Prefabricated sandwich insulation wall based on plate perforated FRP connecting pieces and manufacturing method thereof

A technology for thermal insulation walls and manufacturing methods, which is applied to building components, manufacturing tools, ceramic molding machines, etc., and can solve the problems of low thermal conductivity, poor bonding and anchoring performance between thermal insulation wall connectors and sandwich layer concrete interfaces, and high resistance to heat. Corrosion and other problems, to achieve low thermal conductivity, improve the anchoring effect, improve the effect of interface bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

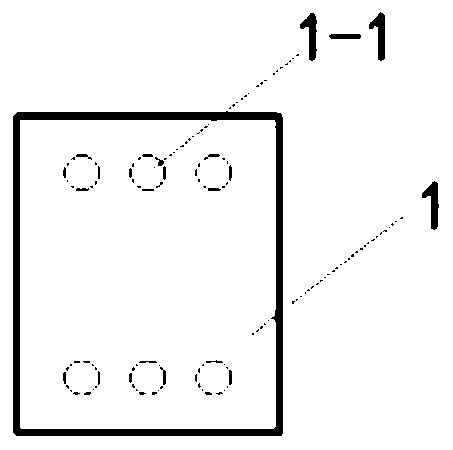

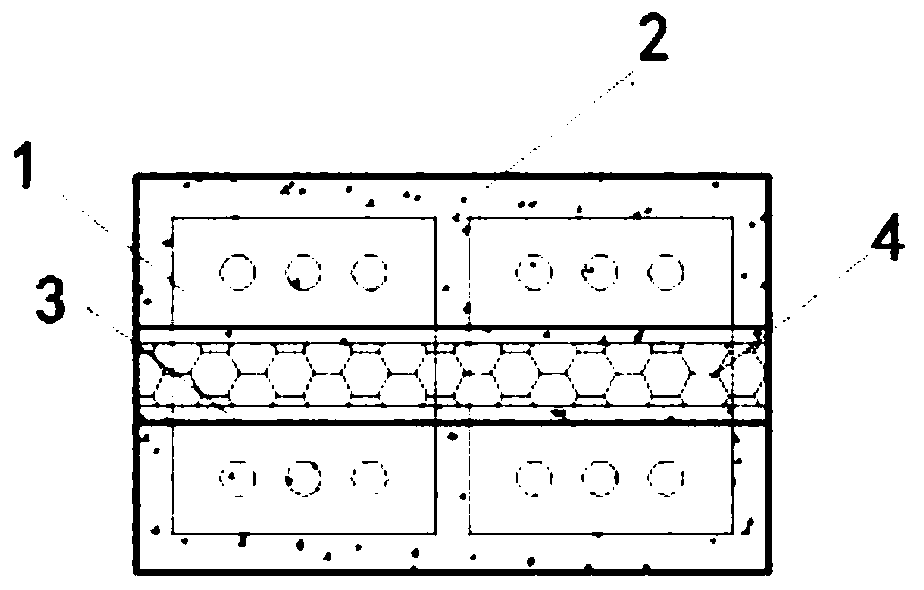

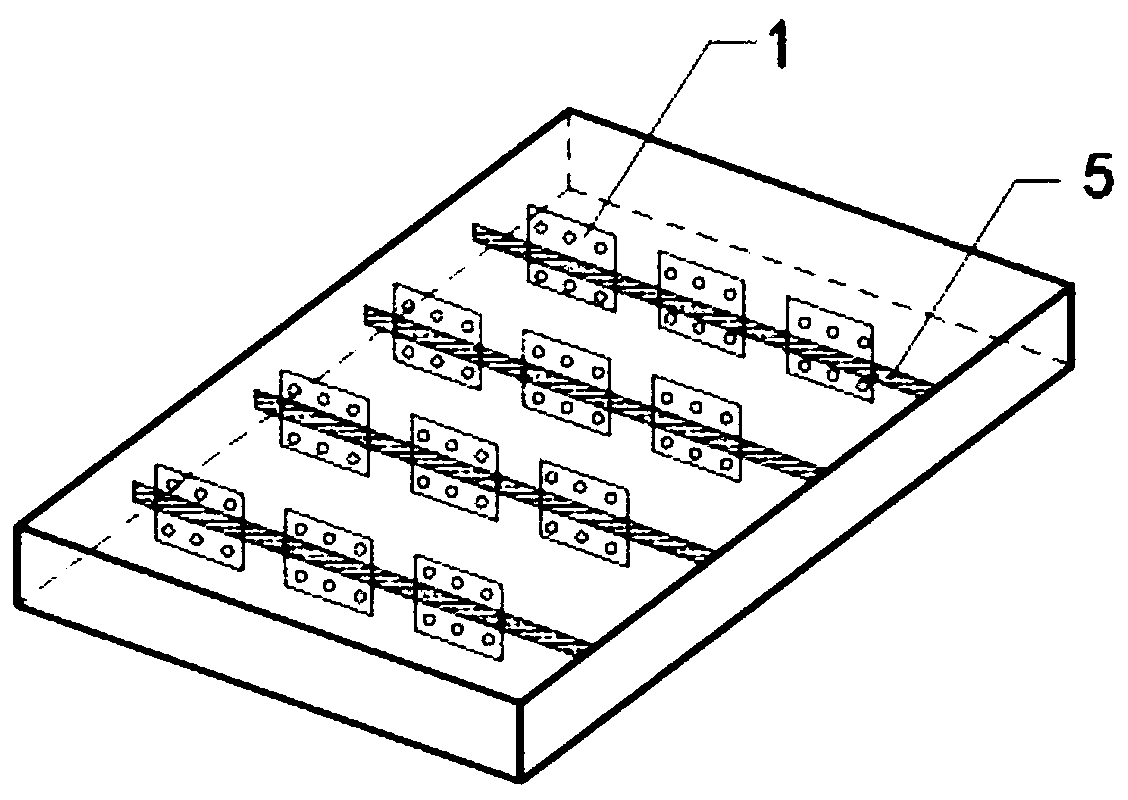

[0036] Such as Figure 1-3 Shown is a prefabricated sandwich insulation wall based on plate-type perforated FRP connectors, including inner concrete slabs, outer concrete slabs, middle insulation layer 4 and FRP connectors 1;

[0037]Wherein, the inner concrete slab and the outer concrete slab are both composed of fiber braided mesh 3 and ECC concrete 2, and the inner concrete slab, the middle insulation layer 4, and the outer concrete slab are realized through the FRP connector 1 installed horizontally. The fixed connection between the plates, and the FRP connectors 1 are located at the inner and outer concrete slabs, and holes 1-1 are opened at the edge positions on both sides of the outer concrete slab at intervals.

[0038] In this embodiment, the fiber braided net 3 is woven into a net in radial and weft directions using one or two of carbon fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com