Patents

Literature

110results about How to "Reduce thermal bridge effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

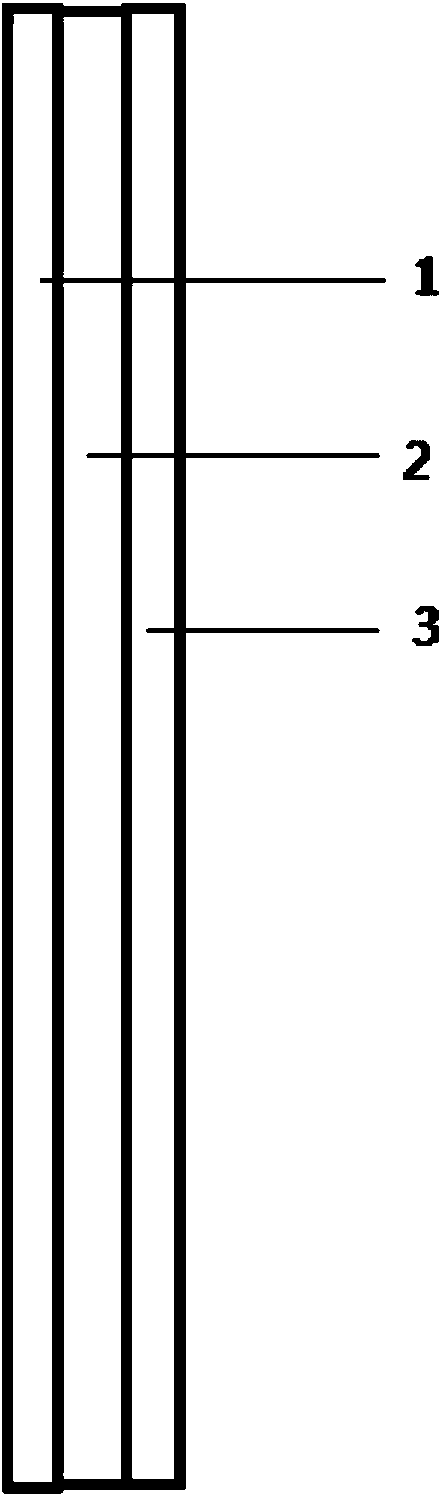

Silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material and preparation method thereof

ActiveCN106567474APromote sheddingReduce thermal bridge effectClimate change adaptationInsulation improvementThermal insulationCarbon nanotube

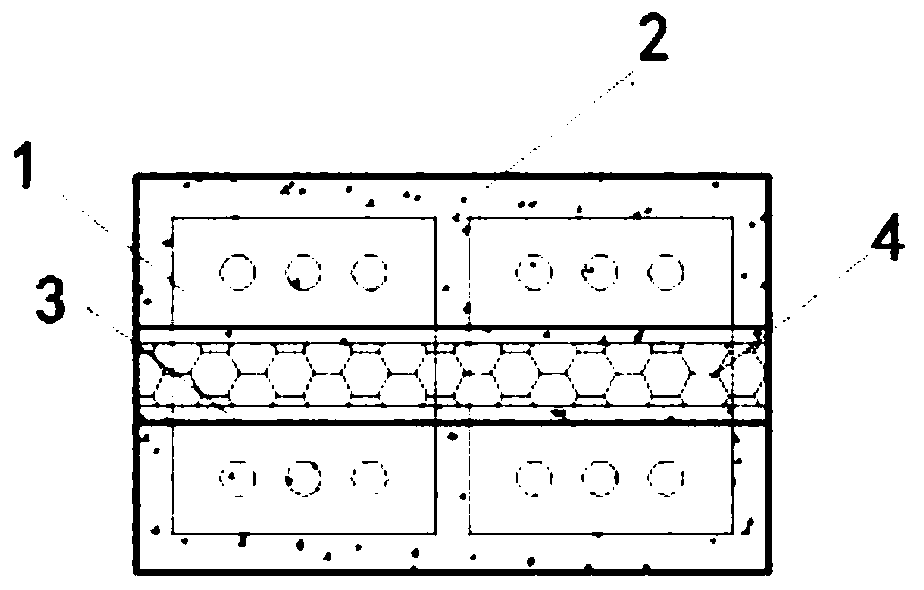

The invention relates to the technical field of insulation building materials and particularly discloses a silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material and a preparation method thereof. The silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material is characterized by comprising an upper inorganic fiber layer and a lower inorganic fiber layer. A composite insulation sandwich layer is bonded between the upper inorganic fiber layer and the lower inorganic fiber layer and is formed by mixing modified silica sol emulsion, melamine aerogel powder or water-soluble powder phenolic resin, a dispersant, a water repellent, silicon dioxide nanometer aerogel, hollow-core glass beads, a carbon nano tube, wollastonite powder, mica powder, a fine foamer, a curing agent and a hydrosolvent according to a certain weight ratio. According to the silicon dioxide nanometer aerogel hollow-core glass bead composite fireproof insulation board material and the preparation method thereof, innovative composite technology and fine foaming technology are adopted, high-tech space thermal insulation materials are changed for industrial and civil use, and the fireproof insulation board material is prepared and becomes an important way for technological development of fireproof insulation materials in the future.

Owner:王贵然

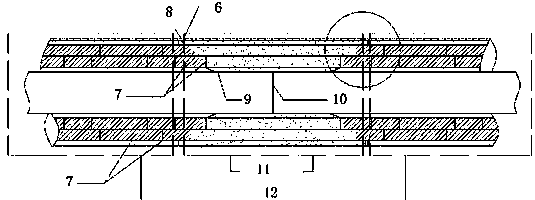

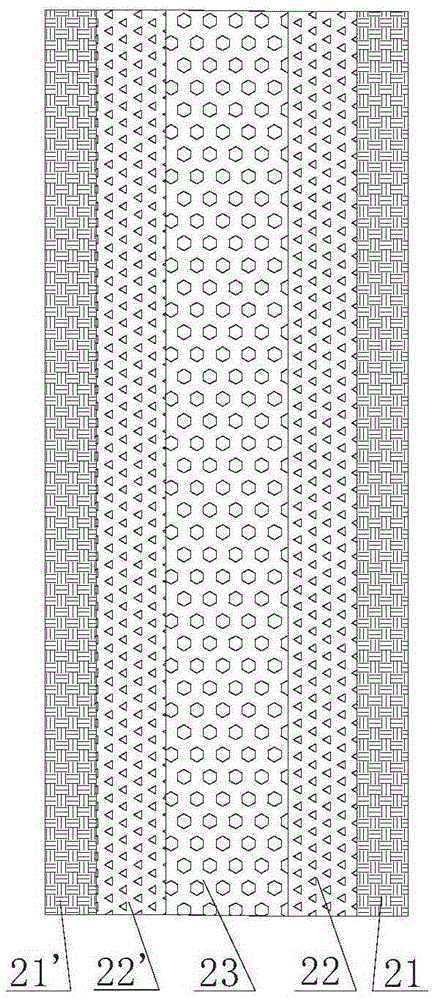

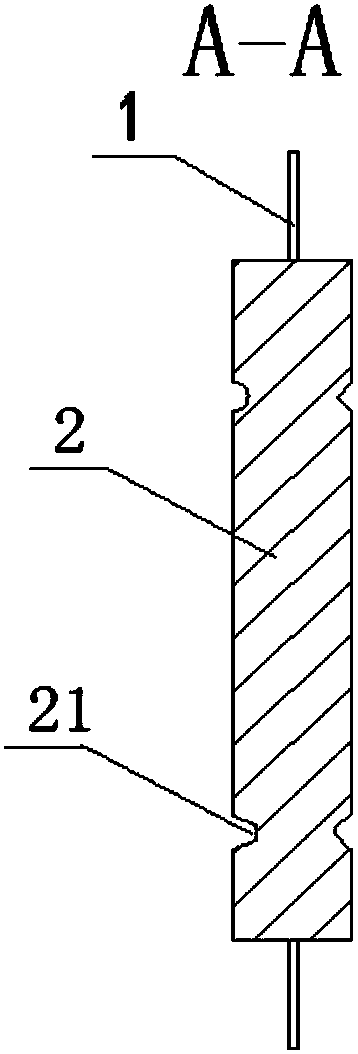

Prefabricated overhead heat insulation pipe

ActiveCN103968190AReduce thermal bridge effectGood consistencyThermal insulationPipe protection by thermal insulationEnvironmentally friendlyEngineering

The invention provides a prefabricated overhead heat insulation pipe. In order to solve the problems that when an overhead pipe delivers hot air at a long distance, heat loss is high, and the construction cycle is long, according to the scheme, the prefabricated overhead heat insulation pipe comprises a working pipe. The prefabricated overhead heat insulation pipe is characterized in that the working pipe is wrapped in an inorganic heat insulation layer, an organic heat insulation layer and an outer protection pipe in sequence, and a protection layer is arranged between the inorganic heat insulation layer and the working pipe; longitudinal joints and transverse joints of the inorganic heat insulation layer, the organic heat insulation layer and the outer protection pipe are all in lap joint in a step shape in a staggered mode; the protection layer is connected in a pressed mode; the lap joint of the inorganic heat insulation layer and the organic heat insulation layer is provided with gaps. According to the measures, compared with a traditional prefabricated overhead heat insulation pipe, the prefabricated overhead heat insulation pipe is lower in heat loss, shorter in construction cycle and more environmentally friendly.

Owner:宁波万里管道有限公司

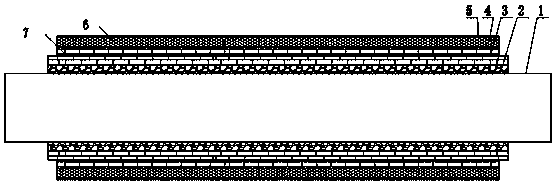

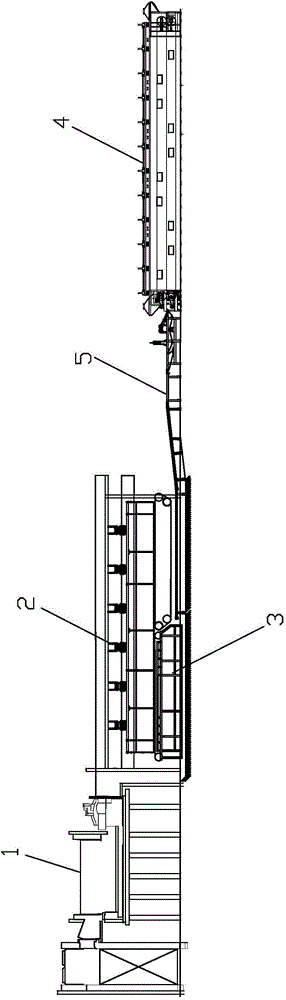

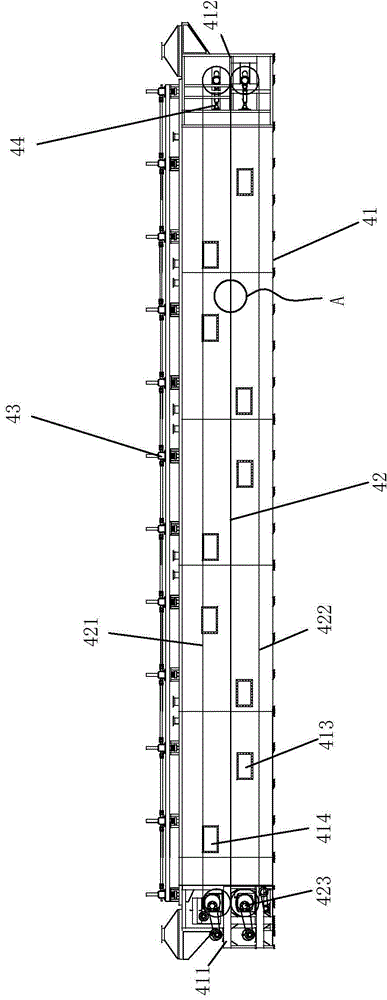

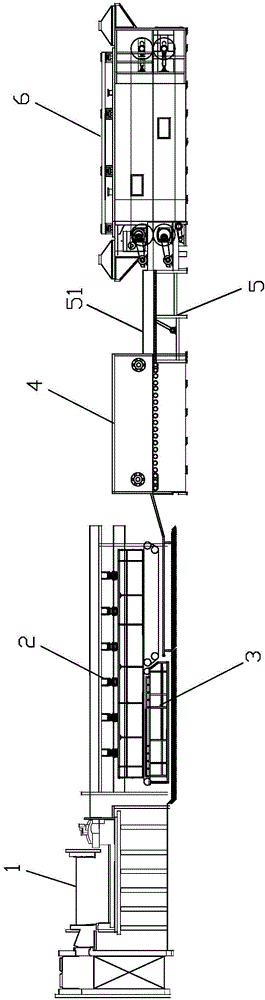

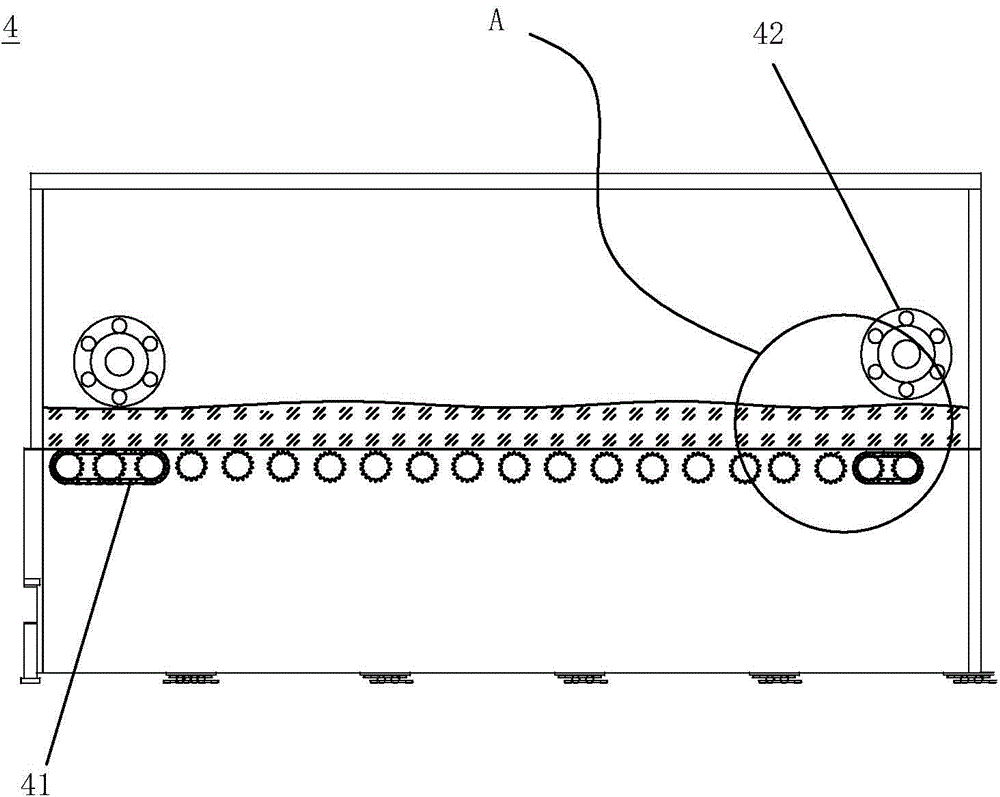

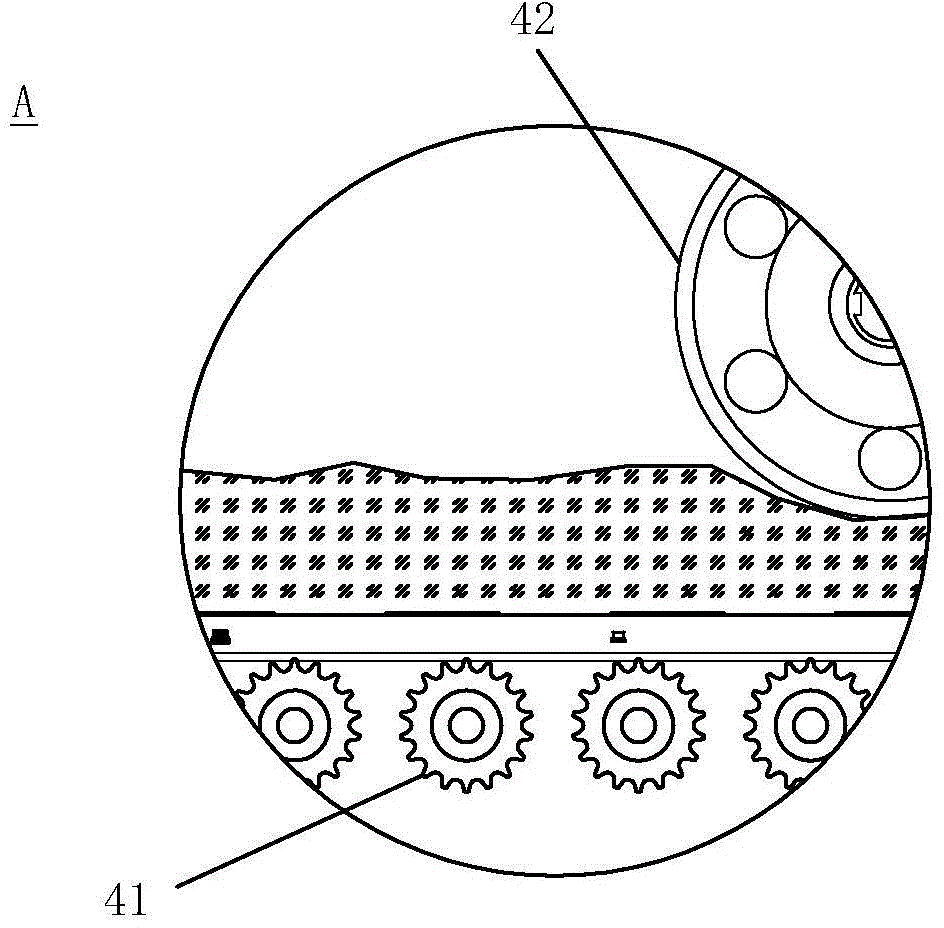

Online dry method glass wool vacuum insulated panel core material production system and method

ActiveCN106149196ARealize online continuous productionIncrease productivityNon-woven fabricsState of artEngineering

The invention discloses an on-line dry-process glass wool vacuum insulation board core material production system, which includes a melting furnace, a centrifuge, a cotton collector and a hot-pressing setting device. The hot-press setting device adopts the upper and lower chain plates to form a pressing gap, and the glass wool is pressed in the pressing gap, and can be continuously hot-pressed during the transmission process. The present invention also provides a production method based on the above production system. Compared with the prior art, the invention realizes on-line continuous production, has high production efficiency, and the prepared glass wool core material has stable structure and good heat insulation effect.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

High-temperature-resisting gel composite heat-preservation material

The invention discloses a high-temperature-resisting gel composite heat-preservation material. The high-temperature-resisting gel composite heat-preservation material is composed of an inner inorganic fiber layer, an outer inorganic fiber layer and a nano core layer, wherein the nano core layer is composed of a protective layer and a nano material layer formed by one to three inorganic fiber cloth aerogel-coated material layers, and connection of all layers of the nano core layer and connection between the nano core layer and the inner inorganic fiber layer and the outer inorganic fiber layer are achieved by adopting a high-temperature bonding agent or a sewing or combining method. The high-temperature-resisting gel composite heat-preservation material is simple in process and has the advantages of being high-temperature-resisting, good in heat-preservation performance and stability and the like.

