Patents

Literature

337results about How to "Lower heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

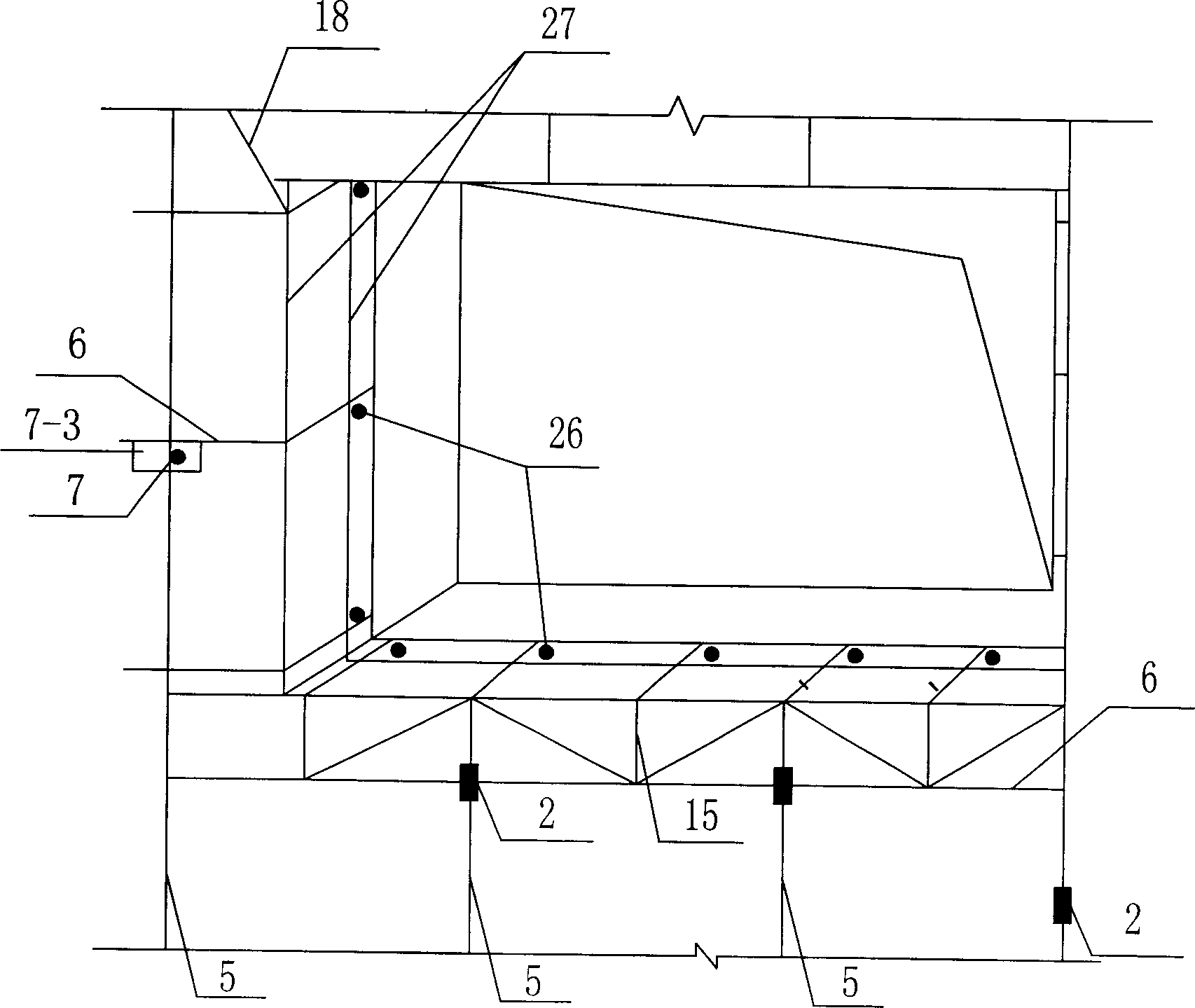

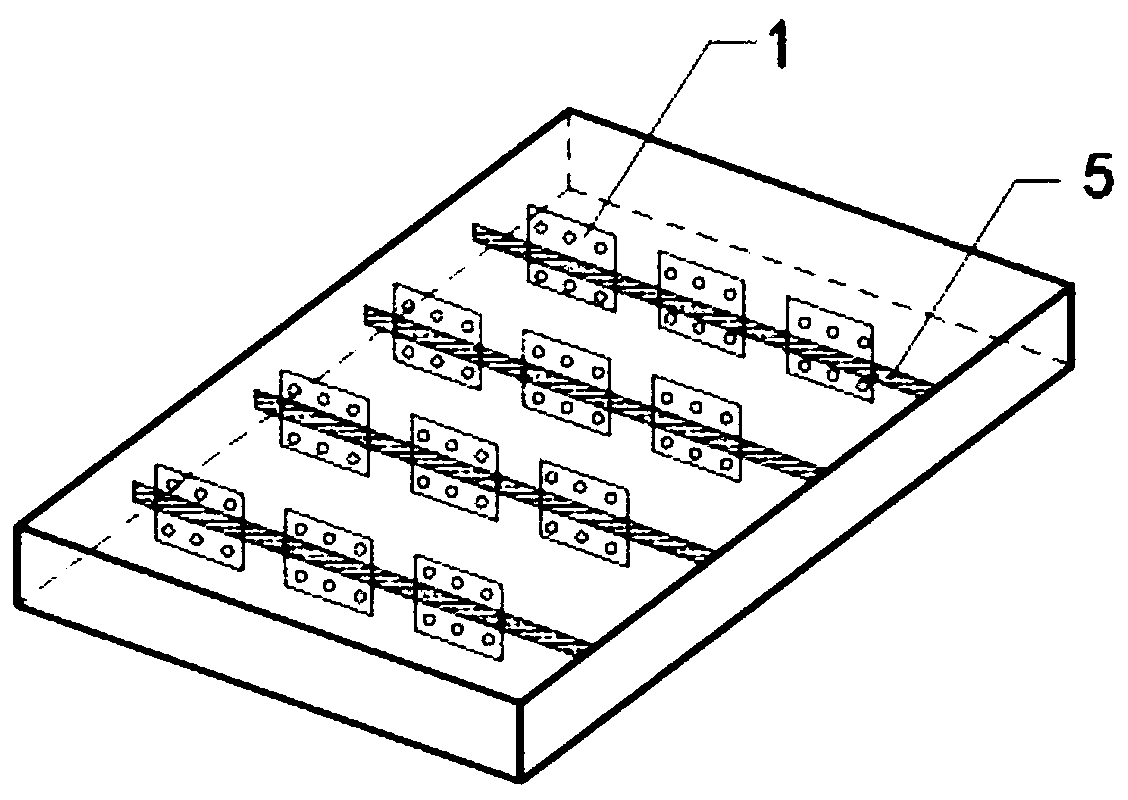

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977AImprove securityImprove mechanical performanceCovering/liningsWallsFloor slabRebar

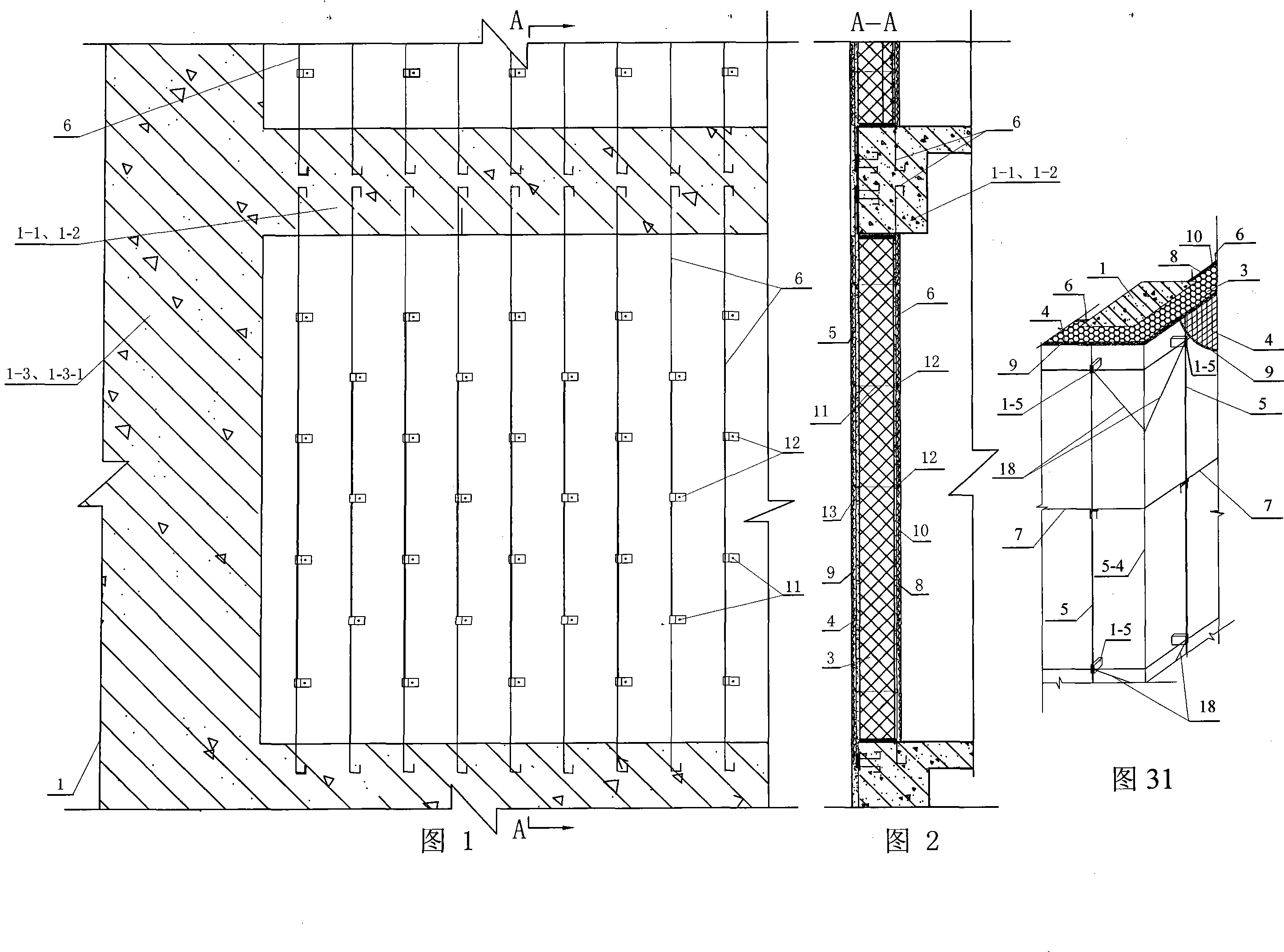

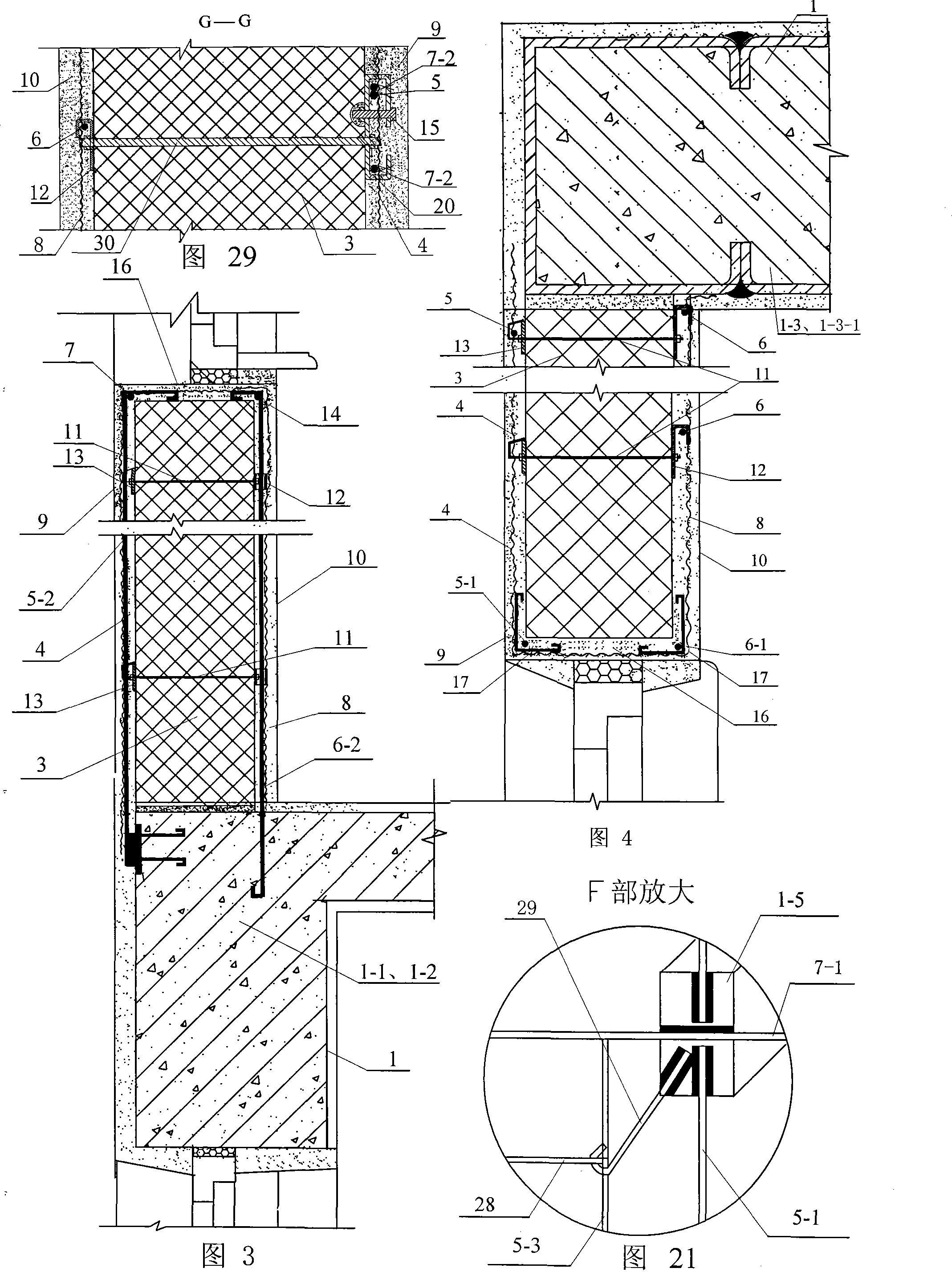

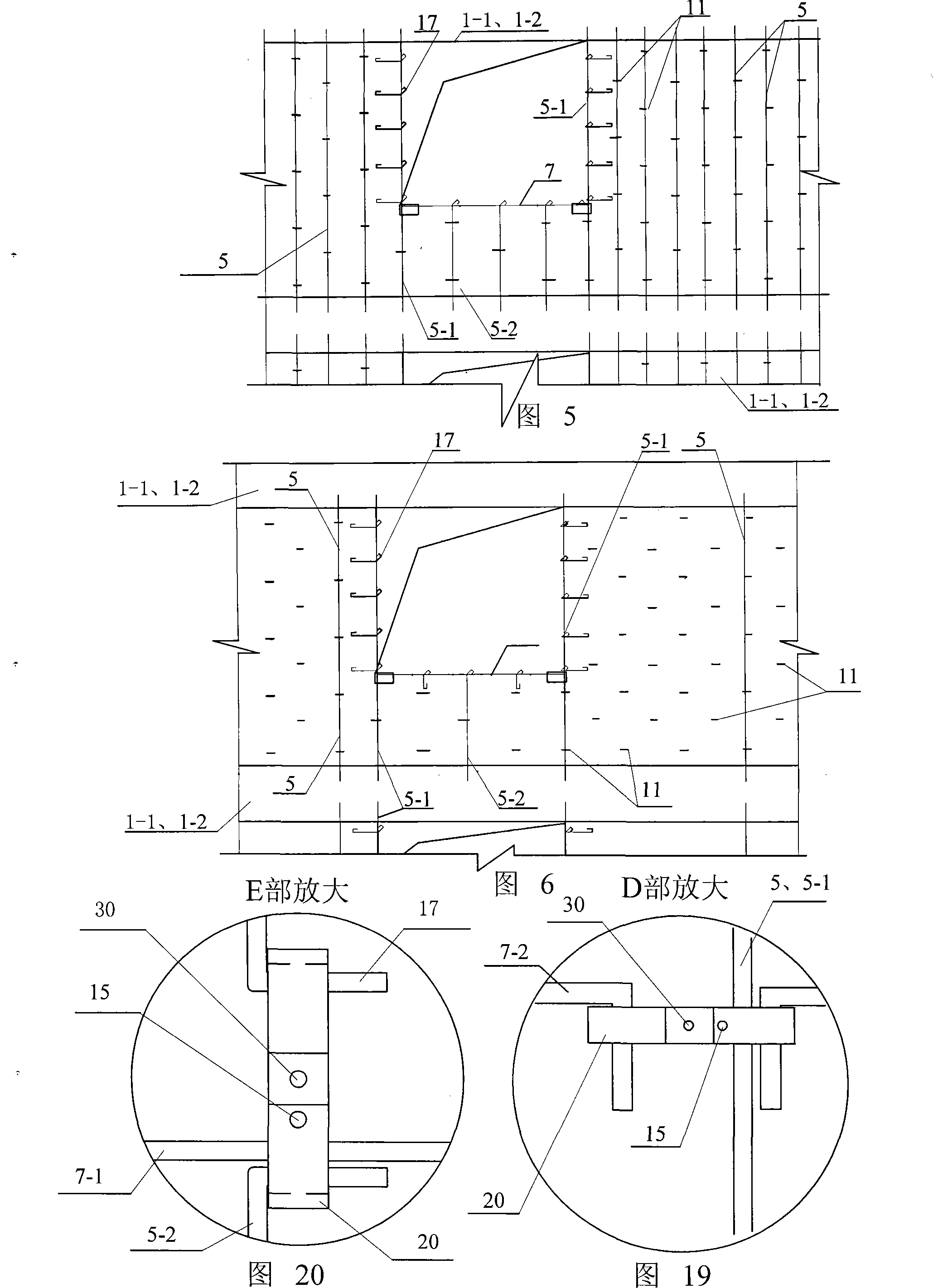

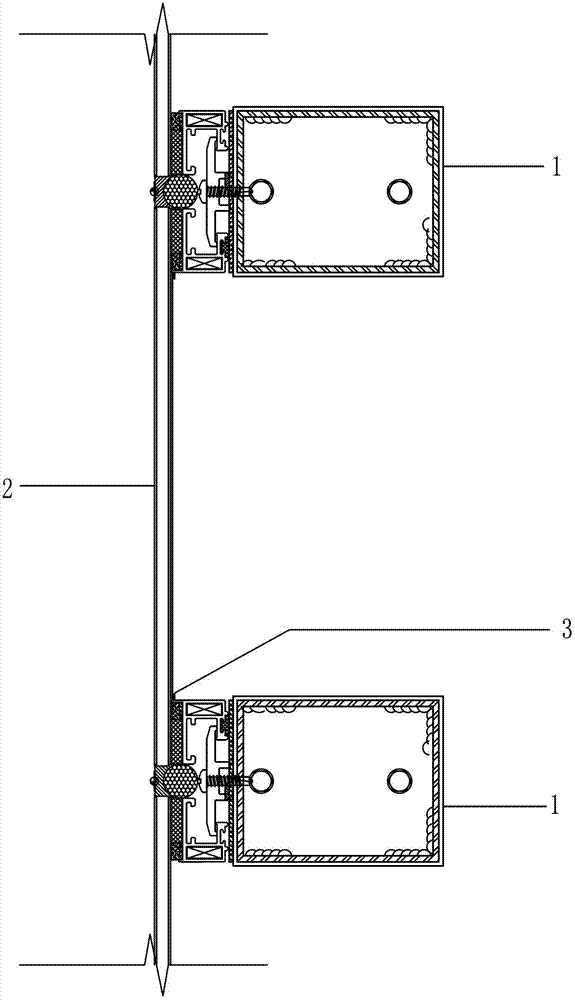

The utility model relates to a compound wall with reinforcing bars and / or metal mesh plastering on the inside and outside or on both sides, which relates to a building compound wall. Aiming at the incomplete structure of the bundled composite thermal insulation wall with support. Option 1: Outdoor vertical steel bars (5) and indoor vertical steel bars (6) are fixed to the outside and inside of the load-bearing member (1) of the main building structure, and the inner and outer sides of the core layer (3) are provided with inner and outer protection plan 2: the vertical steel bar (5-2) under the outdoor window sill and the vertical steel bar (6-2) under the indoor window sill are fixed to the cantilever plate (1-2); plan 3: indoor The vertical reinforcement (6) is fixed to the indoor floor of the load-bearing member (1) of the main structure of the building; scheme 4: the indoor vertical reinforcement (6) on both sides of the air layer, and the inner and outer sides of the indoor metal mesh are provided with protective layers (10 -1), the air layer (3-1) is located between the protective layers (10-1) on both sides. The invention has the advantages of good earthquake resistance, good wind load resistance, low cost, convenient construction, good safety of the outer decorative surface layer, increased indoor usable area, and meets the requirements of low energy consumption buildings.

