Online dry method glass wool vacuum insulated panel core material production system and method

A vacuum insulation panel and production system technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of inability to realize online continuous operation, discontinuous dry process operation, and difficulty in actual production and application, so as to reduce heat transfer and heat, low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

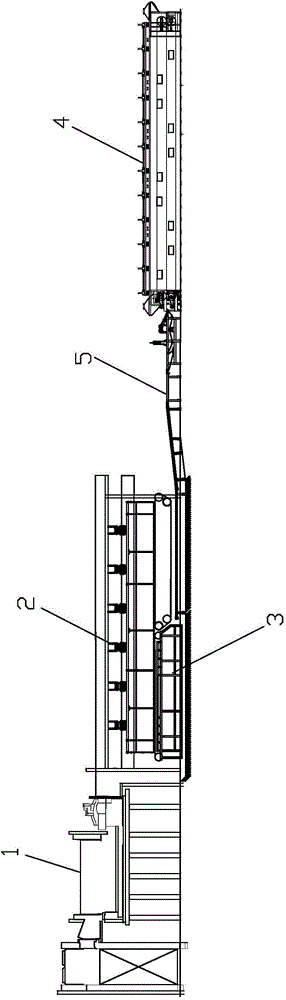

[0033] refer to figure 1 , an on-line dry-process glass wool vacuum insulation board core material production system in this embodiment includes a furnace 1, a centrifuge 2, a cotton collector 3, a hot-press setting device 4 and a transmission device 5. Furnace 1 is used to melt raw materials to form molten glass; centrifuge 2 is used to spin molten glass into glass fibers; cotton collector 3 is arranged under the centrifuge to collect glass fibers to form glass wool; hot pressing device 4 and The cotton collector 3 is connected by a conveying device 5 for hot-pressing glass wool to form a glass wool felt; the conveying device 5 can be known conveying equipment such as a conveyor belt or a conveyor chain.

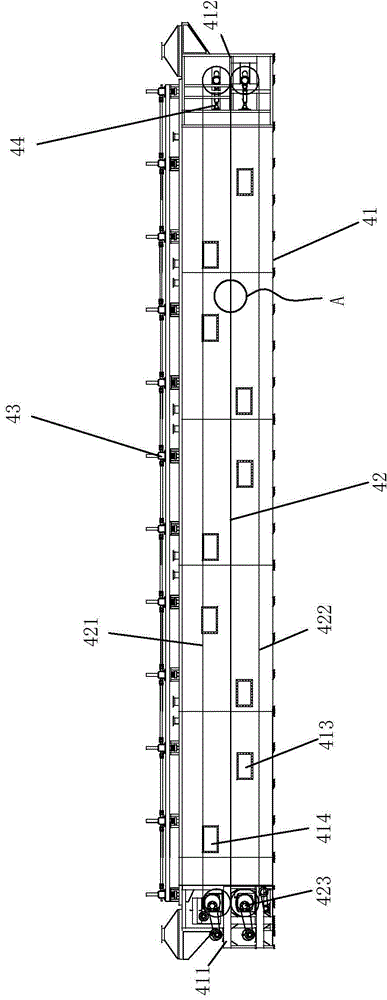

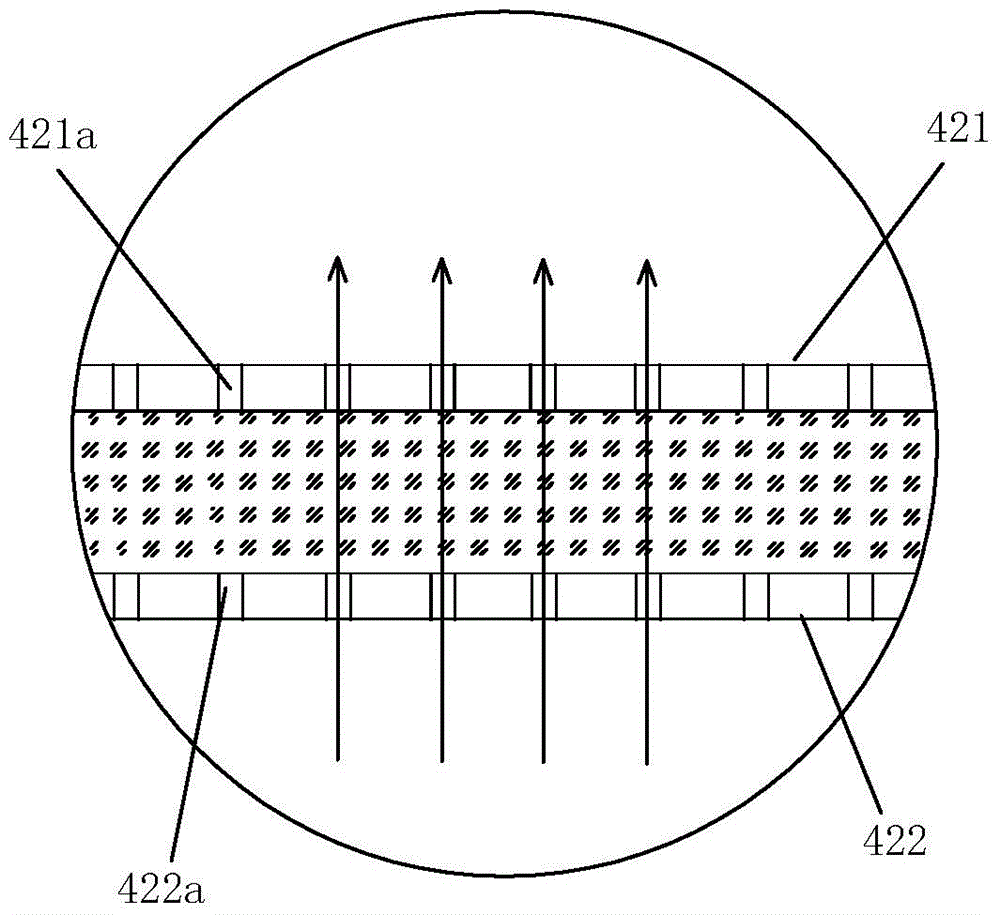

[0034] refer to figure 2 , The thermocompression setting device 4 includes a chamber 41, a transfer pressing system 42 and a heating system (not shown). One end of the chamber 41 close to the cotton collector 3 is provided with a material inlet 411 , the other end is pro...

Embodiment 2

[0043] refer to Figure 5 , an on-line dry-process glass wool vacuum insulation board core material production system in this embodiment includes a melting furnace (omitted in the figure), a centrifuge 2, a cotton collector 3, a hot-press setting device 4', a transmission device 5, Curing furnace 6 and cooling transfer end 7. The settings and functions of the melting furnace, the centrifuge 2 and the cotton collector 3 are the same as in Embodiment 1, and will not be repeated here. The curing furnace 6 is set between the cotton collector 3 and the hot-press setting device 4' and is connected by the conveying device 5 for drying and heating the glass wool, and the hot-press setting device 4' is used for hot-pressing the glass heated by the curing furnace 6 cotton to form a glass wool felt, and the glass wool felt is cooled and sent out by the cooling transmission end 7.

[0044] The hot-press setting device 4' is roughly the same structure as the hot-press setting device 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com