Owner:中申(上海)管道工程股份有限公司

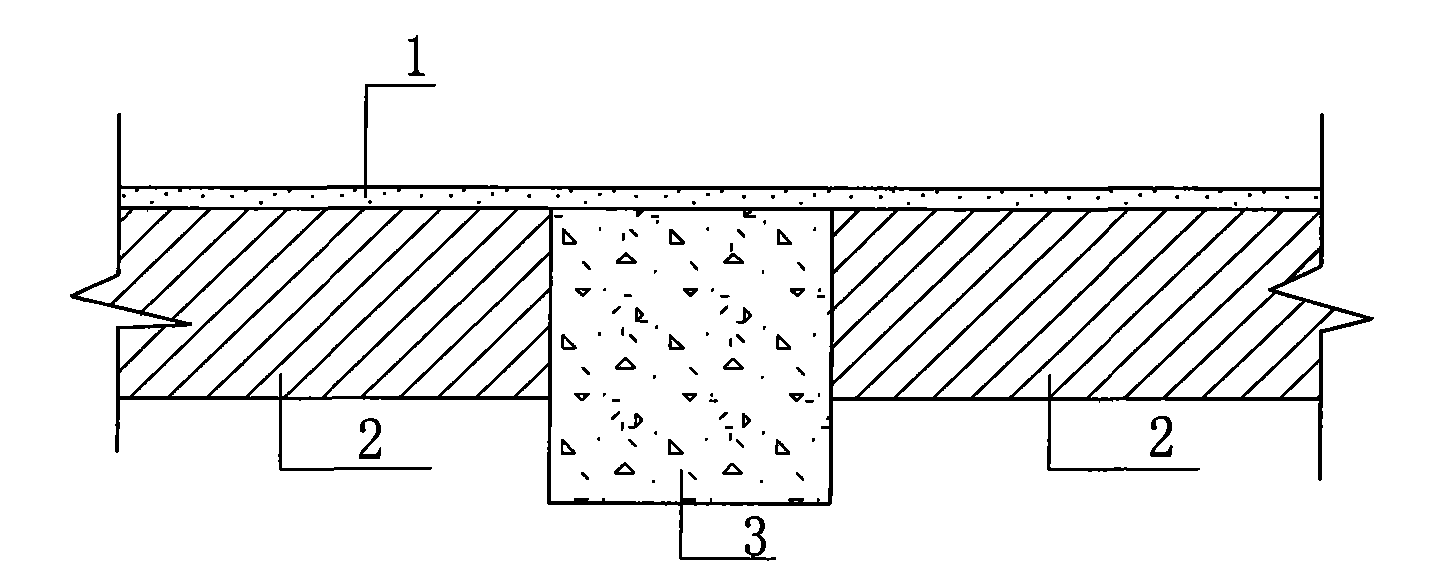

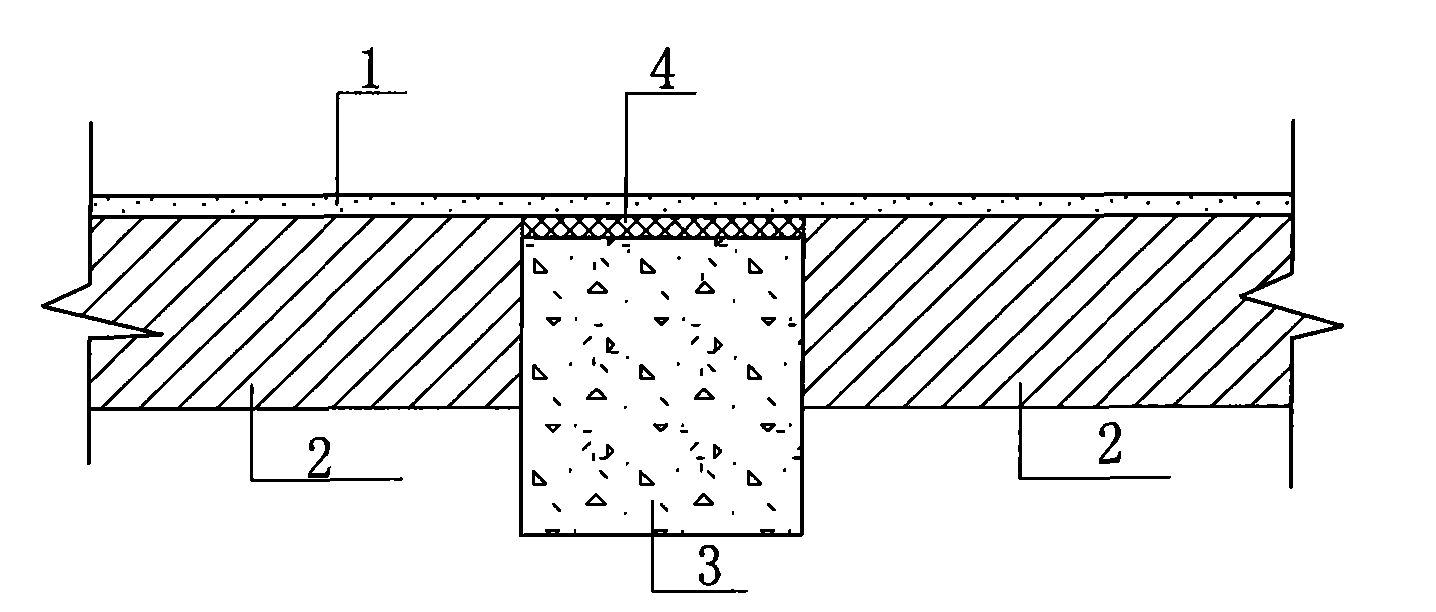

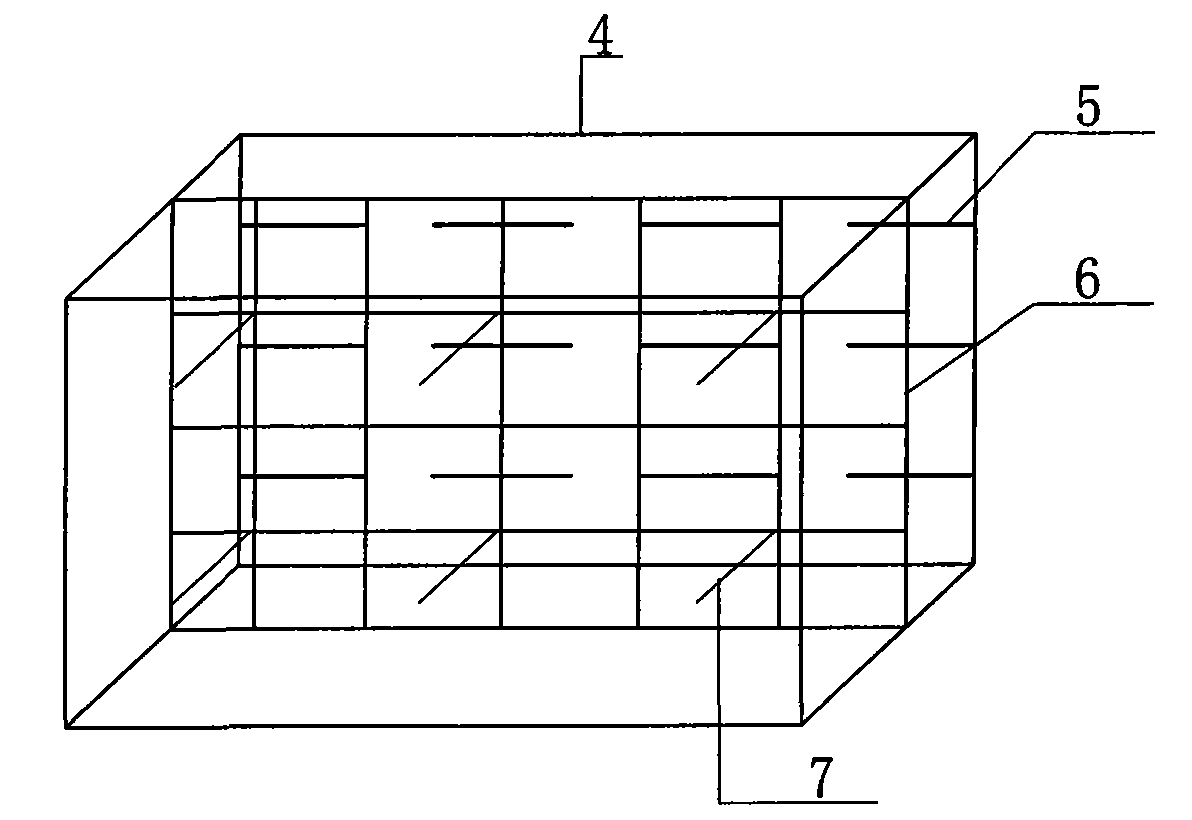

Insulation board of concrete exterior wall

InactiveCN101597940AImprove insulation effectHigh mechanical strengthSolid waste managementCeramic shaping apparatusBreaking strengthFiber

The invention relates to an insulation board of a concrete exterior wall, in particular to the insulation board of the concrete exterior wall at a heat bridge part, which is used in match with the exterior wall body constructed by energy-saving insulation building blocks. The invention is prepared by the following steps: raw materials are mixed, molded by extrusion to obtain the insulation board molding product which is subjected to steam curing and drying to obtain the insulation board molding product of the concrete exterior wall; the invention is characterized in that: before the invention is molded by extrusion, steel mesh is put into the raw materials followed by being molded by extrusion to be the insulation board molding product; the raw materials comprise the following components according to weight percentage: 235-242 parts of silicate cement, 65-67 parts of expanded perlite, 43-45 parts of ceramsite, 80-83 parts of slag, 4-2 parts of plant ash, 1.5-2 parts of wool felt fiber, 0.5-1.0 parts of cloth fiber, 0.5-1.0 parts of bamboo fiber and 94-96 parts of water. The invention has good insulation property, can effectively reduce the heat bridge effect of the exterior wall constructed by energy-saving insulation building blocks, has high breaking strength and can have the same service life with the exterior wall constructed by insulation blocks.

Owner:无锡市康顺节能材料科技有限公司

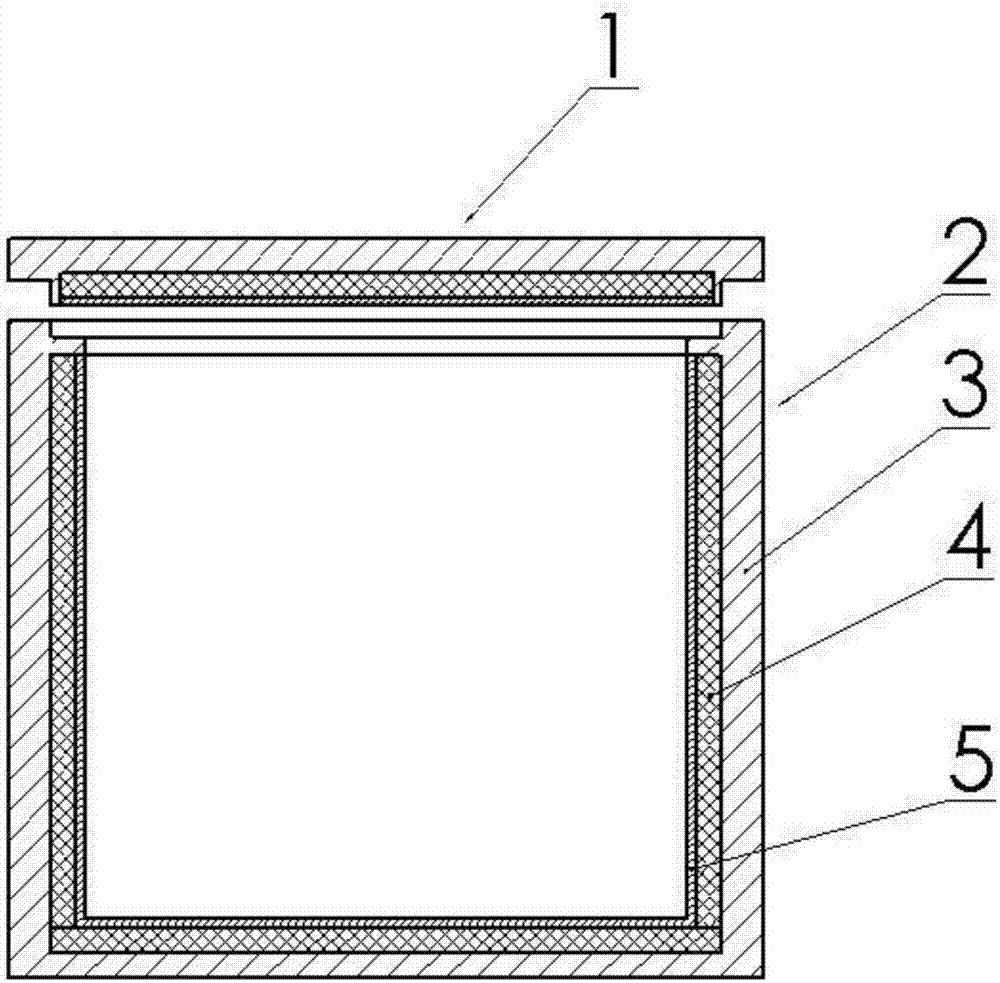

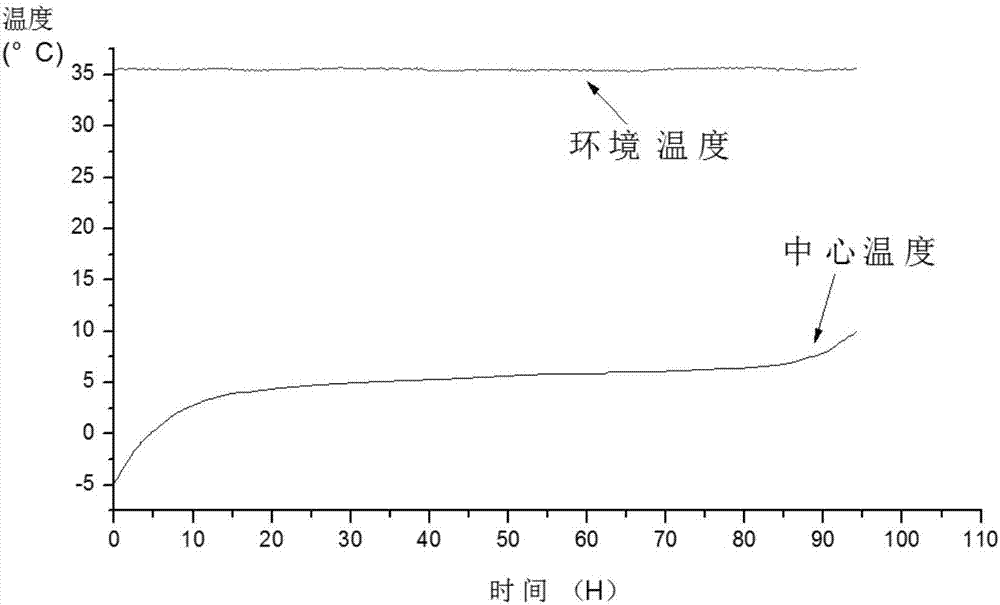

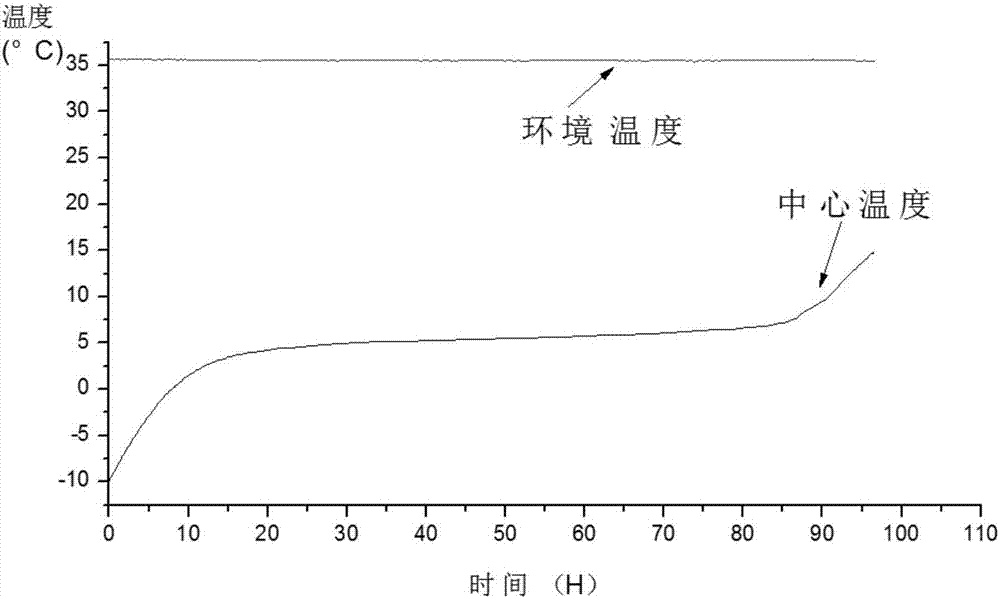

Cold chain thermal insulation box and manufacturing method thereof

PendingCN107323878ASimple processReduce processing costsDomestic cooling apparatusLighting and heating apparatusCold chainThermal insulation

The invention provides a production method for a cold chain thermal insulation box. After a VIP box of which the top end face is an open face is formed by spicing vips, a box inner mold is placed in the VIP box, and then the VIP box and the box inner mold are placed in a box outer mold; a gap space is formed between the outer wall of the VIP box and the inner wall of the box outer mold, and the box inner mold abuts against the inner wall of the VIP box; then a VIP serves as a VIP cover plate, the VIP cover plate is laid on a cover plate inner mold, and a cover plate outer mold is arranged on the VIP cover plate; a gap space is formed between the VIP cover plate and the cover plate outer mold similarly; EPP or EPS particles are injected into the gap spaces; and high-temperature high-pressure steam is led to the gap spaces, and foaming, adhering and forming of the EPP or EPS particles are completed. The production method is simple in process, the VIP box is formed integrally, machining cost is low, and the yield is high. The invention further provides the cold chain thermal insulation box small in overall weight, and protruding, adhesion failure, deformation and other problems are avoided.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Gangue foam concrete building block for realizing self heat insulation of walls

InactiveCN102493593ALow costConducive to high value-added comprehensive utilizationConstruction materialClimate change adaptationFoam concreteInsulation layer