Owner:吴淑环

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

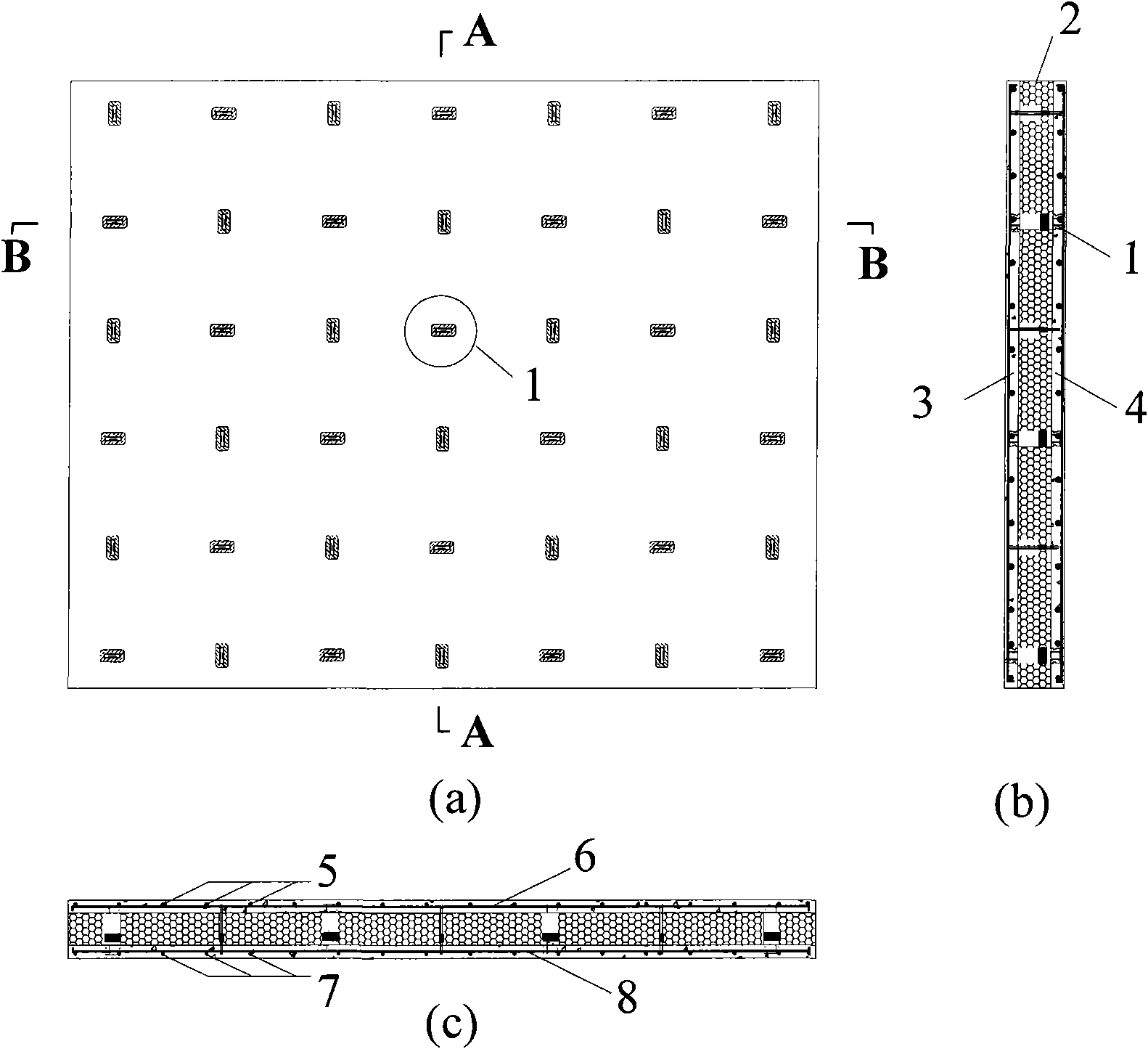

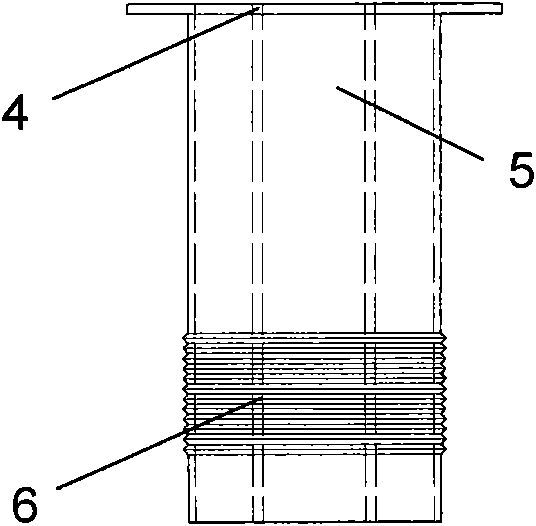

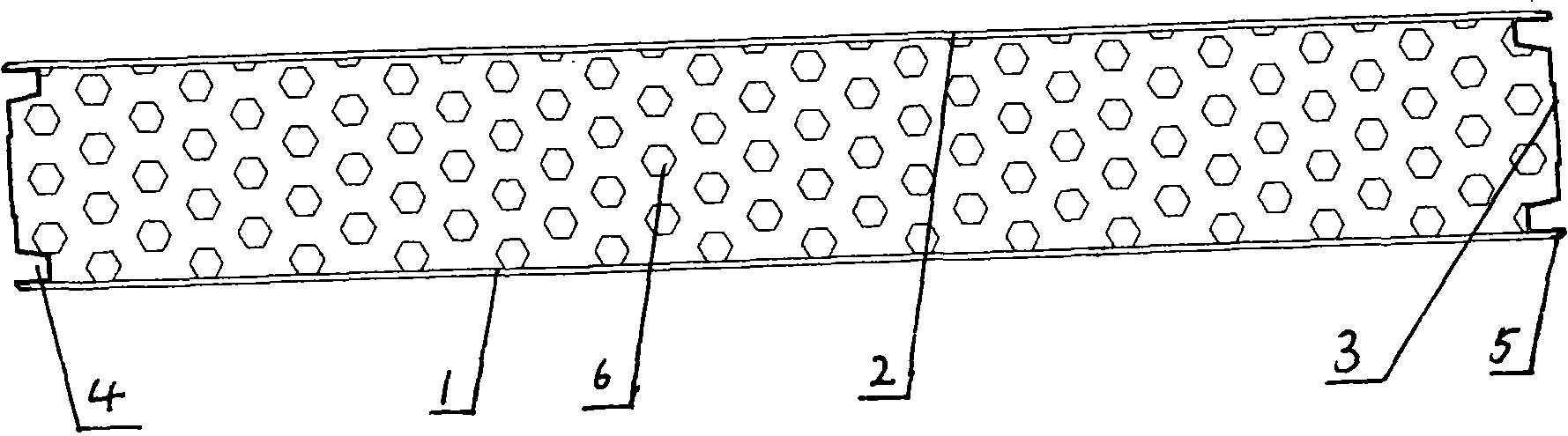

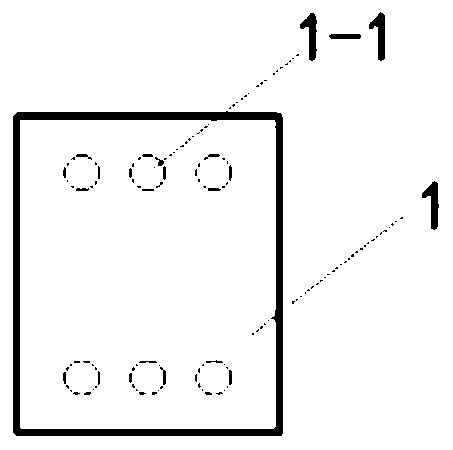

Prefabricated heat preservation wall body

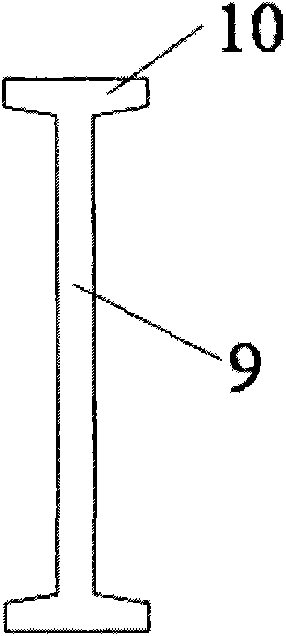

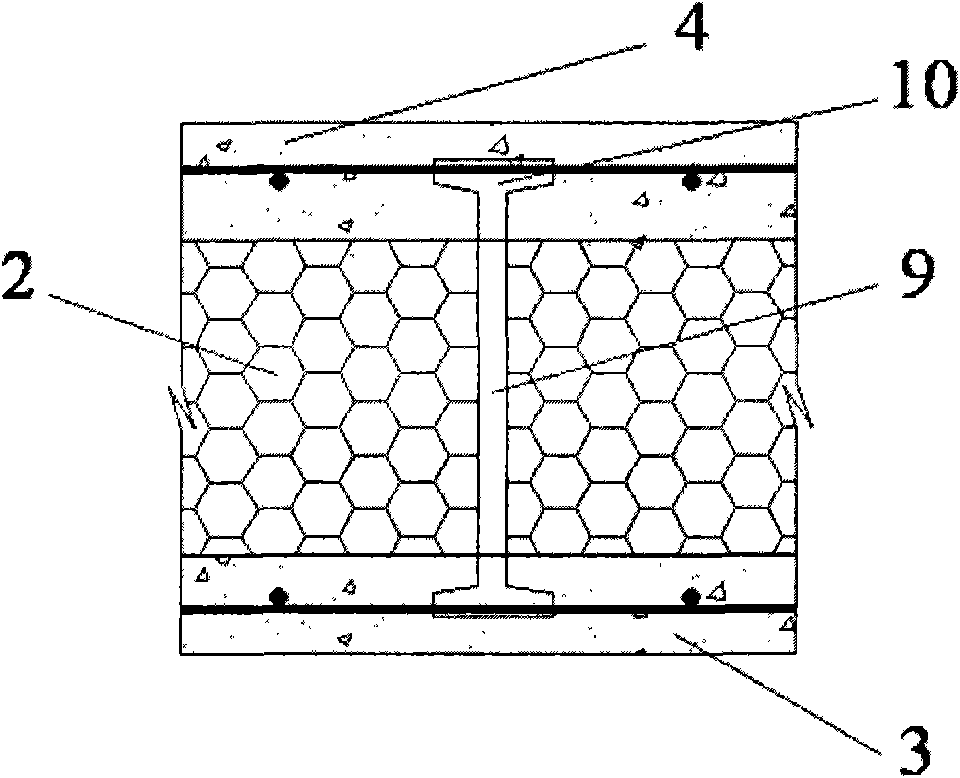

InactiveCN101538903APrevent peelingImprove integrityWallsHeat proofingStructure and functionSteel bar

The invention belongs to the technical field of civil engineering, and concretely relates to prefabricated heat preservation wall body. The prefabricated heat preservation wall body consists of a heat preservation layer, a concrete internal wall panel, a concrete external wall panel and an FRP connecting piece, the concrete internal wall panel is internally provided with longitudinally arranged steel bars and transversely arranged steel bars, the concrete external wall panel is internally provided with longitudinal arranged steel bars and transversely arranged steel bars, the FRP connecting piece is of a recumbent H structure and consists of a ventral shield and flange girths, two flange girths are provided in the invention and are respectively arranged at the two ends of the ventral shield; the heat preservation layer is arranged between the concrete internal wall panel and the concrete external wall panel and is internally provided with hole slots which are arranged in a crisscross way, and the FRP connecting piece is inserted in the hole slots; the end of the heat preservation wall body is provided with a splice bar which is of a U-shape structure, the two ends of the splice bar are respectively inserted into the concrete external wall panel and the concrete internal wall panel. The invention realizes a novel prefabricated heat preservation wall body with an integral structural function, has the advantages of low heat conductivity coefficient, good corrosive nature, simple and convenient construction and the like, and has relatively extensive application prospect in the field of constructional engineering.

