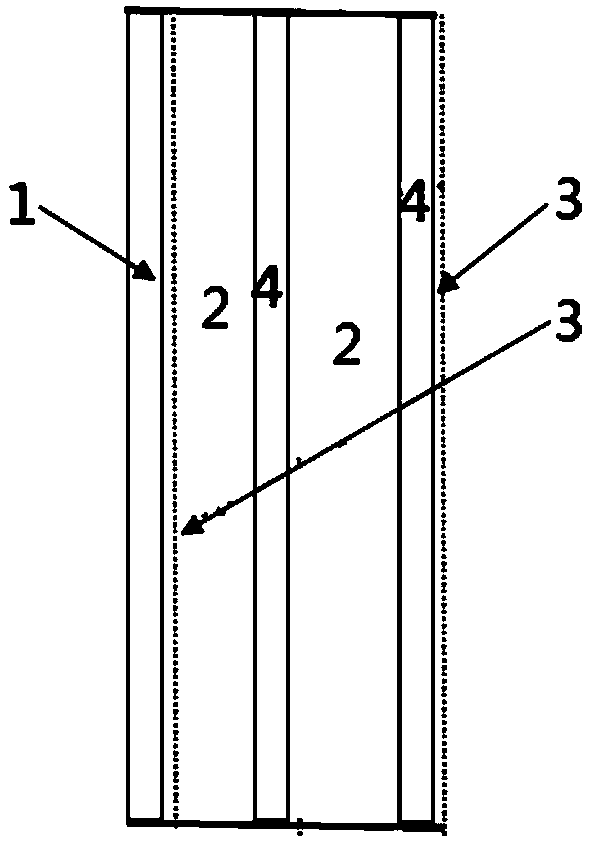

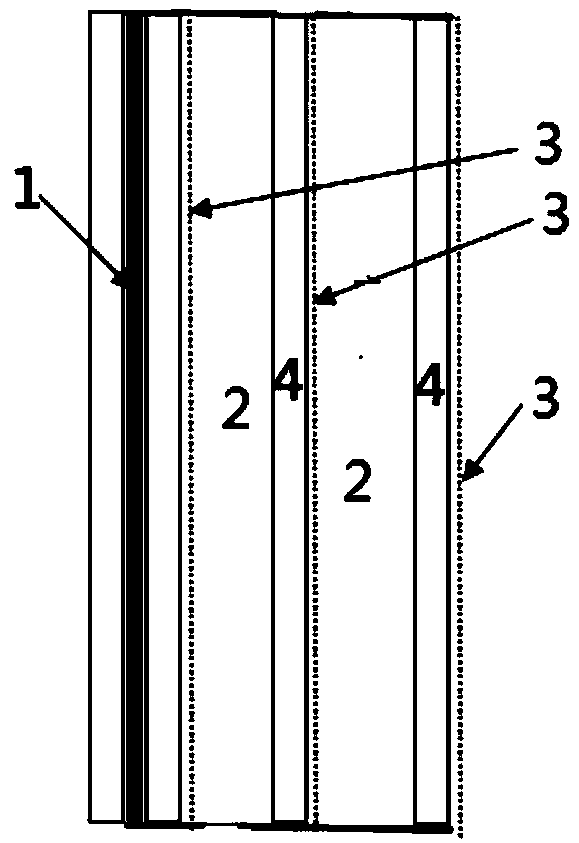

Image

Examples

Embodiment 1

[0143] 66% SiO 2 , 2% Al 2 o 3 , 9% CaO, 4.5% MgO, 15% R 2 O, 0.6% Fe 2 o 3 , after mixing 0.01% CoO and 2.89% SnO evenly, input the evenly mixed material into the kiln head silo, enter the melting furnace through the feeder, melt the material into a liquid state at 1480-1600°C, and then put the liquid The material is shaped by a tin bath, annealed in an annealing kiln, and then cut into heat-absorbing glass.

Embodiment 2

[0145] 66% SiO 2 , 2% Al 2 o 3 , 9% CaO, 4.5% MgO, 15% R 2 O, 0.8% Fe 2 o 3 , 0.02% CoO and 3.89% SnO are evenly mixed, and the evenly mixed material is input into the kiln head bin, and enters the melting furnace through a feeder, and the material is melted into a liquid state at 1480-1600 ° C, and then the liquid state The material is shaped by a tin bath, annealed in an annealing kiln, and then cut into heat-absorbing glass.

Embodiment 3

[0147] The endothermic glass prepared in Example 1 was cleaned and placed in a magnetron sputtering instrument, and doped with 2.5% Al with ZnO 2 o 3 As a target, the working pressure is 0.1-8Pa, the distance between the target and the glass surface is kept at 15 cm, and the glass temperature is 120 degrees Celsius. The deposition rate is controlled at 20 nm / min, and the deposition thickness is at 800 nm. The prepared glass is GLSa1, which absorbs 80% at 300-380 nanometers, 30% at 380-760 nanometers, 85% at 760-2500 nanometers, and has a reflectivity of 92% at 3-100 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com