Owner:CHONGQING HAIFENG CONSTR GROUP

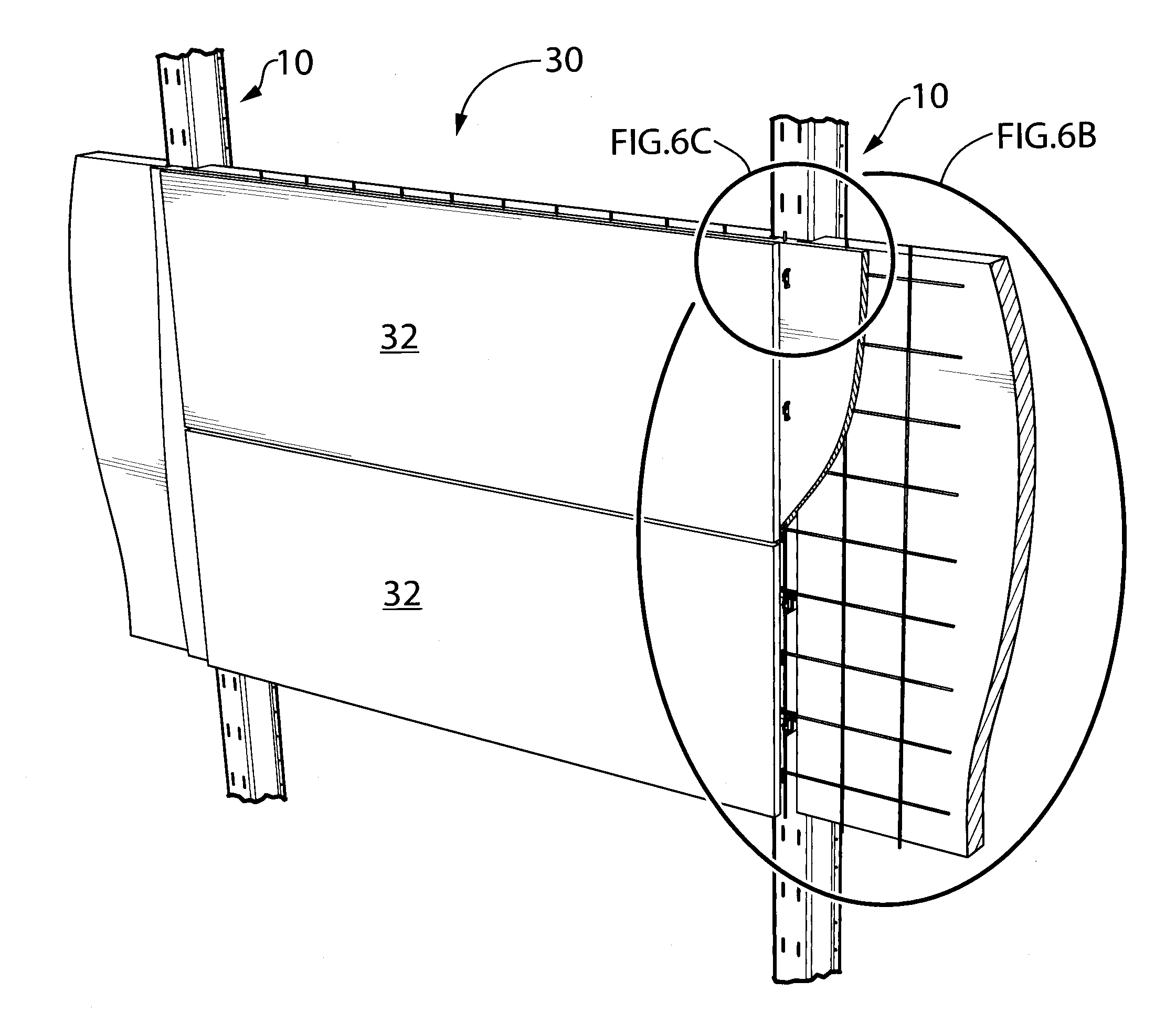

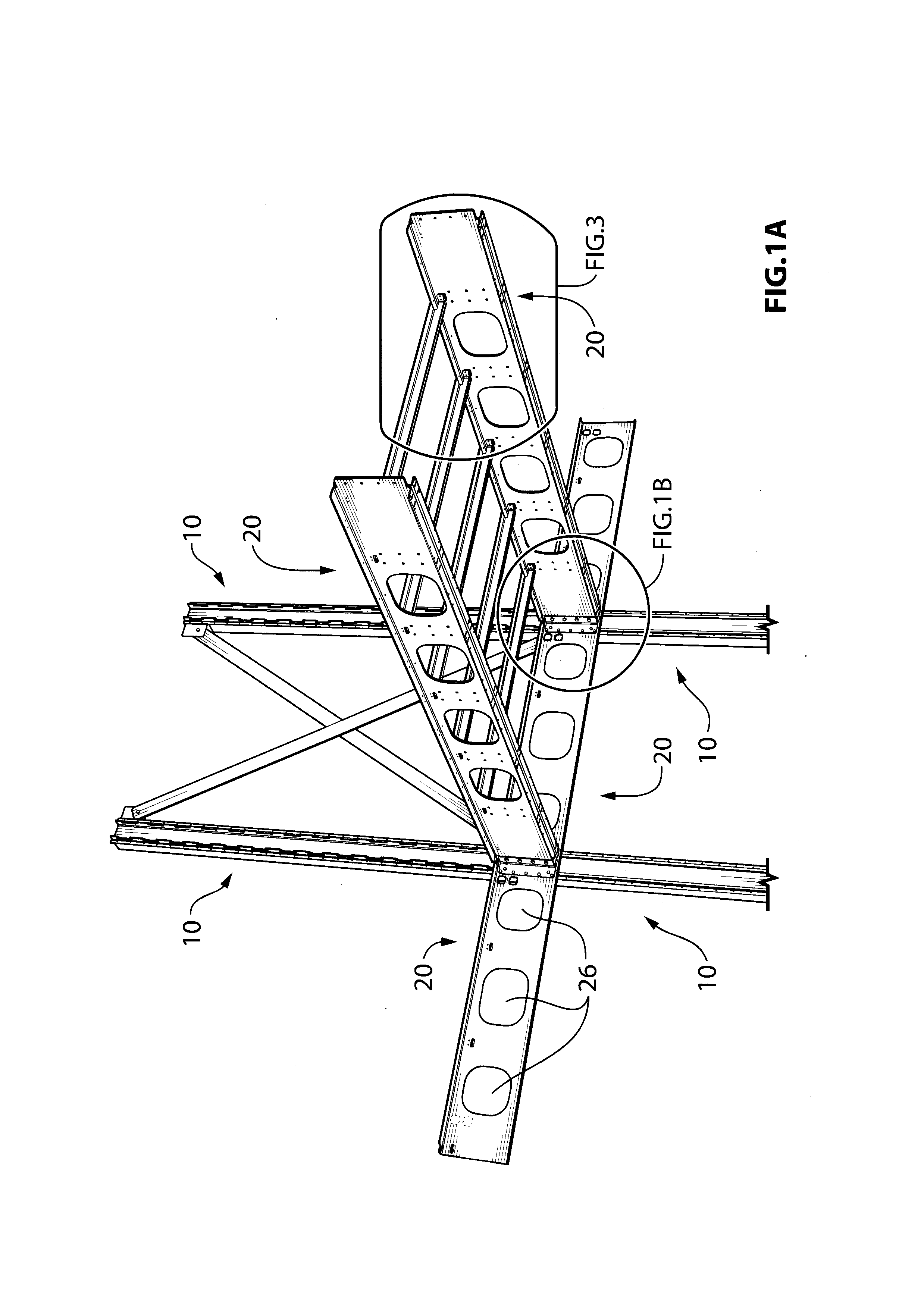

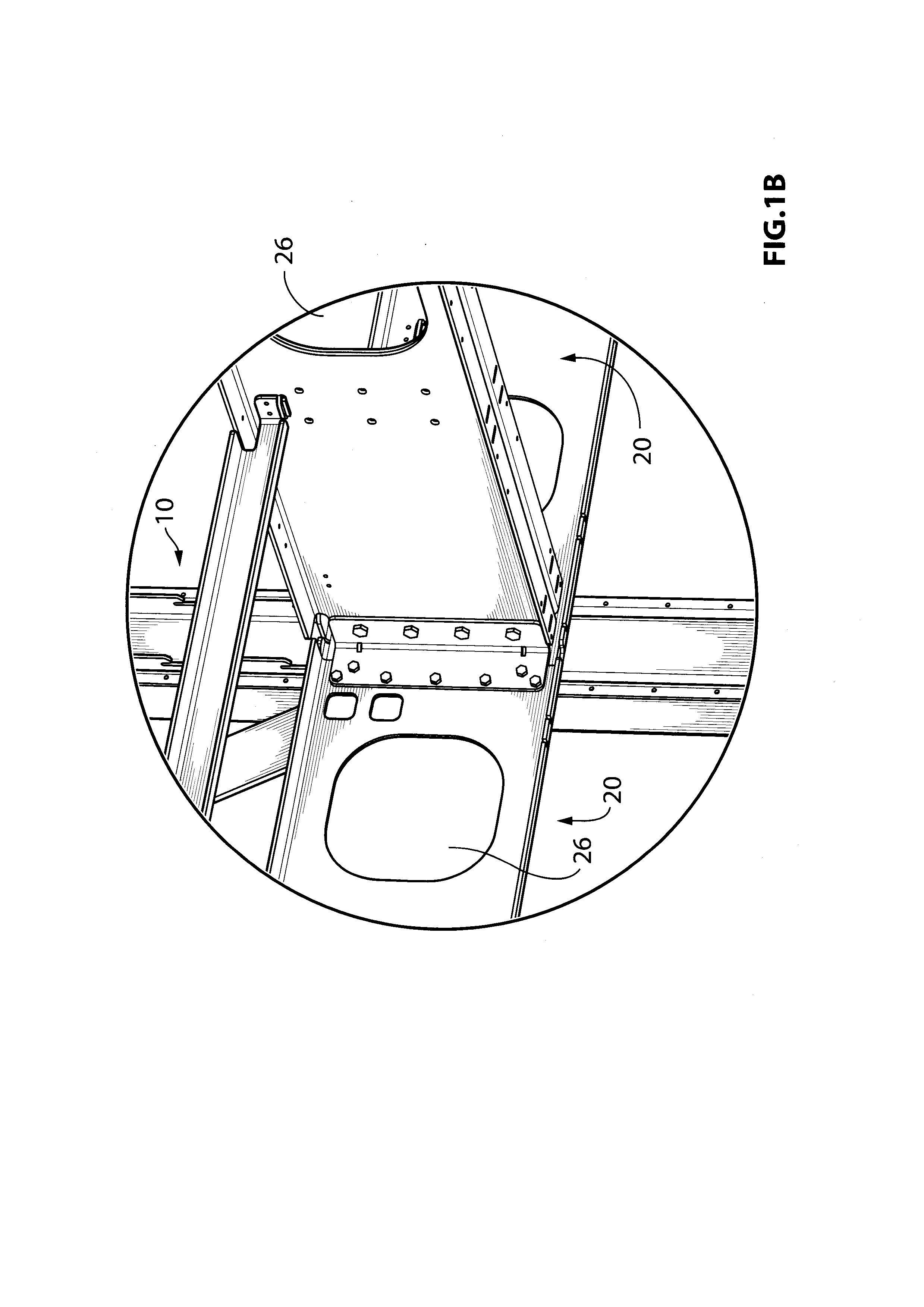

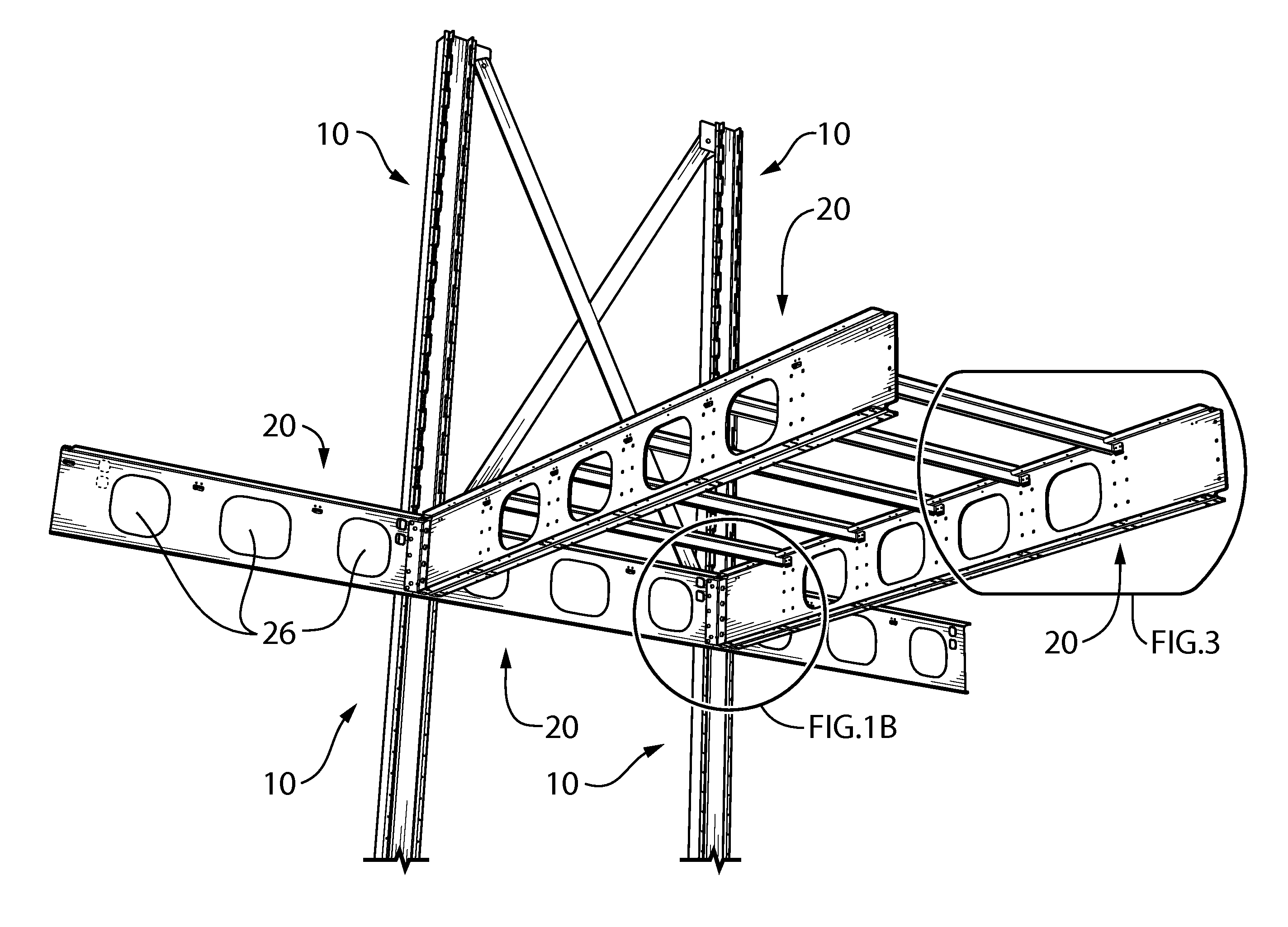

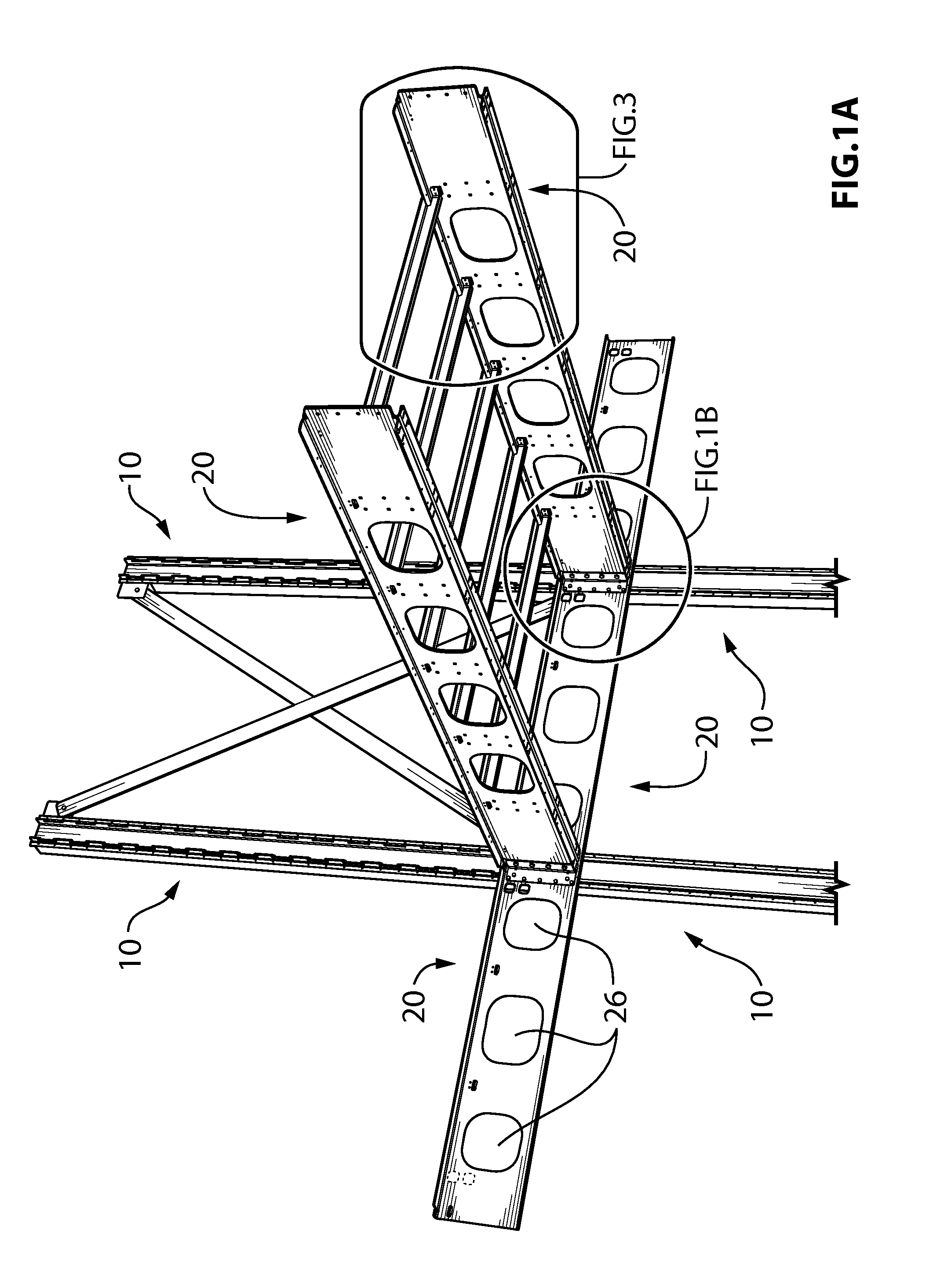

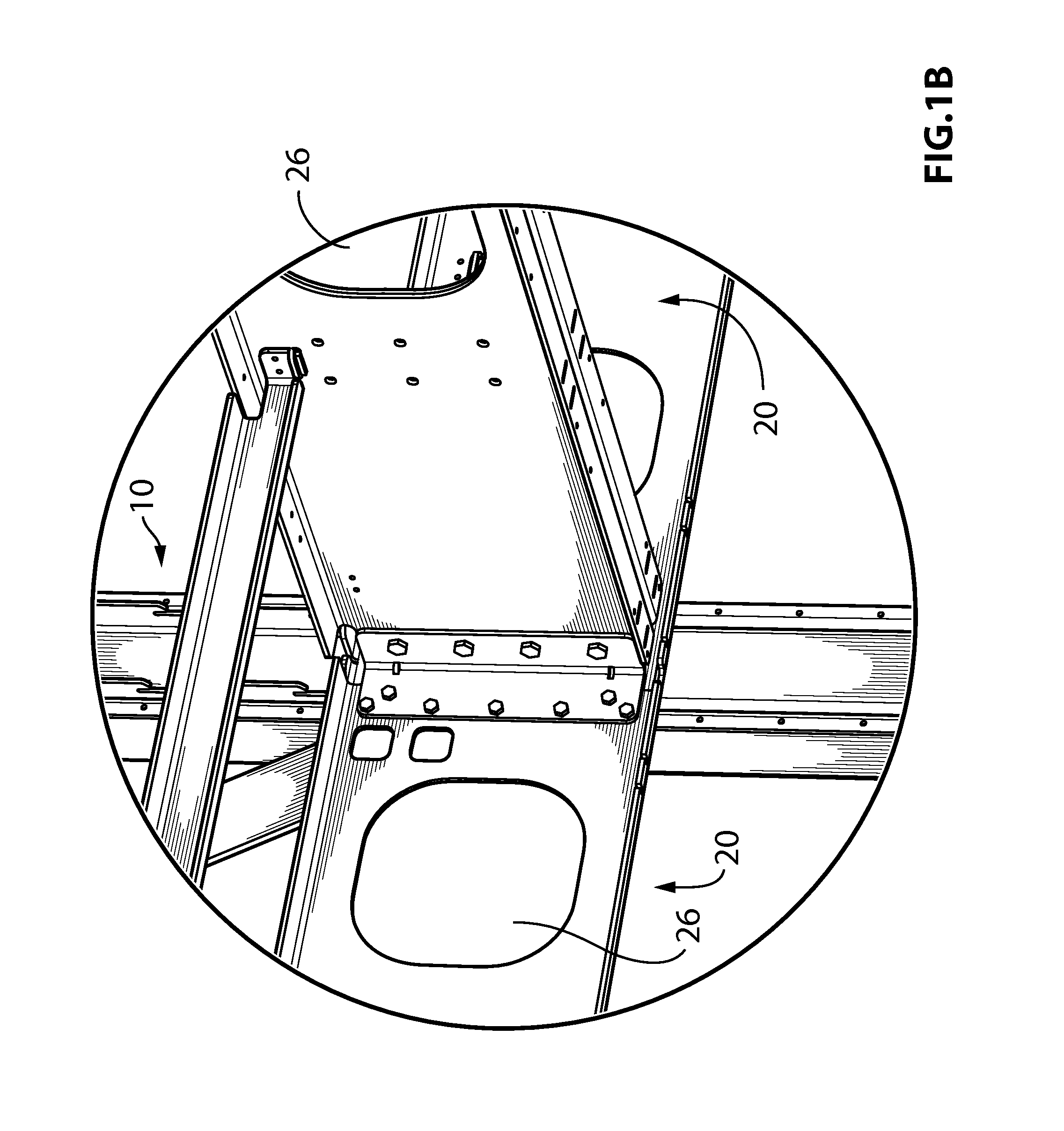

Evolving building structures improvements

InactiveUS20130180190A1Improved evolving building structureSimple structureElectrical apparatusWallsElectrical junctionBiomedical engineering

There is provided building structures that are demountable from a first configuration to be reassemblable to the first configuration or another configuration. The building structures include systems and kits for the structure, post anchors, kits for floor structure, method for assembling floor structures, wall and ceiling support systems, electrical junction box supports, and kits for frame assembly.

Owner:3088 7418 QUEBEC

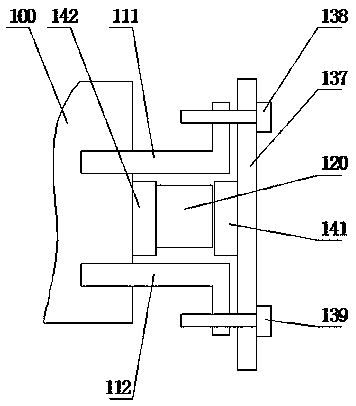

Modular building structures improvements

ActiveUS20150267393A1Easy to optimizeSimple structureConstruction materialCovering/liningsElectrical junctionBiomedical engineering

There is provided building structures that are demountable from a first configuration to be reassemblable to the first configuration or another configuration. The building structures include systems and kits for the structure, post anchors, kits for floor structure, method for assembling floor structures, wall and ceiling support systems, electrical junction box supports, and kits for frame assembly.