Owner:TONGJI UNIV

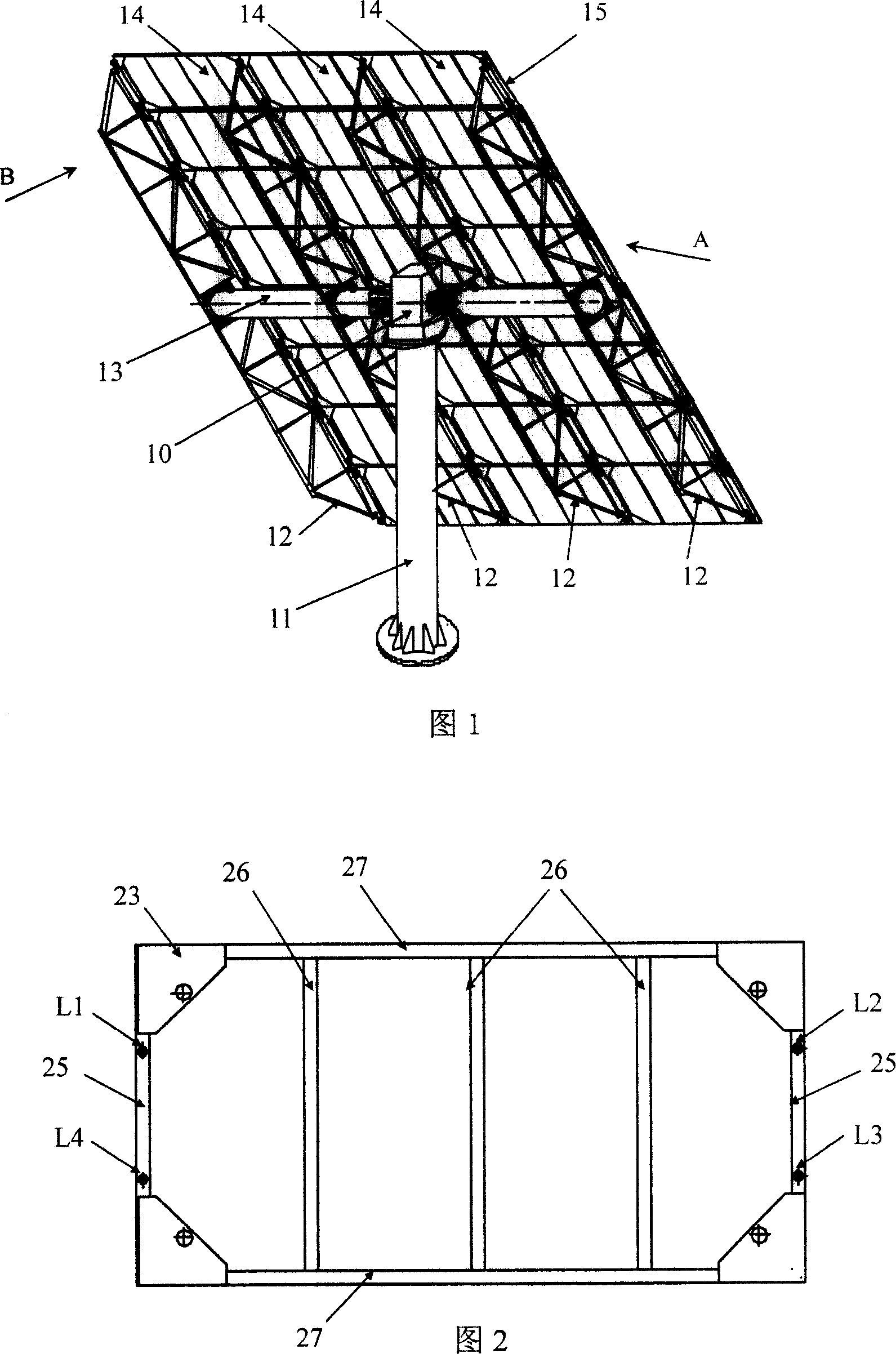

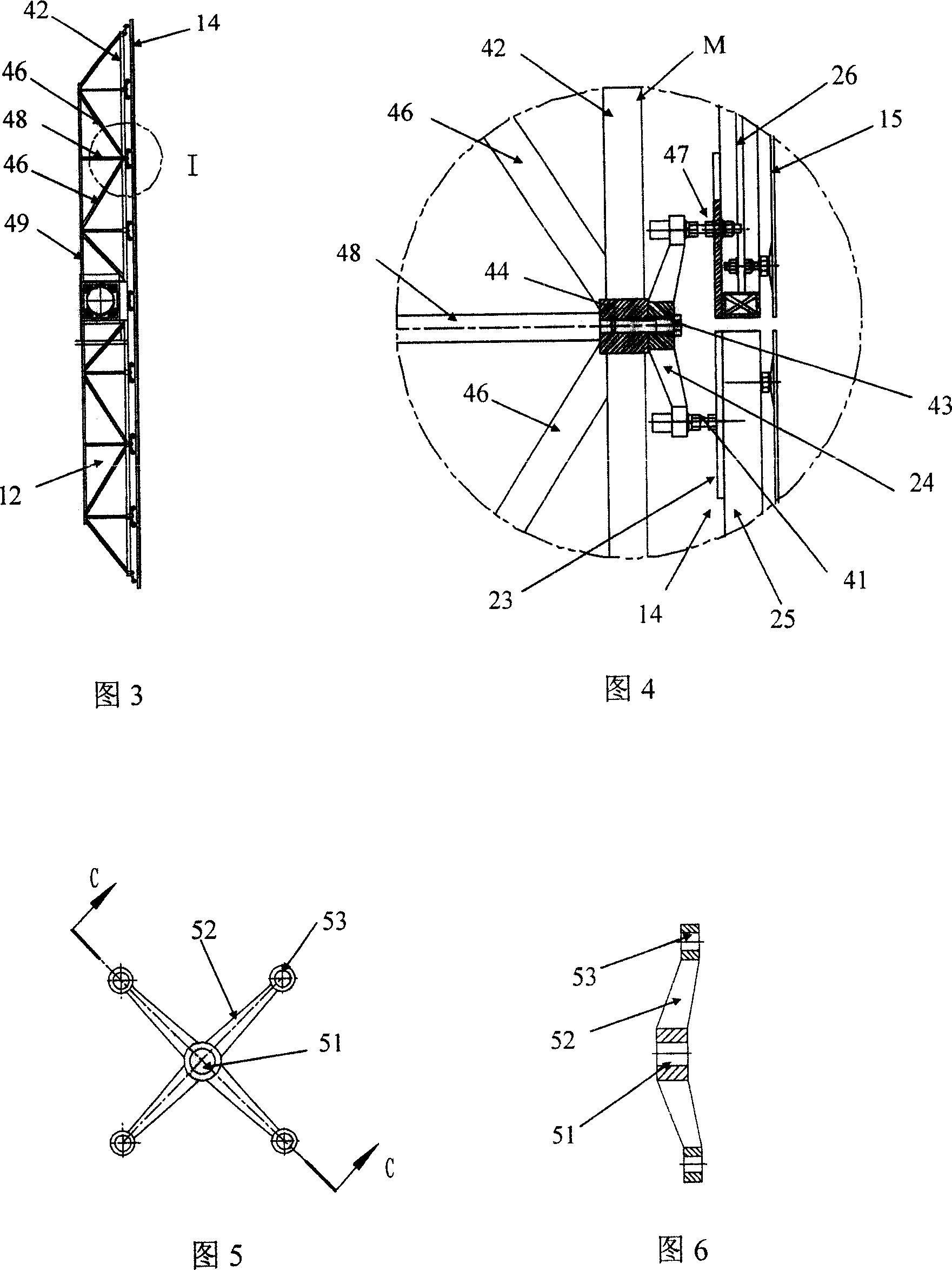

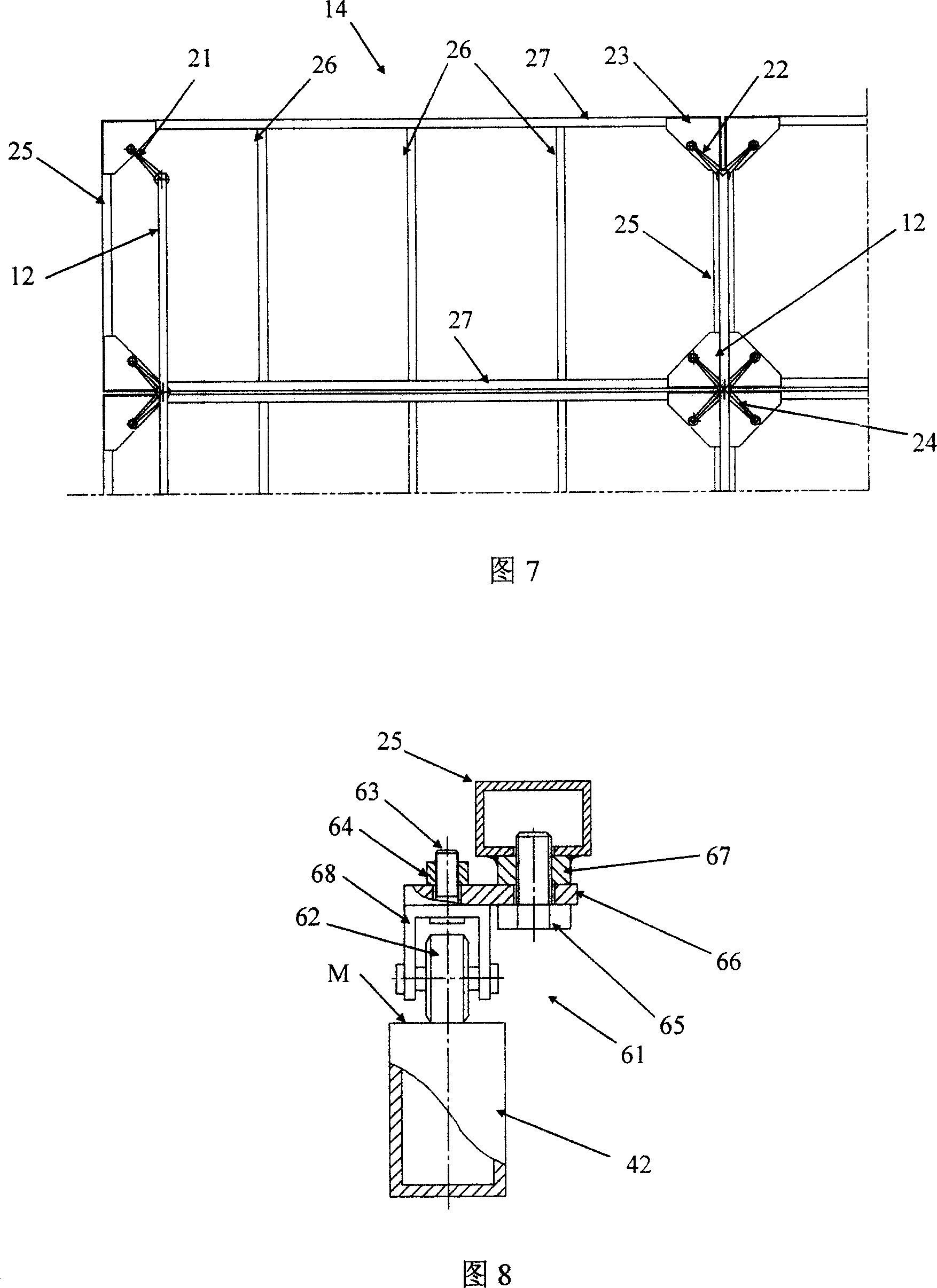

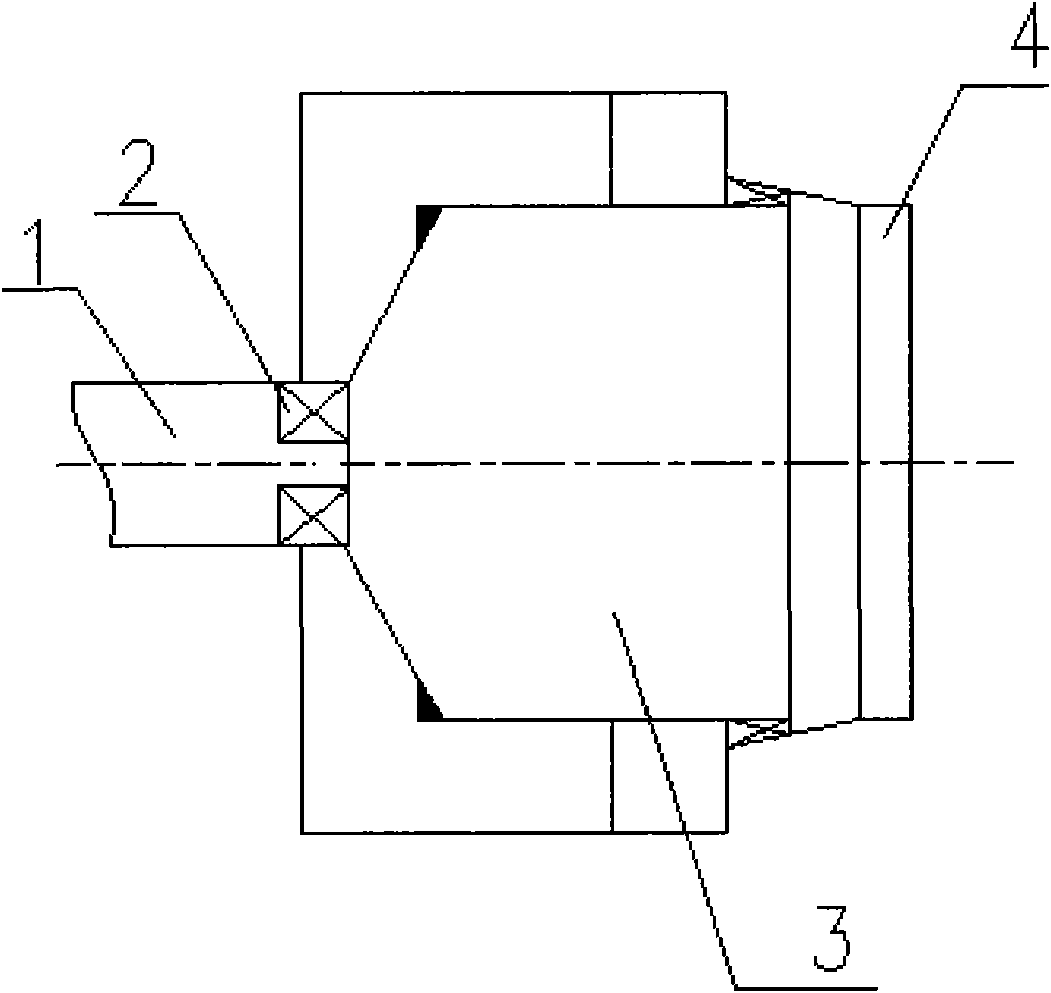

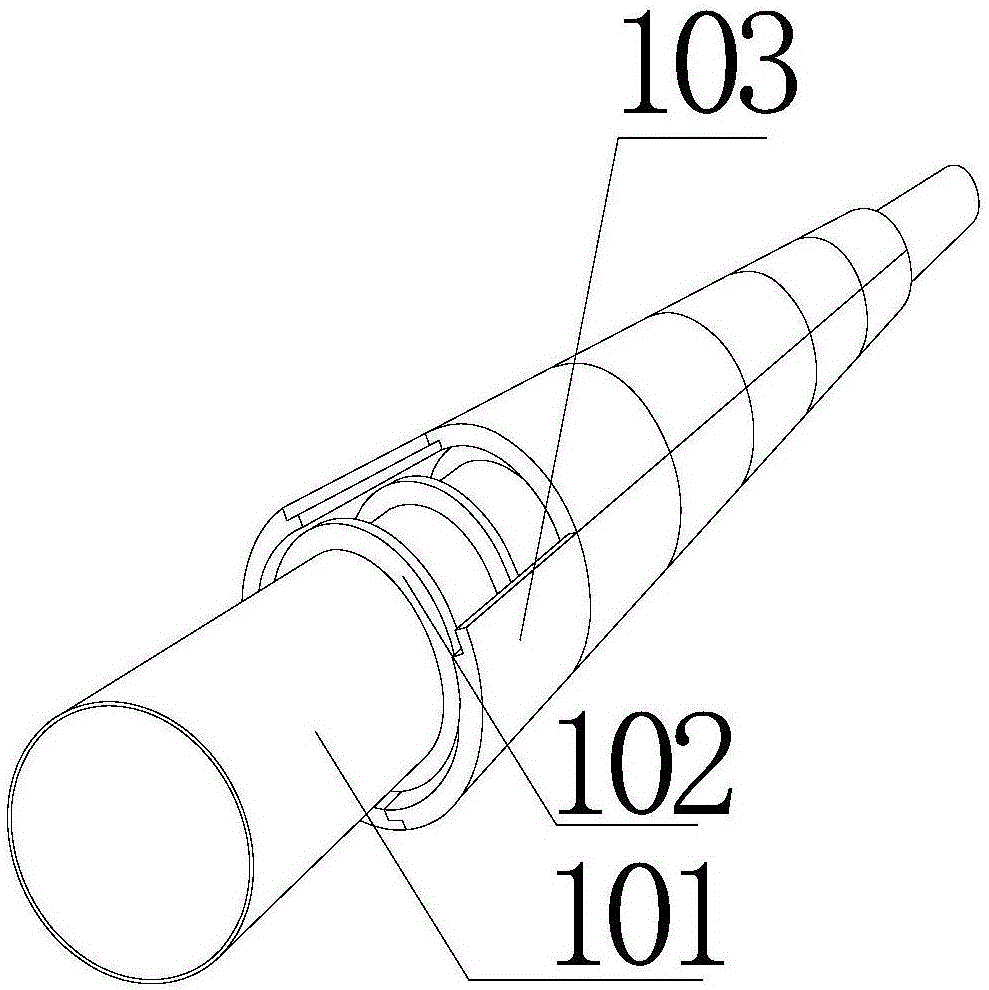

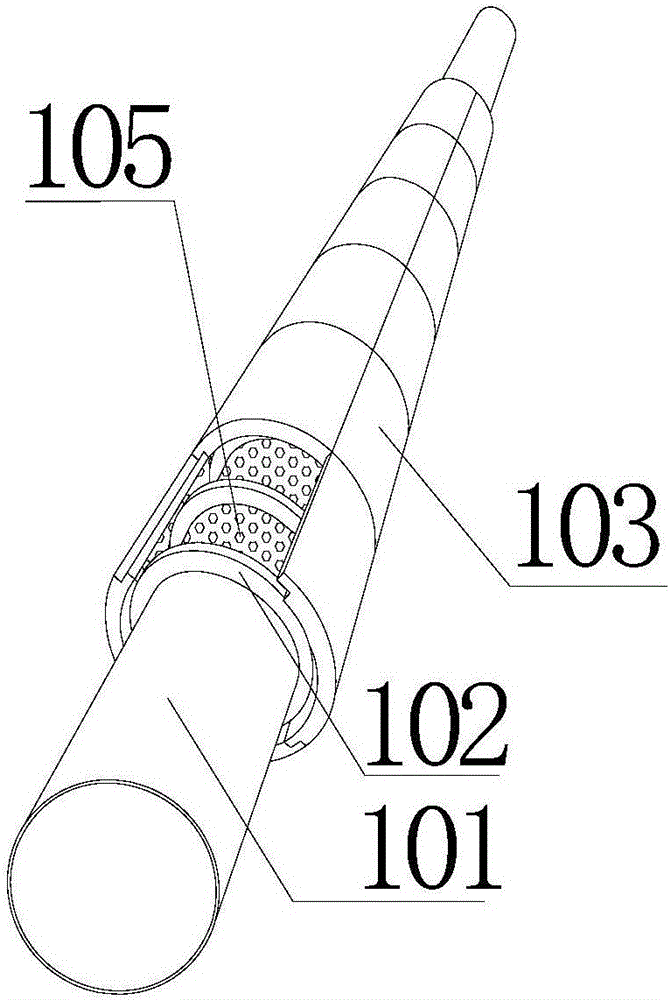

Supporter device of heliostat

InactiveCN101017033ALower heat transfer coefficientGood weather resistanceSolar heating energySolar heat collector controllersHeliostatBraced frame

The invention relates to a heliostat support structure, formed by a post (11), a transverse axle (13), a support arm (12) and a mirror support frame (14), wherein the support arm (12) and the mirror support frame (14) have all elements made from non metal section bar, to reduce weight and the load of transmitter, thereby using small power motor to reduce system cost. The chamber of the non-metal section bar is arranged with rib plates inside, to obtain wind resistant ability. The support arm (12) and the mirror support frame (14) are connected via a porous connector, to support easy installment and adjust the installed height of the mirror support frame (14). The invention can mount a roller element (61) on the mirror support frame (14) to reduce installment time and cost.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

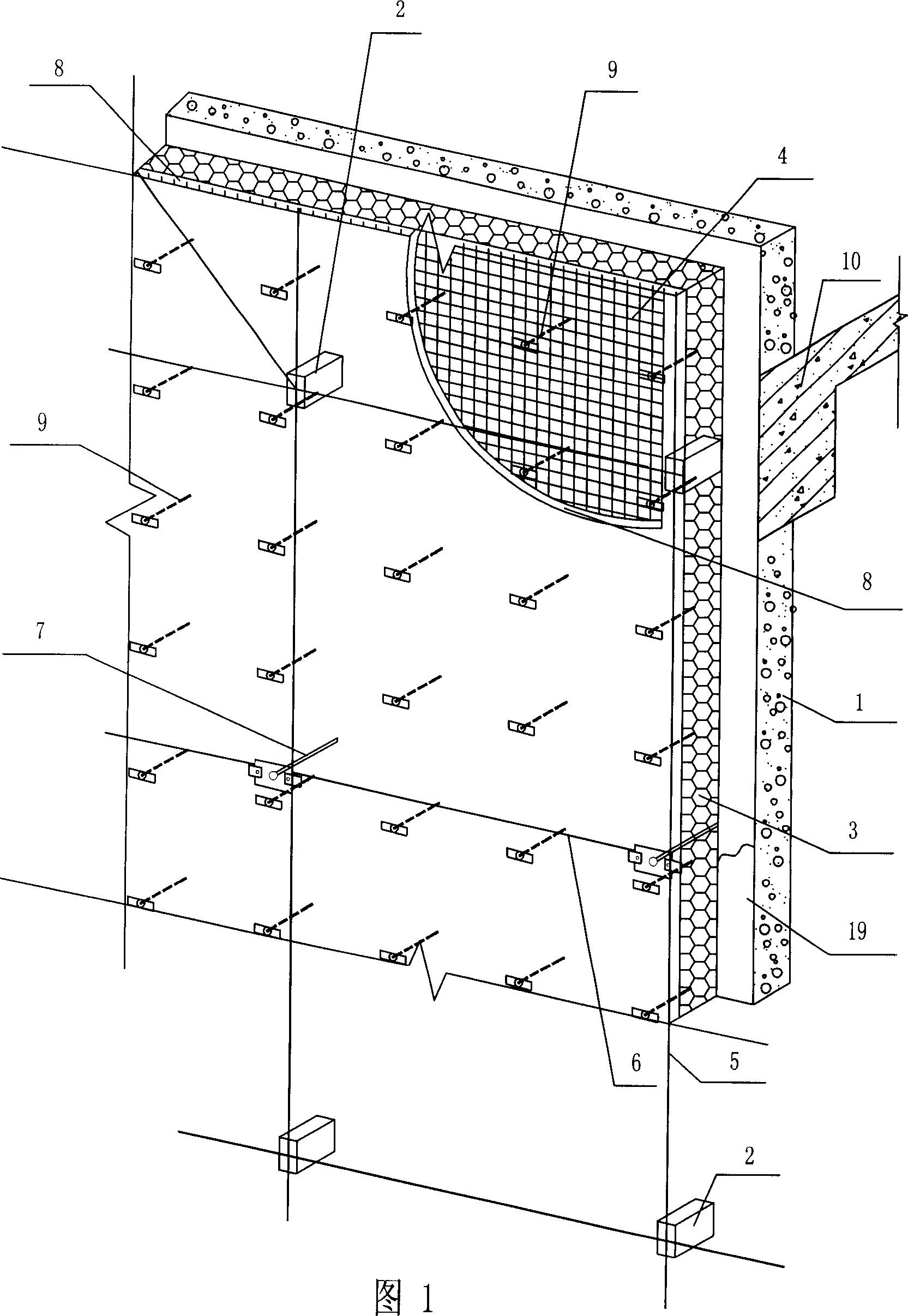

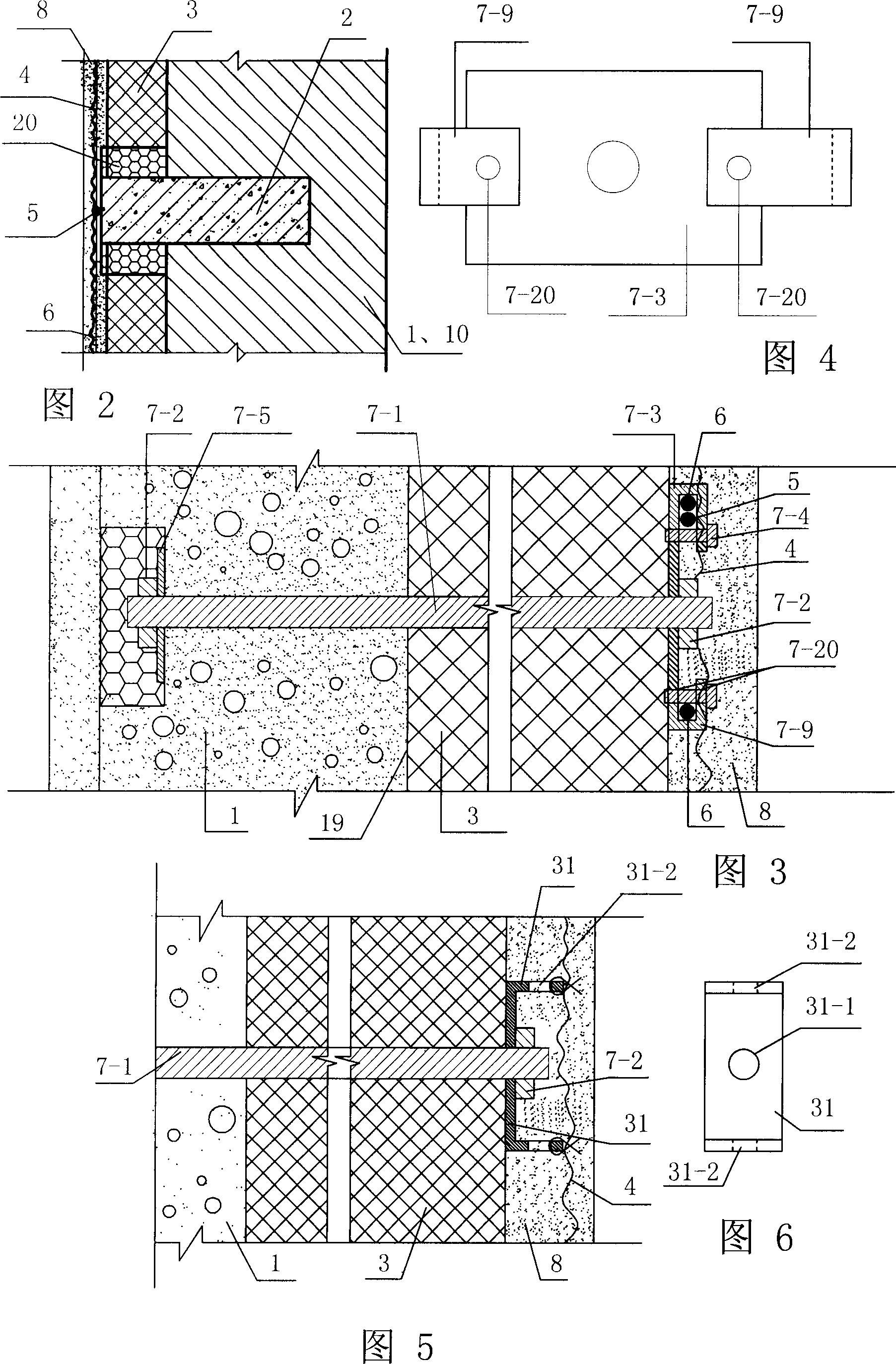

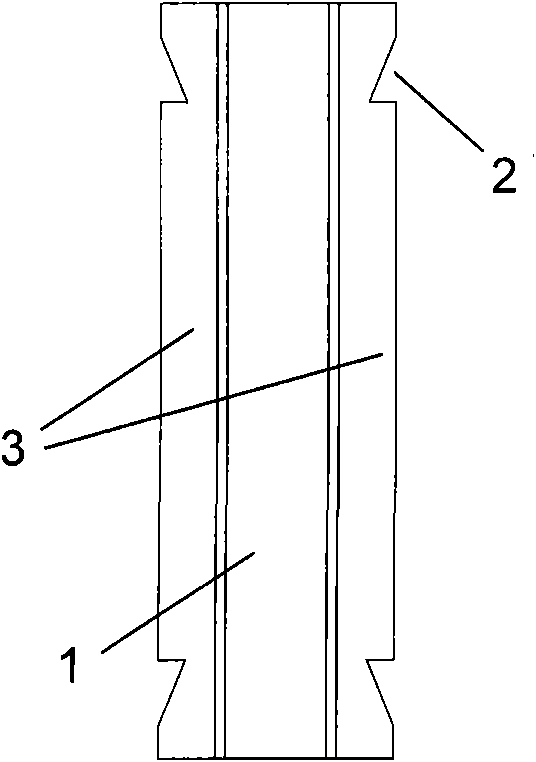

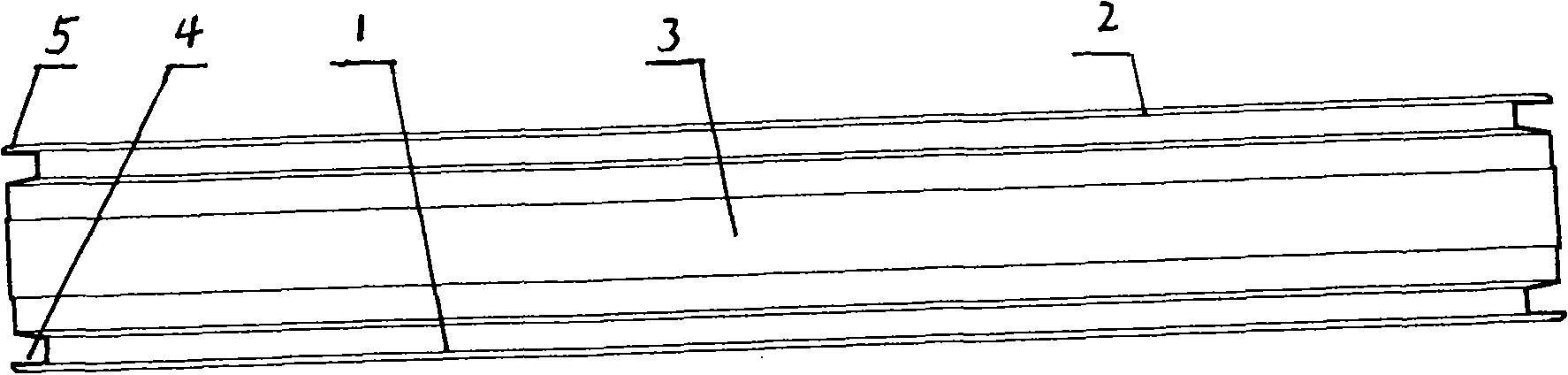

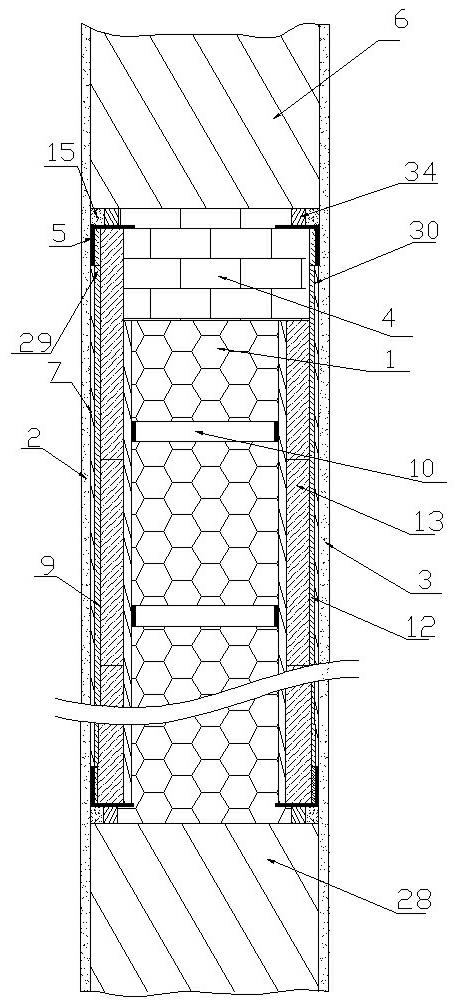

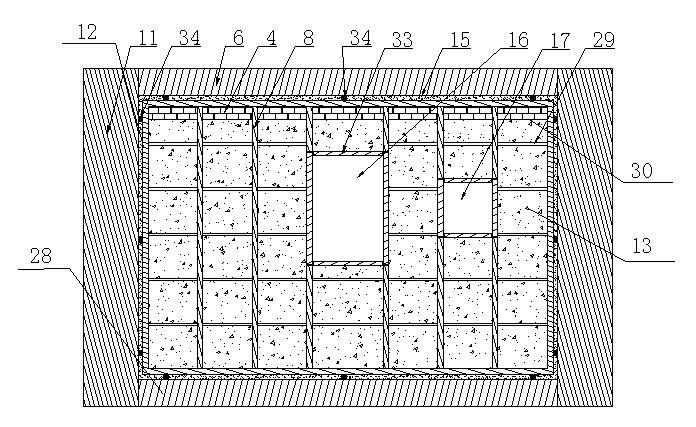

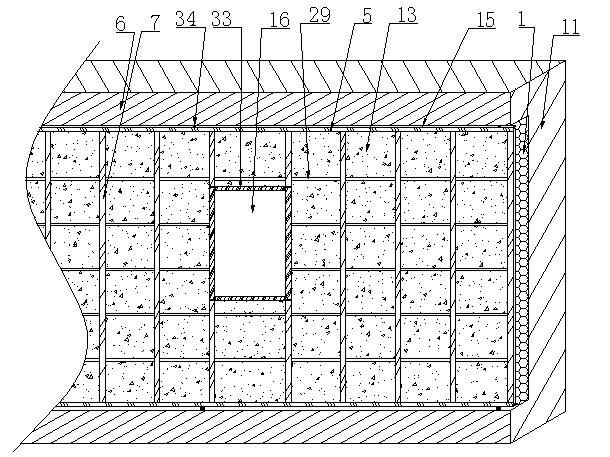

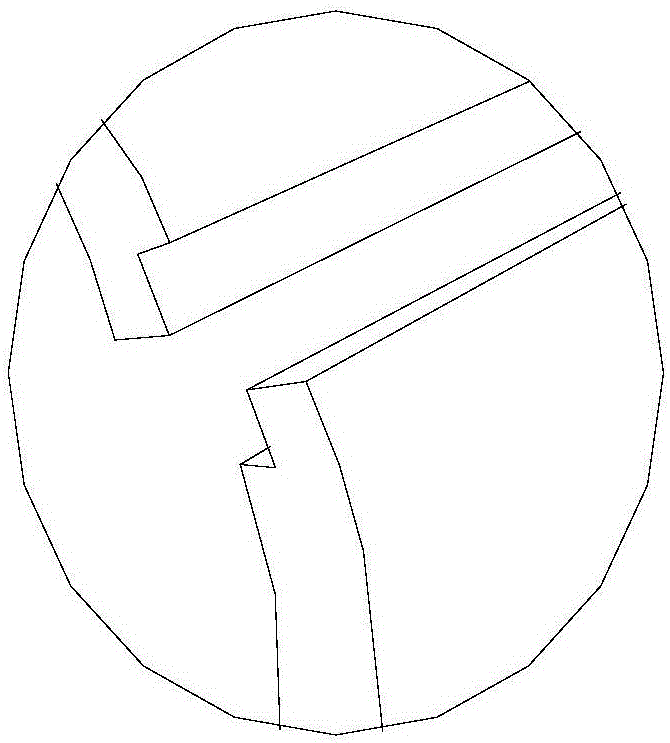

Binding type thermal-insulation composite wall with support

InactiveCN1827937AStrong construction feasibilityReduce thermal bridgesCovering/liningsWallsThermal insulationStructural engineering

