Construction technology for processing glass curtain wall into hollow glass curtain wall

A technology of glass curtain wall and construction technology, applied in the direction of walls, building maintenance, building components, etc., can solve the problems of troublesome construction, high production cost, and insignificant improvement of internal and external temperature difference, and achieve the reduction of heat transfer coefficient, reduction of heat transfer coefficient, The effect of low renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

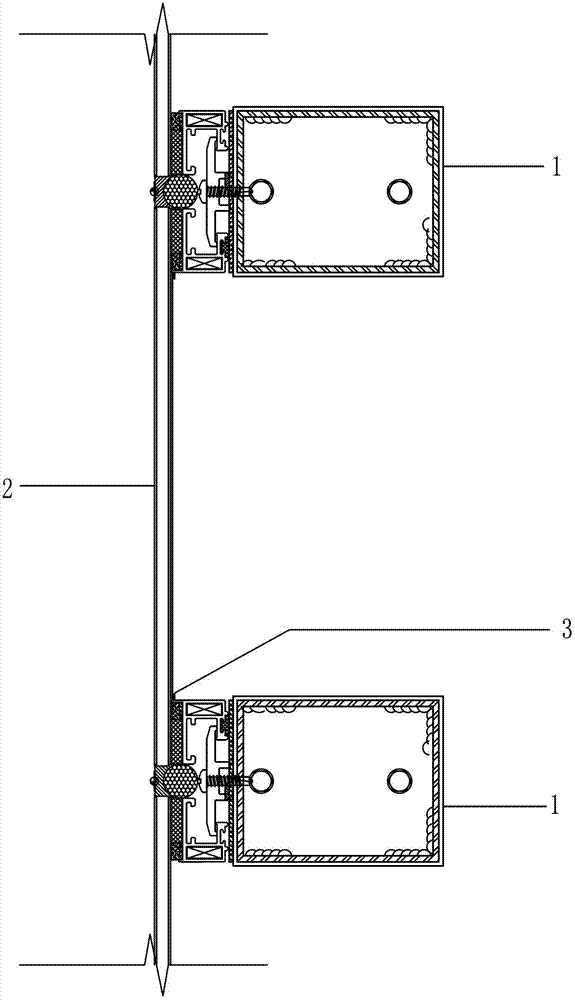

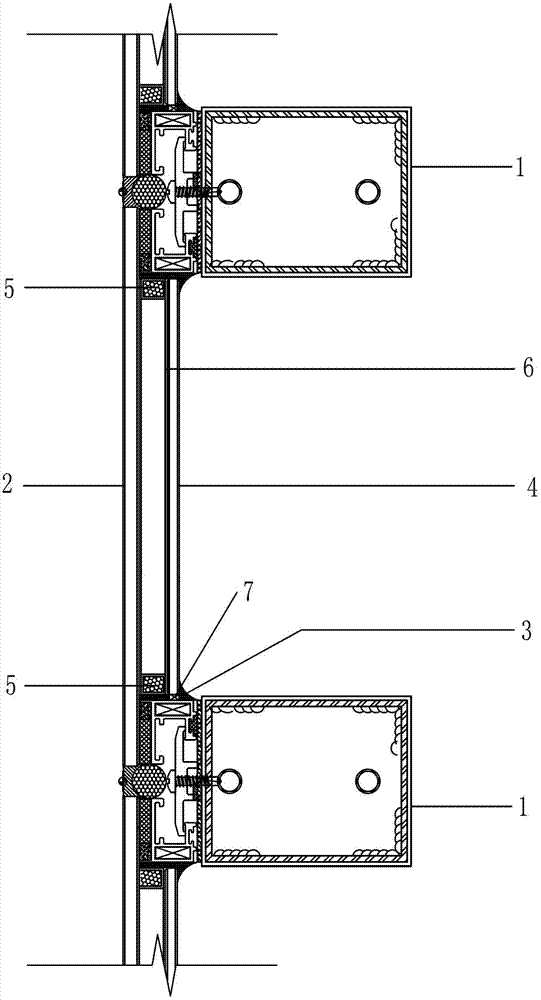

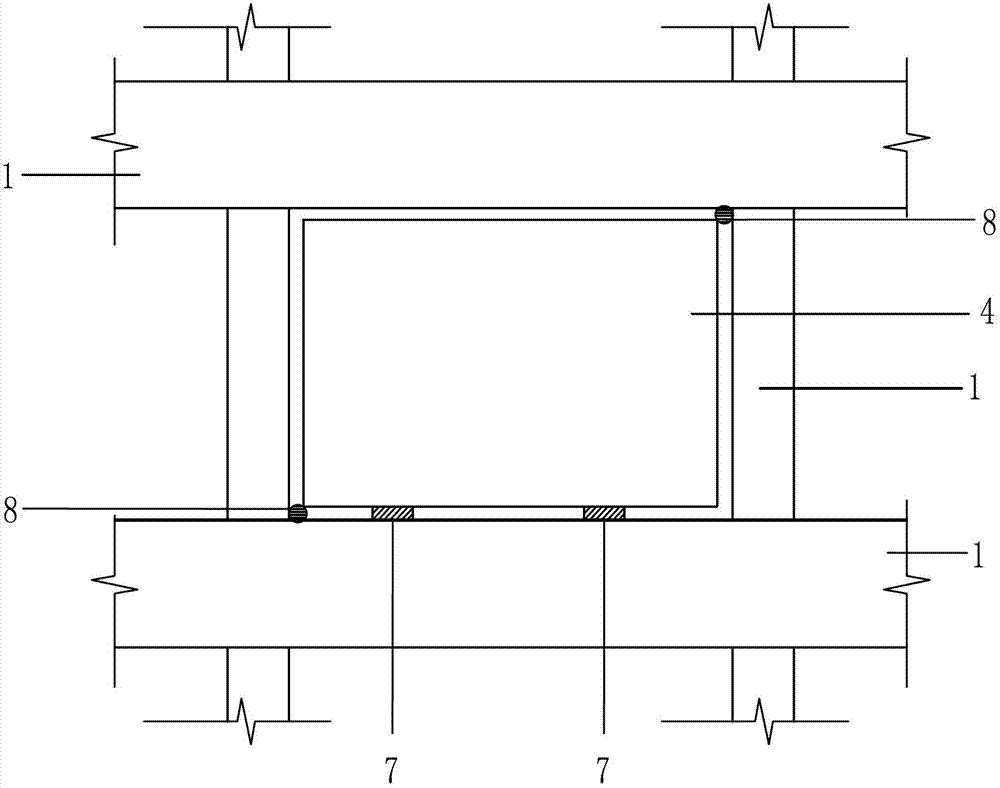

[0033] refer to figure 1 and figure 2 , a construction process for processing a glass curtain wall into a hollow glass curtain wall, which includes the following steps: on the premise that various materials and tools are prepared, firstly wipe off the dust and dirt on the inner surface of the original glass curtain wall 2, Apply a small amount of sealant 3 to the inner corners of the main frame 1 of the original glass curtain wall, and after filling molecular sieves in the four aluminum spacer bars 5, assemble the aluminum spacer bars 5 to form an overall square frame, the size of which is larger than that of the composite sheet Low-E glass 4 is 2mm smaller in size to leave room for glue sealing. Apply butyl rubber strips 6 on both sides of the overall frame, and press the aluminum spacer strips 5 close to the inside of the original glass curtain wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com