Owner:9344 8462 QUEBEC INC

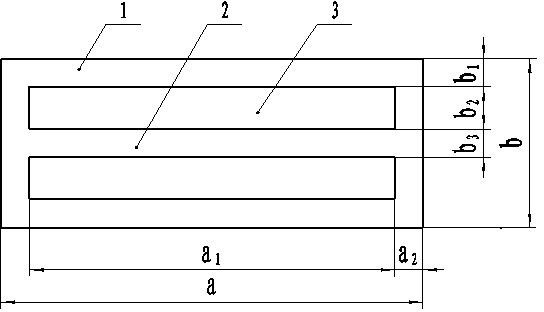

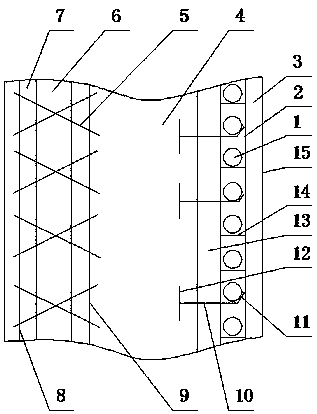

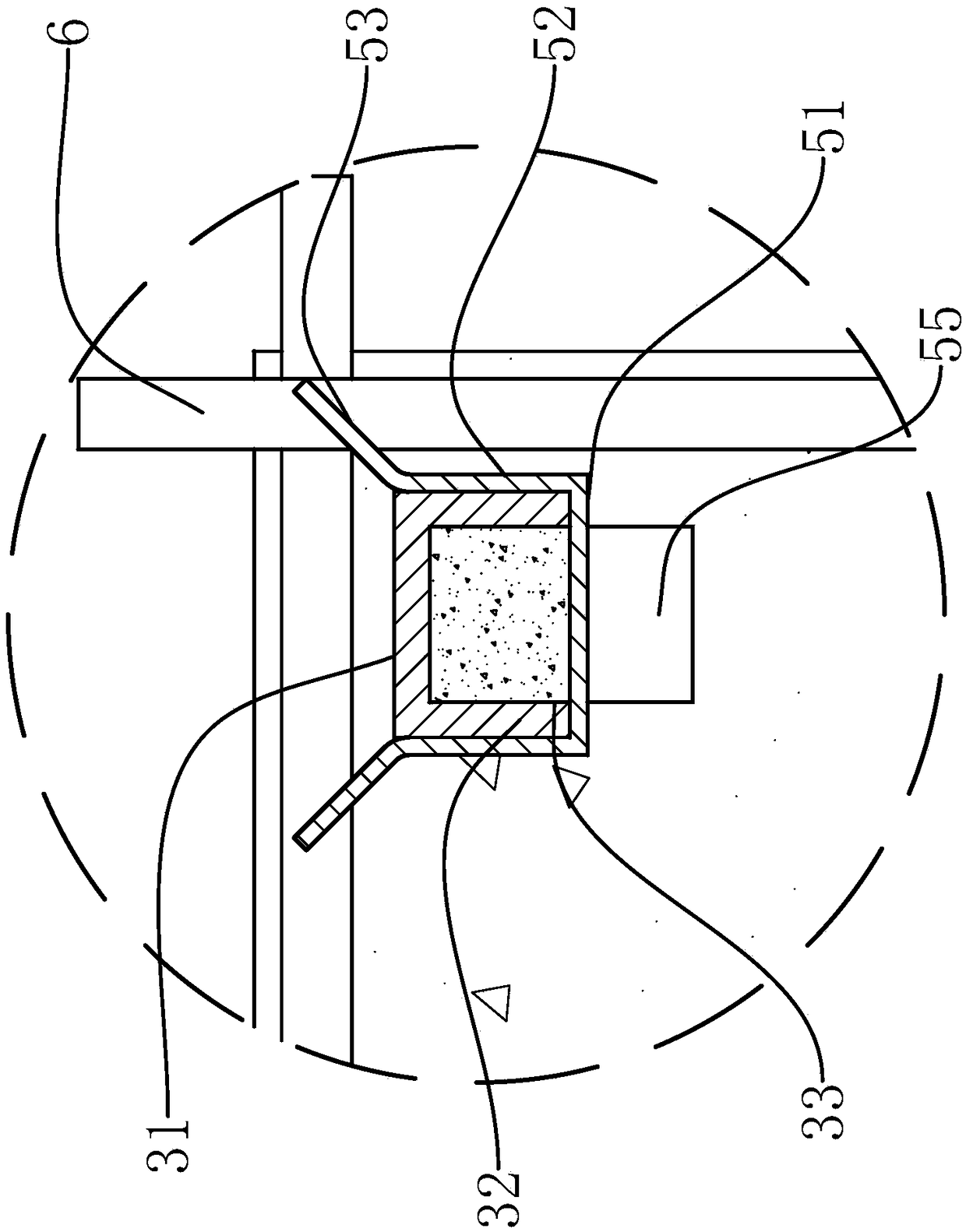

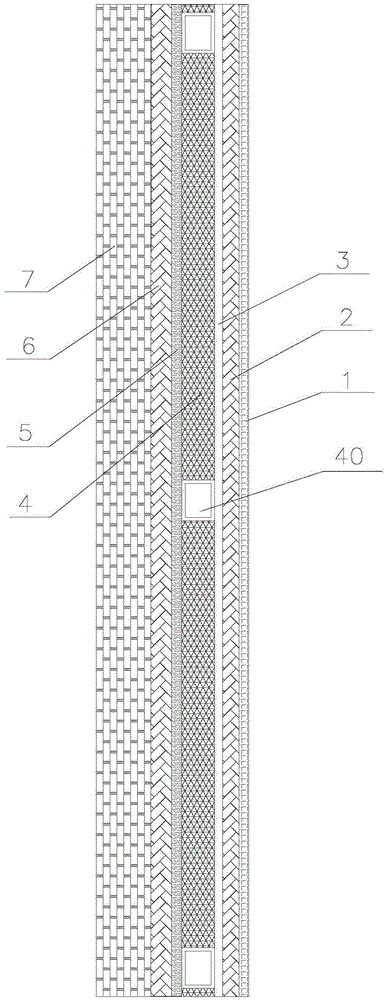

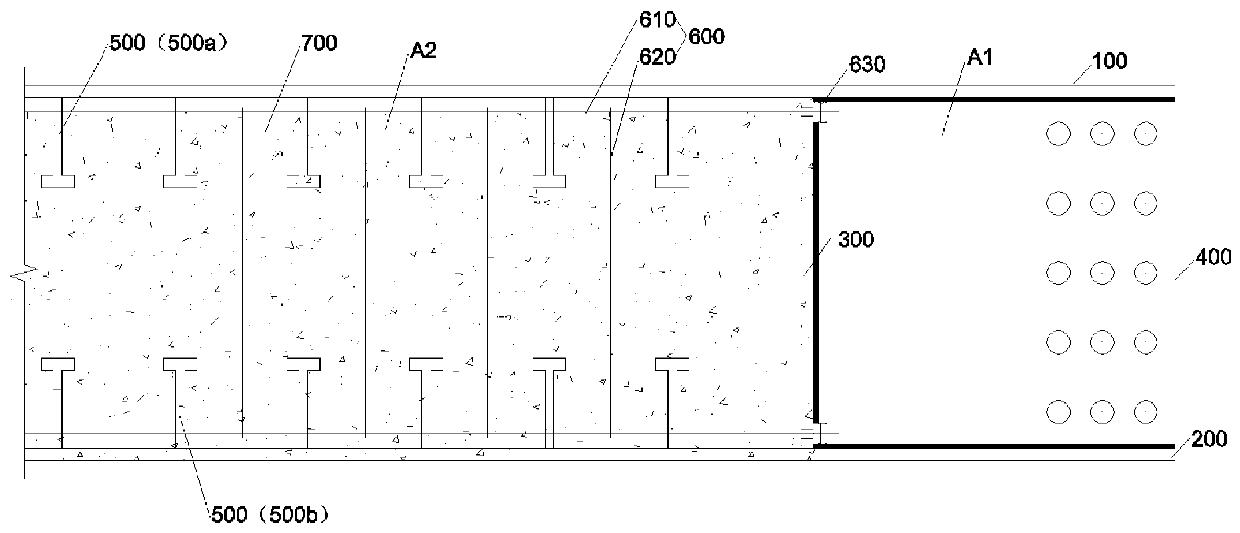

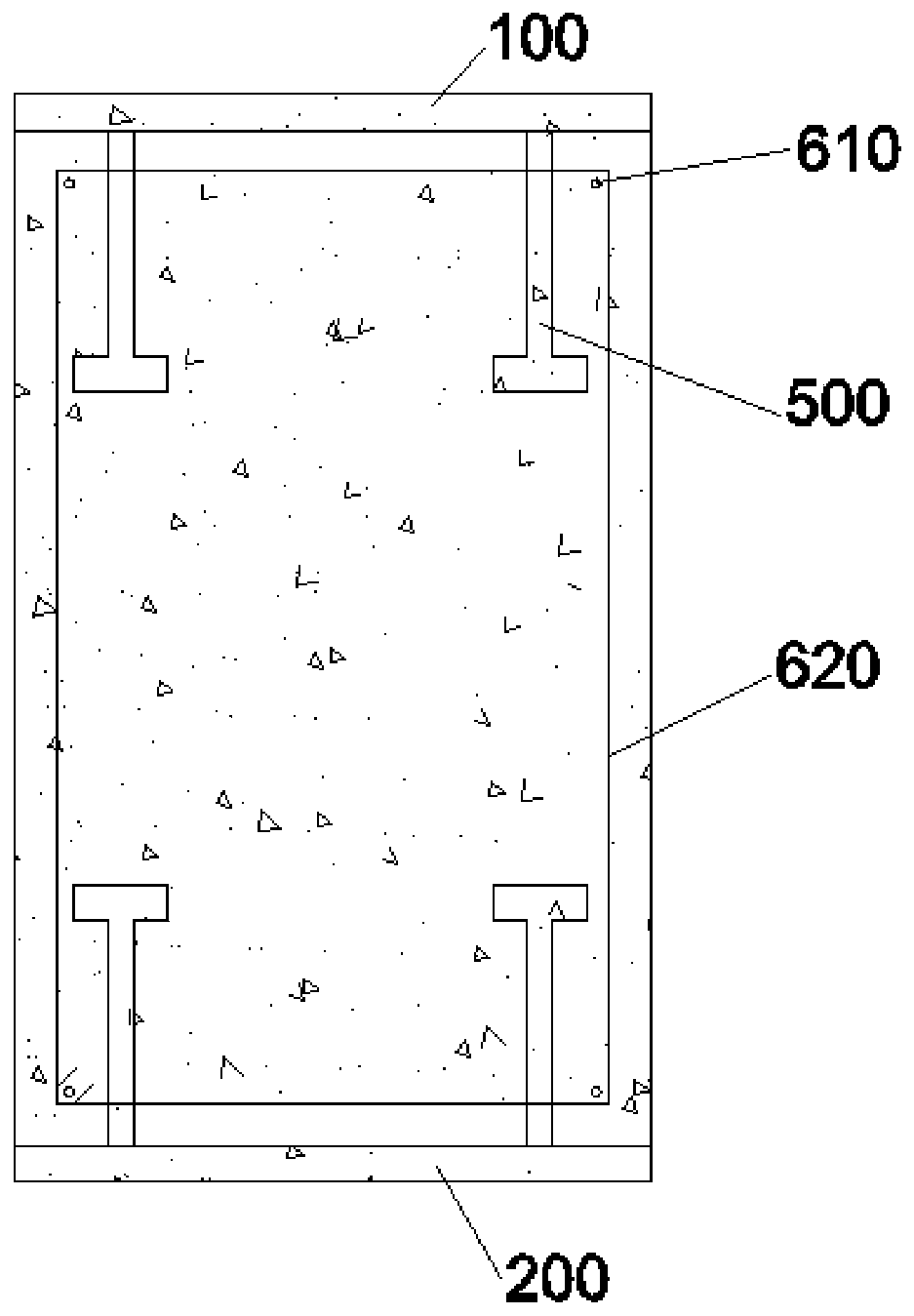

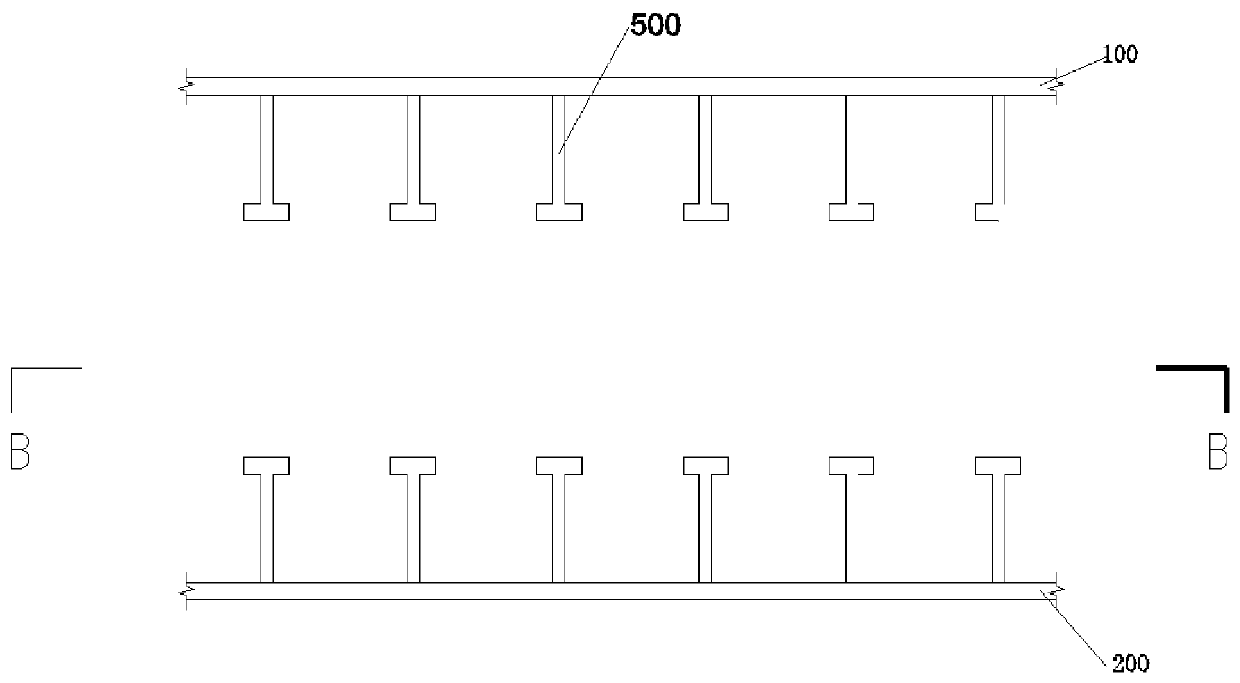

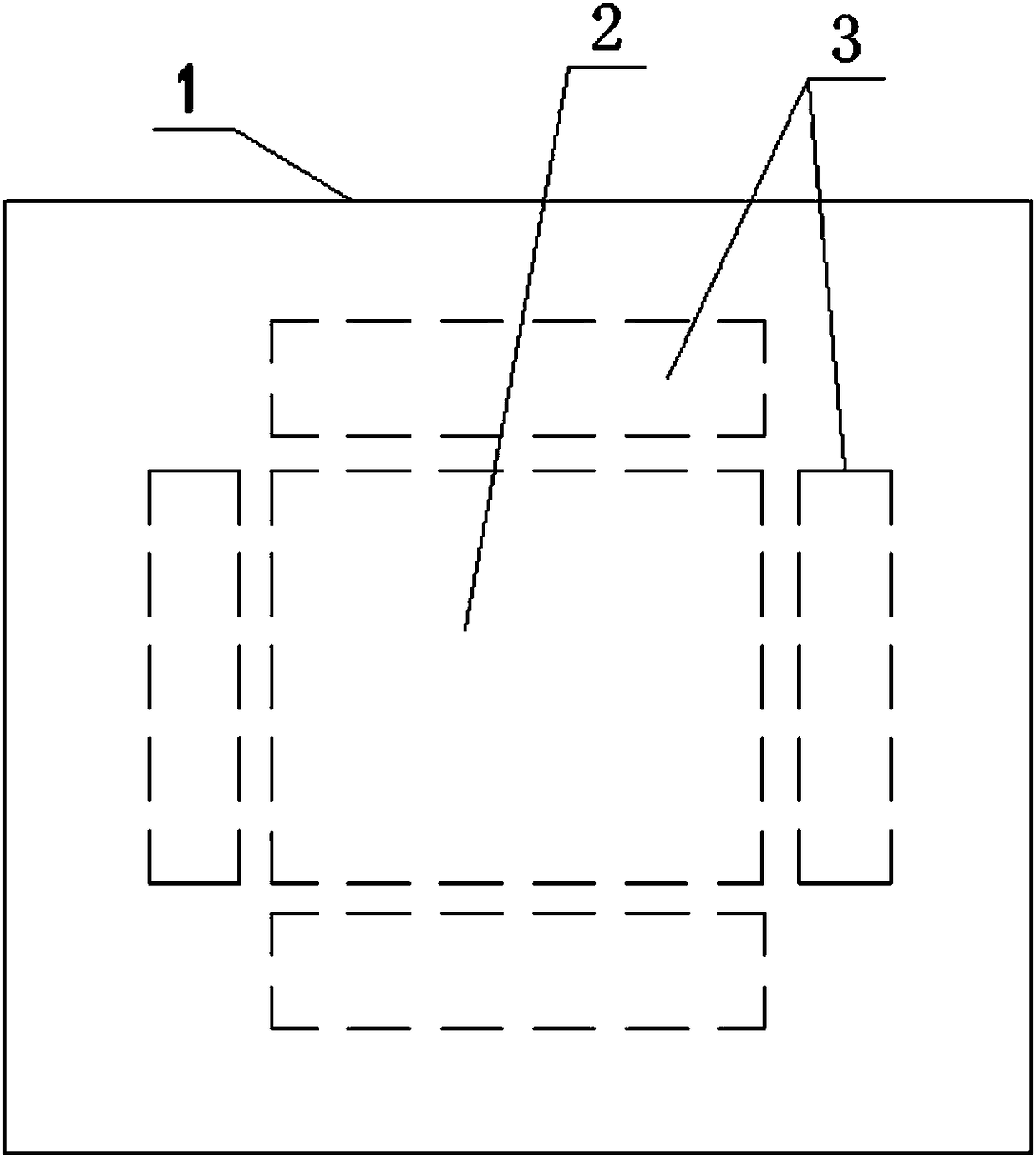

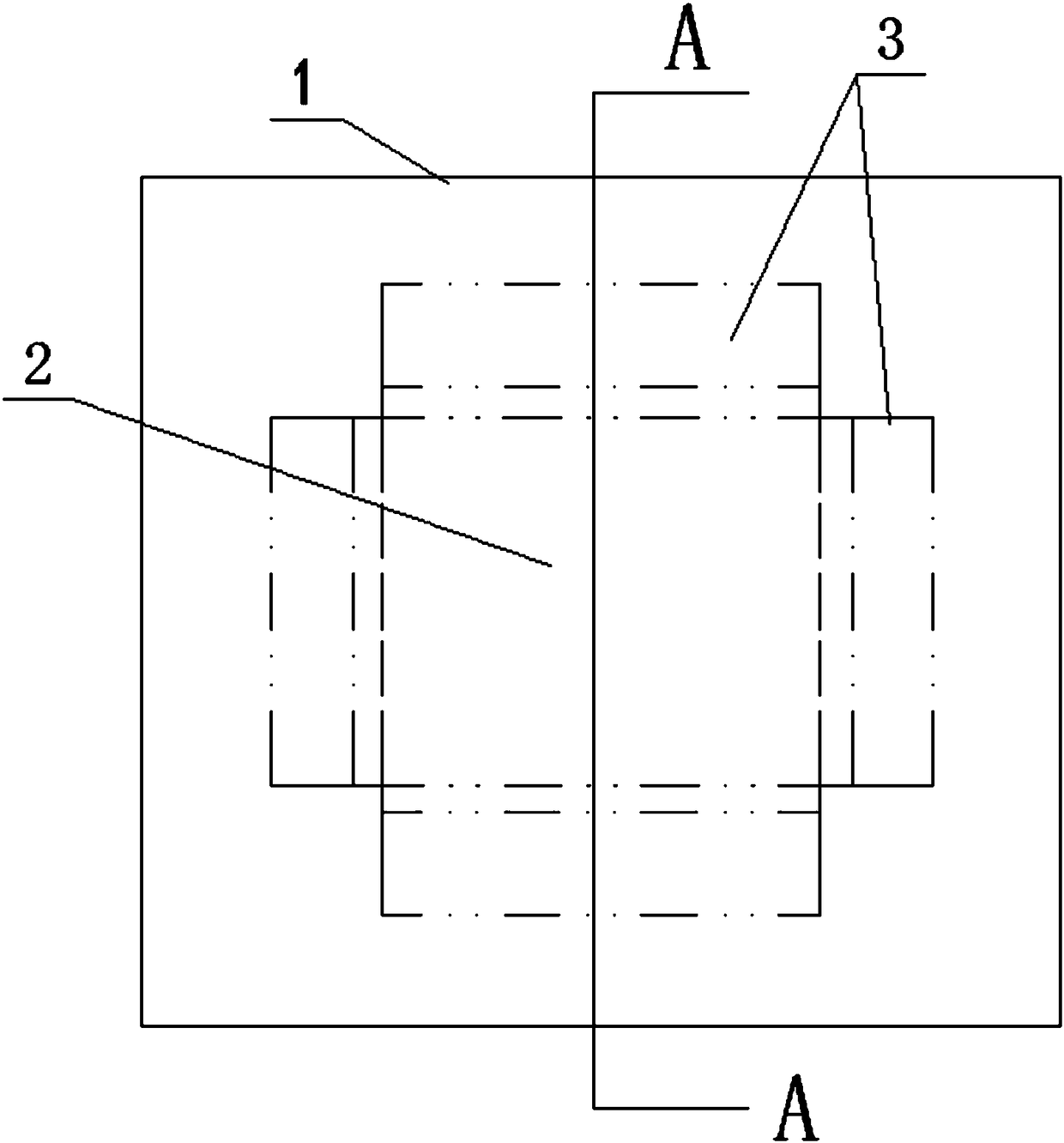

Prefabricated sandwich insulation wall based on plate perforated FRP connecting pieces and manufacturing method thereof

InactiveCN110344537AHigh strengthLow thermal conductivityClimate change adaptationCeramic shaping apparatusInsulation layerThermal bridge

The invention discloses a prefabricated sandwich insulation wall based on plate perforated FRP connecting pieces and a manufacturing method thereof. The prefabricated sandwich insulation wall comprises an inner-layer concrete plate, an outer-layer concrete plate, a middle insulation layer and FRP connecting pieces; the inner-layer concrete plate and the outer-layer concrete plate are compounded byfiber knitted nets and ECC concrete; through transverse penetration of the FRP connecting pieces, the fixed connection among the inner-layer concrete plate, the middle insulation layer and the outer-layer concrete plate is realized; and holes are formed in the two side edge positions, in the inner-layer concrete plate and the outer-layer concrete plate, of the FRP connecting pieces at intervals.Through full use of such characteristics as high corrosion resistance and low heat conducting coefficient of the plate perforated FRP connecting pieces, the thermal bridge effect is eliminated, the safety and the durability of the wall are improved, and meanwhile, such problems as weak bonding and anchoring performances of connecting pieces of a traditional insulation wall with a sandwich layer and a concrete interface are solved.

Owner:CHINA UNIV OF MINING & TECH

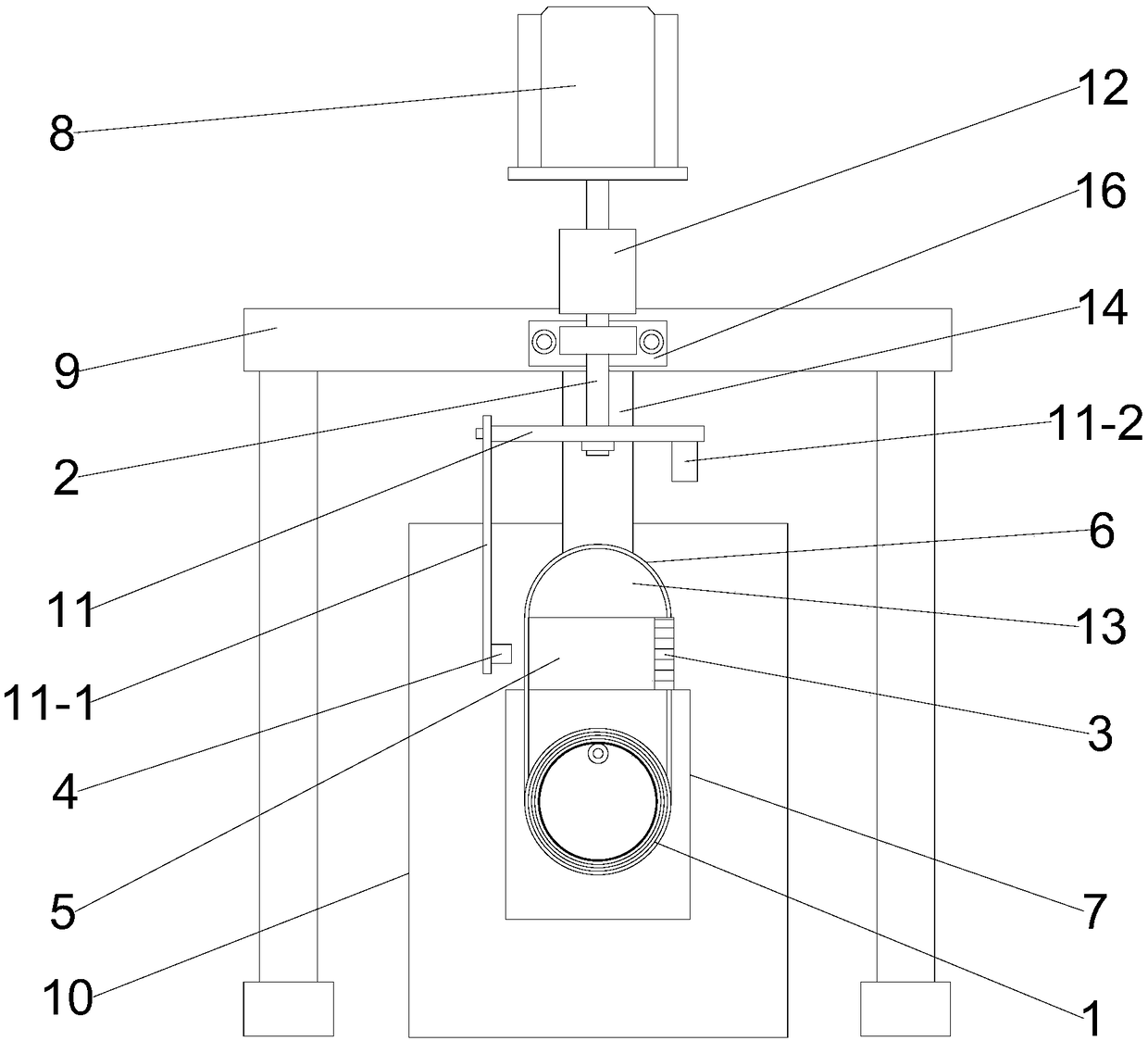

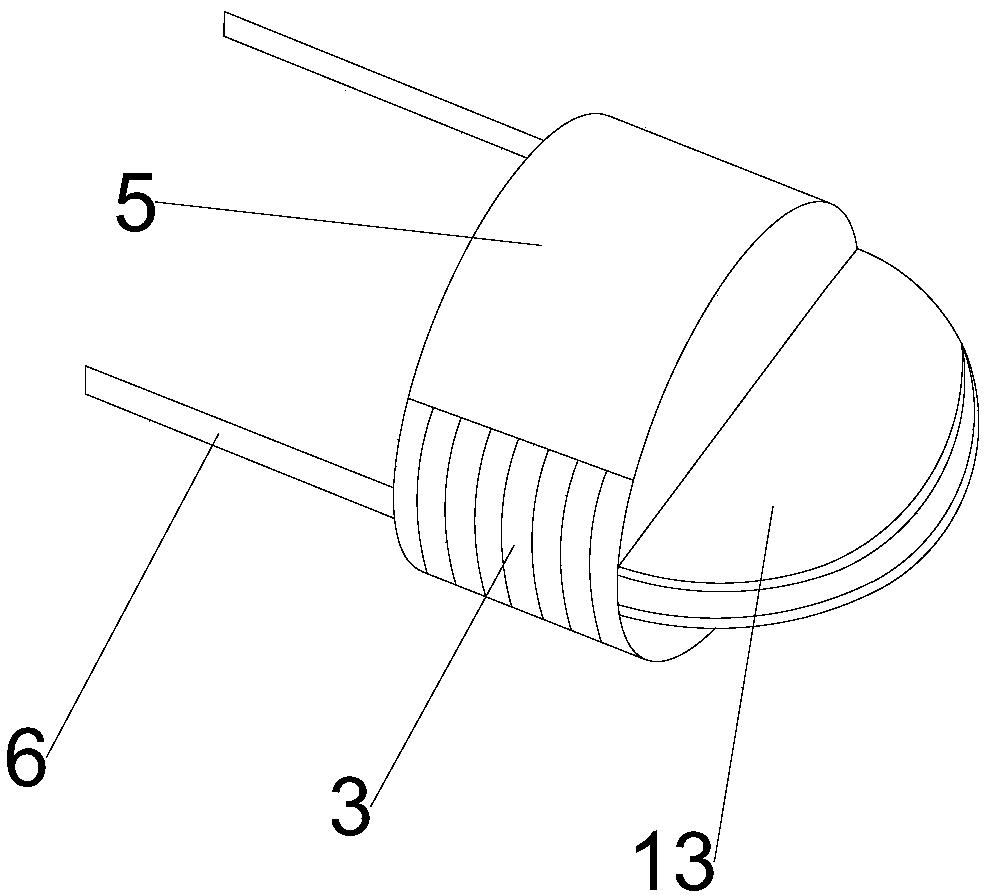

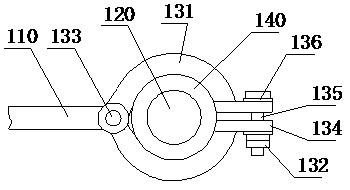

A high-temperature superconducting coil excitation device

ActiveCN109273190AReduce the burden onEliminate Joule heatSuperconducting magnets/coilsHigh-temperature superconductivityHigh energy