The invention relates to a bound thermal-insulation composite wall with supports, which provides an external thermal-insulation composite wall of building, to overcome the defects of present technique. Wherein, the concrete hanging beam support (2), the internal outwards-drawing connector (7), and the inner end of plastic expansion nail (9) are fixed inside the main construct concrete (10) or basic wall (1); the concrete hanging beam support (2) and the outer end of inner outwards-drawing connector (7) are inside the outer protective layer (8) to connect the vertical steel bar (5); the outer side of basic wall (1) has a thermal-insulated layer (3) fixed via plastic expansion nail (9); the outer side of thermal-insulated layer (3) has a vertical steel bar (5); the outer or inner side of vertical steel bar (5) has a metallic network (4) which is connected to the vertical steel bar (5); the outer side of thermal-insulated layer (3) has a outer protective layer (8) made from cement sand pulp or pea stone concrete. The invention has the advantages that safety, long service life, better thermal insulation and flameproof.

Owner:吴淑环

FRP connecting piece of prefabricated heat preservation wall body

The invention belongs to the technical field of civil engineering, and concretely relates to an FRP connecting piece of a prefabricated heat preservation wall body. The connecting piece consists of an FRP connection board and a plastic socket ring and is characterized in that the FRP connection board is fabricated by a pultrusion technique, a fiber layering is compositely laid by adopting unidirectional coarse roving, continuous fibrofelt and positive / negative degree multiple axial directional cloth. After pultrusion, the FRP connection board is cut by fixed length to fabricate an FRP connection board single piece, and mechanical processing equipment is used for cutting one or more than one anchoring rabbet at the end part of the connection board, and finally the melt ABS plastic is cast around the FRP connection board by a casting technique to obtain the finished product of the FRP connecting piece of the prefabricated heat preservation wall body; wherein, the connection board component in the connecting piece is used for connecting the concrete wall pieces at the two sides of a heat preservation board, while the ABS plastic socket ring is used for fixing the position of the connecting piece during concrete casting. The invention realizes a novel connecting system with an integral structural function, has the advantages of low heat conductivity coefficient, good corrosive nature, simple and convenient construction and the like, and has relatively extensive application prospect in the field of civil engineering.

Owner:TONGJI UNIV

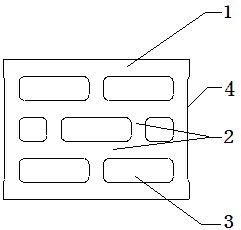

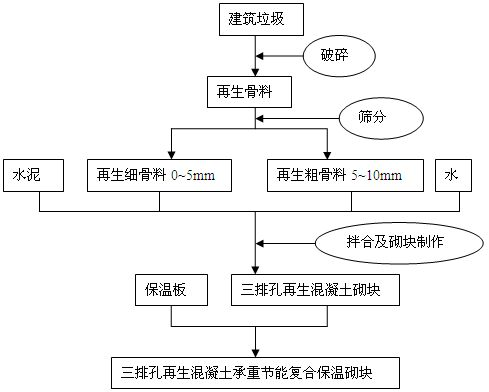

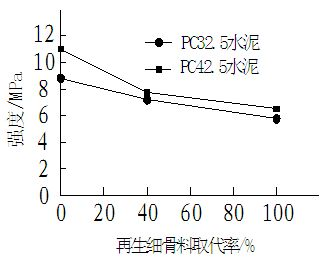

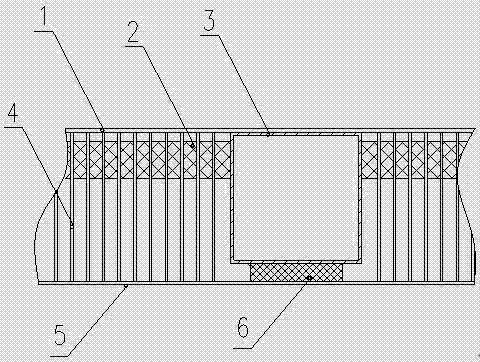

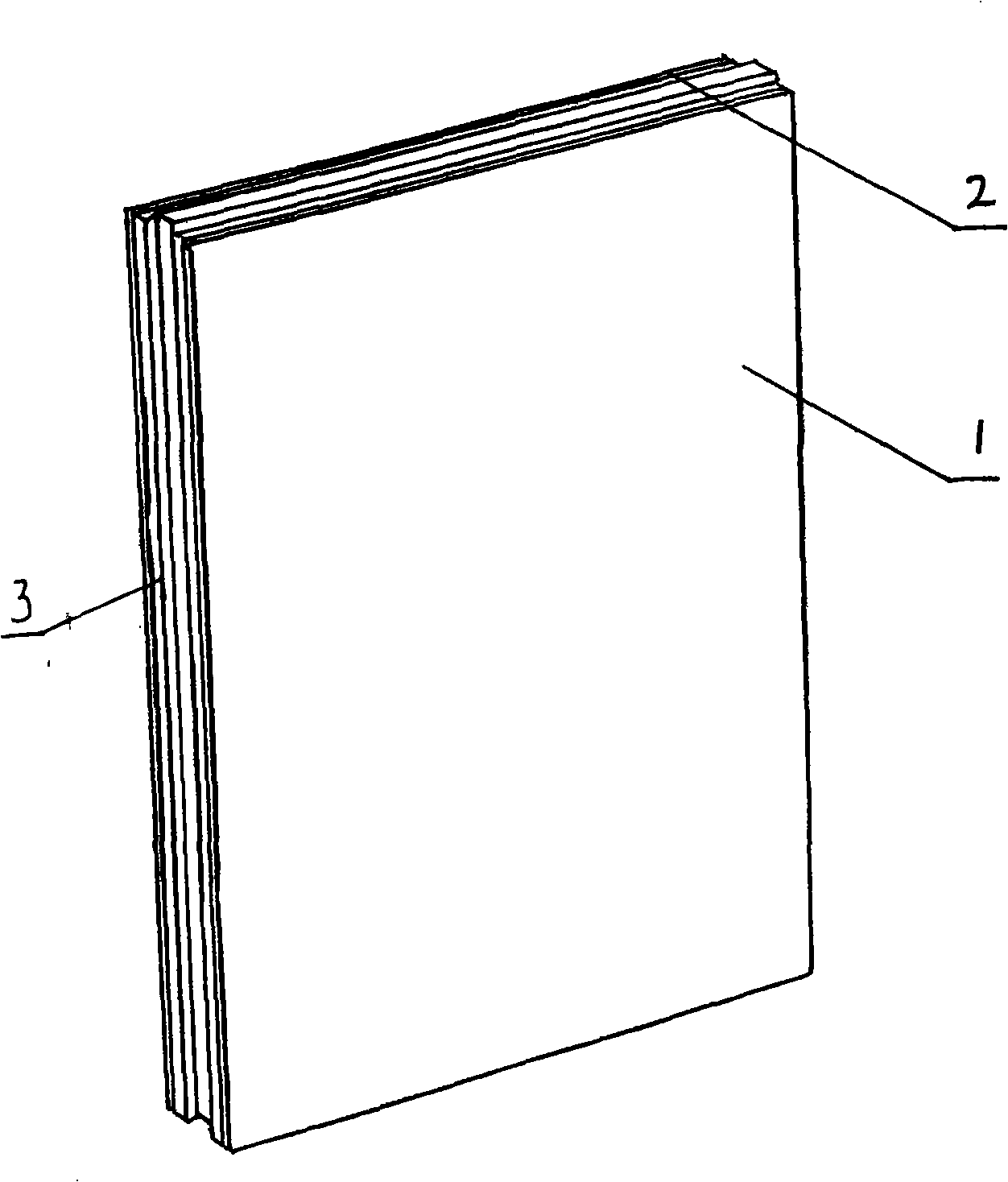

Three-row hole recycled concrete load-bearing energy-saving composite thermal insulation block and preparation method thereof

InactiveCN102277924AImprove insulation performanceRaise the intensity levelConstruction materialCeramic shaping apparatusThermal insulationChemistry

The invention discloses a recycled concrete load-bearing thermal insulation block with three rows of holes, which is characterized in that the block is composed of walls and ribs, and the gaps between the walls and ribs are holes. The holes are filled with insulation boards. Crush construction waste into recycled aggregate, and make recycled fine aggregate and recycled coarse aggregate; weigh cement, water, recycled fine aggregate and recycled coarse aggregate according to the formula, and mix cement: water: recycled fine aggregate : Regenerated coarse aggregate = 375: 150: 664: 811 weight ratio mixing, mixing evenly, through the block forming machine to make a three-row hole recycled concrete load-bearing block with a compression ratio of 0.86; fill the insulation board to the three-row hole regeneration In each hole of the concrete load-bearing block, it is verified by experiments that the block of the present invention has higher compressive strength, has increased heat conduction paths and heat preservation materials, and has better heat preservation effect.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

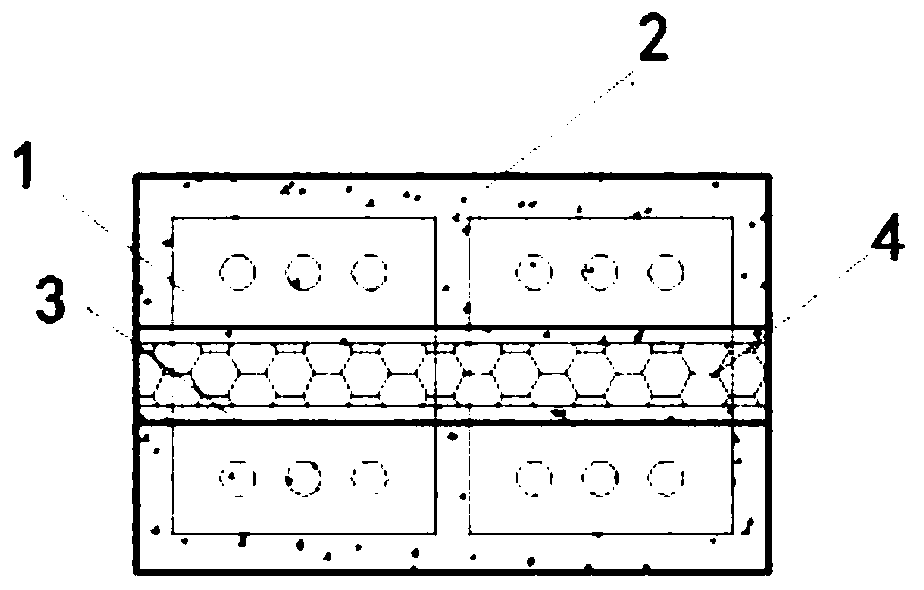

Honeycomb sandwich panel and making method thereof

InactiveCN103587159AImprove insulation effectHigh strengthSynthetic resin layered productsMetal layered productsHoneycombUltimate tensile strength

A honeycomb sandwich panel sequentially comprises an outer covering, a honeycomb core and an inner covering, grids of the honeycomb core are filled with rigid polyurethane foam, and the thickness of the rigid polyurethane foam is above 2mm. The invention also provides a making method of the honeycomb sandwich panel. The honeycomb sandwich panel has a good heat insulation performance and a high strength; and the heat insulation grade of a shelter body made by adopting the honeycomb sandwich panel reaches military standard I grade requirement. The method has the advantages of simple making technology and low cost.

Owner:衡阳泰豪通信车辆有限公司

Carbon-free steel ladle drainage agent for extremely-low carbon steel

ActiveCN102233412AReasonable particle size matchingImprove high temperature fluidityMelt-holding vesselsTO-18BULK ACTIVE INGREDIENT

The invention discloses a carbon-free steel ladle drainage agent for extremely-low carbon steel. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients in percentage by mass: 20 to 36 percent of Cr2O3, 10 to 40 percent of SiO2, 10 to 25 percent of Fe2O3, 5 to 18 percent of Al2O3 and 10 to 20 percent of MgO. The carbon-free steel ladle drainage agent for the extremely-low carbon steel comprises the following active ingredients of 31.28 percent of Cr2O3, 23.52 percent of SiO2, 14.71 percent of MgO, 19.09 percent of Fe2O3 and 9.86percent of Al2O3. The carbon-free steel ladle drainage agent for the extremely-low carbon steel is prepared from the following raw materials in percentage by mass: 50 to 80 percent of chromite sand, 10 to 30 percent of white quartz and 8 to 20 percent of electro-fused magnesia.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Method for preparing split joint buckled type building block composite energy-saving wall board

The invention discloses a preparation method for an assembled buckle-typed building block combination energy-saving wall plate, which is characterized in that a front panel and a rear panel are respectively inserted into panel assembly troughs which are arranged at two ends of four side plates, thus leading the front panel, the rear panel and the four side plates to be assembled together to form a whole hollow wall plate frame; subsequently, a pasty middle filling layer is injected into the hollow wall plate frame through small holes on the upper side plate by a tunnel high-pressure pouring method; after the pouring operation is completed, the solidification is carried out on a conveyor belt; subsequently, the filling layer is smoothly arranged and cured for a certain time; subsequently, the finished product is gained after the packaging is completed. The preparation method of the invention has the advantages of being directly used as screen walls, light weight, high strength, good heat preservation and sound insulation effects, good surface decoration effect, waterproofing and dust-proofing, beauty, saving decoration procedure, thus quickening the decoration progress and the construction time.

Owner:朱春生

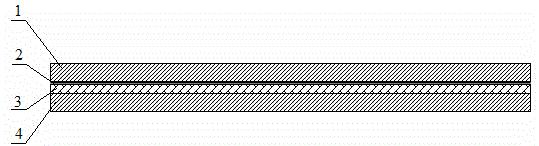

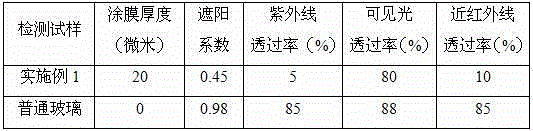

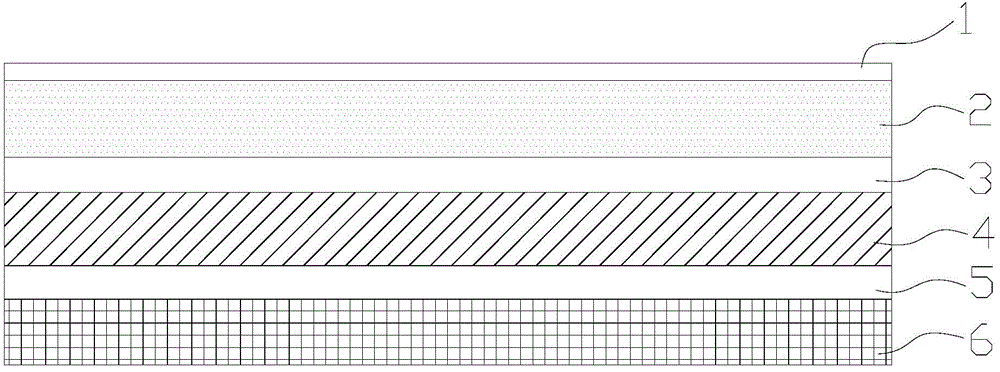

Thermal-insulating heat-preserving laminated safety glass and manufacturing method thereof

ActiveCN104960277ALow costReduce transmittanceLaminationLamination apparatusPolymer adhesiveThermal insulation

The invention provides a thermal-insulating heat-preserving laminated safety glass and a manufacturing method thereof. The structure of the thermal-insulating heat-preserving laminated safety glass comprises, from top to bottom, a first glass layer, a transparent thermal-insulating coating the inner surface of the first glass layer, a polymer film and a second glass layer; or the thermal-insulating heat-preserving laminated safety glass is further provided with a gas spacing layer and a third glass layer. The manufacturing method comprises the following steps: (1) preparing the transparent thermal-insulating coating; and (2) preparing the thermal-insulating heat-preserving laminated safety glass; or preparing a thermal-insulating heat-preserving laminated safe hollow glass from the thermal-insulating heat-preserving laminated safety glass. The thermal-insulating heat-preserving laminated safety glass or thermal-insulating heat-preserving laminated safe hollow glass has good impact resistance, low shading coefficient, low thermal coefficient, low ultraviolet transmittance, high visible transmittance and low near-infrared transmittance and is capable of preventing radiant heat of the sun entering a room in summer so as to realize thermal insulation and capable of reducing indoor heat loss in winter so as to realize heat preservation.