The invention discloses A high-temperature superconducting coil excitation device including the rack, a flux pump and a power mechanism arranged on the rack, and a low-temperature Dewar bottle for placing the flux pump and the high-temperature superconducting coil, A liquid nitrogen is arrange in that low-temperature Dewar bottle, the flux pump includes a support column, A superconduct wafer dispose on that circumferential surface of the support column and a superconducting lead disposed between the support column and the superconducting wafer and connecte with the superconducting wafer, and apermanent magnet mounted on the power mechanism and rotatable around the circumference of the support column, wherein the two ends of the superconducting lead protruding from the superconducting sheet are respectively connected with the two lead ends of the high-temperature superconducting coil, and a gap is arranged between the permanent magnet and the support column. The utility model has the advantages of simple structure, reasonable design, and can effectively solve the problems of expensive DC power supply equipment, high energy consumption, high refrigeration cost and complicated magnetic flux pump device for excitation of high-temperature superconducting coils, and has strong practicability and is convenient to be popularized and used.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

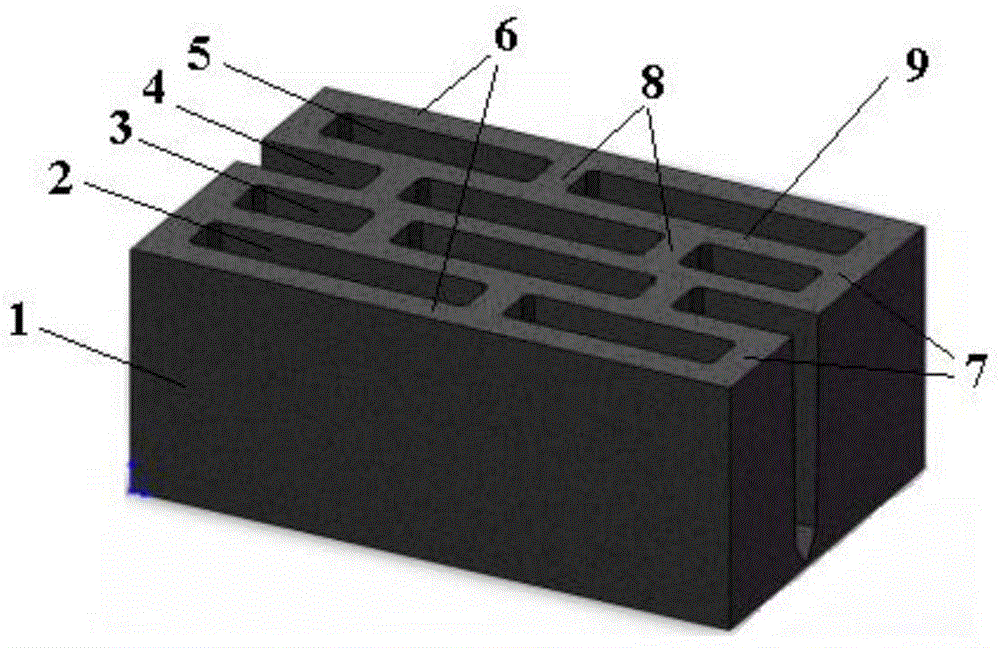

Recycled concrete energy-saving thermal-insulating building block and preparation method thereof

InactiveCN104929298AExtended heat transfer pathReduce thermal bridge effectSolid waste managementClimate change adaptationConstruction aggregateReducing agent

The invention relates to a recycled concrete energy-saving thermal-insulating building block and a preparation method thereof. Four rows of through holes are vertically formed in the building block, two through holes are formed in each of the first row and the fourth row, three through holes are formed in each of the second row and the third row, and the end part of one through hole in each of the second row and the third row is not sealed, so that the end ribs of building blocks are not continuous, the continuous heat transfer among the end ribs is blocked, and the cold-hot bridge effect is reduced; a bottom-sealed structure is adopted at the bottom of the building block, so that the air circulation among through holes of upper and lower building blocks of a wall body is prevented, the grouting and cementation of the building block during vertical construction are enhanced, and the construction strength and shearing strength of the building block are enhanced. The energy-saving thermal-insulating building block consists of recycled aggregate, coal cinders, glass beads, an air entraining agent, cement, coal ash, slag, polypropylene fiber, a water reducing agent and water; the glass beads are added into a building block base body, so that the heat resistance of the building block base body is improved, and the heat transfer of temperature difference between inside and outside of the wall body among building block base bodies is reduced. The building block provided by the invention has the characteristics of being high in mechanical strength and excellent in heat insulation, saves energy, utilizes wastes, is simple in manufacturing method, and is suitable for industrial production.

Owner:CHANGZHOU UNIV

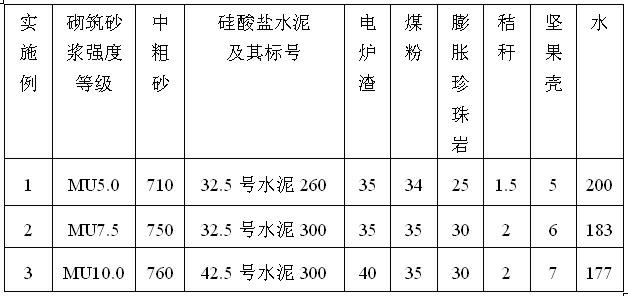

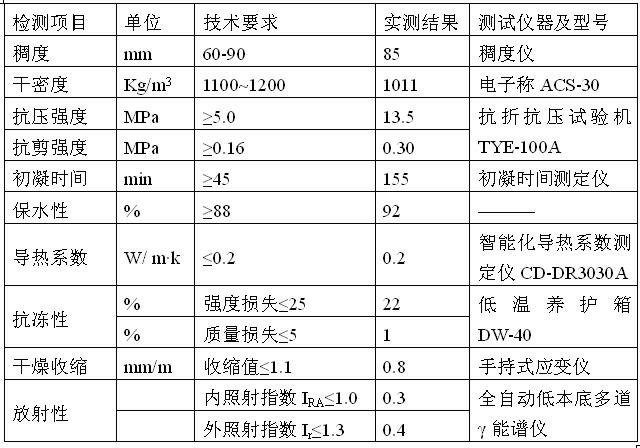

Mortar for building burning-free thermal-insulation bricks

InactiveCN102206069AImprove the anti-seismic and anti-crack effectInsulated heat transferSolid waste managementBrickSlag

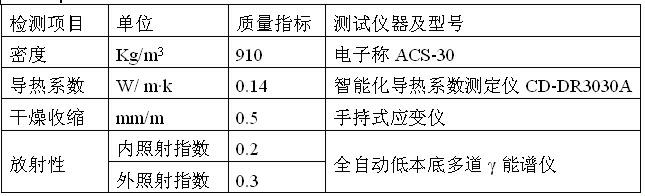

The invention relates to mortar for building burning-free thermal-insulation bricks, which are prepared by the following steps: weighing the raw materials in a mixing ratio, delivering the raw materials to a mixer, and uniformly mixing to obtain finished products, wherein the bricks comprise the following raw material in part by weight: 704 to 796 parts of medium coarse sand, 234 to 324 parts of common portland cement, 35 to 50 parts of electric furnace slag, 33 to 40 parts of pulverized coal, 20 to 35 parts of expanded perlite, 1.4 to 2 parts of straw, 5 to 7 parts of shuck, and 177 to 200 parts of water. The special building mortar for burning-free thermal-insulation bricks, which is produced by the applicant, has high pressure strength, high shearing strength, high water holding performance, high thermal insulation performance and low radioactivity; and the mortar is close to the complete burning-free thermal-insulation bricks in properties such as density, heat conductivity, shrinkage deformation and the like; the mortar has high adaptability and adhesive force with the burning-free thermal-insulation bricks; the cold and heat bridge effect at the joint parts of the bricks is relieved; the cracking and moisture absorption of the wall face are prevented; and thus, the mortar meets the requirements on thermal insulation and heat preservation for building energy conservation.

Owner:无锡市康顺节能材料科技有限公司

Method for preparing vacuum insulated panel core materials by using glass fiber aggregation leftover material and vacuum insulated panel

InactiveCN107355640AHigh mechanical strengthReduce expansionThermal insulationPipe protection by thermal insulationGlass fiberUltimate tensile strength

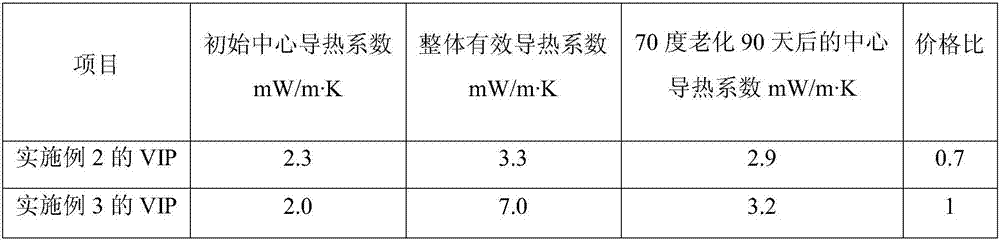

The invention discloses a method for preparing vacuum insulated panel core materials by utilizing glass fiber aggregation leftover materials. The method for preparing the vacuum insulated panel core materials by utilizing the glass fiber aggregation leftover materials comprises the following steps that the insulated panel core materials are obtained by cutting, dispersing, distributing, heating and pressing forming the glass fiber aggregation leftover materials; the heating temperature is 500-630 DEG C, the pressing pressure is 0.2-1.0 MPa, the density of insulated panel core materials is 260-320 kg / m<3>, the prepared core materials are good in mechanical strength and small in expansion rate. The invention further discloses a vacuum insulated panel prepared by utilizing the insulated panel core materials. According to the vacuum insulated panel, the initial center thermal conductivity coefficient of the vacuum insulated panel is lower than 2.5mW / m.K, the overall effective thermal conductivity coefficient is lower to below 3.5 mW / m.K, the service life is over 15 years, and manufacturing cost is greatly reduced.

Owner:四川迈科隆真空新材料有限公司

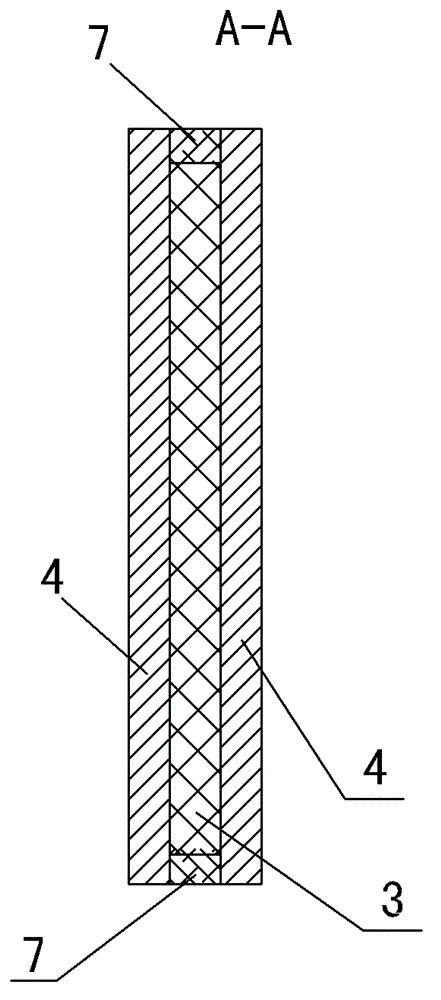

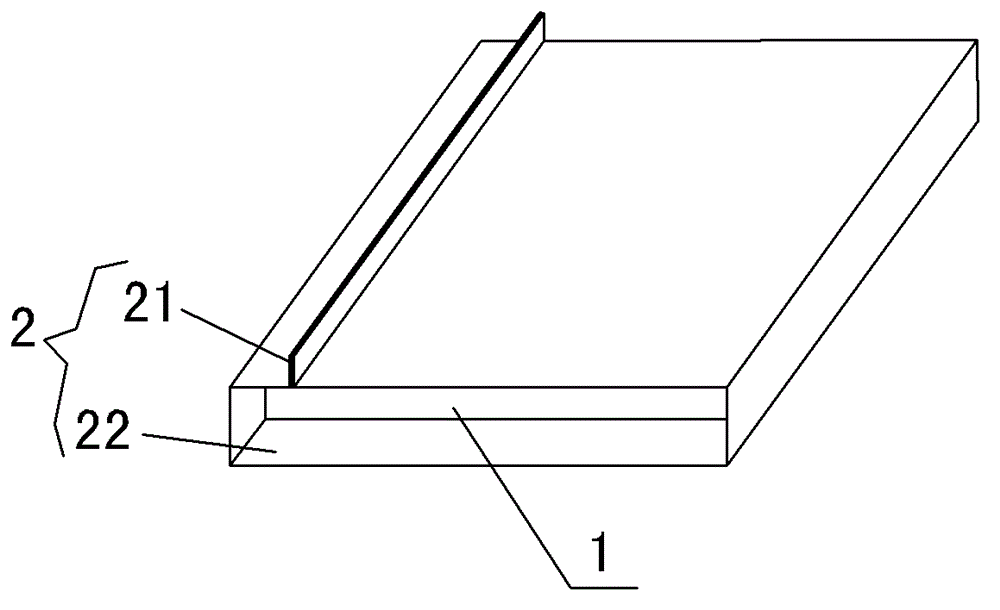

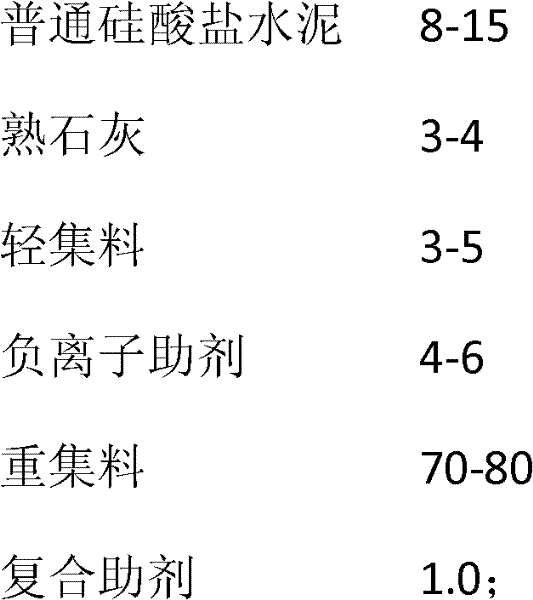

Light-weight and energy-saving plastering mortar and construction method thereof

ActiveCN101891431ALight weightLow thermal conductivitySolid waste managementBuilding constructionsPortland cementThermal bridge

The invention relates to light-weight and energy-saving plastering mortar, which is prepared by mixing the following components in part by weight: 30 to 40 parts of ordinary Portland cement, 2 to 4 parts of hydrated lime, 10 to 20 parts of light aggregate, 40 to 50 parts of heavy aggregate and 1.0 part of compound aid, wherein the light aggregate is an inorganic vitrified hollow microporous material of which the fineness is below 100 meshes; and the heavy aggregate is aeolian sand. During construction, the light-weight and energy-saving plastering mortar is diluted by water added in an amountwhich is 30 to 50 percent based on the weight of the light-weight and energy-saving plastering mortar, and is stirred and mixed mechanically or manually and uniformly until the plastering mortar has the suitable viscosity, and then mechanical spraying or manual construction Is performed. According to the concept of light weight and eco-environmental protection, the light-weight and energy-saving plastering mortar is made light by adopting the inorganic vitrified hollow microporous material, and is matched with the primary elastic modulus of a light-weight wall body to reduce coefficients of heat conductivity and reduce the thermal bridge effect, so the light-weight and energy-saving plastering mortar prevents hollowing, cracking and shedding, insulates heat and reduces noise, and is favorable for mechanized construction. The aeolian sand is used as aggregates, so the plastering mortar has excellent grading distribution and has the prominent three-dimensional texture; and the special compound aid is adopted to improve the peaceability of the mortar to achieve the excellent construction effect.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

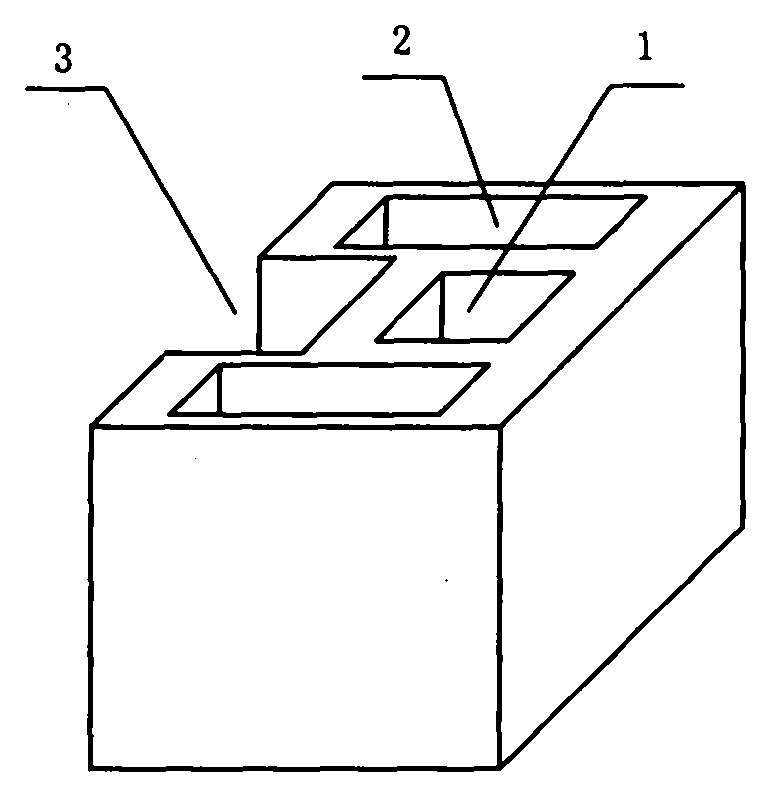

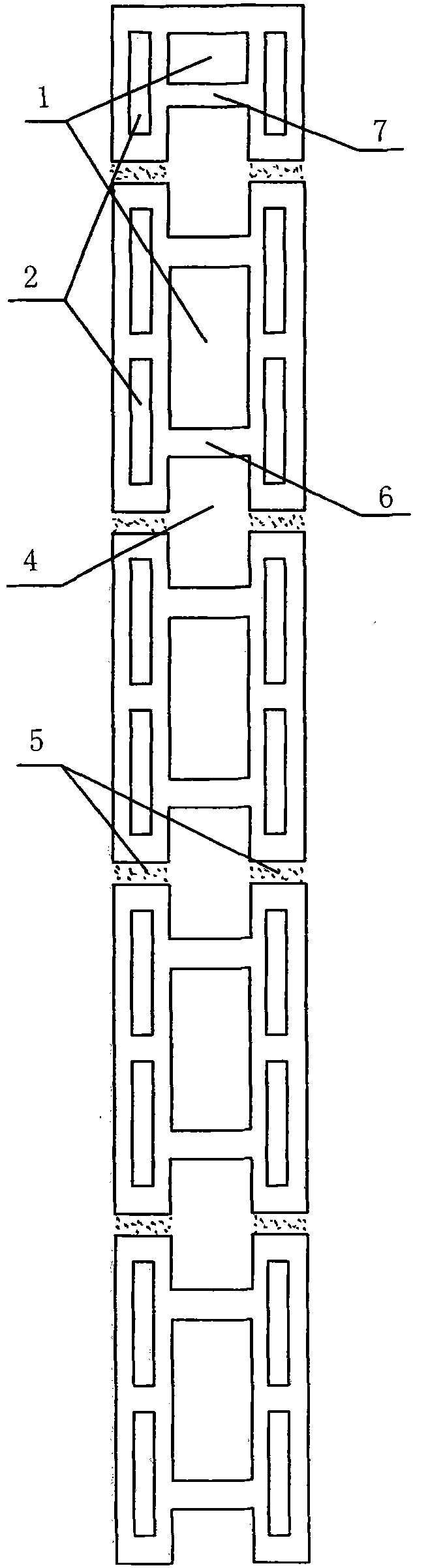

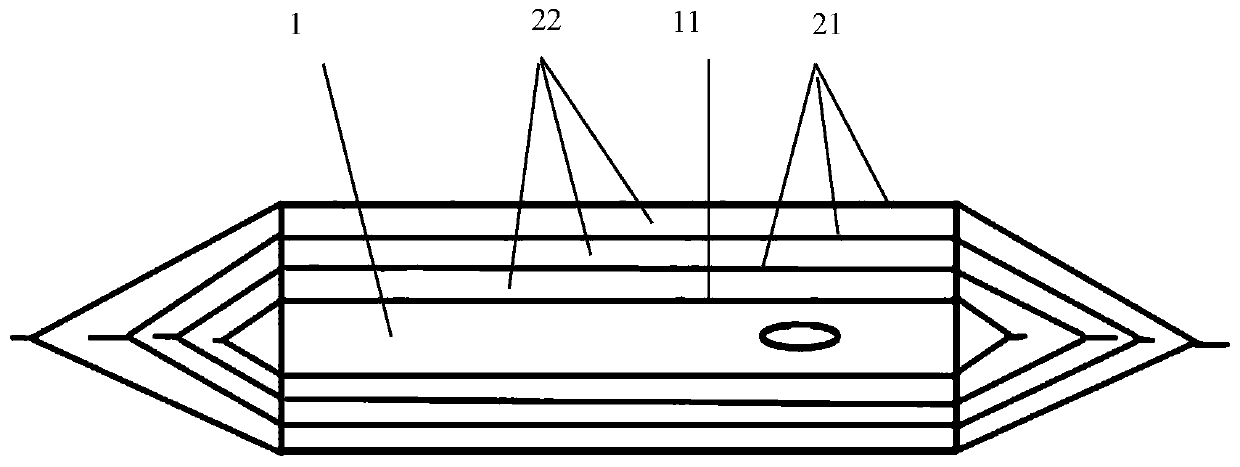

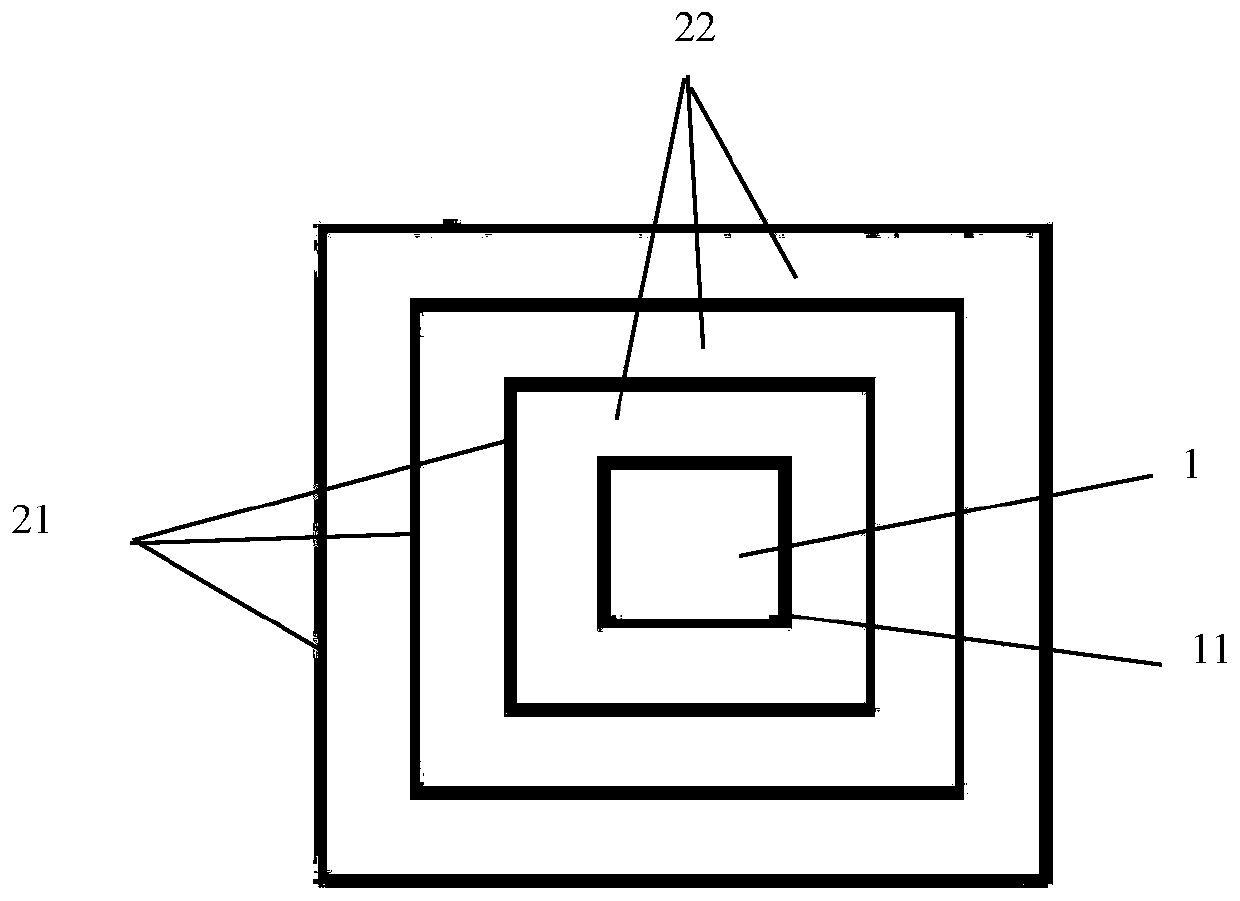

I-shaped hollow building block

InactiveCN101864822AReduce thermal bridge effectWallsHeat proofingArchitectural engineeringHollow core