Owner:湖南省华京粉体材料有限公司

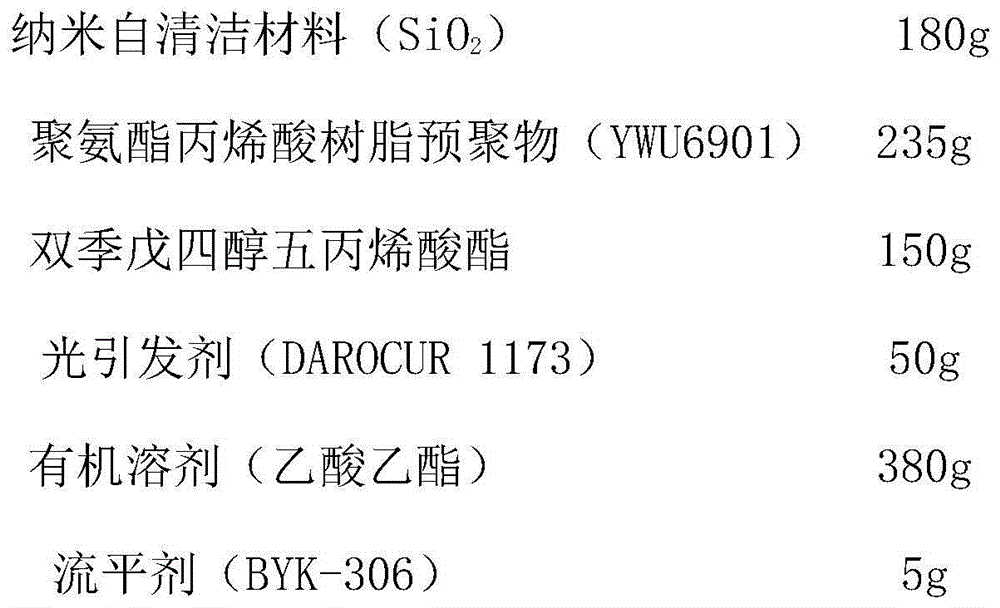

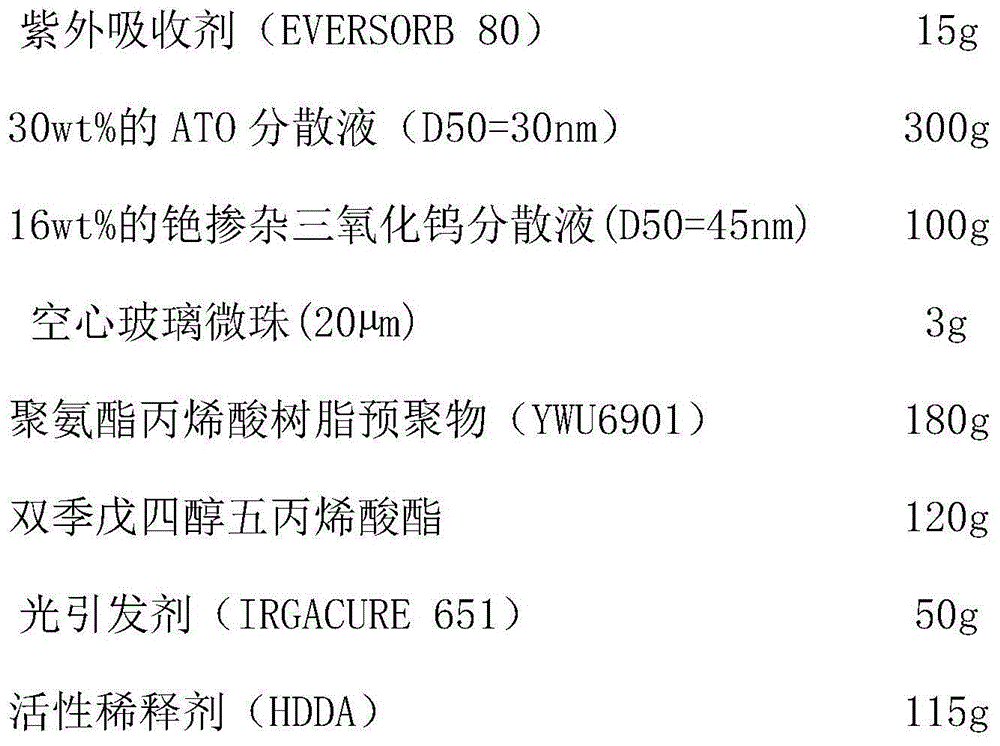

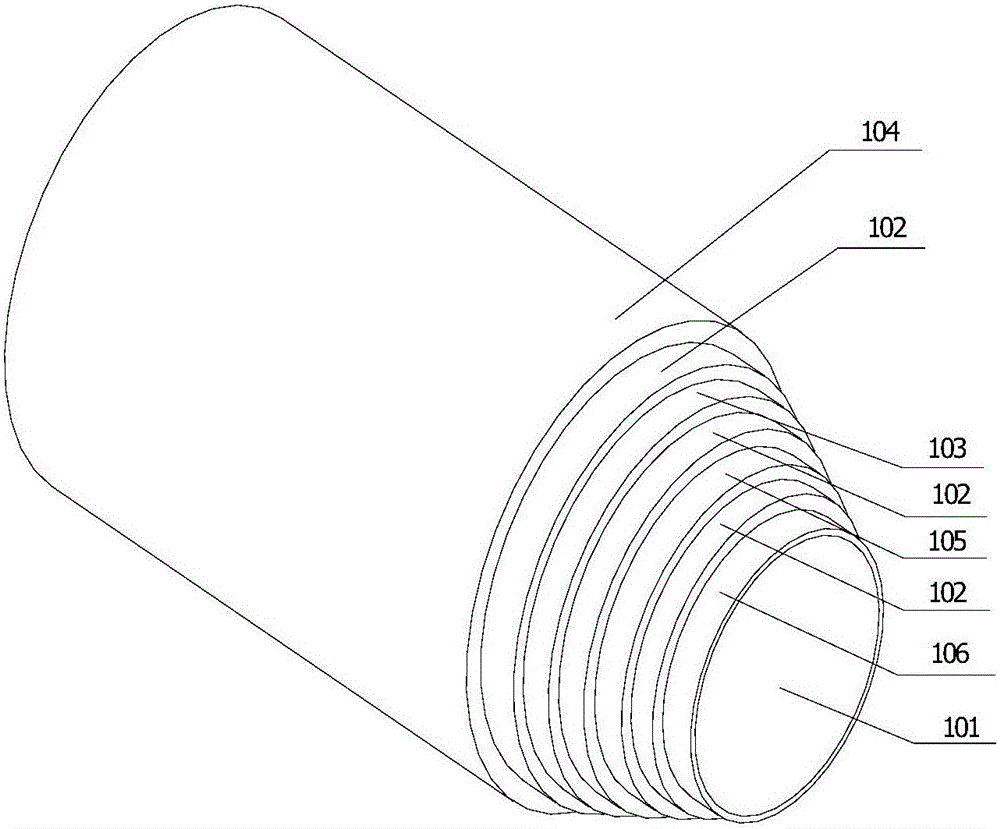

Double-layer polyester film and preparation method thereof

ActiveCN104629641AGuaranteed wear resistanceHydrophobicFilm/foil adhesivesPolyurea/polyurethane coatingsPolyesterThermal insulation

The invention relates to the technical field of thermal-insulation films and particularly relates to a double-layer polyester film and a preparation method thereof. By forming a self-cleaning auxiliary wear-resistant layer on the upper surface of a first substrate layer, the wear resistance of the film is ensured, the film has hydrophobic, oleophobic, anti-frost, anti-fog, pollution-resistant, antibacterial and self-cleaning functions and the transmittance of the film can also be increased; the self-cleaning auxiliary wear-resistant layer is prepared by curing specific component in a specific proportion, the double-layer polyester film is strong in self-cleaning capability, and the contact angle is 140 degrees-158 degrees. A UV-resistant and infrared-resistant thermal-insulation layer is formed between the first substrate layer and the second substrate layer, is prepared by curing specific component in a specific proportion and can well shield ultraviolet and 800-2500nm infrared light; hollow glass microspheres are added so that the thickness of the coating can be precisely controlled and since the hollow glass microspheres have the characteristics of being hollow, light in weight and low in thermal conductivity, the purposes that the heat transfer coefficient is reduced and the thermal-insulation performance of the film is enhanced are achieved.

Owner:FOSHAN JUSHITAI POWDER METALLURGY CO LTD

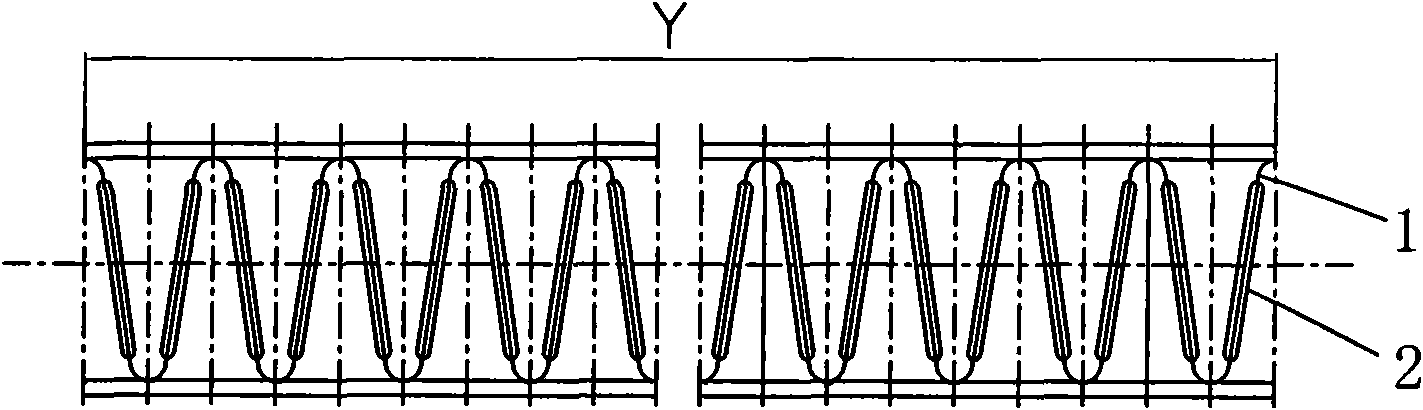

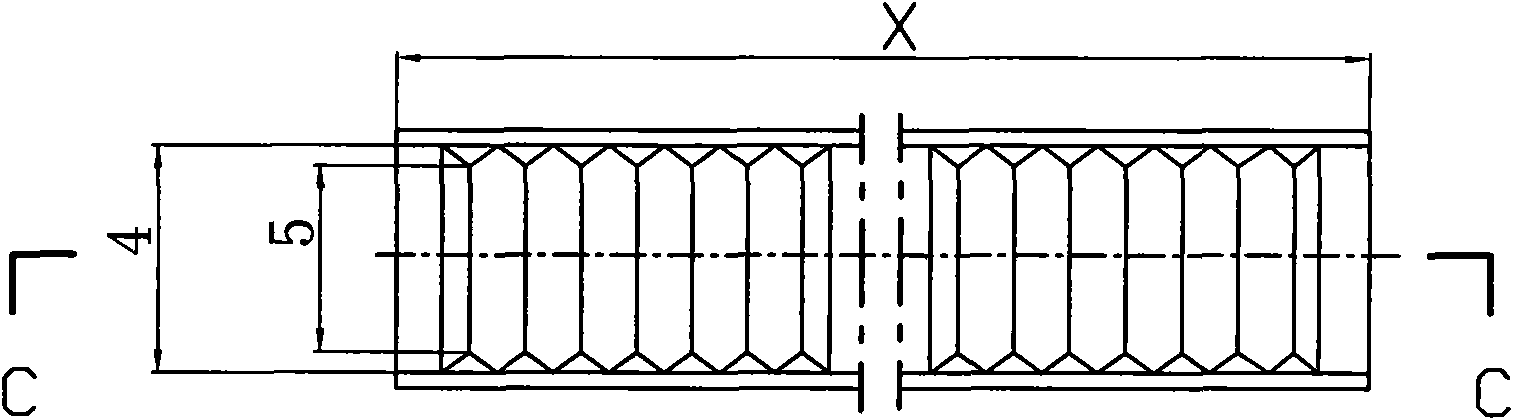

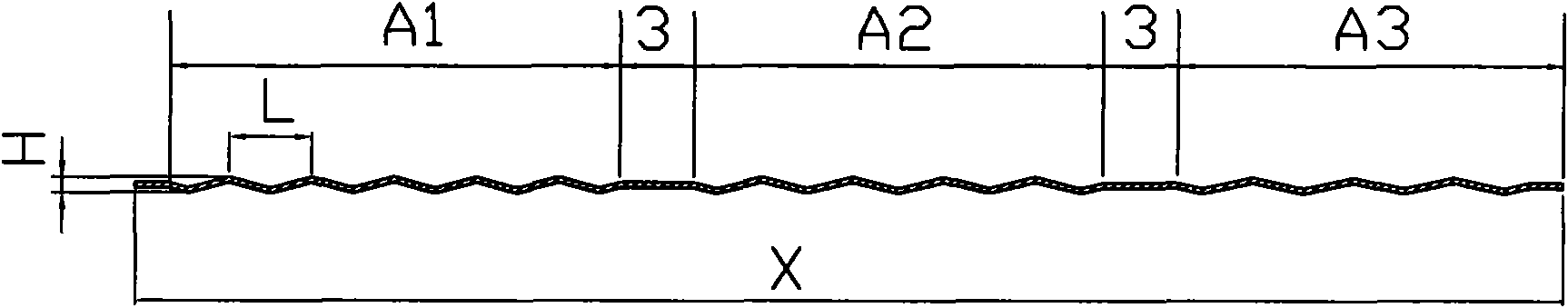

Enhanced heat transfer fin and production process thereof

ActiveCN101603794AAvoid structural deformationReduce thickness requirementsLaminated elementsEnhanced heat transferEngineering

The invention belongs to the technical field of heat exchangers, which relates to an enhanced heat transfer fin and a production process thereof. The enhanced heat transfer fin comprises a flat and straight substrate, wherein waveform fins which are raised on the flat and straight substrate and form certain angle with the flat and straight substrate are formed on the flat and straight substrate, reversing areas are arranged between a plurality of the waveform fins and divide the waveform fins into a plurality of groups waveform fin areas with different numbers of ripples, the wavelength and the wave amplitude of each waveform fin in each group are equal to each other, the number and the wavelength of the waveform fins of different groups are no equal to each other, and the number of the waveform fins in each group of the waveform fin area decreases in turn in the whole fin length while the wavelength increases in turn. The production process of the enhanced heat transfer fin is to put an aluminum strip on a roll forming machine to form the enhanced heat transfer fin provided with the waveform fins and the flat and straight substrate through one-step rolling. The enhanced heat transfer fin has good heat transfer property and small resistance, and is suitable to serve as a heat transfer fin of an automotive heat exchanger, a water tank radiator, a pressurizing intercooler and a wind cooling type hydraulic oil cooler.

Owner:上海银轮热交换系统有限公司

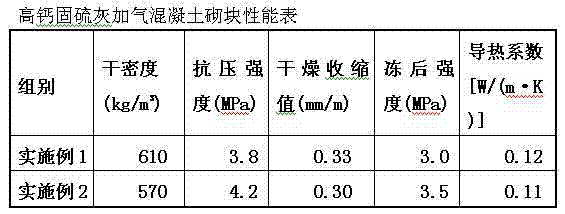

Manufacturing method of high-calcium solid sulfur ash aerated concrete building blocks

The invention discloses a manufacturing method of high-calcium solid sulfur ash aerated concrete building blocks. According to the invention, 40-70 parts of high-calcium solid sulfur ash, 20-40 parts of fly ash, 5-12 parts of cement, 0.1-15 parts of a silicon material, 10-20 parts of lime, 0.1-2 parts of gypsum, and 0.06-0.1 parts of aluminum powder are adopted as raw materials; high-calcium solid sulfur ash, fly ash, the silicon material, and gypsum are added into a mixer; water is added to the mixer, and stirring is carried out, such that a slurry is obtained; aluminum powder, lime, and cement are added to the slurry, and the mixture is well mixed by stirring, such that a casting slurry is obtained; the casting slurry is cast into a mold, and standing and preventive maintenance are carried out; when preventive maintenance is finished, building blocks are obtained by cutting; and the building blocks are subjected to autoclaved maintenance in an autoclave, such that finished products are obtained. With the method provided by the invention, the manufactured product can hardly crack and deform, and has advantages of high compressive strength and after-freeze strength. The method provided by the invention has the advantages of simple technical process, high high-calcium solid sulfur ash utilization amount, low manufacturing cost, convenient construction, and the like.

Owner:贵州省建筑材料科学研究设计院有限责任公司

Foaming wall Y roofing sandwich layer at normal-temperature of vegetive bits enhanced cement and its production

InactiveCN101074156AHas an isolation effectHigh strengthConstruction materialSolid waste managementAl powderFilling rate

A foaming wall / roof sandwich layer of vegetable chip reinforced cement at normal temperature and its production are disclosed. The raw materials consist of vegetable chip 6-20 wt%, cement 46-62 wt%, gypsum powder 1.0-2.5 wt% with fineness 40-80 meshes, CaO 10-15 wt%, calcium chloride 0-3 wt%, foaming pearlite 10-14 wt%, water glass 4.5-6 wt%, sodium fluoro silicate 0.8-1.2 wt%, aluminum powder or degreased aluminum powder or aluminum paste 0.15-0.35 wt%. Cavity filling rate reaches above 90%, it's firm, has better strength and rigidity, excellent thermal-insulating performance and various raw resources and less consumption.

Owner:UNIV OF JINAN

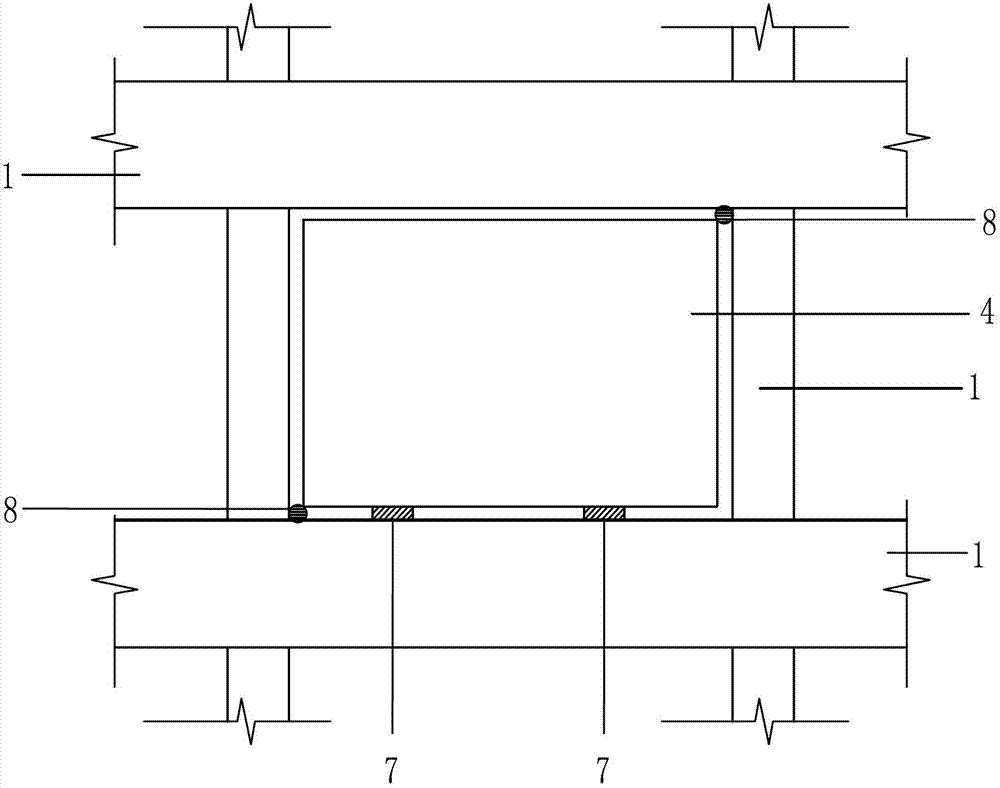

Construction technology for processing glass curtain wall into hollow glass curtain wall

ActiveCN103243845ALower heat transfer coefficientImprove energy savingWallsBuilding repairsEngineeringSealant

The invention discloses a construction technology for processing a glass curtain wall into a hollow glass curtain wall. The construction technology comprises a main frame fixing the glass curtain wall and includes steps of 1) contiguously connecting spacing bars for assembling a support frame to inner edges of the main frame by sealant spread at corners of the spacing bars; 2) attaching the integral glass to the spacing-bar frame so as to form a cavity among the spacing-bar frame, the glass curtain wall and the glass; and 3) injecting sealant to fill space between the spacing-bar frame and the main frame and gaps between the glass and the main frame and reserving two air holes so that the cavity is a sealed cavity with two reserved air holes. After modification, heat transfer coefficient of the hollow glass curtain wall is one third of that of the glass curtain wall, heat transfer coefficient is greatly decreased, and ideal energy-saving effect can be achieved. Furthermore, modification is completed on the original glass curtain wall, so cost is lower.