The invention discloses an I-shaped hollow building block. A recess is respectively formed on both ends of a hollow building block for construction, thereby changing the building block into an I shape. In the masonry process of walls by using the I-shaped hollow building blocks, a closed cavity having the heat insulating function is enclosed by the recesses of two left-right adjacent building blocks and upper-lower adjacent building blocks, and therefore, cold / heat bridges at both ends of the building blocks are eliminated, the cold / heat transfer of the vertical mortar joint is cut off, and the energy-saving effect of the constructed outer wall is obviously improved.

Owner:SHANDONG UNIV OF SCI & TECH

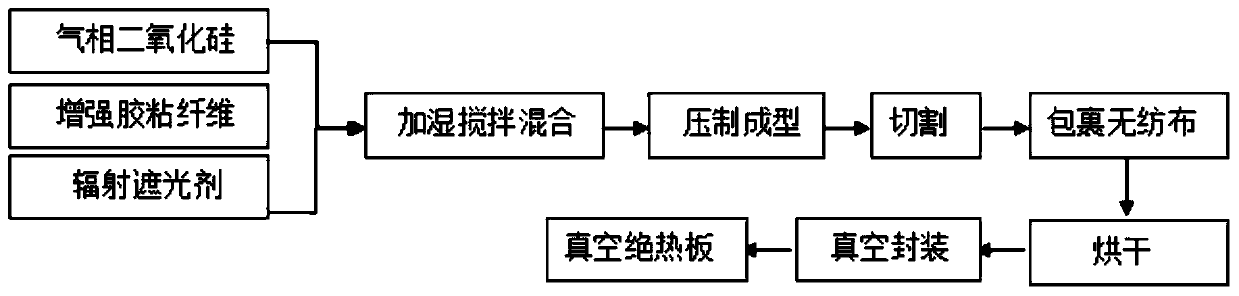

Vacuum insulated panel core material and preparation method thereof and vacuum insulated panel

InactiveCN110285289ALow densityLow shrinkageThermal insulationPipe protection by thermal insulationGas phaseHeat conducting

The invention provides a vacuum insulated panel core material, a preparation method thereof and a vacuum insulated panel. The vacuum insulated panel comprises a core material and a gas barrier bag; and the core material is packed in the gas barrier bag in vacuum to prepare the vacuum insulated panel. The core material consists of three raw materials of nanometer gas-phase silicon dioxide with a mass fraction of 60-95%, reinforced viscous fibers with a mass fraction of 3-35% and radiation light screening agents with a mass fraction of 2-10%. The preparation method of the core material prepares the core material through the steps of uniform mixing of the raw materials, molding through pressing, cutting and wrapping of breathable non-woven cloth materials without transmitting powder; and the core material is dried to load in the gas barrier bag for vacuumizing and sealing to prepare the vacuum insulated panel. The core material is low in solid heat conducting coefficient, low in shrinkage rate, low in density and high in strength; and the corresponding vacuum insulated panel is low in heat conducting coefficient, high in strength and long in service life.

Owner:江西晖烁新材料有限公司

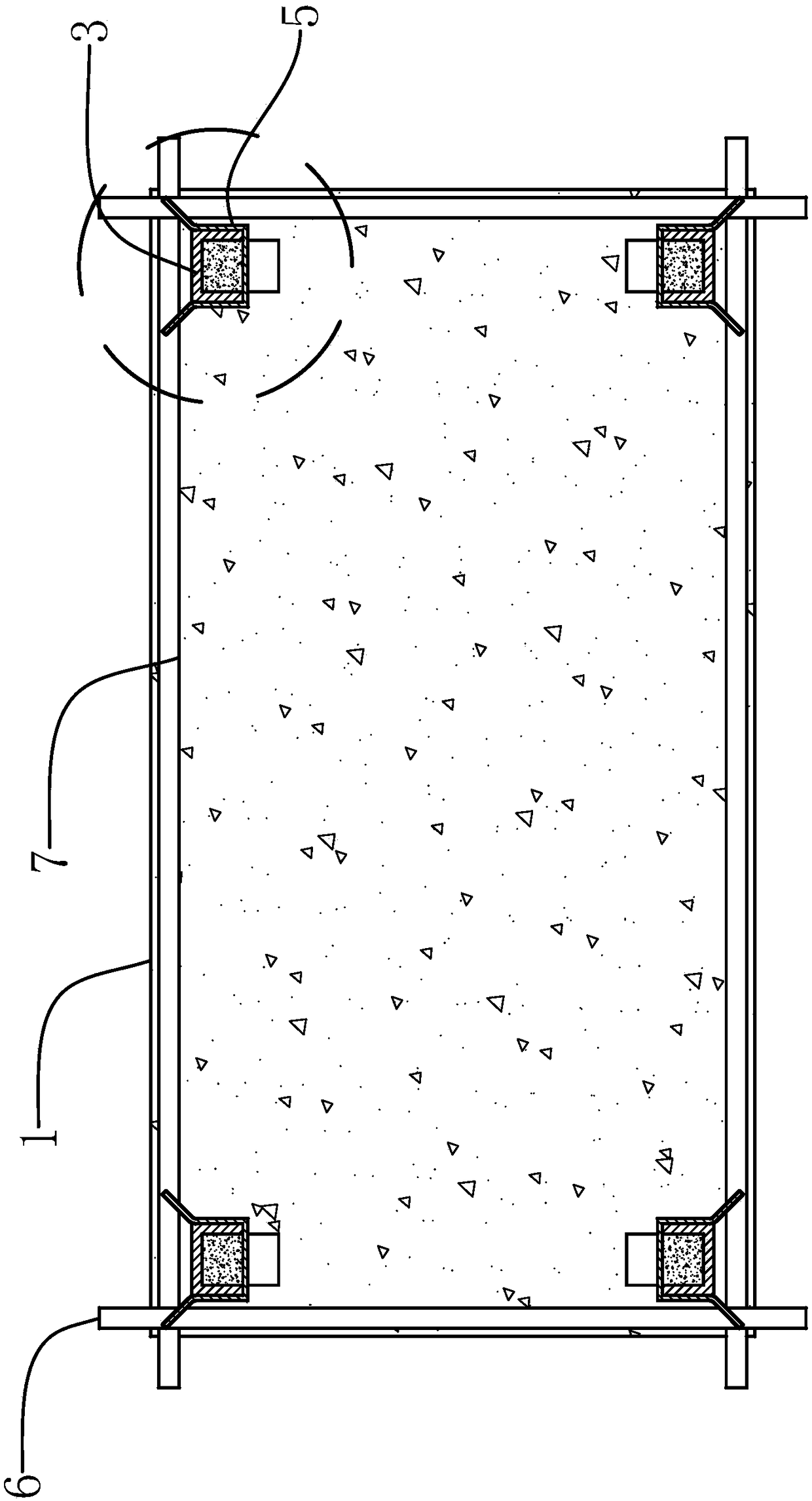

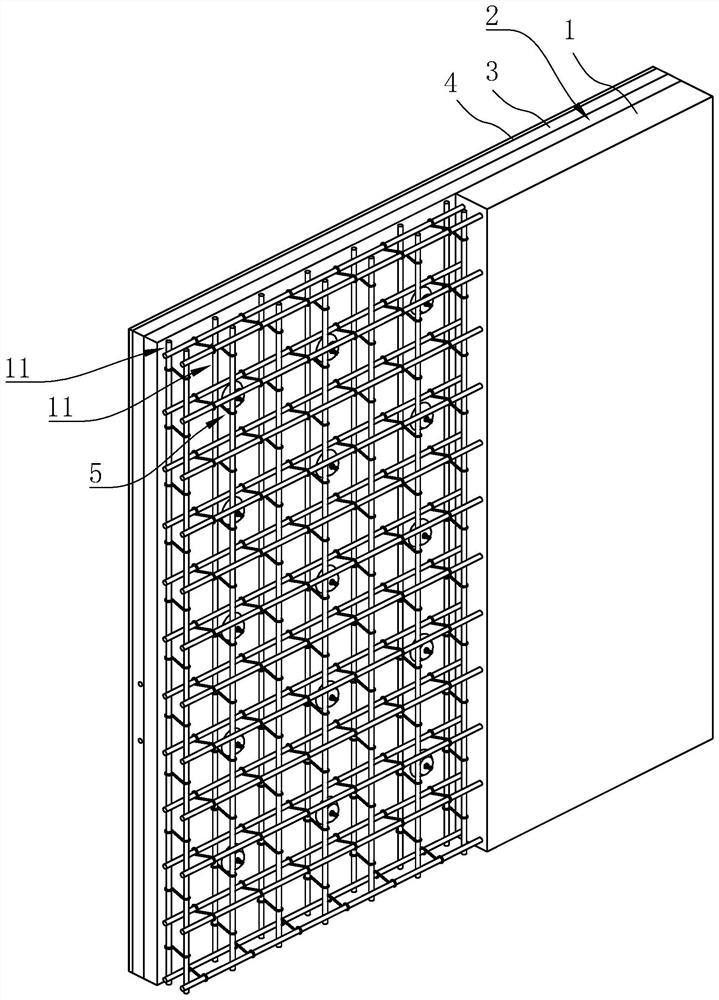

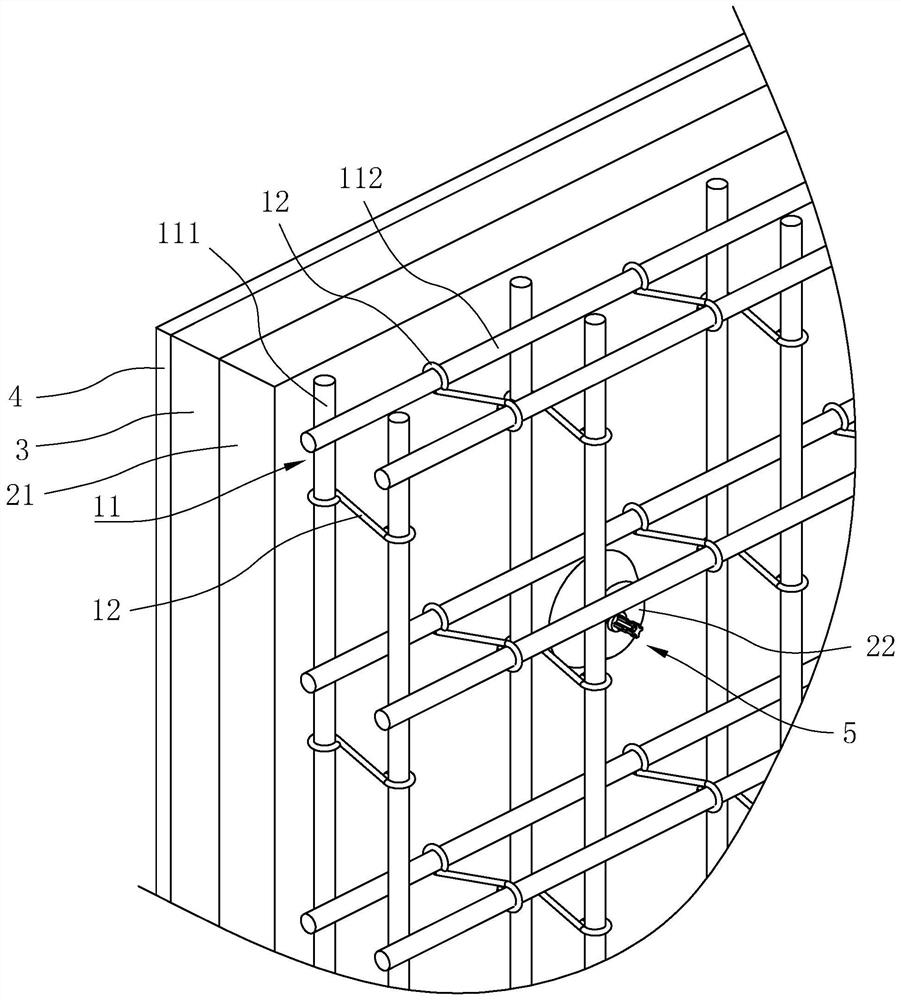

Energy-saving wall with functions of heat preservation and heating

InactiveCN108547399AUniform temperatureImprove insulation effectLighting and heating apparatusWallsInsulation layerReinforced concrete

The invention relates to an energy-saving wall with the functions of heat preservation and heating. The energy-saving wall comprises a composite sandwich steel wire net frame heat-insulation plate, amain body layer formed by a cast-in-place reinforced concrete layer, and an outer protective layer formed by a concrete layer. An inner steel wire net piece and an outer steel wire net piece of the composite sandwich steel wire net frame heat-insulation plate are fixedly bonded in the main body layer and the outer protective layer. An inner heat-insulation layer, a heating bracket, an inner protective plate, a net cloth and a surface coating are arranged on the inner side of the main body layer in sequence. A heating pipeline is mounted in the heating bracket. A heat-insulating pad or a heat-insulating sleeve is arranged between a bracket connecting piece and the heating bracket. The inner protective plate is provided with a plurality of longitudinal through holes. At least part of longitudinal through holes is not shielded by the net cloth. According to the energy-saving wall, the heat-insulation effect of the wall is improved obviously, the heat bridge effect is reduced obviously, the proportion of heat dissipating of heating heat energy to a wall structure and an outdoor space is decreased obviously, the utilization ratio of the heating heat energy is increased obviously, and the good building energy-saving effect is obtained accordingly.

Owner:牛光华

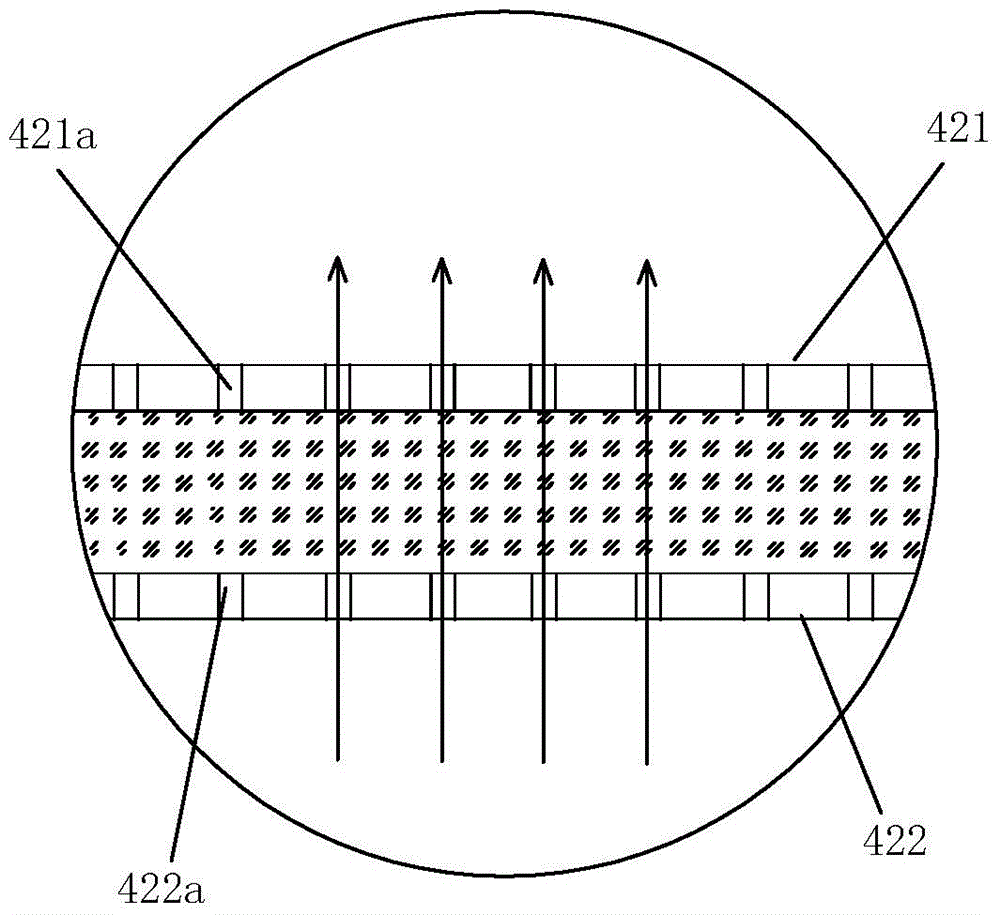

Online dry-process production system and method of glass wool vacuum insulation board core material

ActiveCN106145660ARealize online continuous productionIncrease productivityGlass making apparatusHeating furnaceGlass wool

The invention discloses an online dry-process production system of a glass wool vacuum insulation board core material, the online dry-process production system comprises a smelting furnace, a centrifuge, a cotton collecting machine, a heating furnace and a shaping device. The shaping device adopts upper and lower chain plates to cooperate to form a pressing gap. A glass wool layer heated by the heating furnace at high temperature is pressed in the pressing gap, and can be continuously hot-pressed in the process of transmission. The present invention also provides a production method based on the above production system. Compared with the prior art, online continuous production is realized, production efficiency is high, equipment cost is low, and the obtained glass wool core material has stable structure and good insulation effect.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