Owner:CHENGXIN GREEN INTEGRATION

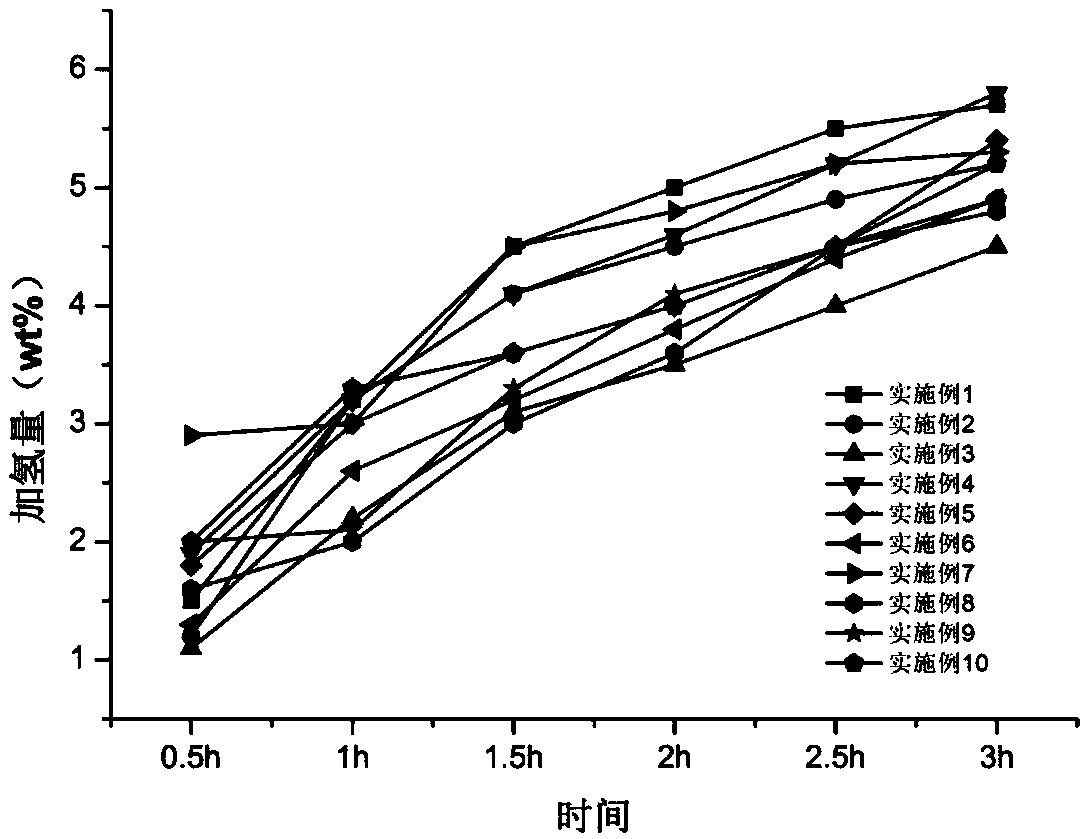

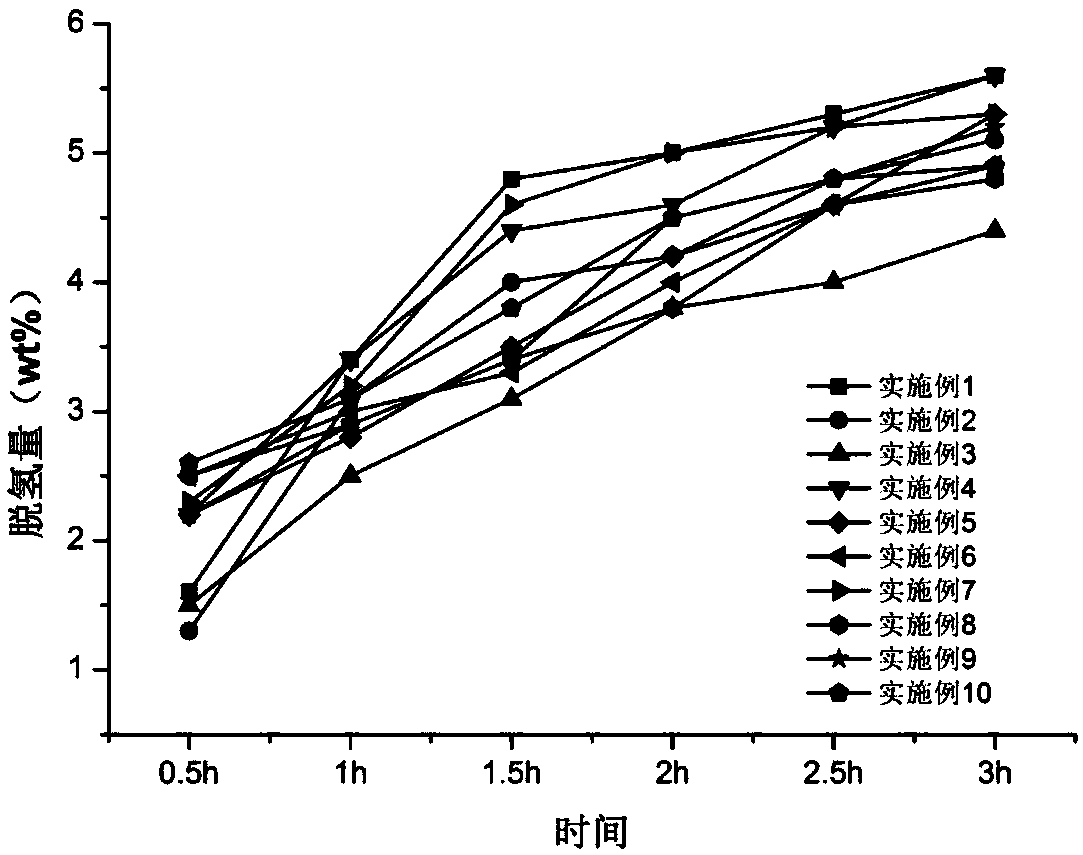

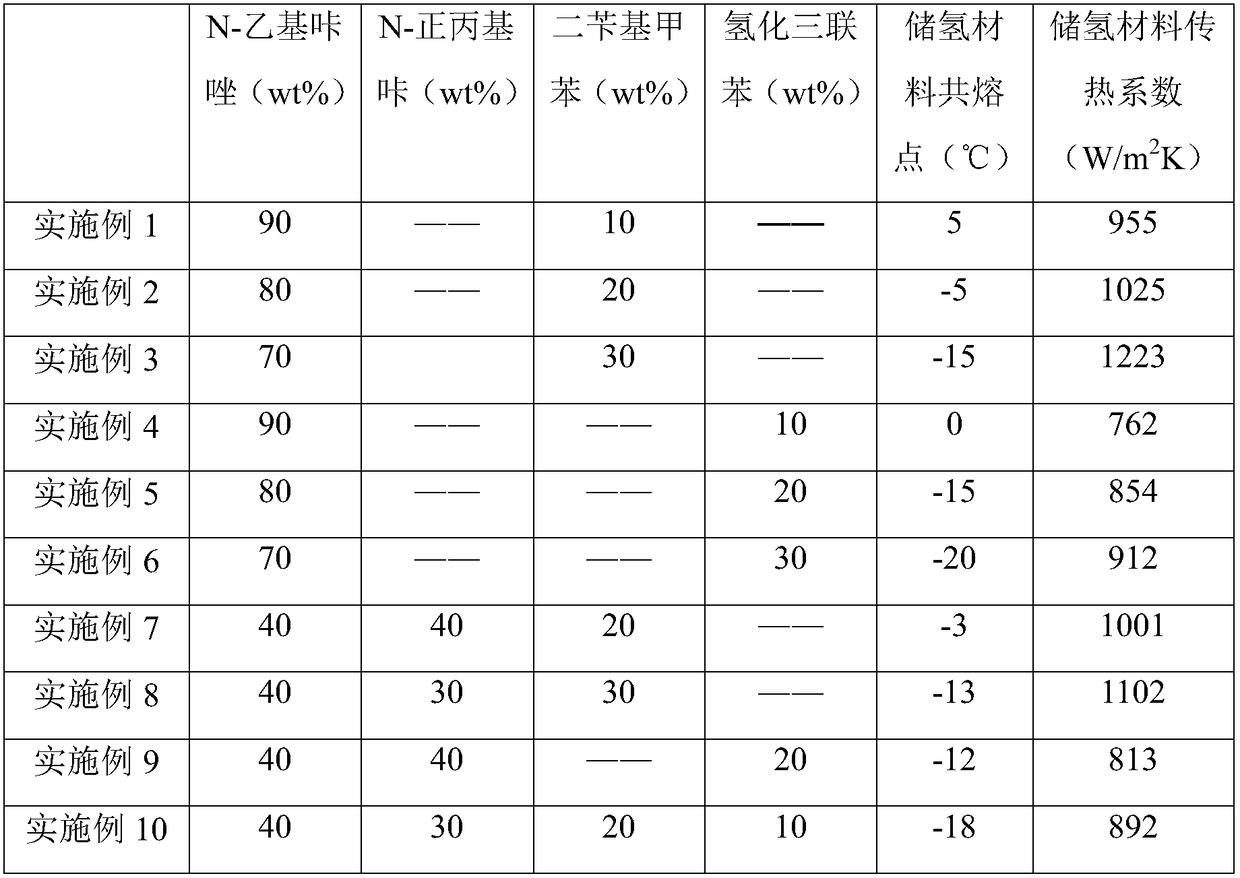

Liquid hydrogen storage material and preparation method thereof

InactiveCN109353987ALow melting pointLower heat transfer coefficientHydrogenDibenzyltolueneLiquid hydrogen

The invention relates to a liquid hydrogen storage material and a preparation method thereof. The liquid hydrogen storage material comprises a carbazole type hydrogen storage component and an additivewith a low melting point and a high heat transfer coefficient; the carbazole type hydrogen storage component is at least one of carbazole, N-methyl carbazole, N-ethyl carbazole, N-n-propyl carbazole,N-isopropyl carbazole or N-n-butyl carbazole; the heat conduction additive component with a low melting point is at least one of benzyltoluene or hydrogenated terphenyl. The liquid hydrogen storage material is a mixture formed by mixing the carbazole type hydrogen storage material with a high melting point with the heat conduction additive with a low melting point and has an eutectic point whichis at least lower than the melting point of one component, and the melting point of the entire hydrogen storage material can drop to 0 DEG C or below. At the same time, the heat conduction additive with a low melting point has a high heat transfer coefficient, and the heat conductivity coefficient of the mixture formed after the additive is mixed with the carbazole type hydrogen storage material can be higher than that of the carbazole type hydrogen storage material; the whole hydrogen storage material can quickly reach the dehydrogenation temperature during dehydrogenation, so that the release rate of hydrogen is increased.

Owner:FAW JIEFANG AUTOMOTIVE CO

Composite armored thermal insulation wall of foamed concrete and construction method thereof

InactiveCN102182260ALow costEasy constructionWallsClimate change adaptationFoam concreteThermal insulation

The invention relates to a composite armored thermal insulation wall of foamed concrete and a construction method thereof, belonging to the field of thermal insulation walls, and the composite armored thermal insulation wall is used for a non-bearing wall of a building. The wall disclosed by the invention comprises an external wall plate layer, an internal wall plate layer, a foamed concrete insulating layer, a trowel finish mortar layer for an external wall surface, a trowel finish mortar layer for an internal wall surface, and foamed concrete filling blocks, wherein the foamed concrete insulating layer is arranged among the internal wall plate layer, a load bearing pillar and the external wall plate layer; the trowel finish mortar layer for the external wall surface and the trowel finish mortar layer for the internal wall surface are arranged on the external surfaces of the external wall plate layer and the internal wall plate layer; and the weight by volume of the foamed concrete of the wall disclosed by the invention is 200 to 400 kg / m<3>. The invention provides the novel thermal insulation wall which has the advantages of low manufacturing cost, convenience and rapidity for construction, light dead weight but high strength, prominent energy-saving effect, superior service performance and no secondary pollution.

Owner:LUOYANG NORMAL UNIV

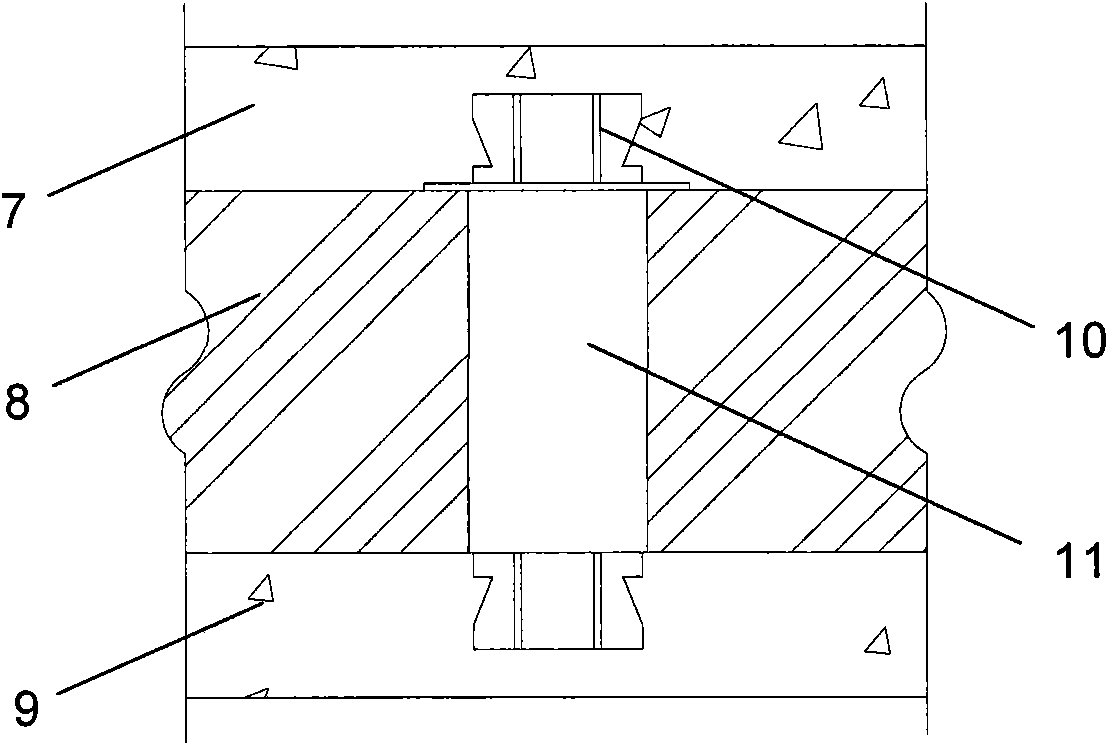

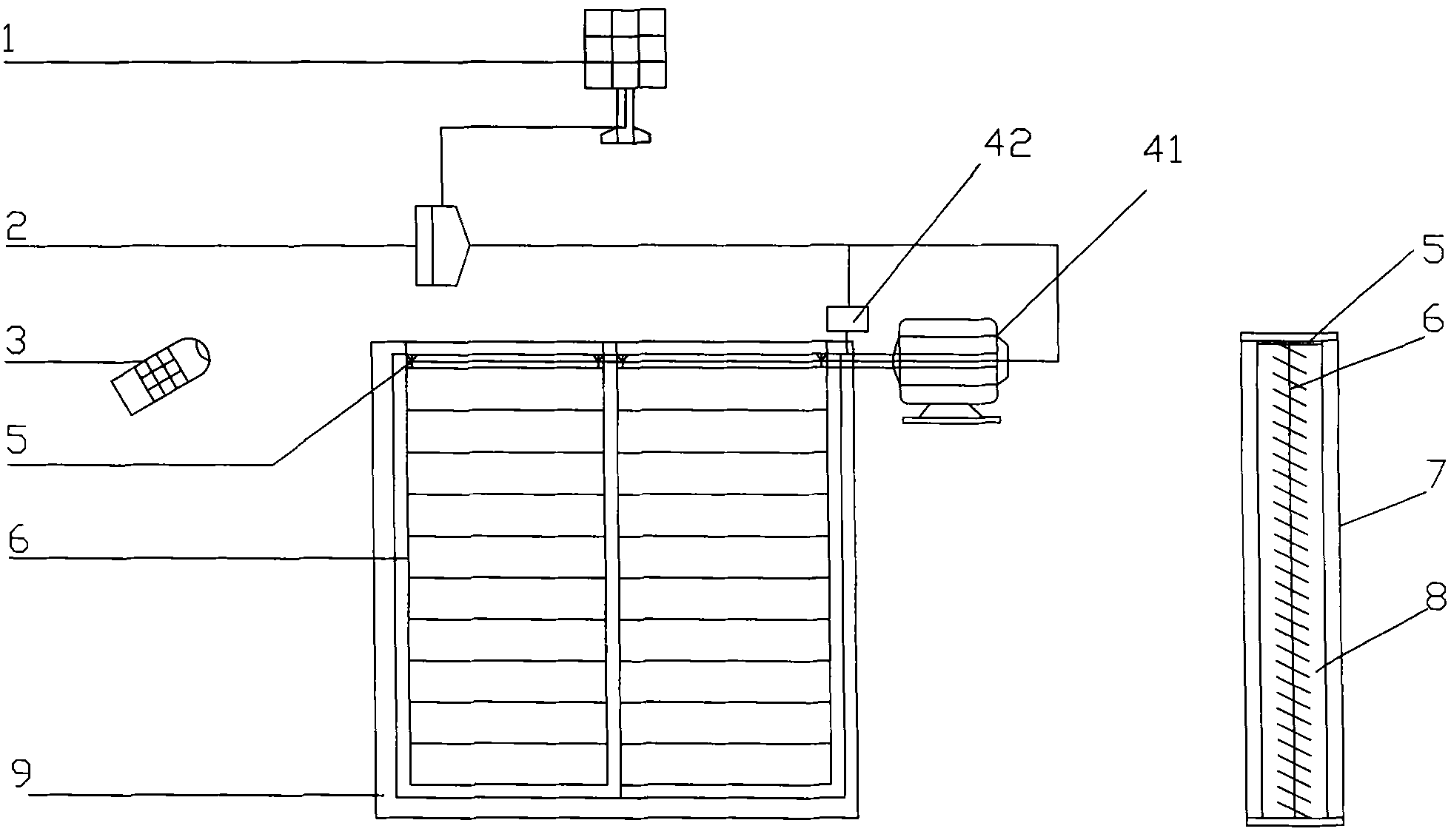

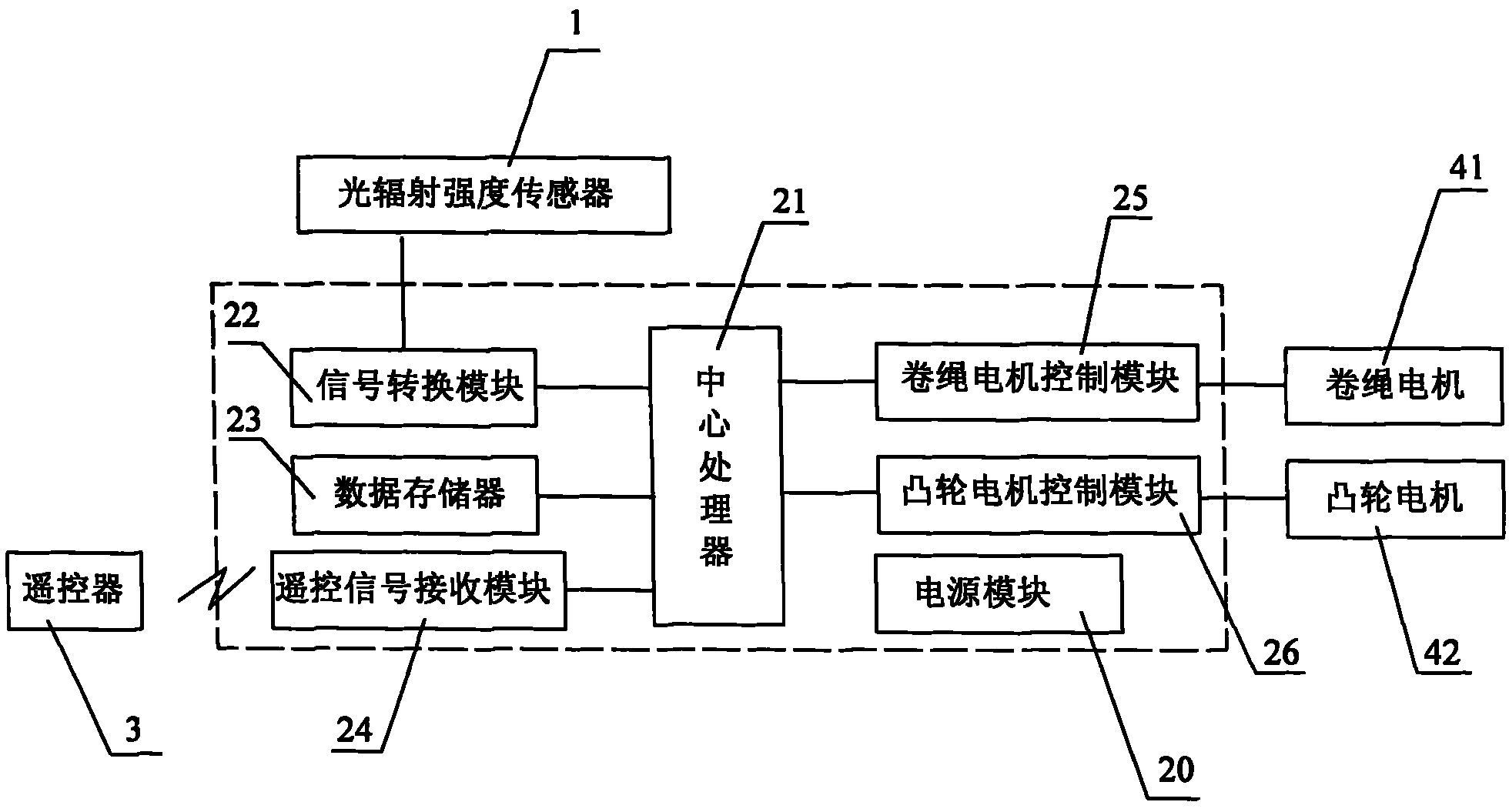

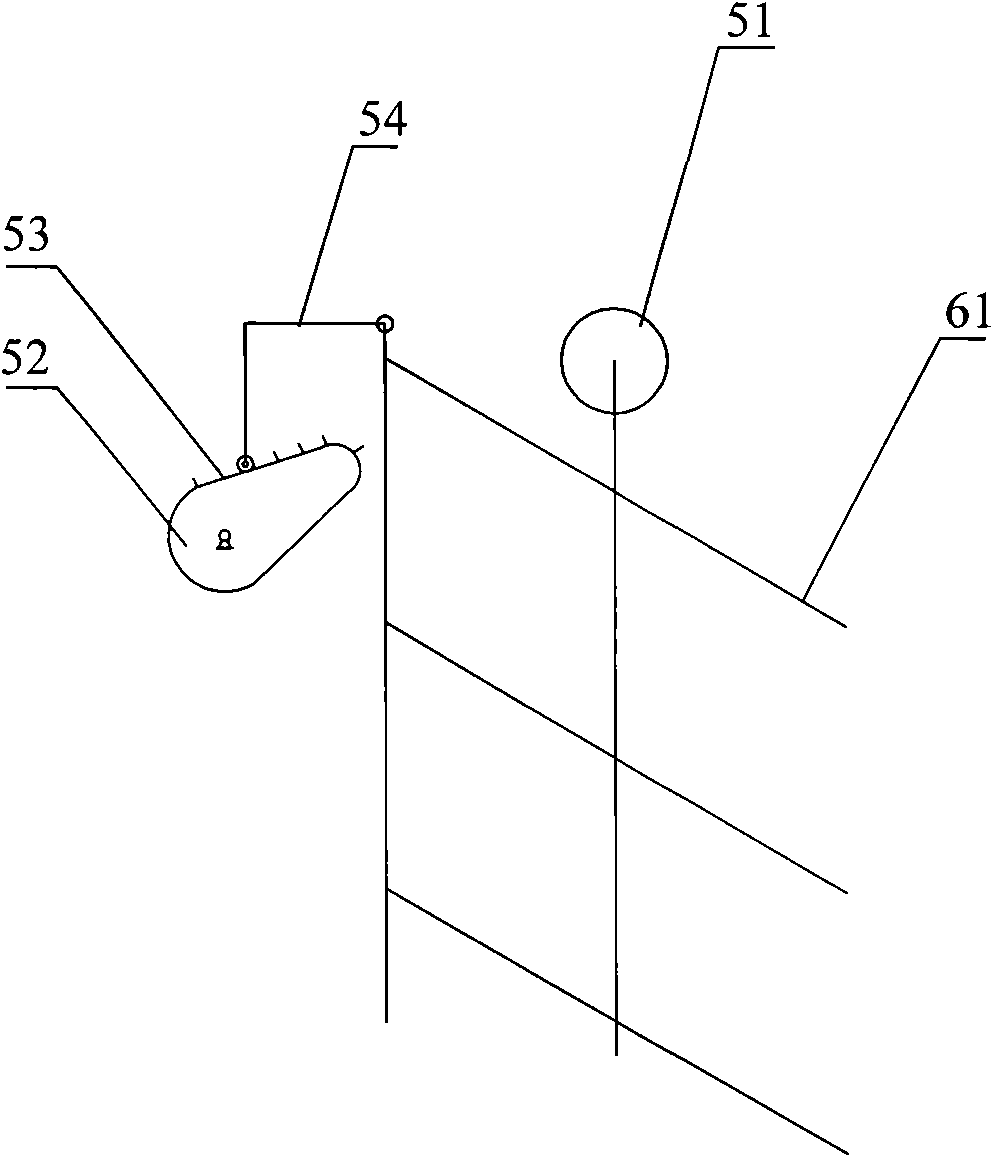

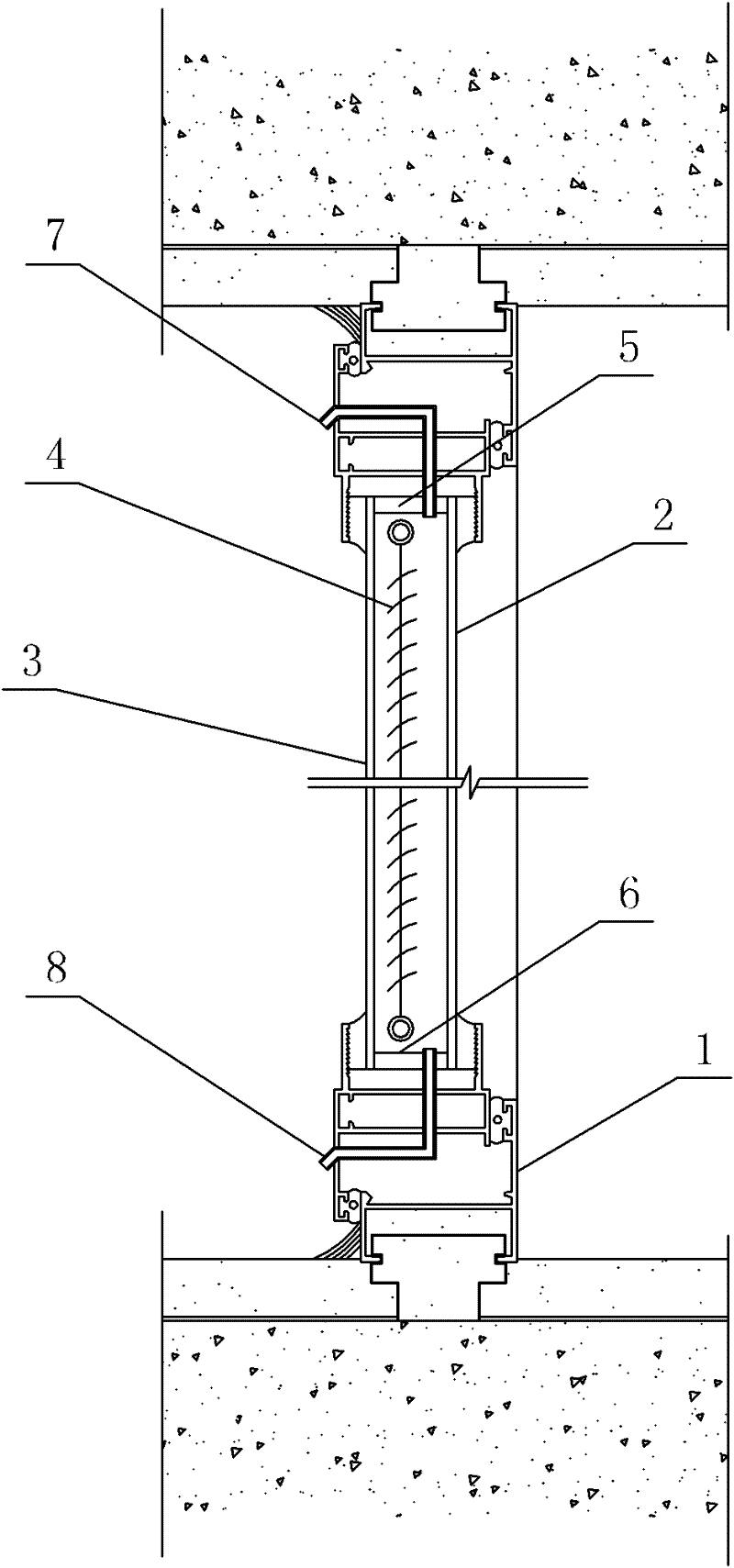

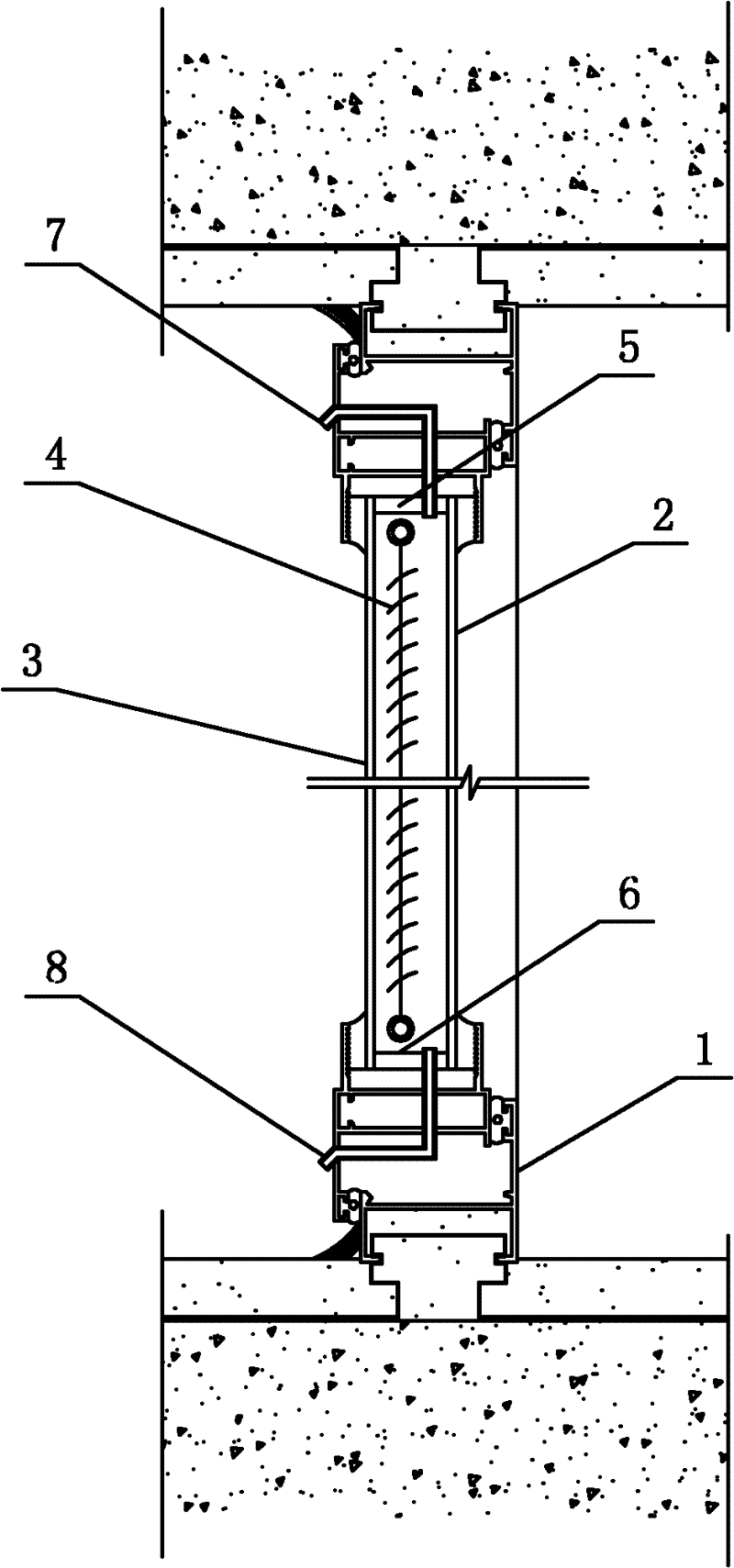

Intelligent door, window and sunshade integrated device

InactiveCN101975017ARealize automatic adjustment functionLower heat transfer coefficientInsect protectionLight protection screensOptical radiationVitreous Bodies

The invention discloses an intelligent door, window and sunshade integrated device. The device comprises an intelligent control system, a window frame system and a sunshade shutter system, wherein the intelligent control system comprises an optical radiation intensity sensor (1), a signal receiving control component (2) and the like; the window frame system comprises a frame (9); a heat insulation hollow vitreous body (7) is arranged in the frame (9); the sunshade shutter system comprises a blind (6) which consists of a dentiform scroll component (5) and aluminum foil leaves (61); the dentiform scroll component (5) is used for controlling the rolling of the blind (6) and an overturning angle of the aluminum foil leaves (61); the blind (6) and the dentiform scroll component (5) are arranged in the cavity of the heat insulation hollow vitreous body (7); and the cavity of the heat insulation hollow vitreous body (7) is full of inert gas (8). The device can not only automatically adjust the blind according to the intensity of light rays, but also has very good functions of sun shading and heat shielding.

Owner:ZHEJIANG UNIV

Spacing bars for porous rubber and hollow glass

InactiveCN101092867AEliminate condensationEasy to passUnits with parallel planesMolecular sievePolymer science

This invention relates to a micro-hole rubber hollow glass spacing strip used in hollow glasses composed of rubber, curing agent and aids characterizing that said rubber is composed of EPT rubber and molecular sieve activation powder with the following weight percentage: EPT rubber 100 portions, activation powder 80-200 portions.

Owner:廖昌荣

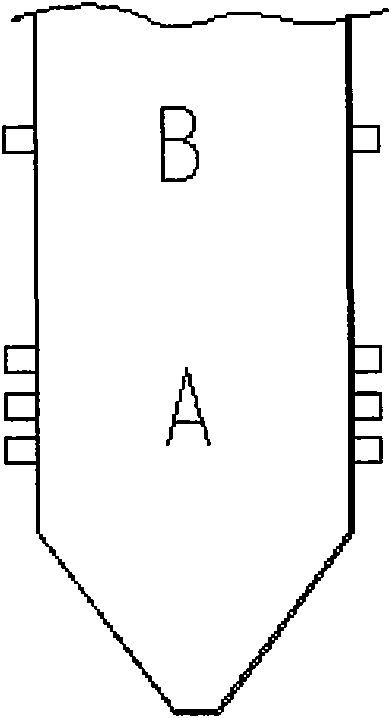

Pulverized coal burner and boiler with same

ActiveCN102032563AAchieve combustionOptimizationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberNitrogen

The invention discloses a pulverized coal burner and a boiler with the same. The disclosed pulverized coal burner comprises a heat source and an internal burning chamber, wherein the internal burning chamber ensures that an internal pulverized coal flow has a predetermined excess air coefficient; the heat source is positioned in the internal burning chamber; the internal burning chamber is provided with an inlet, a long cylindrical main burning chamber and an outlet; the heat source can ignite pulverized coal which passes through the internal burning chamber and ensures that the pulverized coal reducibly burns in the internal burning chamber; preferably, the internal burning chamber comprises the main burning chamber and a decelerating inlet section; and the sectional area of the decelerating inlet section is less than that of the main burning chamber. The internal burning chamber of the pulverized coal burner can maintain a smaller air coefficient, so reducing atmosphere is formed in the internal burning chamber; the pulverized coal reducibly burns in the internal burning chamber, so the pulverized coal flow enters a hearth in the form of high-temperature pulverized coal burning flame to improve the burning stability of the pulverized coal; meanwhile, the reducing burning can also convert a nitrogen element into a reducing intermediate product, so that fuel type nitrogen oxides are prevented from being produced.

Owner:YANTAI LONGYUAN POWER TECH

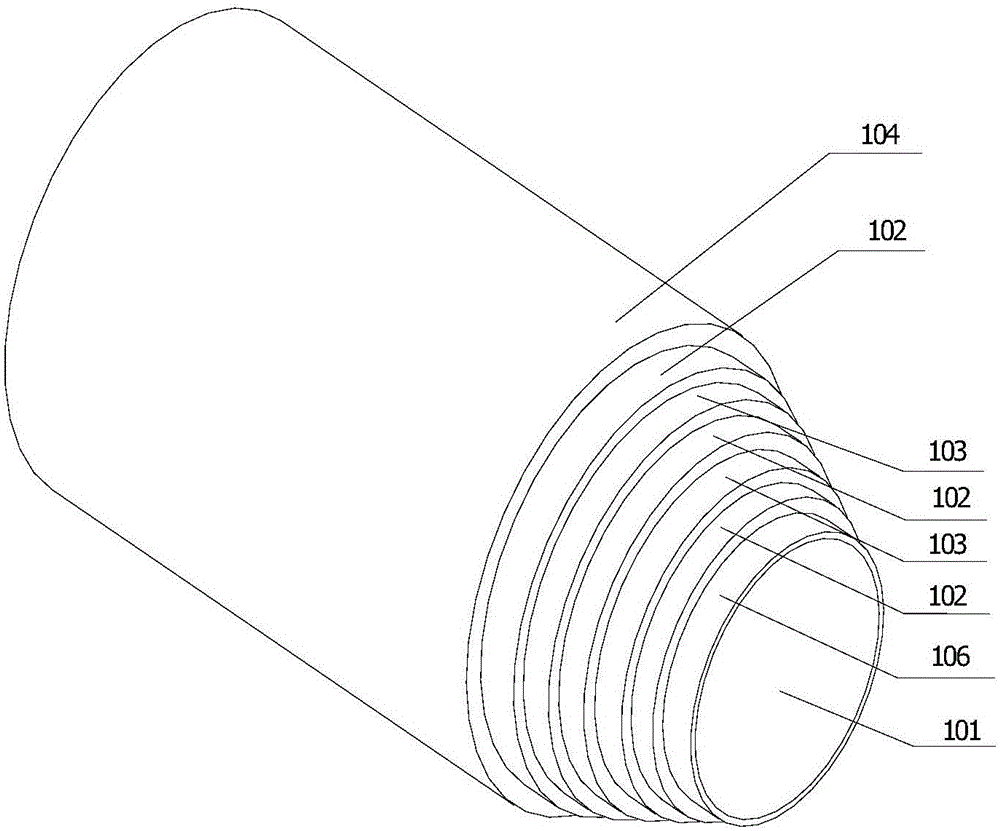

Multifunctional composite thermal-insulating layer

ActiveCN105864581AIncreased durabilityReduce heat lossThermal insulationPipe protection by thermal insulationThermal bridgeHeat losses

The invention provides a multifunctional composite thermal-insulating layer which comprises a pipe or an equipment base, at least one thermal-insulating layer, at least one internal protective layer, and at least one isolating layer. The internal protective layer is used for absorbing swell and supporting the whole thermal-insulating structure to prevent the same from collapsing. The isolating layer made of a high-temperature-resistant emitting material has effects of corrosion resistance and air-tightness, and further has effects of reducing heat-transfer coefficient and thermal conductivity of metal materials, isolating heat conduction and thermal bridge of pipe supports and hangers and improving heat barriers. Specifically, the isolating layers, the internal protective layers and the thermal-insulating layers are sequentially arranged on the outer side of the pipe or equipment base; the internal protective layers and the thermal-insulating layers are composited and interactive with each other, are arranged alternatively to overcome heat loss caused by irradiation, conduction and convection; joints of the different layers are staggered with one another to realize non-convection heat dissipation; and every two adjacent layers are made from different materials. The multifunctional composite thermal-insulating layer solves the problems about heat loss caused by irradiation, conduction and convection.