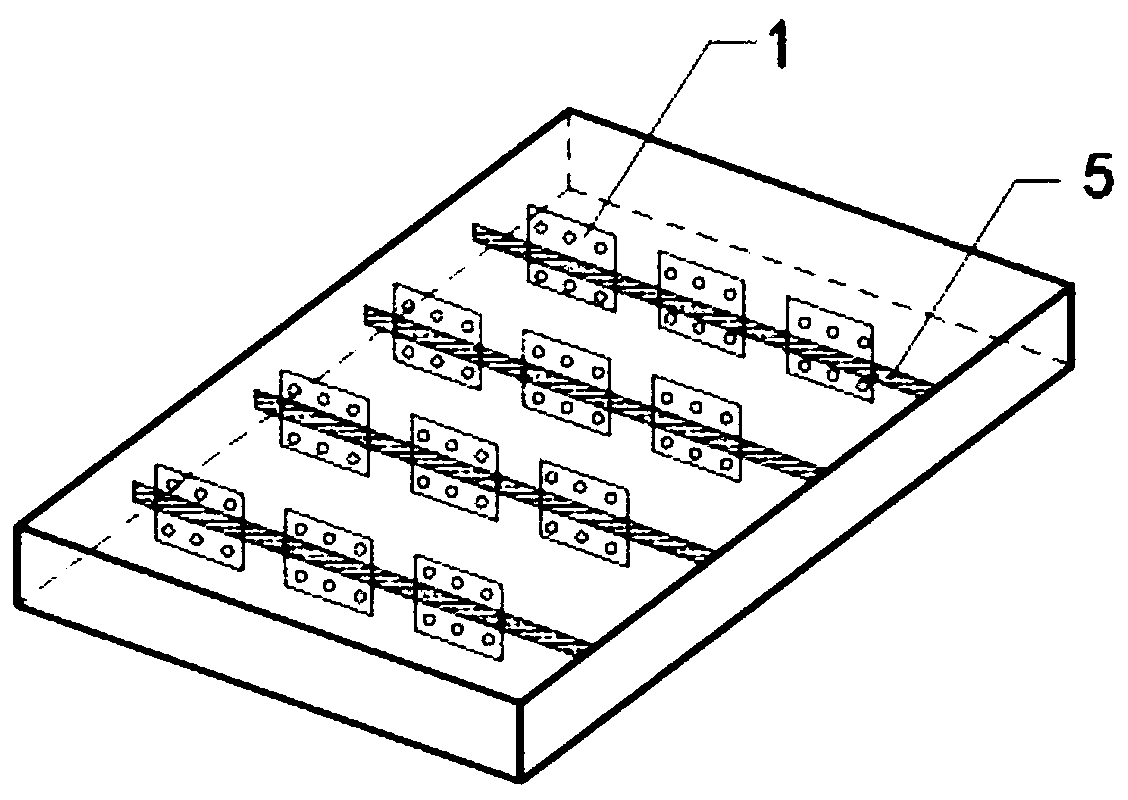

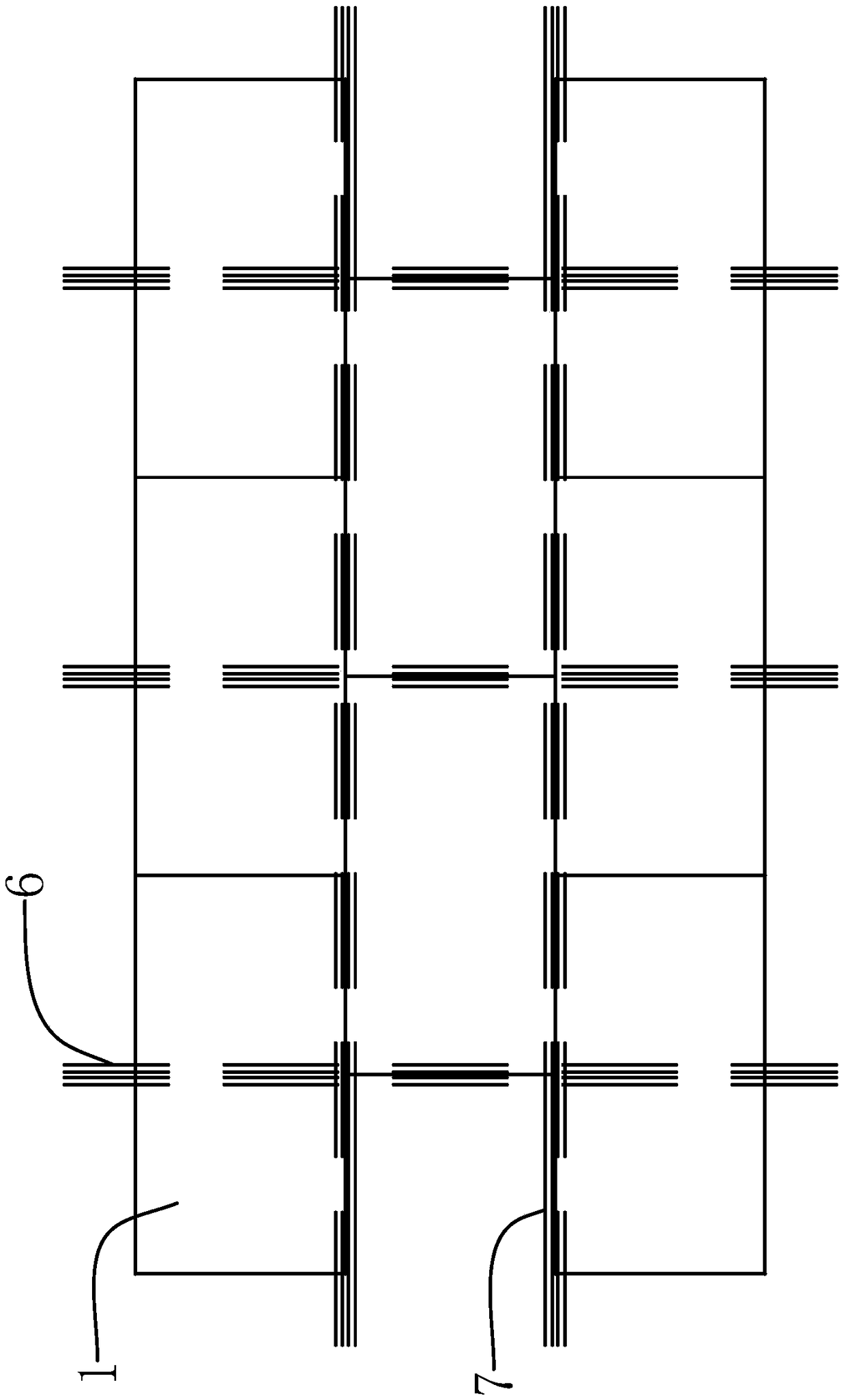

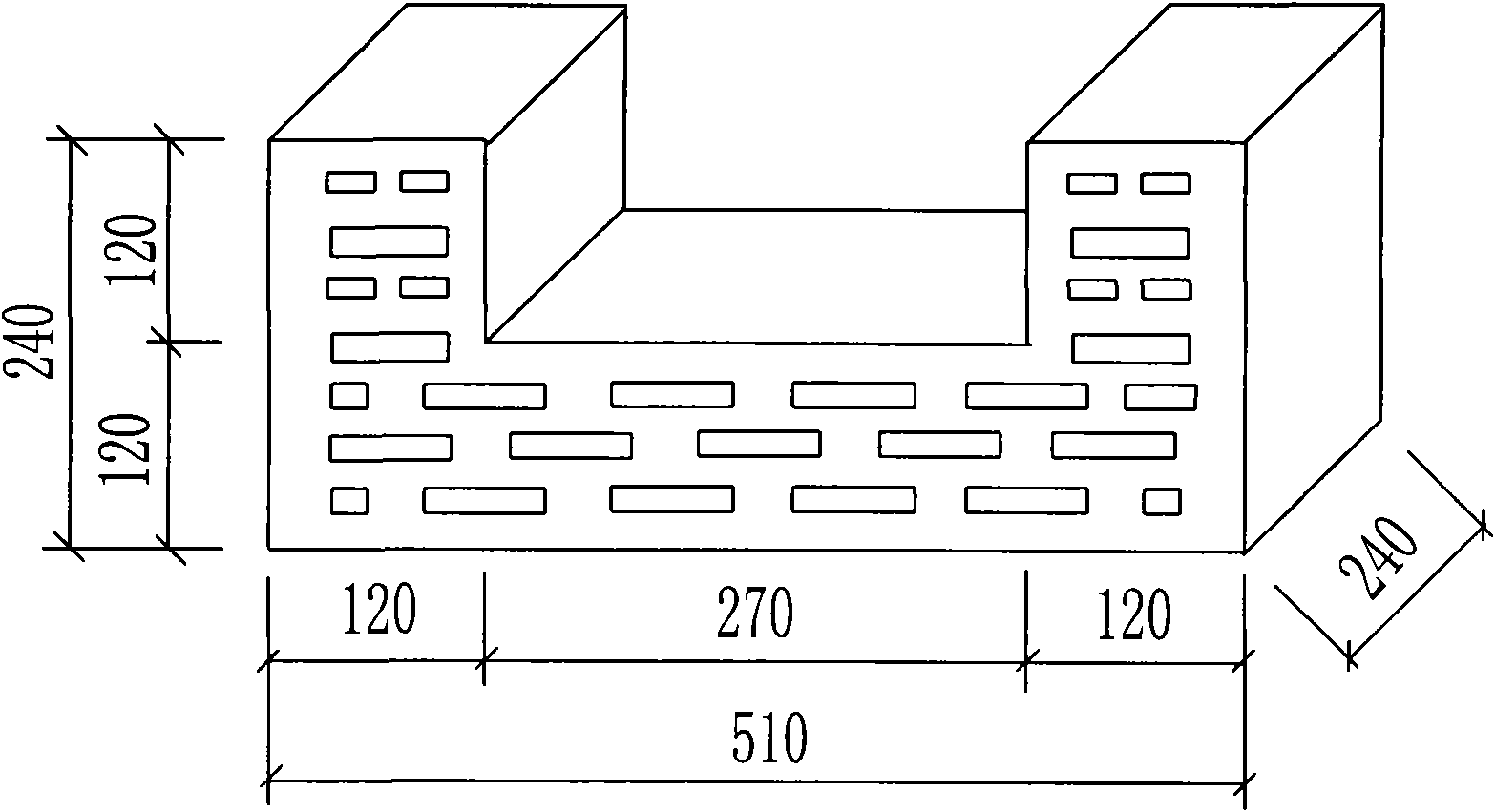

Prefabricated building block, manufacturing thereof, and method for building and forming of wall

ActiveCN109356316AStable structureEliminate connectionConstruction materialCeramic shaping apparatusWave structureArchitectural engineering

The invention provides a prefabricated building block, manufacturing thereof, and a method for building and forming of a wall, and belongs to the field of prefabricated building blocks. According to the prefabricated building block, manufacturing thereof, and the method for building and forming of the wall, the problem of low strength of existing prefabricated building blocks is solved. The prefabricated building block comprises a building block body, the building block body comprises two wall plates and internally provided with a steel framework, the steel framework comprises two connecting frames, each connecting frame comprises two sections of main connecting steel and auxiliary connecting steel, and the main connecting steel and the auxiliary connecting steel are of channel steel structures correspondingly; each connecting frame further comprises two connecting plates, the connecting plates are of a trapezoidal wave structure, the upper and lower side edges of the connecting platesare located in main connecting steel parts of the two connecting frames correspondingly, the two sides of the connecting plates are fixed with two main side plates, and the two sides of the connecting plates are enclosed with two main bottom plates to form a slurry solidifying groove; each connecting frame further comprises four sections of fixing steel, each fixing steel comprises a bottom fixing plate and two side fixing plates, the four sections of fixing steel are connected with four auxiliary connecting steel in a fit mode, and the outer sides of the connecting plates and the outer sidesof the main connecting steel are covered with connecting mortar and form wall plates correspondingly. According to the prefabricated building block, the strength is higher, and manufacturing of the prefabricated building block is easy and convenient.

Owner:台州航权机械科技有限公司

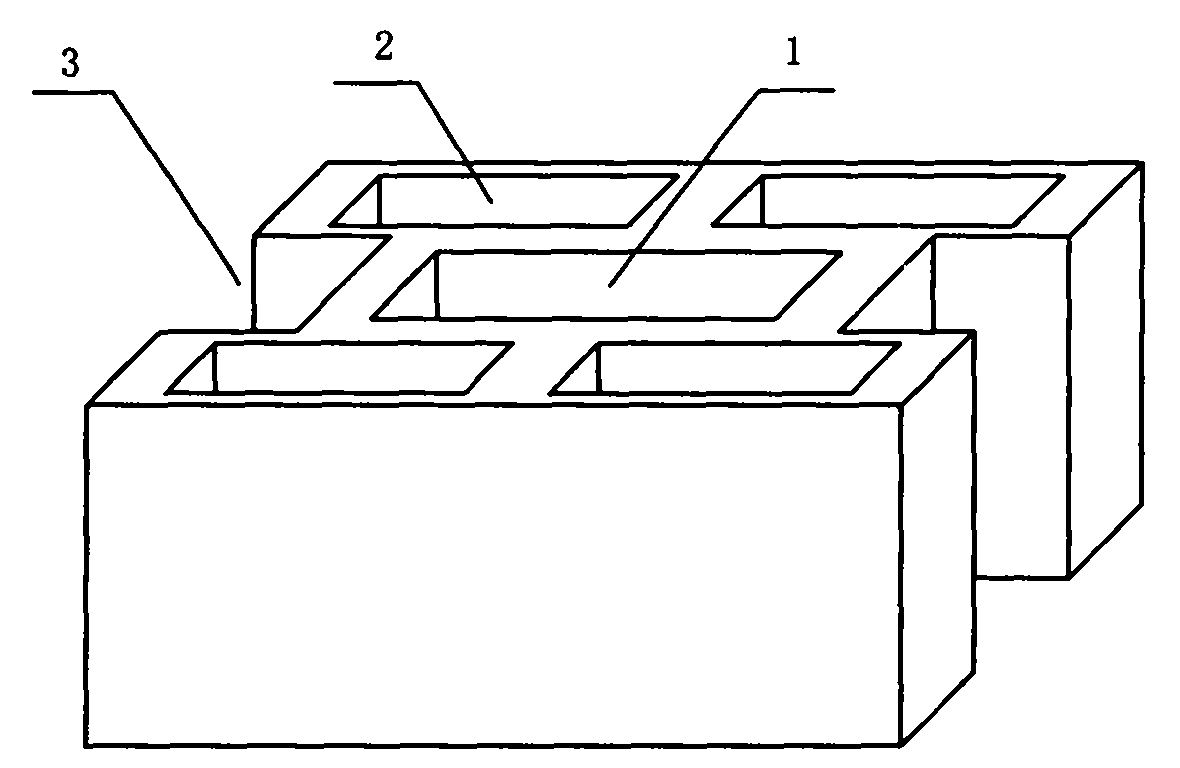

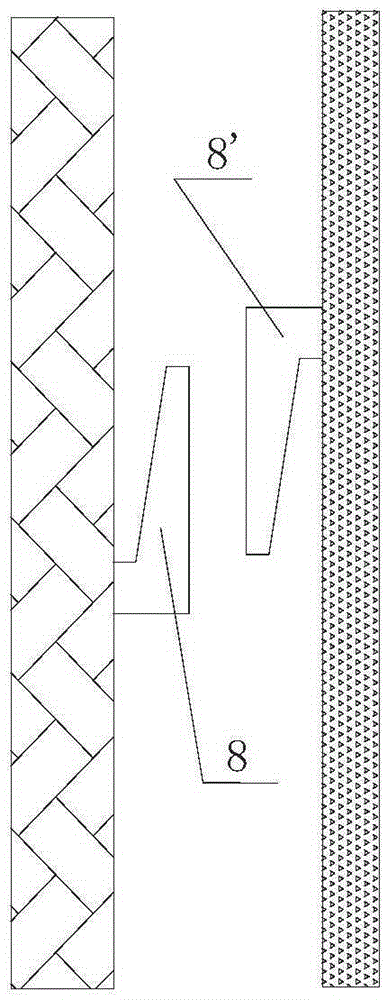

Concave building insulation masonry block and masonry method thereof

InactiveCN101597927AImprove stabilityReduce thermal bridge effectWallsHollow coreBuilding insulation

The invention applies for disclosing a concave building insulation masonry block and a masonry method thereof, which is implemented by making a porous masonry block or a hollow masonry block into a concave shape and inserting the masonry blocks mutually into the groove of the opposite masonry block during the process of masonry blocks with the same skin, thus radically eliminating cold and hot bridge effect at the end part of the masonry blocks and remarkably improving the heat insulation effect and stability of wall body.

Owner:SHANDONG UNIV OF SCI & TECH

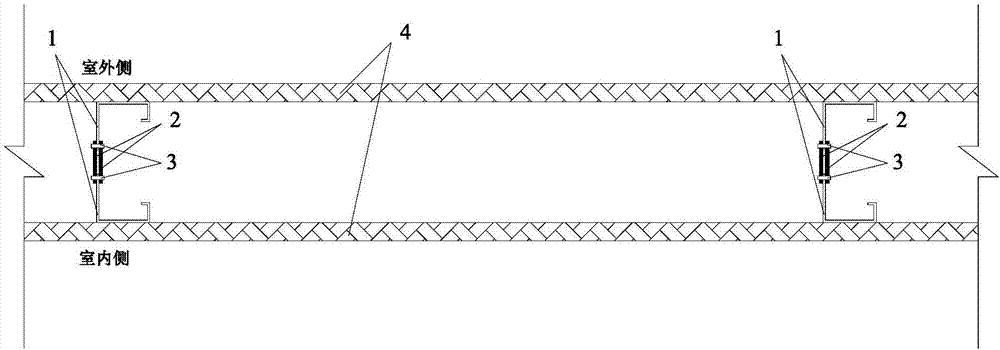

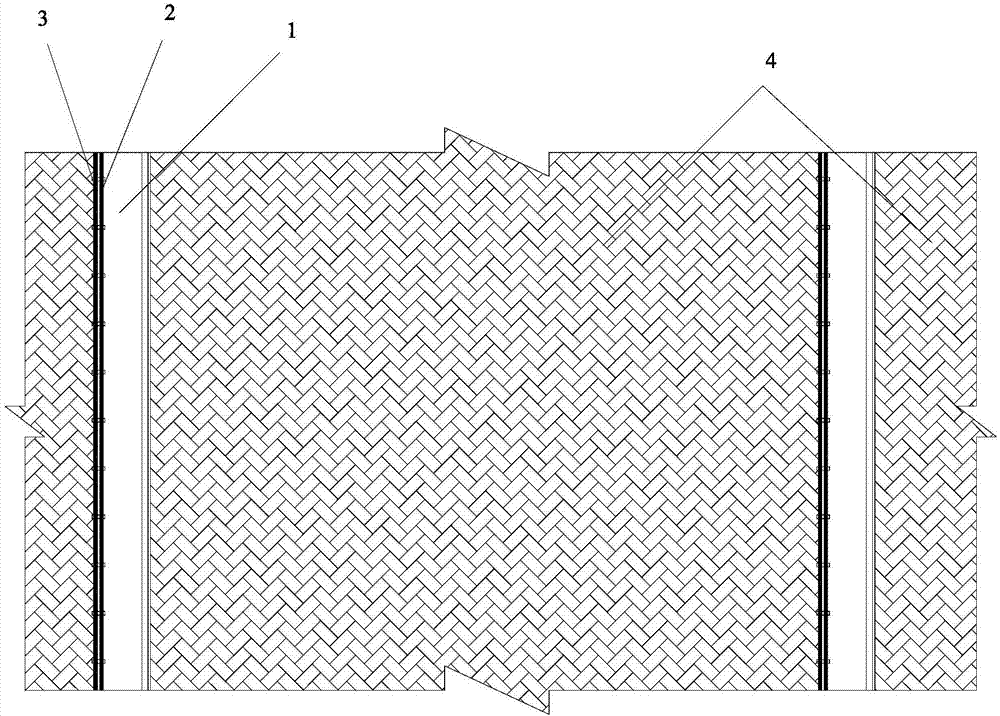

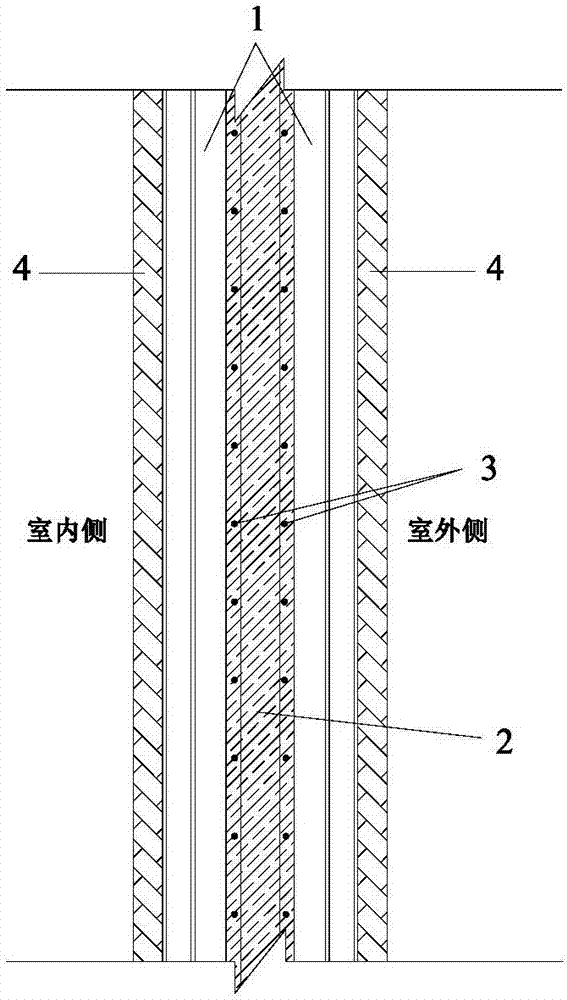

Composite wall body with light steel-wood mixing keels and implementation method thereof

The invention discloses a composite wall body with light steel-wood mixing keels and an implementation method thereof. The composite wall body comprises cold-formed thin-walled structural steel, cork boards, self-tapping screws and light weight boards which are subdivided. The cold-formed thin-walled structural steel comprises two subdivided parts along the central axis of a web of a cold-formed thin-walled lipped channel, steel keels of the mixing keels are formed, and the two parts are placed at the two ends of a cross section of the wall body in the height direction correspondingly; the number of the cork boards is two, wooden keels of the mixing keels are formed, and the cork boards are placed nearby the central axis of the web of the cold-formed thin-walled lipped channel; the cork boards and the cold-formed thin-walled lipped channel are connected to be a whole through the self-tapping screws; and the light weight boards are hung on flanges of the cold-formed thin-walled lipped channel of the two sides of the mixing keels. The composite wall body with the light steel-wood mixing keels has the characteristics that the heat preservation and thermal insulation performance is good, the bearing capacity is high, the weight is light, and energy conservation and environmental protection are achieved. In addition, when the keels cannot meet the requirement for building heat preservation or mechanical property, the keels can be still used after the corresponding parts are changed, and the flexibility is high.

Owner:HUAQIAO UNIVERSITY

External wall system

ActiveCN105256961ASimple construction processConstruction quality is easy to guaranteeCovering/liningsInsulation layerThermal bridge

The invention discloses an external wall system which comprises an internal wall decorating layer, a base plate layer and an external wall decorating layer. An internal wall insulation layer and a pipe layer are arranged between the internal wall decorating layer and the base plate layer; the internal wall insulation layer is paved on the outer end surface of the internal wall decorating layer; the pipe layer is positioned between the internal wall insulation layer and the base plate layer and is formed in an aerial mode; a waterproof and breathable layer and an external wall insulation layer are arranged between the base plate layer and the external wall decorating layer; the waterproof and breathable layer is formed by paving films on the outer end surface of the base plate layer; and the external wall insulation layer is arranged between the waterproof and breathable layer and the external wall decorating layer. The internal wall insulation layer and the external wall insulation layer are insulation rock wool or light magnesium sulfate insulation plates with the thickness of 20 mm. The external wall system is provided with the internal insulation layer and the external insulation layer, is also provided with the hollow pipe layer, not only has the advantages of simple construction technology, easiness in guaranteeing of construction quality and low production cost, but also has reliable insulation performance, and the thermal bridge effect can be reduced effectively.

Owner:上海通璞建筑科技有限公司

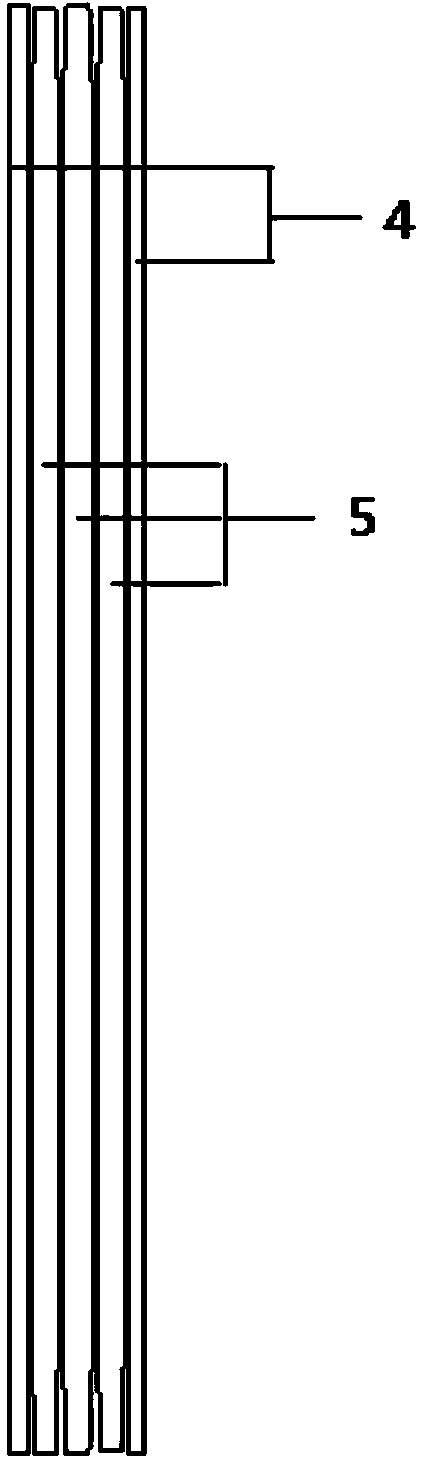

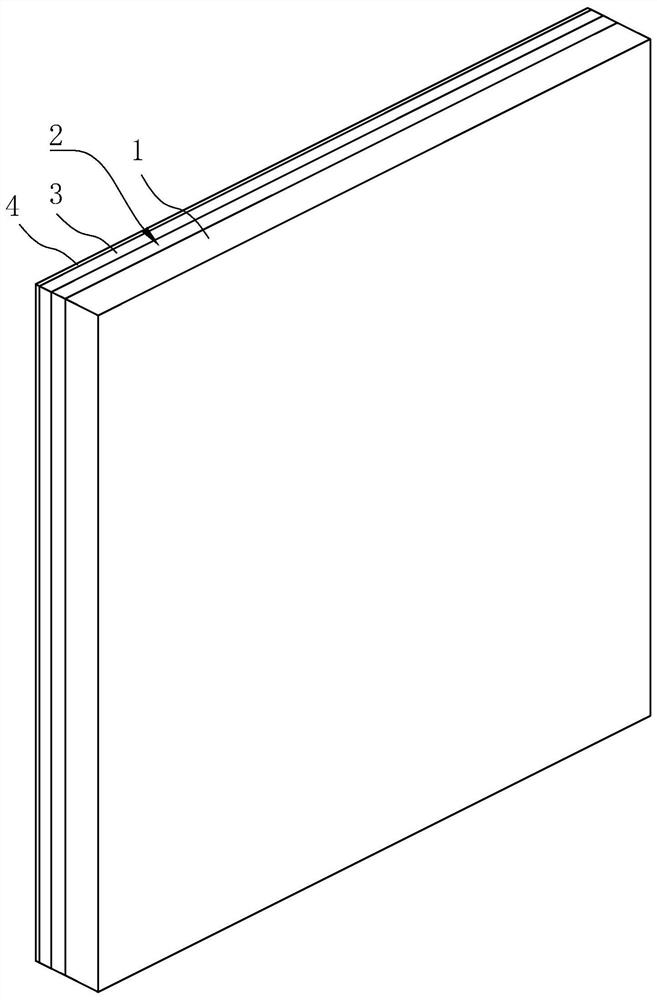

Multifunctional composite vacuum insulation board and manufacturing and packaging method thereof

ActiveCN111578045AImprove insulation effectLow thermal conductivityThermal insulationPipe protection by thermal insulationPolyesterAdhesive cement

The invention discloses a multifunctional composite vacuum insulation board, and relates to the technical field of vacuum insulation boards. The multifunctional composite vacuum insulation board comprises a single-layer vacuum insulation board body, a heat insulation and preservation composite layer and a protective layer, wherein the single-layer vacuum insulation board body comprises a core material and a first polyester base film; the heat insulation and preservation composite layer wraps the single-layer vacuum insulation board body, and the heat insulation and preservation composite layercomprises three polyester-based films and three glass fiber layers; and the protective layer wraps the outer side of the heat insulation and preservation composite layer and comprises a core materialframework, a pore filler and a phenolic resin adhesive. The invention further discloses a manufacturing and packaging method of the multifunctional composite vacuum insulation board. According to themultifunctional composite vacuum insulation board, the heat insulation and preservation composite layer prolongs the permeation path of external gas passing through heat seals and the polyester-basedfilms, the heat insulation and preservation performance and the service life are guaranteed; from the manufacturing perspective of the vacuum insulation board, the six surfaces of the single-layer vacuum insulation board body are covered with the glass fiber layers; and from the packaging perspective, after one glass fiber layer is covered, vacuumizing packaging is carried out once so that heat bridges can be reduced, and the protective layer is high in strength and not prone to deform.

Owner:山东信泰节能科技股份有限公司

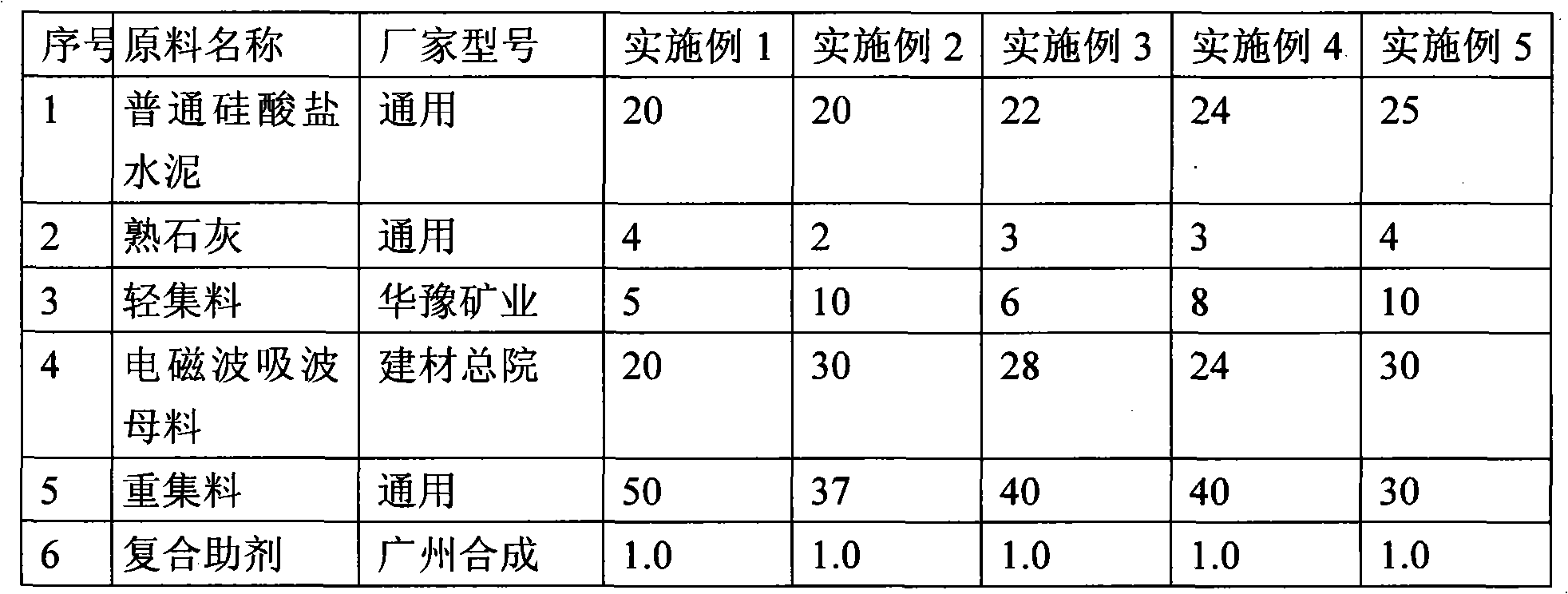

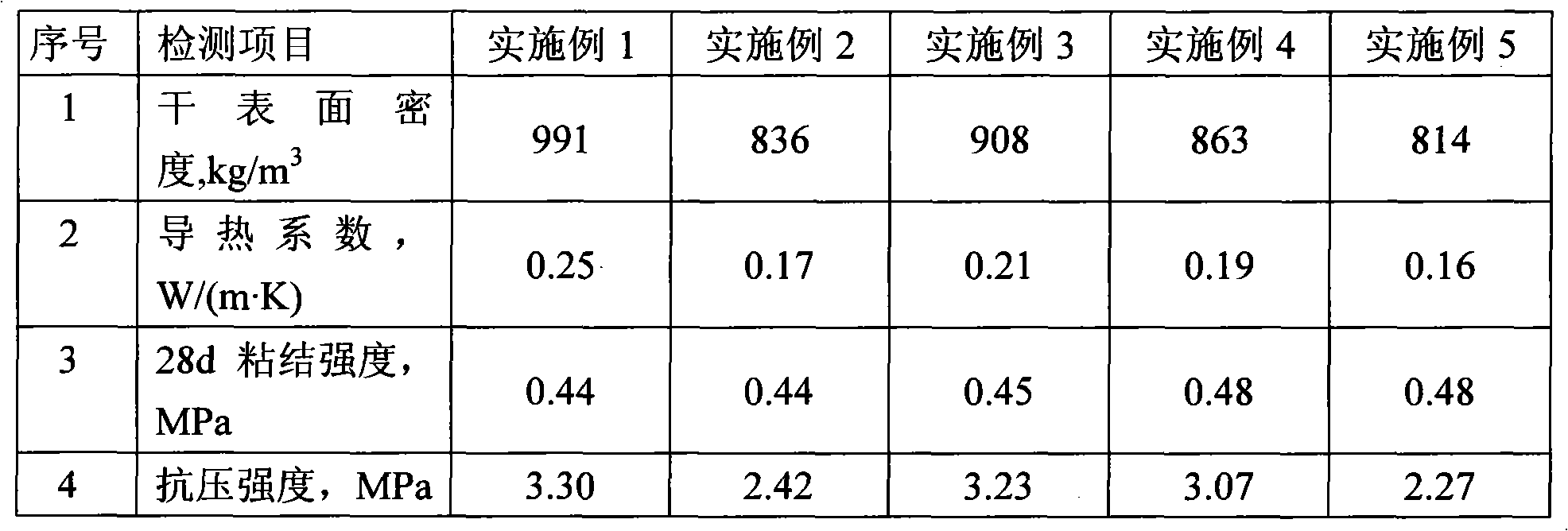

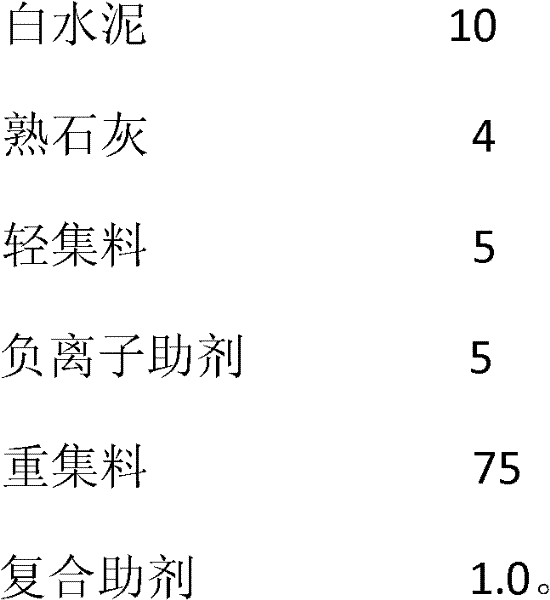

Lightweight plastering mortar and construction method thereof

The invention discloses lightweight plastering mortar, which is characterized in that the mortar is formed by mixing the following components in part by weight: 20 to 25 parts of common silicate cement, 2 to 4 parts of slaked lime, 5 to 10 parts of light aggregate, 20 to 30 parts of electromagnetic wave absorption master batch, 30 to 50 parts of heavy aggregate and 1.0 part of composite auxiliaryagent, wherein the light aggregate is an inorganic vitrified hollow micropore material with fineness of less than 100 meshes, and the heavy aggregate is common river sand. The construction method comprises the following steps of: diluting the lightweight plastering mortar by adding water in an amount which is 30 to 50 percent of the weight of the mortar, mechanically or manually stirring the mortar till the mortar is mixed uniformly, and mechanically coating the mortar or manually constructing the mortar when the mortar reaches the viscosity suitable for mechanical coating or manual construction. The lightweight plastering mortar with function of shielding and absorbing electromagnetic wave can shield and absorb the outdoor electromagnetic wave, absorb the indoor electromagnetic wave and reduce the diffuse reflection of the indoor electromagnetic wave, is light and energy-saving, reduces the consumption of unit area material and has low unit area manufacturing cost; and when used for a lightweight wall, the lightweight plastering mortar can prevent hollowing, cracking and dropping, is favorable for mechanized construction, and has simple process.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

Partially cladding steel-concrete composite member and composite structure building thereof

PendingCN111173195AImprove insulation effectImprove the effective anti-corrosion periodLoad-supporting elementsHeat proofingEarthquake resistanceArchitectural engineering

The invention provides a partially cladding steel-concrete composite member and a composite structure building thereof. The composite member includes a first side steel plate, a second side steel plate, studs, a repair welding steel plate, stiffening steel plates, a reinforcement framework and concrete; the two stiffening steel plates, the first side steel plate and the second side steel plate enclose a prefabricated web cavity in a prefabricated area; concrete is poured into the prefabricated web cavity; and the reinforcement framework is embedded in the concrete. According to the partially cladding steel-concrete composite member and the composite structure building thereof, the advantages of convenient connection and good anti-seismic performance of a steel structure are developed, andmeanwhile the advantages of high rigidity, good anti-corrosion and fire-proof performance and low cost of a concrete structure are integrated; and by using the combined action of steel-concrete, the defects of poor anti-corrosion and fire-proof performance, low rigidity and high cost of a steel member are overcome, and many advantages of the standardized production, assembly construction, long-term durability, economic applicability and the like of the member are achieved, the competitive advantage of the steel structure is greatly enhanced, and the application prospect in prefabricated buildings is broad.

Owner:SHENZHEN YJY BUILDING TECH +2

Decorative heat preserving plate and refrigerating device using same

ActiveCN104421573AImprove adsorption capacityLow thermal conductivityThermal insulationDomestic cooling apparatusEngineeringMechanical engineering

The invention provides a decorative heat preserving plate and a refrigerating device using the decorative heat preserving plate. The decorative heat preserving plate comprises a VIP plate, cellulose plates which are connected to two or one side surface of the VIP plate, and sealing belts or sealing strips arranged about the VIP plate, wherein the sealing belts or the sealing strips are in sealing connection with the inner side surfaces of the cellulose plates; a decorative layer is arranged on the outer side surface of each cellulose plate; a pattern can be conveniently arranged in advance, or color can be coated in advance or various decoration can be performed in advance through the decorative layer, so as to provide a customer a customized personalized refrigerator which can be integrated into the furniture. According to the decorative heat preserving plate, the cellulose plates integrates the outstanding physical performances of wood plastics, and is outstanding in environmental protection, quality in appearance and outstanding in processing performance; the VIP plate is used in some refrigerators at present, thus the decorative heat preserving plate is proposed to be used as the material of the existing white or stainless steel refrigerator housing; decorative layers with any pattern can be used as the surfaces of the cellulose plates, and therefore, customized personalized refrigerator which can be integrated into the furniture is provided to the customer.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

Inner wall decoration mortar and construction method thereof

ActiveCN101857408BAvoid crackingAvoid hollowingSolid waste managementBuilding constructionsHeat conductingHuman health

Owner:SHENZHEN GRANDLAND DECORATION GROUP

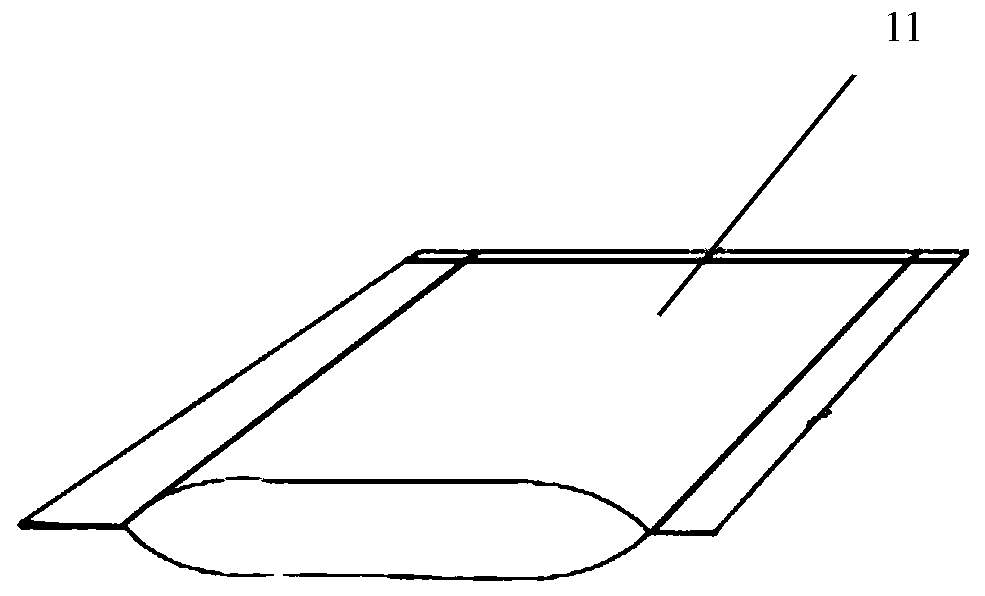

A vacuum insulation panel, cold storage box and production method thereof

ActiveCN106051380BImprove the cooling effectImprove wear resistanceDomestic cooling apparatusThermal insulationEngineeringWear resistance

The invention provides a vacuum thermal insulation plate, a cold keeping box and a production method thereof. The vacuum thermal insulation plate comprises a core plate and a film bag for sealing and coating the core plate and vacuumized, and is characterized in that folding plates are arranged on the same planes of the four sides of the core plate in the film bag; and when all the folding plates are overturned to the same side corresponding to the core plate by 90 degrees, the folding plates and the core plate form a box body with one opened side. The box body can be folded by using one vacuum thermal insulation plate, so that the box body molding steps are simplified; and one vacuum thermal insulation plate is adopted, so that both time and labors are saved in box body molding. As the final size of the box body can be accurately controlled only by accurately controlling the sizes of the core plate and the folding plates, the product size consistency is guaranteed in large-batch production. A foaming material and the vacuum thermal insulation plate are molded as a whole, so that the shape size is further precise, the wear resistance and the impact resistance of the vacuum thermal insulation plate can be greatly improved, and the vacuum thermal insulation plate is not easy to damage.

Owner:CHANGZHOU SANYOU DIOR INSULATION MATERIALS MFG

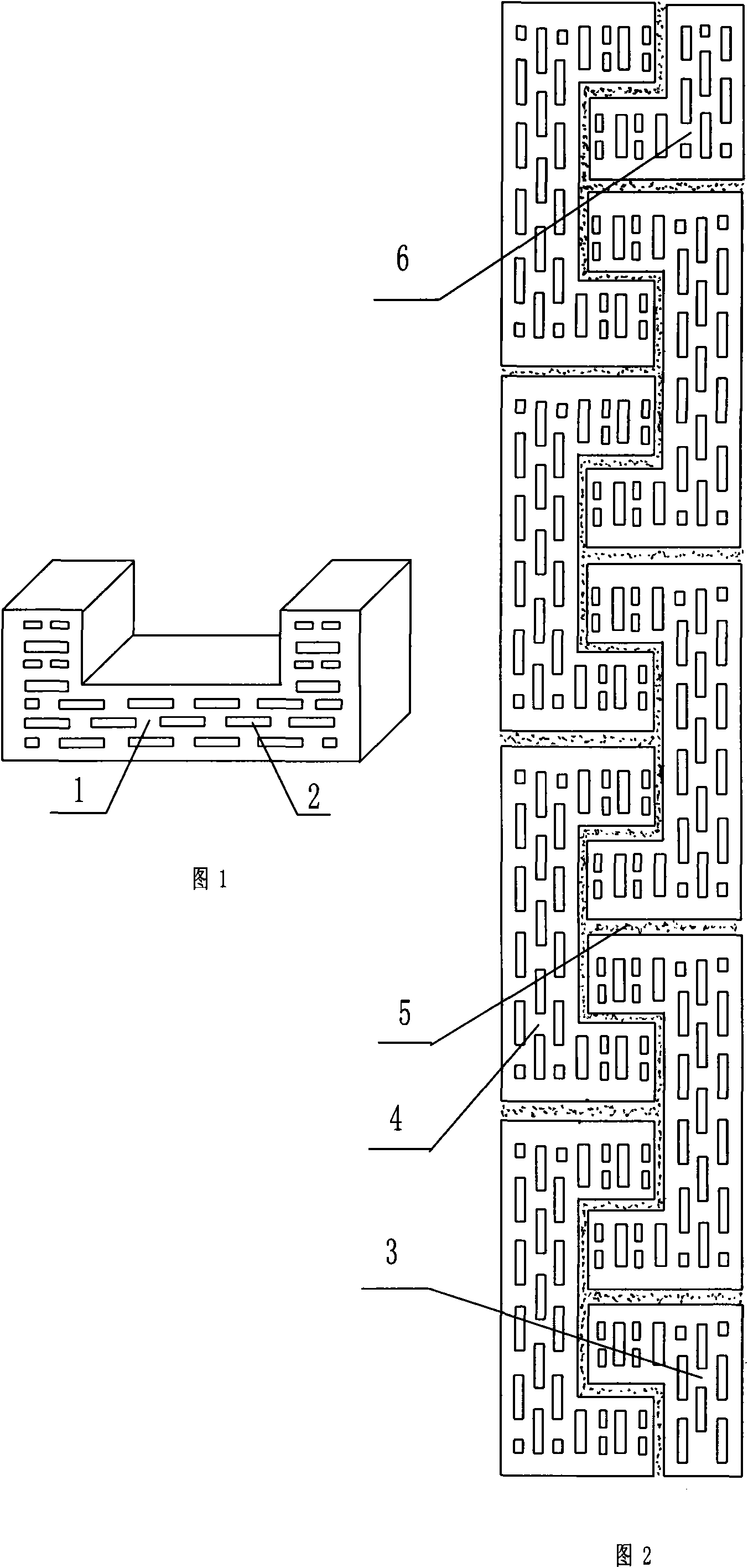

A kind of prefabricated concrete sandwich insulation exterior wall panel and preparation method thereof

The invention relates to a prefabricated concrete sandwich thermal insulation exterior wall panel, which belongs to the technical field of thermal insulation exterior wall panels, and includes an inner leaf concrete wall panel, an airgel fiber felt, an outer leaf concrete wall panel, and a plurality of connectors. The connection core made of carbon fiber material, the connection sleeve made of glass fiber reinforced plastic material, the connection sleeve is sleeved on the outer peripheral surface of the connection core and has an interference fit with it, and one end of the connection core along its length direction is provided with a The feed hole, the connecting core is set on the outer peripheral surface of the connecting sleeve and has multiple discharge holes along its circumferential direction. The discharge hole and the feed hole are connected. The side wall of the connecting sleeve is provided with a A perforation that connects the material holes. The prefabricated concrete sandwich thermal insulation exterior wall panel adopts airgel fiber felt, which has good fireproof performance, and utilizes the mutual cooperation between the connecting core body and the connecting sleeve to reduce the occurrence of "heat" at the joints of the thermal insulation exterior wall panel. The bridge effect improves the thermal insulation effect of the thermal insulation exterior wall panels.

Owner:BCEG ADVANCED CONSTR MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com