Owner:韩松

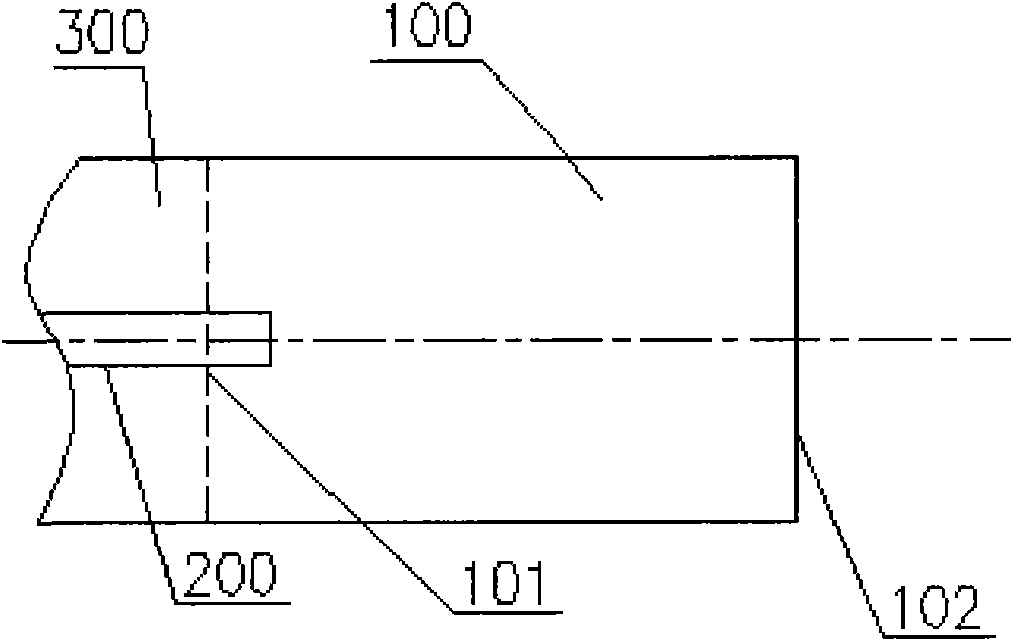

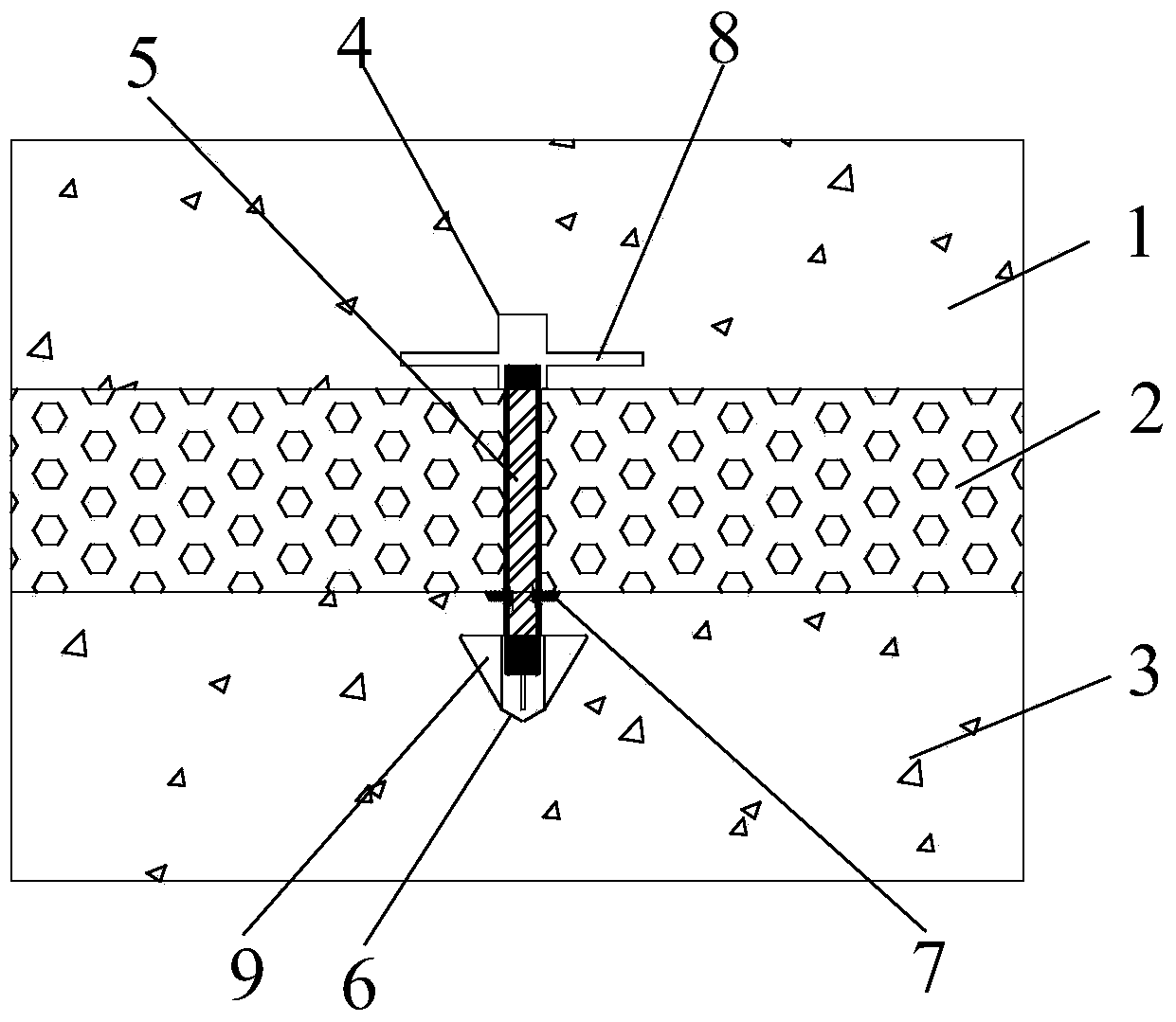

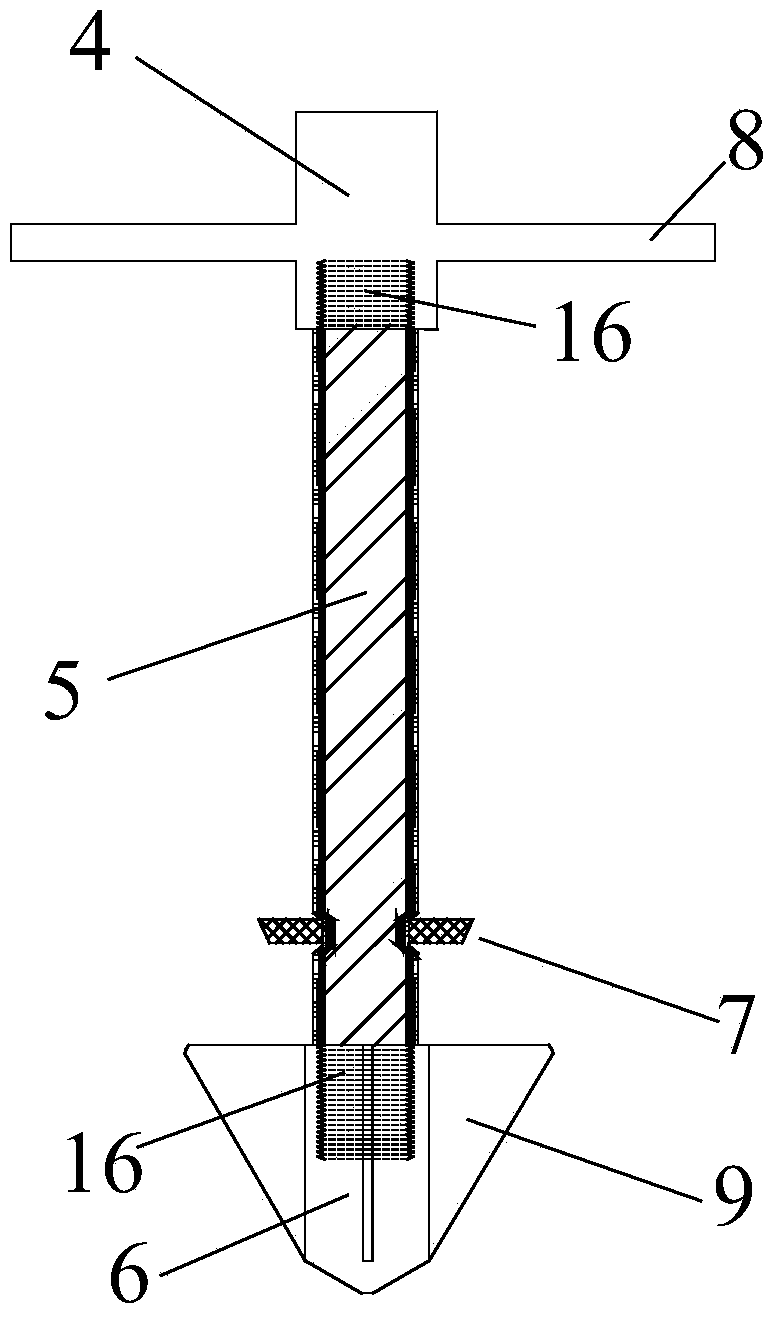

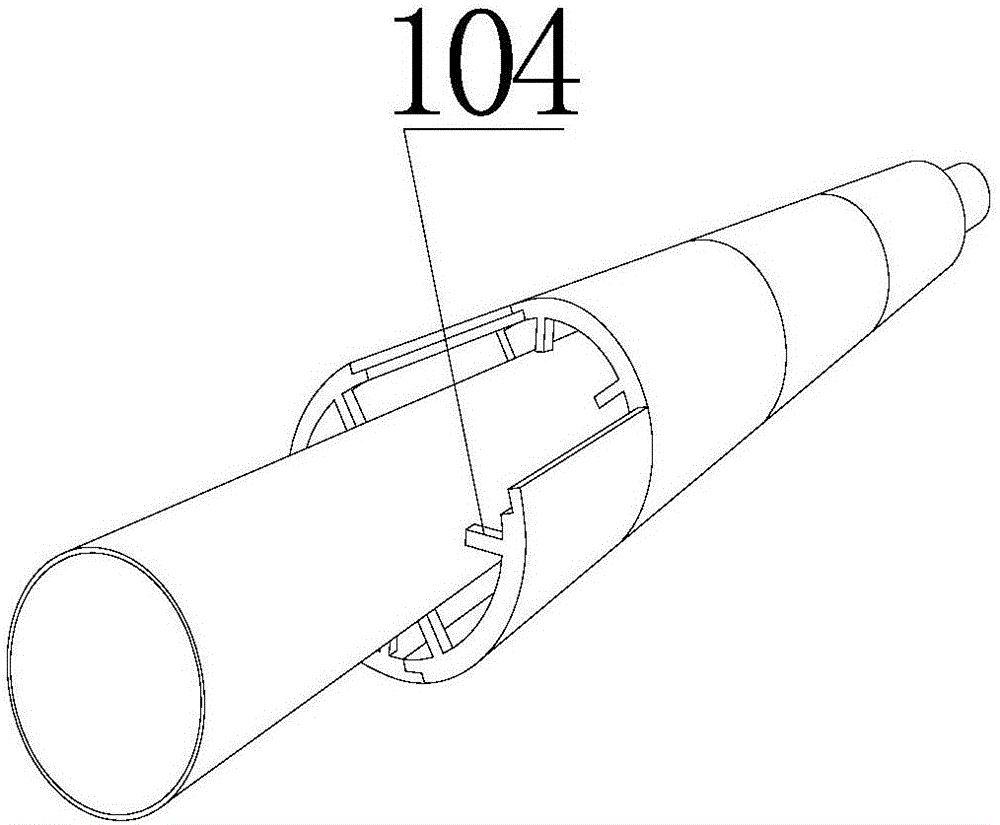

Steel-fiber plastic combined connector, prefabricated sandwich thermal insulation wall and manufacturing method

ActiveCN103967162AStrong bending resistanceStrong shear resistanceWallsBuilding material handlingFiberThermal insulation

The invention discloses a steel-fiber plastic combined connector, a prefabricated sandwich thermal insulation wall and a manufacturing method. The connector comprises a columnar connecting body, a connecting base and a connecting cap, and the connecting base and the connecting ca are fixedly connected to the two ends of the columnar connecting body respectively. The columnar connecting body comprises a metal column, fiber cloth wrapping the outer side of the metal column and a fiber bunch axially wound on the fiber cloth along the metal column. The connecting base comprises a metal base body and a plurality of metal rib angles, and the metal rib angles are distributed on the lateral surface of the metal base body at intervals. The connecting cap comprises a metal cap body, metal inserting ribs and a plastic cap sleeve. The metal inserting ribs transversely penetrate through the metal cap body, and the plastic cap sleeve wraps the exposed part of the metal cap body and the exposed parts of the metal inserting ribs. The connector has the advantages of being high in anti-shear strength, low in processing cost, high in fire resistance, low in heat conduction coefficient, convenient and fast to install and the like. The prefabricated sandwich thermal insulation wall has the advantages of being high in anti-bending performance and anti-shear performance, good in thermal insulation effect, low in manufacturing cost, long in service life and the like.

Owner:SHANGHAI CONSTRUCTION GROUP

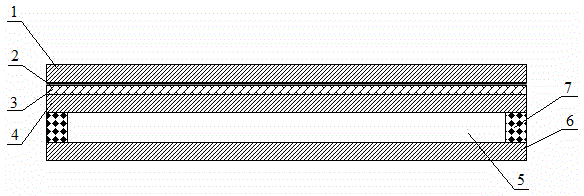

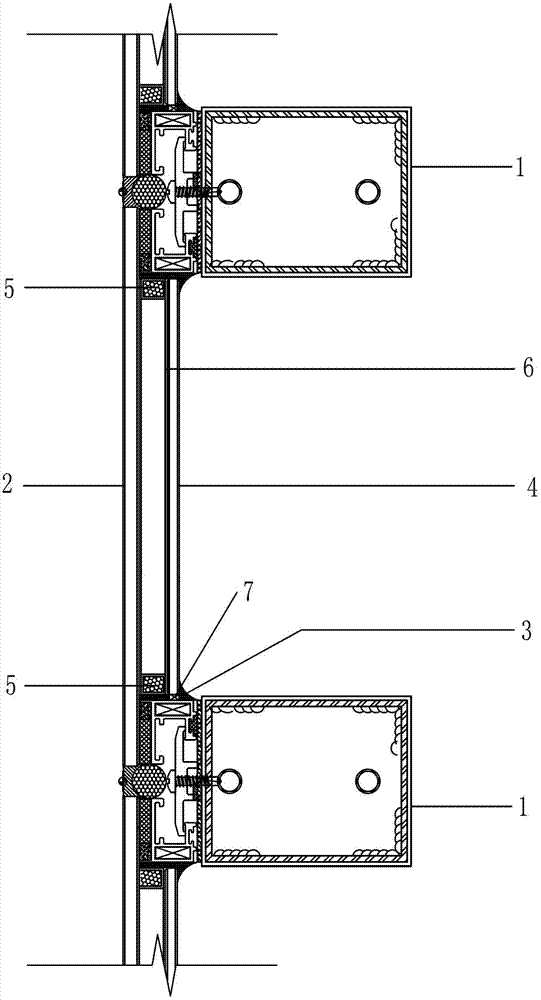

A center-mounted movable sunshade system for building exterior windows with low heat gain rate under sunlight radiation

InactiveCN102287128AHigh reflective sunlight efficiencyHigh interlayer ventilation functionDoor/window protective devicesVentilation arrangementRefrigerationSealant

At present, a sun-shading curtain radiates heat which is more than that obtained by an external sun-shading system under sunlight radiation and is close to that obtained by an internal sun-shading system when being used in a centrally-mounted sun-shading system, and the centrally-mounted sun-shading system has a poor insulation energy-saving effect. The invention provides a centrally-mounted movable sun-shading system of a building external window with low heat gain efficiency under sunlight radiation. The centrally-mounted movable sun-shading system comprises an external window frame, an inner hollow glass layer and an outer hollow glass layer which are installed on the external window frame, a movable sun-shading curtain arranged between the inner hollow glass layer and the outer hollowglass layer, and a control device of the movable sun-shading curtain. The centrally-mounted movable sun-shading system is characterized in that a mirror surface or reflection heat insulation coating is formed on the surface of the outer side of the movable sun-shading curtain; and an upper ventilating pipe and a lower ventilating pipe are respectively embedded in upper sealant and lower sealant which are arranged between the inner hollow glass layer and the outer hollow glass layer. According to the invention, the heat insulation effect is effectively improved, and the purpose of reducing indoor solar radiation heat through an external window and further reducing refrigeration energy consumption of an air conditioner in a building in summer is achieved.

Owner:浙江省建科建筑设计院有限公司

Self-cleaning heat-insulation coating system for exterior wall

ActiveCN102864884ALower heat transfer coefficientCovering/liningsSynthetic resin layered productsCoating systemSolvent

The invention relates to a self-cleaning heat-insulation coating system for an exterior wall. The self-cleaning heat-insulation coating system comprises (a) a hydrophobic undercoat layer, (b) a heat-reflecting surface coating layer and (c) a hydrophilic overcoat layer, wherein the hydrophobic undercoat layer is made from a first coating composition, the first coating composition contains aqueous emulsoid, the water permeability rate of the undercoat layer is 0.3 ml per 24 hours, the heat-reflecting surface coating layer is made from a second coating composition, the second coating composition contains a heat reflecting filler, the surface coating layer has the sun reflectance of at least 85% and / or the hemisphere emission ratio of at least 85%, the hydrophilic overcoat layer which is made from a third coating composition is coated on the heat-reflecting surface coating layer, and the third coating composition contains nano titanium dioxide and an aqueous solvent.

Owner:威士伯涂料(广东)有限公司

Preparation method of flame-retardant antibacterial water-based coating

InactiveCN111073492AGood mechanical propertiesGood antibacterial effectFireproof paintsAntifouling/underwater paintsWormwood extractCoffea

The invention provides a preparation method of flame-retardant antibacterial water-based coating. The content of a plant extract is 0.1-5%; and the plant extract is one or more of a wormwood extract,a Sarcandra glabra extract, a lavender extract, a valerian extract and a seaweed extract, or one or more of quercetin, salicylic acid, emodin, menthol, menthone, hyperoside, fumaric acid, linalool, caffeic acid, calcium alginate and sodium alginate, and slows the coating to have a plant natural antibacterial effect. A preparation process of the coating also comprises the following steps: preparinga film-forming substance, preparing color paste, preparing a diatomite porous material, preparing a functional modifier containing the plant extract, and preparing the water-based coating. Through the preparation process, the flame retardant property of the coating and the mechanical strength of a coating film are improved at the same time, and the application field of the coating is widened.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Composite insulating layer with cavity structures

InactiveCN106195529ALow thermal conductivityImprove insulation effectThermal insulationPipe protection by thermal insulationGratingEngineering

The invention provides a composite insulating layer with cavity structures. The composite insulating layer comprises a pipeline or equipment substrate and at least one insulating layer, wherein block ratings or supports are arranged between the pipeline or equipment substrate and the insulating layer to form part of the cavity structures; block gratings or supports are arranged between the insulating layers to form the rest cavity structures. According to the composite insulating layer with the cavity structures, provided by the embodiment of the invention, as air has a favorable heat insulation effect, equivalently, air layers are added to a common insulating layer structure, and the heat insulation effect of the air layers per se are better than that of the traditional insulating layers, the cost is lowered, heat loss is reduced, successful normal production is guaranteed, the expenditure on frequently replacing the insulating layers is reduced for enterprises, and a certain economical benefit is created.

Owner:BEIJING ENJI ENERGY SAVER TECH

Thermal insulation concrete and production method thereof

The invention discloses a thermal insulation concrete and a production method thereof. The thermal insulation concrete comprises the following components in parts by weight: 100-120 parts of coal ash, 200-250 parts of cement, 50-75 parts of foamed plastic, 25-30 parts of foam glass, 40-55 parts of inflated mineral powder, 0-20 parts of silicate, 15-20 parts of sulfate, 80-100 parts of fine sand, 10-20 parts of silicon powder, 5-10 parts of talcum powder, 10-15 parts of a water reducing agent, 22-25 parts of a foaming agent and the balance of water, wherein the water-binder ratio is maintained at 0.5-0.6, the inflated mineral powder comprises inflated slag or float stone, the water reducing agent is poly-hydroxy acid, and the foaming agent is alkyl sulfate. By utilizing the manner, the thermal insulation concrete is light in mass, low in cost, small in heat transfer coefficient and good in thermal insulation property and sound insulation effect; the production method of the thermal insulation concrete is simple, and the operation process is easy to control.

Owner:SHANDONG HUABANG CONSTR GRP

Prefabricated sandwich insulation wall based on plate perforated FRP connecting pieces and manufacturing method thereof

InactiveCN110344537AHigh strengthLow thermal conductivityClimate change adaptationCeramic shaping apparatusInsulation layerThermal bridge

The invention discloses a prefabricated sandwich insulation wall based on plate perforated FRP connecting pieces and a manufacturing method thereof. The prefabricated sandwich insulation wall comprises an inner-layer concrete plate, an outer-layer concrete plate, a middle insulation layer and FRP connecting pieces; the inner-layer concrete plate and the outer-layer concrete plate are compounded byfiber knitted nets and ECC concrete; through transverse penetration of the FRP connecting pieces, the fixed connection among the inner-layer concrete plate, the middle insulation layer and the outer-layer concrete plate is realized; and holes are formed in the two side edge positions, in the inner-layer concrete plate and the outer-layer concrete plate, of the FRP connecting pieces at intervals.Through full use of such characteristics as high corrosion resistance and low heat conducting coefficient of the plate perforated FRP connecting pieces, the thermal bridge effect is eliminated, the safety and the durability of the wall are improved, and meanwhile, such problems as weak bonding and anchoring performances of connecting pieces of a traditional insulation wall with a sandwich layer and a concrete interface are solved.

Owner:CHINA UNIV OF MINING & TECH

Air preheater of oscillatory flow type heat pipe, and energy saving drying technique of using the preheater

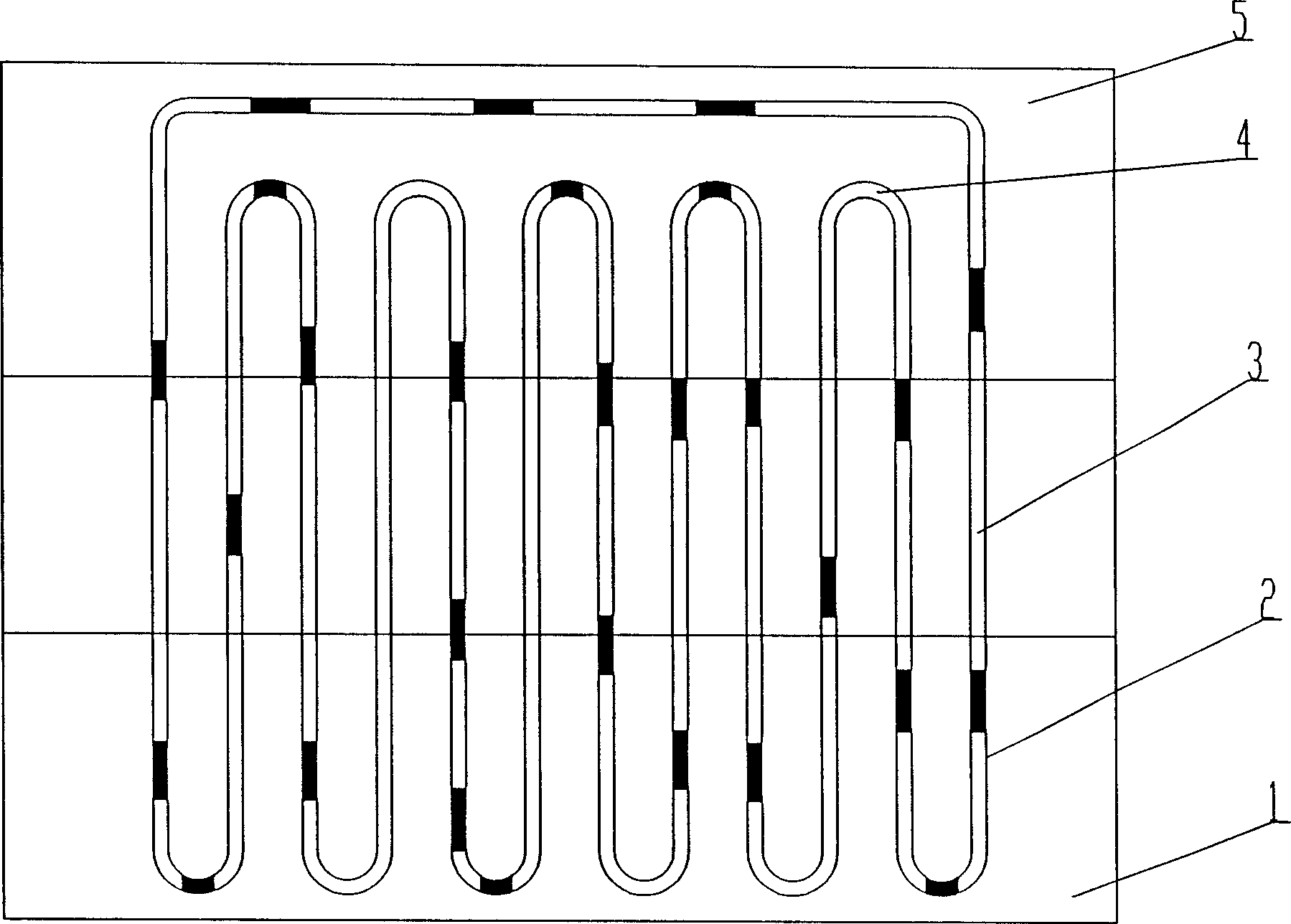

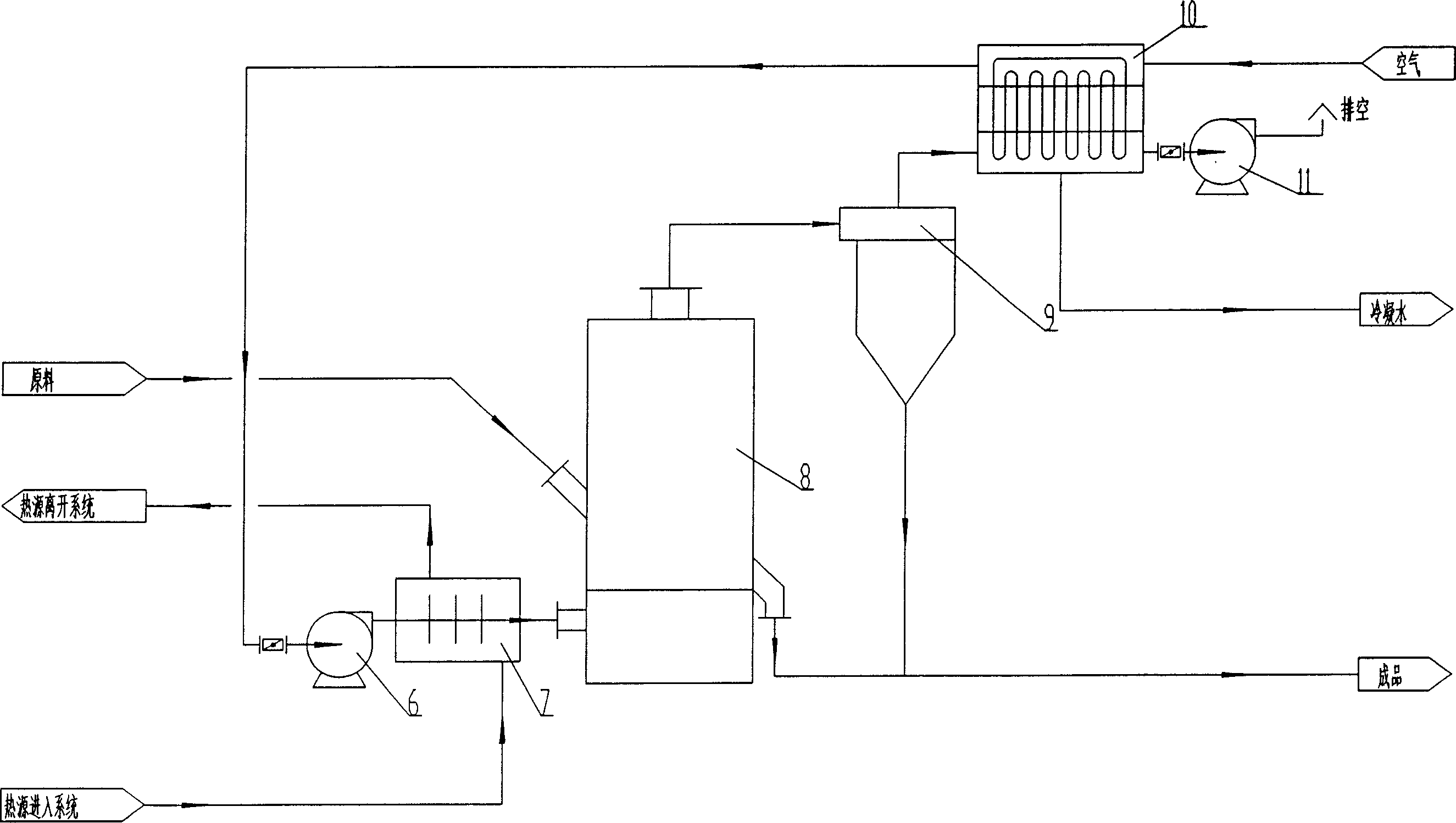

InactiveCN1916546AReduce volumeSimple structureIndirect heat exchangersHeating arrangementThermal energyAir preheater

An energy- saving dry process using air preheater of oscillation stream heat tube includes sending wet material into dryer by conveying device, preheating natural air by said air preheater then using blower to pressurize it and to send it to heat exchanger, heating air to be required temperature and sending it to dryer for drying material in dryer, discharging dried material out from dryer and conveying it together with dried powder collected from cyclone dust remover to final product area, sending tail gas from dryer to said air preheater through draught fan after it is purified by said dust remover and using it to preheat drying media then exhausting it to the air.

Owner:SHAN DONG TIAN LI DRYING EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com